Zinc Slag as a Partial or Total Replacement for Mineral Filler in Warm Mix Asphalt and Its Effects on Self-Healing Capacity and Performance Characteristics

Abstract

:1. Introduction

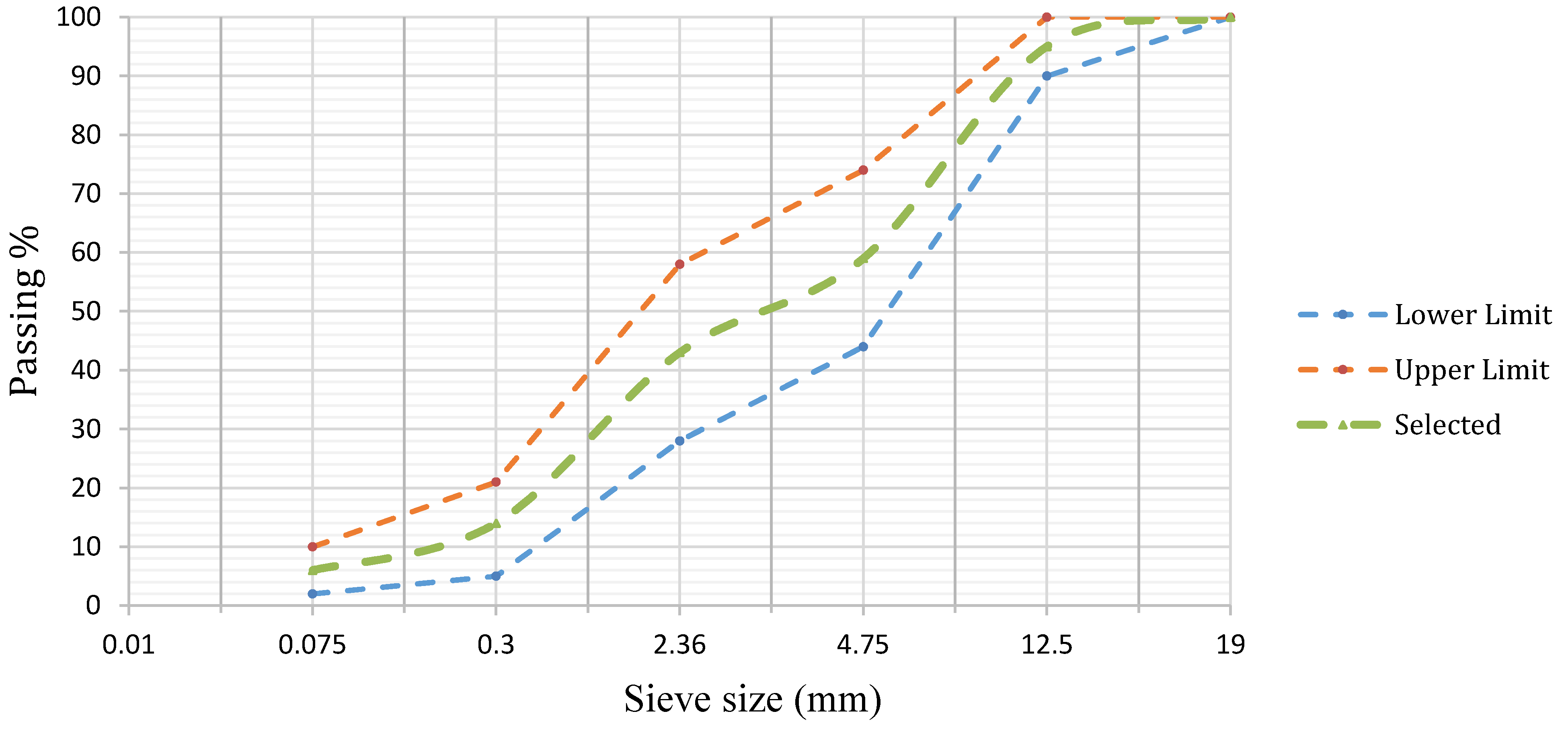

