Combining an Intensive Green Roof with Seismic Retrofitting of Typical Reinforced Concrete Buildings in Israel

Abstract

:1. Introduction

2. Methods

2.1. Research Aims and Framework

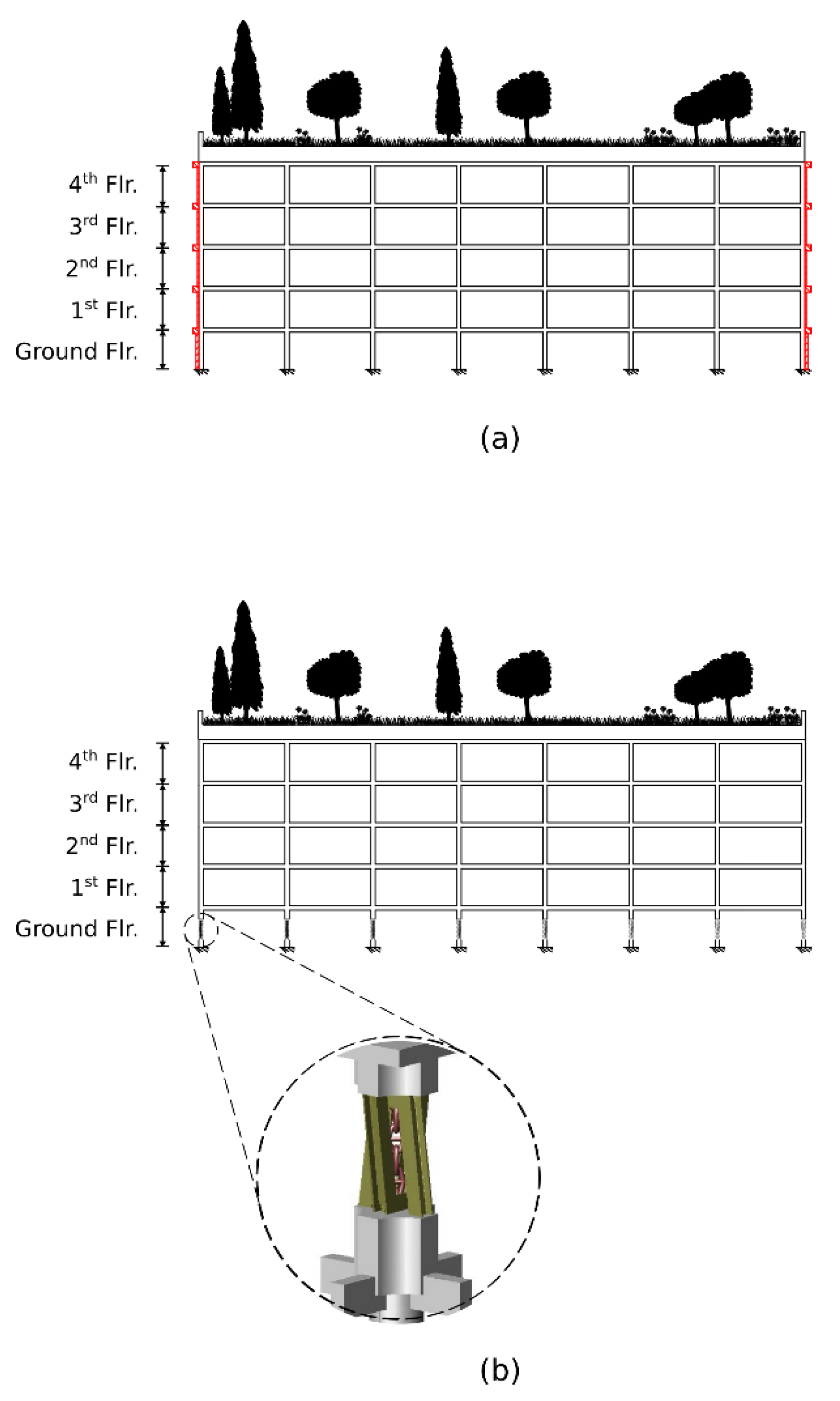

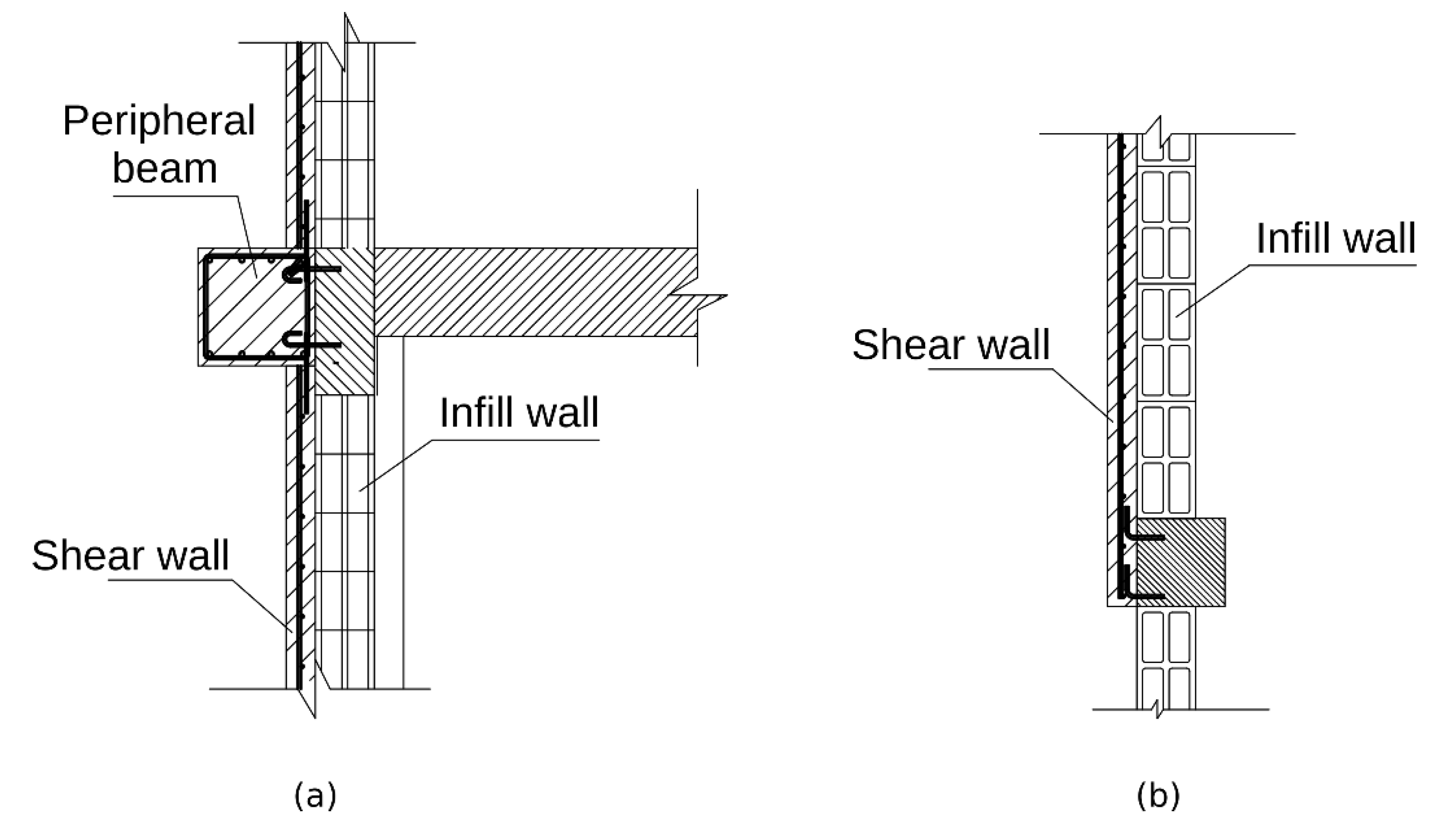

2.2. CWS and SIC

2.3. Intensive Green Roof

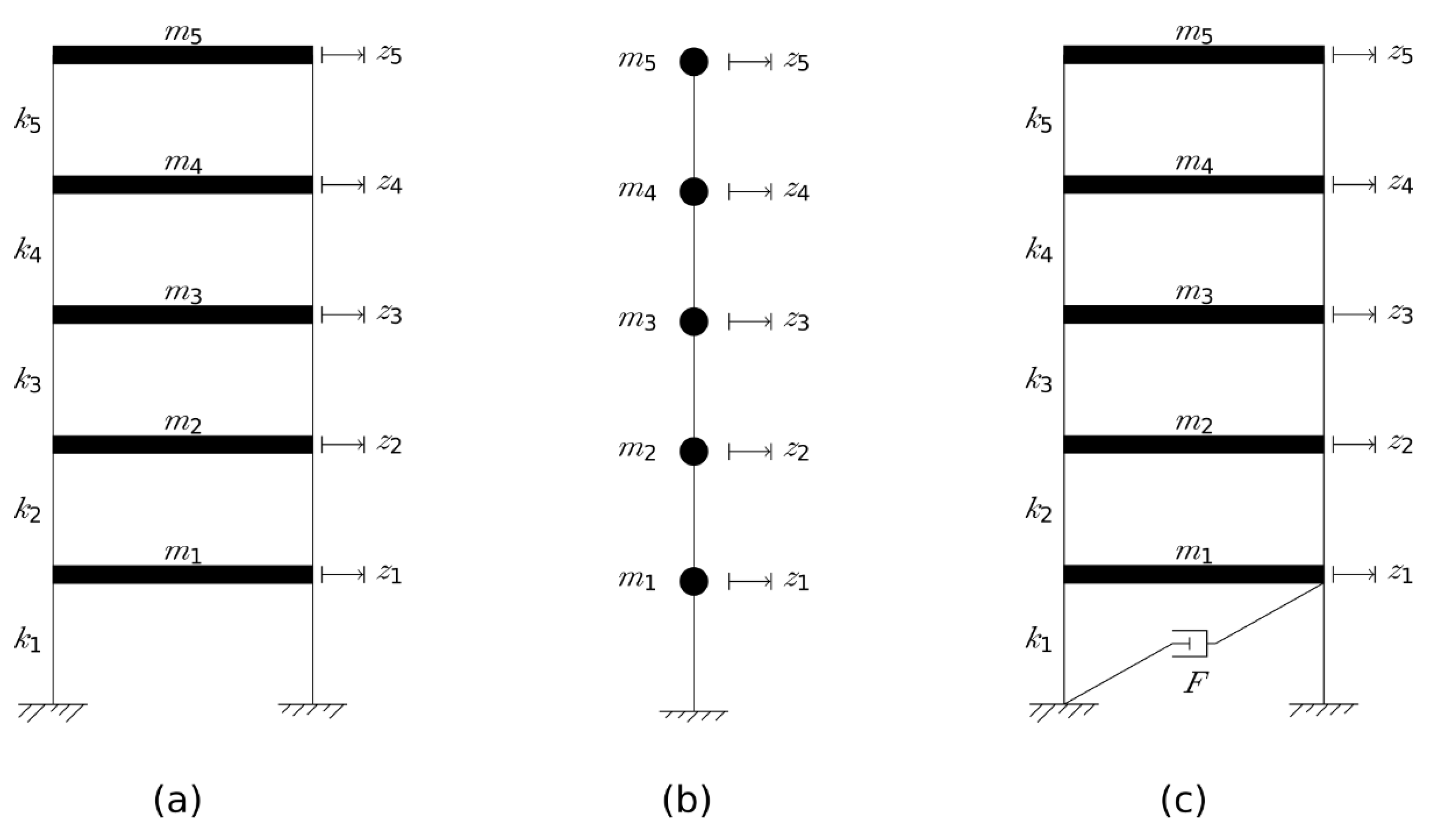

2.4. Seismic Response Evaluation

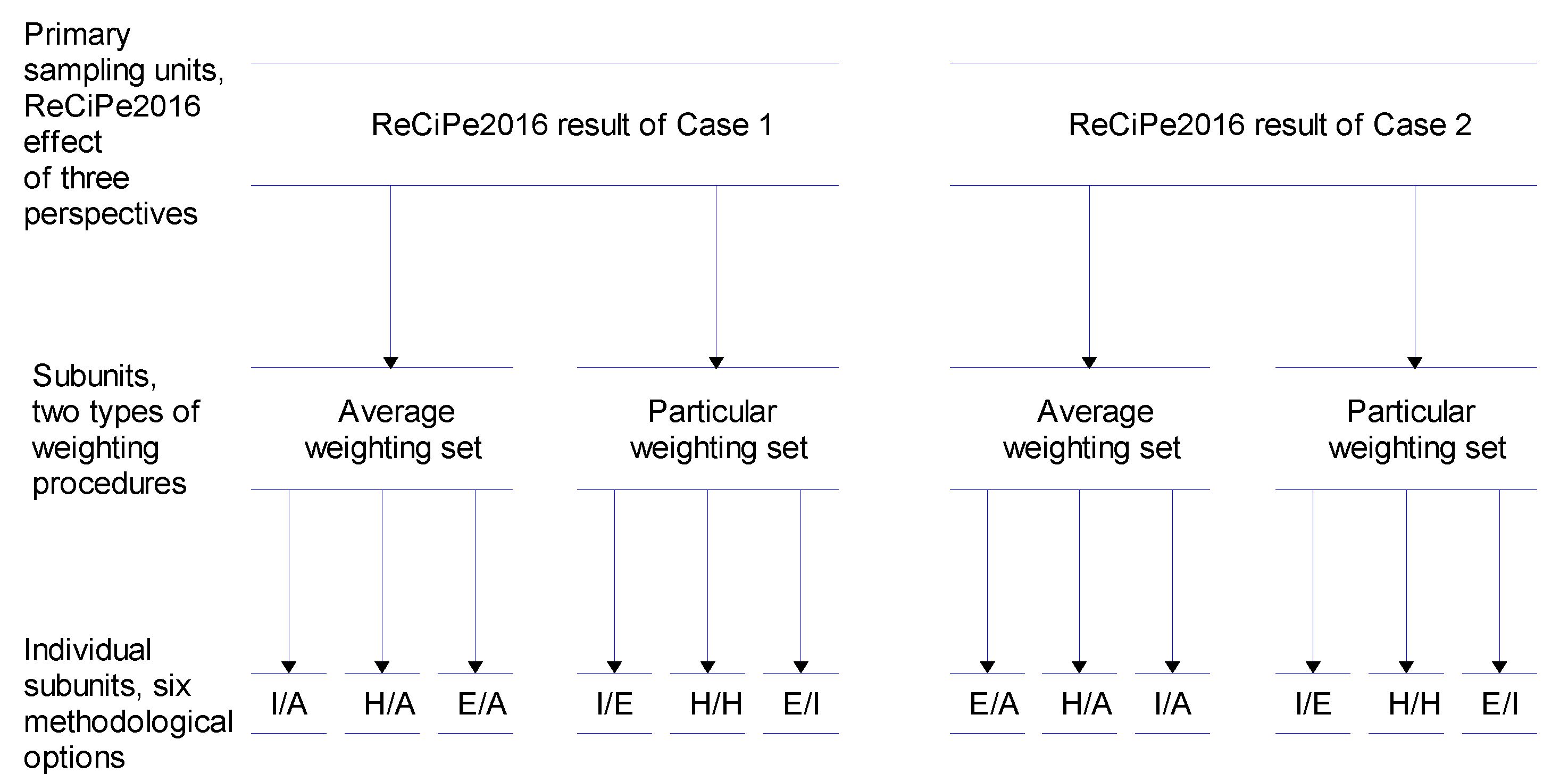

2.5. Environmental Evaluation

2.5.1. LCA: Stages and Methodology

2.5.2. LCA: Goal and Scope

2.5.3. LCA: Life Cycle Inventory

2.5.4. LCA: Life Cycle Impact Assessment

2.5.5. Statistical Evaluation

3. Results and Discussion

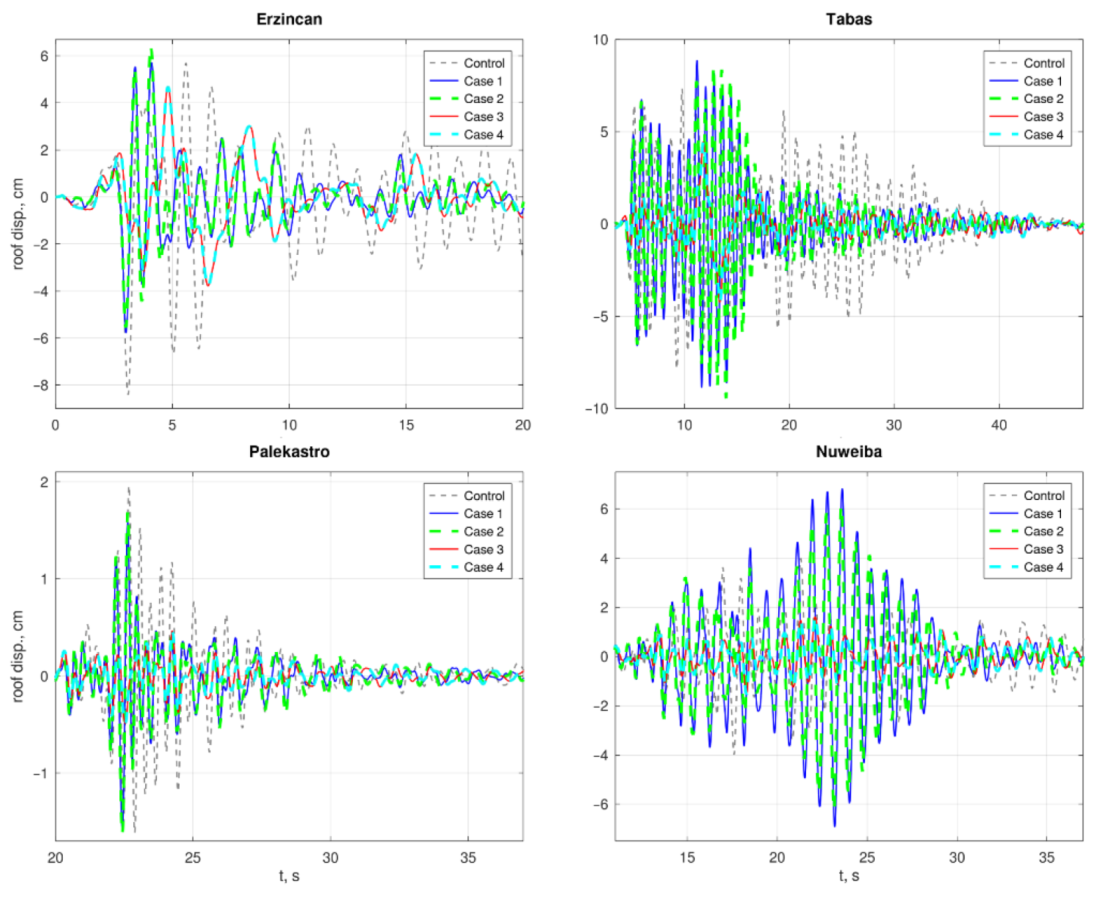

