Seismic Behavior of Existing Reinforced Concrete Columns with Non-Seismic Details under Low Axial Loads

Abstract

:1. Introduction

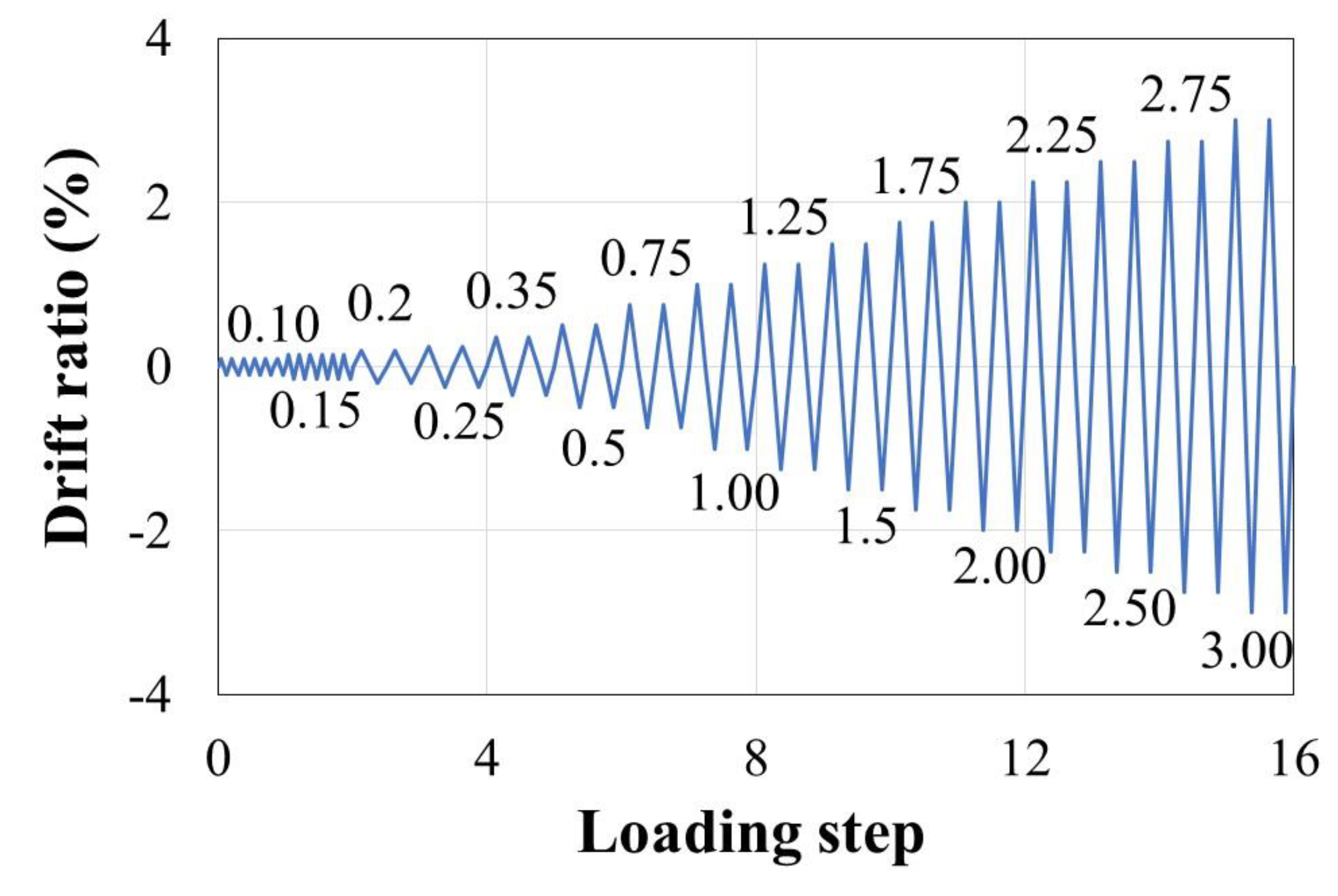

2. Test Plan and Methods

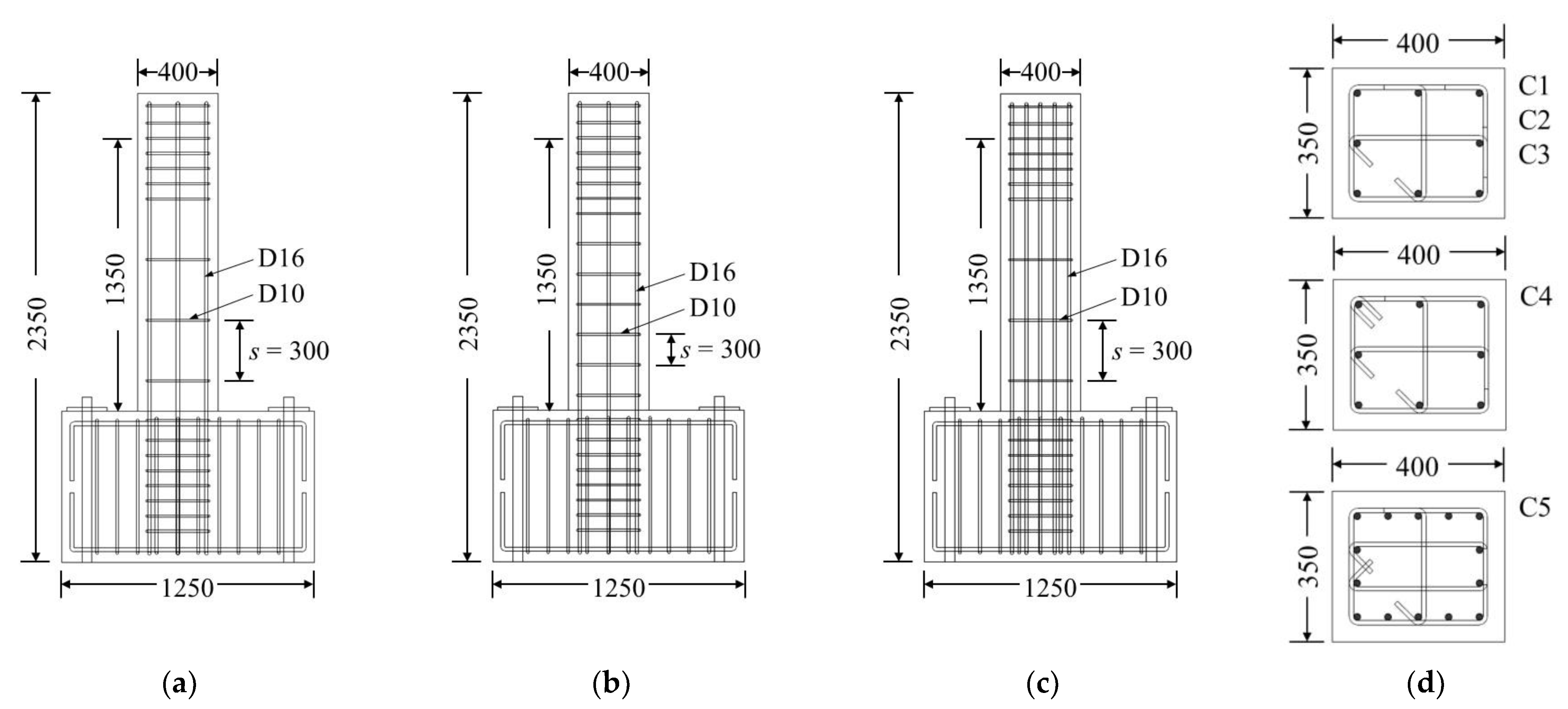

2.1. Specimen Geometry and Configuration

2.2. Material Properties

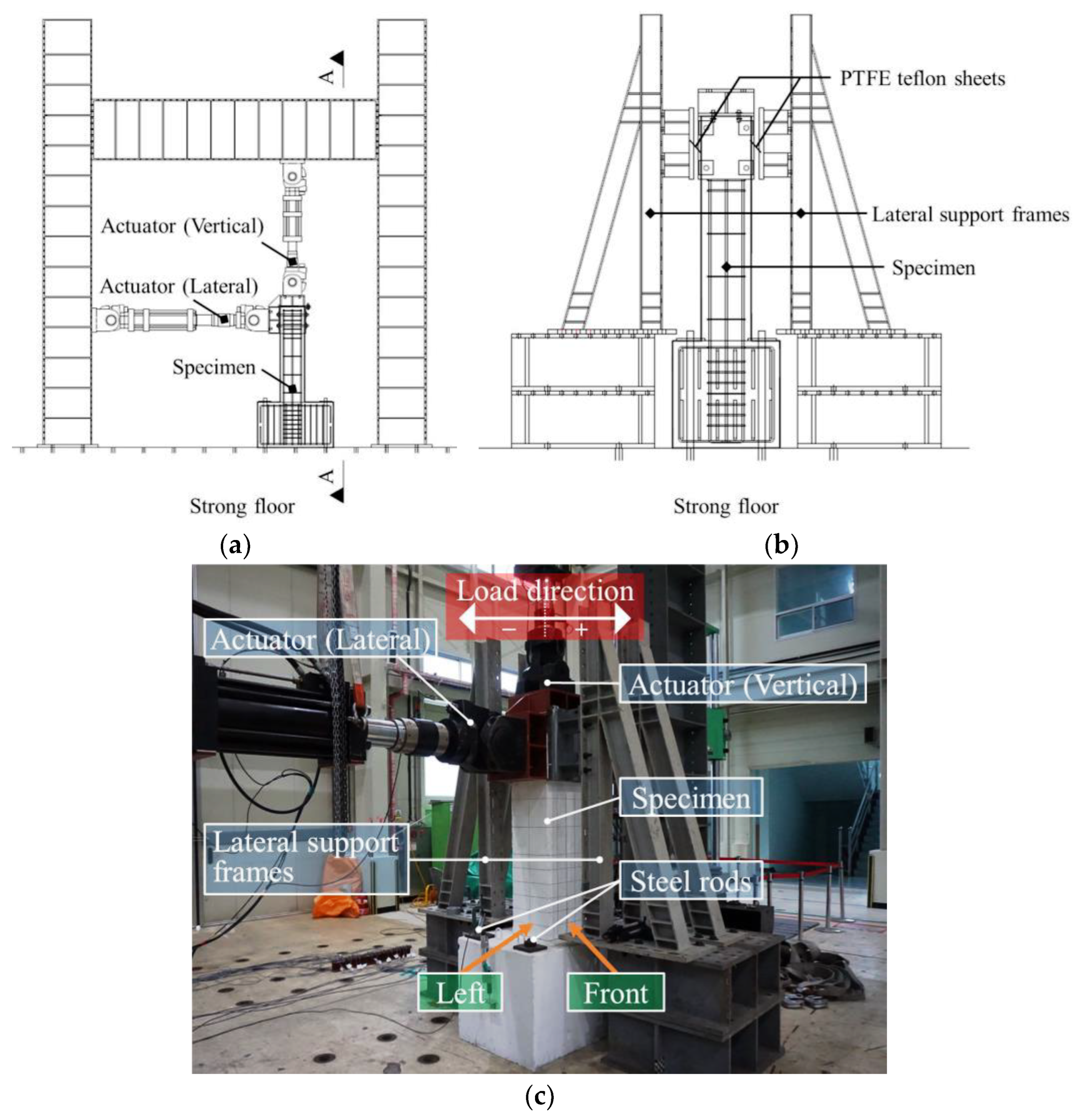

2.3. Test Setup

2.4. Instrumentation

3. Results and Discussion

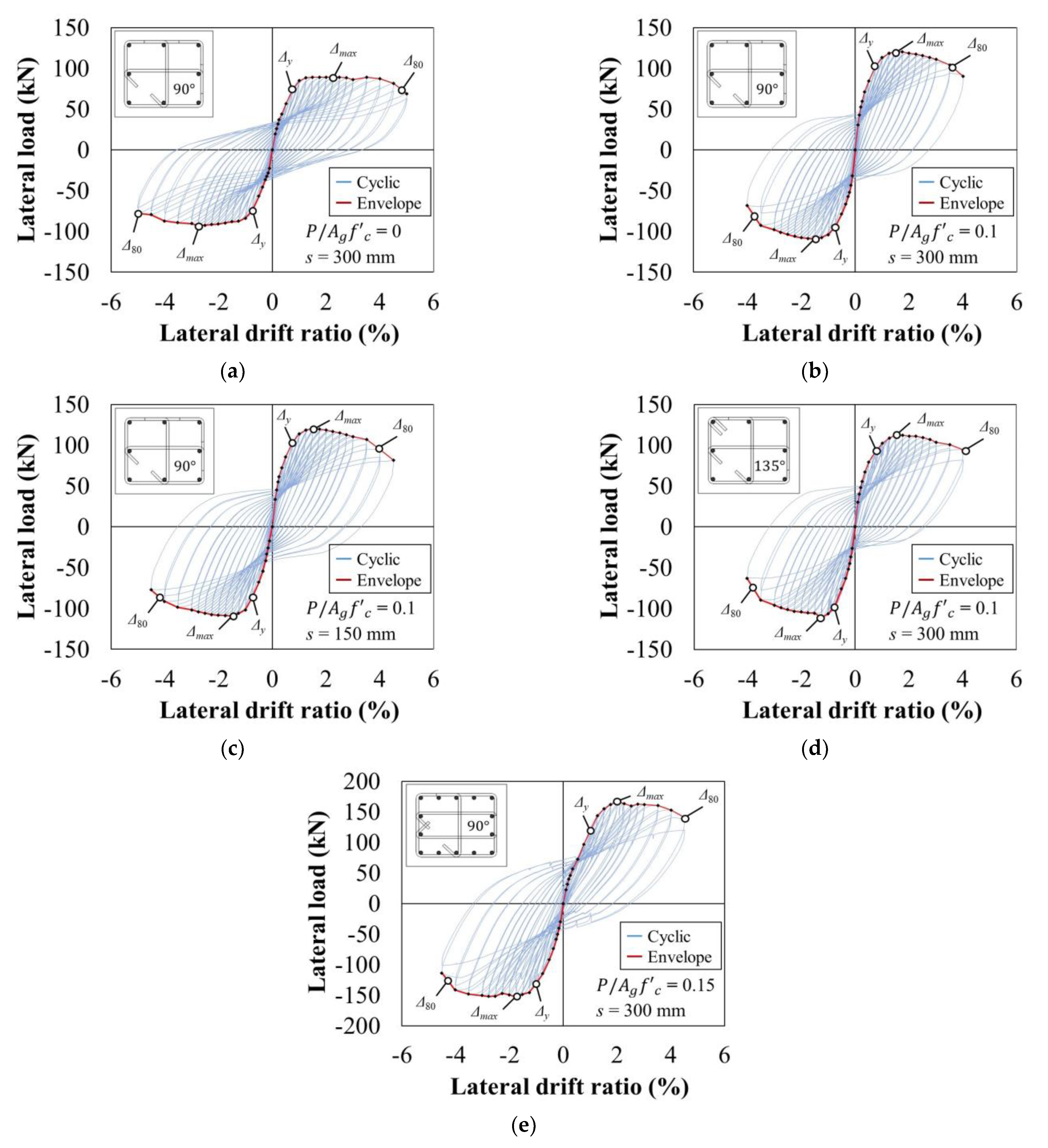

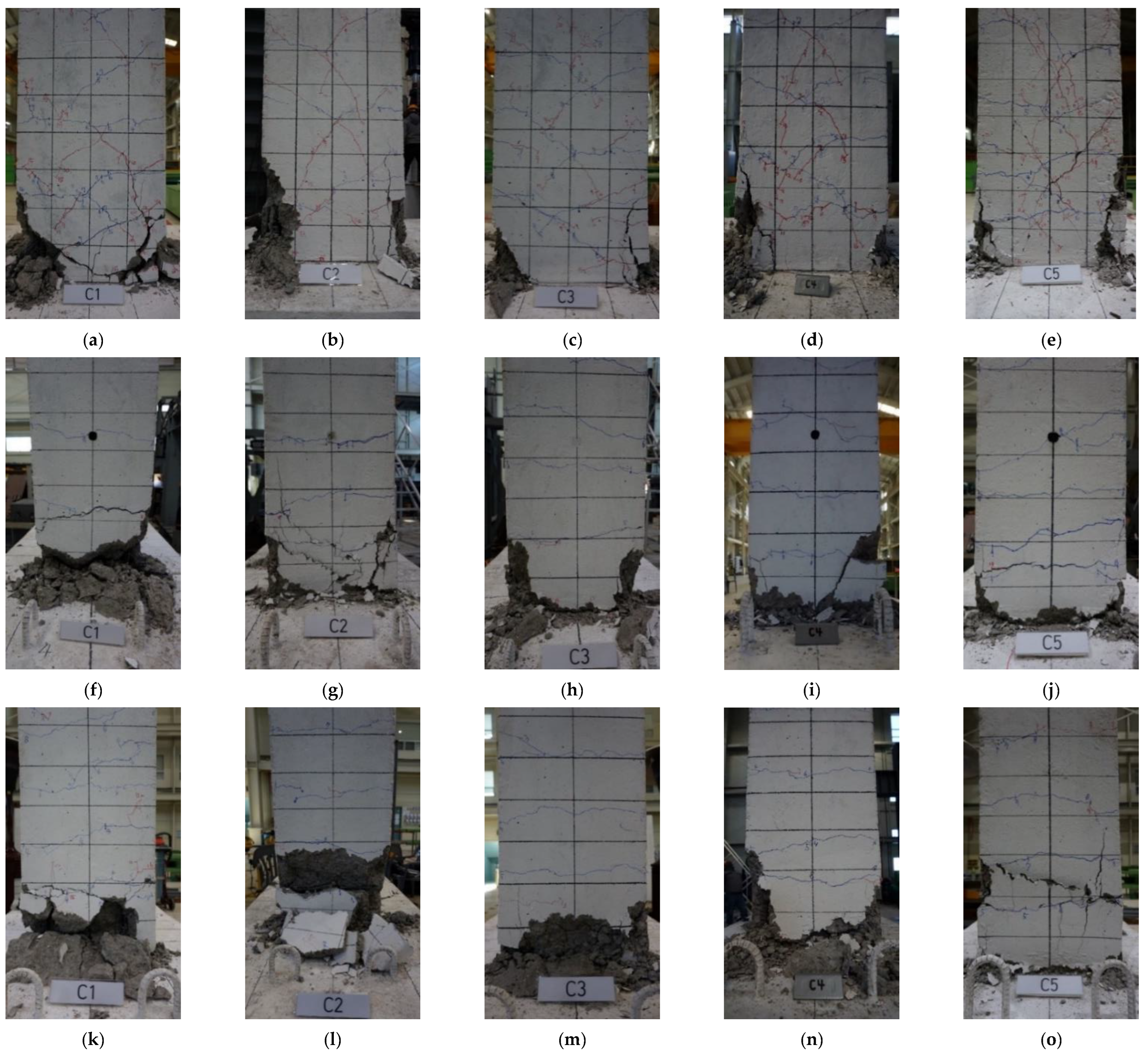

3.1. Load–Drift Relationships and Failure Modes

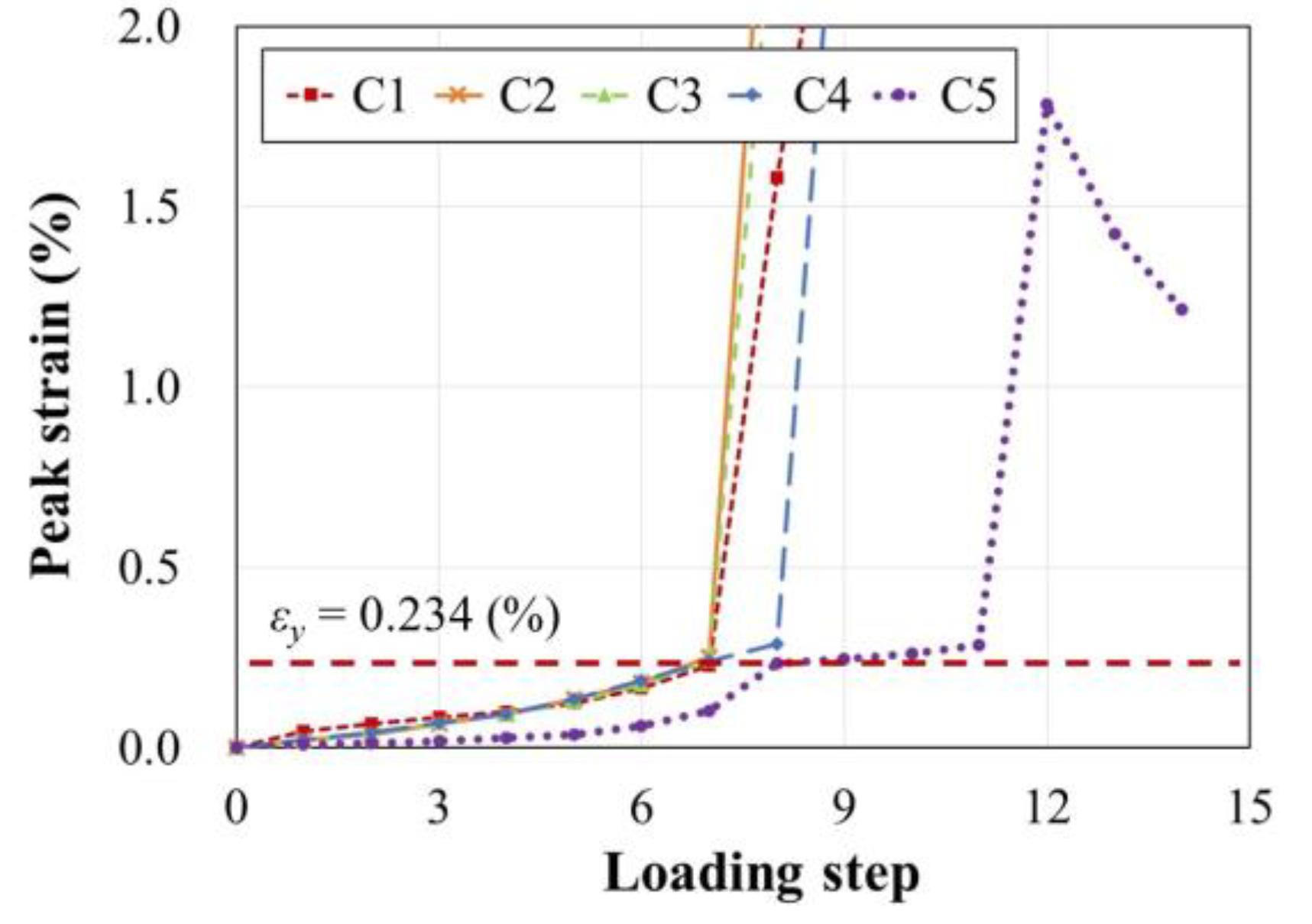

