Microstructures and Tensile Properties of 9Cr-F/M Steel at Elevated Temperatures

Abstract

:1. Introduction

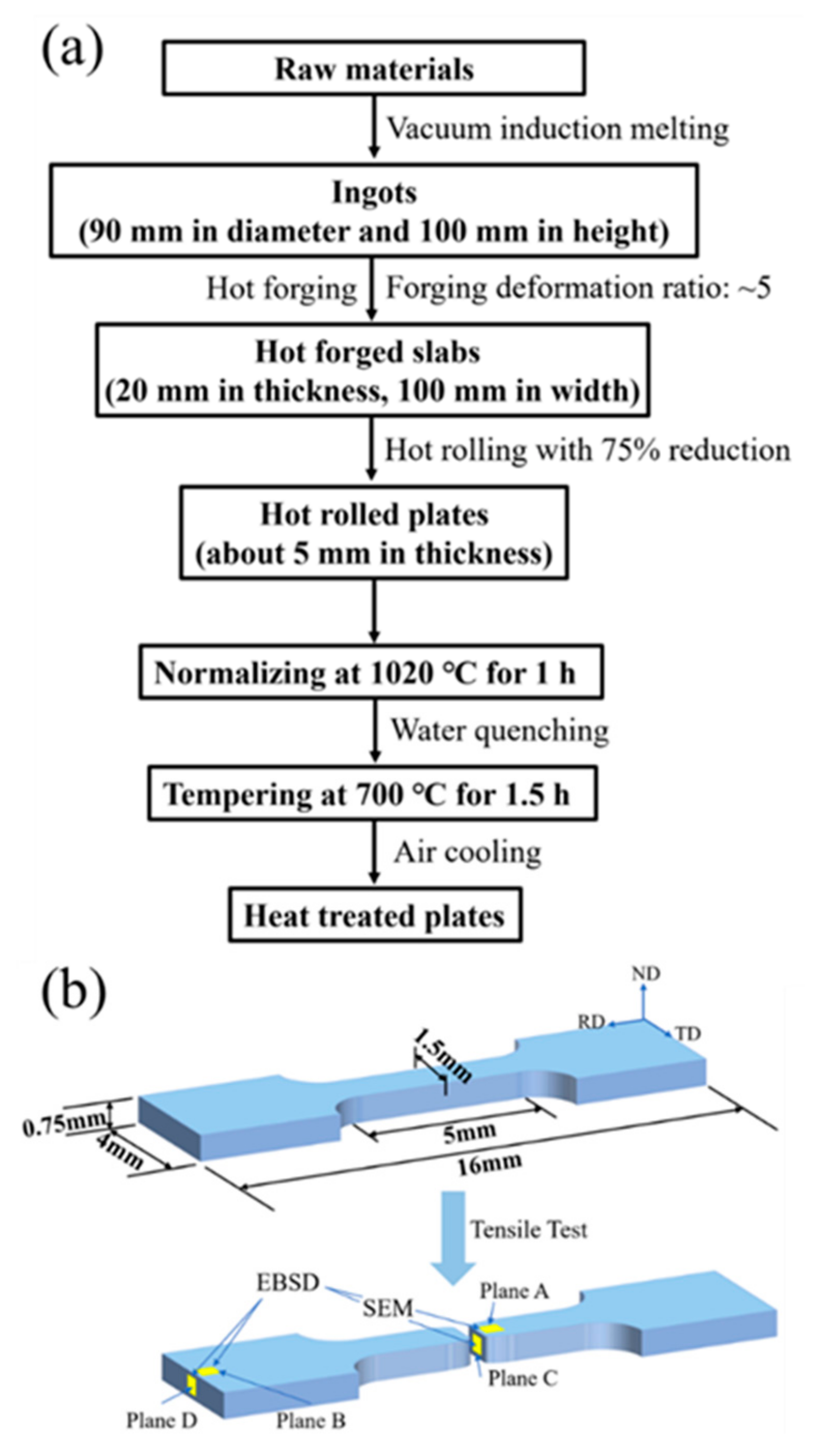

2. Experimental

2.1. Material Preparation

2.2. Mechanical Testing

2.3. Microstructure Characterization

3. Results

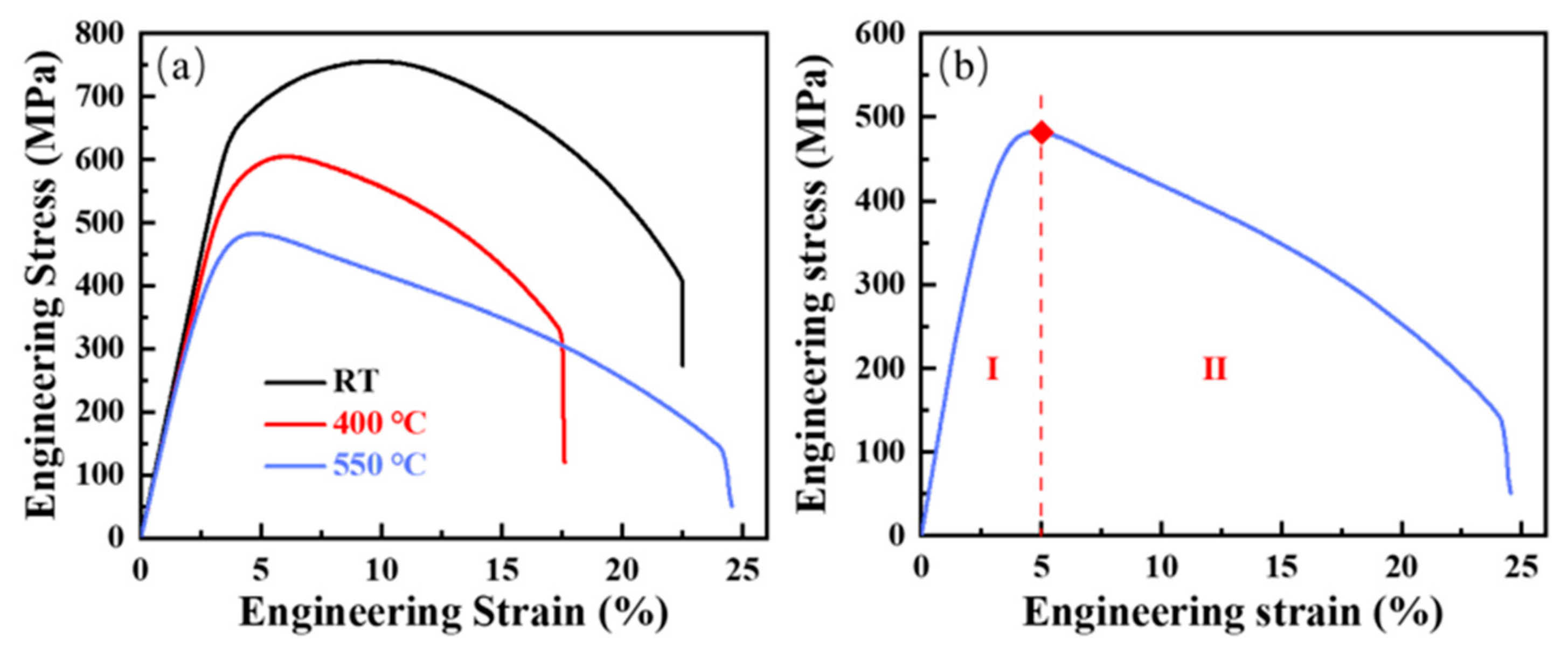

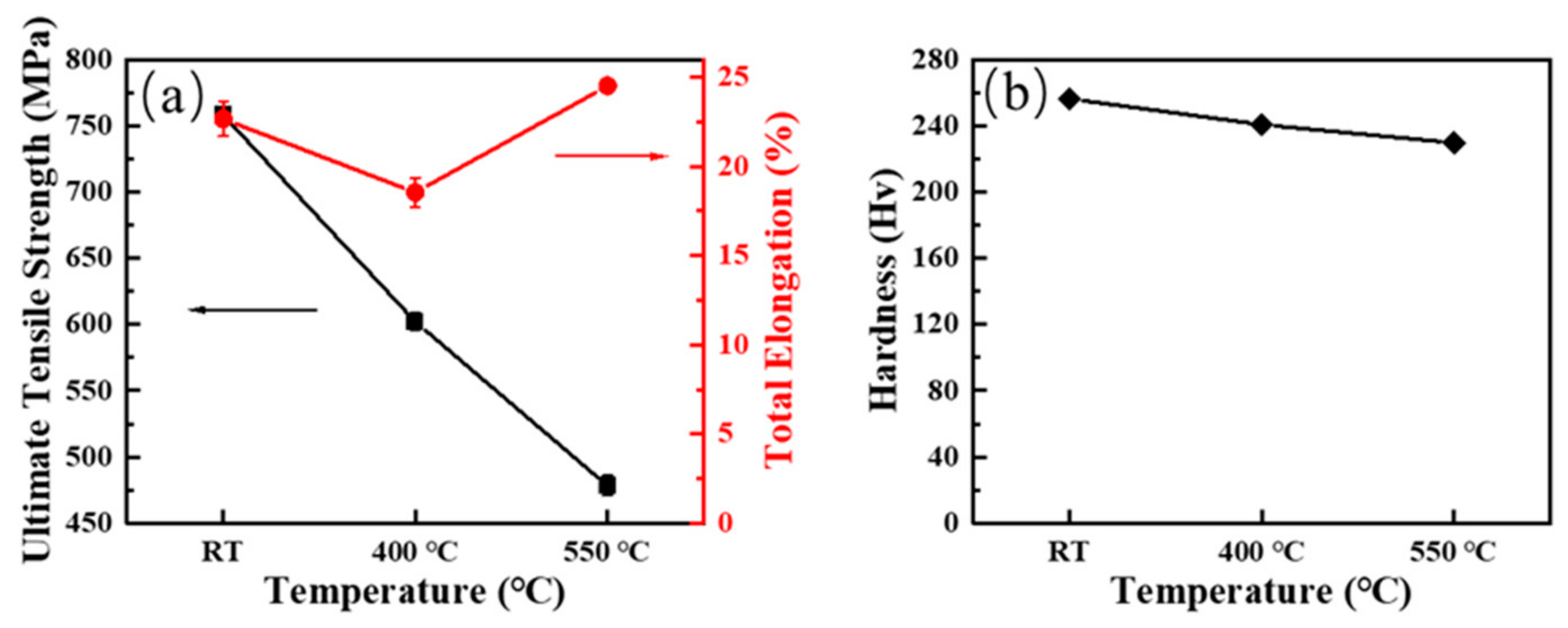

3.1. Mechanical Properties

