Effect of Intercritical Temperature on the Microstructure and Mechanical Properties of a Ferritic–Martensitic Dual-Phase Low-Alloy Steel with Varying Nickel Content

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

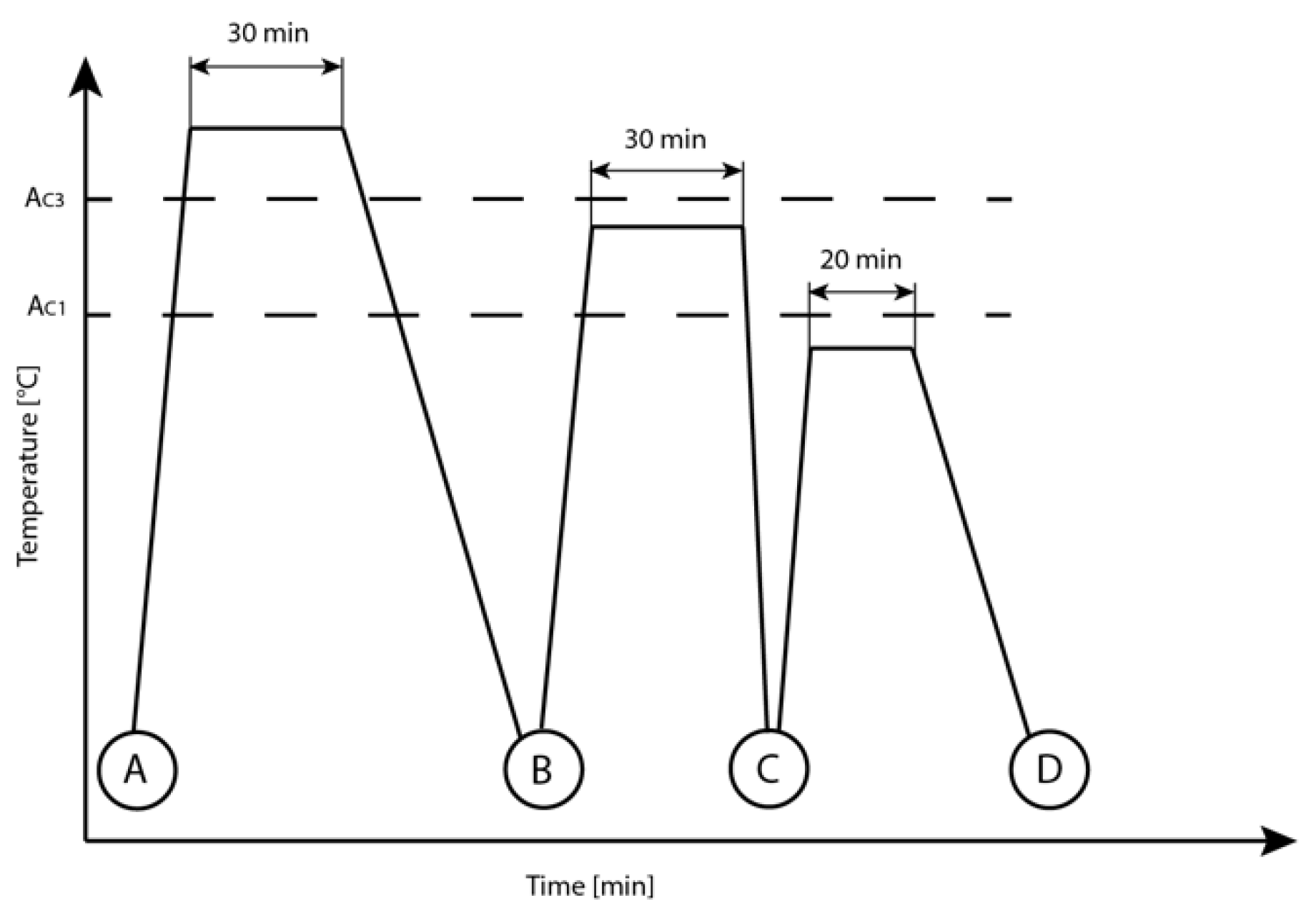

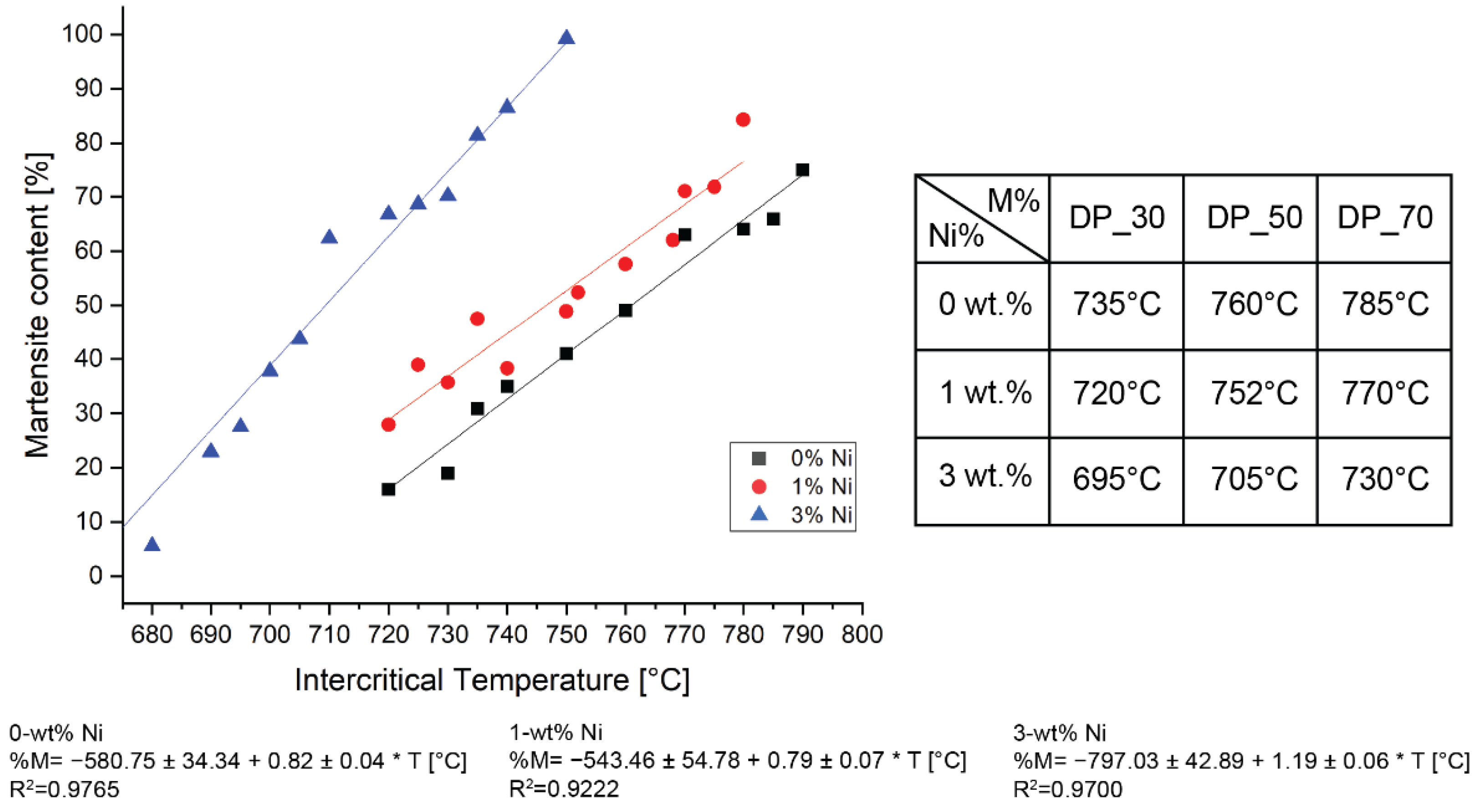

2.2. Heat Treatment Design

2.3. Microstructure Characterisation

2.4. Quantification of Retained Austenite by XRD

