Tunable Energy Absorbing Property of Bilayer Amorphous Glass Foam via Dry Powder Printing

Abstract

1. Introduction

2. Materials and Methods

3. Results

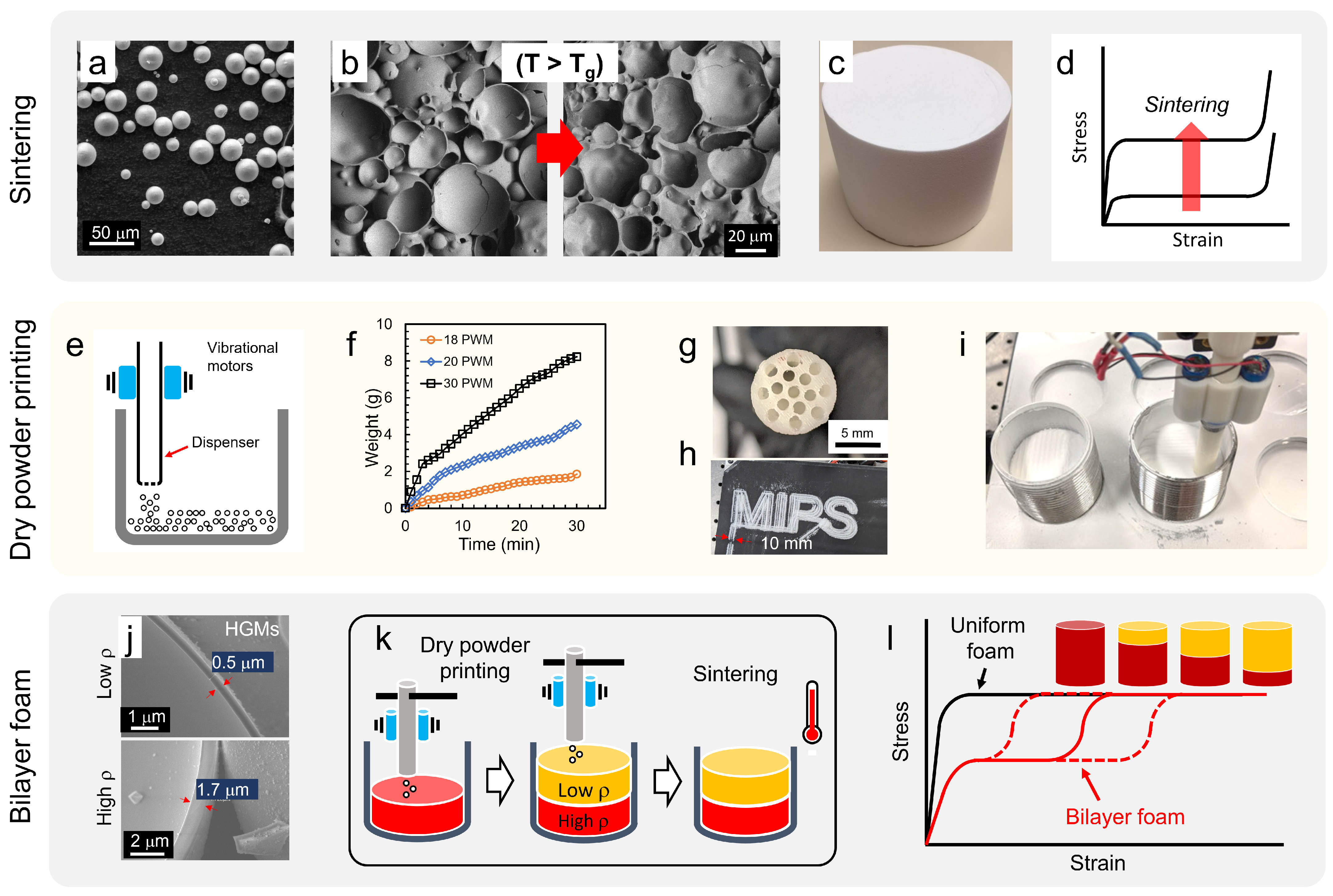

3.1. Dry Powder Printing

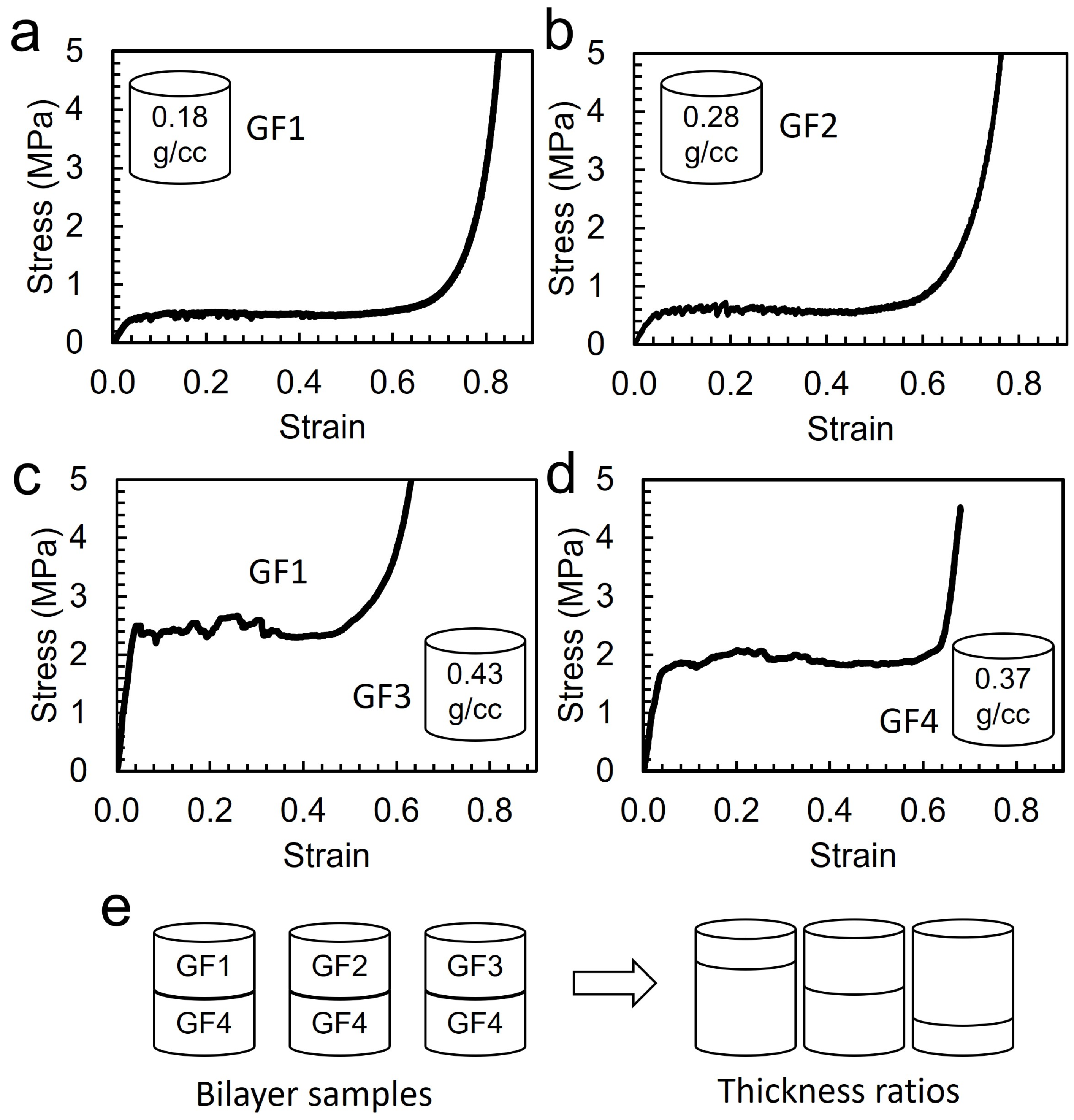

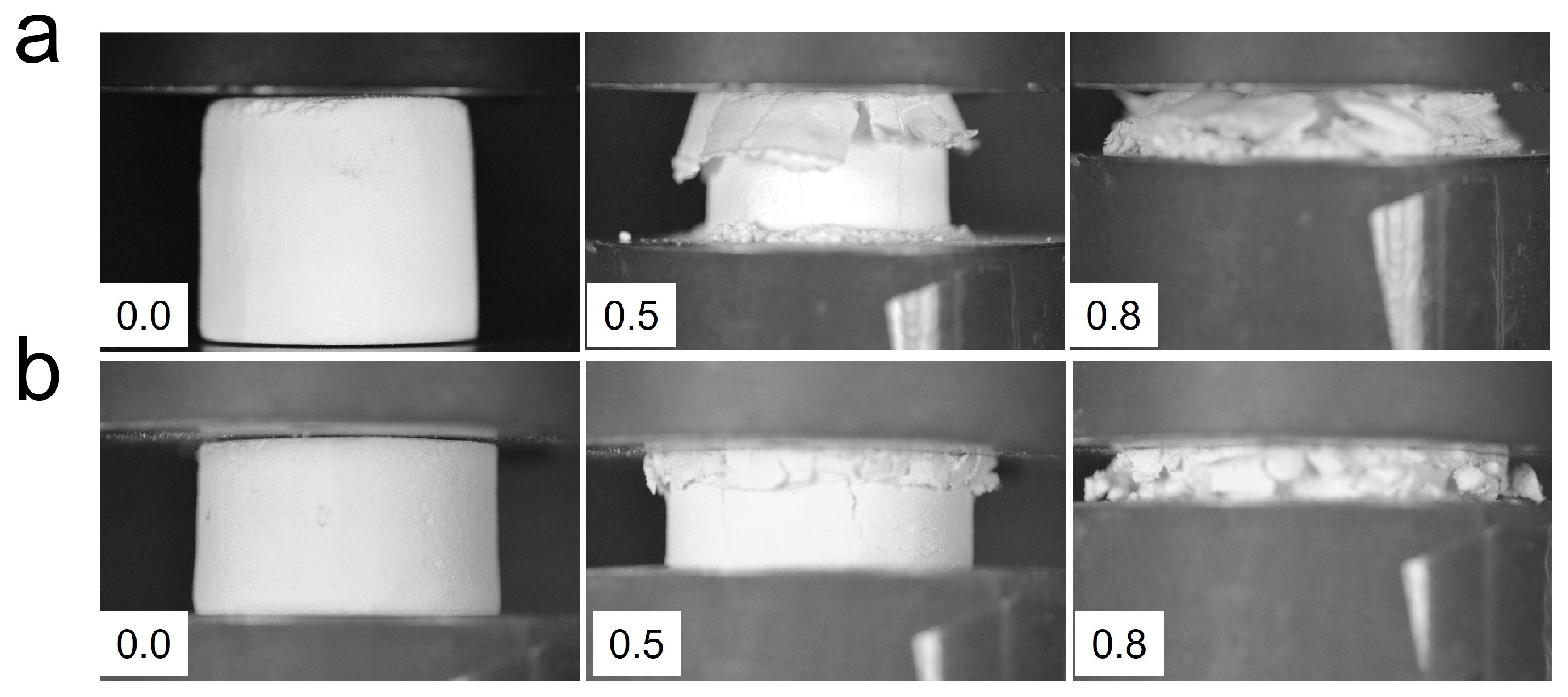

3.2. Uniform Foams

3.3. Bilayer System

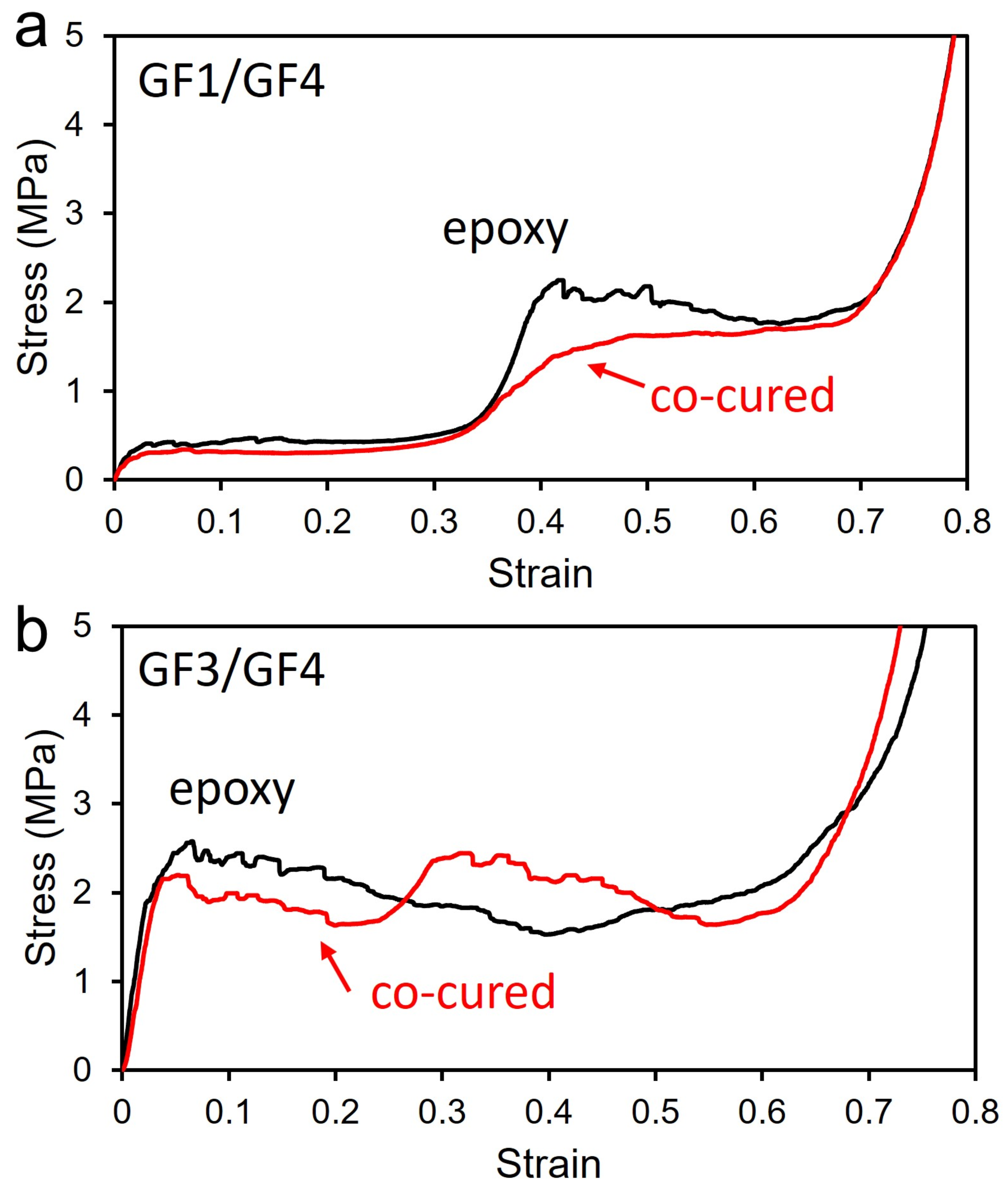

3.4. Epoxy-Bonded vs. Sintered Bilayer Foams

3.5. Energy Absorption and Densification Strain

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DPP | Dry Powder Printing |

| GF | Glass Foam |

