Effect of Volume Fraction of Reinforcement on Microstructure and Mechanical Properties of In Situ (Ti, Nb)B/Ti2AlNb Composites with Tailored Three-Dimensional Network Architecture

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Fabrication of (Ti, Nb)B/Ti2AlNb Composites

2.2. Material Characterization

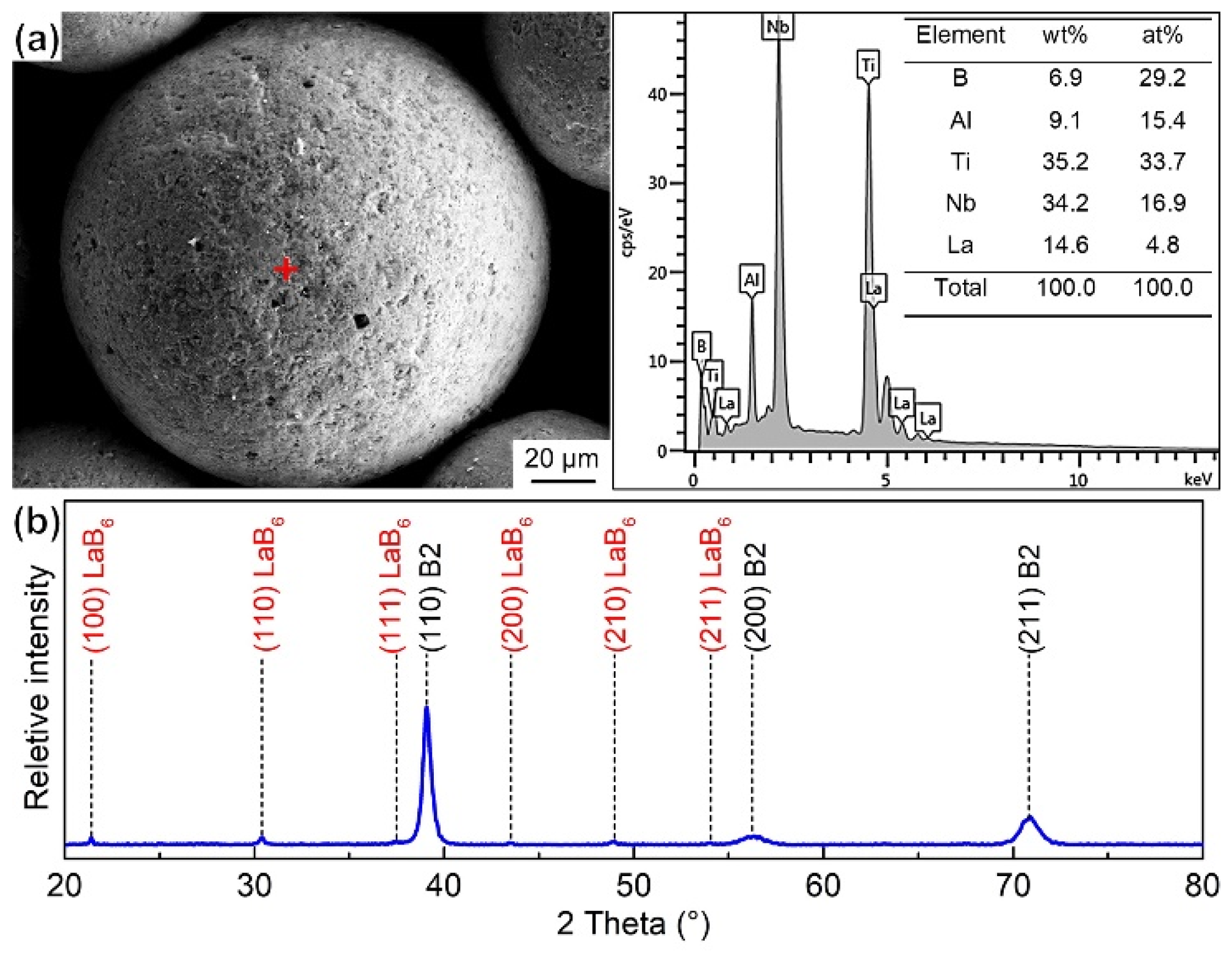

| Phase | Space Group | Composition (at%) | Lattice Parameters (Å) | ||

