Water-Soluble Starch-Based Copolymers Synthesized by Electron Beam Irradiation: Physicochemical and Functional Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

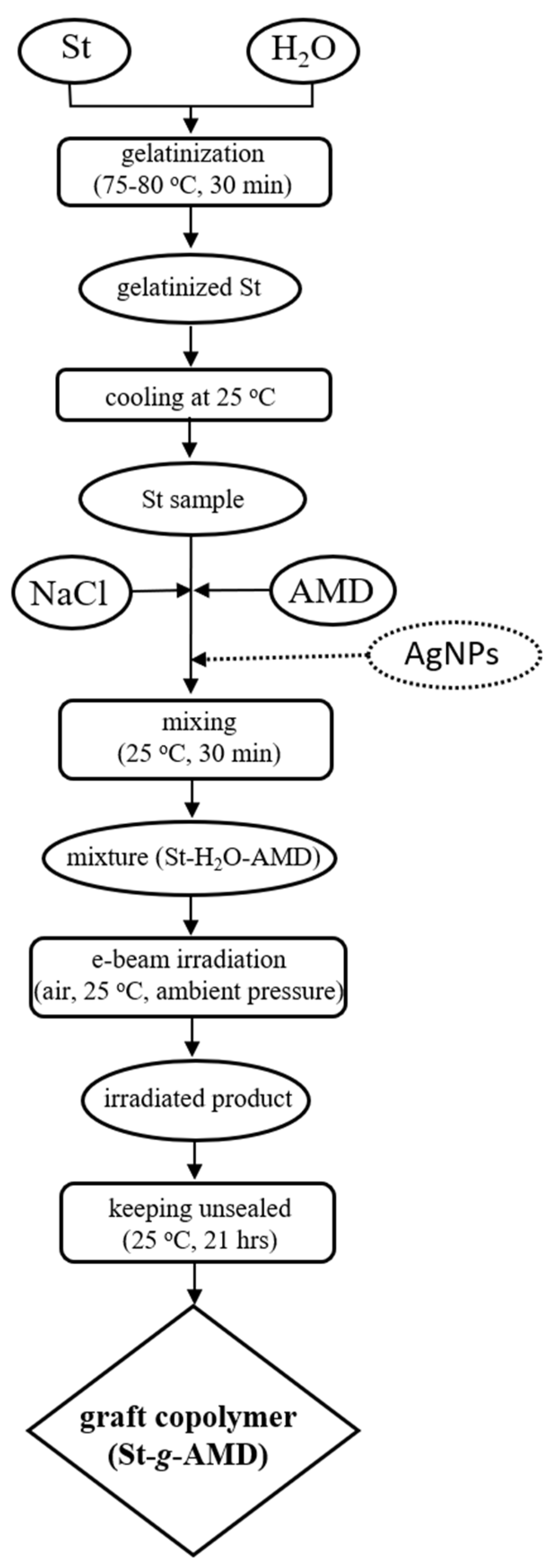

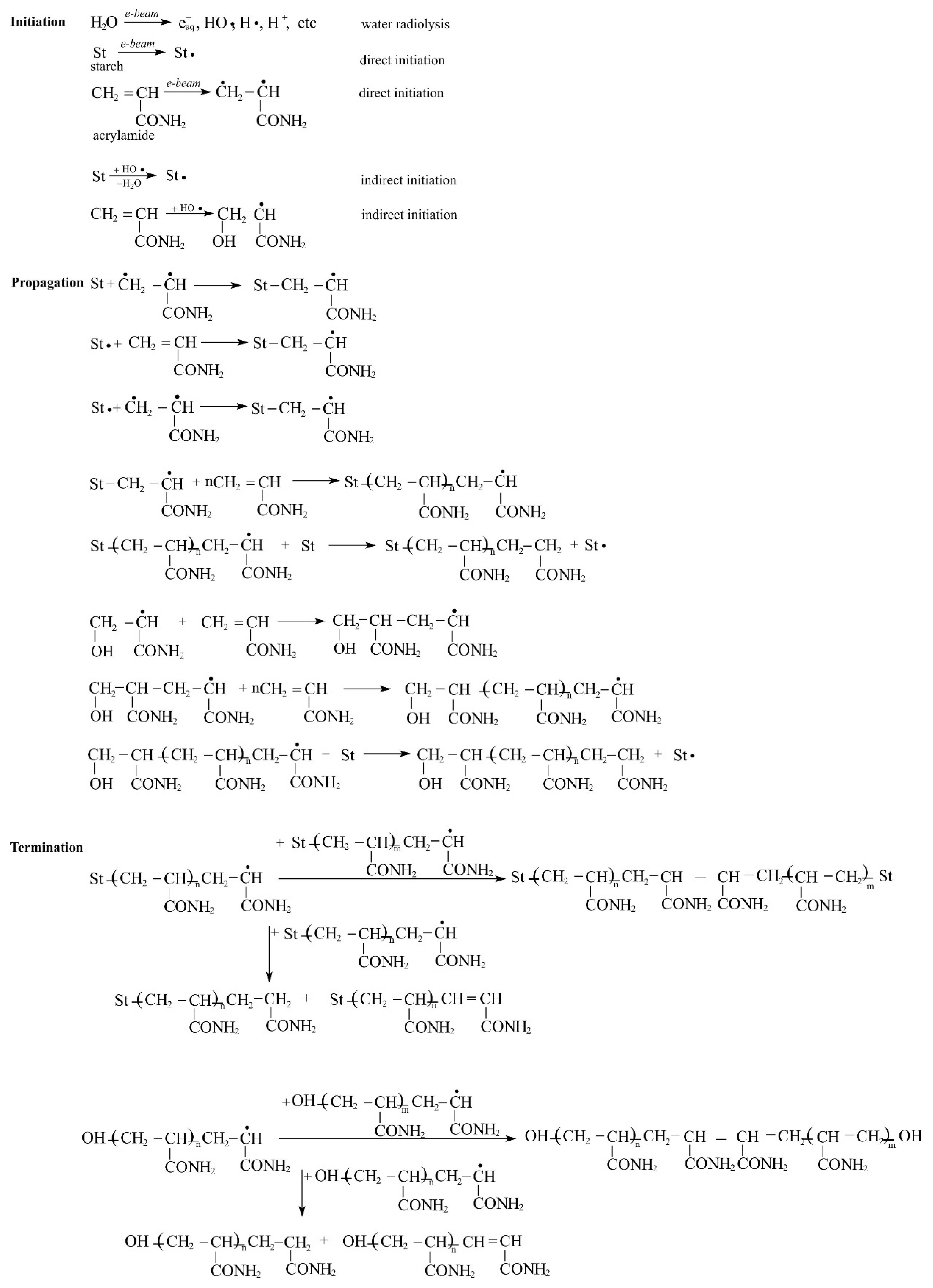

2.2. Synthesis of Starch-Graft Acrylamide Copolymers

2.3. Characterization of Graft Copolymers

2.3.1. Level of Grafting

2.3.2. Intrinsic Viscosity

2.3.3. Differential Scanning Calorimetry (DSC)

2.4. Flocculation Study

2.5. Statistics

3. Results

3.1. Level of Grafting

3.2. Viscosity