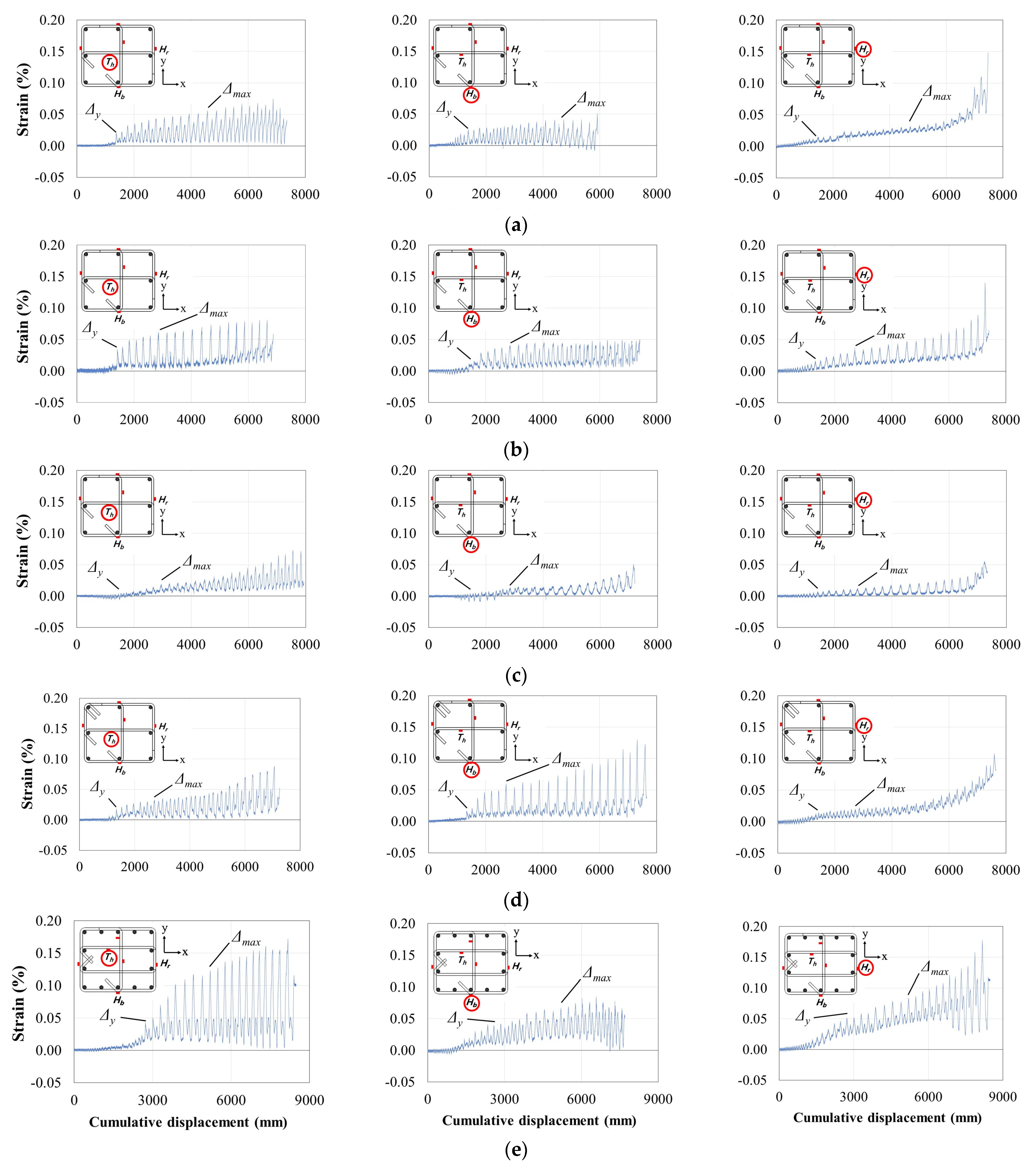

3.2. Strain Behavior

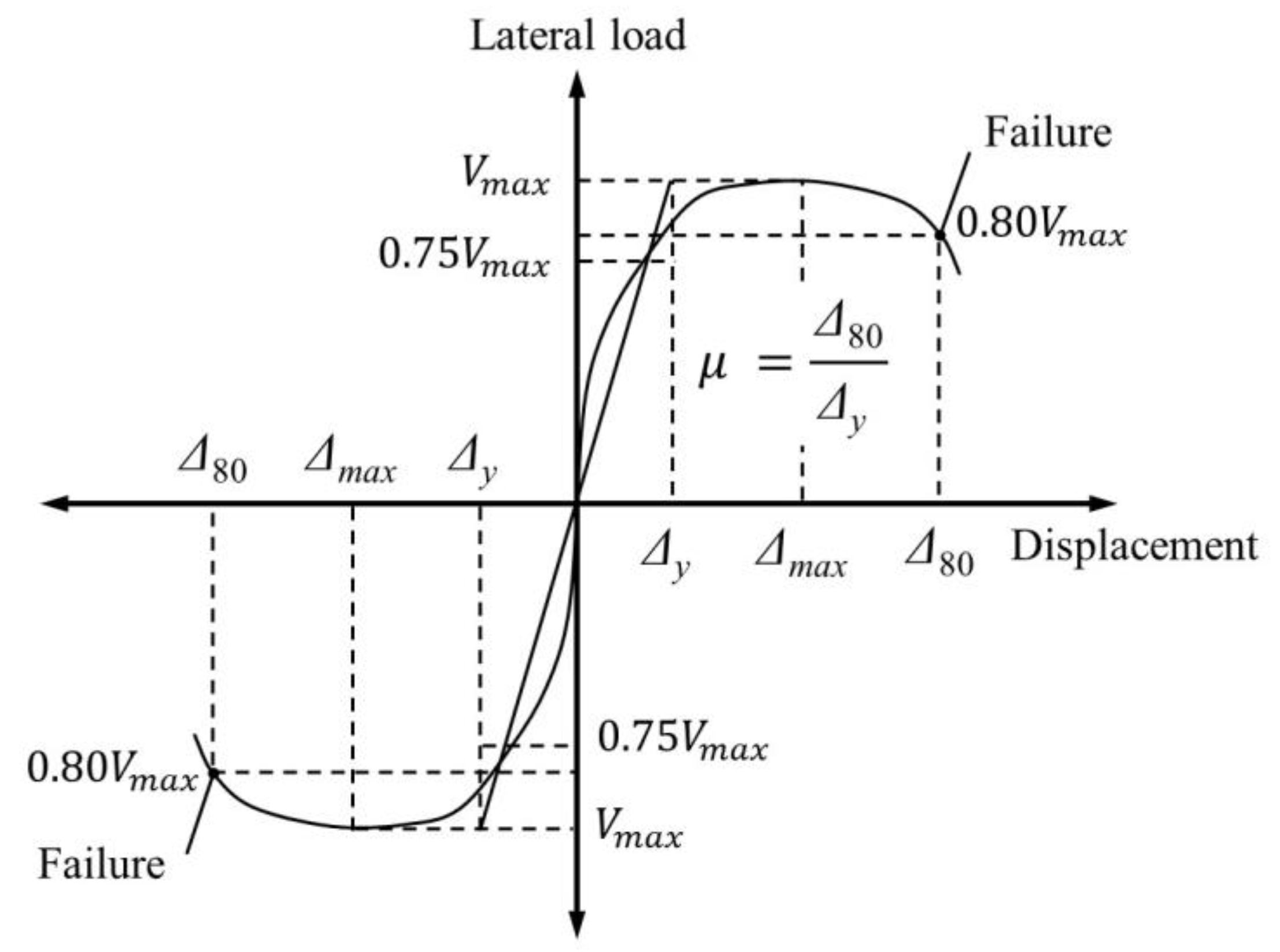

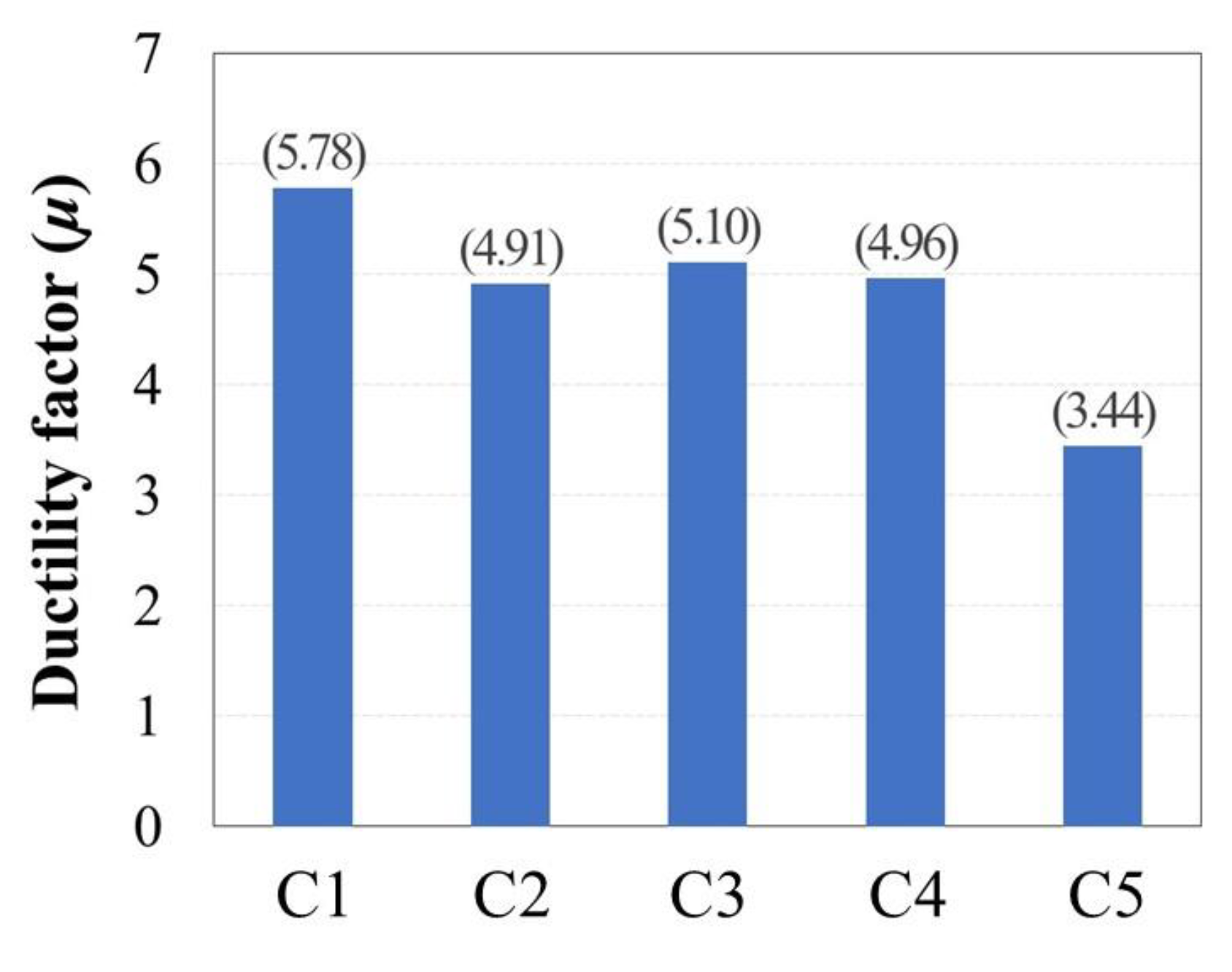

3.3. Ductility

3.4. Energy Dissipation

3.5. Comparison of Experimental Curves with the Evaluation Model Provided in ASCE 41

4. Conclusions

- (1)

- After the longitudinal bars yielded, a shear failure occurred in C5, which was designed and tested as a high axial load column. However, the other specimens (C1–C4) showed typical flexural failure modes accompanied by concrete crushing and cover failure, indicating that RC columns with non-seismic details subjected to low axial load can exhibit ductile behavior.

