Microstructure Evolution and Shear Strength of the Cu/Au80Sn20/Cu Solder Joints with Multiple Reflow Temperatures

Abstract

:1. Introduction

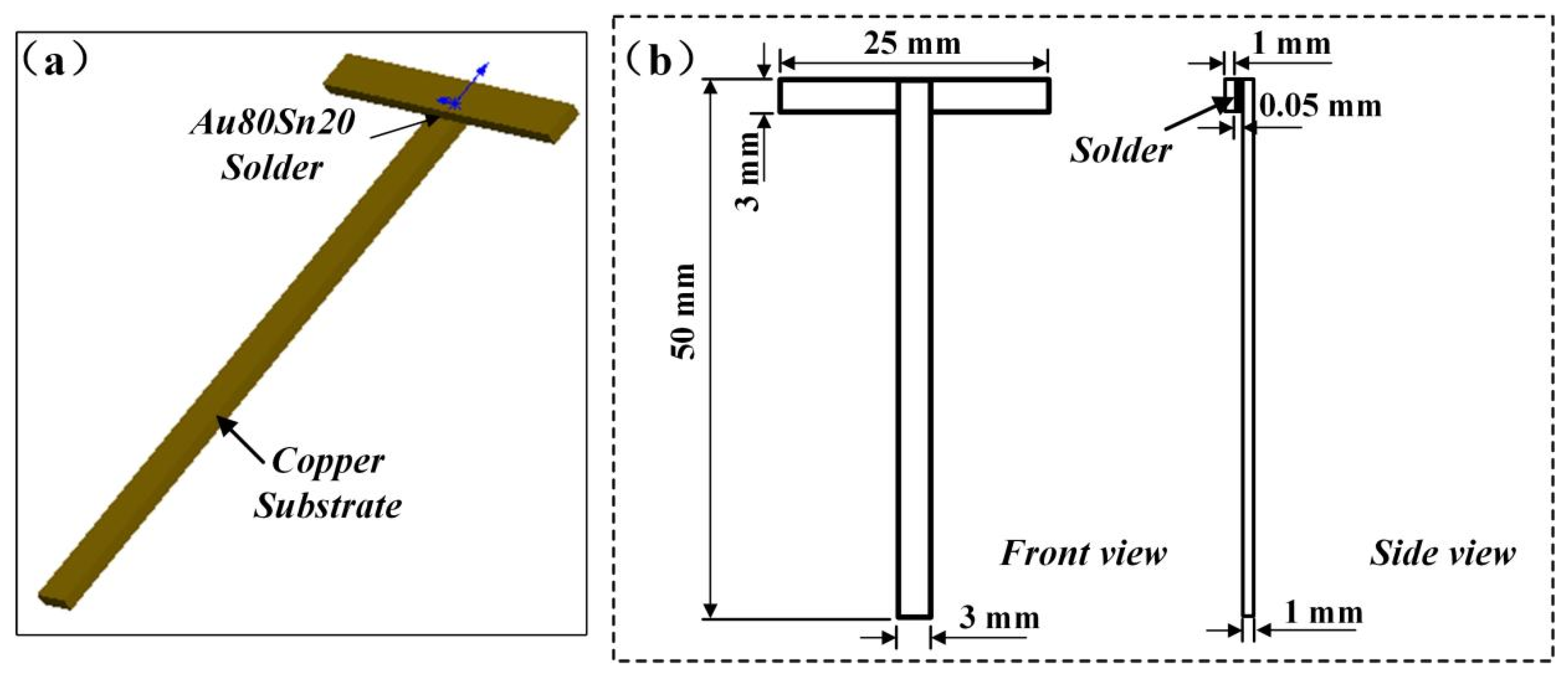

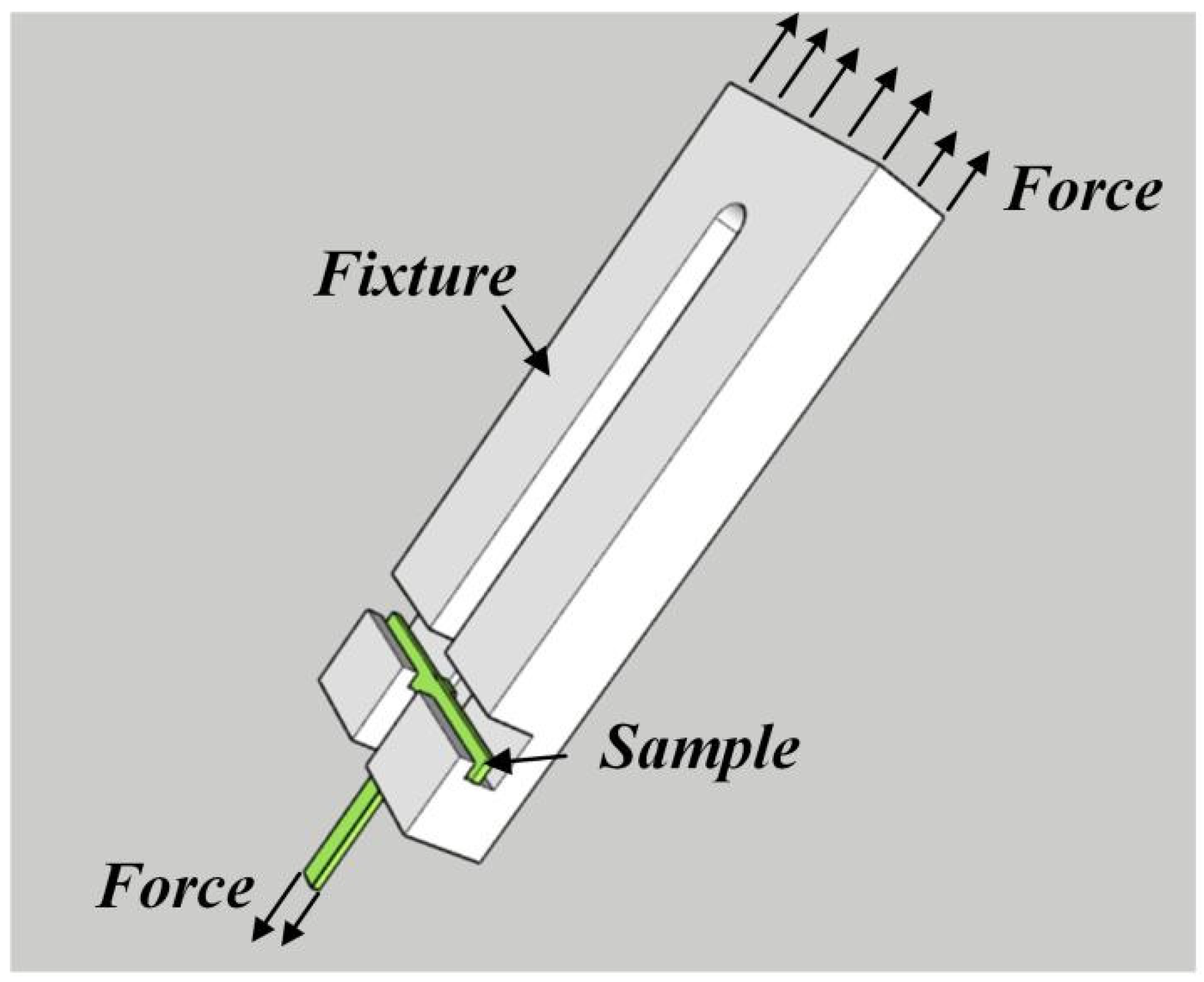

2. Materials and Methods

3. Results and Discussion

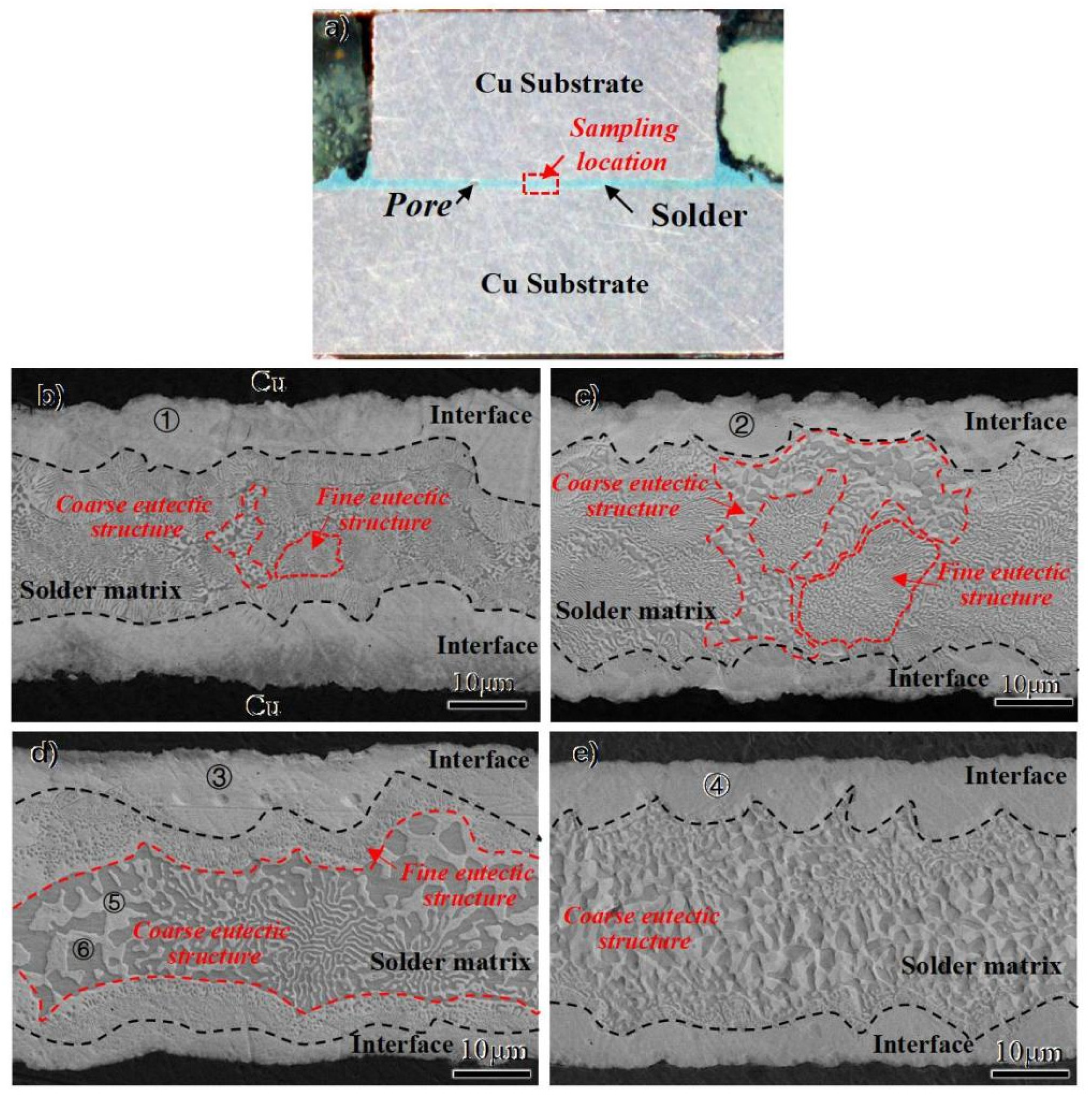

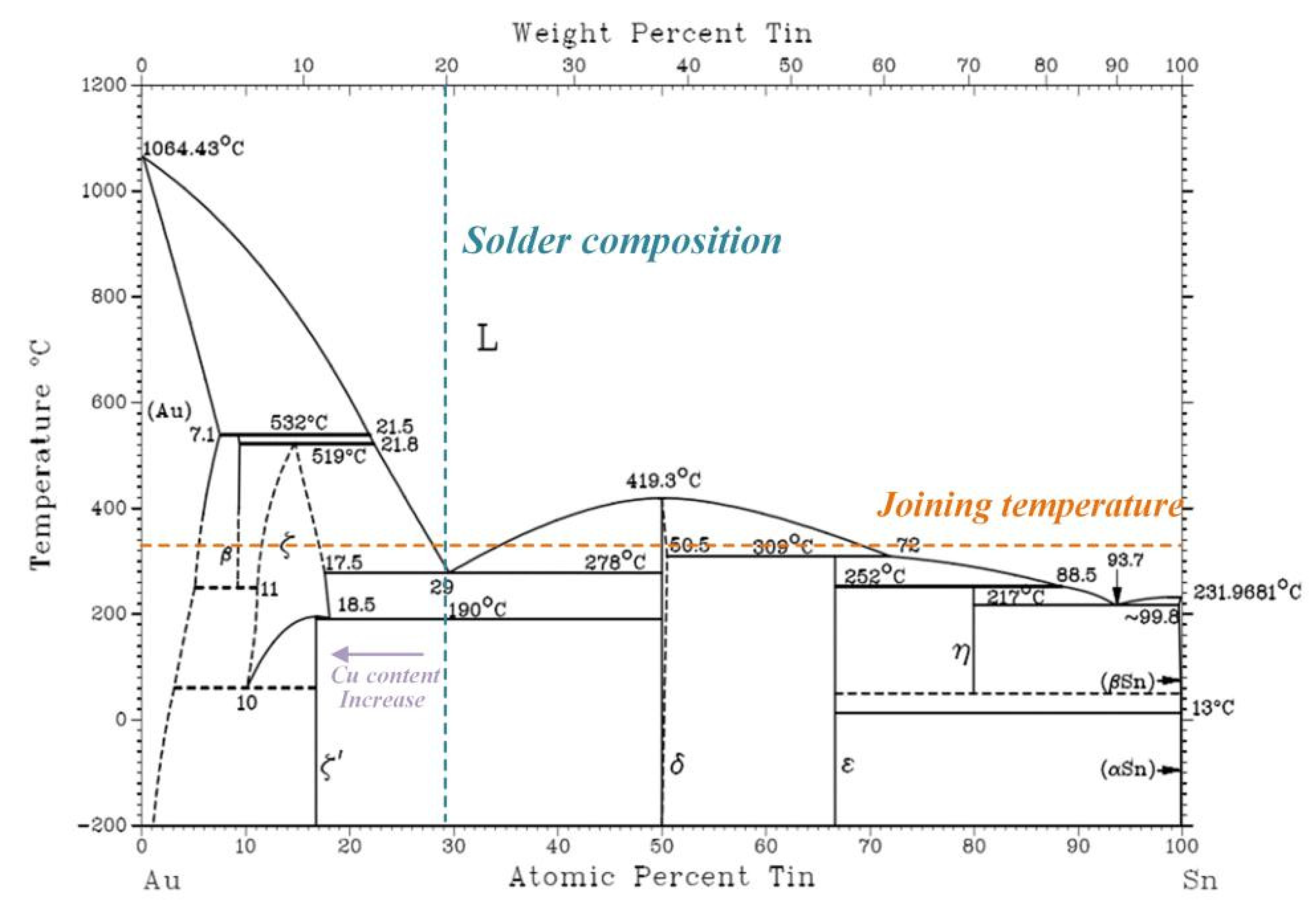

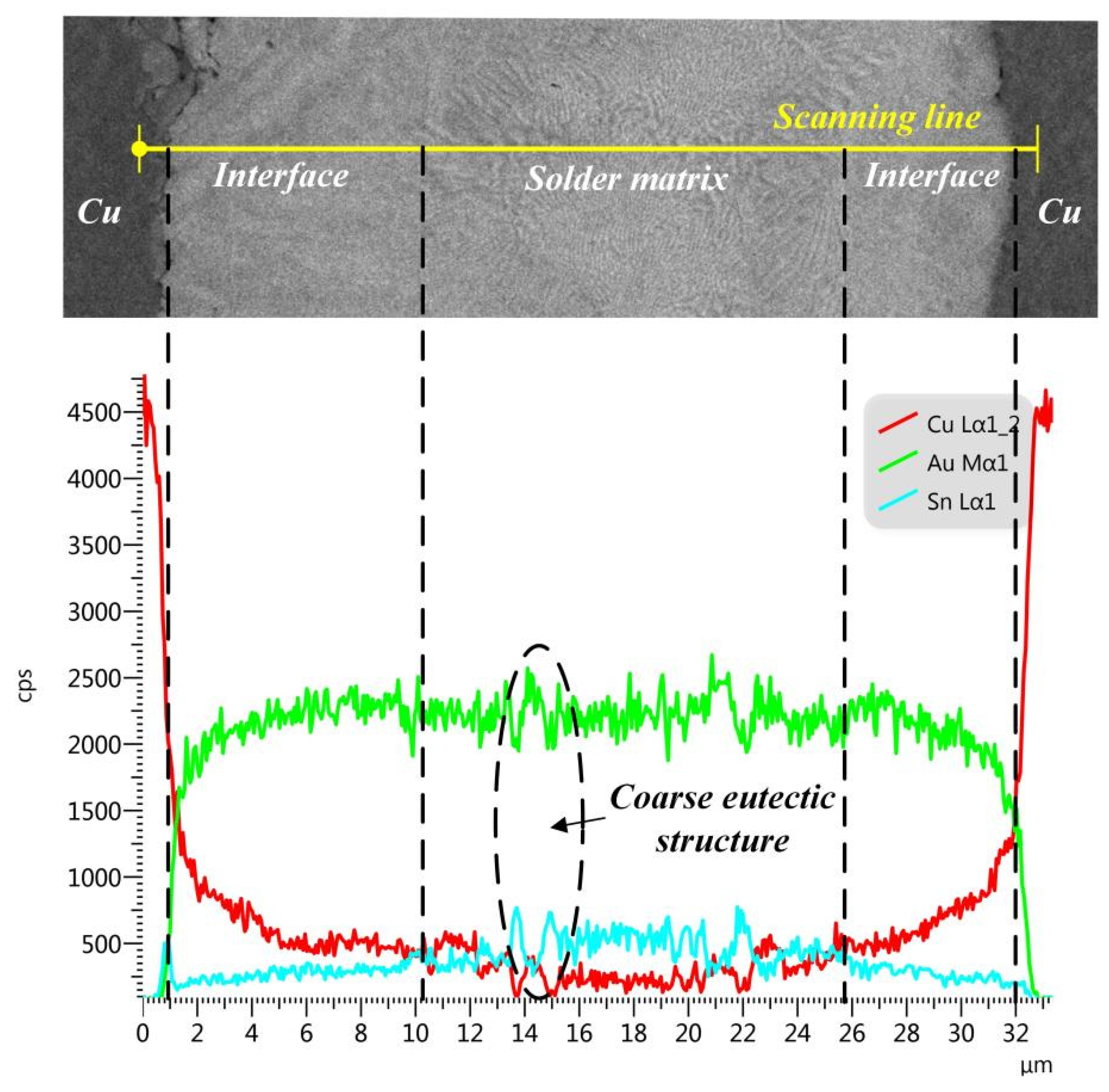

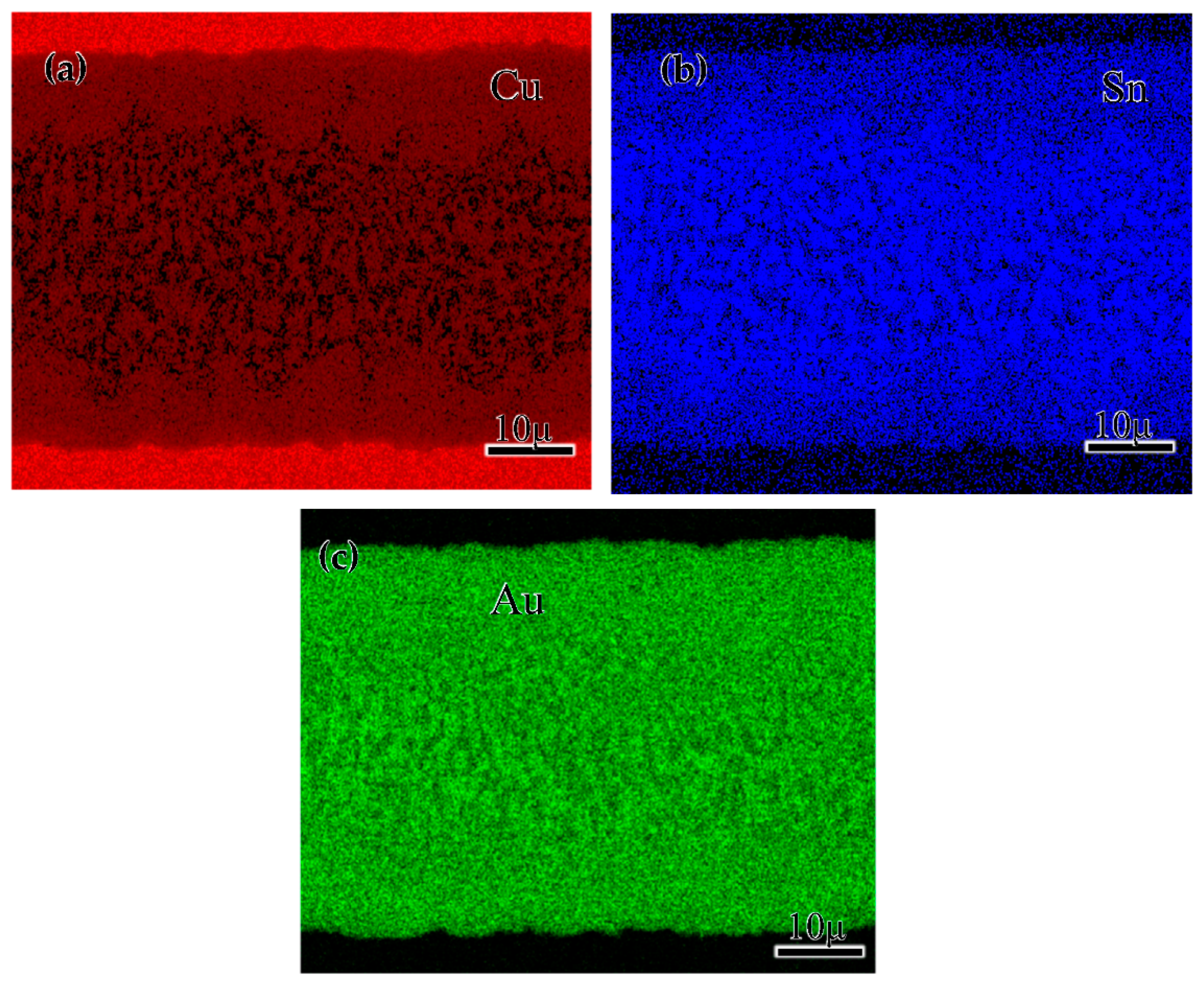

3.1. Microstructure Evolution