| HGM | Hollow Glass Microsphere |

| PWM | Pulsed Width Modulation |

| SEM | Scanning Electron Microscopy |

References

- Hutchinson, T.P. Peak acceleration during impact with helmet materials: Effects of impactor mass and speed. Eur. J. Sport Sci. 2014, 14, S377–S382. [Google Scholar] [CrossRef] [PubMed]

- Subhash, G.; Liu, Q.; Gao, X. Quasistatic and high strain rate uniaxial compressive response of polymeric structural foams. Int. J. Impact Eng. 2006, 32, 1113–1126. [Google Scholar] [CrossRef]

- Gupta, N.; Zeltmann, S.; Shunmugasamy, V.; Pinisetty, D. Applications of polymer matrix syntactic foams. JOM 2014, 66, 245–254. [Google Scholar] [CrossRef]

- Negroni, C. Questioning Safety of Heavy Passengers on Planes. The New York Times, 7 May 2012. [Google Scholar]

- Zhang, H.; Guo, X.; Wu, J.; Fang, D.; Zhang, Y. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 2018, 4, eaar8535. [Google Scholar] [CrossRef] [PubMed]

- Wissman, J.; Ikei, A.; Konarski, S.G.; Rohde, C.A.; Naify, C.J. Tunable acoustics with dielectric elastomer activated granular jamming exhibiting a solid–fluid transition. J. Appl. Phys. 2020, 128, 204901. [Google Scholar] [CrossRef]

- Deshmukh, S.S.; McKinley, G.H. Adaptive energy-absorbing materials using field-responsive fluid-impregnated cellular solids. Smart Mater. Struct. 2006, 16, 106–113. [Google Scholar] [CrossRef]

- Manti, M.; Cacucciolo, V.; Cianchetti, M. Stiffening in soft robotics: A review of the state of the art. IEEE Robot. Autom. Mag. 2016, 23, 93–106. [Google Scholar] [CrossRef]

- Kouwer, P.H.; Koepf, M.; Le Sage, V.A.; Jaspers, M.; Van Buul, A.M.; Eksteen-Akeroyd, Z.H.; Woltinge, T.; Schwartz, E.; Kitto, H.J.; Hoogenboom, R.; et al. Responsive biomimetic networks from polyisocyanopeptide hydrogels. Nature 2013, 493, 651–655. [Google Scholar] [CrossRef]

