Formation Behavior and Reaction Characteristic of a PTFE/Al Reactive Jet

Abstract

:1. Introduction

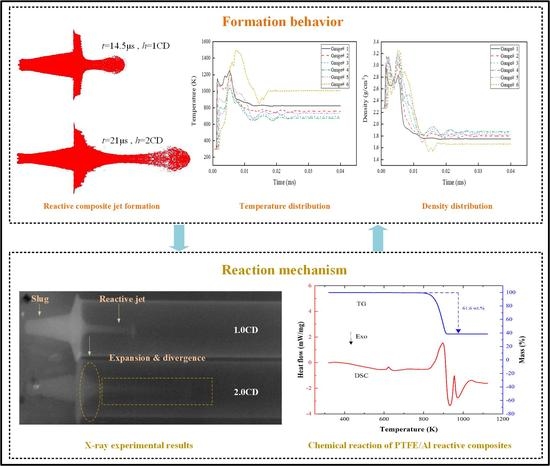

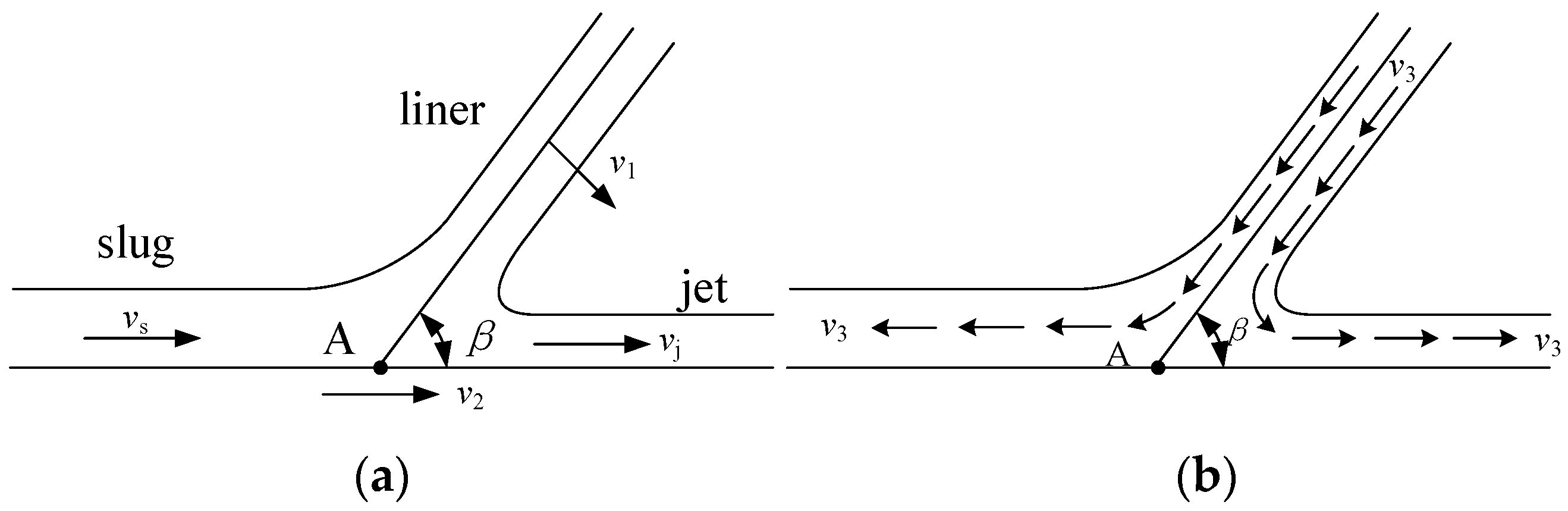

2. Formation Behavior of the Reactive Composite Jet