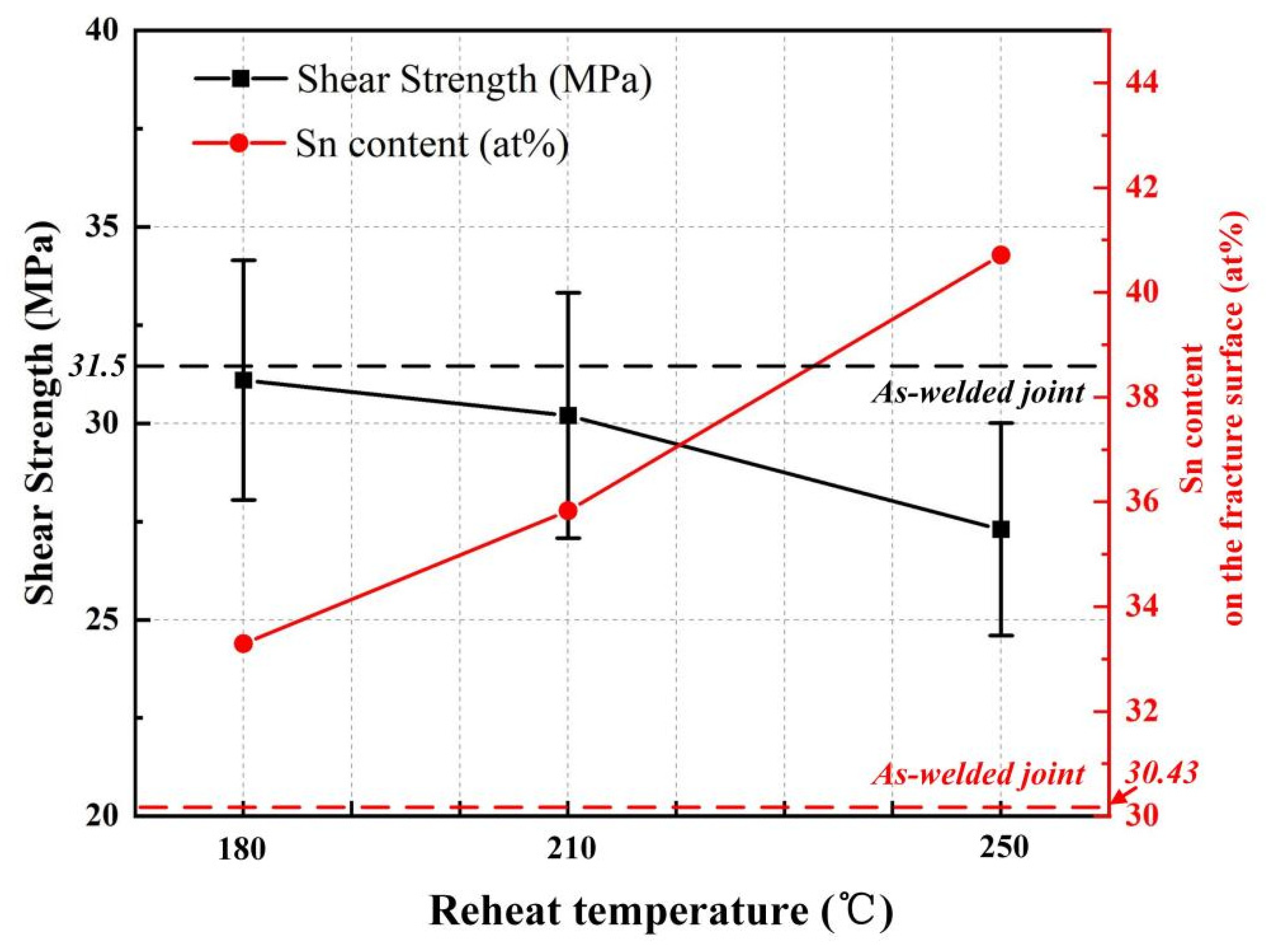

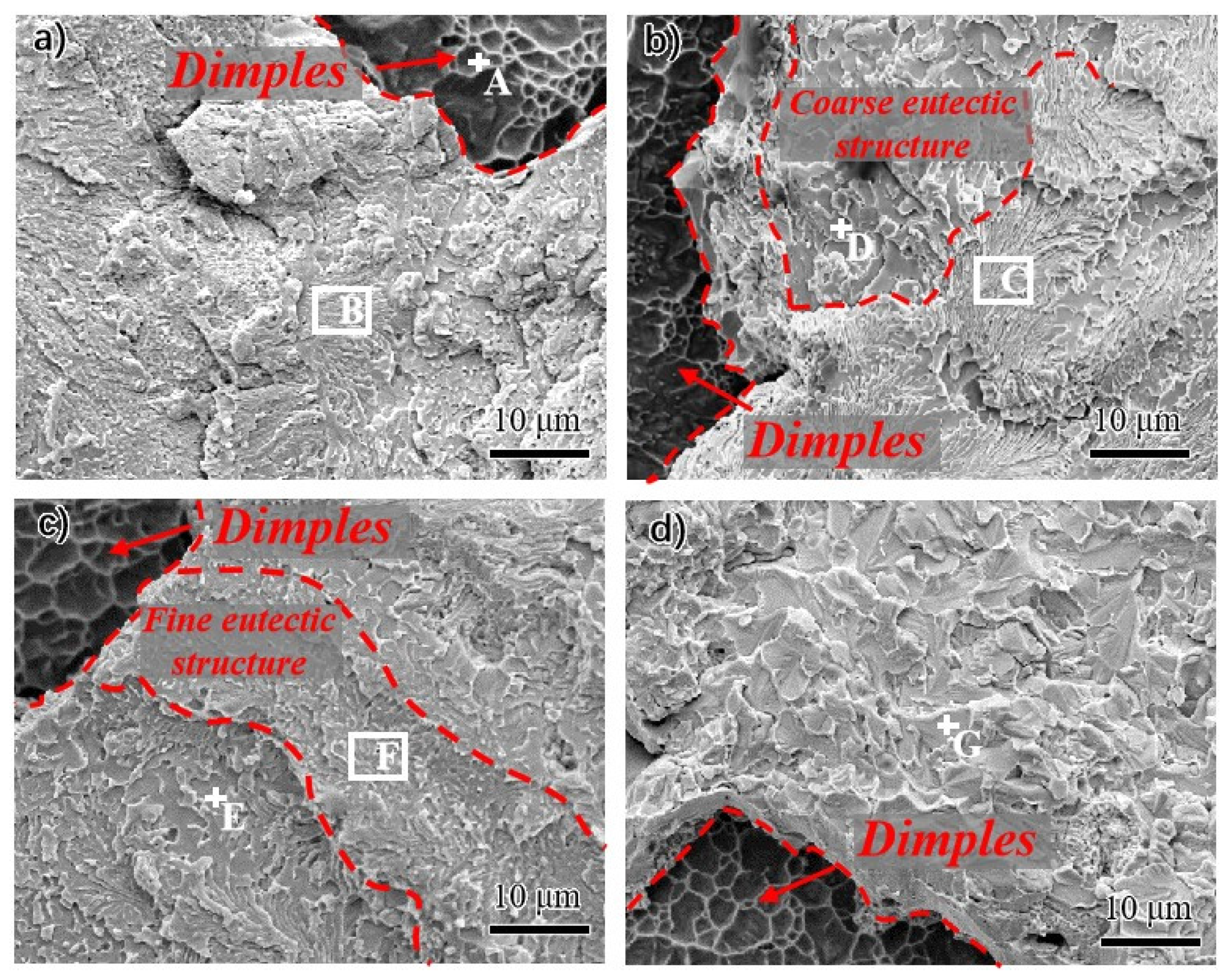

3.2. Shear Strength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.; Yu, X.; Shi, T.; Cheng, C.; Fan, J.; Cheng, S.; Liao, G.; Tang, Z. Low-Temperature and Low-Pressure Cu–Cu Bonding by Highly Sinterable Cu Nanoparticle Paste. Nanoscale Res. Lett. 2017, 12, 255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, W.; Zheng, W.; Hu, S.; Li, M. Synthesis of highly antioxidant and low-temperature sintering