Optimization of Polymer Processing: A Review (Part II-Molding Technologies)

Abstract

1. Introduction

2. Optimization Algorithms in Polymer Processing

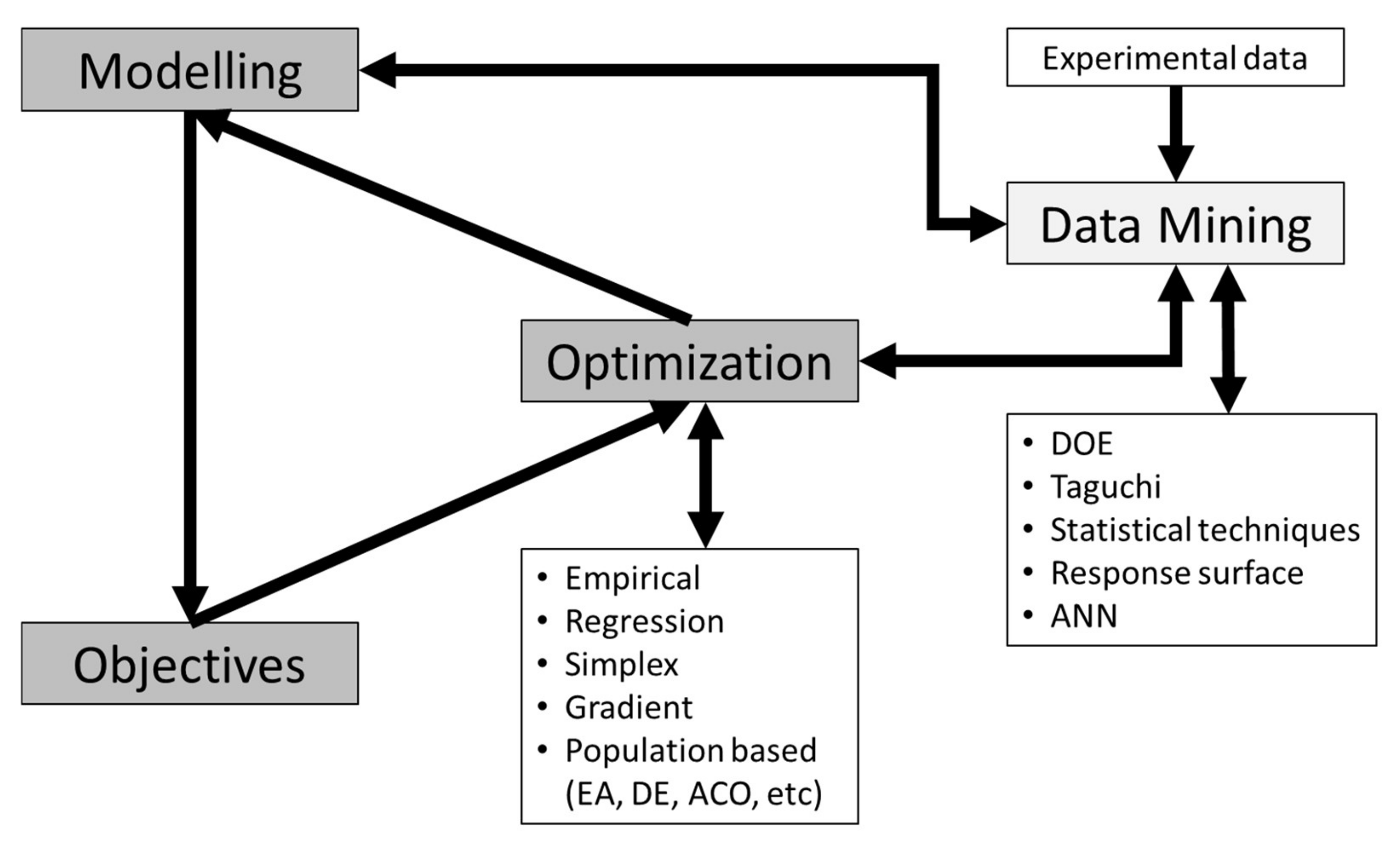

2.1. Methodology

- Objective function, which can be pursued as a Single Objective (SO), Aggregated Product (AP), Aggregated Sum (AS) or Multi-Objective (MO);

- Optimization algorithm, which can include Empirical, Simplex, Complex, Regression, Direct, Gradient, Simulated Annealing (SA), Particle Swarm Optimization (PSO), Artificial Bee Colony (ABC), Data Envelopment Analysis (DEA), Ant Colony Optimization (ACO), Evolutionary Algorithms (EA);

- Process modelling approach, which could be experimental, one-dimensional analytical (1D-A), two-dimensional numerical (2D-N) or three-dimensional numerical (3D-N);

- Decision variables, i.e., the process parameters to optimize;

- Other characteristics, related to the process/modelling approach, optimization, etc.

