Biotreatments Using Microbial Mixed Cultures with Crude Glycerol and Waste Pinewood as Carbon Sources: Influence of Application on the Durability of Recycled Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Bioproducts

2.1.2. Concrete

2.2. Treatment of Concrete Surface

2.3. Test Method

2.3.1. Hardened Concrete Resistance to Pressurized Water Penetration

2.3.2. Water Absorption Caused by Capillarity of Hardened Concrete

2.3.3. Resistance of Hardened Concrete to Freeze–Thaw Cycles

2.3.4. Water Drop Absorption in Hardened Concrete

Indoor–Outdoor

Re-Application

Vertical Exposure

3. Results and Discussion

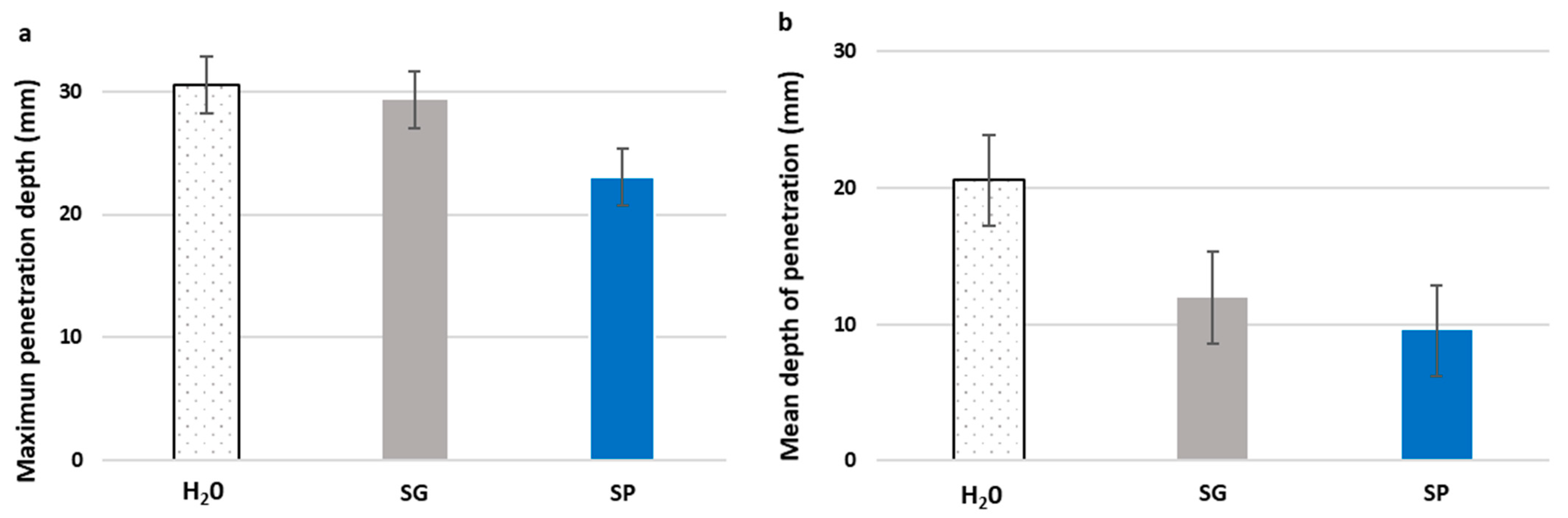

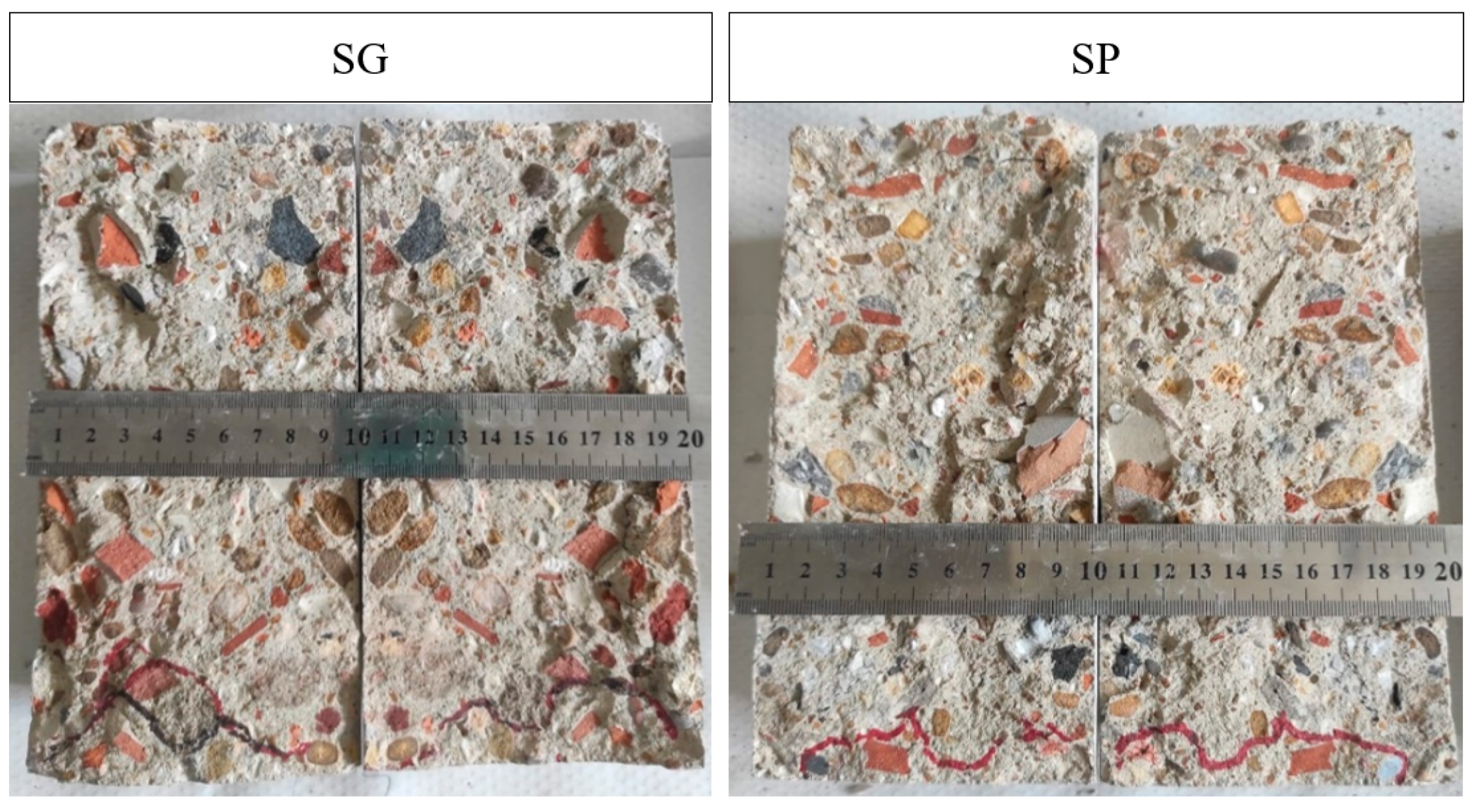

3.1. Depth of Penetration of Water under Pressure

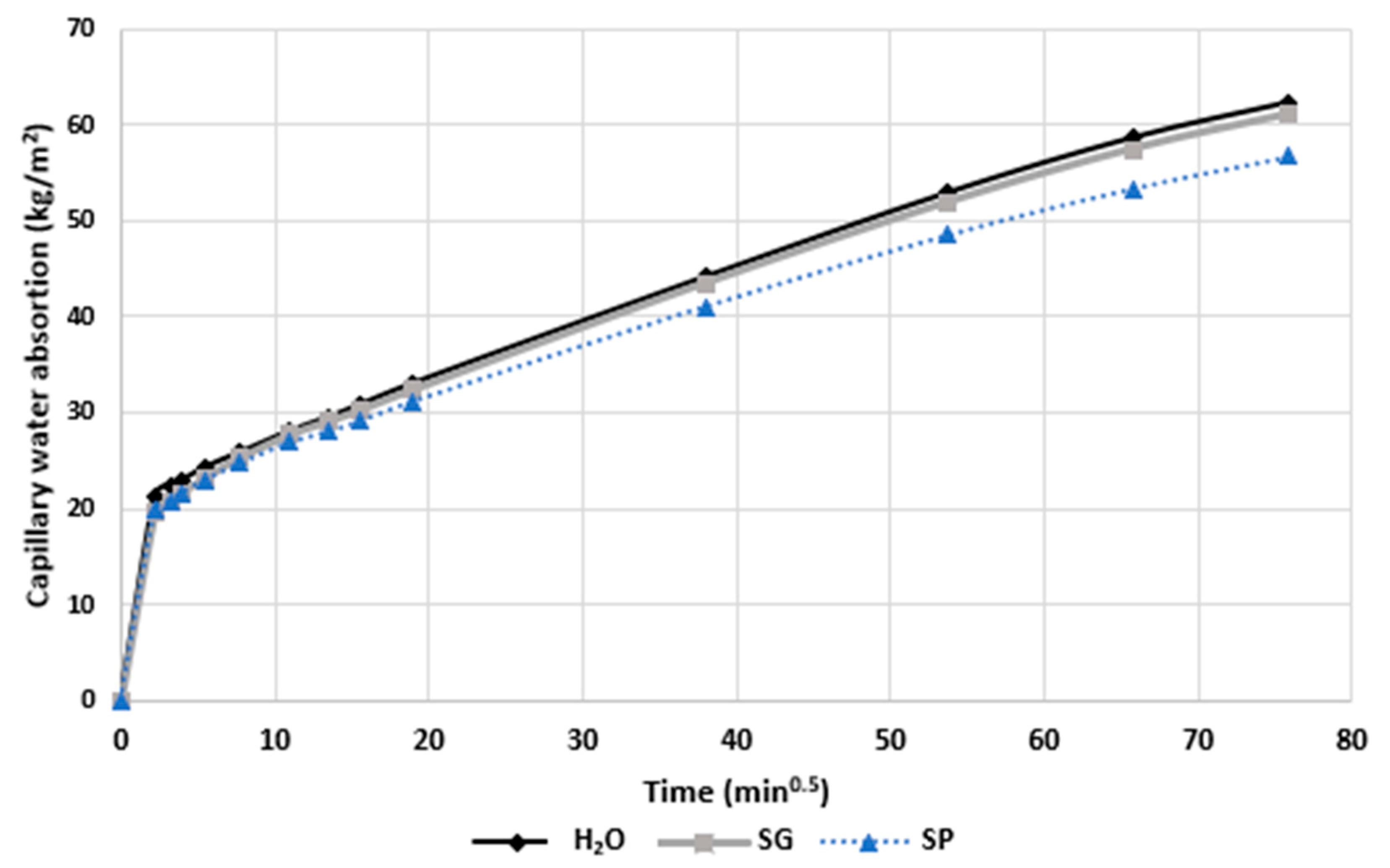

3.2. Water Absorption caused by Capillarity

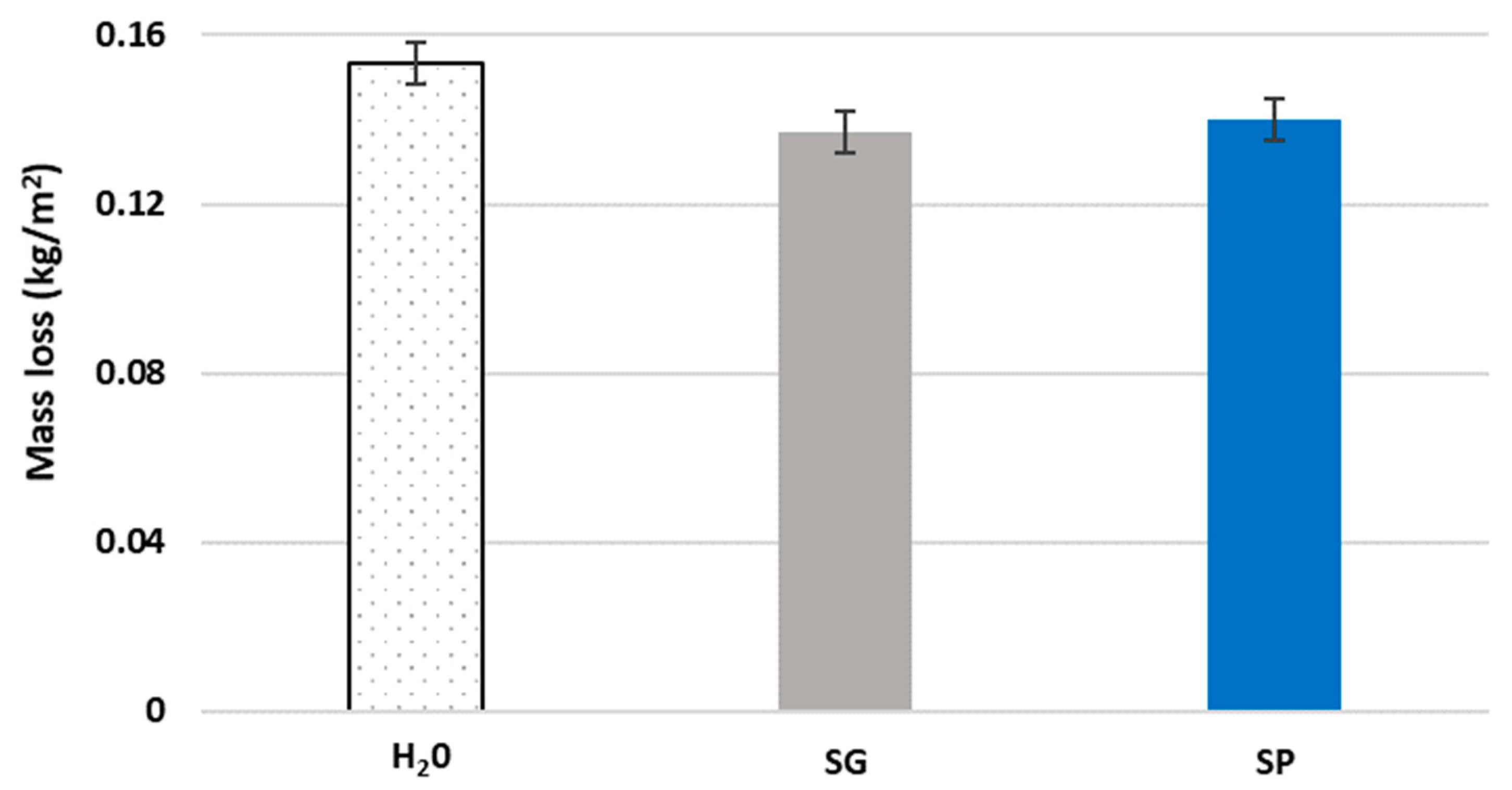

3.3. Resistance to Freeze–Thaw Cycles