|---|---|---|---|---|---|

| a | b | c | |||

| B2 | (221) | (Ti, Al, Nb) solid solution | 3.23 | 3.23 | 3.23 |

| α2 | P63/mmc (194) | Ti3Al | 5.74 | 5.74 | 4.64 |

| O | Cmcm (63) | Ti2AlNb | 6.05 | 9.51 | 4.67 |

| B27-(Ti, Nb)B | Pnma (62) | TiNbB2 | 6.16 | 3.10 | 4.65 |

| La2O3 | (164) | La2O3 | 3.94 | 3.94 | 6.13 |

3. Results and Discussion

3.1. Microstructure of (Ti, Nb)B/Ti2AlNb Composites

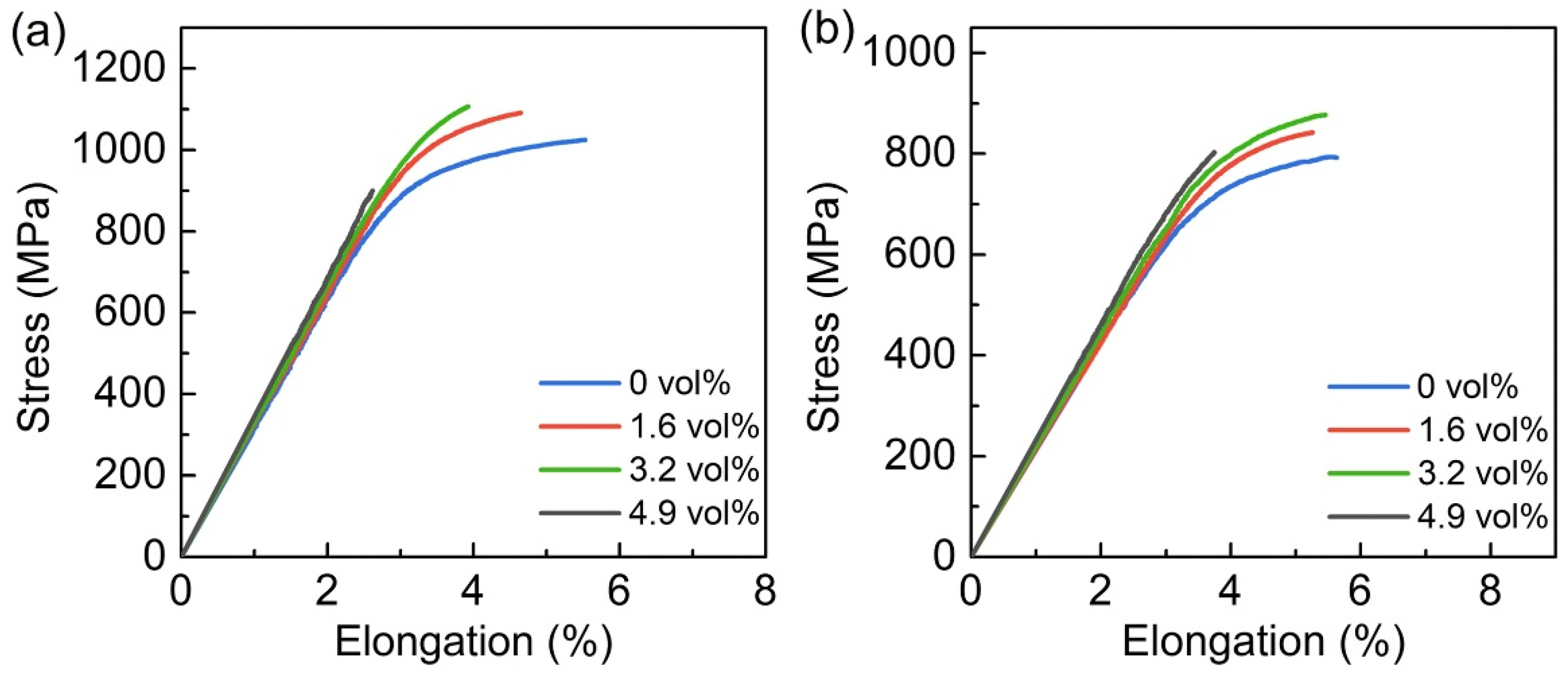

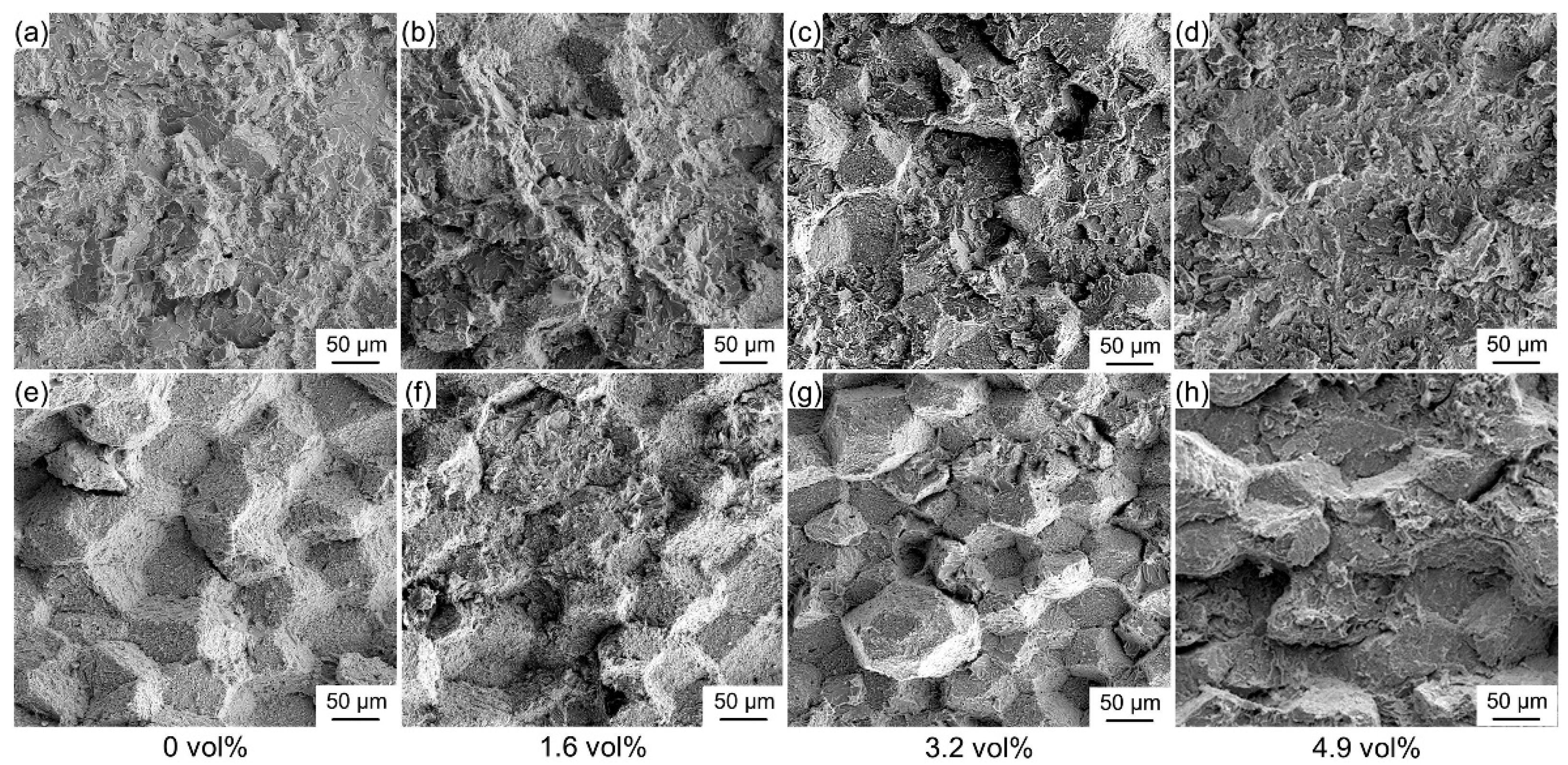

3.2. Mechanical Properties of (Ti, Nb)B/Ti2AlNb Composites

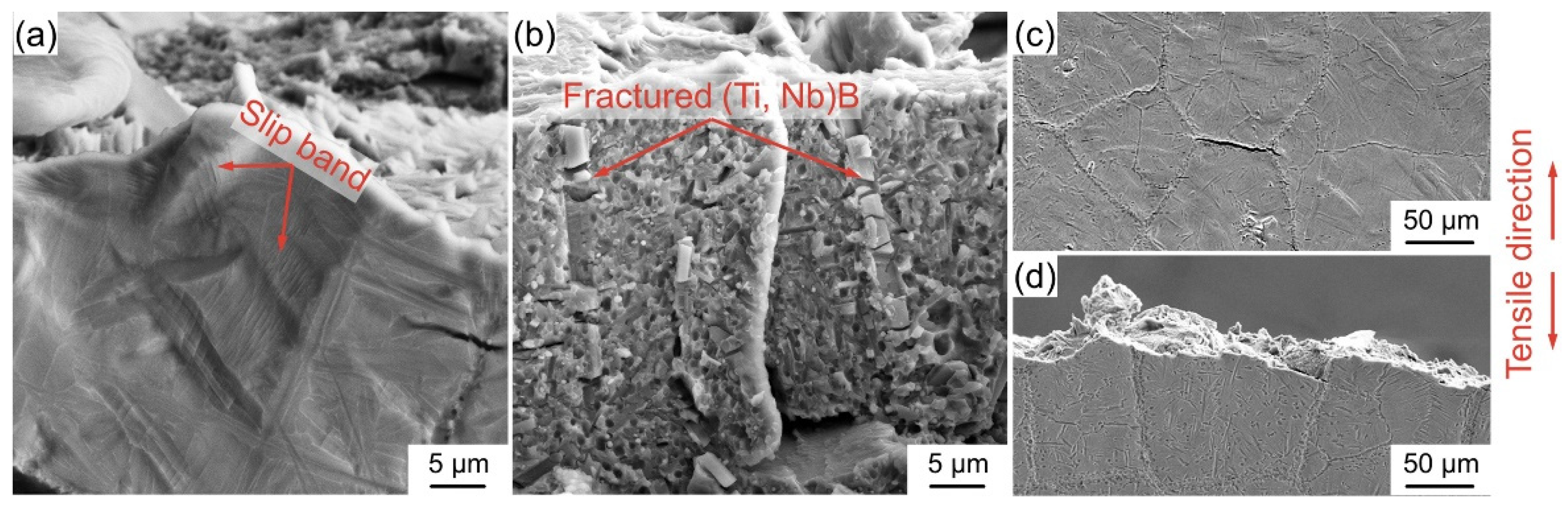

3.3. Relationship between Microstructure and Mechanical Properties

3.3.1. α2-Precipitated Amount

3.3.2. (Ti, Nb)B Morphology and Synthesized Amount

4. Conclusions

- (1)