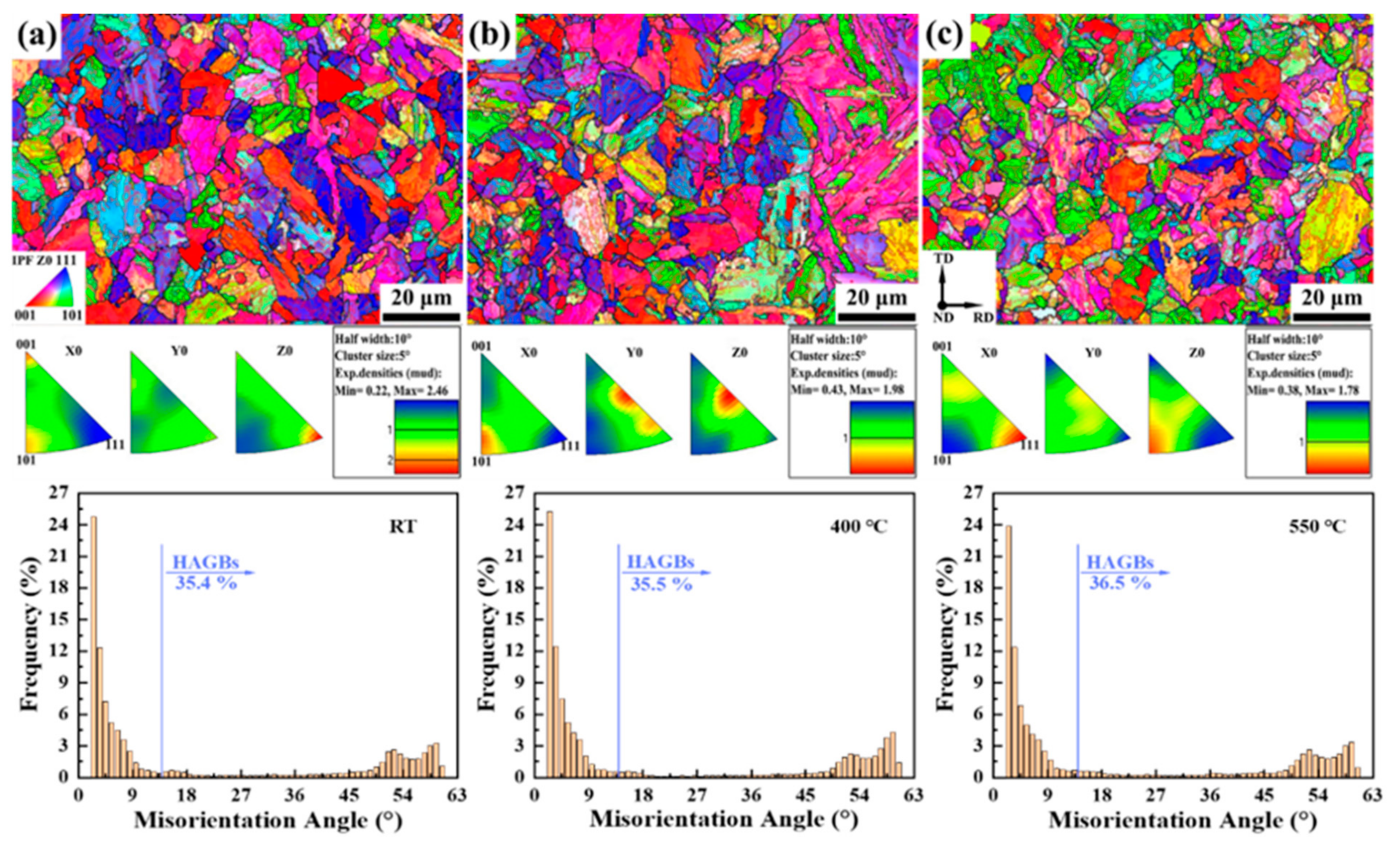

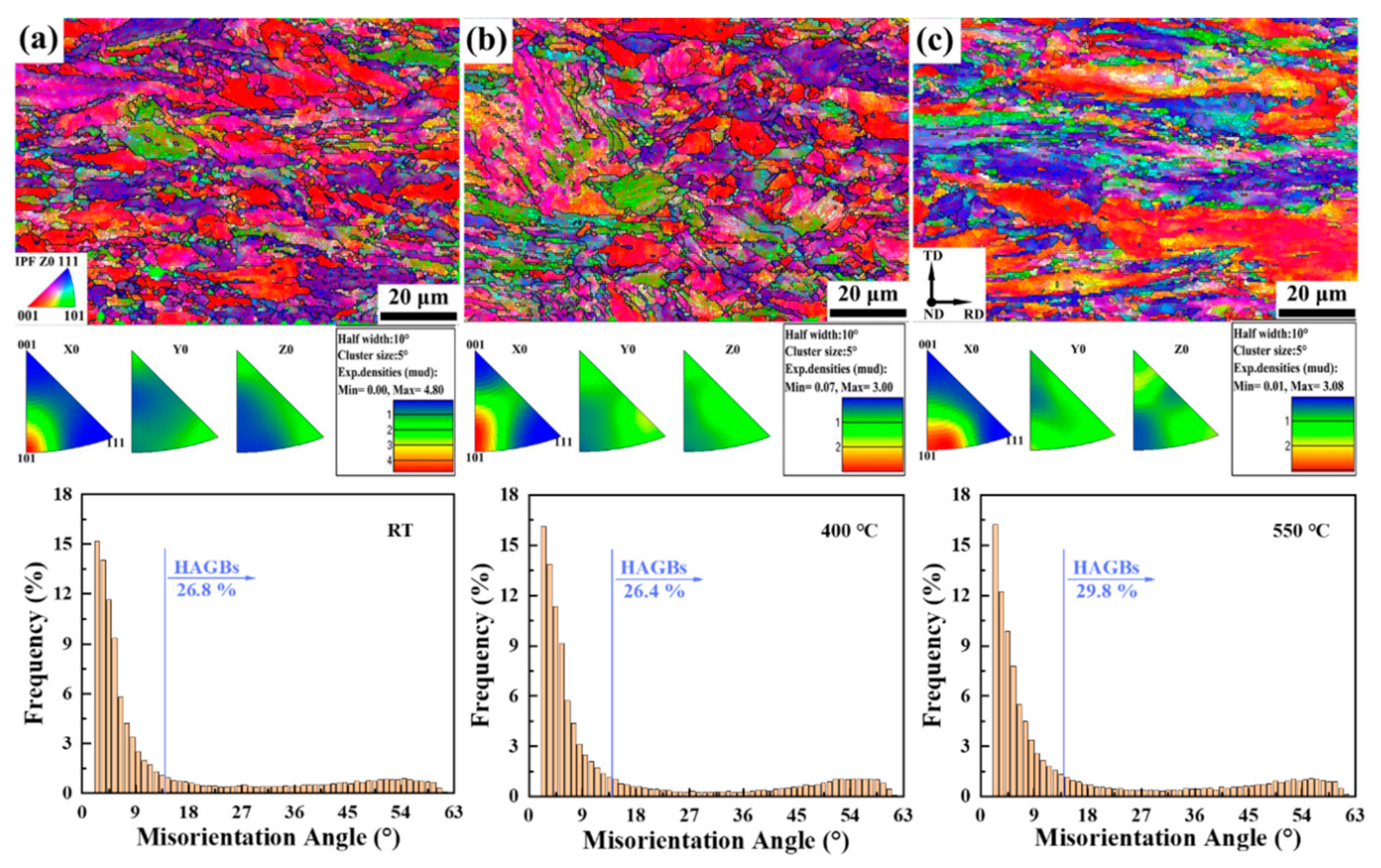

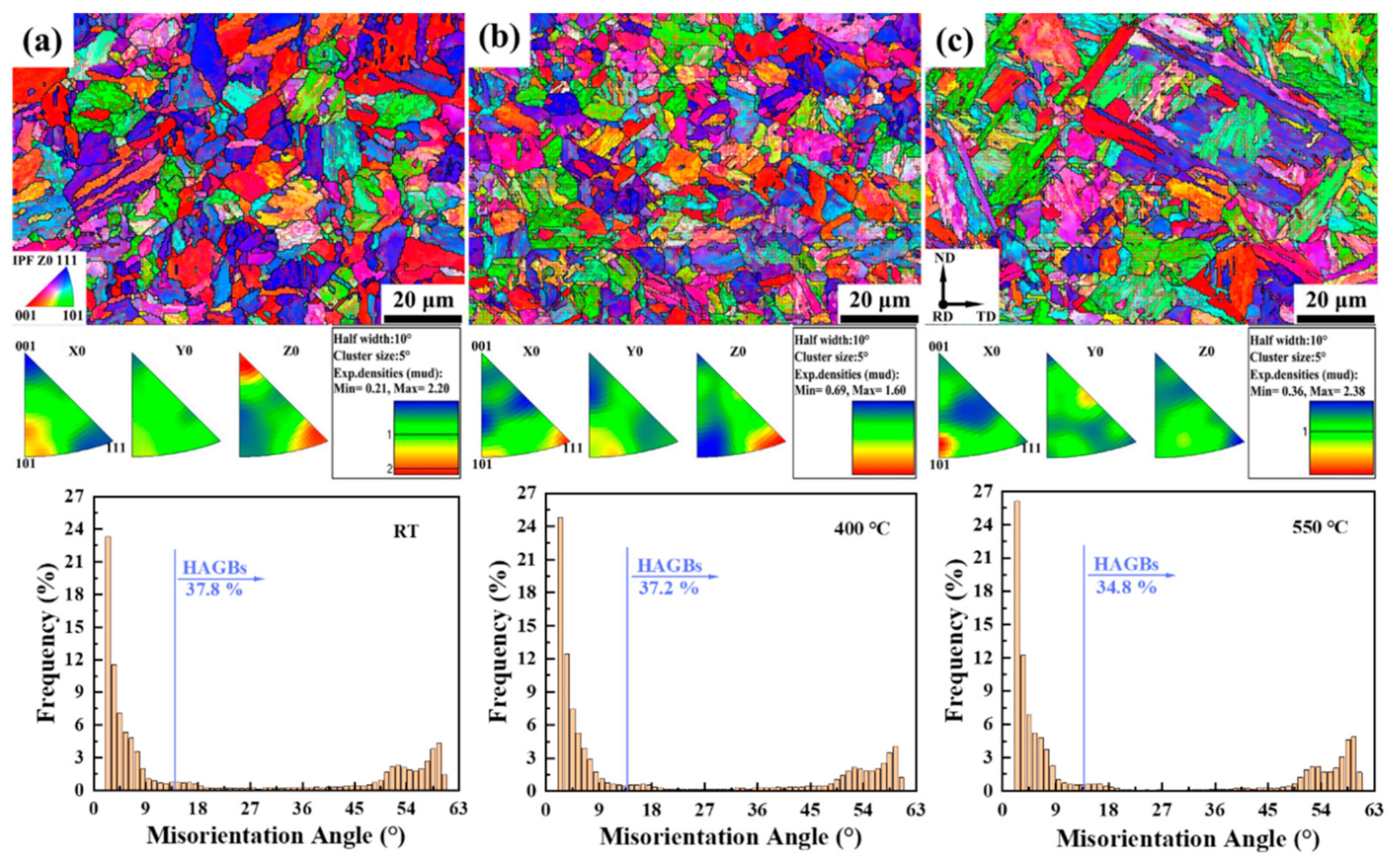

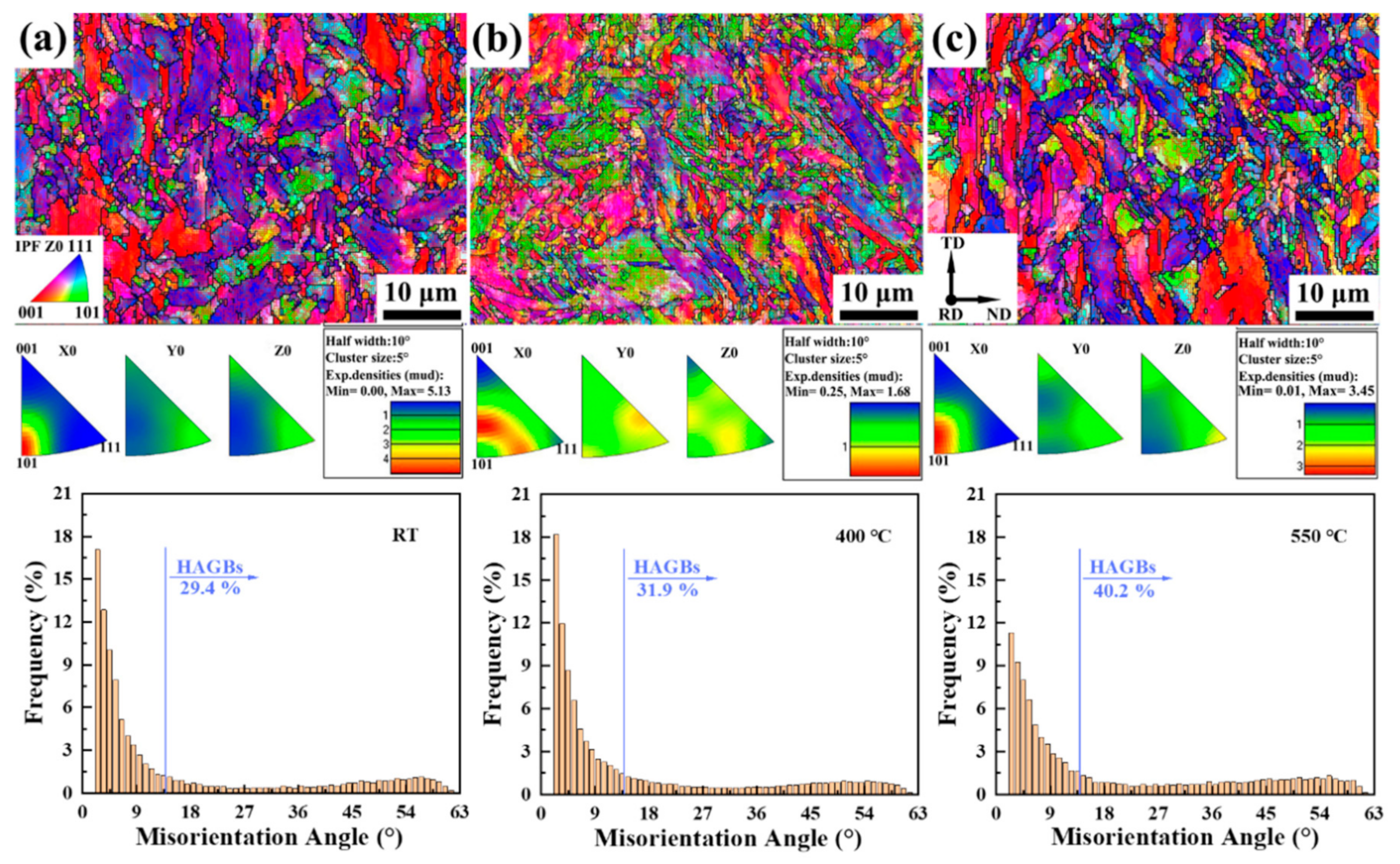

3.2. Effect of Tensile Deformation on Microstructure

4. Conclusions

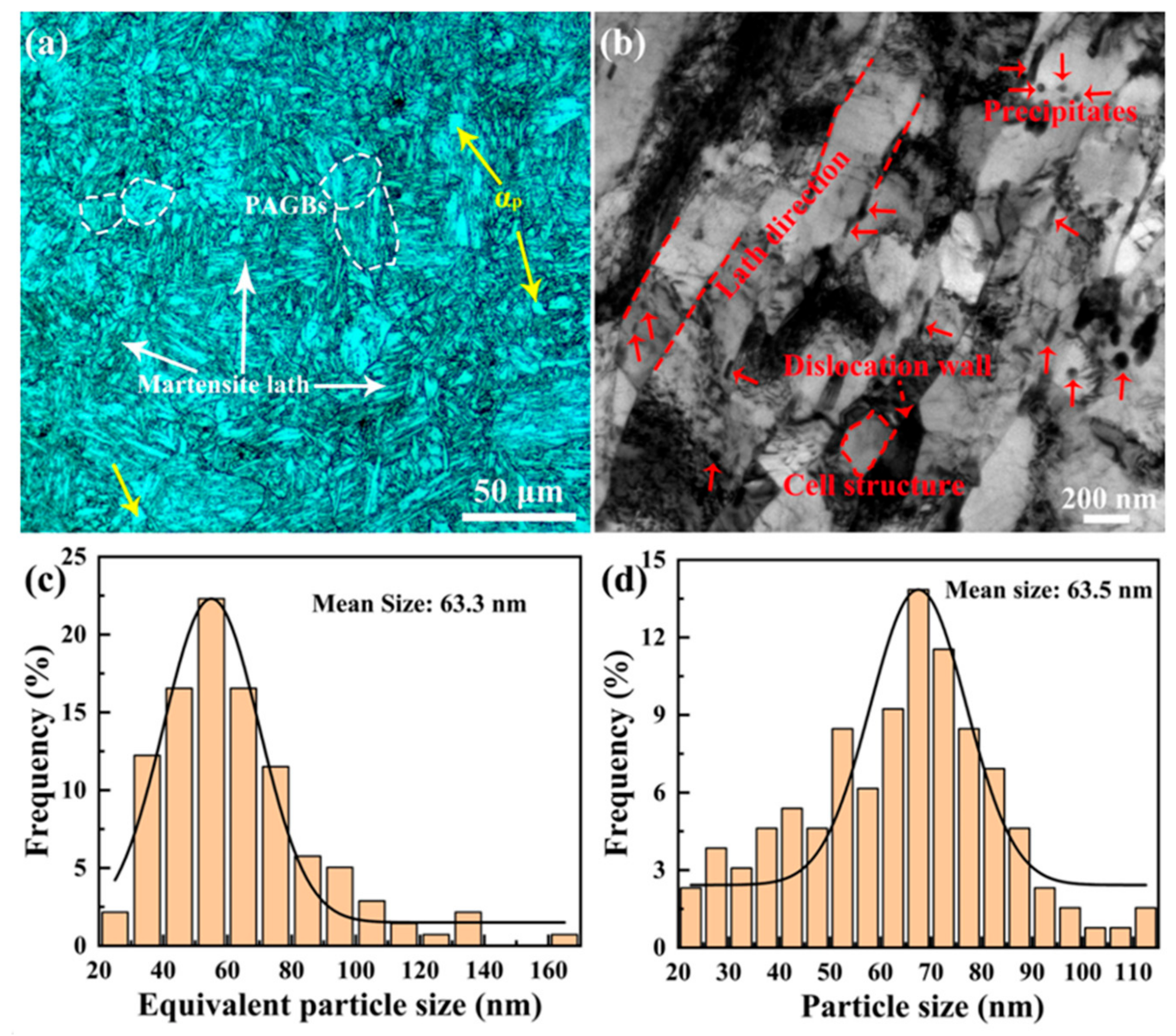

- (1)

- The steel consists of a typical martensitic structure with only a few polygonal ferrites embedded, and two kinds of precipitates nucleated on the lath boundaries or within the sub-grains. One is the M23C6 phase, the other is the MX phase.

- (2)

- The UTS for the steel is in the order of RT > 400 °C > 550 °C, but the TE is in the sequence of 550 °C > RT > 400 °C.

- (3)

- For the RD-TD plane in the necking zone, tensile deformation made the grain elongated to the direction of applied stress and increased the quantity of LAGBs. In the cross-section (ND-TD plane) of the necking zone, equivalent grain refinement occurs within the grain cross-section due to the elongation of the grains.

- (4)

- For samples with rectangular working area cross-section, the deformation in the TD was more severe than that in the ND, which made the grain to be elongated to the TD direction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- Zohuri, B. Generation IV Nuclear Reactors. In Nuclear Reactor Technology Development and Utilization. 2020, pp. 213–246. Available online: https://www.elsevier.com/books/nuclear-reactor-technology-development-and-utilization/khan/978-0-12-818483-7 (accessed on 5 January 2022).

