Influence of Laser Parameters on the Texturing of 420 Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

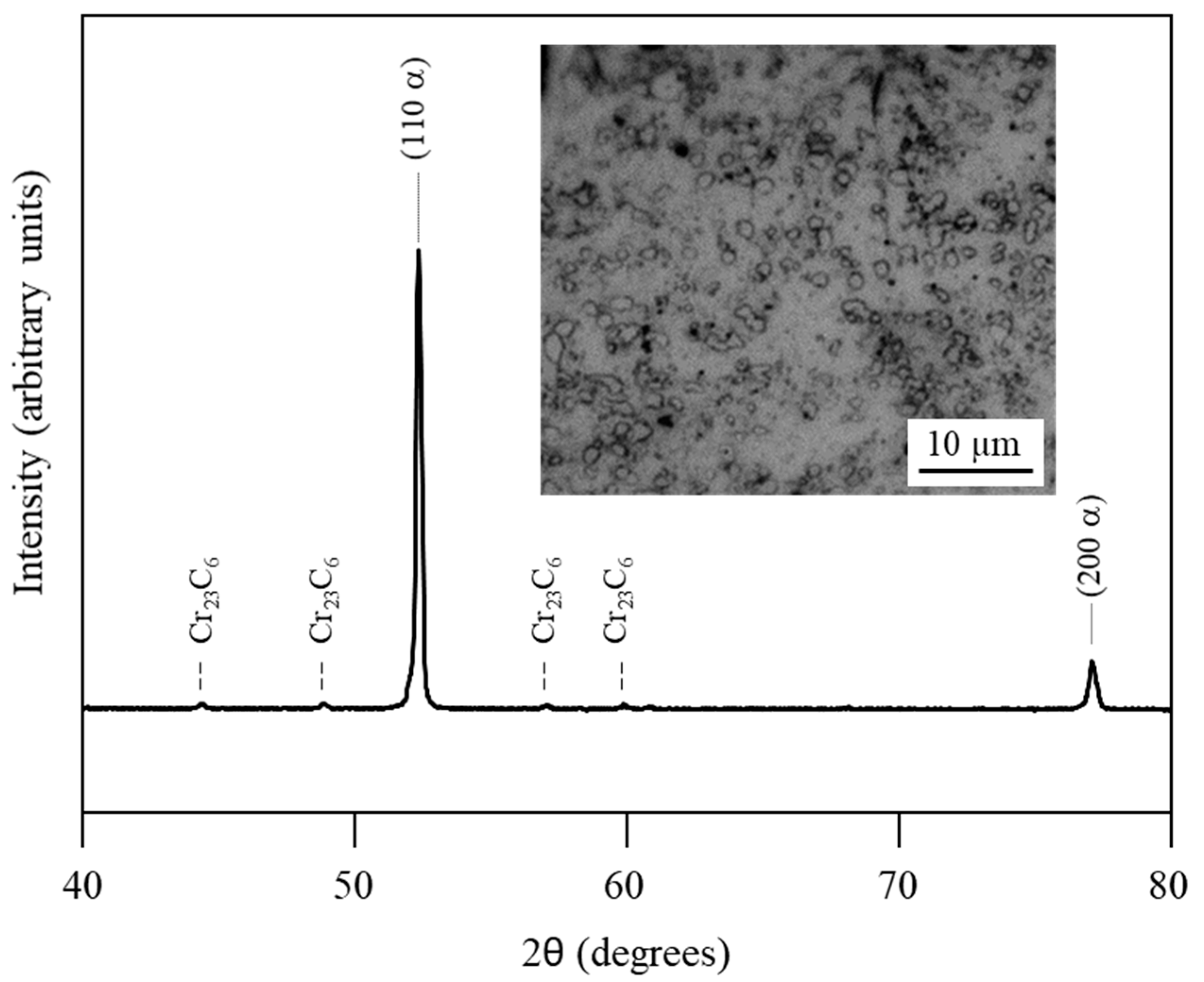

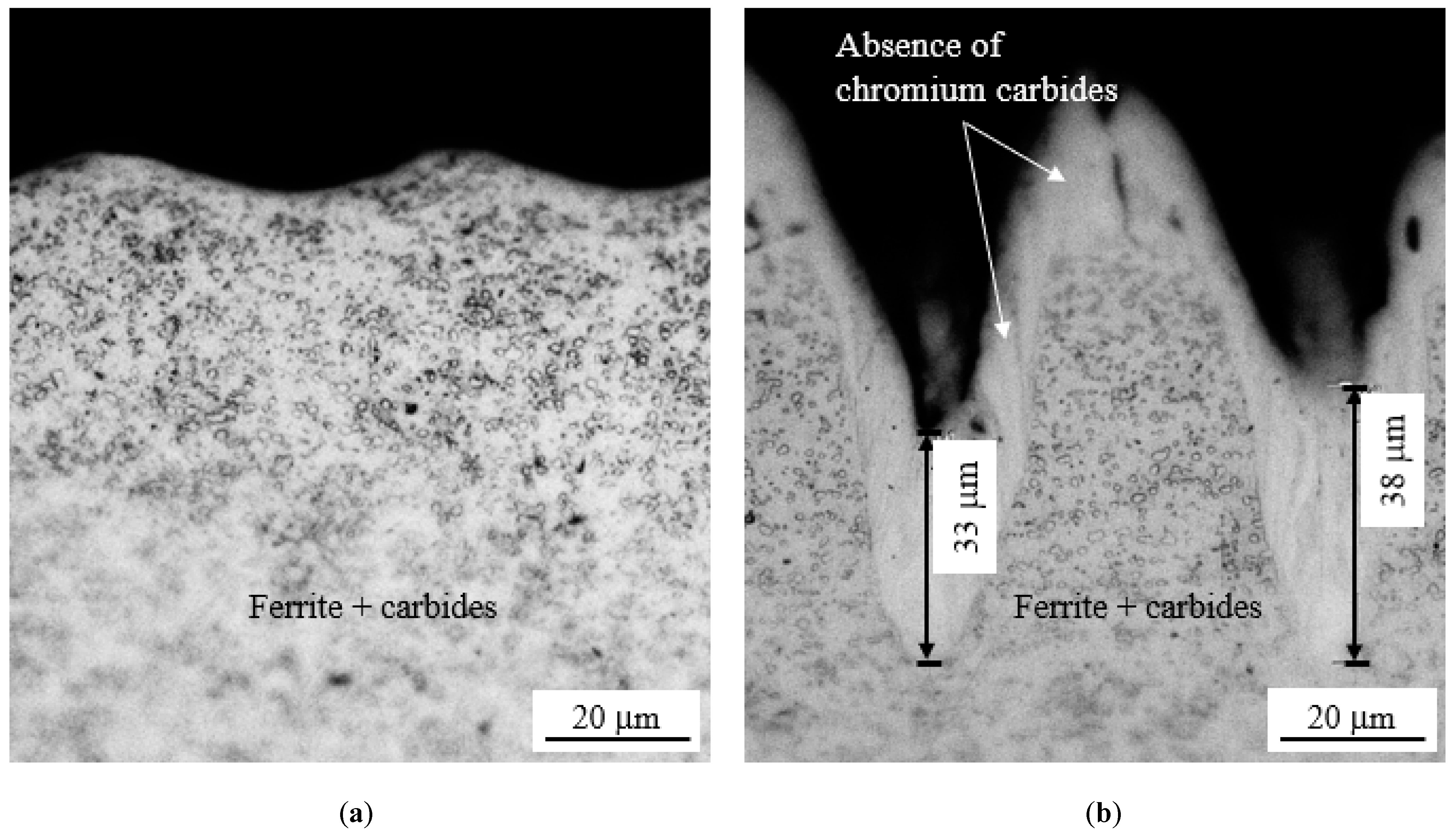

3.1. Raw Material

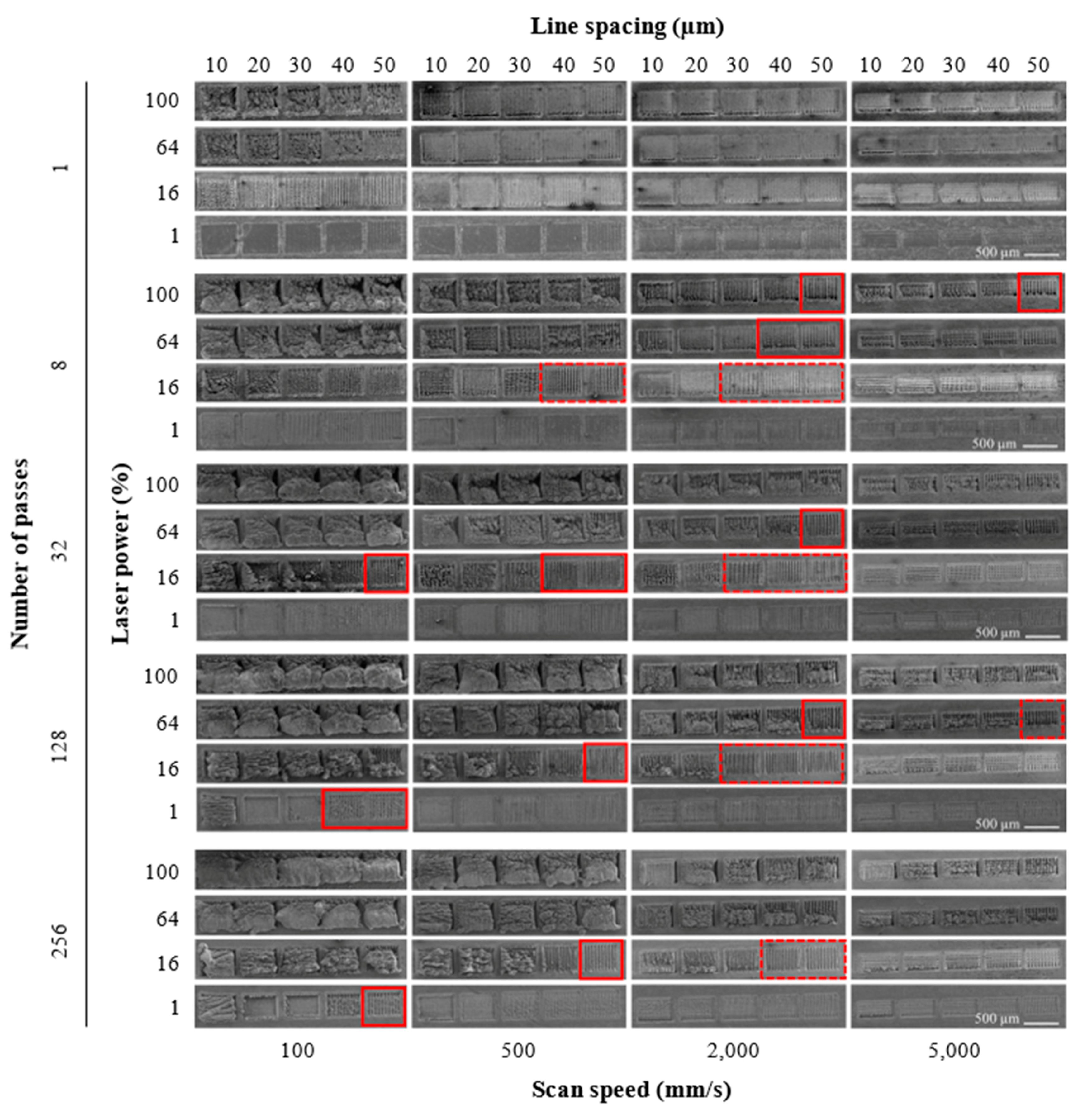

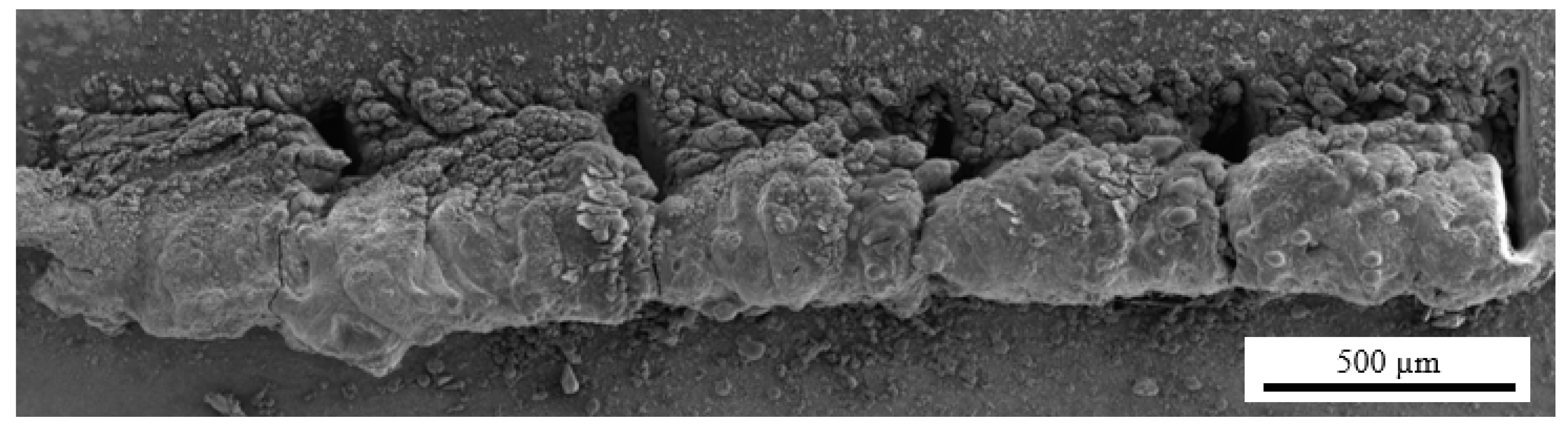