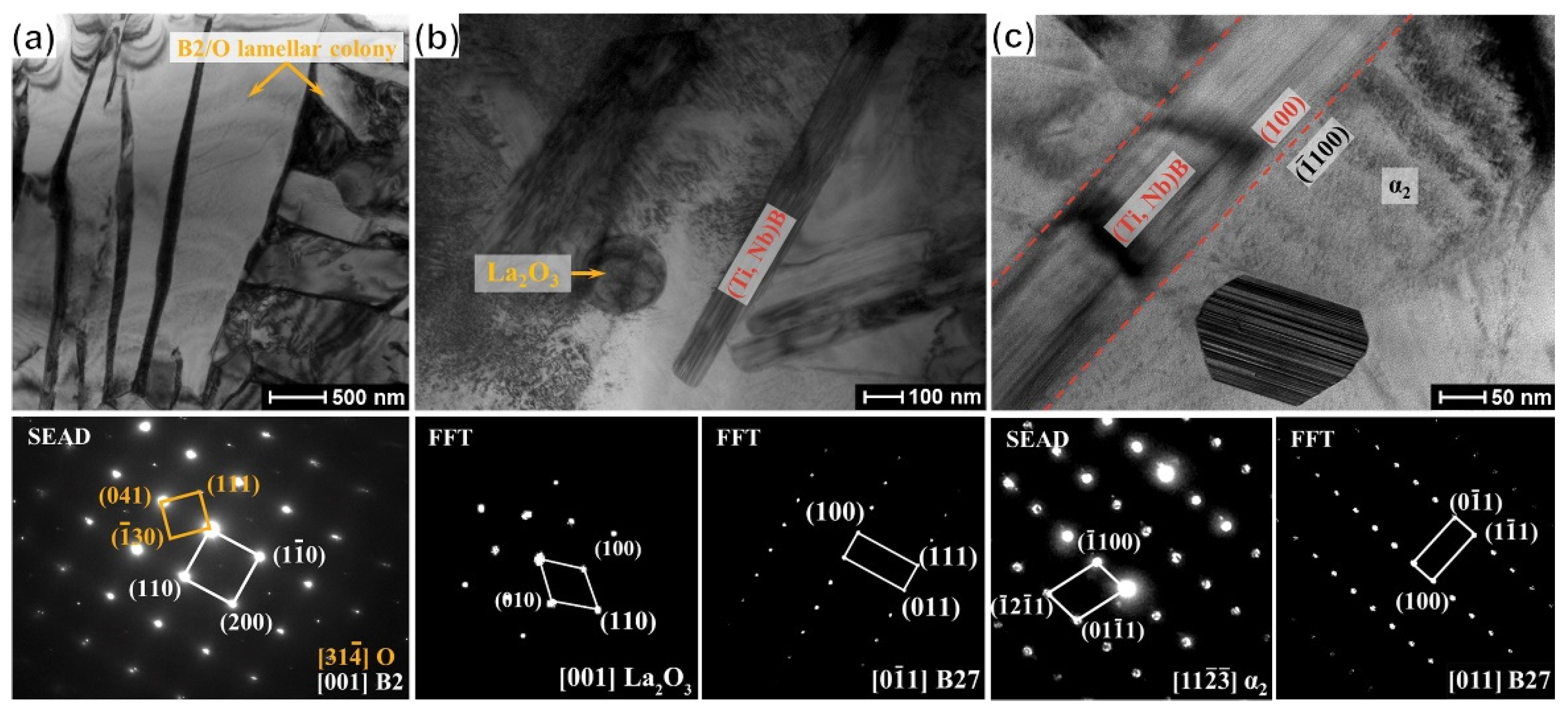

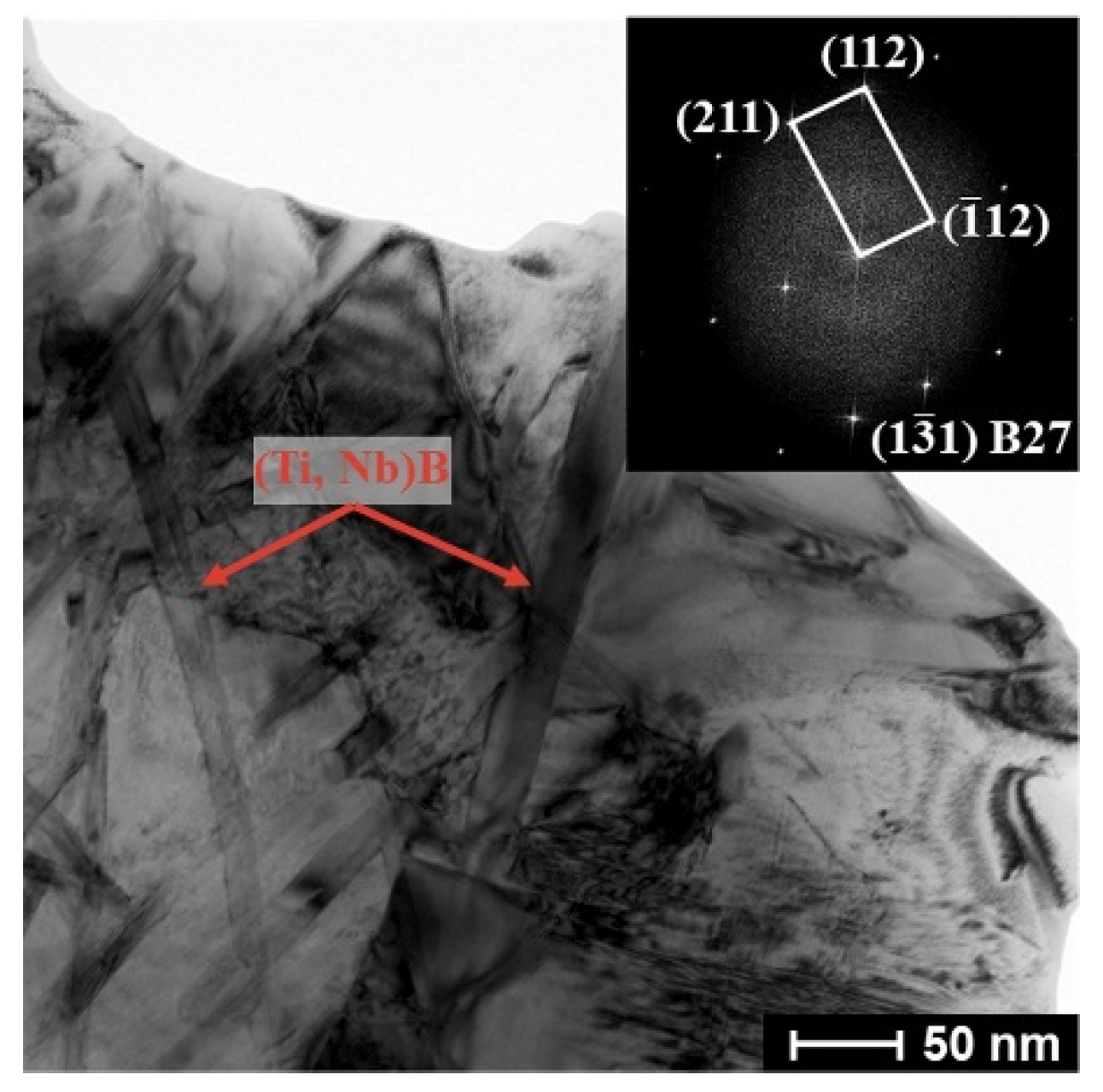

- The (Ti, Nb)B/Ti2AlNb composites with tailored three-dimensional network architecture, in which the boride crystalized into a B27 crystal structure and gathered in the prior article boundaries (PPBs) area, was successfully fabricated by ball milling and subsequent spark plasma sintering.