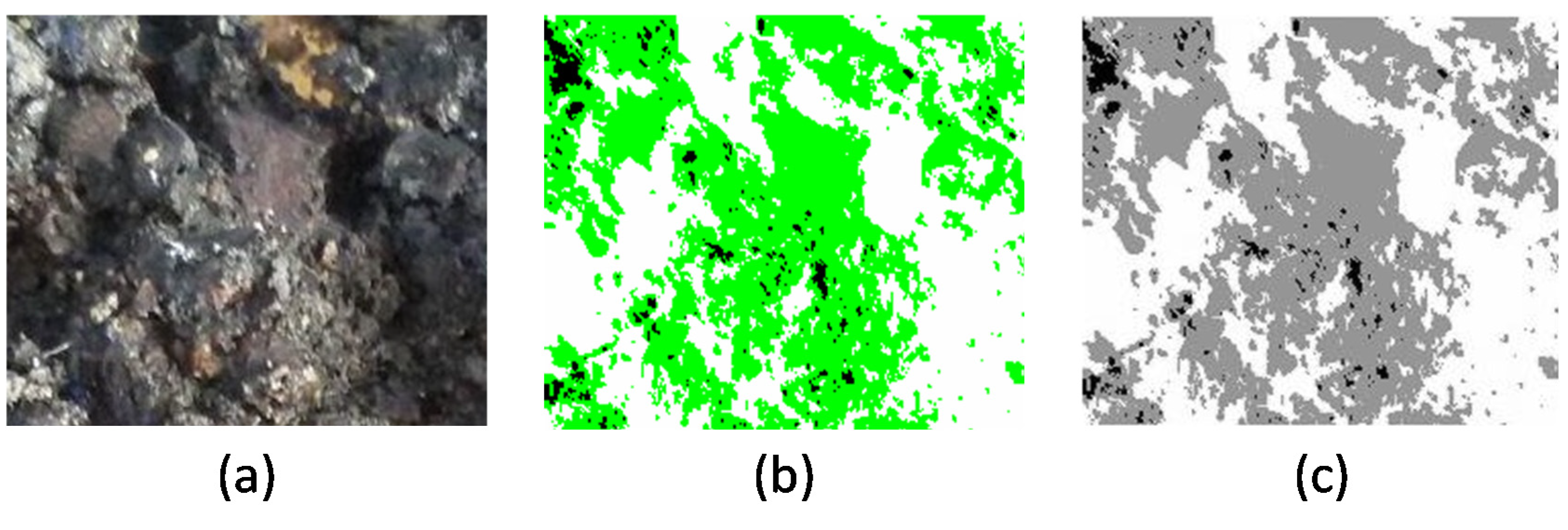

2. Materials and Methods

2.1. Materials

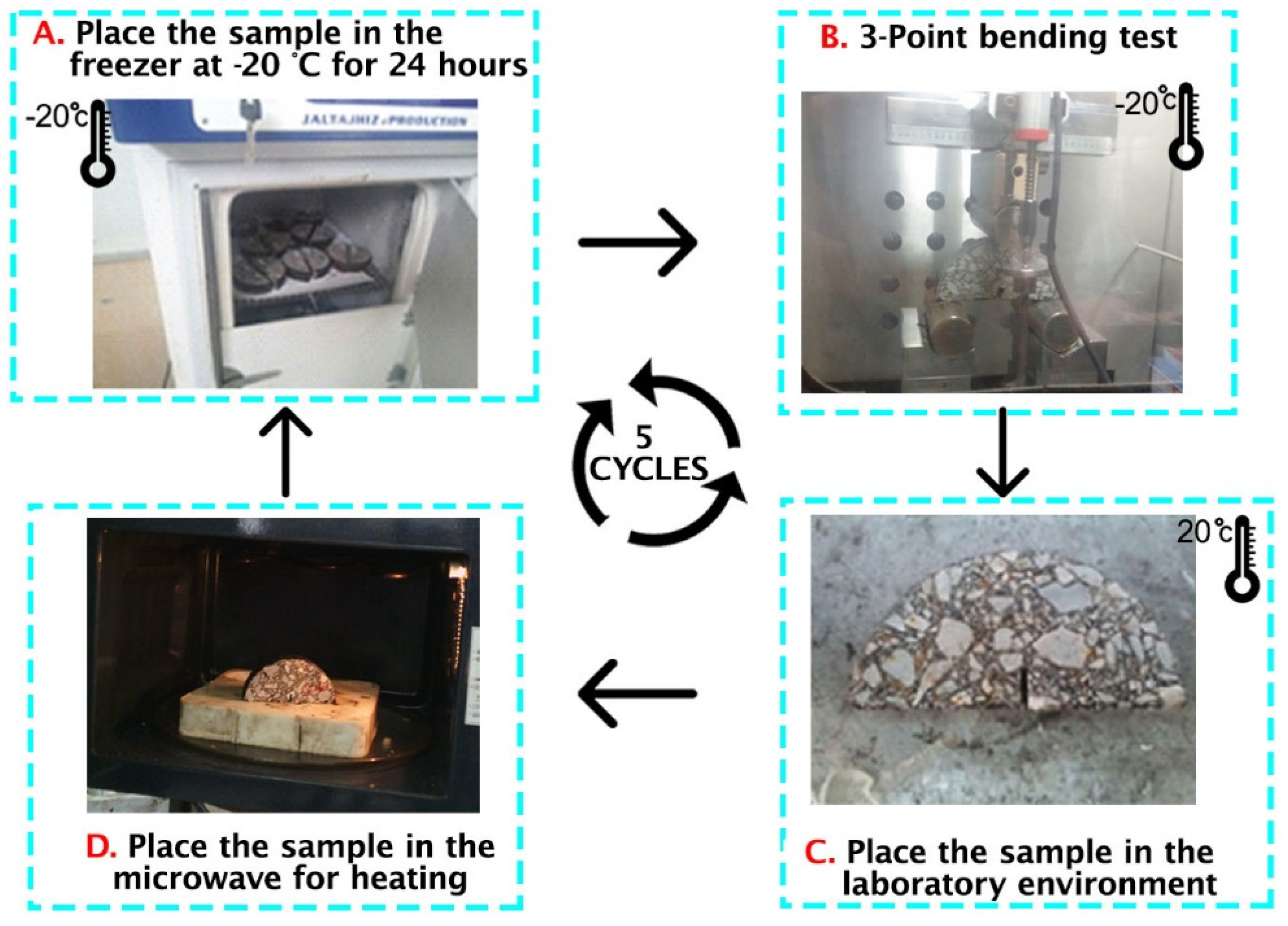

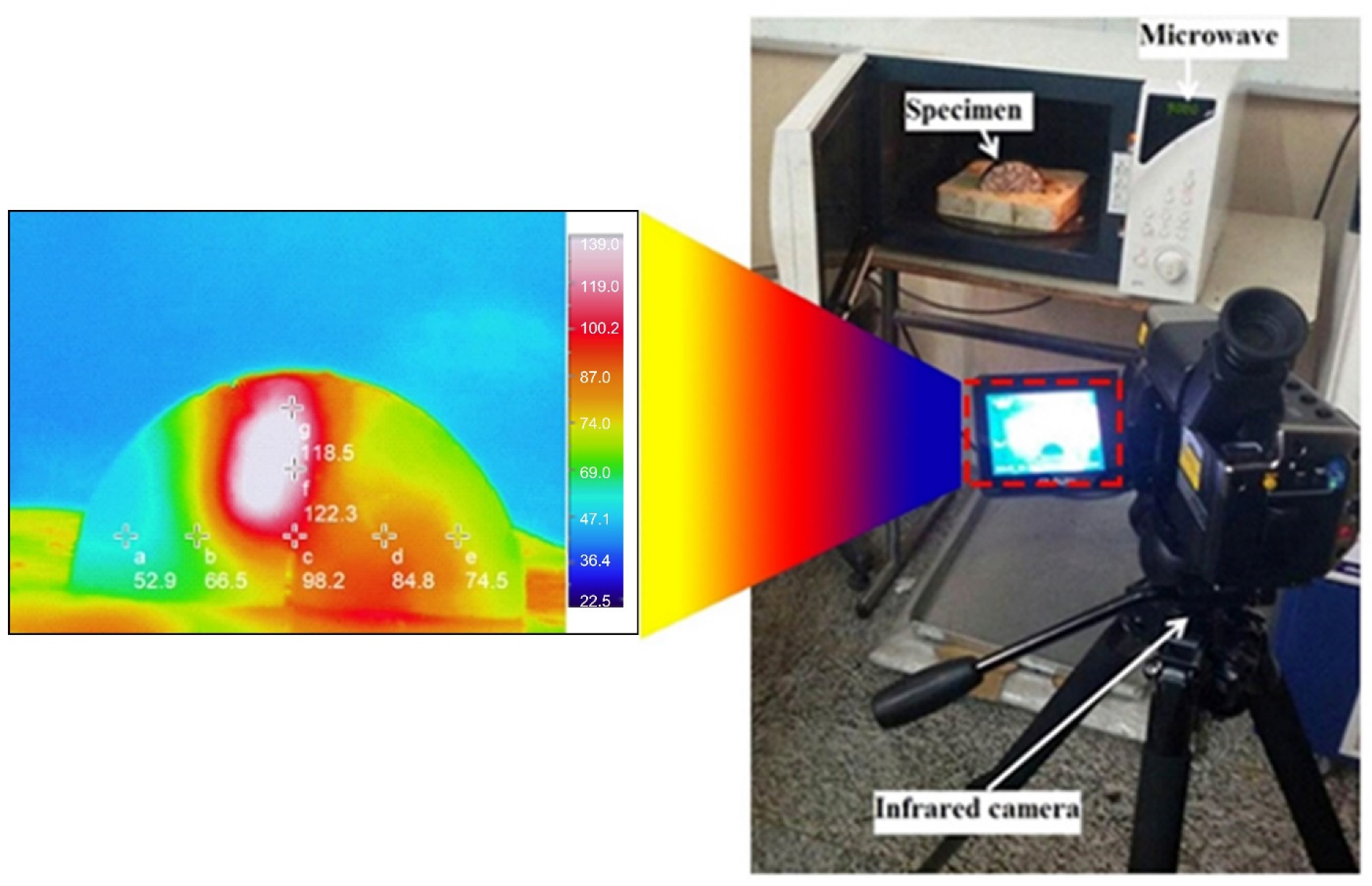

2.2. Experimental

2.3. Moisture Resistance Tests