2.1. SPH Model and Material Parameters

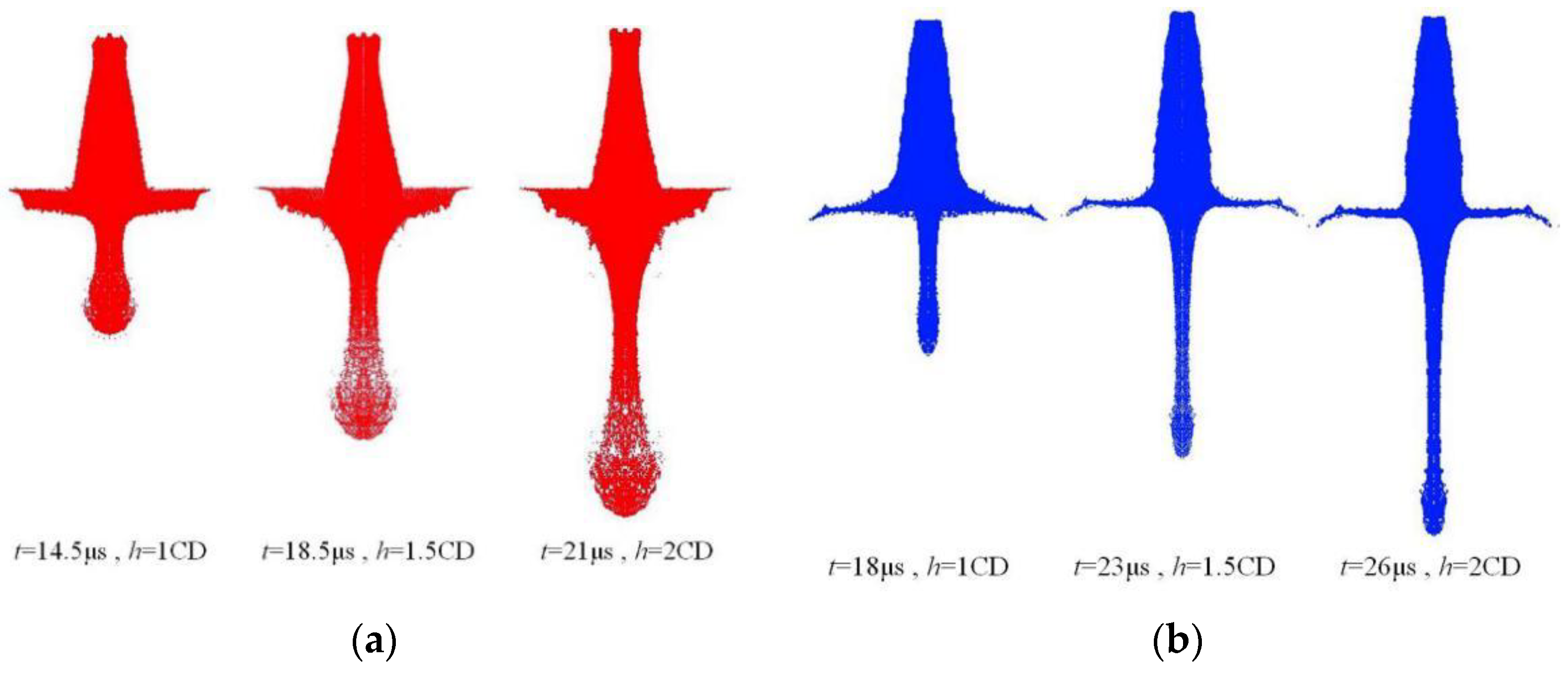

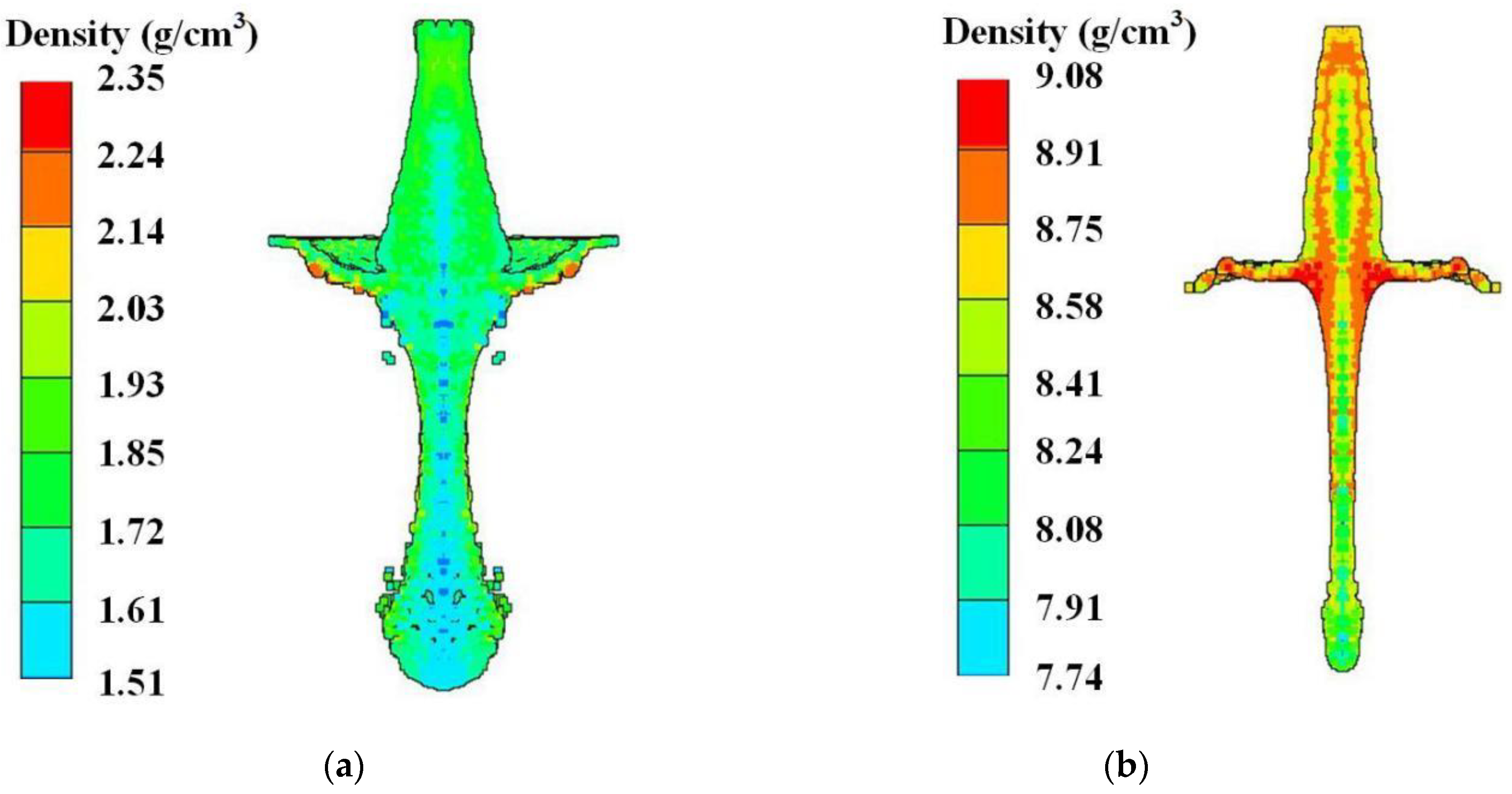

2.2. Comparison between Reactive Composite Jet and Cu Jet

2.3. Temperature Distribution of the Reactive Composite Jet