- (2)

- The strain in the internal crosstie, which had a 90° hook on one end and a 135° hook on the other, was larger when the hoop anchor hook angle was 90° than when it was 135°. In contrast, the confinement effect of the hoops increased when the hoop anchor hook angle was 135° (C4), leading to a decrease in strain in the crosstie. Therefore, the internal crosstie was confirmed to exert more influence on the confinement effect in non-seismic detailed columns with 90° hoop anchor hooks.

- (3)

- Specimens C3 (with half the spacing of 150 mm between transverse reinforcements compared with the other specimens) and C4 (with 135° hoop anchor hooks) both showed similar load–drift curves as the reference specimen, C2, but slightly higher ductility ratios. Specimens C3 and C4 were expected to exhibit more ductile behavior at ultimate load levels beyond failure, but the energy dissipated in the three specimens up to failure was relatively similar. Therefore, existing columns with non-seismic details are expected to display considerable seismic performance without specific reinforcement measures when only a low axial load is applied.

- (4)

- The evaluation model based on ASCE/SEI 41-17 predicted values for the initial stiffness, maximum strength, and strength reduction trend beyond the peak load that were similar to the experimental results. The model was thus deemed to accurately represent the inelastic behavior of RC column components when preceded by flexural yielding, such as in the specimens evaluated in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korean Structural Engineers Association (KSEA). Structural Design Criteria and Commentary for One and Two Story Small Buildings; KSEA: Seoul, Korea, 2012; Chapter 3; pp. 39–69. [Google Scholar]

- Ning, N.; Qu, W.; Ma, Z.J. Design recommendations for achieving “strong column-weak beam” in RC frames. Eng. Struct. 2016, 126, 343–352. [Google Scholar] [CrossRef]

- Gautam, D.; Rodrigues, H.; Bhetwal, K.K.; Neupane, P.; Sanada, Y. Common structural and construction deficiencies of Nepalese buildings. Innov. Infrastruct. Solut. 2016, 1, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Acun, B.; Sucuoglu, H. Performance of Reinforced Concrete Columns Designed for Flexure under Severe Displacement Cycles. ACI Struct. J. 2010, 107, 364–371. [Google Scholar]