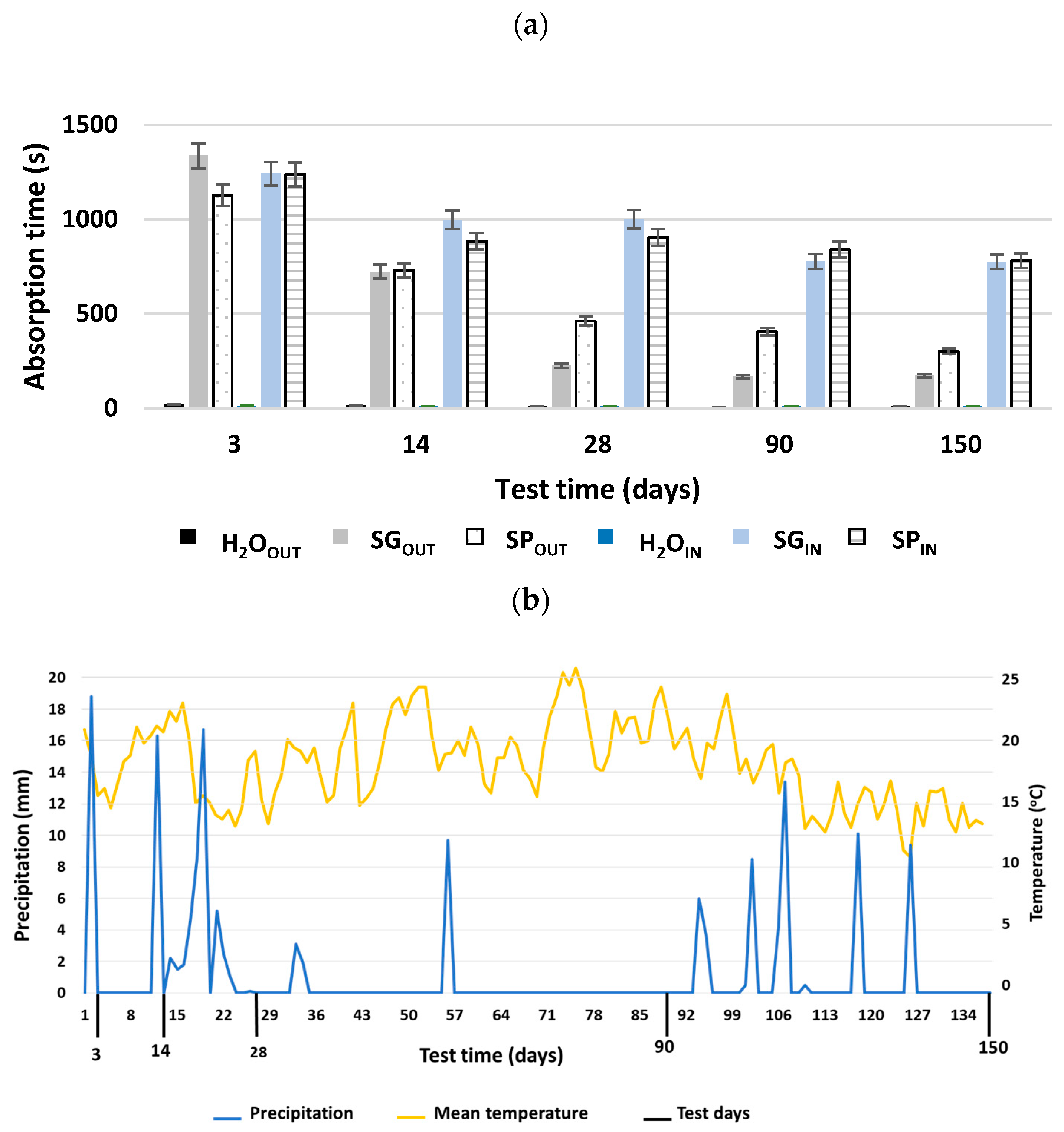

3.4. Water Drop Absorption

3.4.1. Indoor–Outdoor Effect

3.4.2. Reapplied Specimens (Reap)

3.4.3. Vertical Exposure (V.E.)

4. Conclusions

- The treatments with the bioproducts showed significant improvements relative to the reference concrete (treated with H2O) in all tests, although the improvements were particularly noticeable in the pressurized water penetration and water drop absorption tests;