3. Influencing Factors of Reactive Composite Jet Formation

3.1. The Type of Explosive

3.2. Cone Angle of the Reactive Liner

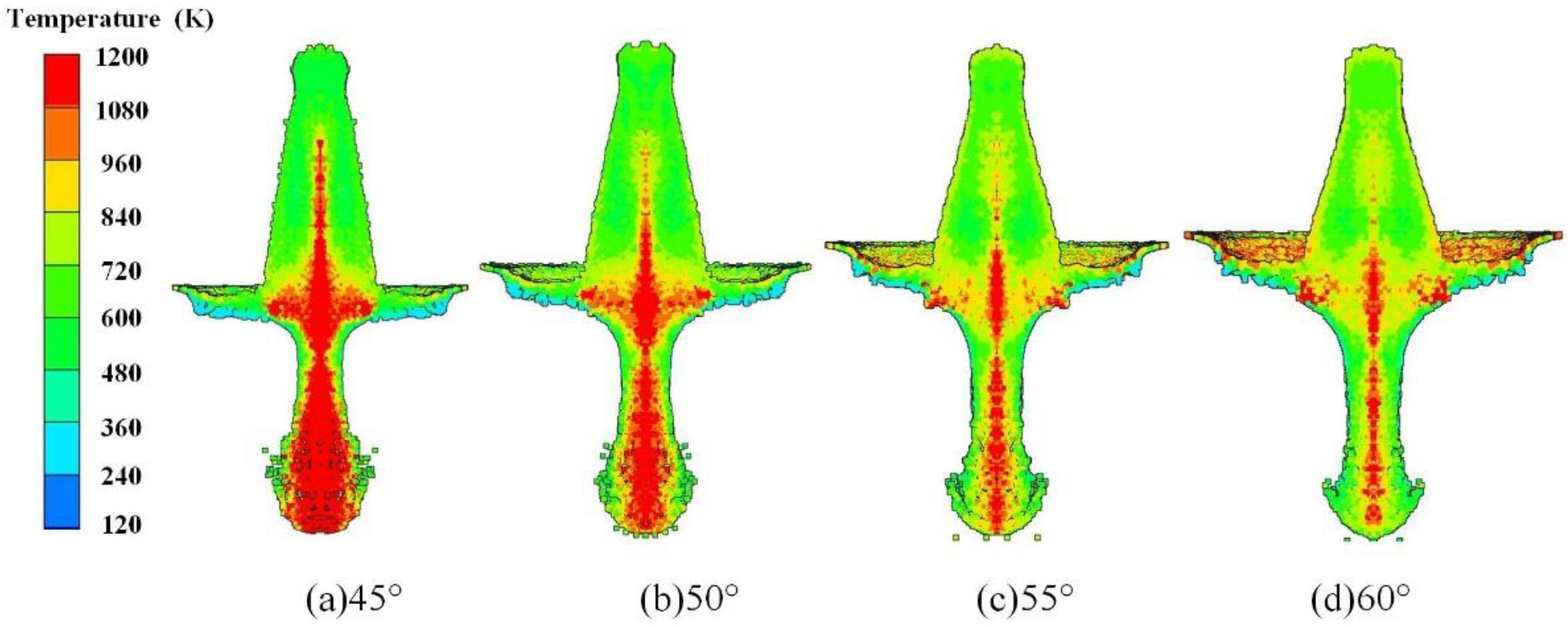

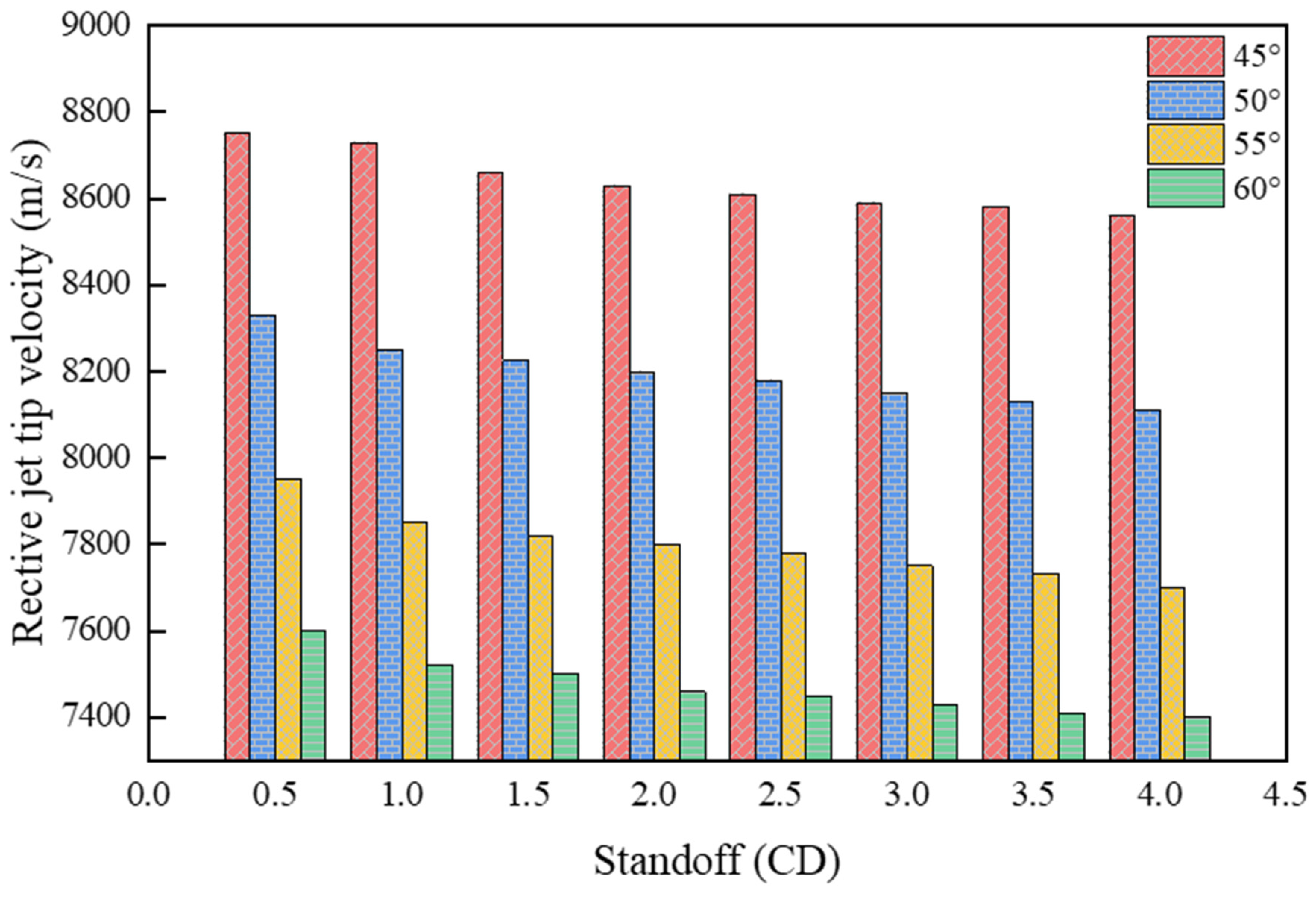