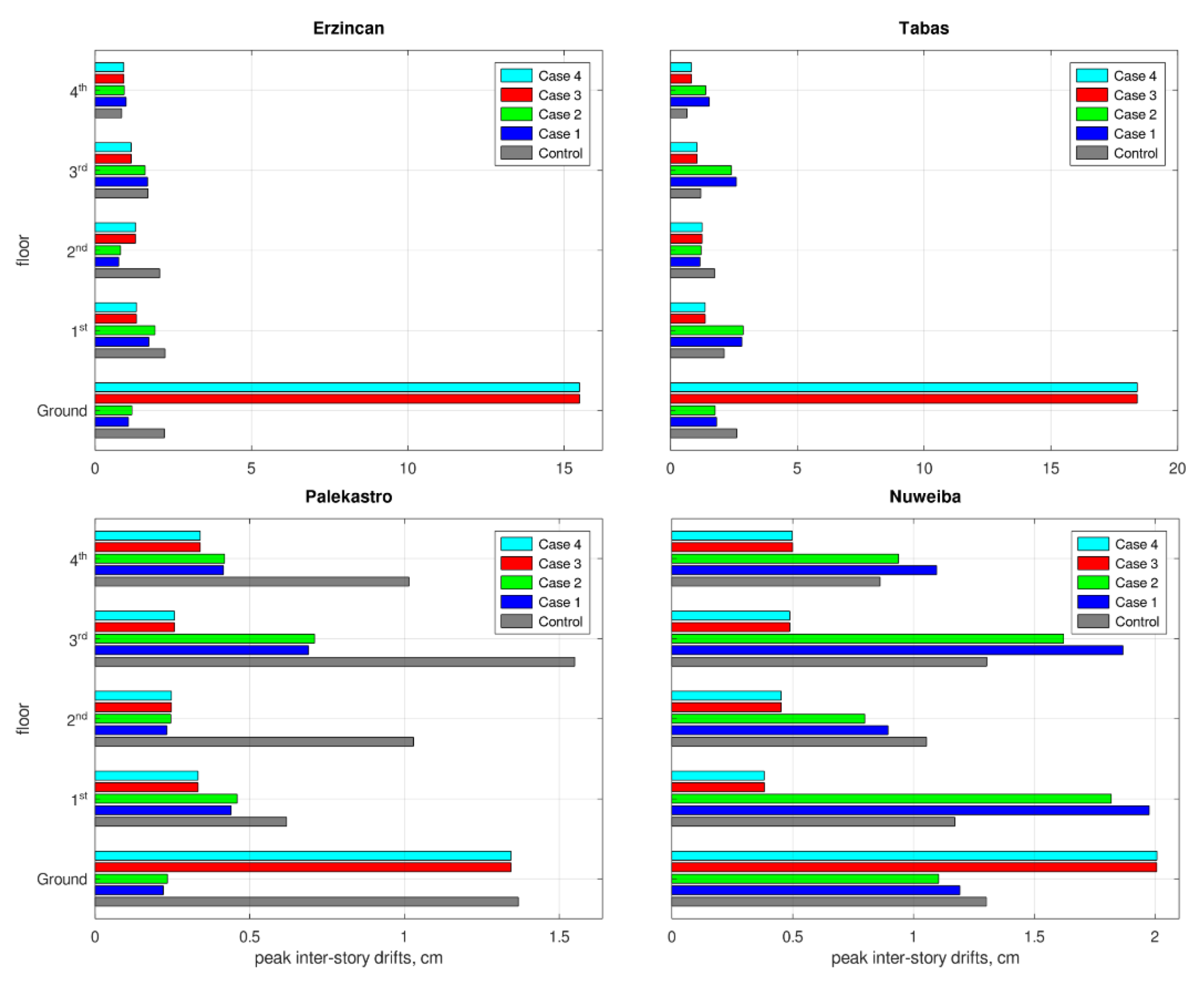

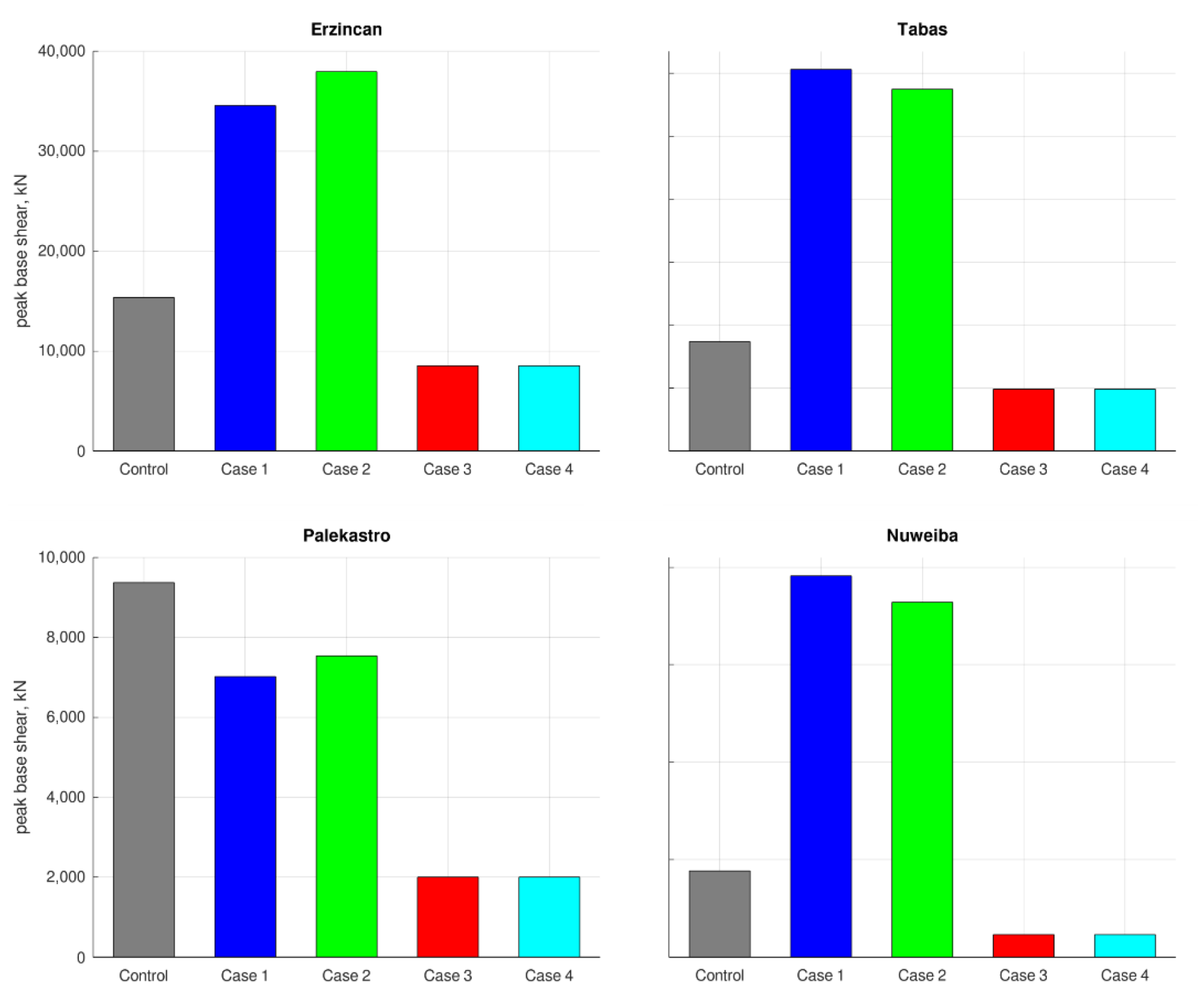

3.1. Seismic Response Evaluation

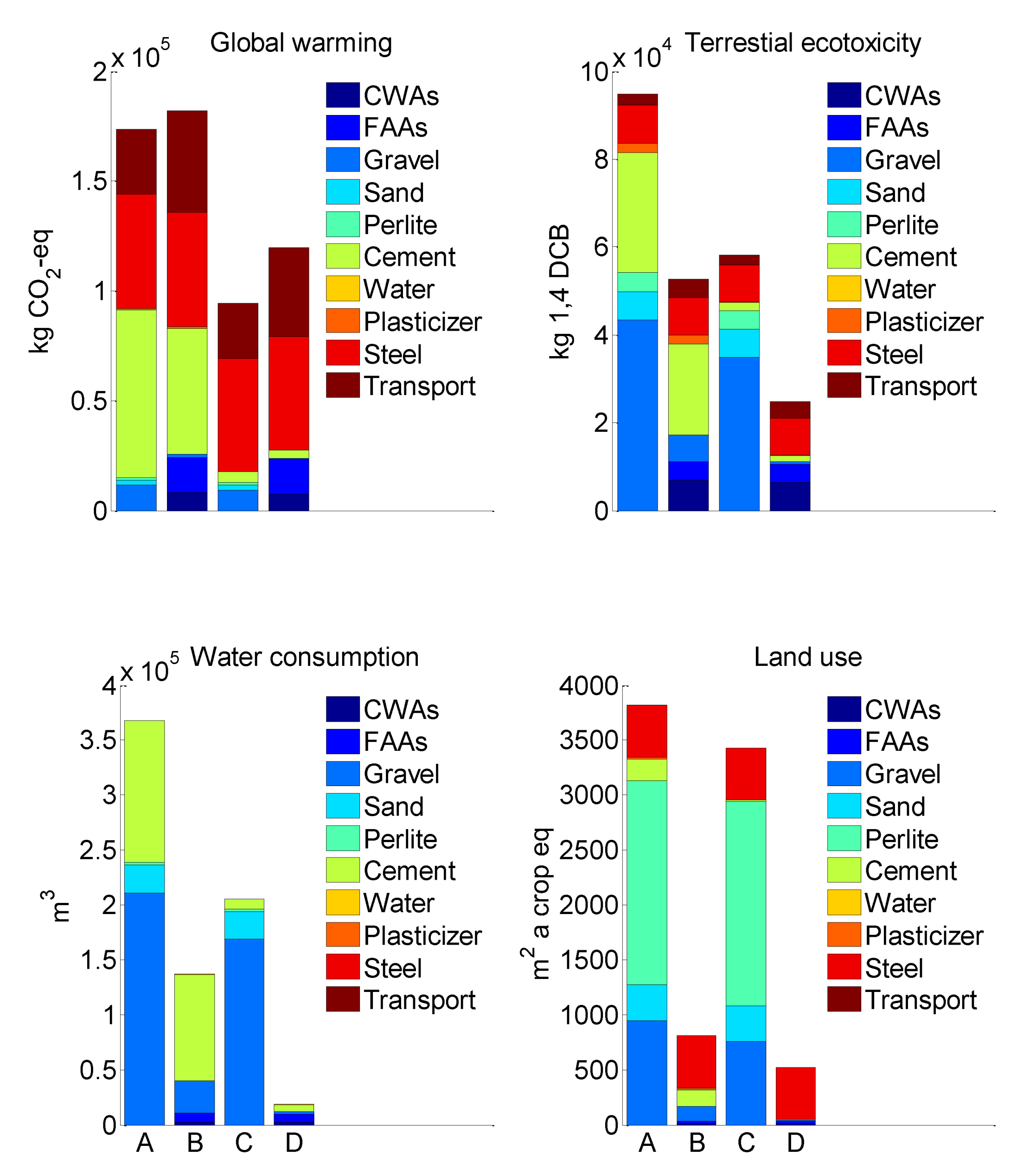

3.2. Environmental Evaluation

3.2.1. ReCiPe 2016 Midpoint Results

3.2.2. ReCiPe 2016 Endpoint Single-Score Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Margalit, T.; Mualam, N. Selective rescaling, inequality and popular growth coalitions: The case of the Israeli national plan for earthquake preparedness. Land Use Policy 2020, 99, 105123. [Google Scholar] [CrossRef]

- Ribakov, Y.; Halperin, I.; Pushkar, S. Seismic resistance and sustainable performance of retrofitted buildings by adding stiff diaphragms or seismic isolation. J. Archit. Eng. 2018, 24, 04017028. [Google Scholar] [CrossRef]