- The effects of the bioproducts in the water under pressure test were better perceived via the average penetration values due to the irregularity of the profiles, showing the greater uniformity of the SP due to the better distribution of the bioproducts;

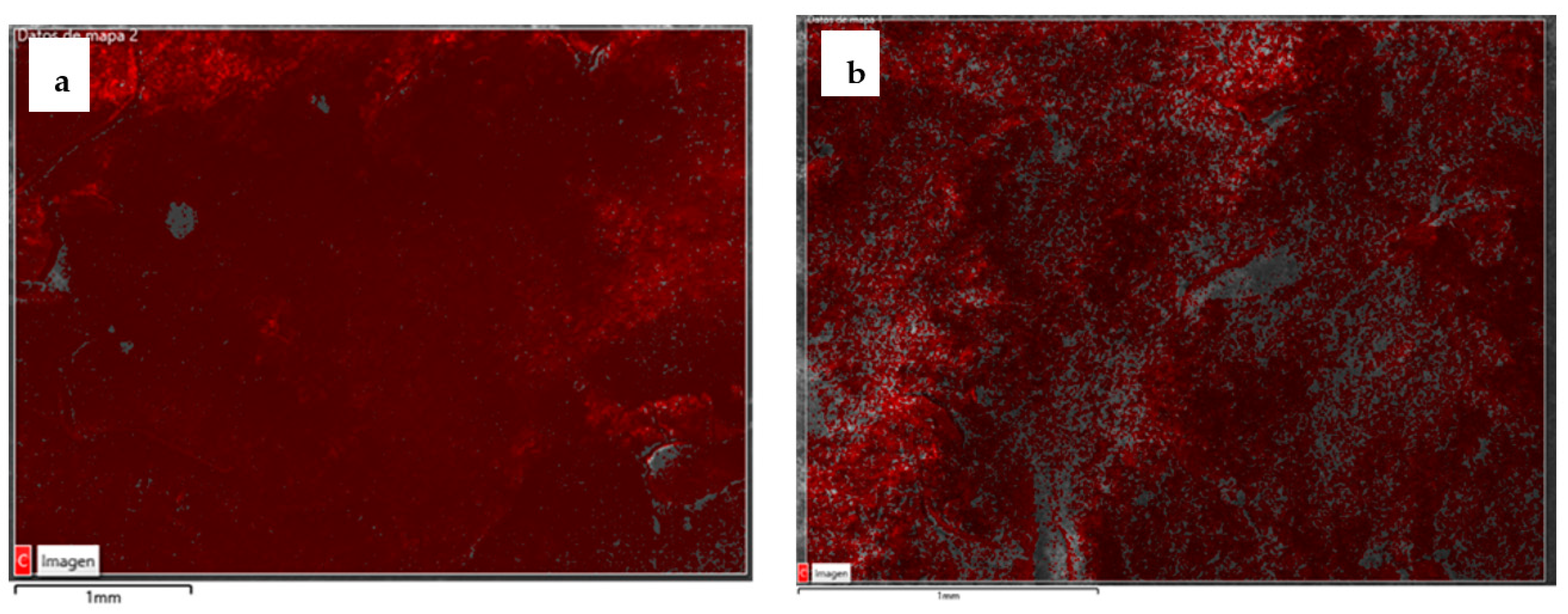

- The bioproducts act on the larger pores walls, making water transport difficult, although due to their high molecular weight they do not seem to interfere with the smallest pores;

- The protective layer of the bioproducts prevents the entry of water through the cracks, explaining the smaller loss of mass in the freeze–thaw test relative to the control and the non-appearance of holes due to the loss of aggregates. The efficacy of the biotreatments was reduced with time under natural exposure conditions, although after 150 days the decrease in water absorption was still 19 times longer in the case of SG and 39 times longer for SP when compared to reference specimens;

- The re-application of bioproducts after 3 days resulted in a significant improvement in the treatment efficacy, which declined over time in natural weathering conditions but remained mostly constant after 90 days;

- The use of both bioproducts in a vertical exposure test generated a significant protective effect, although their efficiency decreased more than 60% after 90 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Xuan, D.; Poon, C.S.; Zheng, W. Management and Sustainable Utilization of Processing Wastes from Ready-Mixed Concrete Plants in Construction: A Review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Cement Technology Roadmap: Carbon Emissions Reductions up to 2050. In World Business Council for Sustainable Development; OECD Publishing: Paris, France, 2009; p. 36. [Google Scholar] [CrossRef]

- Alexander, M.; Mindess, S. Aggregates in Concrete, 1st ed.; CRC Press: London, UK, 2005; p. 448. [Google Scholar] [CrossRef]

- Rockson, C.; Tamanna, K.; Shahria Alam, M.; Rteil, A. Effect of Rebar Embedment Length on the Bond Behavior of Commercially Produced Recycled Concrete Using Beam-End Specimens. Constr. Build. Mater. 2021, 286, 122957. [Google Scholar] [CrossRef]

- EEA. Effectiveness of Environmental Taxes and Charges for Managing Sand, Gravel and Rock Extraction in Selected EU Countries; European Environment Agency: Copenhagen, Denmark, 2008.

- United Nations Environment Program (UNEP). Sand, Rarer than One Thinks; UNEP Global Environmental Alert Service: Nairobi, Kenya, 2014; pp. 1–15. [Google Scholar]

- Botelho, M.J. Construction and Demolition Waste. (Resíduos de Construção e Demolição); Verlag Dashofer: Lisbon, Portugal, 2010. [Google Scholar]

- Bovea, M.D.; Powell, J.C. Developments in Life Cycle Assessment Applied to Evaluate the Environmental Performance of Construction and Demolition Wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar] [CrossRef]

- Guedes, M.; Evangelista, L.; De Brito, J.; Ferro, A.C. Microstructural Characterization of Concrete Prepared with Recycled Aggregates. Microsc. Microanal. 2013, 19, 1222–1230. [Google Scholar] [CrossRef] [PubMed]

- Prakash, S.; Wijayasundara, M.; Pathirana, P.N.; Law, K. De-Risking Resource Recovery Value Chains for a Circular Economy–Accounting for Supply and Demand Variations in Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 168, 105312. [Google Scholar] [CrossRef]

- De Brito, J.; Saikia, D.N. Recycled Aggregate in Concrete: Use of Industrial, Construction and Demolition Waste; Springer Publishing: London, UK, 2012; Volume 54, p. 448. [Google Scholar] [CrossRef]