- Wang, Y.; Ramirez, B.; Carpenter, K.; Naify, C.; Hofmann, D.C.; Daraio, C. Architected lattices with adaptive energy absorption. Extrem. Mech. Lett. 2019, 33, 100557. [Google Scholar] [CrossRef]

- McElroy, H.T.; Guj, L. Modeling the Temperature-Dependent Structural Performance of Rigid Polyurethane and Polyisocyanurate Foams Using Mean-Field Homogenization and Finite Element Analysis. SAMPE J. 2022, 58, 34–43. [Google Scholar]

- Wiest, A.; MacDougall, C.A.; Conner, R.D. Optimization of cellular solids for energy absorption. Scr. Mater. 2014, 84–85, 7–10. [Google Scholar] [CrossRef]

- Avalle, M.; Belingardi, G. A mechanical model of cellular solids for energy absorption. Adv. Eng. Mater. 2019, 21, 1800457. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Maskery, I.; Hussey, A.; Panesar, A.; Aremu, A.; Tuck, C.; Ashcroft, I.; Hague, R. An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 2017, 53, 151–165. [Google Scholar] [CrossRef]

- Mosanenzadeh, S.; Naguib, H.; Park, C.; Atalla, N. Design and development of novel bio-based functionally graded foams for enhanced acoustic capabilities. J. Mater. Sci. 2015, 50, 1248–1256. [Google Scholar] [CrossRef]

- Van Grunsven, W.; Hernandez-Nava, E.; Reilly, G.; Goodall, R. Fabrication and Mechanical Characterisation of Titanium Lattices with Graded Porosity. Metals 2014, 4, 401–409. [Google Scholar] [CrossRef]

- Kaysser, S.T.; Keun, C.A.; Bethke, C.; Altstädt, V. Tailoring epoxy foam properties with an innovative process approach using CO2 as blowing agent. SAMPE J. 2022, 58, 20–33. [Google Scholar]

- Yang, N.; Song, Y.; Huang, J.; Chen, Y.; Maskery, I. Combinational design of heterogeneous lattices with hybrid region stiffness tuning for additive manufacturing. Mater. Des. 2021, 209, 109955. [Google Scholar] [CrossRef]

- He, S.; Lv, Y.; Chen, S.; Dai, G.; Liu, J.; Huo, M. Gradient regulation and compressive properties of density-graded aluminum foam. Mater. Sci. Eng. A 2020, 772, 138658. [Google Scholar] [CrossRef]

- Rodrigo, C.; Xu, S.; Durandet, Y.; Fraser, D.; Ruan, D. Crushing behavior of functionally graded lattice. JOM 2021, 73, 4130–4140. [Google Scholar] [CrossRef]

- Fiedler, T.; Movahedi, N.; York, L.; Broxtermann, S. Functionally-graded metallic syntactic foams produced via particle pre-compaction. Metals 2020, 10, 314. [Google Scholar] [CrossRef]

- Chittineni, K.; Woldesenbet, E. Energy absorption of integrated functionally gradient syntactic foam. J. Cell. Plast. 2010, 46, 295–319. [Google Scholar] [CrossRef]

- Park, J.; Howard, J.; Edery, A.; DeMay, M.; Wereley, N. Bilayer glass foams with tunable energy absorption via localized void clusters. Adv. Eng. Mater. 2021, 23, 2100105. [Google Scholar] [CrossRef]

- Budov, V. Hollow glass microspheres. Use, properties, and technology. Glass Ceramics 1994, 51, 230–235. [Google Scholar] [CrossRef]

- Cochran, J. Ceramic hollow spheres and their applications. Curr. Opin. Solid State Mater. Sci. 1998, 3, 474–479. [Google Scholar] [CrossRef]

- Wang, A.J.; Lu, Y.P.; Sun, R.X. Recent progress on the fabrication of hollow microspheres. Mater. Sci. Eng. A 2007, 460–461, 1–6. [Google Scholar] [CrossRef]

- Bertling, J.; Blömer, J.; Kümmel, R. Hollow microspheres. Chem. Eng. Technol. 2004, 27, 829–837. [Google Scholar] [CrossRef]

- Anirudh, S.; Jayalakshmi, C.; Anand, A.; Kandasubramanian, B.; Ismail, S. Epoxy/glass syntactic foams for structural and functional application - A review. Eur. Polym. J. 2022, 171, 111163. [Google Scholar] [CrossRef]