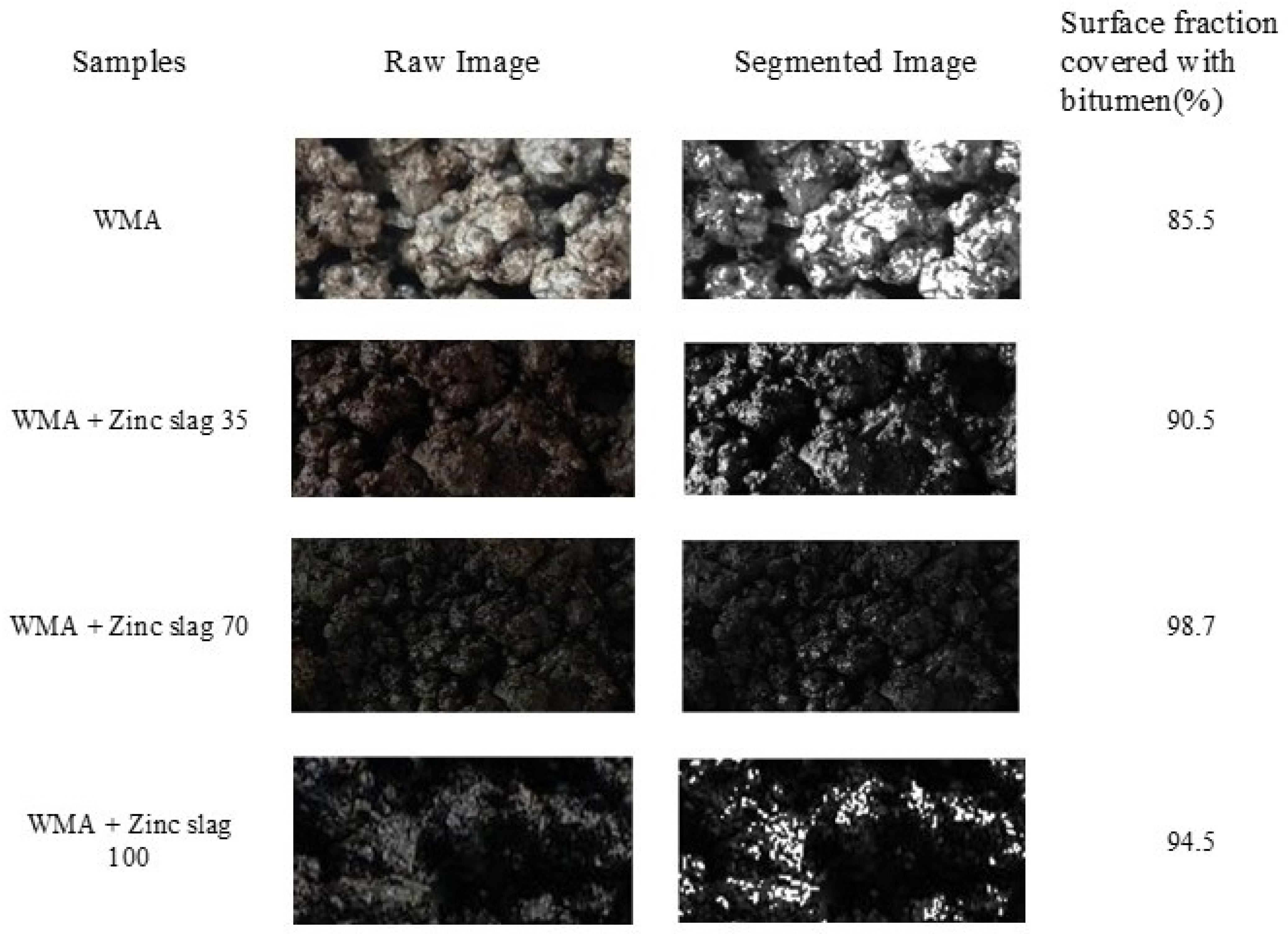

2.3.1. The Texas Boiling Test

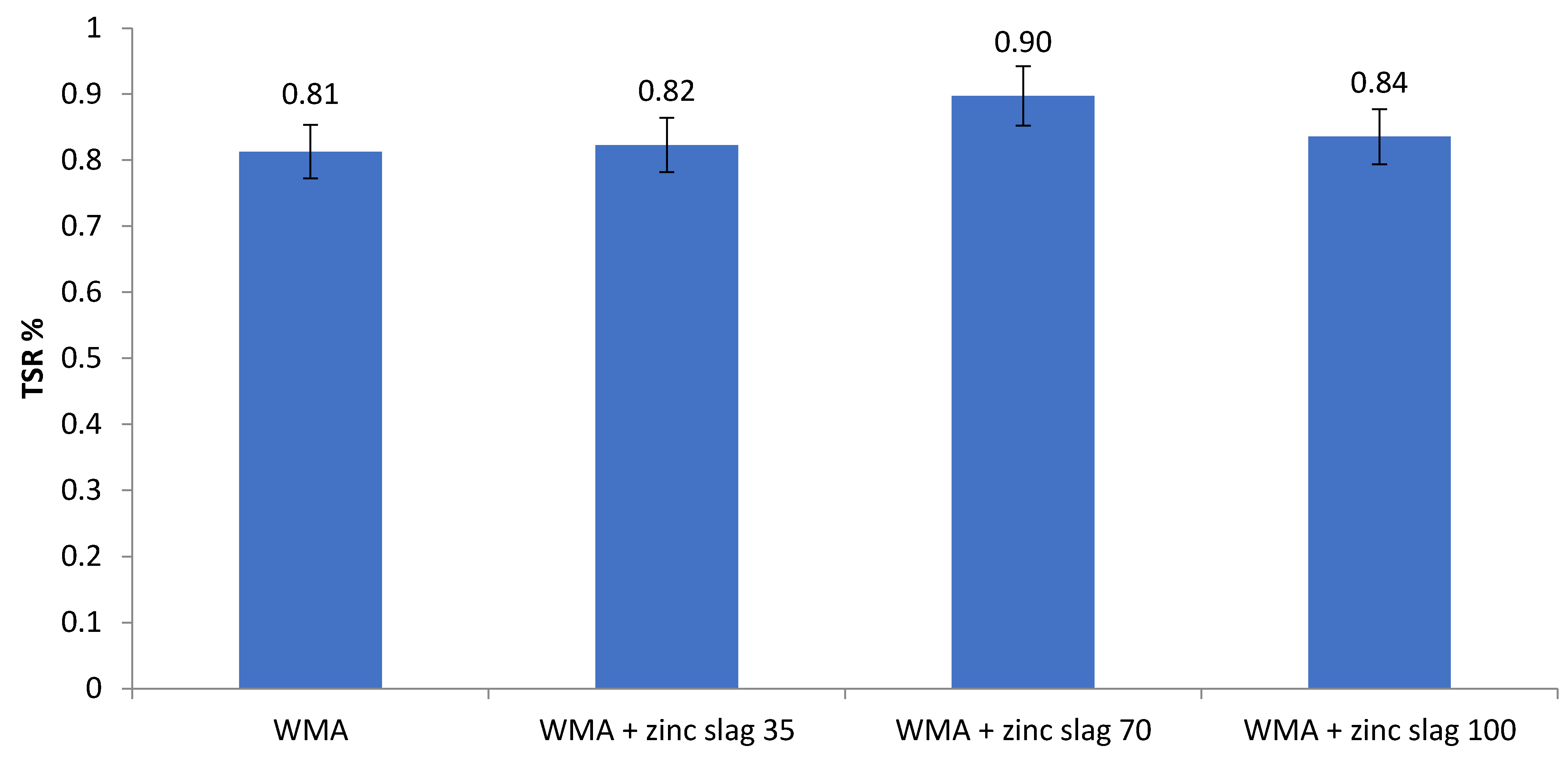

2.3.2. The Indirect Tensile Strength Test (AASHTO T283)

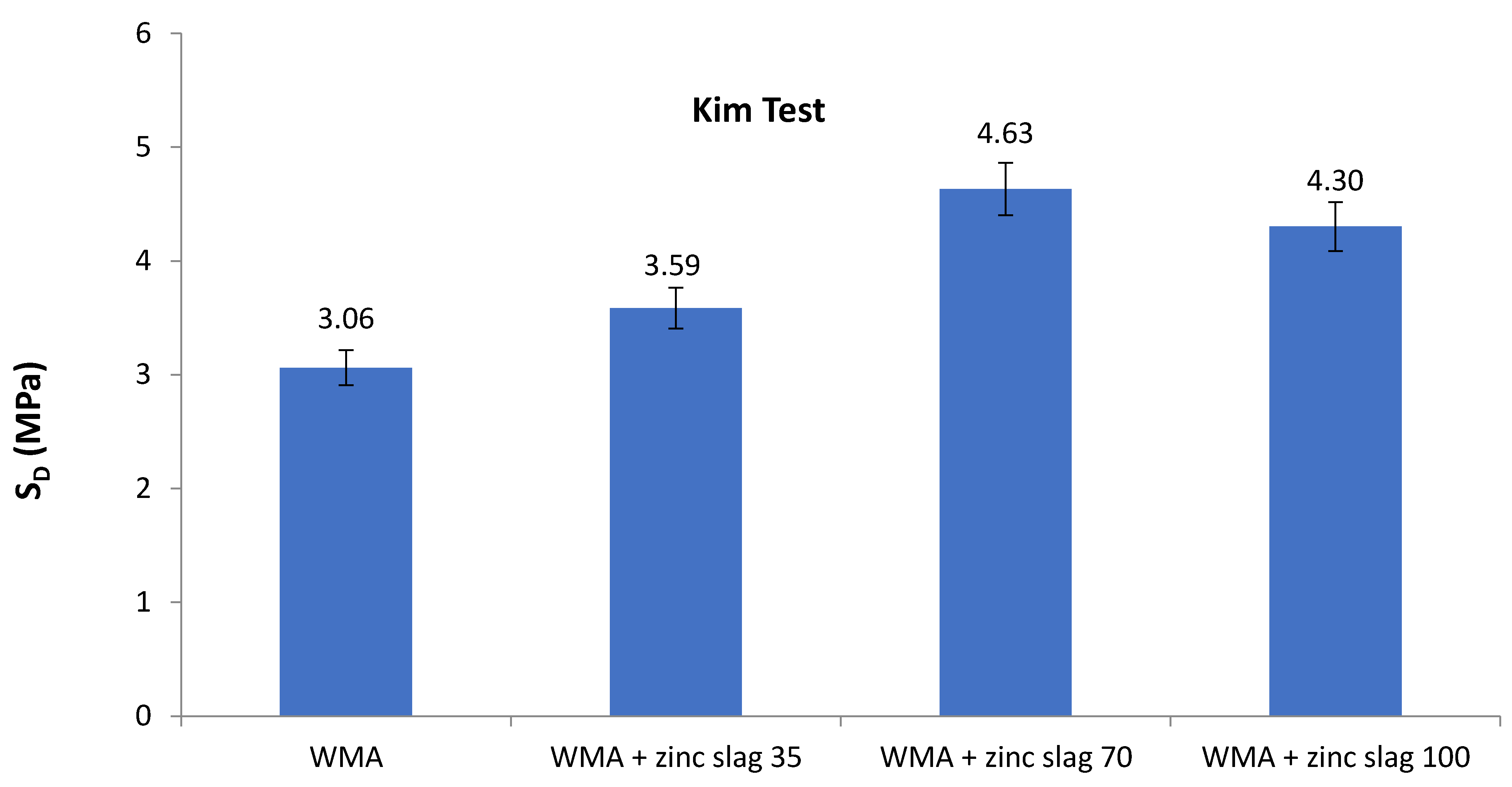

2.4. Deformation Test (Kim Test)