2.2. Injection Molding

2.2.1. Plasticating Unit (Screw Design)

2.2.2. Single Objective Optimization

2.2.3. Aggregation Function Optimization

2.2.4. Multi-Objective Optimization

2.3. Blow-Molding

2.3.1. Extrusion Blow Molding

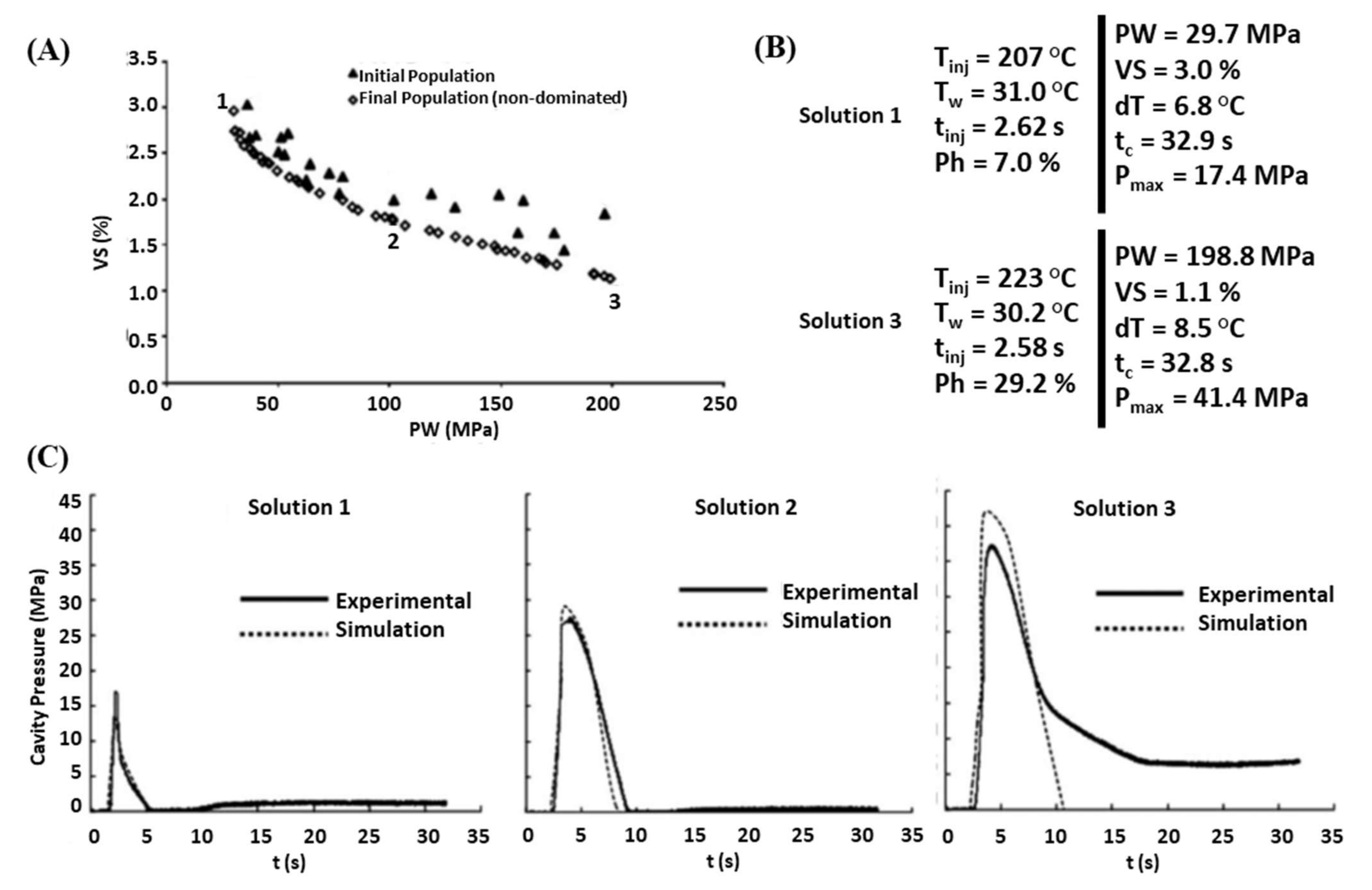

2.3.2. Injection Blow Molding

2.4. Thermoforming

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; Wiley: New York, NY, USA, 2006. [Google Scholar]

- Agassant, J.F.; Avenas, P.; Sergent, J.-P.; Carreau, P.J. Polymer Processing: Principles and Modeling; Carl Hanser: Munich, Germany, 1991. [Google Scholar]

- Osswald, A.T.; Hernández-Ortiz, P.J. Polymer Processing: Modeling and Simulation; Carl Hanser: Munich, Germany, 2006. [Google Scholar]

- Baird, G.D.; Collias, I.D. Polymer Processing: Principles and Design, 2nd ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Gaspar-Cunha, A.; Covas, J.A.; Sikora, J. Optimization of Polymer Processing: A Review (Part I—Extrusion). Materials 2022, 15, 384. [Google Scholar] [CrossRef] [PubMed]

- Deb, K. Multi-Objective Optimization using Evolutionary Algorithms; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Coello, C.C.; Lamont, B.G.; van Veldhuizen, A.D. Evolutionary Algorithms for Solving Multi-Objective Problems, 2nd ed.; Springer: New York, NY, USA, 2007. [Google Scholar]

- Jin, Y.; Wang, H.; Chugh, T.; Guo, D.; Miettinen, K. Data-Driven Evolutionary Optimization: An Overview and Case Studies. IEEE Trans. Evol. Comput. 2019, 23, 442–458. [Google Scholar] [CrossRef]

- Ibañez, R.; Casteran, F.; Argerich, C.; Ghnatios, C.; Hascoet, N.; Ammar, A.; Cassagnau, P.; Chinesta, F. On the Data-Driven Modeling of Reactive Extrusion. Fluids 2020, 5, 94. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Covas, J.A.; Sikora, J. Modelling the effect of grooved barrels on the performance of single screw extruders. In Technological and Design Aspects of the Processing of Composites and Nanocomposites, 1st ed.; Sikora, J., Dulebová, L., Eds.; Technical University of Kosice: Kosice, Slovak Republic, 2018; Volume I, pp. 22–42. [Google Scholar]

- Gaspar-Cunha, A. Global Extruder Modelling: Active grooved feed section, rotational barrel segment and special screws. In Technological and Design Aspects of the Processing of Composites and Nanocomposites, 1st ed.; Sikora, J., Dulebova, L., Eds.; Lublin University of Technology Publishing House: Lublin, Poland, 2019; Volume II, pp. 97–111. [Google Scholar]

- Majewski, Ł.; Debski, H.; Dulebová, L. New concepts of a rotational barrel segment for a new generation extruder. In Technological and Design Aspects of the Processing of Composites and Nanocomposites, 1st ed.; Sikora, J., Dulebova, L., Eds.; Lublin University of Technology Publishing House: Lublin, Poland, 2019; Volume II, pp. 19–60. [Google Scholar]

- Gaspar-Cunha, A. Computational assessment of the rotational barrel segment located on the meetering zone of an extruder. In Technological and Design Aspects of the Processing of Composites and Nanocomposites, 1st ed.; Sikora, J., Dulebová, L., Eds.; Lublin University of Technology Publishing House: Lublin, Poland, 2019; Volume II, pp. 86–96. [Google Scholar]