- Sezen, H.; Moehle, J.P. Seismic Tests of Concrete Columns with Light Transverse Reinforcement. ACI Struct. J. 2006, 103, 842–849. [Google Scholar]

- ACI (American Concrete Institute). Building Code Requirements for Structural Concrete (ACI 318M-19) and Commentary (ACI 318RM-19); ACI: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Gino, D.; Anerdi, C.; Castaldo, P.; Ferrara, M.; Bertagnoli, G.; Giordano, L. Seismic Upgrading of Existing Reinforced Concrete Buildings Using Friction Pendulum Devices: A Probabilistic Evaluation. Appl. Sci. 2020, 10, 8980. [Google Scholar] [CrossRef]

- Alhaddad, M.S.; Siddiqui, N.A.; Abadel, A.A.; Alsayed, S.H.; Al-Salloum, Y.A. Numerical Investigations on the Seismic Behavior of FRP and TRM Upgraded RC Exterior Beam-Column Joints. J. Compos. Constr. 2012, 16, 308–321. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Melo, J.; Rossetto, T.; Varum, H.; D’Ayala, D. Effect of slab and transverse beam on the FRP retrofit effectiveness for existing reinforced concrete structures under seismic loading. Eng. Struct. 2021, 234, 111991. [Google Scholar] [CrossRef]

- Du, K.; Luo, H.; Bai, J.; Sun, J. Integrating of Nonlinear Shear Models into Fiber Element for Modeling Seismic Behavior of Reinforced Concrete Coupling Beams, Wall Piers, and Overall Coupled Wall Systems. Int. J. Concr. Struct. Mater. 2019, 13, 34. [Google Scholar] [CrossRef]

- Joshani, M.; Koloor, S.; Abdullah, R. Damage Mechanics Model for Fracture Process of Steel-Concrete Composite Slabs. Appl. Mech. Mater. 2012, 165, 339–345. [Google Scholar] [CrossRef]

- Kristiawan, S.A.; Hapsari, I.R.; Purwanto, E.; Marwahyudi, M. Evaluation of Damage Limit State for RC Frame Based on FE Modeling. Buildings 2022, 12, 21. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Koloor, S.S.R.; Petrů, M.; Radwan, N. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Kim, J.C.; Shin, S.H.; Oh, S.H. Damage Investigation of Pilotis Structures and Analysis of Damage Causes by Pohang Earthquake. J. Archit. Inst. Korea 2019, 35, 3–10. [Google Scholar]

- Sezen, H.; Moehle, J.P. Shear Strength Model for Lightly Reinforced Concrete Columns. J. Struct. Eng. 2004, 130, 1692–1703. [Google Scholar] [CrossRef]

- Sheikh, S.A.; Yeh, C.C. Flexural Behavior of Confined Concrete Columns. ACI Struct. J. 1986, 83, 389–404. [Google Scholar]

- Sheikh, S.A.; Khoury, S.S. Confined Concrete Columns with Stubs. ACI Struct. J. 1993, 90, 414. [Google Scholar]

- Wu, D.; Ding, Y.; Su, J.; Li, Z.X.; Zong, L.; Feng, K. Effects of tie detailing configurations on reinforcement buckling and seismic performance of high-strength RC columns. Soil Dyn. Earthq. Eng. 2021, 147, 106791. [Google Scholar] [CrossRef]

- Song, H.; Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Maślak, M.; Czarnecki, S.; Aslam, F. Predicting the compressive strength of concrete with fly ash admixture using machine learning algorithms. Constr. Build. Mater. 2021, 308, 125021. [Google Scholar] [CrossRef]

- Mo, Y.L.; Wang, S.J. Seismic Behavior of RC Columns with Various Tie Configurations. J. Struct. Eng. 2000, 126, 1122–1130. [Google Scholar] [CrossRef]

- Popa, V.; Coțofană, D.; Văcăreanu, R. Effective stiffness and displacement capacity of short reinforced concrete columns with low concrete quality. Bull. Earthq. Eng. 2014, 12, 2705–2721. [Google Scholar] [CrossRef]

- Boonmee, C.; Rodsin, K.; Sriboonma, K. Gravity Load Collapse Behavior of Nonengineered Reinforced Concrete Columns. Adv. Civ. Eng. 2018, 2018, 9450978. [Google Scholar] [CrossRef]

- Rajput, A.S.; Sharma, U.K. Seismic Behavior of Under Confined Square Reinforced Concrete Columns. Structures 2018, 13, 26–35. [Google Scholar] [CrossRef]

- Lam, S.; Wu, B.; Wong, Z.; Liu, Z.; Li, C. Drift Capacity of Rectangular Reinforced Concrete Columns with Low Lateral Confinement and High-Axial Load. J. Struct. Eng. 2003, 129, 733–742. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, J.C.; Choi, K.-K. Experimental Study for Investigating Seismic Performances of RC Columns with Non-Seismic Details. J. Archit. Inst. Korea 2016, 32, 35–44. [Google Scholar]

- Kim, C.G.; Park, H.G.; Eom, T.-S. Cyclic Load Test and Shear Strength Degradation Model for Columns with Limited Ductility Tie Details. J. Struct. Eng. 2019, 145, 04018249. [Google Scholar] [CrossRef]

- Kim, C.G.; Park, H.G.; Eom, T.S.; Kim, T.W. Effects of Tie Details on Seismic Performance of RC Columns Subjected to Low Compression Loads. J. Earthq. Eng. Soc. Korea 2015, 19, 195–205. [Google Scholar] [CrossRef]

- KS D 2403; Standard Test Method for Making and Curing Concrete Specimens. Korean Agency for Technology and Standards (KATS): Seoul, Korea, 2019.

- KS D 2405; Standard Test Method for Compressive Strength of Concrete. Korean Agency for Technology and Standards (KATS): Seoul, Korea, 2017.

- KS B 0802; Method of Tensile Test for Metallic Materials. Korean Agency for Technology and Standards (KATS): Seoul, Korea, 2018.

- ACI 374.1-05; Acceptance Criteria for Moment Frames Based on Structural Testing and Commentary. ACI (American Concrete Institute): Farmington Hills, MI, USA, 2005.