Cu-Ag core–shell submicro-particles for high-power density electronic packaging. Mater. Lett. 2021, 299, 129781. [Google Scholar] [CrossRef]

- Chen, K.-N.; Tu, K.-N. Materials challenges in three-dimensional integrated circuits. MRS Bull. 2015, 40, 219–222. [Google Scholar] [CrossRef] [Green Version]

- Ghazalia, M.I.M.; Saranraj, K.; Amanpreet, K.; Premjeet, C. 3D Printed high functional density packaging compatible out-of-plane antennas. Addit. Manuf. 2019, 30, 100863. [Google Scholar]

- Macdonald, W.D.; Ea Gar, T.W. Low Temperature Transient Liquid Phase Bonding of Ti6AI4V. Genetica 2003, 22, 63–74. [Google Scholar]

- Bobzin, K.; Bagcivan, N.; Zhao, L.; Ferrara, S.; Perne, J. Development of new transient liquid phase system Au-Sn-Au for microsystem technology. Front. Mech. Eng. China 2010, 5, 370–375. [Google Scholar] [CrossRef]

- Liu, W.; An, R.; Wang, C.; Tian, Y. Effect of Au-Sn IMCs’ formation and morphologies on shear properties of laser reflowed micro-solder joints. Solder. Surf. Mt. Technol. 