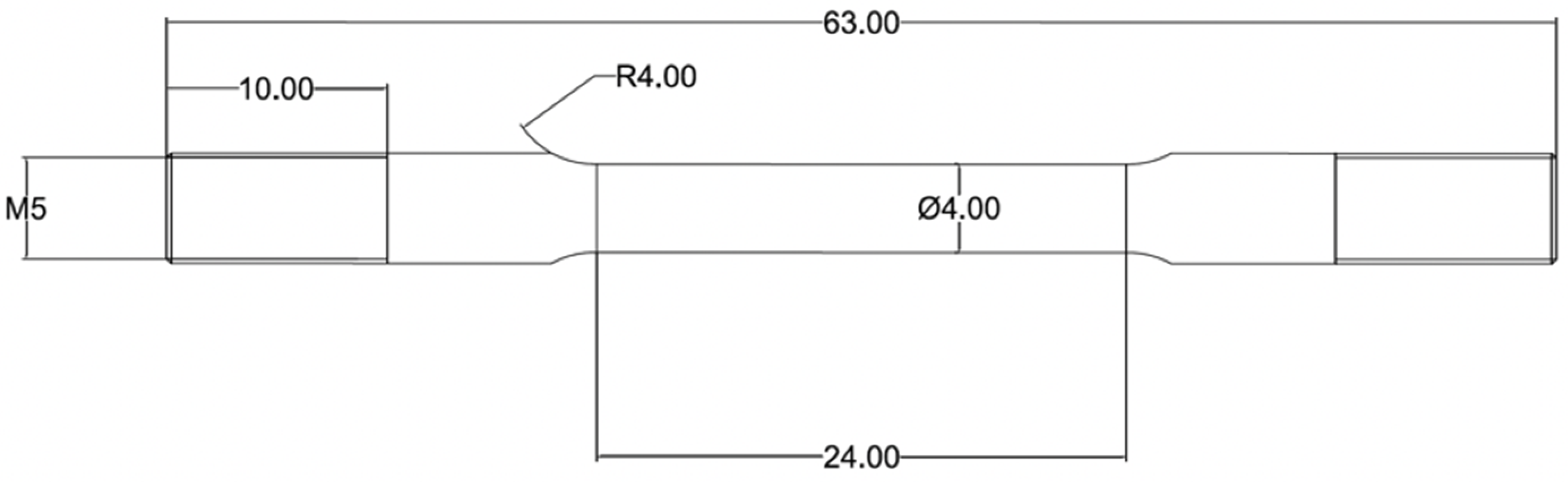

2.5. Mechanical Characterisation and Fractography

3. Results

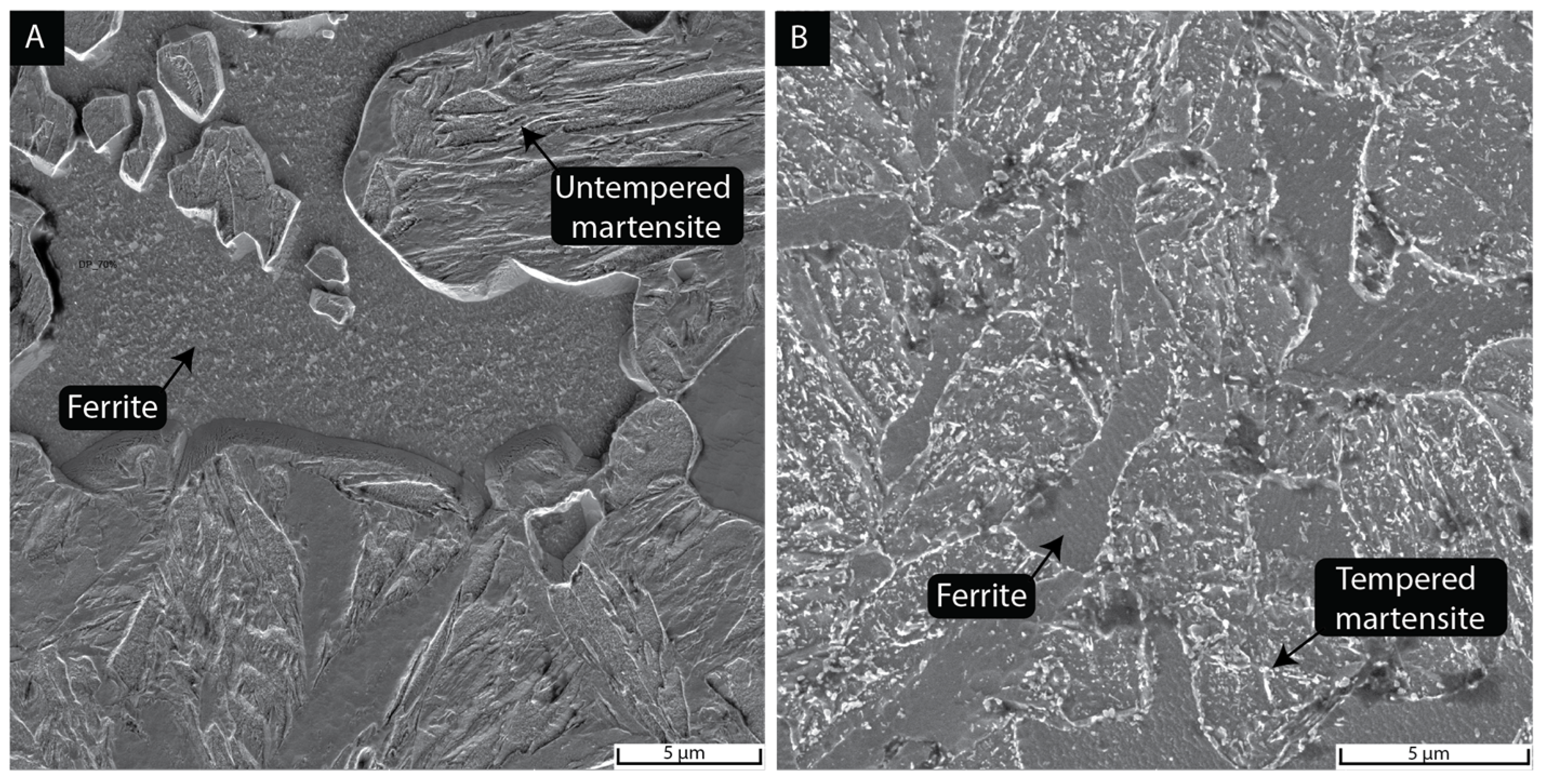

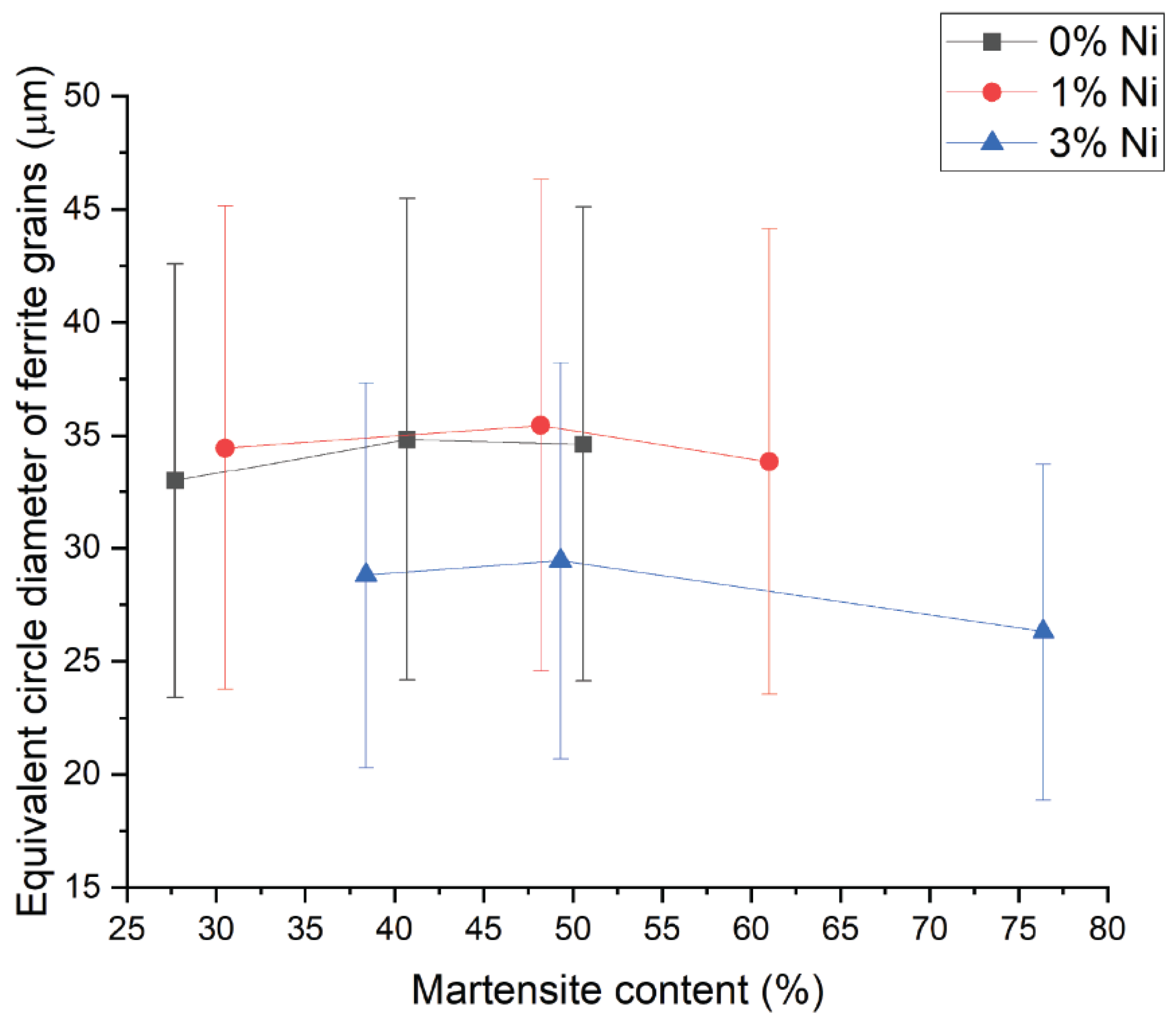