- Gordon, M.; Li, S.M.; Staebler, R.; Darlington, A.; Hayden, K.; O’Brien, J.; Wolde, M. Determining Air Pollutant Emission Rates Based on Mass Balance Using Airborne Measurement Data over the Alberta Oil Sands Operations. Atmos. Meas. Tech. 2015, 8, 3745–3765. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Zheng, Z.; Ma, M.; Su, Y.; Yang, J.; Tan, H.; Wang, Y.; Strnadel, B. New Treatment Technology: The Use of Wet-Milling Concrete Slurry Waste to Substitute Cement. J. Clean. Prod. 2020, 242, 118347. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring Environmental and Economic Costs and Benefits of a Circular Economy Approach to the Construction and Demolition Sector. A Literature Review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Lotfi, S.; Eggimann, M.; Wagner, E.; Mróz, R.; Deja, J. Performance of Recycled Aggregate Concrete Based on a New Concrete Recycling Technology. Constr. Build. Mater. 2015, 95, 243–256. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P. Concrete Resistant to Spalling Made with Recycled Aggregate from Sanitary Ceramic Wastes–The Effect of Moisture and Porosity on Destructive Processes Occurring in Fire Conditions. Constr. Build. Mater. 2018, 173, 58–68. [Google Scholar] [CrossRef]

- Mustafa Al Bakri, A.M.; Mohammad Tamizi, S.; Rafiza, A.R.; Zarina, Y. Investigation of HDPE Plastic Waste Aggregate on the Properties of Concrete. J. Asian Sci. Res. 2011, 1, 340–345. [Google Scholar]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building Materials in a Circular Economy: The Case of Wood Waste as CO2-Sink in Bio Concrete. Resour. Conserv. Recycl. 2021, 166. [Google Scholar] [CrossRef]

- Chen, W.; Jin, R.; Xu, Y.; Wanatowski, D.; Li, B.; Yan, L.; Pan, Z.; Yang, Y. Adopting Recycled Aggregates as Sustainable Construction Materials: A Review of the Scientific Literature. Constr. Build. Mater. 2019, 218, 483–496. [Google Scholar] [CrossRef]

- Solyman, M. Classification of Recycled Sands and Their Applications as Fine Aggregates for Concrete and Bituminous Mixtures. Doctoral Dissertation, Kassel University, Kassel, Germany, 2005. Available online: https://kobra.uni-kassel.de/handle/123456789/2818 (accessed on 8 December 2021).

- Meddah, M.S. Recycled Aggregates in Concrete Production: Engineering Properties and Environmental Impact. MATEC Web Conf. 2017, 101, 05021. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical Properties of Concrete with Recycled Coarse Aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- López-Gayarre, F.; Serna, P.; Domingo-Cabo, A.; Serrano-López, M.A.; López-Colina, C. Influence of Recycled Aggregate Quality and Proportioning Criteria on Recycled Concrete Properties. Waste Manag. 2009, 29, 3022–3028. [Google Scholar] [CrossRef]

- Sanchez de Juan, M.; Gutierrez, P. Influence Ofrecycled Aggregate Quality on Concrete Properties. In Proceedings of the International RILEM Conference: The Use of Recycled Materials in Building and Structures, Barcelona, Spain, 8–11 November 2004; pp. 545–553. [Google Scholar]

- Sandra, N.; Kawaai, K.; Ujike, I. Influence of Copper Slag on Corrosion Behavior of Horizontal Steel Bars in Reinforced Concrete Column Specimen Due to Chloride-Induced Corrosion. Constr. Build. Mater. 2020, 255, 119265. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregate—A Review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Pre-Saturation Technique of the Recycled Aggregates: Solution to the Water Absorption Drawback in the Recycled Concrete Manufacture. Materials 2014, 7, 6224–6236. [Google Scholar] [CrossRef] [Green Version]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. Alternative Processing Procedures for Recycled Aggregates in Structural Concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Serrano-González, L.; Merino-Maldonado, D.; Ignacio Guerra-Romero, M.; Morán-del Pozo, J.M.; Costa Lemos, P.; Santos Pereira, A.; Faria, P.; García-González, J.; Juan-Valdés, A. Use of Bioproducts Derived from Mixed Microbial Cultures Grown with Crude Glycerol to Protect Recycled Concrete Surfaces. Materials 2021, 14, 2057. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.; Wang, Y.; Tong, Y.; Chen, G.Q. Grand Challenges for Industrializing Polyhydroxyalkanoates (PHAs). Trends Biotechnol. 2021, 39, 953–963. [Google Scholar] [CrossRef] [PubMed]

- Yadav, B.; Talan, A.; Tyagi, R.D.; Drogui, P. Concomitant Production of Value-Added Products with Polyhydroxyalkanoate (PHA) Synthesis: A Review. Bioresour. Technol. 2021, 337, 125419. [Google Scholar] [CrossRef]

- Ganesh Saratale, R.; Cho, S.K.; Dattatraya Saratale, G.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Naresh Bharagava, R.; Kumar, G.; Su Kim, D.; Mulla, S.I.; et al. A Comprehensive Overview and Recent Advances on Polyhydroxyalkanoates (PHA) Production Using Various Organic Waste Streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.; Chuah, J.A.; Chek, M.F.; Tan, H.T.; Hakoshima, T.; Sudesh, K. Identification of Regions Affecting Enzyme Activity, Substrate Binding, Dimer Stabilization and Polyhydroxyalkanoate (PHA) Granule Morphology in the PHA Synthase of Aquitalea Sp. USM4. Int. J. Biol. Macromol. 2021, 186, 414–423. [Google Scholar] [CrossRef]

- De Donno Novelli, L.; Moreno Sayavedra, S.; Rene, E.R. Polyhydroxyalkanoate (PHA) Production via Resource Recovery from Industrial Waste Streams: A Review of Techniques and Perspectives. Bioresour. Technol. 2021, 331, 124985. [Google Scholar] [CrossRef]

- Moita, R.; Lemos, P.C. Biopolymers Production from Mixed Cultures and Pyrolysis By-Products. J. Biotechnol. 2012, 157, 578–583. [Google Scholar] [CrossRef]

- Raza, Z.A.; Abid, S.; Banat, I.M. Polyhydroxyalkanoates: Characteristics, Production, Recent Developments and Applications. Int. Biodeterior. Biodegrad. 2018, 126, 45–56. [Google Scholar] [CrossRef]