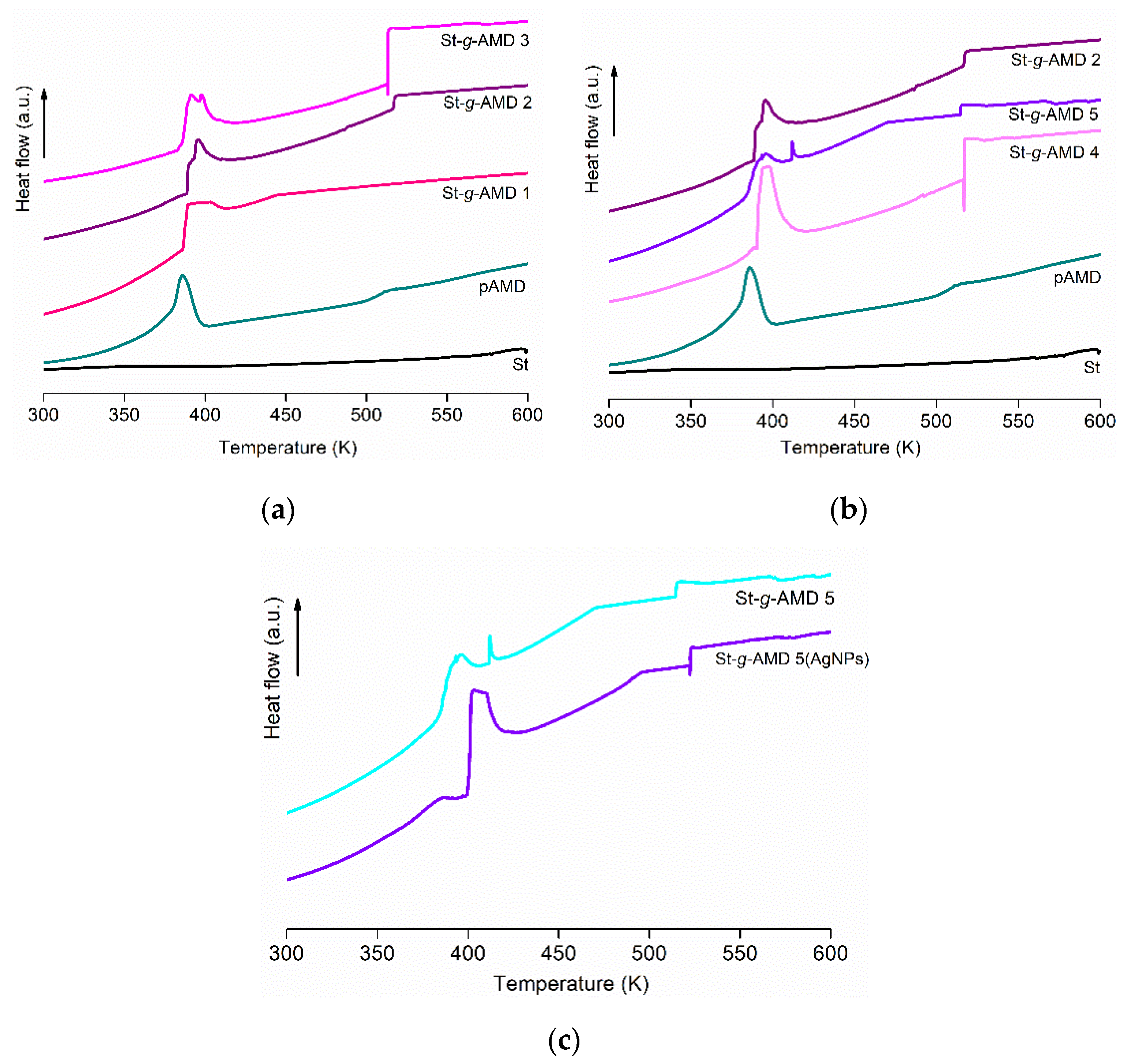

3.3. DSC Study

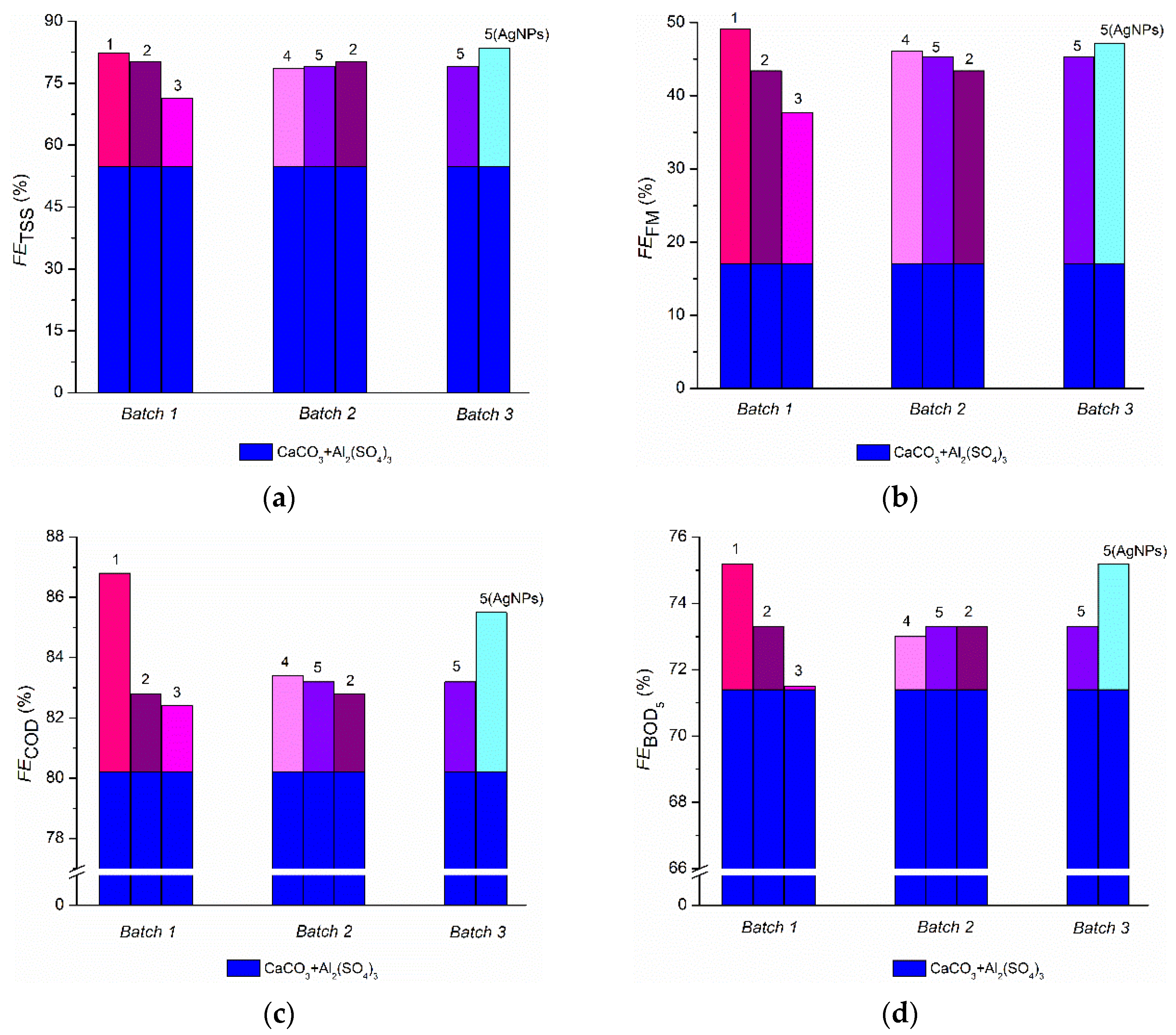

3.4. Flocculation Investigation

4. Conclusions

- The monomer conversion coefficient Cc exceeded 90%, while the residual monomer Rm had values below 3%. However, these grafting parameters were much better correlated with dose rate than irradiation dose .

- All graft copolymers had high intrinsic viscosity values ((η) > 7 dL/g) and Huggins constant kH below unity.

- The addition of AgNPs to the initial sample subjected to irradiation had no influence on the grafting level but led to the formation of copolymer with higher intrinsic viscosity and a lower Huggins constant.

- The graft copolymers presented thermal events characteristic to the native starch (St) and polyacrylamide (pAMD) shifted to higher temperatures in the DSC curves. The identified changes confirmed the grafting process and formation of new chemical bonds between the St backbone and pAMD. At the same time, all graft copolymers showed improved thermal stability in terms of glass transition temperatures higher than the polyacrylamide.