3.1. Microstructure Characterisation

3.2. Quantification of Retained Austenite by XRD

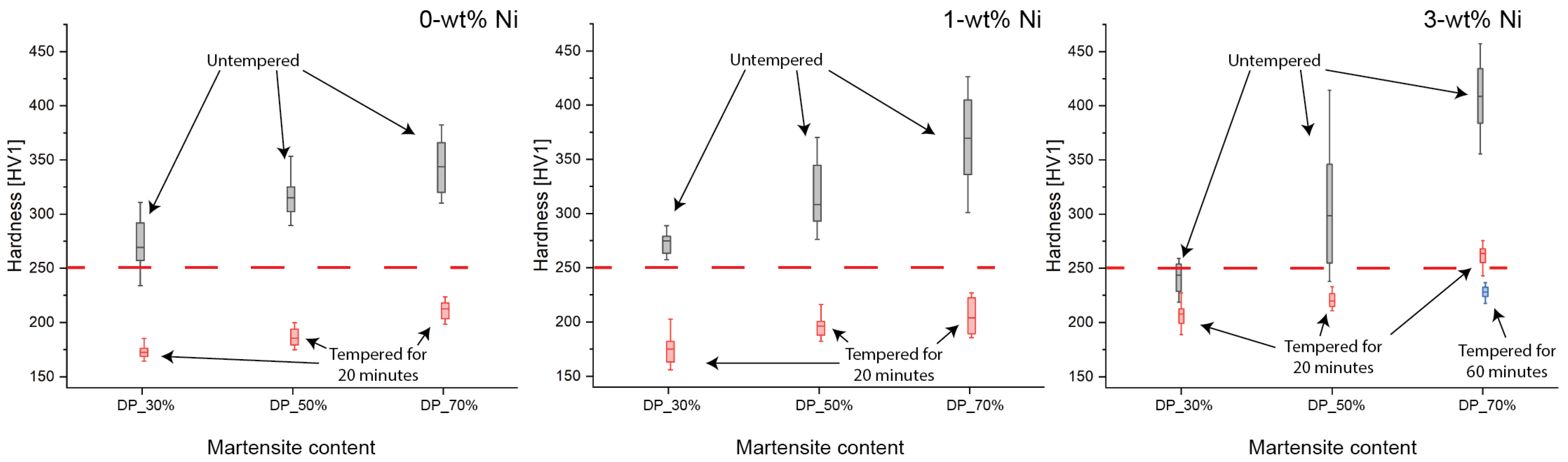

3.3. Mechanical Characterisation

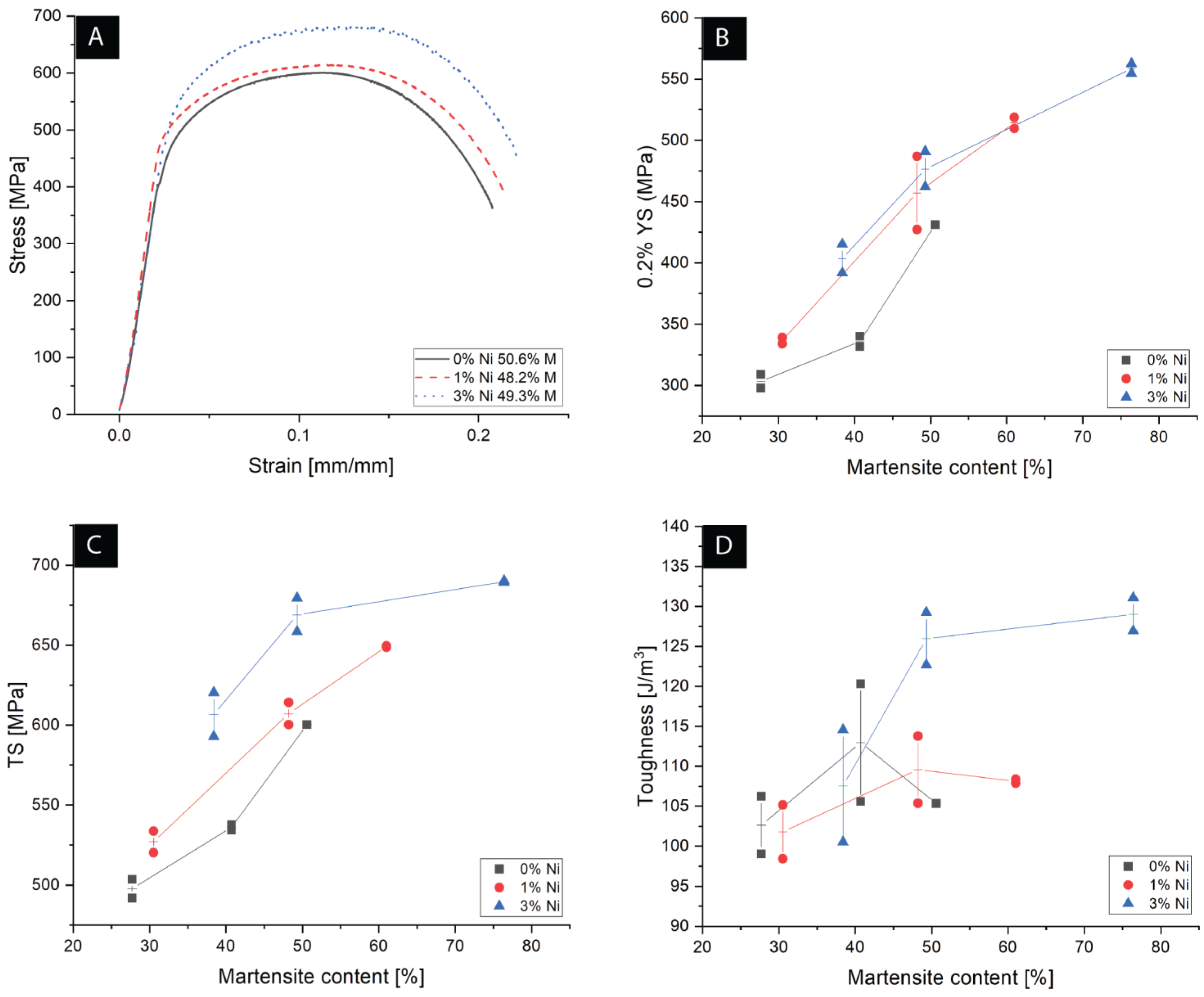