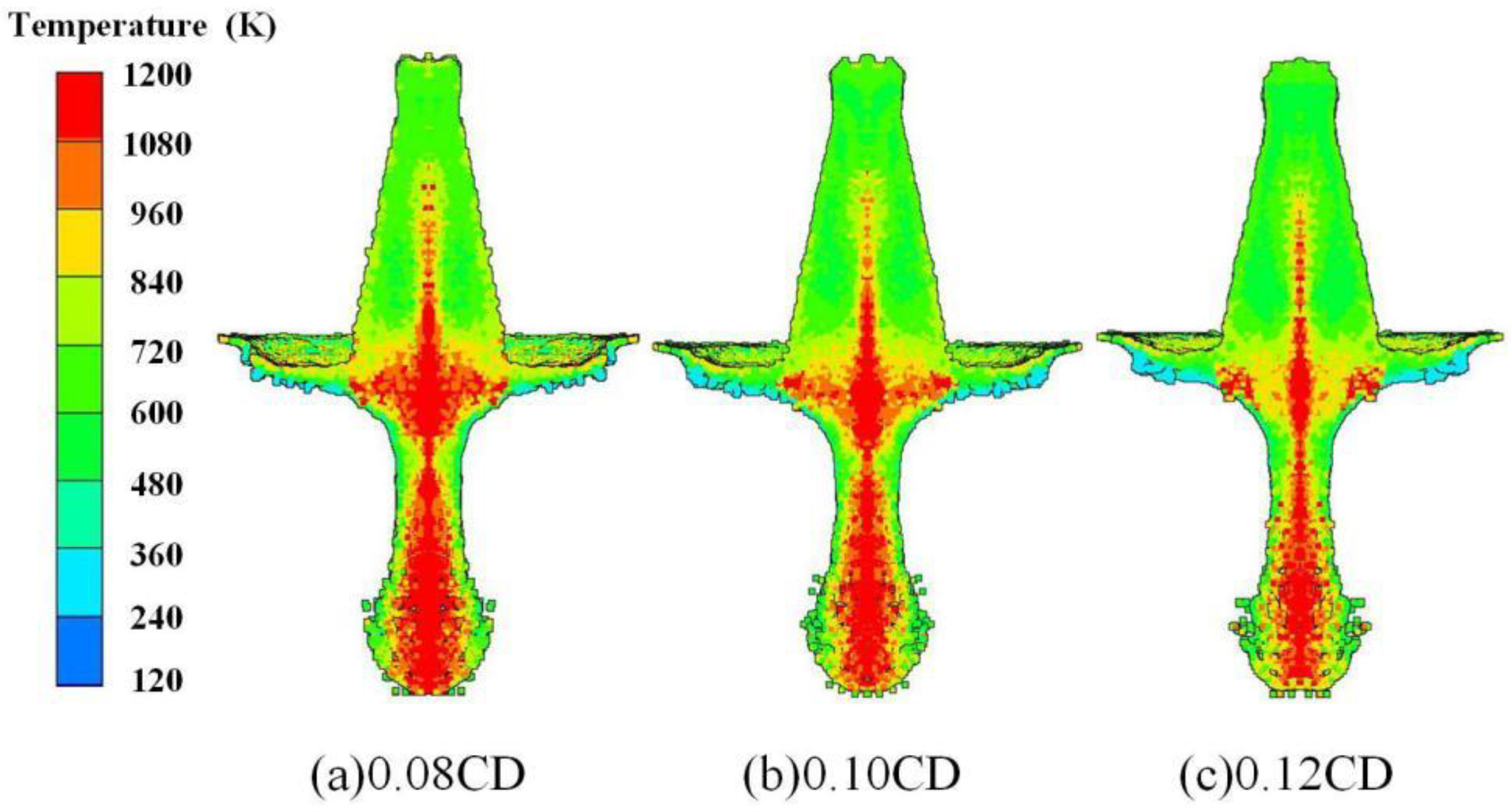

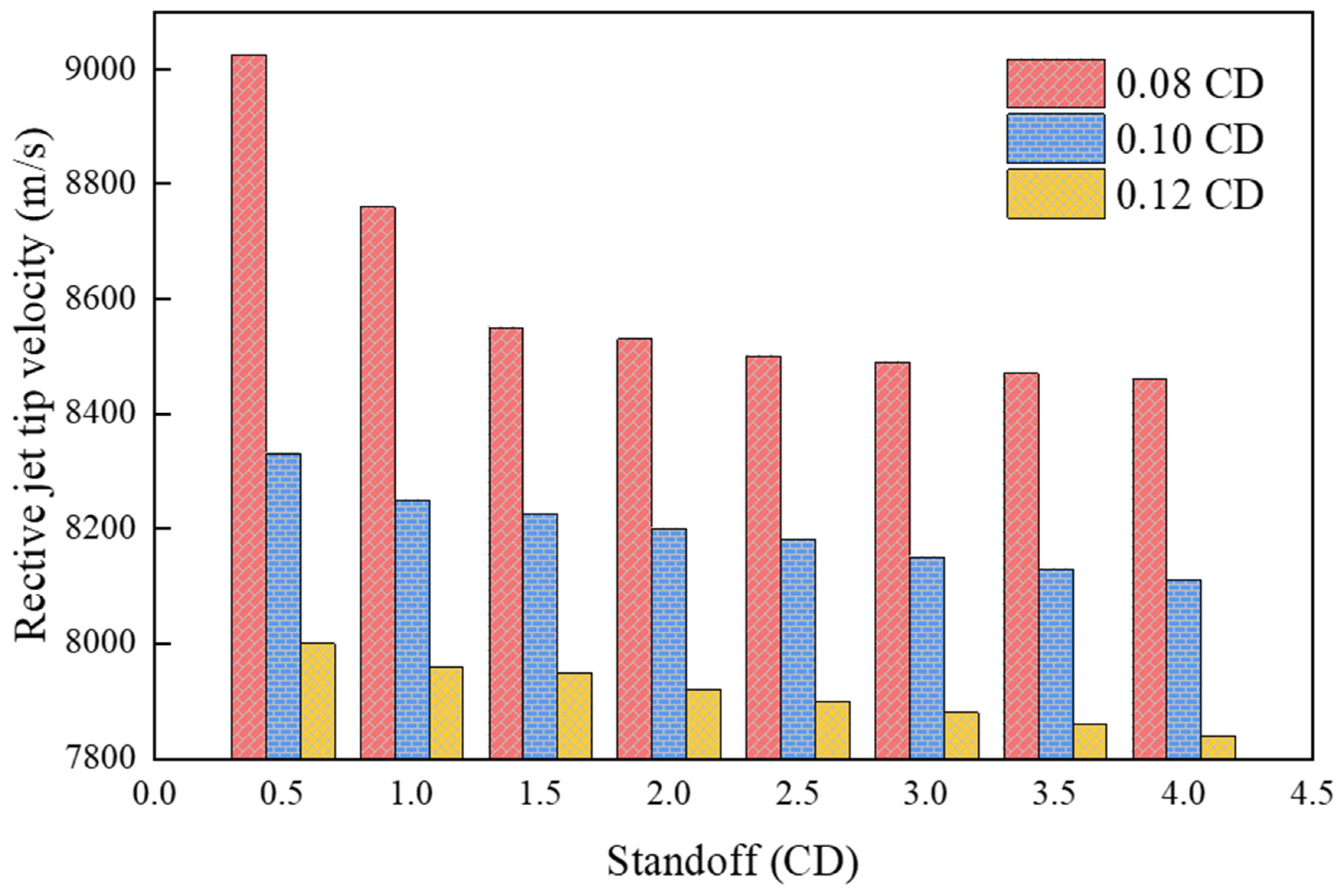

3.3. Wall Thickness of the Reactive Liner

4. Reaction Characteristic of the Reactive Composite Jet

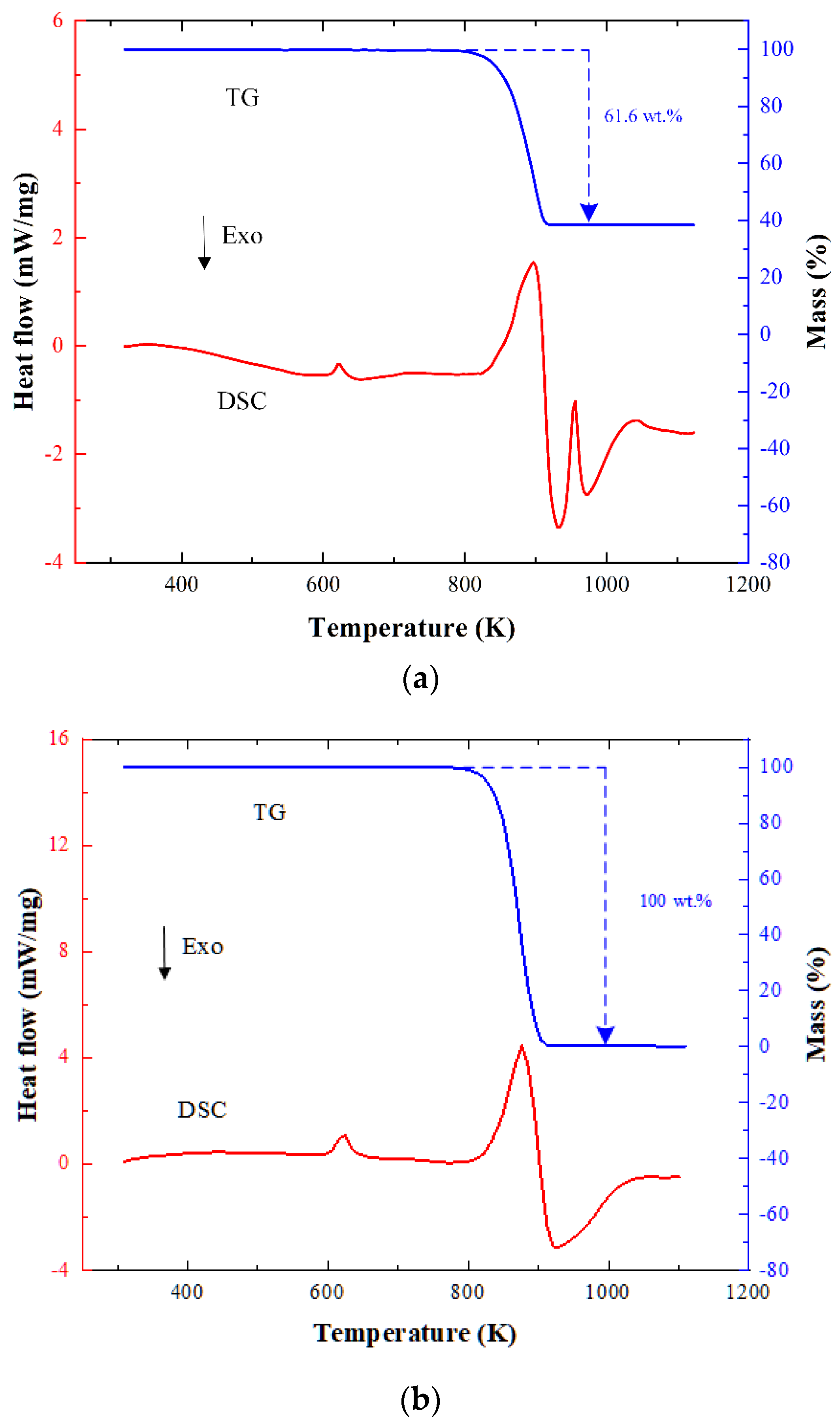

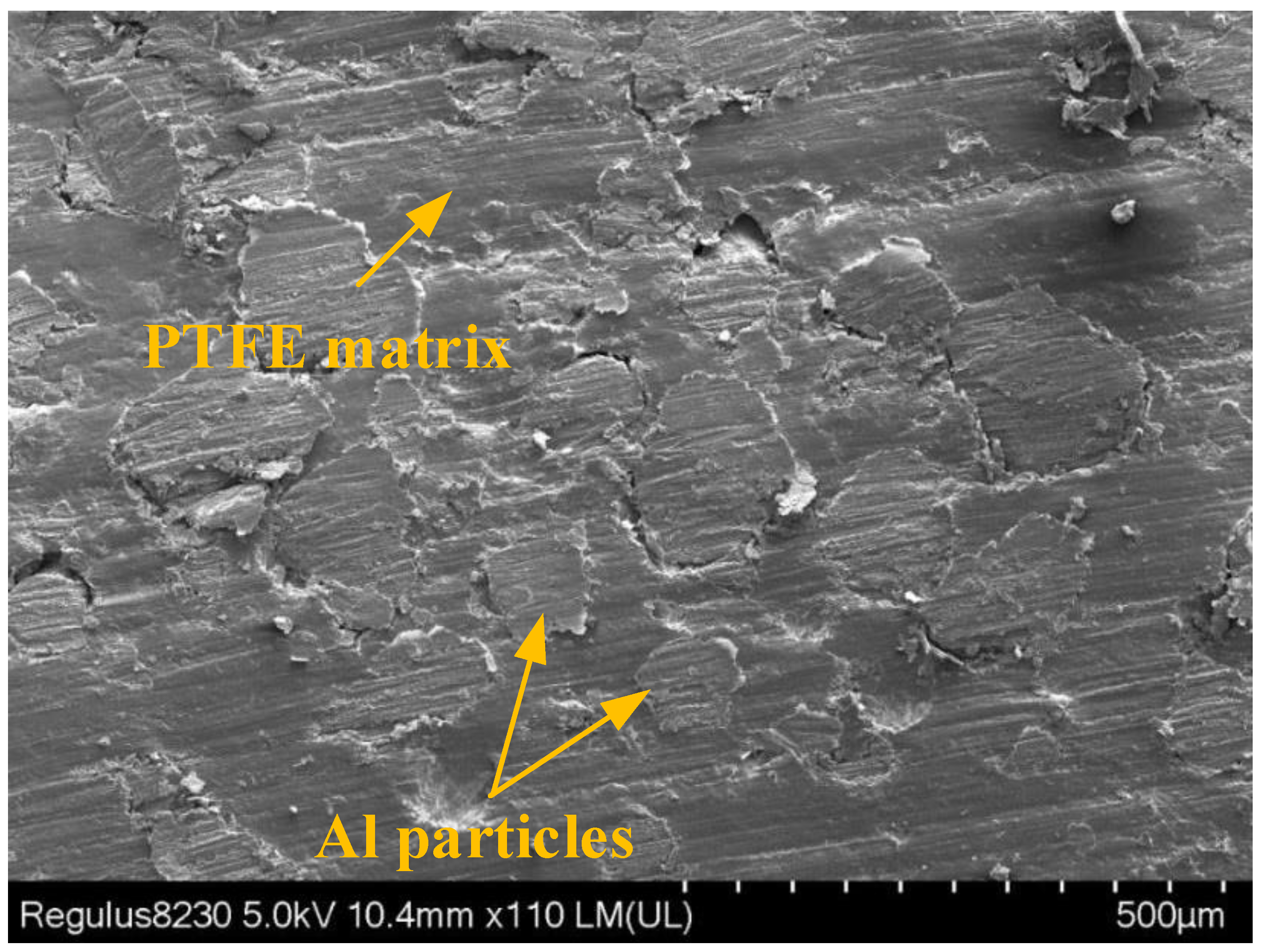