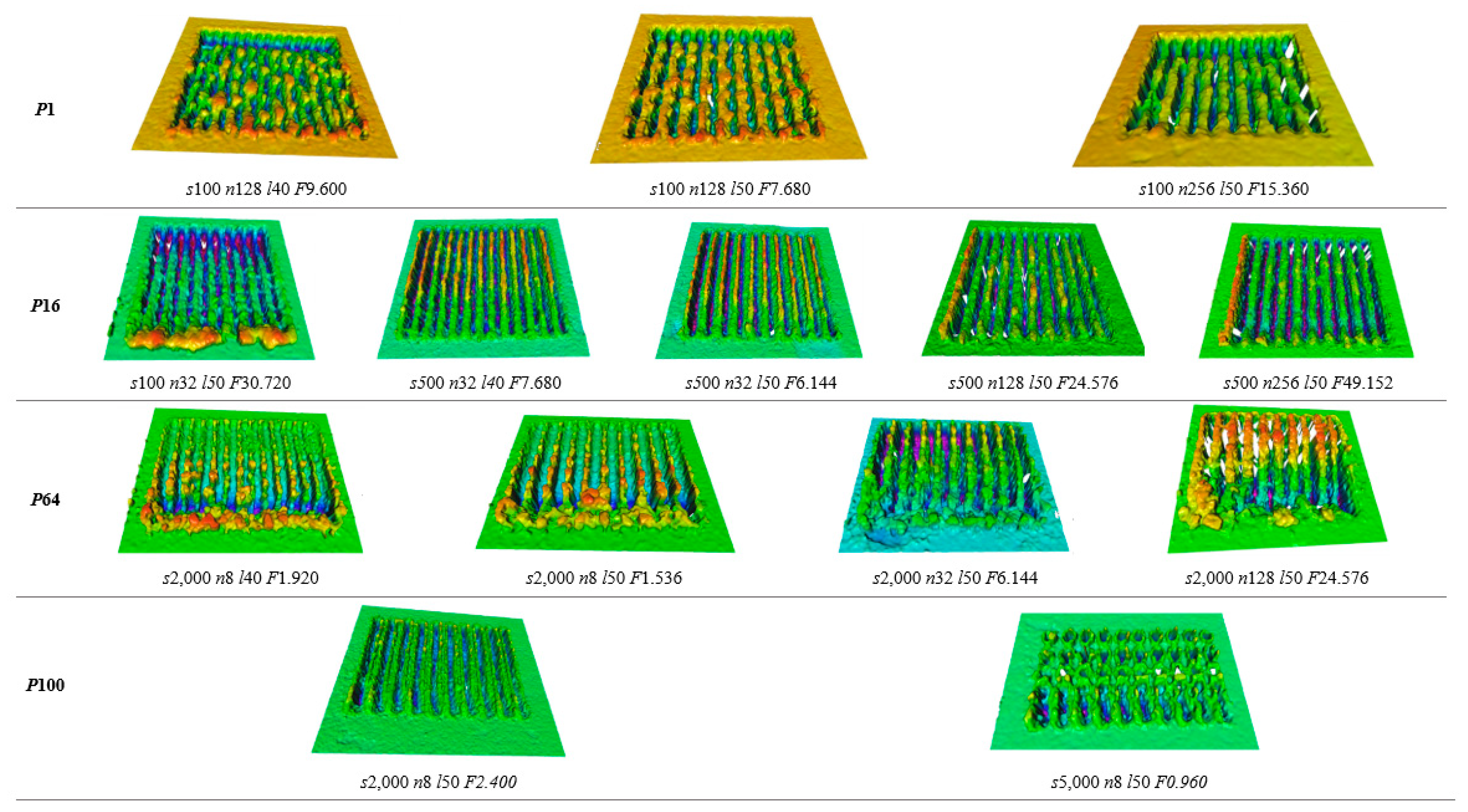

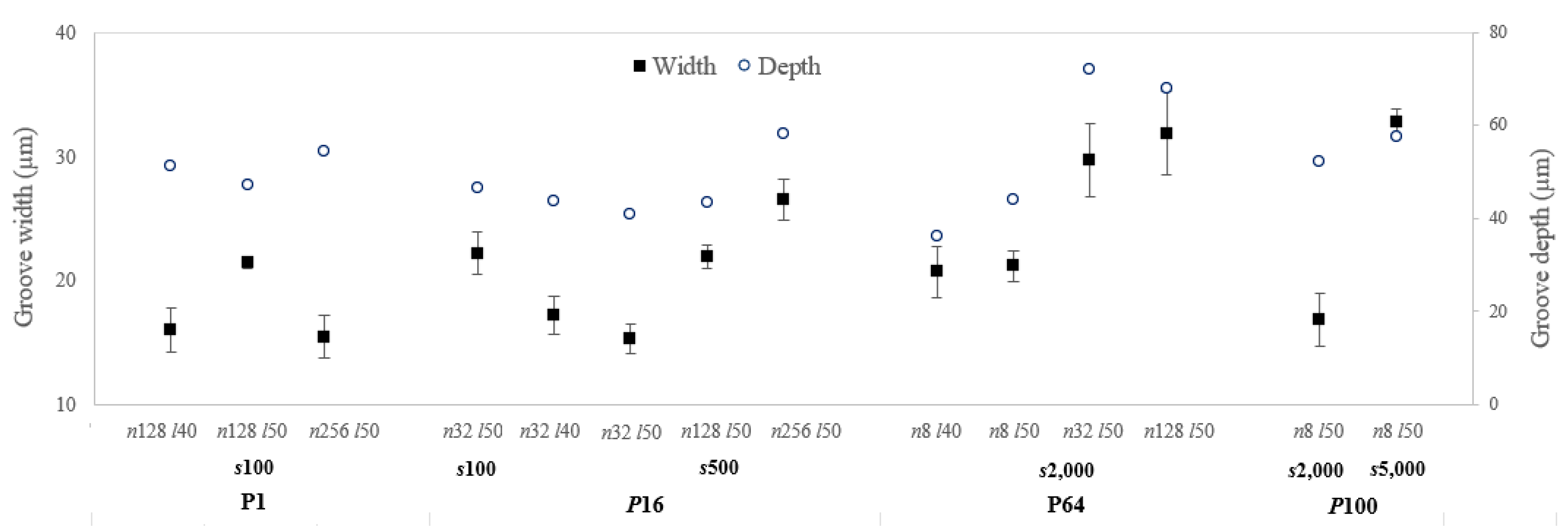

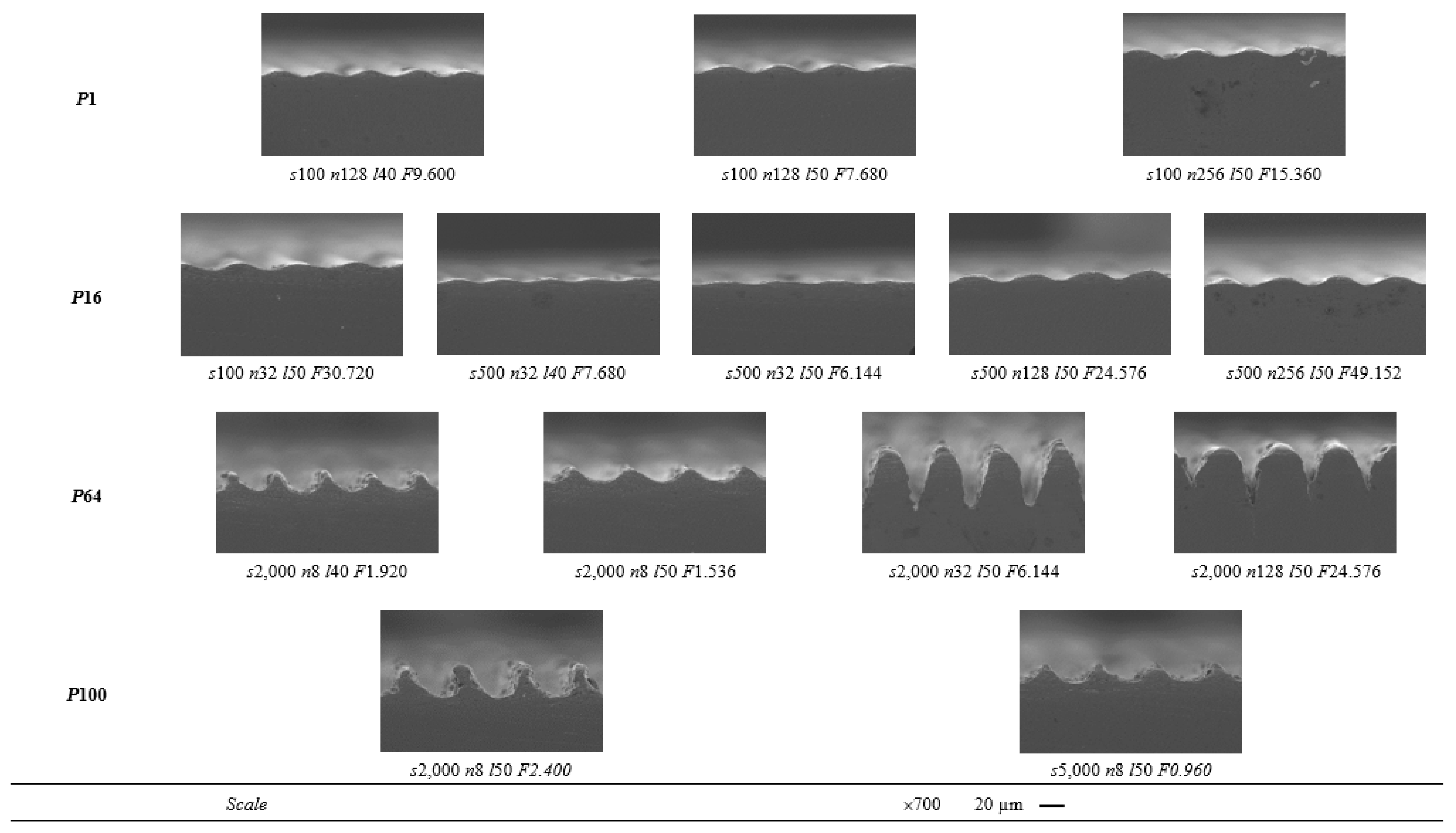

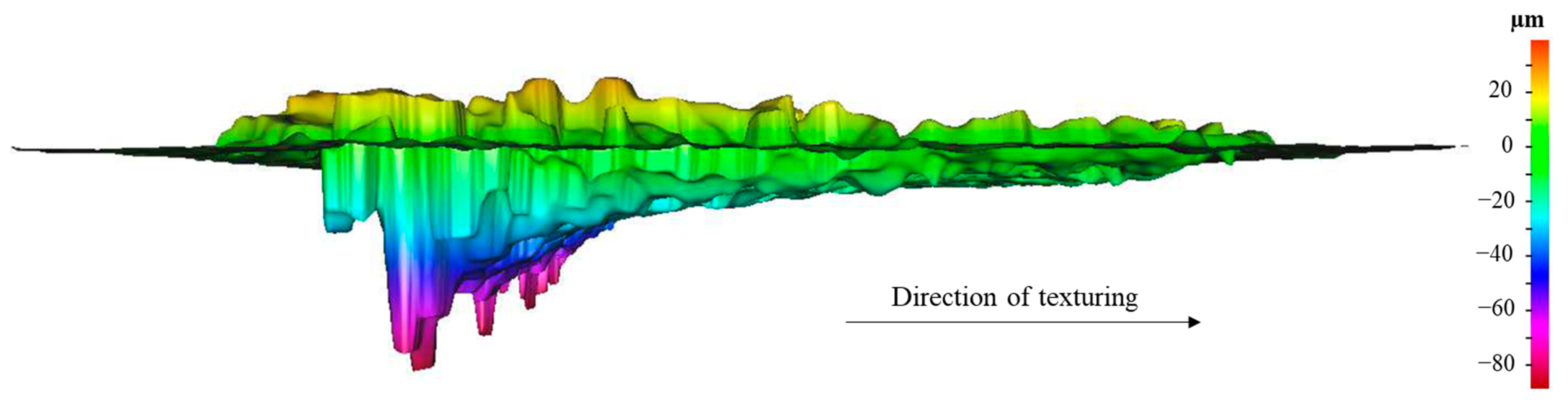

3.2. Texturing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Nath, S.D.; Clinning, E.; Gupta