- The potential of the synthesized copolymers to improve the quality of the surface water from the meat industry was proven in coagulation–flocculation experiments at the laboratory level. Thus, the copolymers were able to reduce the water quality indicators, such as total suspended solids, fatty matters in suspension, chemical and biochemical oxygen demands.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lapointe, M.; Barbeau, B. Dual starch-polyacrylamide polymer system for improved flocculation. Water Res. 2017, 124, 202–209. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Yao, Z.; Wang, X.; Crombeen, M.; Sweeney, D.G.; Tam, K.C. Cellulose-based materials in wastewater treatment of petroleum industry. Green Energy Environ. 2020, 5, 37–49. [Google Scholar] [CrossRef]

- Nayak, A.K.; Hasnain, M.S.; Nanda, S.S.; Yi, D.K. Hydroxyapatite-alginate based matrices for drug delivery. Curr. Pharm. Des. 2019, 25, 3406–3416. [Google Scholar] [CrossRef]

- Nayak, A.K.; Hasnain, M.S.; Aminabhavi, T.M. Drug delivery using interpenetrating polymeric networks of natural polymers: A recent update. J. Drug Deliv. Sci. Technol. 2021, 66, 102915. [Google Scholar] [CrossRef]

- Makmoon, T.; Foungfuchat, A.; Jiratumnukul, N. Modified tapioca starch as a rheology modifier in acrylic dispersion system. Prog. Org. Coat. 2013, 76, 959–962. [Google Scholar] [CrossRef]

- Zheng, Y.J.; Loh, X.J. Natural rheological modifiers for personal care. Polym. Adv. Technol. 2016, 27, 1664–1679. [Google Scholar] [CrossRef]

- Song, W.; Zhao, Z.; Zheng, H.; Wang, G. Gamma-irradiation synthesis of quaternary phosphonium cationic starch flocculants. Water Sci. Technol. 2013, 68, 1778. [Google Scholar] [CrossRef]

- Salehizadeh, H.; Yan, N.; Farnood, R. Recent advances in polysaccharide bio-based flocculants. Biotechnol. Adv. 2018, 36, 92–119. [Google Scholar] [CrossRef]

- Maćczak, P.; Kaczmarek, H.; Ziegler-Borowska, M. Recent achievements in polymer bio-based flocculants for water treatment. Materials 2020, 13, 3951. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, J.; Yan, Y.; Yang, L.; Xing, G.; Li, H.; Wu, P.; Wang, M.; Zheng, H. Application of coagulation/flocculation in oily wastewater treatment: A review. Sci. Total Environ. 2021, 765, 142795. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-P.; Chen, Y.-Z.; Ge, X.-W.; Yu, H.-Q. Gamma radiation-induced grafting of a cationic monomer onto chitosan as a flocculant. Chemosphere 2007, 66, 1752–1757. [Google Scholar] [CrossRef] [PubMed]

- Pillai, C.K.S. Challenges for natural monomers and polymers: Novel design strategies and engineering to develop advanced polymers. Des. Monomers Polym. 2010, 13, 87–121. [Google Scholar] [CrossRef]

- Wang, J.-P.; Chen, Y.-Z.; Zhang, S.-J.; Yu, H.-Q. A chitosan-based flocculant prepared with gamma-irradiation-induced grafting. Bioresour. Technol. 2008, 99, 3397–3402. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.P.; Chen, Y.Z.; Wang, Y.; Yuan, S.J.; Sheng, G.P.; Yu, H.Q. A novel efficient cationic flocculant prepared through grafting two monomers onto chitosan induced by gamma radiation. RSC Adv. 2012, 2, 494–500. [Google Scholar] [CrossRef]

- Zhou, P.; Ru, X.; Yang, W.; Dai, Z.; Ofori, M.A.; Chen, J.; Hou, J.; Zhong, Z.; Jin, H. Study on preparation of cationic flocculants by grafting binary monomer on cellulose substrate by γ-ray co-irradiation. J. Environ. Chem. Eng. 2022, 10, 107138. [Google Scholar] [CrossRef]

- Lee, C.S.; Robinson, J.; Chong, M.F. A review on application of flocculants in wastewater treatment. Process Saf. Environ. Protection. 2014, 92, 489–508. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Y.; Tang, X.; Jiang, J.; He, Q.; Xiong, Z.; Zheng, H. Biopolymer-based flocculants: A review of recent technologies. Environ. Sci. Pollut. Res. 2021, 28, 46934–46963. [Google Scholar] [CrossRef]

- Lee, K.E.; Morad, N.; Teng, T.T.; Poh, B.T. Development, characterization and the application of hybrid materials in coagulation/flocculation of wastewater: A review. Chem. Eng. J. 2012, 203, 370–386. [Google Scholar] [CrossRef]

- Shen, J.; Cui, C.; Li, J.; Wang, L. In situ synthesis of a silver-containing superabsorbent polymer via a greener method based on carboxymethyl celluloses. Molecules 2018, 23, 2483. [Google Scholar] [CrossRef]

- Craciun, G.; Manaila, E.; Ighigeanu, D. New type of sodium alginate-g-acrylamide polyelectrolyte obtained by electron beam irradiation: Characterization and study of flocculation efficacy and heavy metal removal capacity. Polymers 2019, 11, 234. [Google Scholar] [CrossRef] [PubMed]

- Eid, M. Gamma radiation synthesis and characterization of starch based polyelectrolyte hydrogels loaded silver nanoparticles. J. Inorg. Organomet. Polym. 2011, 21, 297–305. [Google Scholar] [CrossRef]