4.1. Chemical Reaction of PTFE/Al Reactive Composites

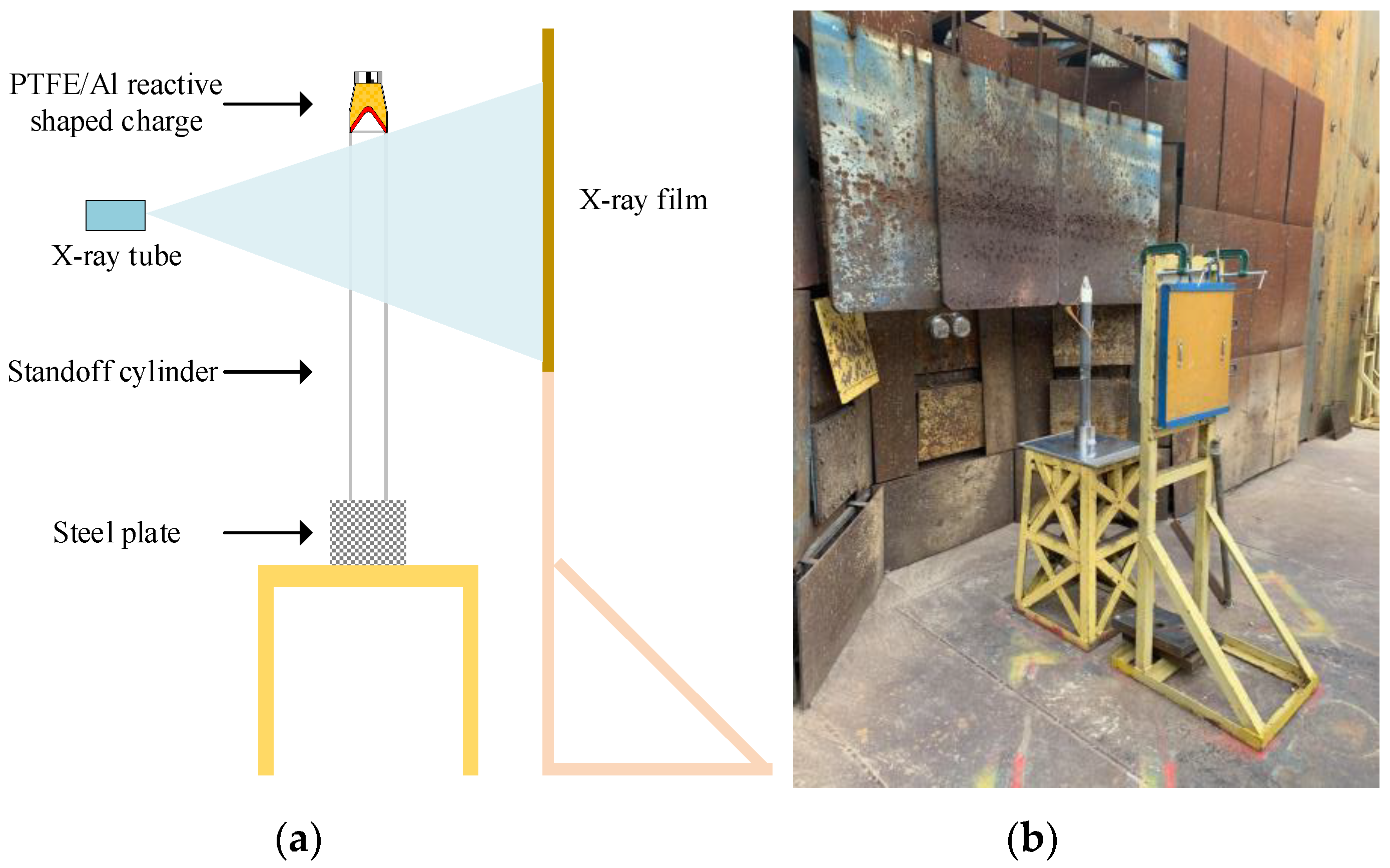

4.2. X-ray Experimental Setup

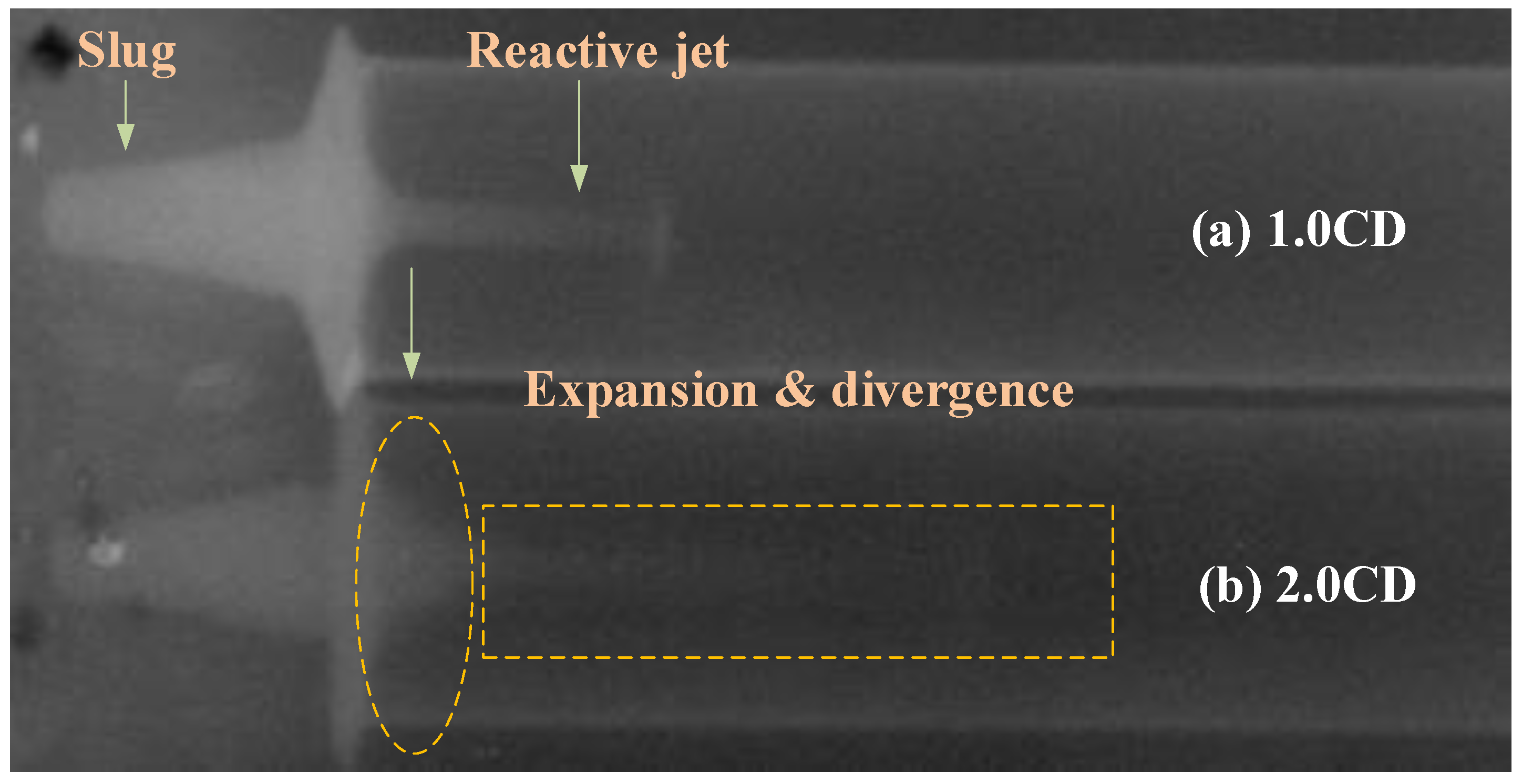

4.3. X-ray Experimental Results

5. Conclusions

- (a)