- Verbraak, C.P.J.M.; Meijer, H.E.H. Screw design in injection molding. Polym. Eng. Sci. 1989, 29, 479–487. [Google Scholar] [CrossRef]

- Huang, M.-S. Design analysis of a standard injection screw for plasticising polycarbonate resins. J. Polym. Eng. 2015, 36, 537–548. [Google Scholar] [CrossRef]

- Wang, M.-W.; Arifin, F.; Kuo, J.-W.; Dzwo, T.-H. Optimal Design of Plasticizing Screw Using Artificial Intelligent Approach. J. Phys. Conf. Ser. 2020, 1500, 012022. [Google Scholar] [CrossRef]

- Seow, L.; Lam, Y. Optimizing flow in plastic injection molding. J. Mater. Process. Technol. 1997, 72, 333–341. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, B.H. Optimization of Part Wall Thicknesses to Reduce Warpage of Injection-Molded Parts Based on The Modified Complex Method. Polym. Plast. Technol. Eng. 1995, 34, 793–811. [Google Scholar] [CrossRef]

- Chang, T.C.; Faison, E. Shrinkage Behaviour and Optimization of Injection Molded Parts Studied by the Taguchi Method. Polym. Eng. Sci. 2001, 41, 703–710. [Google Scholar] [CrossRef]

- Feng, C.; Jeffrey, K.; Su, K. Optimization of Multiple Quality Characteristics for Polyether Ether Ketone Injection Molding Process. Fibers Polym. 2006, 7, 404–413. [Google Scholar] [CrossRef]

- Tang, S.H.; Tan, Y.J.; Sapuan, S.M.; Sulaiman, S.; Ismail, N.; Samin, R. The use of Taguchi Method in the Design of Plastic Injection Mould for Reducing Warpage. J. Mat. Proc. Technol. 2007, 182, 418–426. [Google Scholar] [CrossRef]

- Ahmad, A.; Wahab, M.S.; Shah, A.S.M.; Kamarudin, K.; Hehsan, H. Optimization of processing parameters for plastic injection moulding process towards moulded part shrinkage. AIP Conf. Proc. 2019, 2129, 020168. [Google Scholar] [CrossRef]

- Mukras, S.M.S. Experimental-Based Optimization of Injection Molding Process Parameters for Short Product Cycle Time. Adv. Polym. Technol. 2020, 2020, 1309209. [Google Scholar] [CrossRef]

- Chen, W.; Huang, C.; Hung, C. Optimization of plastic injection molding process by dual response surface method with non-linear programming. Eng. Comput. 2010, 27, 951–966. [Google Scholar] [CrossRef]

- Huang, W.T.; Wu, D.H.; Tasi, Z.Y.; Tsai, C. Optimization of Process Parameters in Plastic Injection Mold Simulation for Auto Lock-Parts Using Taguchi-Grey Method Based on Multi-Objective. In Proceeding of the 2015 International Conference on Structural, Mechanical and Material Engineering 2015; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 52–55. [Google Scholar] [CrossRef][Green Version]

- Smith, D.E.; Tortorelli, D.A.; Tucker, C.L. Analysis and sensitivity analysis for polymer injection and compression molding. Comput. Meth. Appl. Mech. Eng. 1998, 167, 325–344. [Google Scholar] [CrossRef]

- Lam, Y.C.; Seow, L.W. Cavity balance for plastic injection molding. Polym. Eng. Sci. 2000, 40, 1273–1280. [Google Scholar] [CrossRef]

- Lam, Y.; Jin, S. Optimization of Gate Location for Plastic Injection Molding. J. Inject. Mold. Technol. 2001, 5, 180–192. [Google Scholar]

- Pirc, N.; Schmidt, F.; Mongeau, M.; Bugarin, F. 3D BEM-based cooling-channel shape optimization for injection molding processes. Int. J. Simul. Multidiscip. Des. Optim. 2008, 2, 245–252. [Google Scholar] [CrossRef]

- Zhai, M.; Lam, Y.C.; Au, C.K. Algorithms for Two Gate Optimization in Injection Molding. Int. Polym. Process. 2005, 20, 14–18. [Google Scholar] [CrossRef]

- Qiao, H. A Systematic Computer-Aided Approach to Cooling System Optimal Design in Plastic Injection Molding. Intern. J. Mech. Sci. 2006, 48, 430–439. [Google Scholar] [CrossRef]

- Li, J.; Li, D.; Guo, Z.; Lv, H. Single Gate Optimization for Plastic Injection Mold. J. Zhejiang Univ. Sci. A 2007, 8, 1077–1083. [Google Scholar] [CrossRef]

- Ye, H.; Wang, K.K. Optimization of Injection-Molding Process with Genetic Algorithms. In Proceedings of the SPE Annual Technical Conference, New York, NY, USA, 2–6 May 1999; pp. 594–599. [Google Scholar]

- Shi, F.; Lou, Z.L.; Lu, J.G.; Zhang, Y.Q. Optimisation of Plastic Injection Moulding Process with Soft Computing. Int. J. Adv. Manuf. Technol. 2003, 21, 656–661. [Google Scholar] [CrossRef]

- Lam, Y.C.; Zhai, L.Y.; Tai, K.; Fok, S.C. An Evolutionary Approach for Cooling System Optimization in Plastic Injection Molding. Int. J. Prod. Res. 2004, 42, 2047–2061. [Google Scholar] [CrossRef]

- Kurtaran, H.; Ozcelik, B.; Erzurumlu, T. Warpage Optimization of a Bus Ceiling Lamp Base using Neural Network Model and Genetic Algorithm. J. Mat. Proc. Technol. 2005, 169, 314–319. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzurumlu, T. Determination of Effecting Dimensional Parameters on Warpage of Thin Shell Plastic Parts using Integrated Response Surface Method and Genetic Algorithm. Int. Commun. Heat Mass Transf. 2005, 32, 1085–1094. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzurumlu, T. Comparison of the Warpage Optimization in the Plastic Injection Molding using ANOVA, Neural Network Model and Genetic Algorithm. J. Mater. Process. Technol. 2006, 171, 437–445. [Google Scholar] [CrossRef]

- Wu, C.; Ku, C.; Pai, H. Injection Molding Optimization with Weld Line Design Constraint using Distributed Multi-population Genetic Algorithm. Int. J. Adv. Manuf. Technol. 2011, 52, 131–141. [Google Scholar] [CrossRef]

- Iniesta, A.; Alcaraz, G.; Jorge, L.; ManuelIván, R.B. Optimization of injection molding process parameters by a hybrid of artificial neural network and artificial bee colony algorithm. Rev. Fac. Ing. Univ. Antioq. 2013, 67, 43–51. Available online: http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0120-62302013000200004&lng=en&tlng=en (accessed on 1 October 2021).