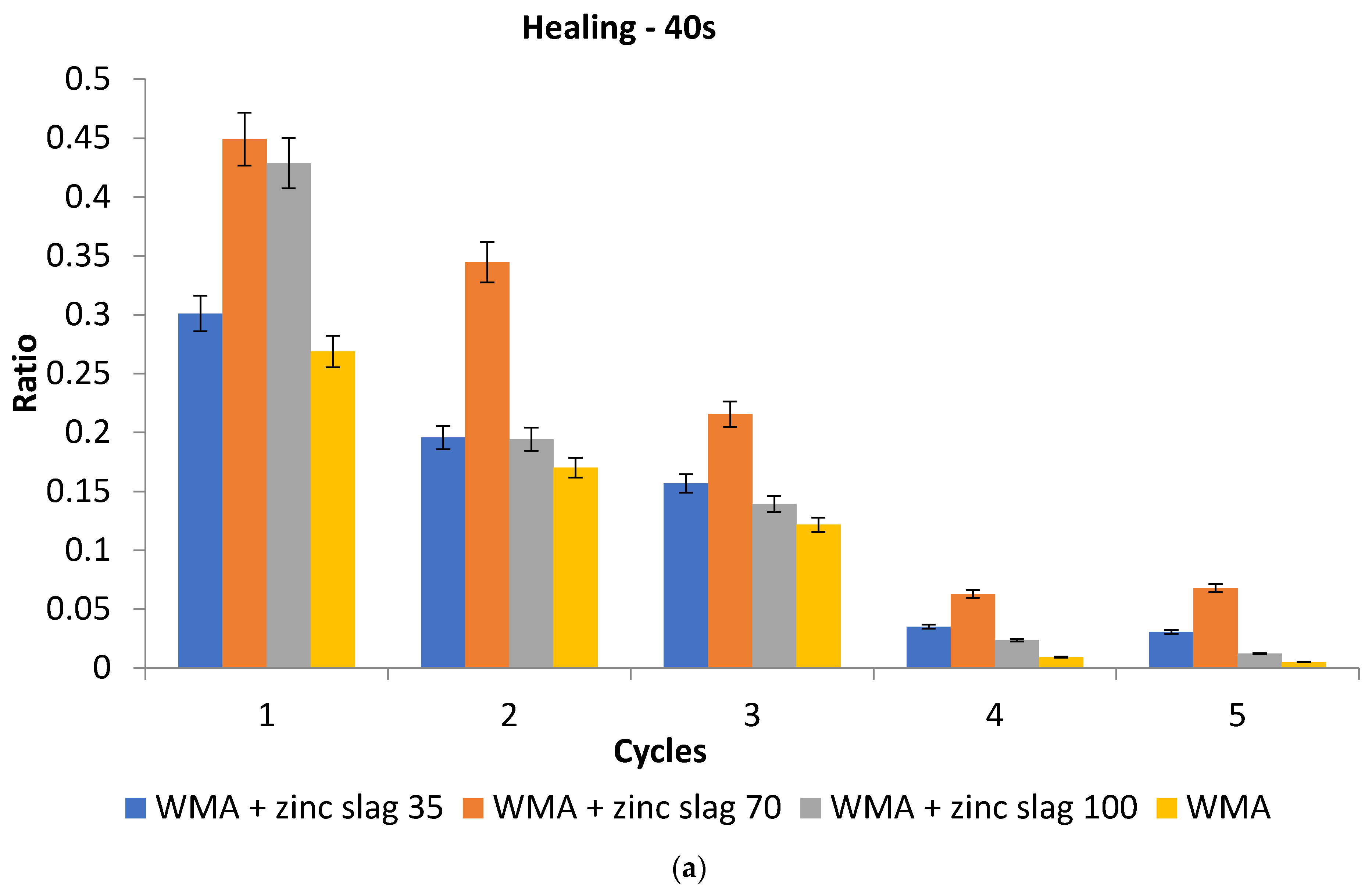

2.5. Self-Healing Test

3. Results

4. Discussion

5. Conclusions

- Zinc-containing mixtures possessed higher Marshall stability and flow values than the control samples.