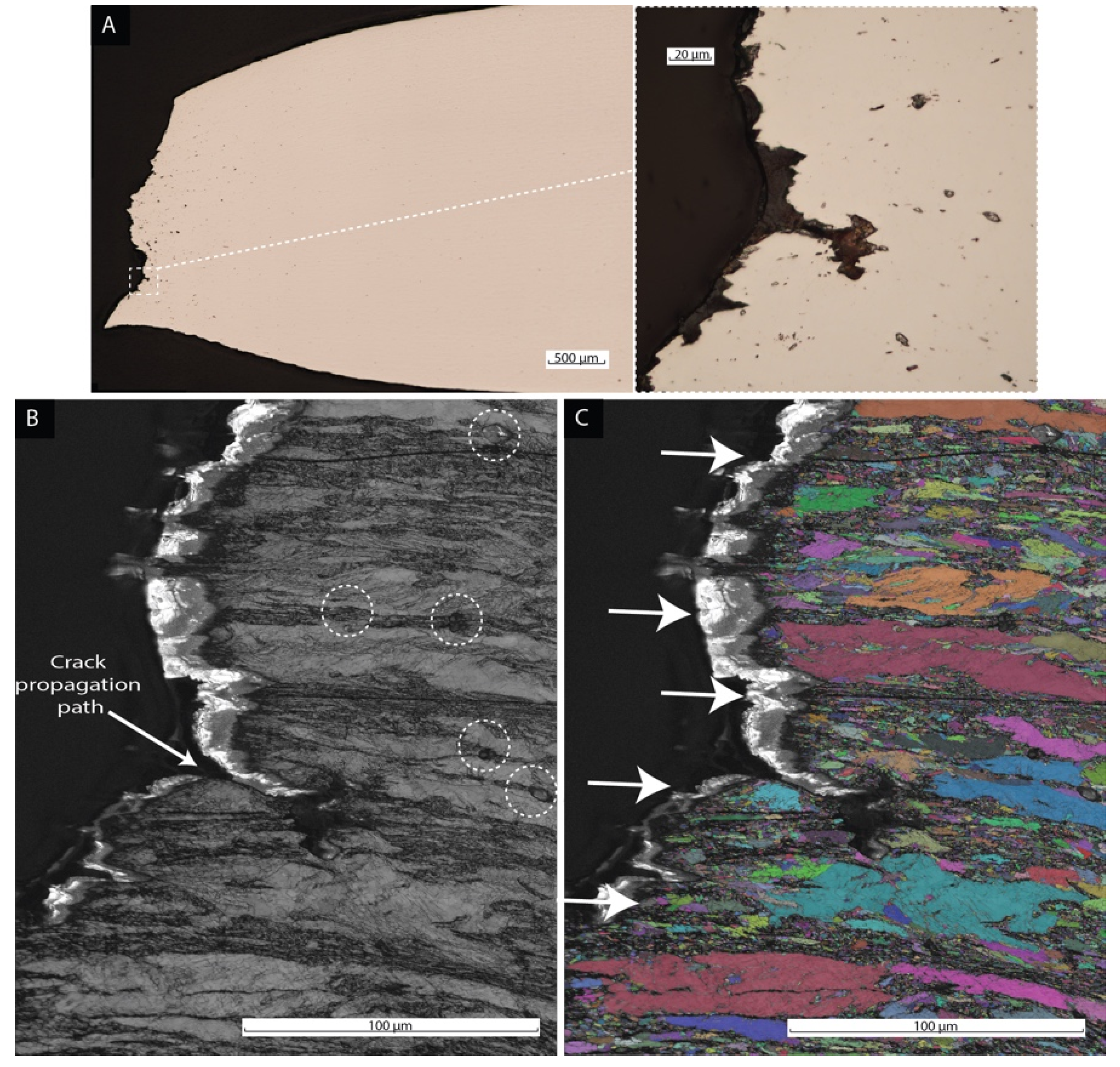

3.4. Fractography

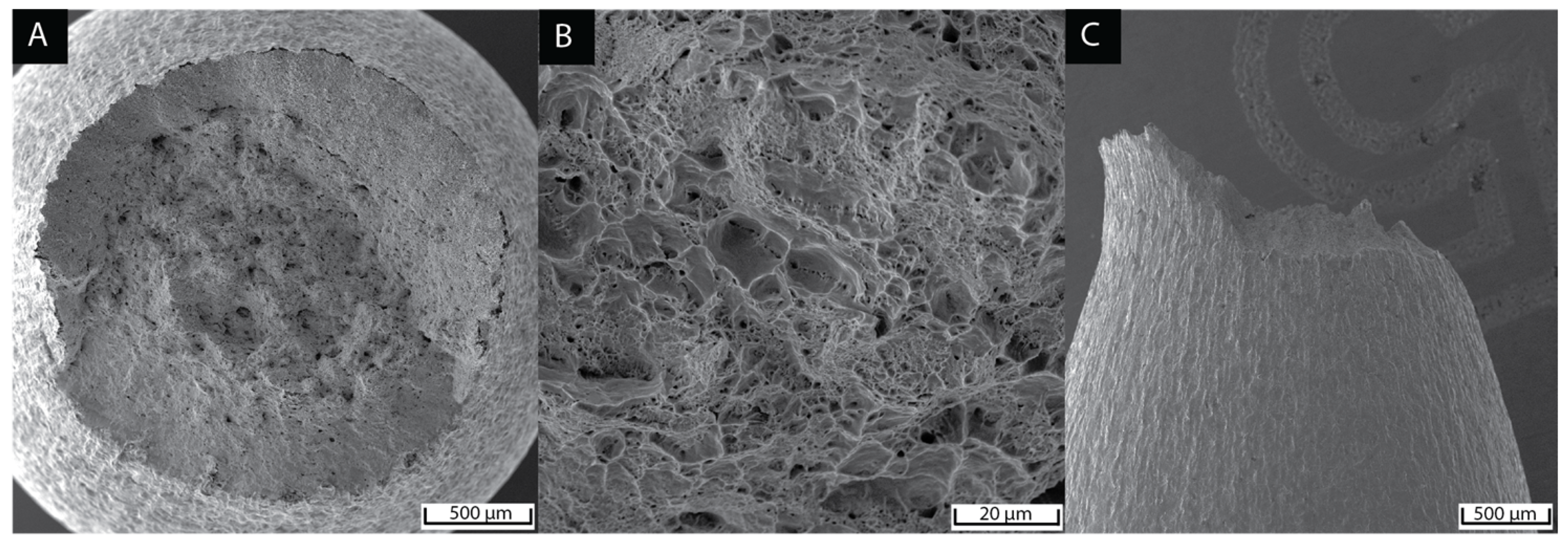

4. Discussion

5. Conclusions

- Except for the 3-wt% Ni case, tempering for 20 min at 550 °C was enough to meet the ASME B31.12 and ISO 15156-2 standard hardness limitation (250-HV). The softening effect obtained after tempering was observed by SEM, revealing fine carbide precipitation.