, G.; Wuelfrath-Poirier, V.; L’Espérance, G.; Gulsoy, O.; Atre, S.V. Effects of Nb and Mo on the microstructure and properties of 420 stainless steel processed by laser-powder bed fusion. Addit. Manuf. 2019, 28, 682–691. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, Q.; Song, B.; Liu, Y.; Luo, X.; Wen, S.; Shi, Y. Fabrication and Characterization of AISI 420 Stainless Steel Using Selective Laser Melting. Mater. Manuf. Process. 2015, 30, 1283–1289. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, X.; Li, D.; Yang, Z.; Lu, R. Effect of sintering temperature on microstructure and properties of MIM420 stainless steel. Powder Metall. 2021, 65, 214–221. [Google Scholar] [CrossRef]

- Nath, S.D.; Gupta, G.; Kearns, M.; Gulsoy, O.; Atre, S.V. Effects of layer thickness in laser-powder bed fusion of 420 stainless steel. Rapid Prototyp. J. 2020, 26, 1197–1208. [Google Scholar] [CrossRef]

- Momenzadeh, N.; Nath, S.D.; Berfield, T.A.; Atre, S.V. In Situ Measurement of Thermal Strain Development in 420 Stainless Steel Additive Manufactured Metals. Exp. Mech. 2019, 59, 819–827. [Google Scholar] [CrossRef]