- (2)

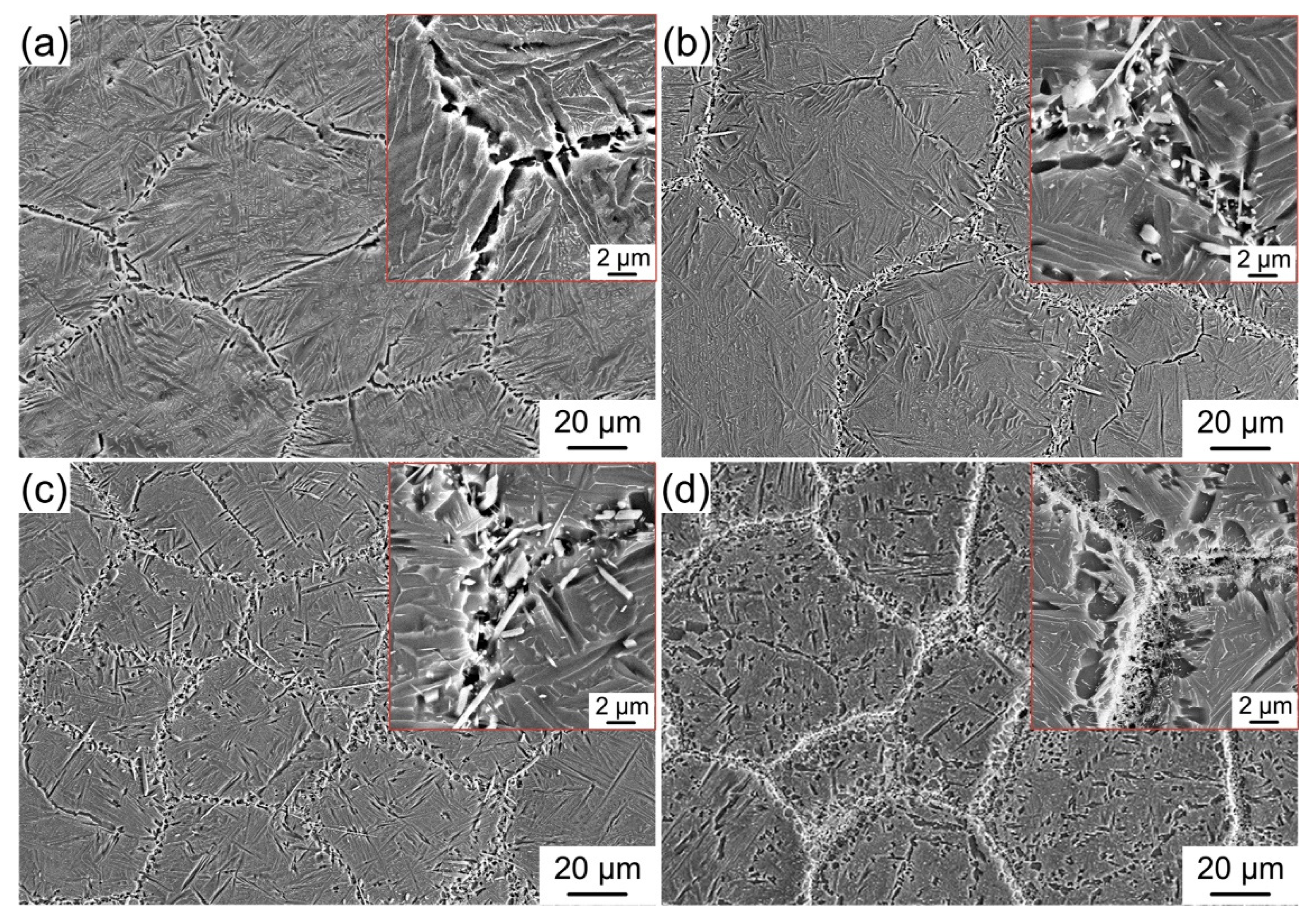

- The synthesized content of boride altered the α2-precipitated amount and the (Ti, Nb)B morphology. When the boride content reached a specific value, the (Ti, Nb)B reinforcement agglomerated in the PPBs area due to insufficient growth, and the brittle α2 phase precipitated continuously adjacent to the reinforcement.

- (3)

- When the (Ti, Nb)B content reached a reasonable range, the yield strength of the composites improved and the ductility exhibited an opposite trend with the increase in the volume fraction of reinforcement. The (Ti, Nb)B incorporation inhibited the strength weakening of the PPBs area at high temperatures, which significantly increased the strength of the composites.

- (4)

- By reducing the α2-precipitated content in the PPBs area and avoiding agglomeration of boride by increasing the (Ti, Nb)B growth length, these were both effective methods to improve the mechanical properties of the composite with a high volume fraction of reinforcement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, S.K.; Shang, Y.; Zhang, J.; Guo, X.P.; Lin, J.P.; Zhao, X.H. Application and Research of Typical Intermetallics-Based High Temperature Structural Materials in China. Acta Met. Sin 2019, 55, 1067–1076. [Google Scholar]

- Praveen, S.; Kim, H.S. High-Entropy Alloys: Potential Candidates for High-Temperature Applications—An Overview. Adv. Eng. Mater. 2018, 20, 1700645. [Google Scholar] [CrossRef]

- Couret, A.; Voisin, T.; Thomas, M.; Monchoux, J.P. Development of a TiAl Alloy by Spark Plasma Sintering. JOM 2017, 69, 2576–2582. [Google Scholar] [CrossRef]