- Naeim, F.; Kelly, J.M. Design of Seismic Isolated Structures: From Theory to Practice; Wiley: Hoboken, NJ, USA, 1999. [Google Scholar]

- Cherry, S.; Filatrault, A. Seismic response control of buildings using friction dampers. Earthq. Spectra 1993, 9, 447–466. [Google Scholar] [CrossRef]

- Stengel, T.; Schiessl, P. Life cycle assessment (LCA) of ultra high performance concrete (UHPC) structures. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Cambridge, UK, 2014; Volume 22, pp. 528–564. ISBN 978-0-85709-045-4. [Google Scholar]

- Wei, H.H.; Shohet, I.M.; Skibniewski, M.J.; Shapira, S.; Yao, X. Assessing the lifecycle sustainability costs and benefits of seismic mitigation designs for buildings. J. Archit. Eng. 2016, 22, 04015011. [Google Scholar] [CrossRef]

- Vitiello, U.; Salzano, A.; Asprone, D.; Di Ludovico, M.; Prota, A. Life-cycle assessment of seismic retrofit strategies applied to existing building structures. Sustainability 2016, 8, 1275. [Google Scholar] [CrossRef] [Green Version]

- Salgado, R.A.; Apul, D.; Guner, S. Life cycle assessment of seismic retrofit alternatives for reinforced concrete frame buildings. JOBE 2020, 28, 101064. [Google Scholar] [CrossRef]

- Ribakov, Y.; Halperin, I.; Pushkar, S. Using Eco-indicator 99 and a two-stage nested analysis of variance test to evaluate building mitigation measures under hazard risks. Adv. Struct. Eng. 2016, 19, 860–870. [Google Scholar] [CrossRef]