- The results of stripping and moisture resistance tests indicated that the presence of zinc slag in the WMA mixtures improved aggregate–binder adhesion as well as the cohesive strength of the mixture’s mastic component.

- Replacing the mineral filler with zinc slag at all rates was found to increase moisture resistance and reduce the rutting susceptibility of the WMA mixtures.

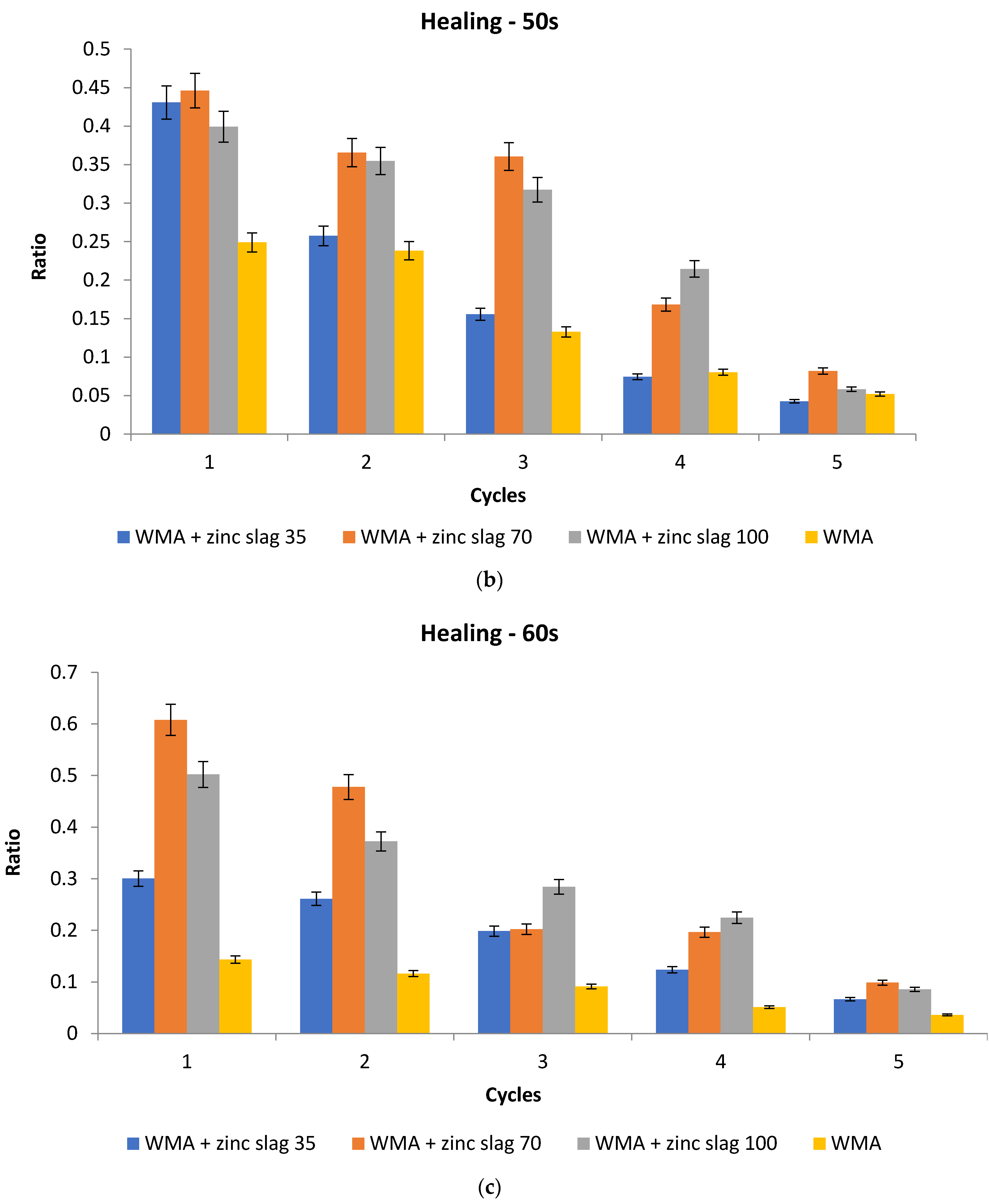

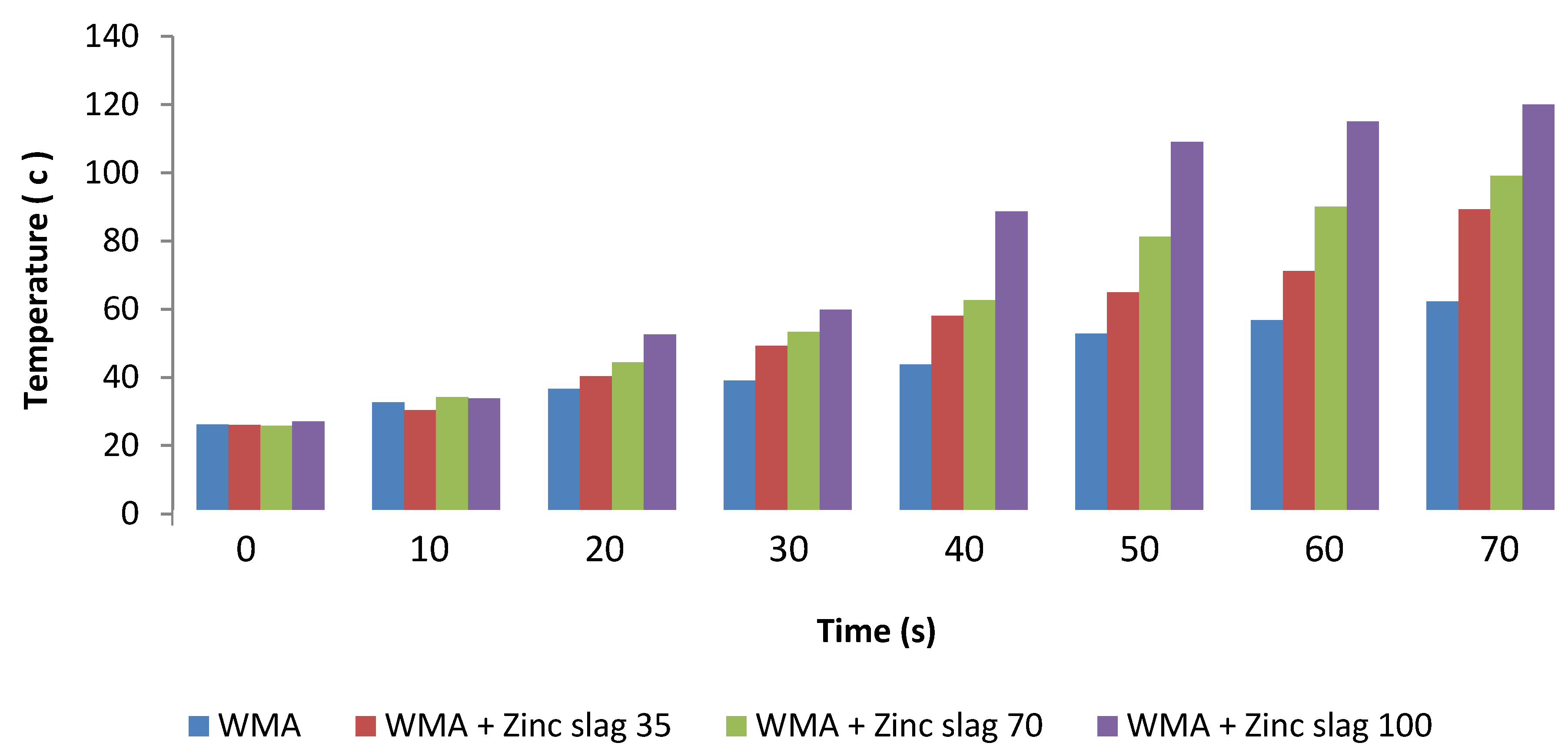

- The slag-containing specimens showed significantly higher heat generation capability under microwave induction without noticeable heat concentration or non-uniformity.

- The overall self-healing capacity of the mixtures was improved by zinc slag, the strength recovery of slag-containing specimens being considerably higher than the control.

- While the strength recovery improvement by slag incorporation is partially attributed to higher heat generation ability, zinc slag was found to positively affect WMA’s healing capacity under induction heating independent of the temperature.

- Strength recovery increased with the heating duration within the studied range of 40–60 s.

- Mixtures with 70% filler replacement displayed the highest Marshall stability and flow, ITS, TSR, and rutting resistance. Furthermore, replacing 70% of the mineral filler with zinc slag resulted in better aggregate–bitumen adhesion and self-healing capability compared to the other replacement rates. Increasing the filler replacement rate led to increased heating capability under microwave induction; however, the strength recovery ratio in the healing test was the highest at a 70% replacement rate.

- The results of this study revealed that the rate at which mineral filler is replaced with zinc slag could have an optimum value, beyond which the performance does not experience further improvement and can relatively degrade. Given the materials and method used in this research, 70% can be considered as the optimum rate of replacing mineral filler with zinc slag. However, care must be taken in generalizing or adopting this finding because this optimum value is specific to materials and mix design.

- Investigating the influence of zinc slag on energy parameters of the asphalt mixture components by future studies can create insights into the mechanisms involved in the interactions between the components of these mixtures, especially in the presence of water. Also, temperature-controlled self-healing tests can distinguish between the healing improvement caused by the mixture’s increased heat generation capability or enhanced healing capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thøgersen, F.; Colette, G.; Josef, S.; Pierre, H.; Yannick, D.; Cyrille, C.; Anita, B.; Broere, P.; Bizjak, K.F.; Hellman, F.; et al. Recycling of road materials into new unbound road layers–main practice in selected European countries. Road Mater. Pavement Des. 2013, 14, 438–444. [Google Scholar] [CrossRef]

- Arabani, M.; Mirabdolazimi, S.M.; Sasani, A.R. The effect of waste tire thread mesh on the dynamic behaviour of asphalt mixtures. Constr. Build. Mater. 2010, 24, 1060–1068. [Google Scholar] [CrossRef]

- Yalcin, E. Effects of microwave and induction heating on the mechanical and self-healing characteristics of the asphalt mixtures containing waste metal. Constr. Build. Mater. 2021, 286, 122965. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Self-healing properties of recycled asphalt mixtures containing metal waste: An approach through microwave radiation heating. J. Environ. Manag. 2018, 214, 242–251. [Google Scholar] [CrossRef] [Green Version]