- Lee, C.H.; Ryu, J.; Kim, D.H.; Ju, Y.K. Improving seismic performance of non-ductile reinforced concrete frames through the combined behavior of friction and metallic dampers. Eng. Struct. 2018, 172, 304–320. [Google Scholar] [CrossRef]

- FEMA 461; Interim Testing Protocols for Determining the Seismic Performance Characteristics of Structural and Nonstructural Components; FEMA (Federal Emergency Management Agency): Washington, DC, USA, 2007.

- ACI 374.2R-13; Guide for Testing Reinforced Concrete Structural Elements under Slowly Applied Simulated Seismic Loads. ACI (American Concrete Institute): Farmington Hills, MI, USA, 2013.

- Lee, C.H.; Kim, J.; Kim, D.H.; Ryu, J.; Ju, Y.K. Numerical and experimental analysis of combined behavior of shear-type friction damper and non-uniform strip damper for multi-level seismic protection. Eng. Struct. 2016, 114, 75–92. [Google Scholar] [CrossRef]

- Kim, J.K.; Han, B.S.; Shin, S.W. Ductility Capacity of Ultra-high Strength R/C Tied Columns Considering the Axial Load Ratio and Configuration of Transverse Reinforcement. J. Archit. Inst. Korea 2009, 25, 3–11. [Google Scholar]

- ASCE/SEI 41-17; Seismic Evaluation and Retrofit of Existing Buildings. ASCE (American Society of Civil Engineers): Reston, VA, USA, 2017.

- Han, S.W.; Lee, C.S.; Paz Zambrana, M.A.; Lee, K. Calibration Factor for ASCE 41-17 Modeling Parameters for Stocky Rectangular RC Columns. Appl. Sci. 2019, 9, 5193. [Google Scholar] [CrossRef] [Green Version]

- Dinh, N.H.; Kim, J.C.; Lee, S.J.; Choi, K.K.; Park, H.G. Modeling parameters for the nonlinear analysis of reinforced concrete beams under cyclic loading. Eng. Struct. 2020, 216, 110715. [Google Scholar] [CrossRef]

- Deng, X.; Koutromanos, I.; Murcia-Delso, J.; Panagiotou, M. Nonlinear truss models for strain-based seismic evaluation of planar RC walls. Earthq. Eng. Struct. Dyn. 2021, 50, 2939–2960. [Google Scholar] [CrossRef]

| Specimen | Longitudinal Reinforcement | Transverse Reinforcement | Hook Angle (Hoop) | Applied Axial Load | |

|---|---|---|---|---|---|

| C1 | 8-D16 | (ρ = 0.0113) | D10@300 | 90° | 0 |

| C2 | 8-D16 | (ρ = 0.0113) | D10@300 | 90° | 0.1Agf′c |

| C3 | 8-D16 | (ρ = 0.0113) | D10@150 | 90° | 0.1Agf′c |

| C4 | 8-D16 | (ρ = 0.0113) | D10@300 | 135° | 0.1Agf′c |

| C5 | 16-D16 | (ρ = 0.0199) | D10@300 | 90° | 0.15Agf′c |

| Specimen | Vy | Vmax | Δy | Δmax | μ | Dissipated Energy (kN∙m) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pos | Neg | Pos | Neg | Pos | Neg | Pos | Neg | |||

| C1 | 67.0 | −69.4 | 89.4 | −92.5 | 8.61 | −9.04 | 30.4 | −37.2 | 5.78 | 73.0 |

| C2 | 90.7 | −81.9 | 121.0 | −109.3 | 7.79 | −7.64 | 20.3 | −20.3 | 4.91 | 64.7 |

| C3 | 90.7 | −81.7 | 120.9 | −109.0 | 7.60 | −9.04 | 20.4 | −20.4 | 5.10 | 63.3 |

| C4 | 84.7 | −83.4 | 113.0 | −111.2 | 7.90 | −7.31 | 20.5 | −17.0 | 4.96 | 65.8 |

| C5 | 125.3 | −114.5 | 167.1 | −152.6 | 13.73 | −10.69 | 13.7 | −10.7 | 3.44 | 83.2 |

| Specimen | Th | Hb | Hr | |||

|---|---|---|---|---|---|---|

| Δy | Δmax | Δy | Δmax | Δy | Δmax | |

| C1 | 0.019 | 0.056 | 0.026 | 0.041 | 0.015 | 0.032 |

| C2 | 0.033 | 0.062 | 0.016 | 0.041 | 0.016 | 0.038 |

| C3 | 0.003 | 0.019 | 0.004 | 0.013 | 0.007 | 0.012 |

| C4 | 0.018 | 0.033 | 0.017 | 0.060 | 0.014 | 0.020 |

| C5 | 0.042 | 0.123 | 0.040 | 0.067 | 0.052 | 0.084 |

| Component | Flexural | Shear | Axial |

|---|---|---|---|

| Columns with compression caused by design gravity loads ≥ 0.5Agf′c | 0.7EcIg | 0.4EcAw | EcAg |

| Columns with compression caused by design gravity loads ≤ 0.1Agf′c or with tension | 0.3EcIg | 0.4EcAw | EcAg (compression) EsAs (tension) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, M.-H.; Lee, C.-H. Seismic Behavior of Existing Reinforced Concrete Columns with Non-Seismic Details under Low Axial Loads. Materials 2022, 15, 1239. https://doi.org/10.3390/ma15031239

Choi M-H, Lee C-H. Seismic Behavior of Existing Reinforced Concrete Columns with Non-Seismic Details under Low Axial Loads. Materials. 2022; 15(3):1239. https://doi.org/10.3390/ma15031239

Chicago/Turabian StyleChoi, Myeong-Ho, and Chang-Hwan Lee. 2022. "Seismic Behavior of Existing Reinforced Concrete Columns with Non-Seismic Details under Low Axial Loads" Materials 15, no. 3: 1239. https://doi.org/10.3390/ma15031239

APA StyleChoi, M.-H., & Lee, C.-H. (2022). Seismic Behavior of Existing Reinforced Concrete Columns with Non-Seismic Details under Low Axial Loads. Materials, 15(3), 1239. https://doi.org/10.3390/ma15031239