- Alemberti, A.; Smirnov, V.; Smith, C.F.; Takahashi, M. Overview of lead-cooled fast reactor activities. Prog. Nucl. Energy 2014, 77, 300–307. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.L.; Lan, Z.K.; Wei, S.Y.; Chen, R.H.; Tian, W.X.; Su, G.H. Review of Thermal-Hydraulic Issues and Studies of Lead-based fast reactors. Renew. Sust. Energy Rev. 2020, 120, 109625. [Google Scholar] [CrossRef]

- Pareige, P.; Etienne, A.; Radiguet, B. Experimental atomic scale investigation of irradiation effects in CW 316SS and UFG-CW 316SS. J. Nucl. Mater. 2009, 389, 259–264. [Google Scholar] [CrossRef]

- Zhu, Z.L.; Xu, H.; Jiang, D.F.; Mao, X.P.; Zhang, N.G. Influence of temperature on the oxidation behaviour of a ferritic-martensitic steel in supercritical water. Corros. Sci. 2016, 113, 172–179. [Google Scholar] [CrossRef]

- Zhang, N.-Q.; Zhu, Z.-L.; Xu, H.; Mao, X.-P.; Li, J. Oxidation of ferritic and ferritic–martensitic steels in flowing and static supercritical water. Corros. Sci. 2016, 103, 124–131. [Google Scholar] [CrossRef]

- Viswanathan, R.; Sarver, J.; Tanzosh, J.M. Boiler Materials for Ultra-Supercritical Coal Power Plants—Steamside Oxidation. J. Mater. Eng. Perform. 2006, 15, 255–274. [Google Scholar] [CrossRef]

- Matijasevic, M.; Lucon, E.; Almazouzi, A. Behavior of ferritic/martensitic steels after n-irradiation at 200 and 300 °C. J. Nucl. Mater. 2008, 377, 101–108. [Google Scholar] [CrossRef]

- Van den Bosch, J.; Coen, G.; Hosemann, P.; Maloy, S.A. On the LME susceptibility of Si enriched steels. J. Nucl. Mater. 2012, 429, 105–112. [Google Scholar] [CrossRef]

- Barbier, F.; Benamati, G.; Fazio, C.; Rusanov, A. Compatibility tests of steels in flowing liquid lead–bismuth. J. Nucl. Mater. 2001, 295, 149–156. [Google Scholar] [CrossRef]

- Schroer, C.; Koch, V.; Wedemeyer, O.; Skrypnik, A.; Konys, J. Silicon-containing ferritic/martensitic steel after exposure to oxygen-containing flowing lead–bismuth eutectic at 450 and 550 °C. J. Nucl. Mater. 2016, 469, 162–176. [Google Scholar] [CrossRef]

- Chen, S.H.; Rong, L.J. Effect of silicon on the microstructure and mechanical properties of reduced activation ferritic/martensitic steel. J. Nucl. Mater. 2015, 459, 13–19. [Google Scholar] [CrossRef]

- Kim, B.; Celada, C.; San Martín, D.; Sourmail, T.; Rivera-Díaz-del-Castillo, P.E.J. The effect of silicon on the nanoprecipitation of cementite. Acta Mater. 2013, 61, 6983–6992. [Google Scholar] [CrossRef] [Green Version]

- Huntz, A.M.; Bague, V.; Beauplé, G.; Haut, C.; Sévérac, C.; Lecour, P.; Longaygue, X.; Ropital, F. Effect of silicon on the oxidation resistance of 9% Cr steels. Appl. Surf. Sci. 2003, 207, 255–275. [Google Scholar] [CrossRef]

- Liu, Z.; Huo, X.; Yu, Y.; Zhang, C.; Xiao, N.; Zhao, J.; Yang, Z. Influence of austenitizing temperature on the mechanical properties and microstructure of reduced activation ferritic/martensitic steel. Mater. Sci. Eng. A 2021, 826, 141934. [Google Scholar] [CrossRef]

- Jones, W.B.; Hills, C.R.; Polonis, D.H. Microstructural evolution of modified 9Cr-1Mo steel. Metall. Trans. A 1991, 22, 1049–1058. [Google Scholar] [CrossRef]

- Li, S.; Eliniyaz, Z.; Zhang, L.; Sun, F.; Shen, Y.; Shan, A. Microstructural evolution of delta ferrite in SAVE12 steel under heat treatment and short-term creep. Mater. Charact. 2012, 73, 144–152. [Google Scholar] [CrossRef]

- Zhang, Y.; He, H.; Wang, H.; Chen, G.; An, X.; Wang, Y. Evolution of microstructure and mechanical properties of 9Cr ferrite/martensite steels with different Si content after long-term aging at 550 °C. J. Alloys Compd. 2021, 873. [Google Scholar] [CrossRef]

- Chen, S.; Jin, X.; Rong, L. Microstructural Evolution and Mechanical Properties of Ultrafine-Grained Ferritic-Martensitic Steel During Thermal Aging. Metall. Mater. Trans. A 2020, 51, 5154–5168. [Google Scholar] [CrossRef]

- Dong, Z.; Li, M.; Behnamian, Y.; Luo, J.-L.; Chen, W.; Amirkhiz, B.S.; Liu, P.; Pang, X.; Li, J.; Zheng, W.; et al. Effects of Si, Mn on the corrosion behavior of ferritic–martensitic steels in supercritical water (SCW) environments. Corros. Sci. 2020, 166, 108432. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.; Zhang, Z.; Qi, Y.; Zhang, C.; Zheng, H.; Xu, Y. Oxidation behavior and high-temperature tensile properties of Fe-9Cr-(Mo, Mo/Ni) alloys. Corros. Sci. 2021, 181, 109243. [Google Scholar] [CrossRef]

- Gao, S.; Huang, Q.; Zhu, Z.; Guo, Z.; Ling, X.; Chen, Y. Corrosion behavior of CLAM steel in static and flowing LiPb at 480 °C and 550 °C. Fusion Eng. Des. 2011, 86, 2627–2631. [Google Scholar] [CrossRef]

- Huang, Q.; Li, C.; Wu, Q.; Liu, S.; Gao, S.; Guo, Z.; Yan, Z.; Huang, B.; Song, Y.; Zhu, Z.; et al. Progress in development of CLAM steel and fabrication of small TBM in China. J. Nucl. Mater. 2011, 417, 85–88. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, W.; Shi, Q.; Li, Y.; Shan, Y.; Yang, K. Silicon enhances high temperature oxidation resistance of SIMP steel at 700 °C. Corros. Sci. 2020, 167, 108519. [Google Scholar] [CrossRef]