2015, 27, 45–51. [Google Scholar] [CrossRef]

- Li, D.; Sun, D.; Bi, X.; Liu, G.; Zhang, Y.; Cui, Y.; Song, Y.; Chi, Z.; Sun, Z.; Chen, C. Sintering of SiC chip via Au80Sn20 solder and its joint strength and thermomechanical reliability. Microelectron. Reliab. 2022, 128, 114443. [Google Scholar] [CrossRef]

- Liu, X.; Chen, B.; Wu, S.; Lin, P.; Ma, Y.; Tang, S.; Huang, Y.; Liu, W. Formation of nano-phase Co3Fe7 intermetallic and its strengthening in Au80Sn20/CrMnFeCoNi solder interface. J. Alloys Compd. 2020, 843, 155924. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Y.; Ma, Y.; Yu, Q.; Huang, Y. Interfacial microstructure evolution and shear behavior of Au–20Sn/(Sn)Cu solder joints bonded at 250 °C. Mater. Sci. Eng. A 2016, 651, 626–635. [Google Scholar] [CrossRef]

- Ho, C.Y.; Lin, C.W.; Lee, Y.Y.; Cheng, S.C. Interfacial evolution and mechanical properties of Au–Sn solder jointed Cu heat sink during high temperature storage test. Mater. Lett. 2020, 275, 128103. [Google Scholar] [CrossRef]

- Lee, C.; Huang, W.-F.; Shie, J.-S. Wafer bonding by low-temperature soldering. Sens. Actuators A Phys. 2000, 85, 330–334. [Google Scholar] [CrossRef]

- Shu, Y.; Rajathurai, K.; Gao, F.; Cui, Q.; Gu, Z. Synthesis and thermal properties of low melting temperature tin/indium (Sn/In) lead-free nanosolders and their melting behavior in a vapor flux. J. Alloys Compd. 2015, 626, 391–400. [Google Scholar] [CrossRef]