- Welsh-Huggins, S.J.; Liel, A.B. A life-cycle framework for integrating green building and hazard-resistant design: Examining the seismic impacts of buildings with green roofs. Struct. Infrastruct. Eng. 2017, 13, 19–33. [Google Scholar] [CrossRef]

- SI 466 Part 1—Concrete Code: General Principles; Standards Institute of Israel: Tel-Aviv, Israel, 2003.

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Prentice-Hall: Englewood Cliffs, NJ, USA, 1995. [Google Scholar]

- ElGawady, M.; Lestuzzi, P.; Badoux, M. A review of conventional seismic retrofitting techniques for URM. In Proceedings of the 13th International Brick and Block Masonry Conference, Amsterdam, The Netherlands, 4–7 July 2004. [Google Scholar]

- Briman, V.; Ribakov, Y. Seismic isolation columns for earthquake-resistant structures. Struct. Des. Tall Spec. Build. 2008, 17, 99–116. [Google Scholar] [CrossRef]

- Al-Hussaini, T.M.; Zayas, V.A.; Constantinou, M.C. Seismic isolation of multi-story frame structures using spherical sliding isolation systems. In Technical Report NCEER 94-0007; State University of New York at Buffalo, Department of Civil Engineering: Buffalo, NY, USA, 1999. [Google Scholar]

- Turk, J.; Cotič, Z.; Ana Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- SI 1045 Part 0—Thermal Insulation of Buildings: General; Standards Institute of Israel: Tel-Aviv, Israel, 2011.