- Emura, S.; Hagiwara, M.; Yang, S.J. Room-Temperature Tensile and High-Cycle-Fatigue Strength of Fine TiB Particulate-Reinforced Ti-22Al-27Nb Composites. Met. Mater Trans A 2004, 35, 2971–2979. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Sha, A.; Li, X. Effect of Surface Integrity on Hot Fatigue Life of Ti2AlNb Intermetallic Alloy. Materials 2021, 14, 4841. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.Y.; Yan, N.; Liang, H.Y.; Liu, Y.C. Phase Transformation and Microstructure Control of Ti2AlNb-Based Alloys: A Review. J. Mater. Sci. Technol. 2021, 80, 203–216. [Google Scholar] [CrossRef]

- Hagiwara, M.; Emura, S.; Araoka, A.; Kong, B.O.; Tang, F. Enhanced Mechanical Properties of Orthorhombic Ti2AlNb-Based Intermetallic Alloy. Met. Mater. Int. 2003, 9, 265–272. [Google Scholar] [CrossRef]

- Yang, S.J.; Emura, S.; Nam, S.W.; Hagiwara, M.; Jeon, H.S.; Yoon, S.B. Improvement of Creep Resistance in TiB Particle Reinforced Ti2AlNb Composite Particularly above 700 °C. Mater. Lett. 2004, 58, 3187–3191. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, H.X.; Wang, Q.J.; Han, Z.R.; Wang, K.S. Preparation and Tribological Behavior of Ti2AlNb/Ag Self-Lubricating Composites. J. Mater. Eng. Perform. 2020, 29, 5959–5967. [Google Scholar] [CrossRef]

- Wang, W.; Han, Z.R.; Wang, Q.J.; Wei, B.J.; Wang, K.S. Influence of Heat Treatment on the Microstructure Evolution and Mechanical Properties of Graphene/Ti2AlNb Composites Synthesized via Spark Plasma Sintering. J. Mater. Eng. Perform. 2020, 29, 7587–7597. [Google Scholar] [CrossRef]

- Wang, W.; Han, Z.R.; Wang, Q.J.; Wei, B.J.; Gao, Y. Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering. Metals 2020, 10, 924. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Cai, Q.; Liu, Y.C.; Ma, Z.Q.; Li, C.; Li, H.J. Evaluation of Precipitation Hardening in TiC-Reinforced Ti2AlNb-Based Alloys. Int. J. Min. Met. Mater. 2018, 25, 453–458. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Cai, Q.; Liu, Y.C.; Guo, Q.Y.; Li, H.J. Precipitation of Carbides and Dissolution of Widmanstätten Structure for Enhanced Hardness in Ti2AlNb-Based Alloys. J. Mater. Eng. Perform. 2019, 28, 1892–1901. [Google Scholar] [CrossRef]

- Polozov, I.; Sufiiarov, V.; Starikov, K.; Popovich, A. In Situ Synthesized Ti2AlNb-Based Composites Produced by Selective Laser Melting by Addition of SiC-Whiskers. Mater. Lett. 2021, 297, 129956. [Google Scholar] [CrossRef]

- Boehlert, C.J.; Sabirov, I.; Ruiz-Palenzuela, B.; Cornide, J.; Ruiz-Navas, E.M. A comparison of Field Assisted Hot Pressing and Hot Isostatic Pressing for Gas Atomized Ti-22Al-26Nb (at.%) and Ti-22Al-26Nb-5B (at.%) Powders. J. Alloy. Compd. 2021, 852, 156870. [Google Scholar] [CrossRef]

- Emura, S.; Hagiwara, M. Effect of Heat Treatment on the Creep Properties of Ti-22Al-27Nb/TiB Composite. Key Eng. Mater. 2007, 345–346, 545–548. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, G.F.; Jiao, X.Y.; Li, X.; Yang, C. Hot Deformation Behavior and Microstructural Evolution of Ti-22Al-25Nb-1.0B Alloy Prepared by Elemental Powder Metallurgy. J. Alloy. Compd. 2017, 695, 1038–1044. [Google Scholar] [CrossRef]

- Yang, S.J.; Emura, S.; Hagiwara, M.; Nam, S.W. The role of TiB Particulate Reinforcement in Ti2AlNb Based Composite Under High Cycle Fatigue. Scr. Mater. 2003, 49, 897–902. [Google Scholar] [CrossRef]

- Tang, F.; Emura, S.; Hagiwara, M. Reinforcing Effect of in situ Grown TiB Fibers on Ti-22Al-11Nb-4Mo Alloy. Scr. Mater. 2000, 43, 573–578. [Google Scholar] [CrossRef]

- Cowen, C.J.; Boehlert, C.J. Comparison of the Microstructure, Tensile, and Creep Behavior for Ti-22Al-26Nb (at. pct) and Ti-22Al-26Nb-5B (at. pct). Met. Mater. Trans. A 2007, 38, 26–34. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/Synthesis of Materials by Electric Current Activated/Assisted Sintering. Mater. Sci. Eng. R Rep. 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Huang, L.Q.; Wang, L.H.; Qian, M.; Zou, J. High tensile-strength and ductile titanium matrix composites strengthened by TiB nanowires. Scr. Mater. 2017, 141, 133–137. [Google Scholar] [CrossRef]

- Huang, L.Q.; Huang, Q. High-Strength Ti–BN Composites with Core-Shell Structured Matrix and Network-Woven Structured TiB Nanowires. Trans. Nonferrous Met. Soc 2022, 32, 1169–1177. [Google Scholar] [CrossRef]

- Zhang, N.; Sun, D.; Han, X.; Wang, Z.; Liu, H.; Wang, Z.; Yang, W.; Wu, G. Effect of Spark Plasma Sintering Temperatures on Microstructure and Mechanical Properties of in-situ (La2O3+TiB)/Ti2AlNb Composites with a Tailored Three-Dimensional Network Architecture. Mater. Sci. Eng. A -Struct. 2020, 772, 138769. [Google Scholar] [CrossRef]