- Yumei, L.; Yamei, L.; Qiang, L.; Jie, B. Rapid biosynthesis of silver nanoparticles based on flocculation and reduction of an exopolysaccharide from Arthrobacter sp. B4: Its antimicrobial activity and phytotoxicity. J. Nanomater. 2017, 2017, 9703614. [Google Scholar] [CrossRef]

- de S. Maria, L.C.; Oliveira, R.O.; Merçon, F.; Borges, M.E.R.S.P.; Barud, H.S.; Ribeiro, S.J.L.; Messaddeq, Y.; Wang, S.H. Preparation and bactericidal effect of composites based on crosslinked copolymers containing silver nanoparticles. Polímeros 2010, 20, 227–230. [Google Scholar] [CrossRef][Green Version]

- Shaik, S.; Kummara, M.R.; Poluru, S.; Allu, C.; Gooty, J.M.; Kashayi, C.R.; Subha, M.C.S. A green approach to synthesize silver nanoparticles in starch-co-poly(acrylamide) hydrogels by Tridax procumbens leaf extract and their antibacterial activity. Int. J. Carbohydr. Chem. 2013, 2013, 539636. [Google Scholar] [CrossRef]

- Das, S.; Sasmal, D.; Pal, S.; Kolya, H.; Pandey, A.; Tripathy, T. Starch based biodegradable graft copolymer for the preparation of silver nanoparticles. Int. J. Biol. Macromol. 2015, 81, 83–90. [Google Scholar] [CrossRef]

- Iravani, S.; Korbekandi, H.; Mirmohammadi, S.V.; Zolfaghari, B. Synthesis of silver nanoparticles: Chemical, physical and biological methods. Res. Pharm. Sci. 2014, 9, 385–406. [Google Scholar]

- Dawadi, S.; Katuwal, S.; Gupta, A.; Lamichhane, U.; Thapa, R.; Jaisi, S.; Lamichhane, G.; Bhattarai, D.P.; Parajuli, N. Current research on silver nanoparticles: Synthesis, characterization, and applications. J. Nanomater. 2021, 2021, 6687290. [Google Scholar] [CrossRef]

- Moura, E.; Somessari, E.S.R.; Silveira, C.G.; Paes, H.A.; Souza, C.A.; Fernandes, W.; Manzoli, J.E.; Geraldo, A.B.C. Influence of physical parameters on mutual polymer grafting by electron beam irradiation. Radiat. Phys. Chem. 2011, 80, 175–181. [Google Scholar] [CrossRef]

- Braşoveanu, M.; Nemţanu, M.R.; Duţă, D. Electron-beam processed corn starch: Evaluation of physicochemical and structural properties and technical-economic aspects of the processing. Braz. J. Chem. Eng. 2013, 30, 847–856. [Google Scholar] [CrossRef]

- Nemțanu, M.R.; Brașoveanu, M. Ionizing irradiation grafting of natural polymers having applications in wastewater treatment. In Polymer Science: Research Advances, Practical Applications and Educational Aspects; Méndez-Vilas, A., Solano-Martín, A., Eds.; Formatex Research Center: Badajoz, Spain, 2016; pp. 270–277. [Google Scholar]

- Brașoveanu, M.; Koleva, E.; Vutova, K.; Koleva, L.; Nemțanu, M.R. Optimization aspects on modification of starch using electron beam irradiation for the synthesis of water-soluble copolymers. Rom. J. Phys. 2016, 61, 1519–1529. [Google Scholar]

- Koleva, L.; Koleva, E.; Nemțanu, M.; Brașoveanu, M. Overall robust optimization approach for electron beam induced grafting processes. Electrotech. Electron. 2019, 54, 153–160. [Google Scholar]

- Nemțanu, M.R.; Brașoveanu, M.; Flore, L.; Anca, V.; Ștefănescu, M. Material polimeric cu însușiri floculante, procedeu de obținere și de utilizare a acestuia pentru îmbunătăţirea parametrilor de calitate a apelor de suprafaţă şi reziduale (Polymeric Material with Flocculating Properties, Process for Obtaining and Using it in Order to Improve the Quality Parameters of Surface and Wastewater). Romanian Patent No. 132660, November 2019. [Google Scholar]

- Martin, D.; Cirstea, E.; Ighigeanu, D.; Craciun, G.; Oproiu, C.; Iovu, H.; Marin, G.h.; Iacob, N.; Nemtanu, M. Polyelectrolytes derived from electron beam-induced polymerization. Vacuum 2005, 77, 475–484. [Google Scholar] [CrossRef]

- Craciun, G.; Manaila, E.; Martin, D.; Toader, D.; Ighigeanu, D. Synthesis of new flocculant materials by copolymerization of acrylamide and acrylic acid by electron beam irradiation. Mater. Plast. 2011, 48, 183–188. [Google Scholar]

- Nemţanu, M.R.; Braşoveanu, M.; Iacob, N. Preparation of metallic nanoparticles by irradiation in starch aqueous solution. AIP Conf. Proc. 2014, 1634, 180–185. [Google Scholar] [CrossRef]

- Ticoș, D.; Scurtu, A.; Oane, M.; Diplașu, C.; Giubega, G.; Călina, I.; Ticoș, C.M. Complementary dosimetry for a 6MeV electron beam. Results Phys. 2019, 14, 102377. [Google Scholar] [CrossRef]