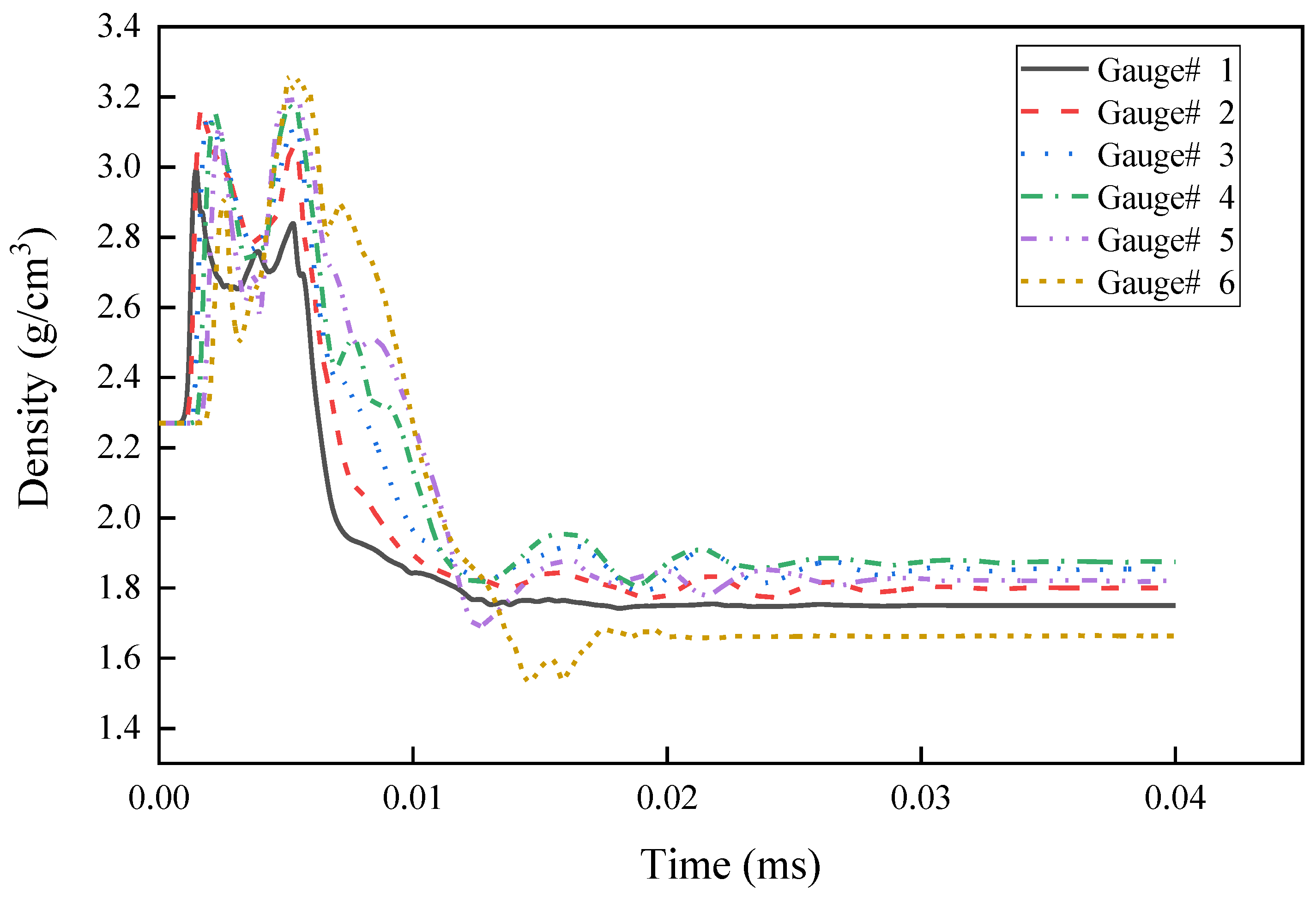

- Compared with the traditional Cu jet, numerical simulations showed that the reactive composite jet has an obvious expansion effect, accompanied by a significant decrease in the overall density. When the reactive composite jet tip reaches the 2.0 CD standoff, the density of the reactive composite jet element drops to 2.0 g/cm3, especially the density of the jet tip element, which is only approximately 1.6 g/cm3.

- (b)