- Hagiwara, M.; Kitaura, T.; Ono, Y.; Yuri, T.; Ogata, T.; Emura, S. Tensile and High Cycle Fatigue Properties of a Minor Boron-Modified Ti-22Al-11Nb-2Mo-1Fe Alloy. Mater. Trans. 2012, 53, 1138–1147. [Google Scholar] [CrossRef]

- Zhang, C.J.; Kong, F.T.; Xiao, S.L.; Zhao, E.T.; Xu, L.J.; Chen, Y.Y. Evolution of Microstructure and Tensile Properties of in situ Titanium Matrix Composites with Volume Fraction of (TiB+TiC) Reinforcements. Mater. Sci. Eng. A -Struct. 2012, 548, 152–160. [Google Scholar] [CrossRef]

- Liu, B.X.; Huang, L.J.; Geng, L.; Wang, B.; Cui, X.P. Effects of Reinforcement Volume Fraction on Tensile Behaviors of Laminated Ti–TiBw/Ti Composites. Mater. Sci. Eng. A -Struct. 2014, 610, 344–349. [Google Scholar] [CrossRef]

- Wang, M.; Lu, W.; Qin, J.; Ma, F.; Lu, J.; Zhang, D. Effect of Volume Fraction of Reinforcement on Room Temperature Tensile Property of in situ (TiB+TiC)/Ti Matrix Composites. Mater. Des. 2006, 27, 494–498. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Liu, Y.C.; Yu, L.M.; Liang, H.Y.; Huang, Y.; Ma, Z.Q. Microstructures and Tensile Properties of Ti2AlNb and Mo-Modified Ti2AlNb Alloys Fabricated by Hot Isostatic Pressing. Mater. Sci. Eng. A -Struct. 2020, 776, 139043. [Google Scholar] [CrossRef]

- Zhang, N.B.; Han, X.L.; Sun, D.L.; Liu, H.; Xue, W.; Ju, B.Y.; Wu, G.H. Crystallographic Orientation Relationships and Interfacial Structures between Reinforcement and Matrix Phases in an in situ (Ti, Nb)B/Ti2AlNb Composite. Appl. Surf. Sci. 2021, 542, 148592. [Google Scholar] [CrossRef]

- Gouteron, J.; Michel, D.; Lejus, A.M.; Zarembowitch, J. Raman Spectra of Lanthanide Sesquioxide Single Crystals: Correlation between A and B-Type Structures. J. Solid State Chem. 1981, 38, 288–296. [Google Scholar] [CrossRef]

- Cowen, C.J.; Boehlert, C.J. Microstructure, Tensile, and Creep Behavior of Boron-Modified Ti-15Al-33Nb (at.%). Met. Mater. Trans. A 2008, 39, 279–293. [Google Scholar] [CrossRef]

- De Graef, M.; Lofvander, J.P.A.; Mccullough, C.; Levi, C.G. The Evolution of Metastable Bf Borides in a Ti-Al-B Alloy. Acta Metall. Et Mater. 1992, 40, 3395–3406. [Google Scholar] [CrossRef]

- Ropars, L.; Dehmas, M.; Gourdet, S.; Delfosse, J.; Tricker, D.; Aeby-Gautier, E. Structure Evolutions in a Ti-6Al-4V Matrix Composite Reinforced with TiB, Characterised Using High Energy X-ray Diffraction. J. Alloy. Compd. 2015, 624, 179–188. [Google Scholar] [CrossRef]

- Zhang, N.B.; Han, X.L.; Sun, D.L.; Liu, S.A.; Li, H.; Yang, W.S.; Wu, G.H. Microstructure Evolution and Mechanical Properties of LaB6-Modified Ti2AlNb Alloy Fabricated by Blended Elemental Powder Metallurgy. Powder Technol. 2020, 369, 334–344. [Google Scholar] [CrossRef]

- Trzaska, Z.; Couret, A.; Monchoux, J.P. Spark Plasma Sintering Mechanisms at the Necks between TiAl Powder Particles. Acta Mater. 2016, 118, 100–108. [Google Scholar] [CrossRef]

- Banerjee, D. The intermetallic Ti2AlNb. Prog. Mater. Sci. 1997, 42, 135–158. [Google Scholar] [CrossRef]

- Chawla, N.; Shen, Y.L. Mechanical Behavior of Particle Reinforced Metal Matrix Composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Song, S.G.; Shi, N.; Gray, G.T.; Roberts, J.A. Reinforcement Shape Effects on the Fracture Behavior and Ductility of Particulate-Reinforced 6061-Al Matrix Composites. Met. Mater. Trans. A 1996, 27, 3739–3746. [Google Scholar] [CrossRef]

- Emura, S.; Araoka, A.; Hagiwara, M. B2 Grain Size Refinement and its Effect on Room Temperature Tensile Properties of a Ti-22Al-27Nb Orthorhombic Intermetallic Alloy. Scr. Mater. 2003, 48, 629–634. [Google Scholar] [CrossRef]

- Xue, C.; Zeng, W.D.; Xu, B.; Liang, X.B.; Zhang, J.W.; Li, S.Q. B2 Grain Growth and Particle Pinning Effect of Ti-22Al-25Nb Orthorhombic Intermetallic Alloy during Heating Process. Intermetallics 2012, 29, 41–47. [Google Scholar] [CrossRef]

- Boehlert, C.J. Part III. The Tensile Behavior of Ti-Al-Nb O+Bcc Orthorhombic Alloys. Met. Mater. Trans. A 2001, 32, 1977–1988. [Google Scholar] [CrossRef]

- Nandy, T.K.; Banerjee, D. Creep of the Orthorhombic Phase Based on the Intermetallic Ti2AlNb. Intermetallics 2000, 8, 915–928. [Google Scholar] [CrossRef]

- Banerjee, D. Deformation of the O and α2 Phase in the Ti-Al-Nb System. Philos. Mag. A 1995, 72, 1559–1587. [Google Scholar] [CrossRef]