- Malešev, M.; Radonjanin, V.; Broćeta, G. Properties of recycled aggregate concrete. Contemp. Mater. 2014, 2, 239–249. [Google Scholar] [CrossRef]

- Marto, A.; Kassim, K.A.A.; Makhtar, M.; Wei, L.F.; Lim, Y.S. Engineering characteristics of Tanjung Bin coal ash Electron. J. Geotech. Eng. 2010, 15, 1117–1129. [Google Scholar]

- Frankovič, A.; Bosiljkov, B.V.; Ducman, V. Lightweight aggregates made from fly ash using the cold-bond process and their use in lightweight concrete. Mater. Technol. 2017, 51, 267–274. [Google Scholar] [CrossRef]

- MATLAB; Version 9.7 (R2019b); The MathWorks Inc.: Natick, MA, USA, 2019.

- Butcher, J.C. A history of Runge-Kutta methods. Appl. Numer. Math. 1996, 20, 247–260. [Google Scholar] [CrossRef]

- SI 413 Part 1—Design Provisions for Earthquake Resistance of Structures; Standards Institute of Israel: Tel-Aviv, Israel, 1995.

- ISO 13315-1 (International Organization for Standardization). Environmental Management for Concrete and Concrete Structures 2012, Part 1: General Principles; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Martin, J. Long Term Performance of Rubber in Seismic and Non-Seismic Bearings: A Literature Review; U.S. Department of Commerce National Institute of Standards and Technology, Building and Fire Research Laboratory: Galthenburg, MD, USA, 1999. [Google Scholar]

- Napolano, L.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. Life cycle environmental impact of different replacement options for a typical old flat roof. Int. J. Life Cycle Assess. 2015, 20, 694–708. [Google Scholar] [CrossRef]

- ISO 14040 (International Organization for Standardization). Environmental Management Life Cycle Assessment Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- SimaPro; Version 9.0; PRé Consultants: Amersfoort, The Netherlands, 2019.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Picquelle, S.J.; Mier, K.L. A practical guide to statistical methods for comparing means from two-stage sampling. Fish. Res. 2011, 107, 1–13. [Google Scholar] [CrossRef]

- Pushkar, S.; Ribakov, Y. Life-cycle assessment of strengthening pre-stressed normal-strength concrete beams with different steel-fibered concrete layers. Sustainability 2020, 12, 7958. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Final collapse of the Neyman-Pearson decision theoretic framework and rise of the neoFisherian. Ann. Zool. Fenn. 2009, 46, 311–349. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef] [Green Version]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Menache, J.; O’Moore, L.M. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Gursel, A.P.; Ostertag, C. Impact of Singapore’s importers on life-cycle assessment of concrete. J. Clean. Prod. 2016, 118, 140–150. [Google Scholar] [CrossRef]

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M.; Zhang, R. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

| Retrofitting Method | CWS | SIC | |

|---|---|---|---|

| Materials | |||

| Conventional concrete + conventional intensive green roof | Case 1 | Case 3 | |

| Waste-included concrete + waste-based intensive green roof | Case 2 | Case 4 | |

| Retrofitting Method | Aggregates (kg) | Recycled Aggregates (kg) | Fly Ash (kg) | Cement (kg) | Water (kg) | Plasticizer (kg) |

|---|---|---|---|---|---|---|

| CWS-conventional concrete | 555,073 | – | – | 92,224 | 50,435 | 576 |

| CWS-waste-included concrete | 365,726 | 156,781 | 23,056 | 69,168 | 57,352 | 576 |