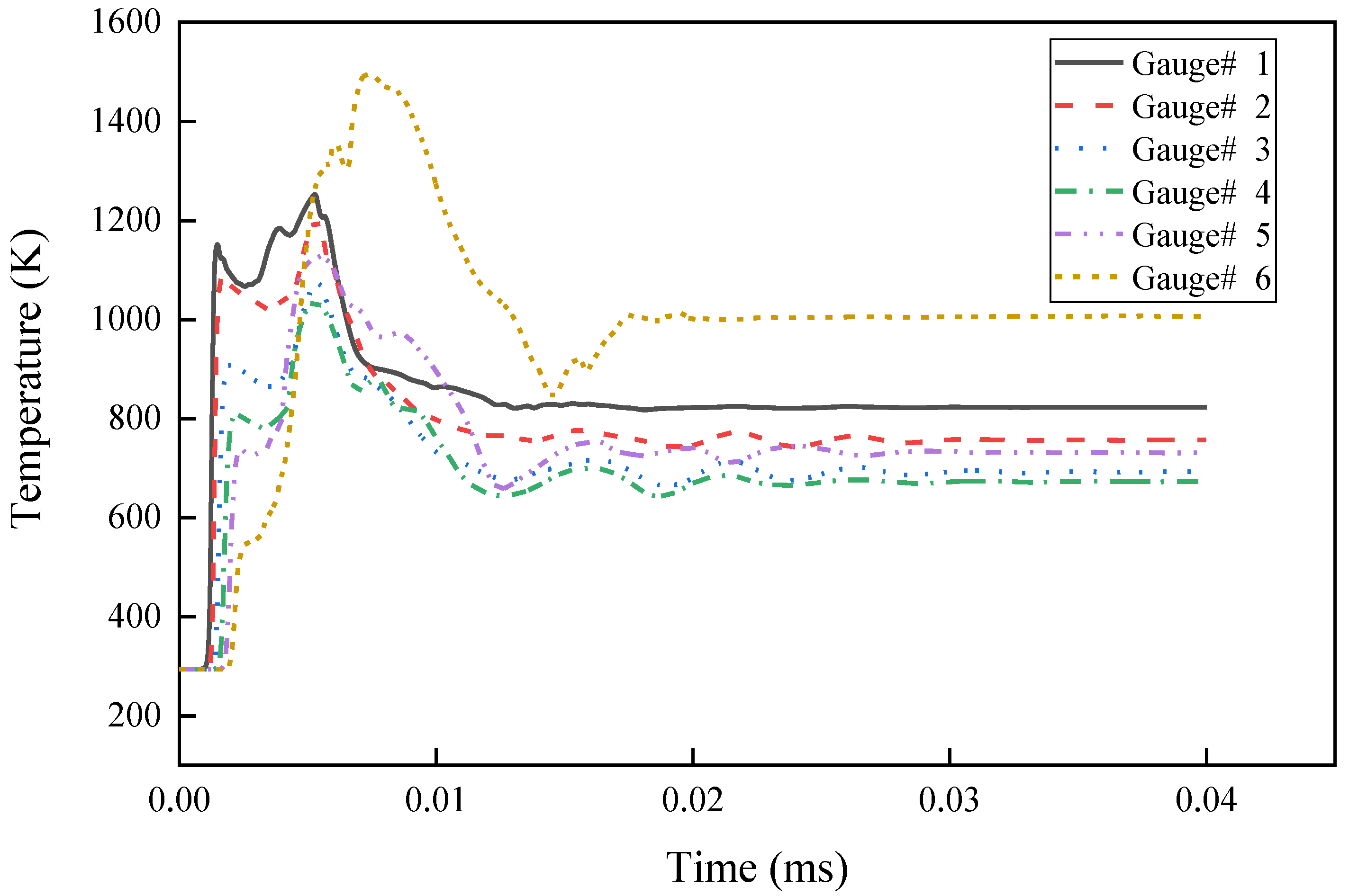

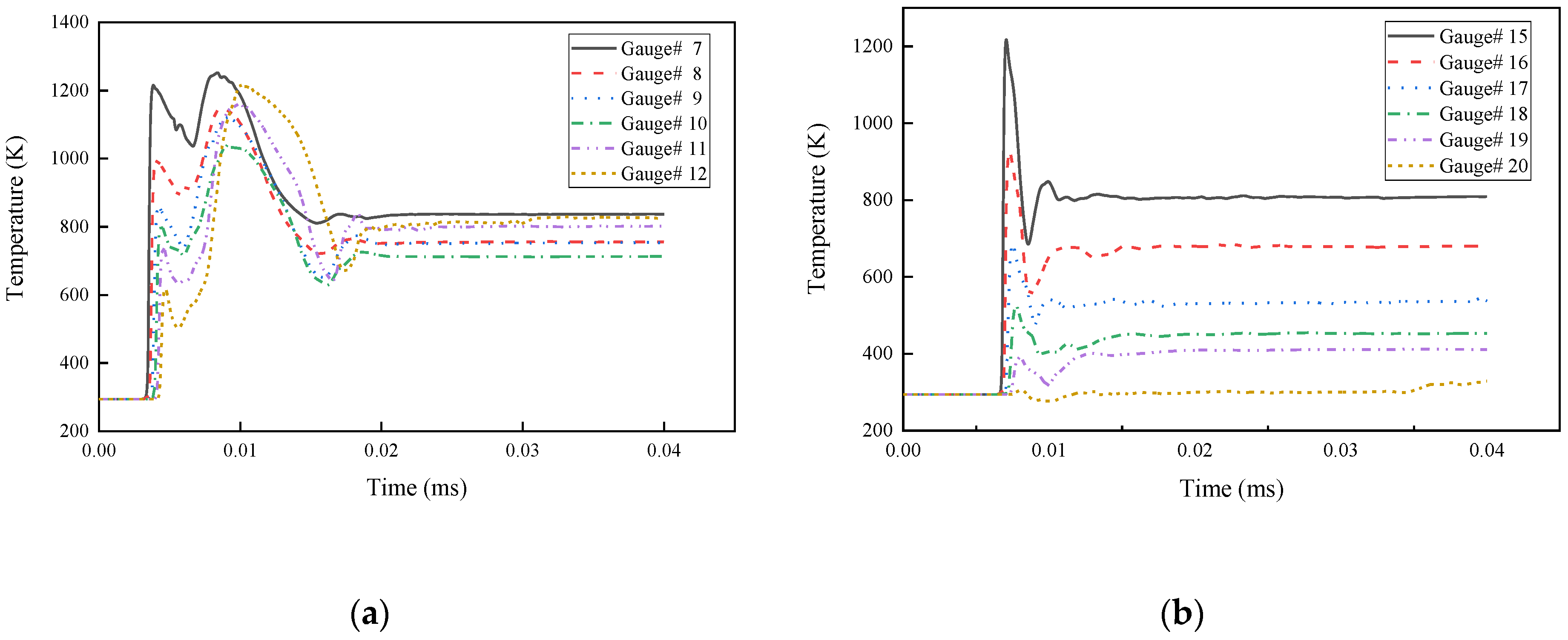

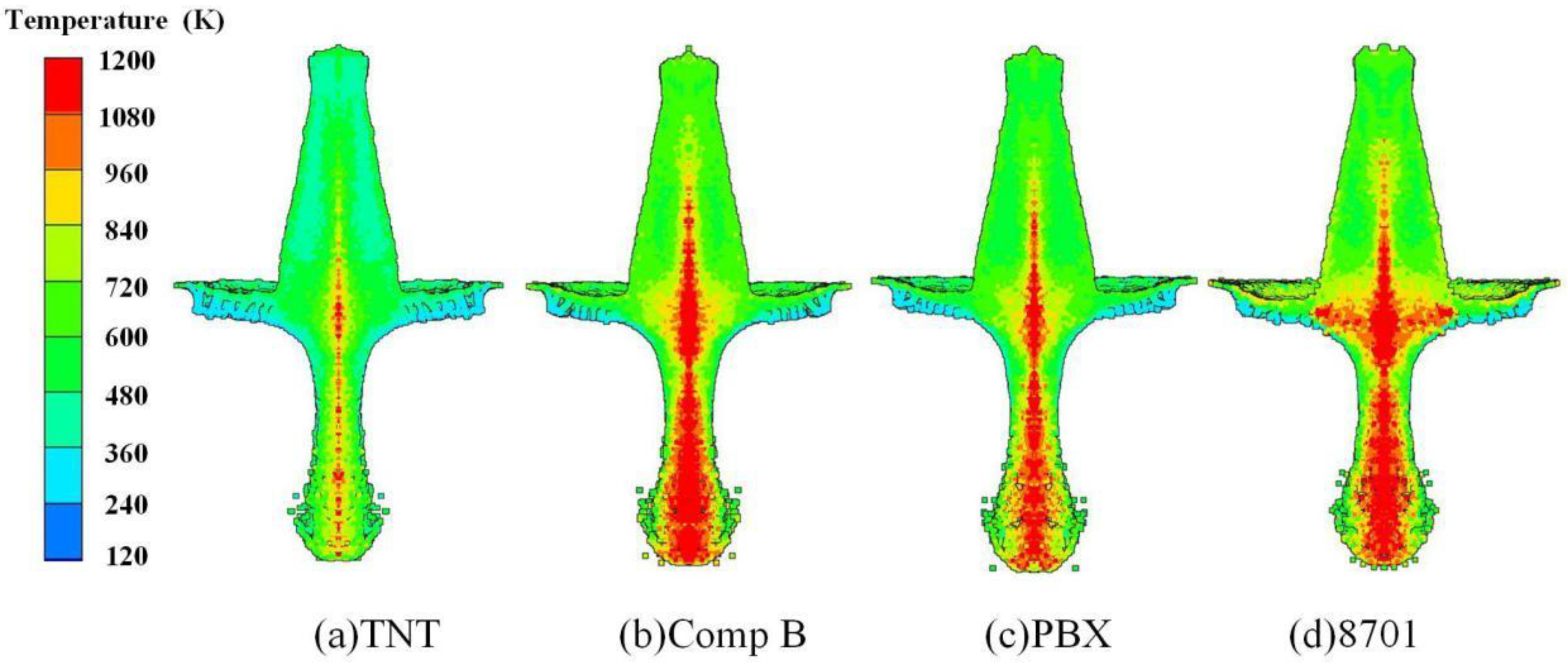

- From the temperature distribution of the reactive composite jet, the reactive composite jet tip and its axis present high-temperature zones while the temperature of the slug and the two wings is lower. For a given caliber RLSC, the type of explosive, cone angle, and wall thickness of the reactive liner have significant effects on the temperature distribution. As the detonation pressure of the explosive increases, the proportion of the high-temperature zone in the reactive composite jet tip will also increase. However, by increasing the cone angle and wall thickness of the reactive liner, the proportion of the high-temperature zone in the reactive composite jet tip will decrease.

- (c)

- A DSC/TG and pulse X-ray experiment was carried out to analyze the reaction characteristic and formation characteristics of the reactive composite jet. Combining the temperature distribution of the reactive composite jet given by the numerical simulation and the experimental results of DSC/TG, it is concluded that the distribution of the high-temperature zone of the reactive composite jet is mainly concentrated at the tip and axis of the jet, and the reactive composite jet tip will react first. The X-ray experiment results show that the reactive composite jet has excellent coaxiality, continuity, and symmetry within a certain range of standoff. The formation morphology of the reactive composite jet is greatly affected by the reaction delay time. As the time increases, the contour of the reactive composite jet is gradually blurred, the tip expansion phenomenon is intensified, and the density decreases. However, due to the non-self-sustaining reaction characteristics of the reactive composites, the reactive composite jet still has the ability of kinetic energy penetration within a reaction delay time.