- XRD showed the absence of retained austenite after tempering. In addition, the refinement effect of Ni on the ferritic grain size was evident, as quantified by EBSD analysis.

- 0.2%YS and TS increased with martensite fraction. Similarly, an evident increase in TS was found with increasing Ni content.

- The 3-wt% Ni with a martensite content exceeding 50% had the highest toughness values, which can be linked to the high 0.2% YS and TS.

- Samples exhibited a ductile fracture with a cup-and-cone appearance. The fracture mechanism was linked to the coalescence of microvoids and decohesion between martensitic grains.

- The 3-wt% DP-LAS with a 50% martensite was the optimal microstructure condition, as it combines high strength and toughness with a hardness that meet the ASME B31.12 and ISO 15156-2 standard limit.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Baykara, S.Z. Hydrogen: A brief overview on its sources, production and environmental impact. Int. J. Hydrogen Energy 2018, 43, 10605–10614. [Google Scholar] [CrossRef]

- ASME B31.12-2019; Hydrogen Piping and Pipelines. ASME—ASME International: New York, NY, USA, 2019; p. 278.

- Fekete, J.R.; Sowards, J.W.; Amaro, R.L. Economic impact of applying high strength steels in hydrogen gas pipelines. Int. J. Hydrogen Energy 2015, 40, 10547–10558. [Google Scholar] [CrossRef] [Green Version]

- NACE/ASTM G193-12d; Standard Terminology and Acronyms Relating to Corrosion. ASTM Internatioal: West Conshohocken, PA, USA, 2021.

- Snape, E. Sulfide Stress Corrosion of Some Medium and Low Alloy Steels. Corrosion 1967, 23, 154–172. [Google Scholar] [CrossRef]

- Kappes, M.; Iannuzzi, M.; Rebak, R.B.; Carranza, R.M. Sulfide stress cracking of nickel-containing low-alloy steels. Corros. Rev. 2014, 32, 101–128. [Google Scholar] [CrossRef] [Green Version]

- Craig, B.D. The effect of nickel on hydrogen cracking resistance in low alloy steels—A review. Corrosion 1982, 38, 457–463. [Google Scholar] [CrossRef]

- ISO 15156-2; Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production—Part 2: Cracking-Resistant Carbon and Low-Alloy Steels, and the Use of Cast Irons. International Organization for Standardization: Geneva, Switzerland, 2020.

- Treseder, R.S.; Swanson, T.M. Factors in sulfide corrosion cracking of high strength steels. Corrosion 1968, 24, 31–37. [Google Scholar] [CrossRef]

- Snape, E. Roles of composition and microstructure in sulfide cracking of steel. Corrosion 1968, 24, 261–282. [Google Scholar] [CrossRef]

- Payer, J.; Pednekar, S.; Boyd, W. Sulfide stress cracking susceptibility of nickel containing steels. Metall. Trans. A 1986, 17, 1601–1610. [Google Scholar] [CrossRef]

- Yoshino, Y.; Minozaki, Y. Sulfide stress cracking resistance of low-alloy nickel steels. Corrosion 1986, 42, 222–233. [Google Scholar] [CrossRef]

- Biagiotti, S.F.; Matlock, D.K.; Krauss, G. Effect of Ni Content and Tempering Temperature on SSC Resistance in Modified 4340 Steels; NACE International: Houston, TX, USA, 1995. [Google Scholar]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Snape, E.; Schaller, R.F.; Forbes Jones, R.M. A method for improving hydrogen sulfide accelerated cracking resistance of low alloy steels. Corrosion 1969, 25, 380–388. [Google Scholar] [CrossRef]

- Davies, R.G. Hydrogen embrittlement of dual-phase steels. Metall. Trans. A 1981, 12, 1667–1672. [Google Scholar] [CrossRef]

- Koyama, M.; Tasan, C.C.; Akiyama, E.; Tsuzaki, K.; Raabe, D. Hydrogen-assisted decohesion and localized plasticity in dual-phase steel. Acta Mater. 2014, 70, 174–187. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, Q.; Venezuela, J.; Zhang, M.; Atrens, A. The role of the microstructure on the influence of hydrogen on some advanced high-strength steels. Mater. Sci. Eng. A 2018, 715, 370–378. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Gu, J.; Chen, N. The influence of hydrogen on the sub-structure of the martensite and ferrite dual-phase steel. Scr. Metall. 1989, 23, 1735–1737. [Google Scholar] [CrossRef]

- Alp, T.; Iskanderani, F.I.; Zahed, A.H. Hydrogen effects in a dual-phase microalloy steel. J. Mater. Sci. 1991, 26, 5644–5654. [Google Scholar] [CrossRef]

- Chan, S.L.I. Hydrogen trapping ability of steels with different microstructures. J. Chin. Inst. Eng. 1999, 22, 43–53. [Google Scholar] [CrossRef]

- ASTM E1019-11; Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM E1479-99; Standard Practice for Describing and Specifying Inductively-Coupled Plasma Atomic Emission Spectrometers. ASTM International: West Conshohocken, PA, USA, 2011.