- Do, H.S.; Mun, P.H.; Keun, R.S. A study on engineering characteristics of asphalt concrete using filler with recycled waste lime. Waste Manag. 2008, 28, 191–199. [Google Scholar] [CrossRef]

- Ajam, H.; Gómez-Meijide, B.; Artamendi, I.; Garcia, A. Mechanical and healing properties of asphalt mixes reinforced with different types of waste and commercial metal particles. J. Clean. Prod. 2018, 192, 138–150. [Google Scholar] [CrossRef]

- Xue, Y.; Hou, H.; Zhu, S.; Zha, J. Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture: Pavement performance and environmental impact. Constr. Build. Mater. 2009, 23, 989–996. [Google Scholar] [CrossRef]

- Javed, S.; Lovell, C.W.; Wood, L.E. Waste foundry sand in asphalt concrete. Transp. Res. Rec. 1994, 1437, 27–34. [Google Scholar]

- Franesqui, M.A.; Yepes, J.; García-González, C. Top-down cracking self-healing of asphalt pavements with steel filler from industrial waste applying microwaves. Constr. Build. Mater. 2017, 149, 612–620. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez, A.; Concha, J.L.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef] [Green Version]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2018, 159, 164–174. [Google Scholar] [CrossRef]

- da Silva, W.R.; da Silva, F.B.V.; Araújo, P.R.M.; Nascimento, C.W.A.D. Assessing human health risks and strategies for phytoremediation in soils contaminated with As, Cd, Pb, and Zn by slag disposal. Ecotoxicol. Environ. Saf. 2017, 144, 522–530. [Google Scholar] [CrossRef] [PubMed]

- Qing, Z.; Qi-Cheng, L.; Peng, L.; Chuan-Sheng, C.; Jiang-Rong, K. Study on modification mechanism of nano-ZnO/polymerised styrene butadiene composite-modified asphalt using density functional theory. Road Mater. Pavement Des. 2020, 21, 1426–1438. [Google Scholar] [CrossRef]

- Taherkhani, H.; Kamsari, S.V. Evaluating the properties of zinc production wastes as filler and their effects on asphalt mastic. Constr. Build. Mater. 2020, 265, 120748. [Google Scholar] [CrossRef]

- Barri, K.; Jahangiri, B.; Davami, O.; Buttlar, W.G.; Alavi, A.H. Smartphone-based molecular sensing for advanced characterization of asphalt concrete materials. Measurement 2020, 151, 107212. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Improving the aging resistance of asphalt by addition of Zinc dialkyldithiophosphate. Fuel 2006, 85, 1060–1066. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Nejad, F.M.; Oveisi, K. Estimating the moisture damage of asphalt mixture modified with nano zinc oxide. Mater. Struct. 2016, 49, 1165–1174. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Mechanical Behavior of Bitumen and Hot-Mix Asphalt Modified with Zinc Oxide Nanoparticle. J. Mater. Civ. Eng. 2019, 31, 04018399. [Google Scholar] [CrossRef]

- Aktaş, B.; Şevket, A. Laboratory Evaluation on Waste Slag Produced Zinc Industry as Mineral Filler in Stone Mastic Asphalt. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Larsen, O.R.; Moen, O.; Robertus, C.; Koenders, B.G. WAM Foam asphalt production at lower operating temperatures as an environmentally friendly alternative to HMA. In Proceedings of the 3rd EUasphalt and Eurobitumen congress, Vienna, Austria, 12–14 May 2004; Volume 1. [Google Scholar]