- (d)

- In this study, the distribution of the density, temperature, and velocity field in the PTFE/Al reactive composite jet formation was only analyzed in the form of a distribution diagram and observation points, and the state of all SPH particles cannot be monitored yet. In future work, we will carry out the secondary development of AUTODYN finite element analysis software. Based on the SPH algorithm, the state of any particle in the process of reactive composite jet formation will be tracked, and high-temperature particles will be screened out. Therefore, the PTFE/Al composite material in the high-temperature region can be replaced to realize the control of the reaction time of the reactive composite jet.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nable, J.; Mercado, A.; Sherman, A. Novel Energetic Composite Materials. MRS Proc. 2005, 896, 0896. [Google Scholar] [CrossRef]

- DE Technologies, Inc. Reactive Fragment Warhead for Enhanced Neutralization of Mortar, Rocket, and Missile Threats. ONR-SRIR 2006: N04-903:1-7. Available online: http://www.detk.com (accessed on 3 January 2022).

- Ge, C.; Maimaitituersun, W.; Dong, Y.; Tian, C. A Study on the mechanical properties and impact-induced initiation characteristics of brittle PTFE/Al/W reactive materials. Materials 2017, 10, 452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, B.; Li, Y.C.; Wu, S.Z.; Wang, H.X.; Tao, Z.M.; Fang, X. A crack-induced initiation mechanism of Al-PTFE under quasi-static compression and the influencing factors. Mater. Des. 2016, 108, 411–417. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Yang, M.; Wang, L.; Lan, J.; Li, S.; He, C.; Xue, X. Effects of multi-component co-addition on reaction characteristics and impact damage properties of reactive materials. Mater. Des. 2018, 153, 1–8. [Google Scholar] [CrossRef]

- Huang, J.; Fang, X.; Wu, S.; Yang, L.; Yu, Z.; Li, Y.-C. Mechanical Response and Shear-Induced Initiation Properties of PTFE/Al/MoO3 Reactive Composites. Materials 2018, 11, 1200. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, Y.; Geng, B.; Sun, T.; Yu, Q.; Wang, H. Impact-Induced Reaction Characteristic and the Enhanced Sensitivity of PTFE/Al/Bi2O3 Composites. Polymers 2019, 11, 2049. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, L.; Zhou, J.; Tang, W.; Ran, X.; Hu, Y. Impact Energy Release Characteristics of PTFE/Al/CuO Reactive Materials Measured by a New Energy Release Testing Device. Polymers 2019, 11, 149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Zheng, Y.; Yu, Q.; Liu, Z.; Yu, W. Impact-induced initiation and energy release behavior of reactive materials. J. Appl. Phys. 2011, 110, 074904. [Google Scholar]

- Arnold, W.; Schäfer, F.K. Behind Armor Blast (BAB) caused by shaped charges. Int. J. Impact Eng. 1999, 23, 13–25. [Google Scholar] [CrossRef]

- Zheng, Y.-F.; Su, C.-H.; Guo, H.-G.; Yu, Q.-B.; Wang, H.-F. Chain damage effects of multi-spaced plates by reactive jet impact. Def. Technol. 2021, 17, 393–404. [Google Scholar] [CrossRef]

- Baker, E.L.; Daniels, A.S.; Ng, K.W.; Martin, V.O.; Orosz, J.P. Barnie: A Unitary Demolition Warhead. In Proceedings of the 19th International Symposium on Ballistics, Interlaken, Switzerland, 7–11 May 2001; pp. 569–574. [Google Scholar]

- Daniels, A.S.; Baker, E.L.; DeFisher, S.E.; Ng, K.W.; Pham, J. Bam bam: Large scale unitary demolition warheads. In Proceedings of the 23rd International Symposium on Ballistics, Tarragona, Spain, 16–20 April 2007; pp. 239–246. [Google Scholar]

- Xiao, J.; Zhang, X.; Wang, Y.; Xu, F.; Wang, H. Demolition mechanism and behavior of shaped charge with reactive liner. Propellants Explos. Pyrotech. 2016, 41, 612–617. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, X.; Guo, Z.; Wang, H. Enhanced damage effects of multi-layered concrete target produced by reactive materials liner. Propellants Explos. Pyrotech. 2018, 43, 955–961. [Google Scholar] [CrossRef]

- Guo, H.; Zheng, Y.; Yu, Q.; Ge, C.; Wang, H. Penetration behavior of reactive liner shaped charge jet impacting thick steel plates. Int. J. Impact Eng. 2019, 126, 76–84. [Google Scholar] [CrossRef]

- Ge, C.; Yu, Q.; Zhang, H.; Qu, Z.; Wang, H.; Zheng, Y. On dynamic response and fracture-induced initiation characteristics of aluminum particle filled PTFE reactive material using hat-shaped specimens. Mater. Des. 2020, 188, 108472. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Yin, J.; Yi, J.; Wang, H. Damage mechanism of PTFE/Al reactive charge liner structural parameters on a steel target. Materials 2021, 14, 3701. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.F.; Shi, A.S.; Zhang, J.; Qiao, L.; He, Y.; Guan, Z.W. Thermochemical modeling of temperature controlled shock-induced chemical reactions in multifunctional energetic structural materials under shock compression. J. Appl. Phys. 2012, 111, 123501. [Google Scholar] [CrossRef]

- Lee, I.; Reed, R.R.; Brady, V.L.; Finnegan, S.A. Energy release in the reaction of metal powders with fluorine containing polymers. J. Therm. Anal. 1997, 49, 1699–1705. [Google Scholar] [CrossRef]

- Osborne, D.T.; Pantoya, M.I. Effect of al particle size on the thermal degradationof al/teflon mixtures. Combust. Sci. Technol. 2007, 179, 1467–1480. [Google Scholar] [CrossRef]

- Nicolich, S. Reactive materials enhanced lethality EFP. In Proceedings of the 42nd Annual Armament Systems: Gun and Missile Systems Conference and Exhibition, Charlotte, NC, USA, 23–26 April 2007; National Defence Industrial Association: Arlington, VA, USA, 2007. [Google Scholar]

- Raftenberg, M.N.; Mock, W., Jr.; Kirby, G.C. Modeling the impact deformation of rods of a pressed PTFE/Al composite mixture. Int. J. Impact Eng. 2008, 35, 1735–1744. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.; Zhang, L.L. Research on jet coherency of PTFE-based energetic liner. Acta Armamentarii 2019, 40, 2433–2439. [Google Scholar]

- Richard, G.A. Energy release characteristics of impact-initiated energetic materials. In MRS Proceedings; Cambridge University Press: Cambridge, CA, USA, 2005. [Google Scholar]

| Part | Materials | EOS | Strength | Erosion |

|---|---|---|---|---|

| Liner | PTFE/Al | Shock | Johnson Cook | None |

| Explosive | 8701 | JWL | None | None |

| Case | #45 steel | Shock | Johnson Cook | None |

| Material | ρ (g/cm3) | G (Gpa) | A (Mpa) | B (Mpa) | n | C | m | Tm (K) | Troom (K) |

|---|---|---|---|---|---|---|---|---|---|

| Reactive liner | 2.27 | 0.67 | 8.04 | 250.6 | 1.8 | 0.4 | 1 | 500 | 294 |

| #45 steel | 7.83 | 77 | 792 | 510 | 0.26 | 0.014 | 1.03 | 1793 | 300 |

| ρ (g/cm3) | D (km/s) | PCJ (GPa) | e (GPa) | A (GPa) | B (GPa) | R1 | R2 | ω | v0 |

|---|---|---|---|---|---|---|---|---|---|

| 1.71 | 8.315 | 28.6 | 8.499 | 524.23 | 7.678 | 4.2 | 1.1 | 0.34 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, C.; Guo, H.; Zheng, Y.; Xie, J.; Wang, H. Formation Behavior and Reaction Characteristic of a PTFE/Al Reactive Jet. Materials 2022, 15, 1268. https://doi.org/10.3390/ma15031268

Su C, Guo H, Zheng Y, Xie J, Wang H. Formation Behavior and Reaction Characteristic of a PTFE/Al Reactive Jet. Materials. 2022; 15(3):1268. https://doi.org/10.3390/ma15031268

Chicago/Turabian StyleSu, Chenghai, Huanguo Guo, Yuanfeng Zheng, Jianwen Xie, and Haifu Wang. 2022. "Formation Behavior and Reaction Characteristic of a PTFE/Al Reactive Jet" Materials 15, no. 3: 1268. https://doi.org/10.3390/ma15031268

APA StyleSu, C., Guo, H., Zheng, Y., Xie, J., & Wang, H. (2022). Formation Behavior and Reaction Characteristic of a PTFE/Al Reactive Jet. Materials, 15(3), 1268. https://doi.org/10.3390/ma15031268