- Swetha, C.; Kumar, R. Quasi-static uni-axial compression behaviour of hollow glass microspheres/epoxy based syntactic foams. Mater. Des. 2011, 32, 4152–4163. [Google Scholar] [CrossRef]

- Kim, H.S.; Oh, H.H. Manufacturing and impact behavior of syntactic foam. J. Appl. Polym. Sci. 2000, 76, 1324–1328. [Google Scholar] [CrossRef]

- Ozkutlu, M.; Dilek, C.; Bayram, G. Effects of hollow glass microsphere density and surface modification on the mechanical and thermal properties of poly(methyl methacrylate) syntactic foams. Compos. Struct. 2018, 202, 545–550. [Google Scholar] [CrossRef]

- Park, J.; Howard, J.M.; Edery, A.; DeMay, M.; Wereley, N. Process parameter effects on cellular structured materials using hollow glass spheres. Mater. Manuf. Process. 2019, 34, 1026–1034. [Google Scholar] [CrossRef]

- Ghosh, D.; Wiest, A.; Conner, R.D. Uniaxial quasistatic and dynamic compressive response of foams made from hollow glass microspheres. J. Eur. Ceram. Soc. 2016, 36, 781–789. [Google Scholar] [CrossRef]

- Dasan, A.; Kraxner, J.; Grigolato, L.; Savio, G.; Elsayed, H.; Galusek, D.; Bernardo, E. 3D printing of hierarchically porous lattice structures based on Åkermanite glass microspheres and reactive silicone binder. J. Funct. Biomater. 2022, 13, 8. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Guo, Z.; Yan, Y.; Liu, Y.; Han, S.; Ji, P.; Yunusov, F.A.; Tolochko, O.V.; Yin, F. Preparation of lightweight glass microsphere/Al sandwich composites with high compressive properties. Mater. Lett. 2022, 308, 131220. [Google Scholar] [CrossRef]

- Ryzhenkov, A.V.; Loginova, N.A.; Belyaeva, E.V.; Lapin, Y.Y.; Prischepov, A.F. Review of binding agents in syntactic foams for heat-insulating structures in power industry Facilities. Mod. Appl. Sci. 2015, 9, 96. [Google Scholar] [CrossRef][Green Version]

- Baumeister, E.; Klaeger, S. Advanced new lightweight materials: Hollow-sphere composites (HSCs) for mechanical engineering applications. Adv. Eng. Mater. 2003, 5, 673–677. [Google Scholar] [CrossRef]

- Gupta, N.; Pinisetty, D. A review of thermal conductivity of polymer matrix syntactic foams—Effect of hollow particle wall thickness and volume fraction. JOM 2013, 65, 234–245. [Google Scholar] [CrossRef]

- Li, Q.M.; Magkiriadis, I.; Harrigan, J.J. Compressive strain at the onset of densification of cellular solids. J. Cell. Plast. 2006, 42, 371–392. [Google Scholar] [CrossRef]

| Name | 3M Name | Foam Density (g/cc) | Sphere Density (g/cc) | Sphere Diameter | Wall Thickness |

|---|---|---|---|---|---|

| GF1 | K20 | 0.18 | 0.20 | 60 | 0.93 |

| GF2 | K1 | 0.28 | 0.12 | 65 | 0.62 |

| GF3 | S32 | 0.43 | 0.32 | 40 | 1.01 |

| GF4 | K46 | 0.37 | 0.46 | 40 | 1.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Howard, J.; Edery, A.; DeMay, M.; Wereley, N. Tunable Energy Absorbing Property of Bilayer Amorphous Glass Foam via Dry Powder Printing. Materials 2022, 15, 9080. https://doi.org/10.3390/ma15249080

Park J, Howard J, Edery A, DeMay M, Wereley N. Tunable Energy Absorbing Property of Bilayer Amorphous Glass Foam via Dry Powder Printing. Materials. 2022; 15(24):9080. https://doi.org/10.3390/ma15249080

Chicago/Turabian StylePark, Jungjin, John Howard, Avi Edery, Matthew DeMay, and Norman Wereley. 2022. "Tunable Energy Absorbing Property of Bilayer Amorphous Glass Foam via Dry Powder Printing" Materials 15, no. 24: 9080. https://doi.org/10.3390/ma15249080

APA StylePark, J., Howard, J., Edery, A., DeMay, M., & Wereley, N. (2022). Tunable Energy Absorbing Property of Bilayer Amorphous Glass Foam via Dry Powder Printing. Materials, 15(24), 9080. https://doi.org/10.3390/ma15249080