- Fakhri, M.; Ahmadi, A. Recycling of RAP and steel slag aggregates into the warm mix asphalt: A performance evaluation. Constr. Build. Mater. 2017, 147, 630–638. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, W.; Wu, S.; Schlangen, E.; Pan, P. A comparative study of the induction healing behaviors of hot and warm mix asphalt. Constr. Build. Mater. 2017, 144, 663–670. [Google Scholar] [CrossRef]

- Cucalon, L.G.; Yin, F.; Martin, A.E.; Arambula, E.; Estakhri, C.; Park, E.S. Evaluation of Moisture Susceptibility Minimization Strategies for Warm-Mix Asphalt: Case Study. J. Mater. Civ. Eng. 2016, 28, 05015002. [Google Scholar] [CrossRef]

- Ziari, H.; Moniri, A.; Imaninasab, R.; Nakhaei, M. Effect of copper slag on performance of warm mix asphalt. Int. J. Pavement Eng. 2019, 20, 775–781. [Google Scholar] [CrossRef]

- Bennert, T. Performance Evaluation of Asphalt Mixtures Statewide; No. C-19-03; NYS Department of Transportation: Albany, NY, USA, 2021.

- Advanced Asphalt Technologies, LLC. A Manual for Design of Hot Mix Asphalt With Commentary; Transportation Research Board: Washington, DC, USA, 2011; Volume 673. [Google Scholar]

- Javilla, B.; Fang, H.; Mo, L.; Shu, B.; Wu, S. Test evaluation of rutting performance indicators of asphalt mixtures. Constr. Build. Mater. 2017, 155, 1215–1223. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement Des. 2021, 22 (Suppl. 1), S498–S513. [Google Scholar] [CrossRef]

- Abdelsalam, M.; Yue, Y.; Khater, A.; Luo, D.; Musanyufu, J.; Qin, X. Laboratory Study on the Performance of Asphalt Mixes Modified with a Novel Composite of Diatomite Powder and Lignin Fiber. Appl. Sci. 2020, 10, 5517. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, F.; Amirkhanian, S.; Singh, D. Moisture characteristics of mixtures with warm mix asphalt technologies—A review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- Fakhri, M.; Hosseini, S.A. Laboratory evaluation of rutting and moisture damage resistance of glass fiber modified warm mix asphalt incorporating high RAP proportion. Constr. Build. Mater. 2017, 134, 626–640. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Wu, Q.; Zhang, L.; Zhang, Z.; Zhang, J.; Miljković, M.; Oeser, M. Decision support for selecting optimal method of recycling waste tire rubber into wax-based warm mix asphalt based on fuzzy comprehensive evaluation. J. Clean. Prod. 2020, 265, 121781. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Performance of hot and warm mix asphalt mixtures enhanced by nano-sized graphene oxide. Constr. Build. Mater. 2019, 217, 273–282. [Google Scholar] [CrossRef]

- Kumar, P.; Chandra, S.; Bose, S. Rheology of the Polymer Modified Binders. Highw. Res. Bull. 2004, 71, 119–135. [Google Scholar]

- Kringos, N.; Schmets, A.; Pauli, T.; Scarpas, T. A finite element base chemomechanical model to stimulate healing in bitumen. In Proceedings of the International Workshop on Chemo-mechanics of Bituminous materials, Delft, The Netherlands, 9–11 June 2009; pp. 9–11. [Google Scholar]

- García, Á. Self-healing of open cracks in asphalt mastic. Fuel 2012, 93, 264–272. [Google Scholar] [CrossRef]

- García, A.; Bueno, M.; Norambuena-Contreras, J.; Manfred, N.P. Induction healing of dense asphalt concrete. Constr. Build. Mater. 2013, 49, 1–7. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Bhasin, A.; Palvadi, S.; Little, D.N. Influence of Aging and Temperature on Intrinsic Healing of Asphalt Binders. Transp. Res. Rec. 2011, 2207, 70–78. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Ajam, H.; González, P.L.; Garcia, A. Effect of air voids content on asphalt self-healing via induction and infrared heating. Constr. Build. Mater. 2016, 126, 957–966. [Google Scholar] [CrossRef]

- Menozzi, A.; Garcia, A.; Partl, M.N.; Tebaldi, G.; Schuetz, P. Induction healing of fatigue damage in asphalt test samples. Constr. Build. Mater. 2015, 74, 162–168. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, S.; Schlangen, E. Induction heating of asphalt mastic for crack control. Constr. Build. Mater. 2013, 41, 345–351. [Google Scholar] [CrossRef]

- Gao, J. Carbon Fiber-Cement Emulsified Asphalt Mortar with Tropical Design and Microwave Deicing Function Research. Master’s Thesis, Chang’an University, Xi’an, China, 2014. [Google Scholar]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Taylor, P.C.; Nahvi, A. Polyurethane-carbon microfiber composite coating for electrical heating of concrete pavement surfaces. Heliyon 2019, 5, e02359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galindo, B.; Benedito, A.; Ramos, F.; Gimenez, E. Microwave heating of polymers: Influence of carbon nanotubes dispersion on the microwave susceptor effectiveness. Polym. Eng. Sci. 2016, 56, 1321–1329. [Google Scholar] [CrossRef] [Green Version]

- Arabzadeh, A.; Notani, M.A.; Zadeh, A.K.; Nahvi, A.; Sassani, A.; Ceylan, H. Electrically conductive asphalt concrete: An alternative for automating the winter maintenance operations of transportation infrastructure. Compos. Part B Eng. 2019, 173, 106985. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Sassani, A. Superhydrophobic Coatings on Asphalt Concrete Surfaces: Toward Smart Solutions for Winter Pavement Maintenance. Transp. Res. Rec. 2016, 2551, 10–17. [Google Scholar] [CrossRef]

- Wuori, A.F. Ice-Pavement Bond Disbonding: Surface Modification and Disbonding; No. SHRP-H-644; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1993. [Google Scholar]

- Osborne, T.L.; Hutcheson, W.R. Asphaltic Compositions and Uses Therefor. U.S. Patent No. 4,849,020, 18 July 1989. [Google Scholar]

- Nabiun, N.; Khabiri, M.M. Mechanical and moisture susceptibility properties of HMA containing ferrite for their use in magnetic asphalt. Constr. Build. Mater. 2016, 113, 691–697. [Google Scholar] [CrossRef]

- Abo-Qudais, S. The effects of damage evaluation techniques on the prediction of environmental damage in asphalt mixtures. Build. Environ. 2007, 42, 288–296. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Alexander, A.J.; Hussain, B.U. Evaluating the effect of warm-mix asphalt technologies on moisture characteristics of asphalt binders and mixtures. Transp. Res. Rec. 2011, 2209, 52–60. [Google Scholar] [CrossRef]

- Lottman, R.P. Predicting Moisture-Induced Damage to Asphaltic Concrete Field Evaluation; Report 246; The National Cooperative Highway Research Program (NCHRP), Transportation Research Board: Washington, DC, USA, 1982. [Google Scholar]

- Fakhri, M.; Javadi, S.; Sedghi, R.; Arzjani, D.; Zarrinpour, Y. Effects of deicing agents on moisture susceptibility of the WMA containing recycled crumb rubber. Constr. Build. Mater. 2019, 227, 116581. [Google Scholar] [CrossRef]