- Changyu, S.; Lixia, W.; Qian, L. Optimization of Injection Molding Process Parameters using Combination of Artificial Neural Network and Genetic Algorithm Method. J. Mater. Process. Technol. 2007, 183, 412–418. [Google Scholar] [CrossRef]

- Singh, G.; Pradhan, M.K.; Verma, A. Multi Response optimization of injection moulding Process parameters to reduce cycle time and warpage. Mater. Today 2018, 5, 8398–8405. [Google Scholar] [CrossRef]

- Sreedharan, J.; Jeevanantham, A.; Rajeshkannan, A. Multi-objective optimization for multi-stage sequential plastic injection molding with plating process using RSM and PCA-based weighted-GRA. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 234, 1014–1030. [Google Scholar] [CrossRef]

- Kumar, B.P.; Venkataramaiah, P.; Ganesh, J.S. Optimization of Process Parameters in Injection Moulding of a Polymer Composite Product by Using Gra. Mater. Today 2019, 18, 4637–4647. [Google Scholar] [CrossRef]

- Yacoub, F.; MacGregor, J.F. Product optimization and control in the latent variable space of nonlinear PLS models. Chemom Intell. Lab. Syst. 2004, 70, 63–74. [Google Scholar] [CrossRef]

- Kitayama, S.; Miyakawa, H.; Takano, M.; Aiba, S. Multi-objective optimization of injection molding process parameters for short cycle time and warpage reduction using conformal cooling channel. Int. J. Adv. Manuf. Technol. 2017, 88, 1735–1744. [Google Scholar] [CrossRef]

- Kitayama, S.; Tamada, K.; Takano, M.; Aiba, S. Numerical optimization of process parameters in plastic injection molding for minimizing weldlines and clamping force using conformal cooling channel. J. Manuf. Process 2018, 32, 782–790. [Google Scholar] [CrossRef]

- Moayyedian, M.; Mamedov, A. Multi-Objective Optimization of Injection Molding Process for Determination of Feasible Moldability Index. Procedia CIRP 2019, 84, 769–773. [Google Scholar] [CrossRef]

- Tang, L.Q.; Chassapis, C.; Manoochehri, S. Optimal cooling system design for multi-cavity injection molding. Finite Elem. Anal. Des. 1997, 26, 229–251. [Google Scholar] [CrossRef]

- Park, S.J.; Kwon, T.H. Optimal cooling system design for the injection molding process. Polym. Eng. Sci. 1998, 38, 1450–1462. [Google Scholar] [CrossRef]

- Huang, J.; Fadel, G.M. Bi-Objective Optimization Design of Heterogeneous Injection Mold Cooling Systems. J. Mech. Des. 2001, 123, 226–239. [Google Scholar] [CrossRef]

- Shen, C.-Y.; Yu, X.-R.; Li, Q.; Li, H.-M. Gate Location Optimization in Injection Molding by Using Modified Hill-Climbing Algorithm. Polym. Plast. Technol. Eng. 2004, 43, 649–659. [Google Scholar] [CrossRef]

- Mathey, E.; Penazzi, L.; Schmidt, F.M.; Rondé-Oustau, F. Automatic Optimization of the Cooling of Injection Mold based on the Boundary Element Method. In Proceedings of the 8th International Conference on Numerical Methods in Industrial Forming Processes, Columbus, OH, USA, 13–17 June 2004; American Institute of Physics: Melville, NY, USA, 2004; Volume 712, pp. 222–227. [Google Scholar]

- Agazzi, A.; Sobotka, V.; Le Goff, R.; Garcia, D.; Jarny, Y. A Methodology for the Design of Effective Cooling System in Injection Moulding. Int. J. Mater. Form. 2010, 3, 13–16. [Google Scholar] [CrossRef]

- Shie, J.R. Optimization of Injection-Molding Process for Mechanical Properties of Polypropylene Components via a Generalized Regression Neural Network. Polym. Adv. Technol. 2008, 19, 7383. [Google Scholar] [CrossRef]

- Pandelidis, I.; Zou, Q. Optimization of Injection Molding Design. Part I: Gate Location Optimization. Polym. Eng. Sci. 1990, 30, 873–882. [Google Scholar] [CrossRef]

- Pandelidis, I.; Zou, Q. Optimization of Injection Molding Design. Part II: Molding Conditions Optimization. Polym. Eng. Sci. 1990, 30, 883–892. [Google Scholar] [CrossRef]

- Turng, L.-S.; Peić, M. Computer aided process and design optimization for injection moulding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 1523–1532. [Google Scholar] [CrossRef]

- Lam, Y.C.; Deng, Y.M.; Au, C.K. A GA/Gradient Hybrid Approach for Injection Molding Conditions Optimisation. Eng. Comput. 2006, 21, 193–202. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, K.; Kim, Y.I. Optimization of Injection-Molding Conditions using Genetic Algorithm. In Proceedings of the 4th International Conference on Computer Aided Design and Computer Graphics, Wuhan, China, 22 March 1996; Volume 2644, pp. 173–180. [Google Scholar] [CrossRef]

- Chen, W.C.; Fu, G.L.; Tai, P.H.; Deng, W.J. Process Parameter Optimization for MIMO Plastic Injection Molding via Soft Computing. Exp. Syst. Appl. 2007, 36, 1114–1122. [Google Scholar] [CrossRef]

- Meiabadi, M.; Vafaei, A.; Sharifi, F. Optimization of Plastic Injection Molding Process by Combination of Artificial Neural Network and Genetic Algorithm. J. Optim. Ind. Eng. 2013, 6, 49–54. [Google Scholar]