- Nath, S.D.; Okello, A.; Kelkar, R.; Gupta, G.; Kearns, M.; Atre, S.V. Adapting L-PBF process for fine powders: A case study in 420 stainless steel. Mater. Manuf. Process. 2021, 37, 1320–1331. [Google Scholar] [CrossRef]

- Nath, S.D.; Irrinki, H.; Gupta, G.; Kearns, M.; Gulsoy, O.; Atre, S. Microstructure-property relationships of 420 stainless steel fabricated by laser-powder bed fusion. Powder Technol. 2019, 343, 738–746. [Google Scholar] [CrossRef]

- Cunha, A.; Marques, A.; Gasik, M.; Trindade, B. Influence of temperature processing on the microstructure and hardness of the 420 stainless steel produced by hot pressing. Mater. Manuf. Process. 2022, 1–8. [Google Scholar] [CrossRef]

- Horodek, P.; Eseev, M.K.; Kobets, A.G. Studies of stainless steel exposed to sandblasting. Nukleonika 2015, 60, 721–724. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Mufti, R.A.; Mosarof, M.H.; Khuong, L.S.; Quazi, M.M. Surface Texture Manufacturing Techniques and Tribological Effect of Surface Texturing on Cutting Tool Performance: A Review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 447–481. [Google Scholar] [CrossRef]

- Babu, V.; Yaradi, M.; Thammineni, D.T. A Review on Recent Trends in Surface Coatings. IOP Conf. Ser. Mater. Sci. Eng. 2018, 390, 012079. [Google Scholar] [CrossRef]

- Wahab, J.A.; Ghazali, M.J.; Yusoff, W.M.W.; Sajuri, Z. Enhancing material performance through laser surface texturing: A review. Trans. Inst. Met. Finish. 2016, 94, 193–198. [Google Scholar] [CrossRef]

- Ormanova, M.; Petrov, P.; Kovacheva, D. Electron beam surface treatment of tool steels. Vacuum 2016, 135, 7–12. [Google Scholar] [CrossRef]

- Thomas, S.J.; Kalaichelvan, K. Comparative study of the effect of surface texturing on cutting tool in dry cutting. Mater. Manuf. Process. 2018, 33, 683–694. [Google Scholar] [CrossRef]

- Steyer, P.; Valette, S.; Forest, B.; Millet, J.P.; Donnet, C.; Audouard, E. Surface modification of martensitic stainless steels by laser marking and its consequences regarding corrosion resistance. Surf. Eng. 2006, 22, 167–172. [Google Scholar] [CrossRef]

- Netprasert, O.; Tangwarodomnukun, V. Surface Hardening of AISI 420 Stainless Steel by Using a Nanosecond Pulse Laser. Mater. Sci. Forum 2018, 911, 44–48. [Google Scholar] [CrossRef]

- Mahmoudi, B.; Torkamany, M.J.; Rouh, A.R.S.; Sabbaghzade, J. Laser surface hardening of AISI 420 stainless steel treated by pulsed Nd: YAG laser. Mater. Des. 2010, 31, 2553–2560. [Google Scholar] [CrossRef]

- Gora, W.S.; Carstensen, J.V.; Wlodarczyk, K.L.; Laursen, M.B.; Hansen, E.B.; Hand, D.P. A Novel Process for Manufacturing High-Friction Rings with a Closely Defined Coefficient of Static Friction (Relative Standard Deviation 3.5%) for Application in Ship Engine Components. Materials 2022, 15, 448. [Google Scholar] [CrossRef]

- Zul, M.H.; Ishak, M.; Aiman, M.H.; Quazi, M.M. Influence of laser power in nanosecond laser texturing for a hydrophobic state on SS316L. J. Mech. Eng. Sci. 2021, 15, 8592–8600. [Google Scholar] [CrossRef]

- Kurniawan, R.; Ko, T.J. A Study of Surface Texturing Using Piezoelectric Tool Holder Actuator on Conventional CNC Turning. Int. J. Precis. Eng. Manuf. 2013, 14, 199–206. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent progresses and applications in laser-based surface texturing systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Amoroso, P.J.; Ramalho, A.; Richhariya, V.; Silva, F.S.; Cavaleiro, A. Tribological performance of laser-textured steel surfaces in unidirectional sliding line-contact (block-on-ring). Lubr. Sci. 2021, 33, 417–431. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Das, S.; Sharma, A.; Pradhan, B.B.; Chatterjee, S. Laser surface texturing on Ti-6Al-4V. Mater. Manuf. Process. 2021, 36, 858–867. [Google Scholar] [CrossRef]