- Călina, I.; Demeter, M.; Scărișoreanu, A.; Sătulu, V.; Mitu, B. One step e-beam radiation cross-linking of quaternary hydrogels dressings based on chitosan-poly(vinyl-pyrrolidone)-poly(ethylene glycol)-poly(acrylic acid). Int. J. Mol. Sci. 2020, 21, 9236. [Google Scholar] [CrossRef]

- Braşoveanu, M.; Oane, M.; Nemţanu, M.R. Heat transport in starch exposed to ionizing radiation: Experiment versus theoretical computer modeling. Starch-Stärke 2019, 71, 1900147. [Google Scholar] [CrossRef]

- Braşoveanu, M.; Nemţanu, M.R. Temperature profile in starch during irradiation. Indirect effects in starch by radiation-induced heating. Materials 2021, 14, 3061. [Google Scholar] [CrossRef]

- Sehested, K. The Fricke dosimeter. In Manual on Radiation Dosimetry; Holm, N.W., Berry, R.J., Eds.; Marcel Dekker: New York, NY, USA, 1970; pp. 313–317. [Google Scholar]

- Matthews, R.W. Aqueous chemical dosimetry. Int. J. Appl. Radiat. Isot. 1982, 33, 1159–1170. [Google Scholar] [CrossRef]

- Nemtanu, M.R.; Oproiu, C.; Brasoveanu, M.; Oane, M. Characterization of the electron beam radiation field by chemical dosimetry. Rom. J. Phys. 2009, 54, 613–617. [Google Scholar]

- Costa, C.; Vandenborre, J.; Crumière, F.; Blain, G.; Essehli, R.; Fattahi, M. Chemical dosimetry during alpha irradiation: A specific system for UV-Vis in situ measurement. Am. J. Anal. Chem. 2012, 3, 6–11. [Google Scholar] [CrossRef][Green Version]

- Koleva, E.; Koleva, L.; Braşoveanu, M.; Nemţanu, M.R. Experimental design sequential generation and overall D-efficiency criterion for electron beam grafting of corn starch. J. Phys. Conf. Ser. 2018, 1089, 012018. [Google Scholar] [CrossRef]

- Biswal, J.; Kumar, V.; Bhardwaj, Y.K.; Goel, N.K.; Dubey, K.A.; Chaudhari, C.V.; Sabharwal, S. Radiation-induced grafting of acrylamide onto guar gum in aqueous medium: Synthesis and characterization of grafted polymer guar-g-acrylamide. Radiat. Phys. Chem. 2007, 76, 1624–1630. [Google Scholar] [CrossRef]

- Banks, C.J.; Wang, Z. Treatment of meat wastes. In Waste Treatment in the Food Processing Industry; Wang, L.K., Hung, Y.-T., Lo, H.H., Yapijakis, C., Eds.; CRC Press, Taylor&Francis Group: Boca Raton, FL, USA, 2005; pp. 67–100. [Google Scholar]

- SR 872:2005—Water Quality. Determination of Suspended Solids. Method by Filtration through Glass Fibre Filters. International Organization for Standardization (ISO): Geneva, Switzerland.

- SR 7587:1996—Determination of Extractable Compounds with Solvents. Gravimetric Method. International Organization for Standardization (ISO): Geneva, Switzerland.

- SR ISO 6060:1996—Water Quality. Determination of the Chemical Oxygen Demand. International Organization for Standardization (ISO): Geneva, Switzerland.

- SR EN ISO 1899-2:2002—Water Quality. Determination of Biochemical Oxygen Demand after n days (BODn). Part 2: Method for Undiluted Samples. International Organization for Standardization (ISO): Geneva, Switzerland.

- Di Rienzo, J.A.; Casanoves, F.; Balzarini, M.G.; Gonzalez, L.; Tablada, M.; Robledo, C.W. InfoStat versión 2018; InfoStat Group, Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba: Córdoba, Argentina, 2018. [Google Scholar]

- Nasef, M.M.; Guven, O. Radiation-grafted copolymers for separation and purification purposes: Status, challenges and future directions. Prog. Polym. Sci. 2012, 27, 1597–1656. [Google Scholar] [CrossRef]

- Singh, V.; Tiwari, A.; Pandey, S.; Singh, S.K. Microwave-accelerated synthesis and characterization of potato starch-g-poly(acrylamide). Starch-Starke 2006, 58, 536–543. [Google Scholar] [CrossRef]

- Mishra, S.; Mukul, A.; Sen, G.; Jha, U. Microwave assisted synthesis of polyacrylamide grafted starch (St-g-PAM) and its applicability as flocculant for water treatment. Int. J. Biol. Macromol. 2011, 48, 106–111. [Google Scholar] [CrossRef] [PubMed]

- Sen, G.; Sharon, A.; Pal, S. Grafted Polysaccharides: Smart Materials of Future, Synthesis and Applications. In Biopolymers: Biomedical and Environmental Applications; Kalia, S., Avérous, L., Eds.; Wiley-Scrivener: Salem, MA, USA, 2011; pp. 101–109. [Google Scholar]

- Meimoun, J.; Wiatz, V.; Saint-Loup, R.; Parcq, J.; Favrelle, A.; Bonnet, F.; Zinck, F. Modification of starch by graft copolymerization. Starch-Stärke 2018, 70, 1600351. [Google Scholar] [CrossRef]