- Mok, S.L.; Kwong, C.K.; Lau, W.S. A Hybrid Neural Network and Genetic Algorithm Approach to the Determination of Initial Process Parameters for Injection Moulding. Int. J. Adv. Manuf. Technol. 2001, 18, 404–409. [Google Scholar] [CrossRef]

- Alam, K.; Kamal, M.R. A Genetic Optimization of Shrinkage by Runner Balancing. In Proceedings of the SPE Annual Technical Conference, Nashville, TN, USA, 4–8 May 2003; pp. 639–641. [Google Scholar]

- Alam, K.; Kamal, M.R. Runner Balancing by a Direct Genetic Optimization of Shrinkage. Polym. Eng. Sci. 2004, 44, 1949–1959. [Google Scholar] [CrossRef]

- Alam, K.; Kamal, M.R. A Robust Optimization of Injection Molding Runner Balancing. Comp. Chem. Eng. 2005, 29, 1934–1944. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Viana, J. Using Multi-Objective Evolutionary Algorithms to Optimize Mechanical Properties of Injection Molded Part. Int. Polym. Process. 2005, 20, 274–285. [Google Scholar] [CrossRef]

- Castro, C.; Ríos, M.C.; Castro, J.M.; Lilly, B. Multiple criteria optimization with variability considerations in injection molding. Polym. Eng. Sci. 2007, 47, 400–409. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Using Multiobjective Evolutionary Algorithms in the Optimization of Operating Conditions of Polymer Injection Molding. Polym. Eng. Sci. 2010, 50, 1667–1678. [Google Scholar]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Using Multi-objective Evolutionary Algorithms for Optimization of the Cooling System in Polymer Injection Molding. Int. Polym. Proc. 2012, 27, 213–223. [Google Scholar] [CrossRef]

- Xu, G.; Yang, Z.; Long, G. Multi-objective optimization of MIMO plastic injection molding process conditions based on particle swarm optimization. Int. J. Adv. Manuf. Technol. 2012, 58, 521–531. [Google Scholar] [CrossRef]

- Tahboub, K.; Rawabdeh, I. A design of experiments approach for optimizing an extrusion blow molding process. J. Qual. Maint. Eng. 2004, 10, 47–54. [Google Scholar] [CrossRef]

- Agrawal, V.; Vimal, J.; Chaturvedi, V. Optimisation of extrusion blow molding process parameters using grey relational analysis and taguchi. Int. J. Res. Eng. App. Sci. 2012, 2, 407–417. [Google Scholar]

- Dohare, J.; Chaturvedi, V.; Vimal, J. Investigation of Optimal Process Parameters of Extrusion Blow Molding Process Using Grey Taguchi Analysis. Int. J. Manuf. Mater. Process. 2018, 4, 1. [Google Scholar] [CrossRef]

- Di Raddo, R.W.; Garcia-Rejon, A. Profile optimization for the prediction of initial parison dimensions from final blow moulded part specifications. Comput. Chem. Eng. 1993, 17, 751–764. [Google Scholar] [CrossRef]

- Thibault, F.; Chantal, G.; Laroche, D.; Diraddo, R. Development of an MDO Software Environment for the Blow Moulding. In Proceedings of the 6th International Conference on Computer Supported Cooperative Work Design (CSCWD), London, ON, Canada, 12–14 July 2001. [Google Scholar]

- Gauvin, C.; Thibault, F.; Laroche, D. Optimization of blow molded part performance through process simulation. Polym. Eng. Sci. 2003, 43, 1407–1414. [Google Scholar] [CrossRef]

- Yu, J.-C.; Hung, T.-R.; Juang, J.-Y.; Thibault, F. Design Optimization Using Soft Computing Techniques for Extrusion Blow Molding Processes. In Proceedings of the NSC-NRC Taiwan-Canada Joint Workshop on Advanced Manufacturing, London, ON, Canada, 23–24 September 2002. [Google Scholar]

- Yu, J.-C.; Chen, X.-X.; Hung, T.-R.; Thibault, F. Optimization of Extrusion Blow Molding Processes using Soft Computing and Taguchi’s Method. J. Intell. Manuf. 2004, 15, 625–634. [Google Scholar] [CrossRef]

- Hsu, Y.-L.; Liu, T.-C.; Thibault, F.; Lanctot, B. Design optimization of the blow moulding process using a fuzzy optimization algorithm. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 197–212. [Google Scholar] [CrossRef]

- Yu, J.-C.; Juang, J.-Y. Design Optimization of Extrusion-Blow-Molded Parts Using Prediction-Reliability-Guided Search of Evolving Network Modeling. J. App. Polym. Sci. 2010, 117, 222–234. [Google Scholar] [CrossRef]

- Huang, G.-Q.; Huang, H.-X. Optimizing parison thickness for extrusion blow molding by hybrid method. J. Mater. Process. Technol. 2007, 182, 512–518. [Google Scholar] [CrossRef]

- Hopmann, C.; Rasche, S.; Windeck, C. Simulative design and process optimization of the two-stage stretch-blow molding process. In Proceedings of PPS-30: The 30th International Conference of the Polymer Processing Society; AIP Publishing: Melville, NY, USA, 2015; Volume 1664. [Google Scholar] [CrossRef]

- Bordival, M.; Schmidt, F.M.; Maoult, Y.L.; Velay, V. Optimization of preform temperature distribution for the stretch-blow molding of PET bottles: Infrared heating and blowing modeling. Polym. Eng. Sci. 2009, 49, 783–793. [Google Scholar] [CrossRef]

- Biglione, J. Simulation et Optimisation du Procédé d’Injection Souflage Cycle Chaud. Modélisation et Simulation. Ph.D. Thesis, Institut National des Sciences Appliquées, Lyon, France, 2015. [Google Scholar]

- Biglione, Y.; Béreaux, J.-Y.; Charmeau, J.B.; Chhay, S. Numerical simulation and optimization of the injection blow molding of polypropylene bottles-a single stage process. Int. J. Mater. Form. 2016, 9, 471–487. [Google Scholar] [CrossRef]