- Mannina, G.; Presti, D.; Montiel-Jarillo, G.; Carrera, J.; Suárez-Ojeda, M.E. Recovery of Polyhydroxyalkanoates (PHAs) from Wastewater: A Review. Bioresour. Technol. 2020, 297, 122478. [Google Scholar] [CrossRef]

- Kleerebezem, R.; van Loosdrecht, M.C. Mixed Culture Biotechnology for Bioenergy Production. Curr. Opin. Biotechnol. 2007, 18, 207–212. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Hou, D.; Yu, J.; Zhao, T.; Yin, B. Experiment and Molecular Dynamics Study on the Mechanism for Hydrophobic Impregnation in Cement-Based Materials: A Case of Octadecane Carboxylic Acid. Constr. Build. Mater. 2019, 229, 116871. [Google Scholar] [CrossRef]

- Freches, A.; Lemos, P.C. Microbial Selection Strategies for Polyhydroxyalkanoates Production from Crude Glycerol: Effect of OLR and Cycle Length. N. Biotechnol. 2017, 39, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.; Pereira, A.S.; Lemos, P.C.; Guerra, J.P.; Silva, V.; Faria, P. Effect of Innovative Bioproducts on Air Lime Mortars. J. Build. Eng. 2021, 35. [Google Scholar] [CrossRef]

- Weast, R.C. CRC Handbook of Chemistry and Physics, 53rd ed.; CRC Press: Cleveland, OH, USA, 1971. [Google Scholar]

- The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com (accessed on 24 August 2021).

- nix Color Sensor. Available online: https://www.nixsensor.com/free-color-converter/ (accessed on 24 August 2021).

- EHE-08 Code on Structural Concrete, 4th ed.; Fomento, Centro de Publicaciones Secretaría General Técnica Ministerio de: Madrid, Spain, 2010.

- EN 12620:2013; Aggregates for Concrete. CEN: Brussels, Belgium, 2014.

- García González, J. Concrete with Ceramic Mixed Construction and Demolition Waste: Optimization of Physical, Mechanical and Durability Properties by Aggregate Pre-Saturation, Use of Superplasticizers and Microbially Induced Carbonate Precipitation. Doctoral Dissertation, University of León and University of Gante, León, Spain, 2016. [Google Scholar] [CrossRef]

- EN 12390-8:2019; Testing Hardened Concrete-Part 8: Depth of Penetration of Water under Pressure. CEN: Brussels, Belgium, 2019.

- EN 12390-6:2010; Testing Hardened Concrete. Part 6: Tensile Splitting Strength of Test Specimens. CEN: Brussels, Belgium, 2010.

- ImageJ. Computer Software; ImageJ. nd. Version 1.8.0; National Institutes of Health: Bethesda, MD, USA. Available online: https://imagej.nih.gov/ij/ (accessed on 10 June 2020).

- EN 12390-8:2009; Testing Hardened Concrete. Part 8: Depth of Penetration of Water under Pressure. CEN: Madrid, Spain, 2011.

- de Medeiros, M.H.F.; Pereira, E.; Figura, A.S.; Tissot, F.M.; Artioli, K.A. Avaliação da Eficiência de Sistemas de Proteção de Superfície para Concreto: Absorção de Água, Migração de Cloretos e Ângulo de Contato. Rev. Mater. 2015, 20, 145–159. [Google Scholar] [CrossRef] [Green Version]

- de Medeiros, M.H.F. Contribuição Ao Estudo da Durabilidade de Concretos Com Proteção Superficial Frente à Ação de Íons Cloretos. Ph.D. Thesis, Escola Politécnica, Universidade de São Paulo, São Paulo, Brazil, 10 January 2008. [Google Scholar] [CrossRef]

- Gao, Q.; Ma, Z.; Xiao, J.; Li, F. Effects of Imposed Damage on the Capillary Water Absorption of Recycled Aggregate Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 2890931. [Google Scholar] [CrossRef] [Green Version]

- UNE 83982; Concrete Durability. Test Methods. Determination of the Capillary Absorption in Hardened Concrete. Fagerlund Method. AENOR: Madrid, Spain, 2008.

- UNE 83966; Concrete Durability. Test Methods. Conditioning of Concrete Test Pieces for the Purpose of Gas Permeability and Capilar Suction Test. AENOR: Madrid, Spain, 2008.

- Guo, T.; Weng, X. Evaluation of the Freeze-Thaw Durability of Surface-Treated Airport Pavement Concrete under Adverse Conditions. Constr. Build. Mater. 2019, 206, 519–530. [Google Scholar] [CrossRef]

- Medina, C.; Sánchez De Rojas, M.I.; Frías, M. Freeze-Thaw Durability of Recycled Concrete Containing Ceramic Aggregate. J. Clean. Prod. 2013, 40, 151–160. [Google Scholar] [CrossRef]

- EN 1339:2003/AC:2006; Concrete Paving Flags-Requirements and Test Methods. CEN: Brussels, Belgium, 2008.

- Parracha, J.L.; Pereira, A.S.; Velez da Silva, R.; Almeida, N.; Faria, P. Efficacy of Iron-Based Bioproducts as Surface Biotreatment for Earth-Based Plastering Mortars. J. Clean. Prod. 2019, 237, 117803. [Google Scholar] [CrossRef]

- Dang, Y.; Xie, N.; Kessel, A.; McVey, E.; Pace, A.; Shi, X. Accelerated Laboratory Evaluation of Surface Treatments for Protecting Concrete Bridge Decks from Salt Scaling. Constr. Build. Mater. 2014, 55, 128–135. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A Review on Concrete Surface Treatment Part I: Types and Mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Odriozola, M.Á.B.; Gutiérrez, P.A. Comparative Study of Different Test Methods for Reinforced Concrete Durability Assessment in Marine Environment. Mater. Struct. Constr. 2008, 41, 527–541. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; de Brito, J.; Sáez del Bosque, I.F.; Medina, C. Water Transport and Shrinkage in Concrete Made with Ground Recycled Concrete-Additioned Cement and Mixed Recycled Aggregate. Cem. Concr. Compos. 2021, 118, 103957. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Martínez-Abella, F.; Vázquez-Herrero, C.; Pérez-Ordóñez, J.L. Properties of Plain Concrete Made with Mixed Recycled Coarse Aggregate. Constr. Build. Mater. 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Husni, H.; Nazari, M.R.; Yee, H.M.; Rohim, R.; Yusuff, A.; Mohd Ariff, M.A.; Ahmad, N.N.R.; Leo, C.P.; Junaidi, M.U.M. Superhydrophobic Rice Husk Ash Coating on Concrete. Constr. Build. Mater. 2017, 144, 385–391. [Google Scholar] [CrossRef]