- Cruz-Gandarilla, F.; Salcedo-Garrido, A.M.; Bolmaro, R.E.; Baudin, T.; De Vincentis, N.S.; Avalos, M.; Cabañas-Moreno, J.G.; Mendoza-Leon, H. Microstructural evolution and mechanical properties on an ARB processed IF steel studied by X-ray diffraction and EBSD. Mater. Charact. 2016, 118, 332–339. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, P.; Li, D.; Li, Y. M23C6 precipitates induced inhomogeneous distribution of silicon in the oxide formed on a high-silicon ferritic/martensitic steel. Scr. Mater. 2015, 97, 45–48. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, X.; Huang, X.; Fan, Z.; Ma, X.; Chen, H.; Shi, X. Identification of precipitate phases in CLAM steel. Fusion Eng. Des. 2021, 163. [Google Scholar] [CrossRef]

- Tan, L.; Zhong, W.; Chen, T. Microstructural stability of tantalum-alloyed ferritic-martensitic steel with neutron irradiation to 7.4 dpa at ~490 °C. Materialia 2020, 9. [Google Scholar] [CrossRef]

- Tan, L.; Graening, T.; Hu, X.; Zhong, W.; Yang, Y.; Zinkle, S.J.; Katoh, Y. Effects of carbonitrides and carbides on microstructure and properties of castable nanostructured alloys. J. Nucl. Mater. 2020, 540, 152376. [Google Scholar] [CrossRef]

- Sawada, K.; Kubo, K.; Abe, F. Contribution of coarsening of MX carbonitrides to creep strength degradation in high chromium ferritic steel. Mater. Sci. Technol. 2013, 19, 732–738. [Google Scholar] [CrossRef]