- Demirel, D. Optimisation of mould surface temperature and bottle residence time in mould for the carbonated soft drink PET containers. Polym. Test. 2017, 60, 220–228. [Google Scholar] [CrossRef]

- Lee, D.K.; Soh, S.K. Prediction of optimal preform thickness distribution in blow molding. Polym. Eng. Sci. 1996, 36, 1513–1520. [Google Scholar] [CrossRef]

- Thibault, F.; Malo, A.; Lanctot, B.; Diraddo, R. Preform Shape and Operating Condition Optimization for the Stretch Blow Molding Process. Polym. Eng. Sci. 2007, 47, 289–301. [Google Scholar] [CrossRef]

- Denysiuk, R.F.; Duarte, P.N.; Gaspar-Cunha, A. Evolving Neural Networks to Optimize Material Usage in Blow Molded Containers. In Proceedings of the EUROGEN 2017, Madrid, Spain, September 2017; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Denysiuk, R.; Gonçalves, N.; Pinto, R.; Silva, H.; Duarte, F.; Nunes, J.; Gaspar-Cunha, A. Optimization of Injection Stretch Blow Molding: Part I—Defining Part Thickness Profile. Int. Polym. Process. 2019, 34, 314–323. [Google Scholar] [CrossRef]

- Pinto, R.; Hugo, S.; Duarte, F.; Nunes, J.; Gaspar-Cunha, A. Neuroevolutionary Multiobjective Methodology for the Optimization of the Injection Blow Molding Process. In Proceedings of the Evolutionary Multi-Criterion Optimization—10th International Conference, EMO 2019, East Lansing, MI, USA, 10–13 March 2019; pp. 743–754. [Google Scholar]

- Pinto, R.S.; Hugo, M.S.; Duarte, F.M.; Nunes, J.P.; Gaspar-Cunha, A. Neuroevolutionary Multiobjective Optimization of Injection Stretch Blow Molding Process in the Blowing Phase. Comput. Methods Appl. Sci. 2021, 55, 307–318. [Google Scholar]

- Duarte, F.M.; Covas, J.A. Heating Thermoplastic Sheets for Thermoforming: Solution to the Direct and Inverse Problems. Plast. Rubb. Comp. Proc. Appl. 1997, 26, 213. [Google Scholar]

- Duarte, F.M.; Covas, J.A. IR sheet heating in roll fed thermoforming: Part 1—Solving direct and inverse heating problems. Plast. Rubber Compos. 2002, 31, 307–317. [Google Scholar] [CrossRef]

- Wang, C.; Nied, H.F. Temperature Optimization for Improved Thickness Control in Thermoforming. J. Mater. Process. Manuf. Sci. 1999, 8, 113–126. [Google Scholar] [CrossRef]

- Bordival, M.; Andrieu, S.; Schmidt, F.; Maoult, Y.L.; Monteix, S. Optimization of infrared heating system for the thermoforming process. In Proceedings of the 8th ESAFORM conference on material forming ESAFORM 2005, Cluj-Napoca, Romania, 27–29 April 2005; pp. 925–928. [Google Scholar]

- Chy, M.M.; Boulet, B. A Conjugate Gradient Method for the Solution of the Inverse Heating Problem in Thermoforming. In Proceedings of the IEEE Industry Applications Society Annual Meeting, Houston, TX, USA, 3–7 October 2010; pp. 1–8. [Google Scholar]

- Chy, M.M.; Boulet, B.; Haidar, A. A model predictive controller of plastic sheet temperature for a thermoforming process. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; pp. 4410–4415. [Google Scholar]

- Li, Z.; Heo, K.; Seol, S. Time-dependent Optimal Heater Control in Thermoforming Preheating Using Dual Optimization Steps. Int. J. Precis. Eng. Manuf. 2008, 9, 51–56. [Google Scholar]

- Li, Z.; Ma, G.; Xuan, D.; Seol, S.; Shen, Y. A study on control of heater power and heating time for thermoforming. Int. J. Precis. Eng. Manuf. 2010, 11, 873–878. [Google Scholar] [CrossRef]

- Erchiqui, F.; Nahas, N.; Nourelfath, M.; Souli, M. Metaheuristic algorithms for optimisation of infrared heating in thermoforming process. Int. J. Metaheuristics 2011, 1, 199–221. [Google Scholar] [CrossRef]

- Bachir, C.K.; Rebaine, D.; Erchiqui, F.; Fofana, I. Metaheuristics as a Solving Approach for the Infrared Heating in the Thermoforming Process; Report GERAD-G-2015-139; GERARD: Montreal, QC, Canada, 2015. [Google Scholar]

- Erchiqui, F. Application of genetic and simulated annealing algorithms for optimization of infrared heating stage in thermoforming process. Appl. Therm. Eng. 2018, 128, 1263–1272. [Google Scholar] [CrossRef]

- Bachir, C.K.; Rebaine, D.; Erchiqui, F.; Fofana, I.; Nahas, N. Numerically Optimizing the Distribution of the Infrared Radiative Energy on a Surface of a Thermoplastic Sheet Surface. J. Heat Transf. 2018, 140, 102101. [Google Scholar] [CrossRef]

- Bachir, C.K. Optimisation de L’étape de Chauage Infrarouge en Thermoformage à L’aide de Métaheuristiques. Ph.D. Thesis, Université du Québec, Chicoutimi, QC, Canada, 2019. [Google Scholar]

- Yang, C.; Hung, S.-W. Modeling and Optimization of a Plastic Thermoforming Process. J. Reinf. Plast. Compos. 2004, 23, 109–121. [Google Scholar] [CrossRef]

- Chang, Y.-Z.; Wen, T.-T.; Liu, S.-J. Derivation of optimal processing parameters of polypropylene foam thermoforming by an artificial neural network. Polym. Eng. Sci. 2005, 45, 375–384. [Google Scholar] [CrossRef]

- Leite, W.O.; Campos Rubio, J.C.; Mata Cabrera, F.; Carrasco, A.; Hanafi, I. Vacuum Thermoforming Process: An Approach to Modeling and Optimization Using Artificial Neural Networks. Polymers 2018, 10, 143. [Google Scholar] [CrossRef] [PubMed]