- Hu, K.M.; Huang, J.C.; Wei, Z.Y.; Peng, Q.; Xie, Z.Y.; Sa, B.S.; Wu, B. Elastic and Thermodynamic Properties of the Ti2AlNb Orthorhombic Phase from First-Principles Calculations. Phys. Status Solidi B 2017, 254, 1600634. [Google Scholar] [CrossRef]

- Wu, B.; Zinkevich, M.; Aldinger, F.; Chu, M.Y.; Shen, J.Y. Prediction of the Ordering Behaviours of the Orthorhombic Phase Based on Ti2AlNb Alloys by Combining Thermodynamic Model with ab Initio Calculation. Intermetallics 2008, 16, 42–51. [Google Scholar] [CrossRef]

- Zeng, X.S.; Peng, R.F.; Yu, Y.L.; Hu, Z.F.; Wen, Y.F.; Song, L. Pressure Effect on Elastic Constants and Related Properties of Ti3Al Intermetallic Compound: A First-Principles Study. Materials 2018, 11, 2015. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites: A Model for Predicting Their Yield Strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W.; Wang, X.; Li, Y.; Ning, F.; Wang, H. Laser Deposition-Additive Manufacturing of TiB-Ti Composites with Novel Three-Dimensional Quasi-Continuous Network Microstructure: Effects on Strengthening and Toughening. Compos. Part B Eng. 2018, 133, 91–100. [Google Scholar] [CrossRef]

- Cai, C.; He, S.; Li, L.F.; Teng, Q.; Song, B.; Yan, C.Z.; Wei, Q.S.; Shi, Y.S. In-situ TiB/Ti-6Al-4V Composites with a Tailored Architecture Produced by Hot Isostatic Pressing: Microstructure Evolution, Enhanced Tensile Properties and Strengthening Mechanisms. Compos. Part B Eng. 2019, 164, 546–558. [Google Scholar] [CrossRef]

- Feng, Y.Q.; Feng, K.; Yao, C.W.; Li, Z.G. Effect of LaB6 Addition on the Microstructure and Properties of (Ti3Al+TiB)/Ti Composites by Laser Cladding. Mater. Des. 2019, 181, 107959. [Google Scholar] [CrossRef]

- Koko, A.; Elmukashfi, E.; Becker, T.H.; Karamched, P.S.; Wilkinson, A.J.; Marrow, T.J. In situ Characterisation of the Strain Fields of Intragranular Slip Bands in Ferrite by High-Resolution Electron Backscatter Diffraction. Acta Mater. 2022, 239, 118284. [Google Scholar] [CrossRef]

- Yang, Q.; Hu, Y.; Zuo, J.-M. The Dislocation Structure of Slip Bands in Deformed High Entropy Alloy Nanopillars. J. Mater. Sci. Technol. 2021, 95, 136–144. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Savvakin, D.G.; Stasiuk, O.O.; Rad, M.N.; Prikhodko, S.V. Multi-layered Structures of Ti-6Al-4V Alloy and TiC and TiB Composites on its Base Fabricated Using Blended Elemental Powder Metallurgy. J. Mater. Process. Technol. 2019, 269, 172–181. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Huang, L.; An, Q.; Geng, L.; Wang, S.; Jiang, S.; Cui, X.; Zhang, R.; Sun, F.; Jiao, Y.; Chen, X.; et al. Multiscale Architecture and Superior High-Temperature Performance of Discontinuously Reinforced Titanium Matrix Composites. Adv. Mater. 2021, 33, e2000688. [Google Scholar] [CrossRef] [PubMed]

| V(Ti,Nb)B (vol%) | Dm (μm) | Dr (μm) | VL (vol%) |

|---|---|---|---|

| 0.0 | 92.0 | — | — |

| 1.6 | 15.5 | 3.8 | |

| 3.2 | 13.8 | 8.3 | |

| 4.9 | 2.0 | 76.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Ju, B.; Deng, T.; Fu, S.; Duan, C.; Song, Y.; Jiang, Y.; Shen, Q.; Yao, C.; Liu, M.; et al. Effect of Volume Fraction of Reinforcement on Microstructure and Mechanical Properties of In Situ (Ti, Nb)B/Ti2AlNb Composites with Tailored Three-Dimensional Network Architecture. Materials 2022, 15, 9070. https://doi.org/10.3390/ma15249070

Zhang N, Ju B, Deng T, Fu S, Duan C, Song Y, Jiang Y, Shen Q, Yao C, Liu M, et al. Effect of Volume Fraction of Reinforcement on Microstructure and Mechanical Properties of In Situ (Ti, Nb)B/Ti2AlNb Composites with Tailored Three-Dimensional Network Architecture. Materials. 2022; 15(24):9070. https://doi.org/10.3390/ma15249070

Chicago/Turabian StyleZhang, Ningbo, Boyu Ju, Taiqing Deng, Sen Fu, Cungao Duan, Yiwei Song, Yijun Jiang, Qin Shen, Caogen Yao, Mingda Liu, and et al. 2022. "Effect of Volume Fraction of Reinforcement on Microstructure and Mechanical Properties of In Situ (Ti, Nb)B/Ti2AlNb Composites with Tailored Three-Dimensional Network Architecture" Materials 15, no. 24: 9070. https://doi.org/10.3390/ma15249070

APA StyleZhang, N., Ju, B., Deng, T., Fu, S., Duan, C., Song, Y., Jiang, Y., Shen, Q., Yao, C., Liu, M., Wu, P., Xiu, Z., & Yang, W. (2022). Effect of Volume Fraction of Reinforcement on Microstructure and Mechanical Properties of In Situ (Ti, Nb)B/Ti2AlNb Composites with Tailored Three-Dimensional Network Architecture. Materials, 15(24), 9070. https://doi.org/10.3390/ma15249070