- Serrano-González, L.; Merino-Maldonado, D.; Guerra-Romero, M.I.; Morán-del Pozo, J.M.; Lemos, P.C.; Pereira, A.S.; Faria, P.; García-González, J.; Juan-Valdés, A. Use of Mixed Microbial Cultures to Protect Recycled Concrete Surfaces: A Preliminary Study. Materials 2021, 14, 6545. [Google Scholar] [CrossRef]

- Scarfato, P.; Di Maio, L.; Fariello, M.L.; Russo, P.; Incarnato, L. Preparation and Evaluation of Polymer/Clay Nanocomposite Surface Treatments for Concrete Durability Enhancement. Cem. Concr. Compos. 2012, 34, 297–305. [Google Scholar] [CrossRef]

- Ioannou, I.; Hamilton, A.; Hall, C. Capillary Absorption of Water and N-Decane by Autoclaved Aerated Concrete. Cem. Concr. Res. 2008, 38, 766–771. [Google Scholar] [CrossRef]

- Fagerlund, G. On the Capillarity of Concrete; Nordic Concrete Federation Publisher: Oslo, Norway, 1982; Volume 24. [Google Scholar]

- Howland, J.J.; Martín, A.R. Estudio de la Absorción Capilar y la Sorptividad de Hormigones con Áridos Calizos Cubanos. Mater. Constr. 2013, 63, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Chandra, S.; Eklund, L.; Villareal, R. Use of Cactus in Mortars and Concrete. Cem. Concr. Res. 1998, 28, 41–51. [Google Scholar] [CrossRef]

- Martínez Molina, W.; Alonso-Guzmán, E.M.; Chávez García, H.L.; Arteaga Arcos, J.C.; Torres-Acosta, A.A.; Bedolla Arroyo, J.A.; Gómez, C.L.; Acha Palomares, A. Influence of the Organic and Mineral Additions in the Porosity of Lime Mortars. Adv. Mater. Res. 2014, 887–888, 830–837. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W.; Jiang, Z. Non-Ureolytic Bacterial Carbonate Precipitation as a Surface Treatment Strategy on Cementitious Materials. J. Mater. Civ. Eng. 2014, 26, 983–991. [Google Scholar] [CrossRef]

- EN 1504-2:2004; Products and Systems for the Protection and Repair of Concrete Structures. Definitions, Requirements, Quality Control and Conformity. Part 2: Surface Protection Systems for Concrete. CEN: Brussels, Belgium, 2004.

- Fagerlund, G. Frost Destruction of Concrete–A Study of the Validity of Different Mechanisms. Nord. Concr. Res. 2018, 58, 35–54. [Google Scholar] [CrossRef] [Green Version]

- Henry, K.S. A Review of the Thermodynamics of Frost Heave. Technical Report; ERDC/CRREL TR-00-16, Cold Reg. Res. Enginnering Lab, US Army Corps of Engineers: Fort Belvoir, Virginia, USA, 2000; pp. 1–26. [Google Scholar]

- Meldrum, F.C.; O’Shaughnessy, C. Crystallization in Confinement. Adv. Mater. 2020, 32, 2001068. [Google Scholar] [CrossRef]

- Luan, H.; Wu, J.; Pan, J. Freeze-Thaw Durability of Recycled Aggregate Concrete: An Overview. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2021, 36, 58–69. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Field Performance of Bacteria-Based Repair System: Pilot Study in a Parking Garage. Case Stud. Constr. Mater. 2015, 2, 11–17. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.R.; Pan, Y.; Chen, B. Physical and Mechanical Properties of Sustainable Vegetal Concrete Exposed to Extreme Weather Conditions. Constr. Build. Mater. 2021, 287, 123024. [Google Scholar] [CrossRef]

- García-González, J.; Lemos, P.C.; Pereira, A.S. Eco-Friendly Healing Agents for Recycled Concrete. In International Conference on Construction Research-Eduardo Torroja. Architecture, Engineering, Concrete; Castineira Libreria Tecnica: Madrid, Spain, 2018; pp. 1–8. [Google Scholar]

- García-González, J.; Pereira, A.S.; Lemos, P.C.; Almeida, N.; Silva, V.; Candeias, A.; Juan-Valdés, A.; Faria, P. Effect of Surface Biotreatments on Construction Materials. Constr. Build. Mater. 2020, 241, 118019. [Google Scholar] [CrossRef]

- Delucchi, M.; Barbucci, A.; Temtchenko, T.; Poggio, T.; Cerisola, G. Study of the Crack-Bridging Ability of Organic Coatings for Concrete: Analysis of the Mechanical Behaviour of Unsupported and Supported Films. Prog. Org. Coat. 2002, 44, 261–269. [Google Scholar] [CrossRef]

- Franzoni, E.; Pigino, B.; Pistolesi, C. Ethyl Silicate for Surface Protection of Concrete: Performance in Comparison with Other Inorganic Surface Treatments. Cem. Concr. Compos. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- Delucchi, M.; Barbucci, A.; Cerisola, G. Study of the Physico-Chemical Properties of Organic Coatings for Concrete Degradation Control. Constr. Build. Mater. 1997, 11, 365–371. [Google Scholar] [CrossRef]

- Eymard, M.; Plassiard, J.P.; Perrotin, P.; Le Fay, S. Interfacial Strength Study between a Concrete Substrate and an Innovative Sprayed Coating. Constr. Build. Mater. 2015, 79, 345–356. [Google Scholar] [CrossRef]

- Basheer, P.A.M.; Basheer, L.; Cleland, D.J.; Long, A.E. Surface Treatments for Concrete: Assessment Methods and Reported Performance. Constr. Build. Mater. 1997, 11, 413–429. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A Review on Surface Treatment for Concrete–Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Garnacho Saucedo, G.M.; Salido Vallejo, R.; Moreno Giménez, J.C. Effects of Solar Radiation and an Update on Photoprotection. Anal. Pediatr. 2020, 92, 377. [Google Scholar] [CrossRef]

- Jones, M.R.; Dhir, R.K.; Gill, J.P. Concrete Surface Treatment: Effect of Exposure Temperature on Chloride Diffusion Resistance. Cem. Concr. Res. 1995, 25, 197–208. [Google Scholar] [CrossRef]

- De Vries, I.J. Hydrophobic Treatment. Constr. Build. Mater. 1997, 11, 259–265. [Google Scholar] [CrossRef]

- Levi, M.; Ferro, C.; Regazzoli, D.; Dotelli, G.; Lo Presti, A. Comparative Evaluation Method of Polymer Surface Treatments Applied on High Performance Concrete. J. Mater. Sci. 2002, 37, 4881–4888. [Google Scholar] [CrossRef]

- Ashok, M.K. Measuring Concrete Surface pH—A Proposed Test Method; Concrete Repair Bulletin ICRI: St. Paul, MN, USA, 2014; pp. 16–20. Available online: https://www.icri.org/ (accessed on 8 December 2021).