- Leite, W.; Rubio, J.; Mata, F.; Hanafi, I.; Carrasco, A. Dimensional and Geometrical Errors in Vacuum Thermoforming Prod-ucts: An Approach to Modeling and Optimization by Multiple Response Optimization. Meas. Sci. Rev. 2018, 18, 113–122. [Google Scholar] [CrossRef]

- Sasimowski, E. The use of utility function for optimization of thermoforming. Polimery 2018, 63, 807–814. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Costa, P.; Galuppo, W.d.C.; Nóbrega, J.M.; Duarte, F.; Costa, L. Multi-Objective Optimization of Plastics Thermoforming. Mathematics 2021, 9, 1760. [Google Scholar] [CrossRef]

- Trinh, C.; Meimaroglou, D.; Hoppe, S. Machine Learning in Chemical Product Engineering: The State of the Art and a Guide for Newcomers. Processes 2021, 9, 1456. [Google Scholar] [CrossRef]

| Algorithm | Single Objective | Global Optimum | Discontinuous Objective Space | Multi-Objective | Flexibility |

|---|---|---|---|---|---|

| Empirical | + | --- | --- | --- | --- |

| Simplex | + | -- | --- | --- | --- |

| Complex | ++ | -- | -- | --- | --- |

| Regression | ++ | -- | --- | --- | -- |

| Direct | + | --- | --- | --- | --- |

| Gradient | +++ | - | - | --- | --- |

| Simulated Annealing | +++ | + | + | ++ | + |

| Particle Swarm Optimization | +++ | + | + | +++ | + |

| Artificial Bee Colony | +++ | + | + | +++ | + |

| Data Envelopment Analysis | ++ | + | + | ++ | - |

| Ant Colony Optimization | +++ | +++ | +++ | +++ | ++ |

| Evolutionary Algorithms | +++ | +++ | +++ | +++ | +++ |

| Objective Function | Optimization Algorithm | Modelling Approach | Decision Variables | Other Characteristics | Authors (Year), Reference |

|---|---|---|---|---|---|

| SO | Empirical | Experimental | SD | Variousgeometries | Verbraak and Meijer (1989) [14] |

| SO | Regression | 3D-N | SD | Huang (2016) [15] | |

| WS | EA | 3D-N | SD | Wang et al. (2020) [16] | |

| SO | Empirical | 3D-N | CB | Seow and Lam (1997) [17] | |

| SO | Complex | 3D-N | OC | Lee and Kim (1995) [18] | |

| SO | Regression | Experimental | OC | DOE | Chang and Faison (2001) [19] |

| SO | Regression | Experimental | OC | ANN | Feng et al. (2006) [20] |

| SO | Regression | Experimental | OC | ANN | Tang et al. (2007) [21] |

| SO | Regression | Experimental | OC | Taguchi | Ahmad et al. (2019) [22] |

| SO | Regression | Experimental | OC | Kriging model | Mukras (2020) [23] |

| SO | Regression | 3D-N | OC | Chen et al. (2010) [24] | |

| SO | Regression | 3D-N | OC | Huang et al. (2015) [25] | |

| SO | Gradient | 3D-N | GL + OC | Smith et al. (1998) [26] | |

| SO | Gradient | 3D-N | CB | Lam and Seow (2000) [27] | |

| SO | Gradient | 3D-N | GL | Lam and Jin (2001) [28] | |

| SO | Gradient | 2D-N | CC | SQP | Pirc et al. (2008) [29] |

| SO | EA + Gradient | 2D-N + 3D-N | GL | Zhai et al. (2005) [30] | |

| SO | EA + Gradient | 2D-N | CC | Qiao (2006) [31] | |

| SO | SA | 3D-N | GL | Li et al. (2007) [32] | |

| SO | EA | 3D-N | OC + GL | Ye and Wang (1999) [33] | |

| SO | EA | 3D-N | OC | ANN | Shi et al. (2003) [34] |

| SO | EA | 3D-N | OC + CC | Lam et al. (2004) [35] | |

| SO | EA | 3D-N | OC | Kurtaran et al. (2005) [36] | |

| SO | EA | 3D-N | CC | Ozcelik and Erzurumlu (2005) [37] | |

| SO | EA | 3D-N | OC | ANN | Ozcelik and Erzurumlu (2006) [38] |

| SO | EA | 3D-N | OC + RS + PG | Wu et al. (2011) [39] | |

| SO | ABC | 3D-N | OC | ANN | Iniesta et al. (2013) [40] |

| SO | EA | 3D-N | OC | ANN | Changyu et al. (2007) [41] |

| AS(2) | Regression | Experimental | OC | Taguchi | Singh et al. (2018) [42] |

| AS(8) | Regression | Experimental | OC | Sreedharan et al. (2019) [43] | |

| AS(3) | Regression | Experimental | OC | Gray Rel. Anal. | Kumar et al. (2019) [44] |

| AS (20) | Regression | Experimental | OC | SQP | Yacoub and MacGregor (2004) [45] |

| AS(2) | Regression | 3D-N | OC | RBF | Kitayama et al. (2017, 2018) [46,47] |

| AS(3) | Regression | 3D-N | OC | Fuzzy analysis | Moayyedian and Mamedov (2019) [48] |

| AS(2) | Gradient | 3D-N | CC | Tang et al. (1997) [49] | |

| AS(2) | Gradient | 3D-N | OC | Park and Kwon (1998) [50] | |

| AS(2) | Gradient | 3D-N | CC | Huang and Fadel (2001) [51] | |

| AS(4) | Gradient | 3D-N | GL | Shen et al. (2004) [52] | |

| AS(2) | Gradient | 3D-N | CC | SQP | Mathey et al. (2004) [53] |

| AS(2) | Gradient | 3D-N | CC | Agazzi et al. (2010) [54] | |

| AP(3) | Gradient | 3D-N | OC | Shie (2008) [55] | |

| AS(3) | Gradient + SA | 3D-N | GL and OC | Pandelidis and Zou (1990, 1990) [56,57] | |