- Kim, K.W.; Doh, Y.S.; Amrikhanian, S.N. Feasibility of deformation strength for estimation of rut resistance of asphalt concrete. Road Mater. Pavement Des. 2004, 5, 303–322. [Google Scholar] [CrossRef]

- Doh, Y.S.; Yun, K.K.; Amirkhanian, S.N.; Kim, K.W. Framework for developing a static strength test for measuring deformation resistance of asphalt concrete mixtures. Constr. Build. Mater. 2007, 21, 2047–2058. [Google Scholar] [CrossRef]

- Fakhri, M.; Maleki, H.; Hosseini, S.A. Investigation of different test methods to quantify rutting resistance and moisture damage of GFM-WMA mixtures. Constr. Build. Mater. 2017, 152, 1027–1040. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez-Torre, I. Influence of the microwave heating time on the self-healing properties of asphalt mixtures. Appl. Sci. 2017, 7, 1076. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Zhong, S.; Zhu, X.; Chen, H. High-efficiency heating characteristics of ferrite-filled asphalt-based composites under microwave irradiation. J. Mater. Civ. Eng. 2017, 29, 04017007. [Google Scholar] [CrossRef]

- Fakhri, M.; Javadi, S.; Sedghi, R.; Sassani, A.; Arabzadeh, A.; Bahmai, B.B. Microwave Induction Heating of Polymer-Modified Asphalt Materials for Self-Healing and Deicing. Sustainability 2021, 13, 10129. [Google Scholar] [CrossRef]

- Xu, S.; García, A.; Su, J.; Liu, Q.; Tabaković, A.; Schlangen, E. Self-Healing Asphalt Review: From Idea to Practice. Adv. Mater. Interfaces 2018, 5, 1800536. [Google Scholar] [CrossRef]

- Tan, Y.; Guo, M. Using surface free energy method to study the cohesion and adhesion of asphalt mastic. Constr. Build. Mater. 2013, 47, 254–260. [Google Scholar] [CrossRef]

- Lytton, R.L.; Masad, E.A.; Zollinger, C.; Bulut, R.; Little, D.N. Measurements of Surface Energy and Its Relationship to Moisture Damage; No. FHWA/TX-05/0-4524-2; Texas Department of Transportation: Austin, TX, USA, 2005.

- Kim, Y.-R.; Little, D.N.; Lytton, R.L. Fatigue and Healing Characterization of Asphalt Mixtures. J. Mater. Civ. Eng. 2003, 15, 75–83. [Google Scholar] [CrossRef]

- Arabani, M.; Hamedi, G.H. Using the surface free energy method to evaluate the effects of liquid antistrip additives on moisture sensitivity in hot mix asphalt. Int. J. Pavement Eng. 2014, 15, 66–78. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. The Prospect of Microwave Heating: Towards a Faster and Deeper Crack Healing in Asphalt Pavement. Processes 2021, 9, 507. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.S.M.; Gopalakrishnan, K.; Taylor, P.C.; Abdualla, H. Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

| Bitumen Properties | Bitumen (60/70) | Test Method | Unit |

|---|---|---|---|

| Specific gravity | 1.017 | ASTM D70 | g/cm3 |

| Penetration grade at 25 °C | 65 | ASTM D5 | 0.1 mm |

| Softening point | 49.8 | ASTM D36 | °C |

| Ductility at 25 °C | >100 | ASTM D113 | cm |

| Flash point | 334 | ASTM D92 | °C |

| WMA | WMA + Zinc Slag 35 | WMA + Zinc Slag 70 | WMA + Zinc Slag 100 | |

|---|---|---|---|---|

| Mixture type * | 100/0 | 65/35 | 30/70 | 0/100 |

| Optimum Bitumen Content (%) | 5.2% | 5.3% | 5.4% | 5.5% |

| Marshall stability (KN) | 9.6 | 14.25 | 14.7 | 14.4 |

| Marshal flow (mm) | 3.2 | 3.4 | 3.5 | 3.6 |

| Bulk specific gravity | 2.33 | 2.32 | 2.31 | 2.29 |

| VMA 1 | 14.9 | 15 | 15.1 | 15.2 |

| VFA 2 | 73.1 | 73.3 | 73.5 | 73.7 |

| Description | Test Results | Test Method | Unit |

|---|---|---|---|

| LA abrasion value | 22.3 | AASHTO T96 | - |

| Particle shape Flakiness index | 16 | BS 812 | - |

| The Percentage of Fractured Particles in Coarse Aggregate | 93 | ASTM D5821 | - |

| Maximum water absorption of coarse aggregate | 2.2 | AASHTO T85 | - |

| Maximum water absorption of fine aggregate | 2.4 | AASHTO T84 | - |

| SSD specific gravity of coarse aggregate | 2.59 | ASTM C127 | g/cm3 |

| SSD specific gravity of fine aggregate | 2.32 | ASTM C128 | g/cm3 |

| Composition | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | K2O | ZnO | Other |

|---|---|---|---|---|---|---|---|---|---|

| Filler | Content (% wt.) | ||||||||

| Mineral | 49.05 | 10.19 | 0.71 | 1.20 | 0.77 | 0.10 | 0.40 | - | 37.47 |

| Slag | 0.22 | 0.73 | 1.88 | - | - | - | 1.20 | 60.05 | 35.92 |

| WMA | WMA + Zinc Slag 35 | WMA + Zinc Slag 70 | WMA + Zinc Slag 100 | |

|---|---|---|---|---|

| Mixture type * | 100/0 | 65/35 | 30/70 | 0/100 |

| O.B.C % | 5.2% | 5.3% | 5.4% | 5.5% |

| Marshall stability (KN) | 9.6 | 14.25 | 14.7 | 14.4 |

| Marshal flow (mm) | 3.2 | 3.4 | 3.5 | 3.6 |

| Bulk specific gravity | 2.33 | 2.32 | 2.31 | 2.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fakhri, M.; Javadi, S.; Sassani, A.; Torabi-Dizaji, M. Zinc Slag as a Partial or Total Replacement for Mineral Filler in Warm Mix Asphalt and Its Effects on Self-Healing Capacity and Performance Characteristics. Materials 2022, 15, 736. https://doi.org/10.3390/ma15030736

Fakhri M, Javadi S, Sassani A, Torabi-Dizaji M. Zinc Slag as a Partial or Total Replacement for Mineral Filler in Warm Mix Asphalt and Its Effects on Self-Healing Capacity and Performance Characteristics. Materials. 2022; 15(3):736. https://doi.org/10.3390/ma15030736

Chicago/Turabian StyleFakhri, Mansour, Sajad Javadi, Alireza Sassani, and Mohsen Torabi-Dizaji. 2022. "Zinc Slag as a Partial or Total Replacement for Mineral Filler in Warm Mix Asphalt and Its Effects on Self-Healing Capacity and Performance Characteristics" Materials 15, no. 3: 736. https://doi.org/10.3390/ma15030736

APA StyleFakhri, M., Javadi, S., Sassani, A., & Torabi-Dizaji, M. (2022). Zinc Slag as a Partial or Total Replacement for Mineral Filler in Warm Mix Asphalt and Its Effects on Self-Healing Capacity and Performance Characteristics. Materials, 15(3), 736. https://doi.org/10.3390/ma15030736