- Cunha, A.; Ferreira, R.; Trindade, B.; Silva, F.S.; Carvalho, O. Reinforcement of a laser-textured 316L steel with CuCoBe-diamond composites through laser sintering. Mater. Manuf. Process. 2020, 35, 1032–1039. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Ito, S.; Takahashi, K.; Sasaki, S. Generation mechanism of friction anisotropy by surface texturing under boundary lubrication. Tribol. Int. 2020, 149, 105598. [Google Scholar] [CrossRef]

- Pan, Q.; Cao, Y.; Xue, W.; Zhu, D.; Liu, W. Picosecond Laser-Textured Stainless Steel Superhydrophobic Surface with an Antibacterial Adhesion Property. Langmuir 2019, 35, 11414–11421. [Google Scholar] [CrossRef]

- Fatoba, O.S.; Popoola, P.A.I.; Pityana, S.L.; Adesina, O.S. Computational Dynamics of Anti-Corrosion Performance of Laser Alloyed Metallic Materials. In Fiber Laser; Paul, M.C., Ed.; InTech Open: Rijeka, Croatia, 2016; ISBN 978-953-51-2257-9. [Google Scholar]

- Pereira, H.; Carvalho, O.; Miranda, G.; Silva, F.S. Pure magnesium laser surface modification using Nd:YAG laser. Mater. Technol. 2020, 36, 811–815. [Google Scholar] [CrossRef]

- Lickschat, P.; Metzner, D.; Weißmantel, S. Fundamental investigations of ultrashort pulsed laser ablation on stainless steel and cemented tungsten carbide. Int. J. Adv. Manuf. Technol. 2020, 109, 1167–1175. [Google Scholar] [CrossRef]

- Hazzan, K.E.; Pacella, M.; See, T.L. Laser processing of hard and ultra-hard materials for micro-machining and surface engineering applications. Micromachines 2021, 12, 895. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vijayaraghavan, L.; Vasa, N.J.; Krishnan, S. Influence of pulse width in laser assisted texturing on moly-chrome films. Appl. Phys. A Mater. Sci. Process. 2018, 124, 167. [Google Scholar] [CrossRef]

- Brown, M.S.; Arnold, C.B. Fundamentals of Laser-Material Interaction and Application to Multiscale Surface Modification. In Laser Precision Microfabrication; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 135, pp. 91–120. ISBN 978-3-642-10522-7. [Google Scholar]

- Xi, X.; Pan, Y.; Wang, P.; Fu, X. Effect of laser processing parameters on surface texture of Ti6Al4V alloy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 563, 4–10. [Google Scholar] [CrossRef]

- Marques, A.; Cunha, A.; Faria, S.; Silva, F.S.; Carvalho, O. Predictive models on the influence of laser texturing parameters on the Inconel 718 surface by using Nd: YVO4 laser. Opt. Laser Technol. 2022, 154, 108320. [Google Scholar] [CrossRef]

| Laser Parameters | Drawing Parameters | Laser Energy Fluence—F (J/mm2) | ||

|---|---|---|---|---|

| Laser Power—P (%) | Scanning Speed—s (mm/s) | Number of Passes—n | Line Spacing—l (µm) | |

| 1 (0.3 W) | 100 | 1 | 10 | |

| 16 (4.8 W) | 500 | 8 | 20 | |

| 64 (19.2 W) | 2000 | 32 | 30 | 0 to 7680 |

| 100 (30 W) | 5000 | 128 | 40 | |

| 256 | 50 | |||

| Element | Fe | Cr | Mn | C | P + S + O |

|---|---|---|---|---|---|

| (wt.%) | 81.9 ± 0.5 | 14.1 ± 0.3 | 0.25 ± 0.08 | 1.5 ± 0.1 | balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cunha, Â.; Bartolomeu, F.; Silva, F.; Trindade, B.; Carvalho, Ó. Influence of Laser Parameters on the Texturing of 420 Stainless Steel. Materials 2022, 15, 8979. https://doi.org/10.3390/ma15248979

Cunha Â, Bartolomeu F, Silva F, Trindade B, Carvalho Ó. Influence of Laser Parameters on the Texturing of 420 Stainless Steel. Materials. 2022; 15(24):8979. https://doi.org/10.3390/ma15248979

Chicago/Turabian StyleCunha, Ângela, Flávio Bartolomeu, Filipe Silva, Bruno Trindade, and Óscar Carvalho. 2022. "Influence of Laser Parameters on the Texturing of 420 Stainless Steel" Materials 15, no. 24: 8979. https://doi.org/10.3390/ma15248979

APA StyleCunha, Â., Bartolomeu, F., Silva, F., Trindade, B., & Carvalho, Ó. (2022). Influence of Laser Parameters on the Texturing of 420 Stainless Steel. Materials, 15(24), 8979. https://doi.org/10.3390/ma15248979