- Ashfaq, A.; Clochard, M.C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulański, P.; Al-Sheikhly, M. Polymerization reactions and modifications of polymers by ionizing radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Velazco-Medel, M.A.; Camacho-Cruz, L.A.; Magaña, H.; Palomino, K.; Bucio, E. Simultaneous grafting polymerization of acrylic acid and silver aggregates formation by direct reduction using γ radiation onto silicone surface and their antimicrobial activity and biocompatibility. Molecules 2021, 26, 2859. [Google Scholar] [CrossRef] [PubMed]

- Biswal, D.R.; Singh, R.P. Characterisation of carboxymethyl cellulose and polyacrylamide graft copolymer. Carbohydr. Polym. 2004, 57, 379–387. [Google Scholar] [CrossRef]

- Krishnamoorthi, S.; Mal, D.; Singh, R.P. Characterization of graft copolymer based on polyacrylamide and dextran. Carbohydr. Polym. 2007, 69, 371–377. [Google Scholar] [CrossRef]

- Marani, D.; Hjelm, J.; Wandel, M. Use of intrinsic viscosity for evaluation of polymer-solvent affinity. Ann. T Nord. Rheol. Soc. 2013, 21, 255–261. [Google Scholar]

- Pamies, R.; Cifre, J.G.H.; del Carmen Lopez Martinez, M.; de la Torre, J.G. Determination of intrinsic viscosity of macromolecules and nanoparticles. Comparison of single-point and dilution procedures. Colloid Polym. Sci. 2008, 286, 1223–1231. [Google Scholar] [CrossRef]

- Radoiu, M.T.; Martin, D.I.; Calinescu, I.; Iovu, H. Preparation of polyelectrolytes for wastewater treatment. J. Hazard Mater. 2004, 106B, 27–37. [Google Scholar] [CrossRef]

- e Silva, M.E.S.R.; Dutra, E.R.; Mano, V.; Machado, J.C. Preparation and thermal study of polymers derived from acrylamide. Polym. Degrad. Stab. 2000, 67, 491–495. [Google Scholar] [CrossRef]

- Ho, Y.C.; Norli, I.; Alkarkhi, A.F.M.; Morad, N. Characterization of biopolymeric flocculant (pectin) and organic synthetic flocculant (PAM): A comparative study on treatment and optimization in kaolin suspension. Biores. Technol. 2010, 101, 1166–1174. [Google Scholar] [CrossRef]

- da Silva, D.A.; de Paula, R.C.M.; Feitosa, J.P.A. Graft copolymerization of acrylamide onto cashew gum. Eur. Polym. J. 2007, 43, 2620–2629. [Google Scholar] [CrossRef]

- Worzakowska, M. Starch-g-poly(benzyl methacrylate) copolymers. Characterization and thermal properties. J. Therm. Anal. Calorim. 2016, 124, 1309–1318. [Google Scholar] [CrossRef]

- Xu, Z.; Yang, Y.; Jiang, Y.; Sun, Y.; Shen, Y.; Pang, J. Synthesis and characterization of konjac glucomannan-graft-polyacrylamide via γ-irradiation. Molecules 2008, 13, 490–500. [Google Scholar] [CrossRef]

- Abo Eldahab, H.M.M.; Hassan, R.S.; Shehata, F.A.; El-Reefy, S.A.; Mohamed, S.A. Grafting copolymerization of sodium alginate/acrylic acid/methacrylic acid by gamma radiation: Preparation and characterization. Arab J. Nucl. Sci. Appl. 2021, 54, 1–8. [Google Scholar] [CrossRef]

- Al-Mutairi, N.Z.; Hamoda, M.F.; Al-Ghusain, I.A. Coagulant selection and sludge conditioning in a slaughterhouse wastewater treatment plant. Biores. Technol. 2004, 95, 115–119. [Google Scholar] [CrossRef] [PubMed]

| Substance | Chemical Formula | Chemical Properties |

|---|---|---|

| Starch (St) | (C6H10O5)n | Amylose content: ~27% Amylopectin content: ~73% Moisture content: 12% |

| Acrylamide (AMD) | CH2=CHCONH2 or C3H5NO | Molecular weight: 71.08 g/mol Density: 1.322 g/cm3 Boiling point: 125 °C/25mm Melting point: 82–85 °C Flash point: 138 °C |

| Silver nitrate (used for preparation of silver nanoparticles) | AgNO3 | Molecular weight: 169.86g/mol Melting point: 212 °C |

| Sodium chloride | NaCl | Molecular weight: 58.44 g/mol Density: 2.165 g/cm3 Boiling point: 1413 °C Melting point: 801 °C |