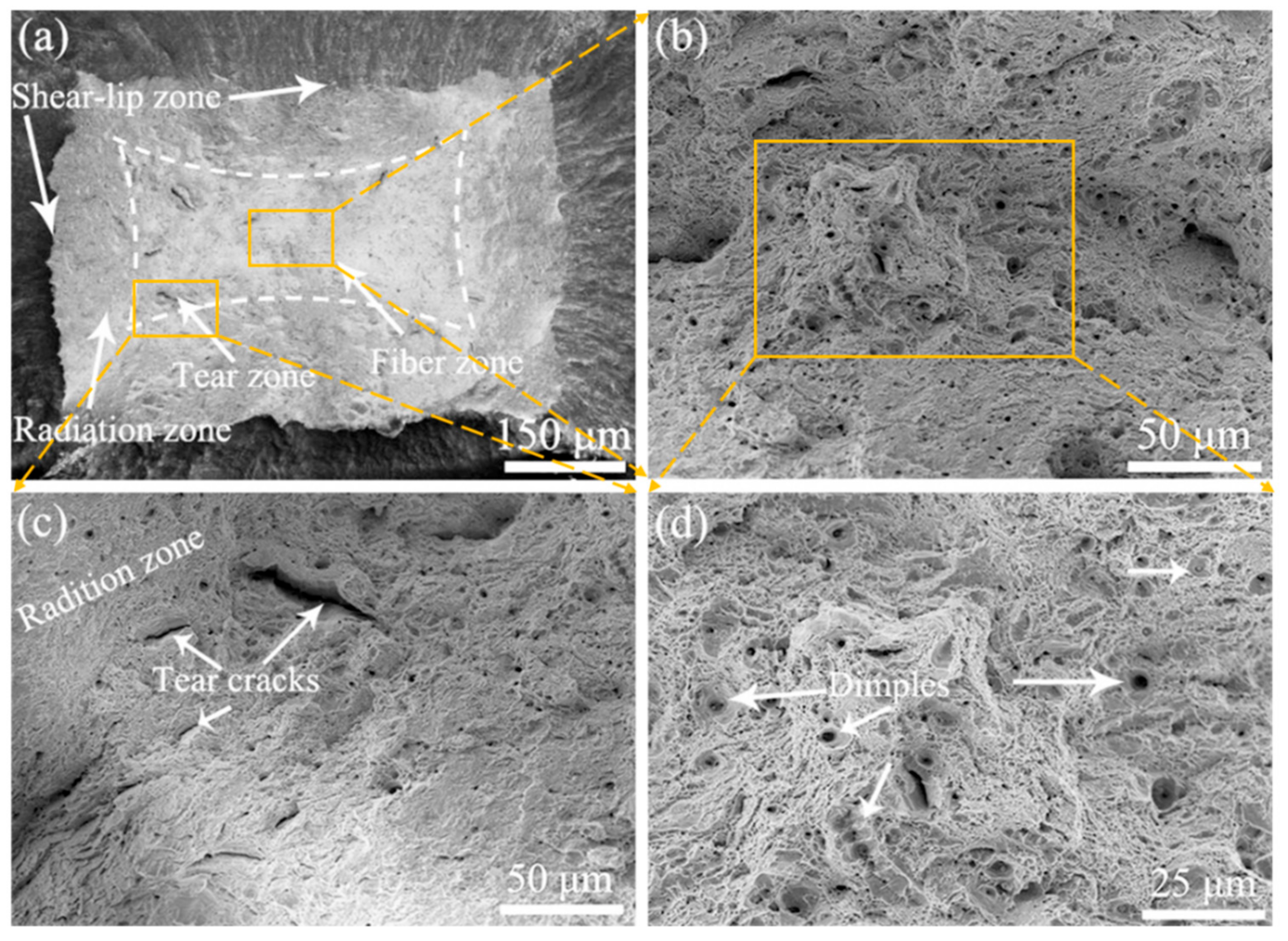

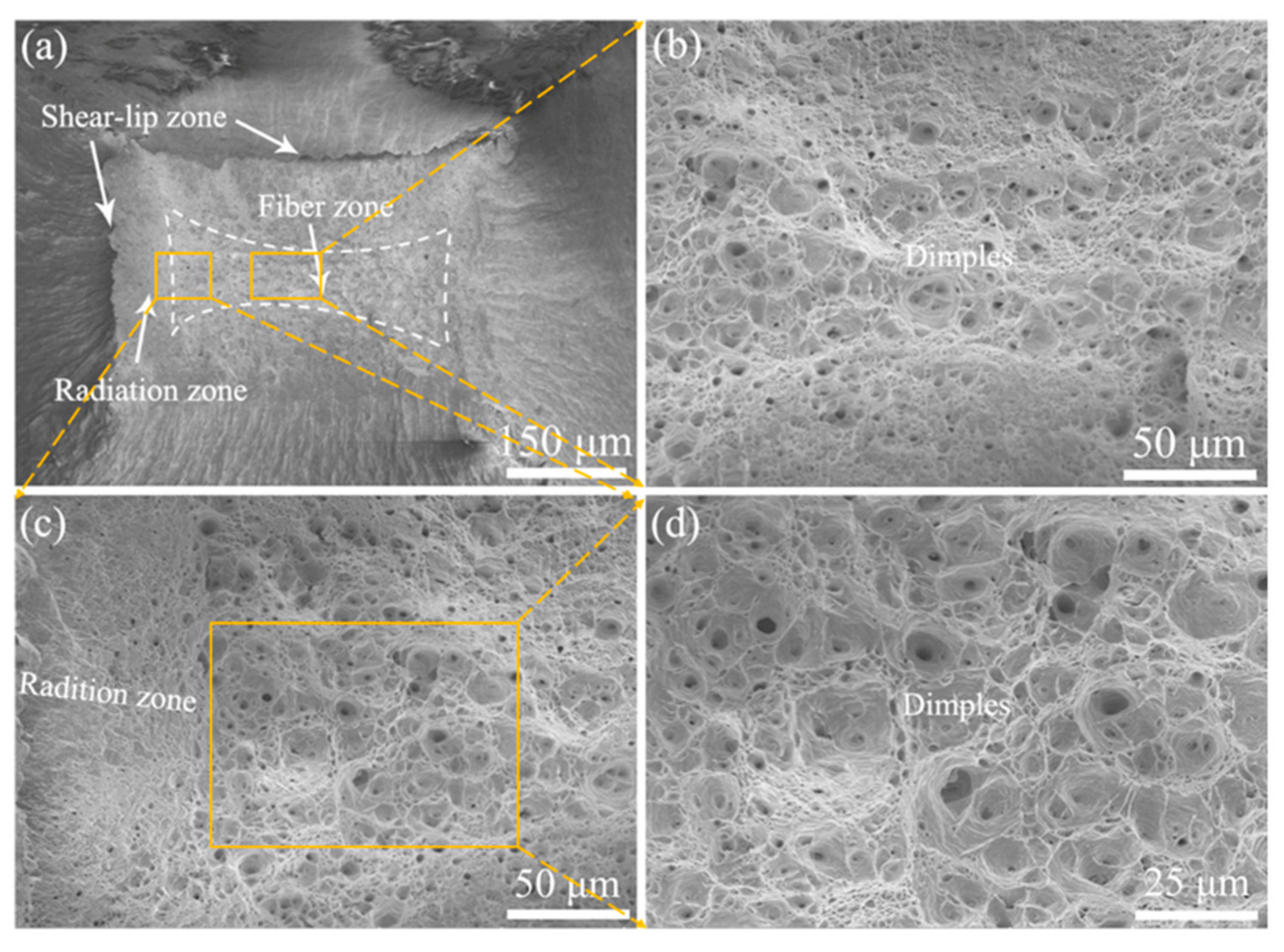

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y. Tensile mechanical properties, constitutive equations, and fracture mechanisms of a novel 9% chromium tempered martensitic steel at elevated temperatures. Mater. Sci. Eng. A 2017, 690, 104–119. [Google Scholar] [CrossRef]

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y.; Tang, Z. Microstructure evolution and fracture mechanism of a novel 9Cr tempered martensite ferritic steel during short-term creep. Mater. Sci. Eng. A 2017, 707, 466–477. [Google Scholar] [CrossRef]

- Wang, L.; Li, M.; Almer, J. In situ characterization of Grade 92 steel during tensile deformation using concurrent high energy X-ray diffraction and small angle X-ray scattering. J. Nucl. Mater. 2013, 440, 81–90. [Google Scholar] [CrossRef]

- Keller, C.; Margulies, M.M.; Hadjem-Hamouche, Z.; Guillot, I. Influence of the temperature on the tensile behaviour of a modified 9Cr–1Mo T91 martensitic steel. Mater. Sci. Eng. A 2010, 527, 6758–6764. [Google Scholar] [CrossRef]

- Giroux, P.F.; Dalle, F.; Sauzay, M.; Malaplate, J.; Fournier, B.; Gourgues-Lorenzon, A.F. Mechanical and microstructural stability of P92 steel under uniaxial tension at high temperature. Mater. Sci. Eng. A 2010, 527, 3984–3993. [Google Scholar] [CrossRef]

- Shankar, V.; Valsan, M.; Rao, K.B.S.; Mannan, S.L. Effects of temperature and strain rate on tensile properties and activation energy for dynamic strain aging in alloy 625. Metall. Mater. Trans. A 2004, 35, 3129–3139. [Google Scholar] [CrossRef]

- Roy, A.K.; Kumar, P.; Maitra, D. Dynamic strain ageing of P91 grade steels of varied silicon content. Mater. Sci. Eng. A 2009, 499, 379–386. [Google Scholar] [CrossRef]

| Designation | Fe | Cr | C | W | Si | Mn | Ta | V | Zr |

|---|---|---|---|---|---|---|---|---|---|

| 9Cr-F/M | Bal. | 9 | 0.12 | 1.5 | 0.7 | 0.5 | 0.1 | 0.2 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zhang, Q.; Yang, J.; Xie, Z.; Zhang, L.; Liu, R.; Li, G.; Wang, H.; Fang, Q.; Wang, X. Microstructures and Tensile Properties of 9Cr-F/M Steel at Elevated Temperatures. Materials 2022, 15, 1248. https://doi.org/10.3390/ma15031248

Zhang G, Zhang Q, Yang J, Xie Z, Zhang L, Liu R, Li G, Wang H, Fang Q, Wang X. Microstructures and Tensile Properties of 9Cr-F/M Steel at Elevated Temperatures. Materials. 2022; 15(3):1248. https://doi.org/10.3390/ma15031248

Chicago/Turabian StyleZhang, Guangjie, Qinggang Zhang, Junfeng Yang, Zhuoming Xie, Linchao Zhang, Rui Liu, Gang Li, Hui Wang, Qianfeng Fang, and Xianping Wang. 2022. "Microstructures and Tensile Properties of 9Cr-F/M Steel at Elevated Temperatures" Materials 15, no. 3: 1248. https://doi.org/10.3390/ma15031248

APA StyleZhang, G., Zhang, Q., Yang, J., Xie, Z., Zhang, L., Liu, R., Li, G., Wang, H., Fang, Q., & Wang, X. (2022). Microstructures and Tensile Properties of 9Cr-F/M Steel at Elevated Temperatures. Materials, 15(3), 1248. https://doi.org/10.3390/ma15031248