| SIC-conventional concrete | 36,979 | – | – | 6144 | 3360 | 38 |

| SIC-waste-included concrete | 24,365 | 10,445 | 1536 | 4608 | 3821 | 38 |

| Layer | Thickness (m) | Material | Weight (kg/m2) | Weight (kg/Roof Area) |

|---|---|---|---|---|

| Substrate | 1 | Gravel | 1325 | 2,051,100 |

| Sand | 625 | 967,500 | ||

| Perlite | 275 | 425,700 | ||

| Filter layer | – | Polypropylene sheet | 0.60 | – |

| Drainage | 0.1 | Perlite | 110 | 170,280 |

| Protection layer | – | Polypropylene sheet | 0.60 | – |

| Roof barrier | 0.0004 | HDPE | 0.385 | – |

| Insulation | 0.05 | Polystyrene | 1.5 | – |

| Total | – | – | 2340 | – |

| Layer | Thickness (m) | Material | Weight (kg/m2) | Weight (kg/Roof Area) |

|---|---|---|---|---|

| Substrate | 1 | CWAs | 1193 | 1,846,764 |

| CBA | 335 | 518,580 | ||

| FAAs | 296 | 458,208 | ||

| Filter layer | – | Polypropylene sheet | 0.60 | – |

| Drainage | 0.1 | FAAs | 118 | 182,664 |

| Protection layer | – | Polypropylene sheet | 0.60 | – |

| Roof barrier | 0.0004 | HDPE | 0.385 | – |

| Insulation | 0.05 | Polystyrene | 1.5 | – |

| Total | – | – | 1945 | – |

| Control Case | Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|---|

| , ton | 1904 | 2066 | 2066 | 1904 | 1904 |

| , ton | 1904 | 2066 | 2066 | 1904 | 1904 |

| , ton | 1904 | 2036 | 2036 | 1904 | 1904 |

| , ton | 1904 | 2036 | 2036 | 1904 | 1904 |

| , ton | 1333 | 5846 | 5234 | 5714 | 5102 |

| Control Case | Case 3 | Case 4 | |

|---|---|---|---|

| , kN/mm | 658.1 | 46.245 | 46.245 |

| , kN/mm | 658.1 | 658.1 | 658.1 |

| , kN/mm | 658.1 | 658.1 | 658.1 |

| , kN/mm | 658.1 | 658.1 | 658.1 |

| , kN/mm | 658.1 | 658.1 | 658.1 |

| F, kN | – | 1255.2 | 1198 |

| Control case | 0.89 | 0.17 | 0.33 | 0.46 | 0.55 | 0.59 |

| 2.6 | 0.46 | 0.57 | 0.24 | −0.27 | −0.58 | |

| 4 | 0.58 | 0.083 | −0.57 | −0.16 | 0.55 | |

| 5.1 | 0.51 | −0.49 | −0.026 | 0.52 | −0.48 | |

| 5.7 | 0.28 | −0.49 | 0.57 | −0.51 | 0.31 | |

| Case 1 | 1.2 | 0.12 | 0.31 | 0.39 | 0.56 | 0.65 |

| 4.3 | 0.33 | 0.67 | 0.6 | 0.063 | −0.28 | |

| 8.7 | 0.89 | −0.041 | −0.26 | −0.36 | 0.11 | |

| 9.7 | 0.34 | −0.26 | −0.23 | 0.86 | −0.19 | |

| 14 | 0.14 | −0.69 | 0.7 | −0.091 | −0.012 | |

| Case 2 | 1.2 | 0.12 | 0.31 | 0.39 | 0.56 | 0.65 |

| 4.3 | 0.33 | 0.67 | 0.59 | 0.039 | −0.3 | |

| 8.7 | 0.89 | −0.051 | −0.27 | −0.34 | 0.12 | |

| 9.8 | 0.31 | −0.25 | −0.22 | 0.86 | −0.21 | |

| 14 | 0.14 | −0.69 | 0.7 | −0.09 | −0.014 | |

| Case 3 | 0.28 | 0.4 | 0.43 | 0.45 | 0.47 | 0.48 |

| 1.5 | 0.68 | 0.54 | 0.27 | −0.082 | −0.41 | |

| 3.2 | 0.58 | −0.042 | −0.62 | −0.49 | 0.2 | |

| 4.6 | 0.43 | −0.58 | −0.18 | 0.66 | −0.1 | |

| 5.6 | 0.23 | −0.57 | 0.65 | −0.45 | 0.046 | |

| Case 4 | 0.28 | 0.41 | 0.43 | 0.45 | 0.47 | 0.48 |

| 1.6 | 0.67 | 0.53 | 0.24 | −0.11 | −0.44 | |

| 3.2 | 0.58 | −0.052 | −0.62 | −0.47 | 0.22 | |

| 4.6 | 0.43 | −0.58 | −0.17 | 0.66 | −0.12 | |

| 5.6 | 0.23 | −0.56 | 0.65 | −0.45 | 0.053 | |

| Material/Process | Process |

|---|---|

| Gravel | Gravel, crushed, at mine/CH U |

| Sand | Sand, at mine/CH U |

| Perlite | Perlite, at mine/DE U |

| Cement | Portland cement, strength class Z 42.5, at plant/CH U |

| CWAs | Disposal, building, concrete, not reinforced, to recycling/CH U |

| Water | Top water, at user/CH U |

| FAAs | FAAs, production (modeled according to Frankovič et al. [17]). |

| Plasticizer | Polycarboxylates, 40% active substance (RER) |

| Steel | Steel rebar/EU |

| Transportation | Lorry transport, Euro 0, 1, 2, 3, 4 mix, 22 t total weight, 17.3 t |

| Material/Process | GWP (kg CO2) | TE (kg 1,4-DCB) | WC (m3) | LU (m2a crop eq) |

|---|---|---|---|---|

| Gravel | 0.00445 | 0.0167 | 0.081 | 0.000362 |

| Sand | 0.00242 | 0.0067 | 0.026 | 0.000337 |

| Perlite | 0.00169 | 0.00706 | 0.00409 | 0.00312 |

| Cement | 0.828 | 0.297 | 1.4 | 0.00218 |

| Water | 0.000171 | 0.000409 | 0.00448 | 0.0000166 |

| CWAs | 0.00403 | 0.00343 | 0.00136 | 0.00000676 |

| FAAs | 0.025 | 0.00661 | 0.0113 | 0.000031 |

| Plasticizer | 1.15 | 3.75 | 0.0137 | 0.0204 |

| Steel | 2.31 | 0.381 | 0.00246 | 0.0211 |

| Transportation | 0.0663 | 0.00587 | 0.00000529 | 0 |

| Retrofitted Design Alternatives | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Case1: CWS-conventional concrete + conventional green roof | X | 0.0011 | 0.0010 | 0.0002 |

| Case 2: CWS-waste-included concrete + waste-based green roof | X | 0.4141 | 0.0006 | |

| Case 3: SIC-conventional concrete + conventional green roof | X | 0.0005 | ||

| Case 4: SIC-waste-included concrete + waste-based green roof | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S.; Halperin, I.; Ribakov, Y. Combining an Intensive Green Roof with Seismic Retrofitting of Typical Reinforced Concrete Buildings in Israel. Materials 2022, 15, 889. https://doi.org/10.3390/ma15030889

Pushkar S, Halperin I, Ribakov Y. Combining an Intensive Green Roof with Seismic Retrofitting of Typical Reinforced Concrete Buildings in Israel. Materials. 2022; 15(3):889. https://doi.org/10.3390/ma15030889

Chicago/Turabian StylePushkar, Svetlana, Ido Halperin, and Yuri Ribakov. 2022. "Combining an Intensive Green Roof with Seismic Retrofitting of Typical Reinforced Concrete Buildings in Israel" Materials 15, no. 3: 889. https://doi.org/10.3390/ma15030889

APA StylePushkar, S., Halperin, I., & Ribakov, Y. (2022). Combining an Intensive Green Roof with Seismic Retrofitting of Typical Reinforced Concrete Buildings in Israel. Materials, 15(3), 889. https://doi.org/10.3390/ma15030889