- Rodrigues, M.P.M.C.; Costa, M.R.N.; Mendes, A.M.; Eusébio Marques, M.I. Effectiveness of Surface Coatings to Protect Reinforced Concrete in Marine Environments. Mater. Struct. Constr. 2000, 33, 618–626. [Google Scholar] [CrossRef]

- Seneviratne, A.M.G.; Sergi, G.; Page, C.L. Performance Characteristics of Surface Coatings Applied to Concrete for Control of Reinforcement Corrosion. Constr. Build. Mater. 2000, 14, 55–59. [Google Scholar] [CrossRef]

- Khanzadeh Moradllo, M.; Shekarchi, M.; Hoseini, M. Time-Dependent Performance of Concrete Surface Coatings in Tidal Zone of Marine Environment. Constr. Build. Mater. 2012, 30, 198–205. [Google Scholar] [CrossRef]

- Li, G.; Yang, B.; Guo, C.; Du, J.; Wu, X. Time Dependence and Service Life Prediction of Chloride Resistance of Concrete Coatings. Constr. Build. Mater. 2015, 83, 19–25. [Google Scholar] [CrossRef]

| ρ | ν | µ | pH | Condition | Colorimetry | ||||

|---|---|---|---|---|---|---|---|---|---|

| (kg/dm3) | (mm2/s) | (Pa·s) | L | a | b | ||||

| SP | 0.99722 | 1.29491 | 1.29132 | 6.36 | liquid | 15.675 | 21.2 | 26.53 |  |

| indoor | 61.846 | 5.658 | 19.468 |  | |||||

| outdoor | 73.142 | 1.366 | 10.486 |  | |||||

| SG | 0.996 | 1.44603 | 1.44025 | 5.12 | liquid | 28.18 | 7.48 | 28.79 |  |

| indoor | 68.822 | 3.076 | 14.53 |  | |||||

| outdoor | 73.696 | 1.844 | 12.246 |  | |||||

| Material | Composition (/m3) |

|---|---|

| Water (L) | 215 |

| Cement (kg) | 391 |

| Sand (kg) | 716 |

| Gravel (kg) | 447 |

| MRA (kg) | 447 |

| Components | wt% |

|---|---|

| Unbound aggregate (natural aggregate with no attached cement mortar) | 23.98 |

| Masonry and fired clay (bricks, tiles, stoneware, sanitary ware, …) | 26.18 |

| Concrete and mortar (natural aggregate with bound cement mortar) | 49.38 |

| Asphalt | 0 |

| Glass | 0.33 |

| Gypsum | 0 |

| Other impurities (wood, paper, metals, plastic, …) | 0.06 |

| Test | Specimens | Test Surface (mm2) | Volume of Bioproduct per Specimen (mL) | ||

|---|---|---|---|---|---|

| No | Dimensions (mm3) | ||||

| Water under pressure | 9 | 200 × 100 | π × 502 | 7.85 | |

| Capillary | 9 | 100 × 100 × 100 | 100 × 100 | 10.0 | |

| Freeze–thaw | 9 | 100 × 77 × 60 | Π × 502 | 7.85 | |

| Water drop absorption | In-out | 90 | 50 × 100 × 100 | 50 × 50 | 2.50 |

| Reap | 27 | 50 × 100 × 100 | 50 × 50 | 5.00 | |

| V.E. | 36 | 50 × 100 × 100 | 50 × 50 | 2.50 | |

| Treatment | Capillary Water Absorption Coefficient (kg⋅m−2⋅min−0.5) | Standard Deviation |

|---|---|---|

| H2O | 8.63 × 10−4 | 7.32 × 10−5 |

| SG | 7.89 × 10−4 | 2.77 × 10−5 |

| SP | 7.06 × 10−4 | 7.31 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano-González, L.; Merino-Maldonado, D.; Antolín-Rodríguez, A.; Lemos, P.C.; Pereira, A.S.; Faria, P.; Juan-Valdés, A.; García-González, J.; Morán-del Pozo, J.M. Biotreatments Using Microbial Mixed Cultures with Crude Glycerol and Waste Pinewood as Carbon Sources: Influence of Application on the Durability of Recycled Concrete. Materials 2022, 15, 1181. https://doi.org/10.3390/ma15031181

Serrano-González L, Merino-Maldonado D, Antolín-Rodríguez A, Lemos PC, Pereira AS, Faria P, Juan-Valdés A, García-González J, Morán-del Pozo JM. Biotreatments Using Microbial Mixed Cultures with Crude Glycerol and Waste Pinewood as Carbon Sources: Influence of Application on the Durability of Recycled Concrete. Materials. 2022; 15(3):1181. https://doi.org/10.3390/ma15031181

Chicago/Turabian StyleSerrano-González, Lorena, Daniel Merino-Maldonado, Andrea Antolín-Rodríguez, Paulo C. Lemos, Alice S. Pereira, Paulina Faria, Andrés Juan-Valdés, Julia García-González, and Julia Mª Morán-del Pozo. 2022. "Biotreatments Using Microbial Mixed Cultures with Crude Glycerol and Waste Pinewood as Carbon Sources: Influence of Application on the Durability of Recycled Concrete" Materials 15, no. 3: 1181. https://doi.org/10.3390/ma15031181

APA StyleSerrano-González, L., Merino-Maldonado, D., Antolín-Rodríguez, A., Lemos, P. C., Pereira, A. S., Faria, P., Juan-Valdés, A., García-González, J., & Morán-del Pozo, J. M. (2022). Biotreatments Using Microbial Mixed Cultures with Crude Glycerol and Waste Pinewood as Carbon Sources: Influence of Application on the Durability of Recycled Concrete. Materials, 15(3), 1181. https://doi.org/10.3390/ma15031181