- Andrews, K.W. Empirical formulae for the calculation of some transformation temperatures. J. Iron. Steel. Inst. 1965, 203, 721–727. [Google Scholar]

- Parodi, S. Obtaining Low Alloy Steels with Different Ni Contents and Similar Microstructures and Mechanical Properties; Matéria: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- ASTM E562-19e1; Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E2627-13; Standard Practice for Determining Average Grain Size Using Electron Backscatter Diffraction (EBSD) in Fully Recrystallized Polycrystalline Materials. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E8/E8M-21; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Liu, A.F. Mechanics and Mechanisms of Fracture: An Introduction; ASM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Kuang, C.; Li, J.; Zhang, S.; Wang, J.; Liu, H.; Volinsky, A. Effects of quenching and tempering on the microstructure and bake hardening behavior of ferrite and dual phase steels. Mater. Sci. Eng. A 2014, 613, 178–183. [Google Scholar] [CrossRef]

- Hosford, W.F. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–28.

- Krauss, G. Steels: Processing, Structure, and Performance; ASM International: Materials Park, OH, USA, 2015. [Google Scholar]

- Callister, W.D. Fundamentals of Materials Science and Engineering; Wiley London: London, UK, 2000; Volume 471660817. [Google Scholar]

- Movahed, P.; Kolahgar, S.; Marashi, S.P.H.; Pouranvari, M.; Parvin, N. The effect of intercritical heat treatment temperature on the tensile properties and work hardening behavior of ferrite–martensite dual phase steel sheets. Mater. Sci. Eng. A 2009, 518, 1–6. [Google Scholar] [CrossRef]

- Krauss, G.; Marder, A. The morphology of martensite in iron alloys. Metall. Trans. 1971, 2, 2343–2357. [Google Scholar] [CrossRef]

- Handbook, A.S.M.M. Heat Treatment; American Society for metals: New York, NY, USA, 1991; Volume 4, pp. 291–324. [Google Scholar]

- Kim, K.; Lee, S.-J. Effect of Ni addition on the mechanical behavior of quenching and partitioning (Q&P) steel. Mater. Sci. Eng. A 2017, 698, 183–190. [Google Scholar]

- Ghaheri, A.; Shafyei, A.; Honarmand, M. Effects of inter-critical temperatures on martensite morphology, volume fraction and mechanical properties of dual-phase steels obtained from direct and continuous annealing cycles. Mater. Des. (1980–2015) 2014, 62, 305–319. [Google Scholar] [CrossRef]

- Marder, A.R. Deformation characteristics of dual-phase steels. Metall. Trans. A 1982, 13, 85–92. [Google Scholar] [CrossRef]

- Davies, R.G. Influence of martensite composition and content on the properties of dual phase steels. Metall. Trans. A 1978, 9, 671–679. [Google Scholar] [CrossRef]

- Mazinani, M.; Poole, W.J. Effect of martensite plasticity on the deformation behavior of a low-carbon dual-phase steel. Metall. Mater. Trans. A 2007, 38, 328–339. [Google Scholar] [CrossRef]

- Lacroix, G.; Pardoen, T.; Jacques, P.J. The fracture toughness of TRIP-assisted multiphase steels. Acta Mater. 2008, 56, 3900–3913. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodoni, E.; Verbeken, K.; Depover, T.; Iannuzzi, M. Effect of Intercritical Temperature on the Microstructure and Mechanical Properties of a Ferritic–Martensitic Dual-Phase Low-Alloy Steel with Varying Nickel Content. Materials 2022, 15, 9018. https://doi.org/10.3390/ma15249018

Rodoni E, Verbeken K, Depover T, Iannuzzi M. Effect of Intercritical Temperature on the Microstructure and Mechanical Properties of a Ferritic–Martensitic Dual-Phase Low-Alloy Steel with Varying Nickel Content. Materials. 2022; 15(24):9018. https://doi.org/10.3390/ma15249018

Chicago/Turabian StyleRodoni, Esteban, Kim Verbeken, Tom Depover, and Mariano Iannuzzi. 2022. "Effect of Intercritical Temperature on the Microstructure and Mechanical Properties of a Ferritic–Martensitic Dual-Phase Low-Alloy Steel with Varying Nickel Content" Materials 15, no. 24: 9018. https://doi.org/10.3390/ma15249018

APA StyleRodoni, E., Verbeken, K., Depover, T., & Iannuzzi, M. (2022). Effect of Intercritical Temperature on the Microstructure and Mechanical Properties of a Ferritic–Martensitic Dual-Phase Low-Alloy Steel with Varying Nickel Content. Materials, 15(24), 9018. https://doi.org/10.3390/ma15249018