| SO + AS(2) | Gradient + EA + DE + SA | 3D-N | OC | Turng and Peić (2002) [58] | |

| AS(2) | Gradient+EA | 3D-N | OC | Lam et al. (2006) [59] | |

| AS(3) | EA | 3D-N | OC | Kim et al. (1996) [60] | |

| AS(2) | EA | Exp. + ANN | OC | Chen et al. (2007) [61] | |

| AS(3) | EA | 3D-N | OC | ANN | Meiabadi et al. (2013) [62] |

| AS(4) | EA | 3D-N | OC + MD + PD | ANN | Mok et al. (2001) [63] |

| MO(3) | EA | 3D-N | OC + RS | Alam and Kamal (5 April 2003 [64,65,66] | |

| MO(3) | EA | 3D-N | OC | morphology | Gaspar-Cunha et al. (2005) [67] |

| MO(5) | DEA | 3D-N | OC + GL | ANN | Castro et al. (2007) [68] |

| MO(4) | EA | 3D-N | OC | Fernandes et al. (2010) [69] | |

| MO(2) | EA | 3D-N | OC+CC | Fernandes et al. (2012) [70] | |

| MO(3) | PSA | Experimental | OC | Taguchi + ANN | Xu et al. (2012) [71] |

| Objective Function | Optimization Algorithm | Modelling Approach | Decision Variables | Processing Technology | Reference |

|---|---|---|---|---|---|

| SO | Regression | Experimental | OC | Extrusion | Tahboub and Rawabdeh (2004) [72] |

| SO | Regression | Experimental | OC | Extrusion | Agrawal et al. (2012) [73] |

| SO | Regression | Experimental | OC | Extrusion | Dohare et al. (2018) [74] |

| SO | Gradient | 3D | PaTP | Extrusion | Diraddo and Garcia-Rejon (1993) [75] |

| SO | Gradient | 3D | PTP | Extrusion | Thibault et al. (2001) [76] |

| So | Gradient | 3D | PTP + DGO | Extrusion | Gauvin et al. (2003) [77] |

| SO | Gradient+EA | 3D | PTP + DGO | Extrusion | Yu et al. (2002, 2004) [78,79] |

| SO | Gradient+EA | 3D | PTP + DGO | Extrusion | Hsu et al. (2004) [80] |

| SO | Gradient | 3D | DGO | Extrusion | Yu and Juang (2010) [81] |

| SO | EA | 3D | PTP | Extrusion | Huang and Huang (2007) [82] |

| SO | Empirical | 3D | PfTP | Injection | Hopmann et al. (2015) [83] |

| SO | Simplex | 3D | PfTP | Injection | Bordival et al. (2009) [84] |

| SO | Simplex | 3D | PfTP | Injection | Biglione (2015) [85] |

| SO | Simplex | 3D | PfTP | Injection | Biglione et al. (2016) [86] |

| SO | Regression | Experimental | OC | Injection | Demirel (2017) [87] |

| SO | Gradient | 3D | PfTP | Injection | Lee and Soh (1996) [88] |

| SO | Gradient | 3D | PfTP + OC | Injection | Thibault et al. (2007) [89] |

| MO(3) | EA | 3D | PTP | Injection | Denysiuk et al. (2017, 2019) [90,91] |

| MO(3) | EA | 3D | PTP | Injection | Pinto et al. (2019) [92] |

| MO(3) | EA | 3D | PfTP | Injection | Pinto et al. (2021) [93] |

| Objective Function | Optimization Algorithm | Modelling Approach | Decision Variables | Other Characteristics | Reference |

|---|---|---|---|---|---|

| SO | Empirical | 1D-N | TempD | Duarte and Covas (1997, 2002) [94,95] | |

| SO | Gradient | 3D-N | TempD | Wang and Nied (1998) [96] | |

| SO | Gradient | 1D-A | TempD | Bordival et al. (2005) [97] | |

| SO | Gradient | 3D-N | TempD | Chy and Boulet (2010) [98] | |

| SO | Gradient | 3D-N | TempD | Chy et al. (2011) [99] | |

| SO | Regression | 3D-N | TempD | Li et al. (2008) [100] | |

| SO | Regression | 3D-N | TempD | Li et al. (2010) [101] | |

| SO | SA + EA | 3D-N | TempD | Erchiqui et al. (2011 [102]) | |

| SO | SA + EA | 3D-N | TempD | Bachir-Cherif et al. (2015) [103] | |

| SO | SA + EA | 3D-N | TempD | Erchiqui (2018) [104] | |

| SO | Gradient | 3D-N | TempD | Bachir-Cherif et al. (2018) [105] | |

| SO | SA + EA | 3D-N | TempD | Bachir-Cherif (2019) [106] | |

| SO | IANN | Experimental | OC | Plug assisted | Yang and Hung (2004) [107] |

| SO | IANN | Experimental | OC | Plug assisted | Chang et al. (2005) [108] |

| SO | Regression | Experimental | OC | Vacuum | Leite et al. (2018, 2018) [109,110] |

| SO | Regression | Experimental | OC | Vacuum, pre-blow | Sasimowski (2018) [111] |

| MO(2) | EA | 3D-N | SThD | Plug assisted | Gaspar-Cunha et al. (2021) [112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaspar-Cunha, A.; Covas, J.A.; Sikora, J. Optimization of Polymer Processing: A Review (Part II-Molding Technologies). Materials 2022, 15, 1138. https://doi.org/10.3390/ma15031138

Gaspar-Cunha A, Covas JA, Sikora J. Optimization of Polymer Processing: A Review (Part II-Molding Technologies). Materials. 2022; 15(3):1138. https://doi.org/10.3390/ma15031138

Chicago/Turabian StyleGaspar-Cunha, António, José A. Covas, and Janusz Sikora. 2022. "Optimization of Polymer Processing: A Review (Part II-Molding Technologies)" Materials 15, no. 3: 1138. https://doi.org/10.3390/ma15031138

APA StyleGaspar-Cunha, A., Covas, J. A., & Sikora, J. (2022). Optimization of Polymer Processing: A Review (Part II-Molding Technologies). Materials, 15(3), 1138. https://doi.org/10.3390/ma15031138