| Sample | (kGy) | (kGy/min) |

|---|---|---|

| Batch 1 | ||

| St-g-AMD 1 | 0.7 | 0.7 |

| St-g-AMD 2 | 1.0 | 0.7 |

| St-g-AMD 3 | 1.2 | 0.7 |

| Batch 2 | ||

| St-g-AMD 4 | 1.0 | 0.5 |

| St-g-AMD 5 | 1.0 | 0.6 |

| St-g-AMD 2 | 1.0 | 0.7 |

| Batch 3 | ||

| St-g-AMD 5 | 1.0 | 0.6 |

| St-g-AMD 5 (AgNPs) | 1.0 | 0.6 |

| Sample | (kGy) | (kGy/min) | Cc (g/100g) | Rm (g/100g) | [η] (dL/g) | kH |

|---|---|---|---|---|---|---|

| Batch 1 | ||||||

| St-g-AMD 1 | 0.7 | 0.7 | 91.6 ± 0.3 | 2.8 ± 0.1 | 7.9 ± 0.1 | 0.18 |

| St-g-AMD 2 | 1.0 | 0.7 | 96.6 ± 0.5 | 1.1 ± 0.2 | 7.3 ± 0.0 | 0.33 |

| St-g-AMD 3 | 1.2 | 0.7 | 95.3 ± 0.3 | 1.5 ± 0.1 | 7.8 ± 0.6 | 0.71 |

| Batch 2 | ||||||

| St-g-AMD 4 | 1.0 | 0.5 | 95.3 ± 0.4 | 1.6 ± 0.1 | 7.0 ± 0.2 | 0.37 |

| St-g-AMD 5 | 1.0 | 0.6 | 96.1 ± 0.4 | 1.3 ± 0.1 | 7.4 ± 0.1 | 0.72 |

| St-g-AMD 2 | 1.0 | 0.7 | 96.6 ± 0.5 | 1.1 ± 0.2 | 7.3 ± 0.0 | 0.33 |

| Batch 3 | ||||||

| St-g-AMD 5 | 1.0 | 0.6 | 96.1 ± 0.4 | 1.3 ± 0.1 | 7.4 ± 0.1 | 0.72 |

| St-g-AMD 5 (AgNPs) | 1.0 | 0.6 | 96.5 ± 0.3 | 1.2 ± 0.1 | 9.0 ± 0.2 | 0.19 |

| Sample | Peak I | Peak II | Glass Transition | ||||

|---|---|---|---|---|---|---|---|

| TI (K) | TI* (K) | ΔHI (J/g) | TII (K) | ΔHII (J/g) | Tg (K) | ΔCp (J/g K) | |

| St | 339.70 ± 0.41 | - | 248.77 ± 1.76 | 560.86 ± 1.55 | - | - | - |

| pAMD | 384.87 ± 0.46 | - | 681.33 ± 1.00 | - | - | 505.94 ± 0.83 | 5.23 ± 0.44 |

| Batch 1 | |||||||

| St-g-AMD 1 | 386.53 ± 0.54 | - | 337.20 ± 0.74 | - | - | - | - |

| St-g-AMD 2 | 387.88 ± 0.78 | 393.53 ± 0.63 | 412.73 ± 1.34 | - | - | 514.84 ± 0.52 | 11.23 ± 1.12 |

| St-g-AMD 3 | 387.47 ± 0.87 | 391.15 ± 0.32 | 542.73 ± 0.95 | - | - | 516.25 ± 0.74 | 43.30 ± 0.44 |

| Batch 2 | |||||||

| St-g-AMD 4 | 384.30 ± 0.41 | - | 4.94 ± 0.53 | 390.12 ± 0.35 | 514.27 ± 0.69 | 516.18 ± 0.30 | 23.62 ± 0.38 |

| St-g-AMD 5 | 385.90 ± 0.66 | - | 194.99 ± 0.38 | 411.21 ± 0.45 | 18.24 ± 0.38 | 515.02 ± 0.36 | 7.89 ± 0.34 |

| St-g-AMD 2 | 387.88 ± 0.78 | 393.53 ± 0.63 | 412.73 ± 1.34 | - | - | 514.84 ± 0.52 | 11.23 ± 1.12 |

| Batch 3 | |||||||

| St-g-AMD 5 | 385.90 ± 0.66 | - | 194.99 ± 0.38 | 411.21 ± 0.45 | 18.24 ± 0.38 | 515.02 ± 0.36 | 7.89 ± 0.34 |

| St-g-AMD 5 (AgNPs) | 371.94 ± 0.43 | - | 44.90 ± 0.17 | 400.33 ± 0.56 | 381.68 ± 0.41 | 522.03 ± 0.47 | 5.80 ± 0.38 |

| Parameter | Raw Water | Maximum Allowed Level * |

|---|---|---|

| pH | 8.5 | 6.5–8.5 |

| TSS (mg/L) | 182 | 35 |

| FM (mg/L) | 106 | 20 |

| COD (mg O2/L) | 227 | 125 |

| BOD5 (mg O2/L) | 105 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemțanu, M.R.; Brașoveanu, M.; Pincu, E.; Meltzer, V. Water-Soluble Starch-Based Copolymers Synthesized by Electron Beam Irradiation: Physicochemical and Functional Characterization. Materials 2022, 15, 1061. https://doi.org/10.3390/ma15031061

Nemțanu MR, Brașoveanu M, Pincu E, Meltzer V. Water-Soluble Starch-Based Copolymers Synthesized by Electron Beam Irradiation: Physicochemical and Functional Characterization. Materials. 2022; 15(3):1061. https://doi.org/10.3390/ma15031061

Chicago/Turabian StyleNemțanu, Monica R., Mirela Brașoveanu, Elena Pincu, and Viorica Meltzer. 2022. "Water-Soluble Starch-Based Copolymers Synthesized by Electron Beam Irradiation: Physicochemical and Functional Characterization" Materials 15, no. 3: 1061. https://doi.org/10.3390/ma15031061

APA StyleNemțanu, M. R., Brașoveanu, M., Pincu, E., & Meltzer, V. (2022). Water-Soluble Starch-Based Copolymers Synthesized by Electron Beam Irradiation: Physicochemical and Functional Characterization. Materials, 15(3), 1061. https://doi.org/10.3390/ma15031061