- Choi, W.K.; Premachandran, C.S.; Chiew, O.S.; Ling, X.; Ebin, L.; Khairyanto, A.; Ratmin, B.; Sheng, K.C.W.; Thaw, P.P.; Lau, J.H. Development of novel intermetallic joints using thin film indium based solder by low temperature bonding technology for 3D IC stacking. In Proceedings of the 2009 59th Electronic Components and Technology Conference, San Diego, CA, USA, 26–29 May 2009. [Google Scholar]

- Welch, W.C.; Najafi, K. Gold-indium Transient Liquid Phase (TLP) wafer bonding for MEMS vacuum packaging. In Proceedings of the 2008 IEEE 21st International Conference on Micro Electro Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008. [Google Scholar]

- Lee, J.-B.; Hwang, H.Y.; Rhee, M.-W. Reliability Investigation of Cu/In TLP Bonding. J. Electron. Mater. 2014, 44, 435–441. [Google Scholar] [CrossRef]

- Wang, F.; Li, D.; Tian, S.; Zhang, Z.; Wang, J.; Yan, C. Interfacial behaviors of Sn-Pb, Sn-Ag-Cu Pb-free and mixed Sn-Ag-Cu/Sn-Pb solder joints during electromigration. Microelectron. Reliab. 2017, 73, 106–115. [Google Scholar] [CrossRef]

- Han, C.; Qi, L.; Ivey, D.G. Electrochemical composite deposition of Sn–Ag–Cu alloys. Mater. Sci. Eng. B 2009, 164, 172–179. [Google Scholar] [CrossRef]

- Loomans, M.E.; Fine, M.E. Tin-silver-copper eutectic temperature and composition. Met. Mater. Trans. A 2000, 31, 1155–1162. [Google Scholar] [CrossRef]

- Chung, H.; Chen, C.; Lin, C.; Chen, C. Microstructural evolution of the Au–20wt.% Sn solder on the Cu substrate during reflow. J. Alloys Compd. 2009, 485, 219–224. [Google Scholar] [CrossRef]

- Hu, J.; Xie, M.; Zhang, J. First principles study of Au-Sn intermetallic compounds. Acta Phys. Sin. 2013, 62, 272–279. [Google Scholar]

- Dong, H.; Vuorinen, V.; Laurila, T. Microstructural evolution and mechanical properties in (AuSn)eut-Cu interconnections. J. Electron. Mater. 2016, 10, 5478–5486. [Google Scholar] [CrossRef]

| Au | Sn | Cu | Possible Phase | |

|---|---|---|---|---|

| 1 | 53.47 | 12.90 | 33.63 | ζ |

| 2 | 52.96 | 12.83 | 34.21 | ζ |

| 3 | 52.97 | 12.69 | 34.33 | ζ |

| 4 | 53.48 | 12.97 | 33.55 | ζ |

| 5 | 54.91 | 14.26 | 30.38 | ζ |

| 6 | 49.91 | 48.40 | 1.70 | δ |

| Reheating Temperature (°C) | As-Welded | 180 | 210 | 250 |

|---|---|---|---|---|

| Shear strength (MPa) | 31.5 | 31.1 | 30.2 | 27.3 |

| Sn content (at%) | 30.43 | 32.51 | 35.83 | 40.71 |

| Au | Sn | Cu | Possible Phases | |

|---|---|---|---|---|

| A | 0.78 | 0.22 | 99.01 | Cu(s,s) |

| B | 55.32 | 30.43 | 14.26 | (ζ + δ) |

| C | 55.39 | 32.51 | 12.10 | (ζ + δ) |

| D | 50.33 | 43.61 | 6.06 | δ |

| E | 48.62 | 44.21 | 7.17 | δ |

| F | 52.30 | 35.83 | 11.88 | (ζ + δ) |

| G | 52.27 | 40.71 | 7.02 | δ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Sun, M.; Cheng, Z.; Liang, Y. Microstructure Evolution and Shear Strength of the Cu/Au80Sn20/Cu Solder Joints with Multiple Reflow Temperatures. Materials 2022, 15, 780. https://doi.org/10.3390/ma15030780

Chen C, Sun M, Cheng Z, Liang Y. Microstructure Evolution and Shear Strength of the Cu/Au80Sn20/Cu Solder Joints with Multiple Reflow Temperatures. Materials. 2022; 15(3):780. https://doi.org/10.3390/ma15030780

Chicago/Turabian StyleChen, Chaoyu, Mingxu Sun, Zhi Cheng, and Yao Liang. 2022. "Microstructure Evolution and Shear Strength of the Cu/Au80Sn20/Cu Solder Joints with Multiple Reflow Temperatures" Materials 15, no. 3: 780. https://doi.org/10.3390/ma15030780

APA StyleChen, C., Sun, M., Cheng, Z., & Liang, Y. (2022). Microstructure Evolution and Shear Strength of the Cu/Au80Sn20/Cu Solder Joints with Multiple Reflow Temperatures. Materials, 15(3), 780. https://doi.org/10.3390/ma15030780