Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting

Abstract

1. Introduction

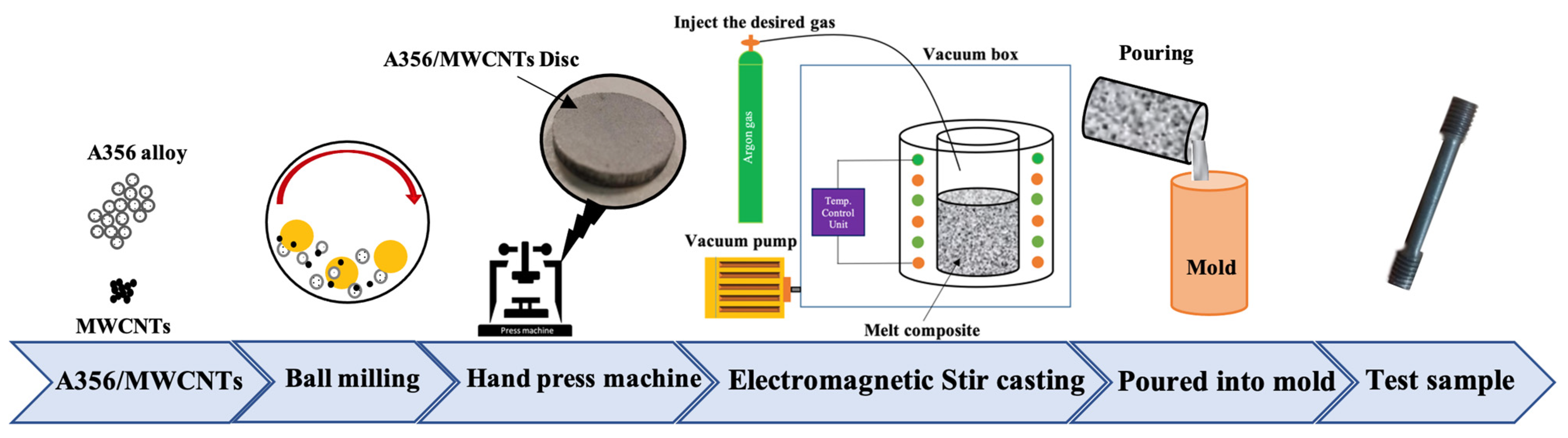

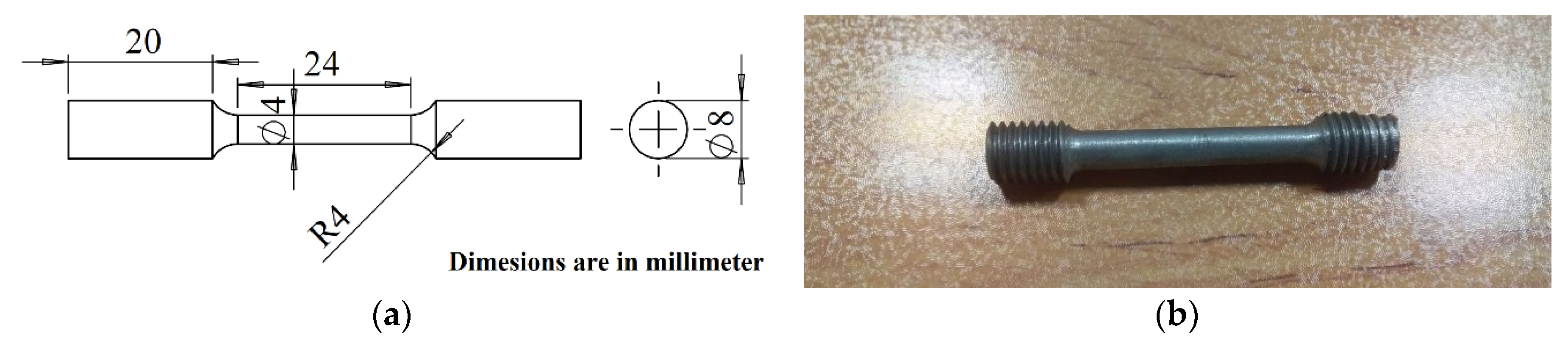

2. Materials and Methods

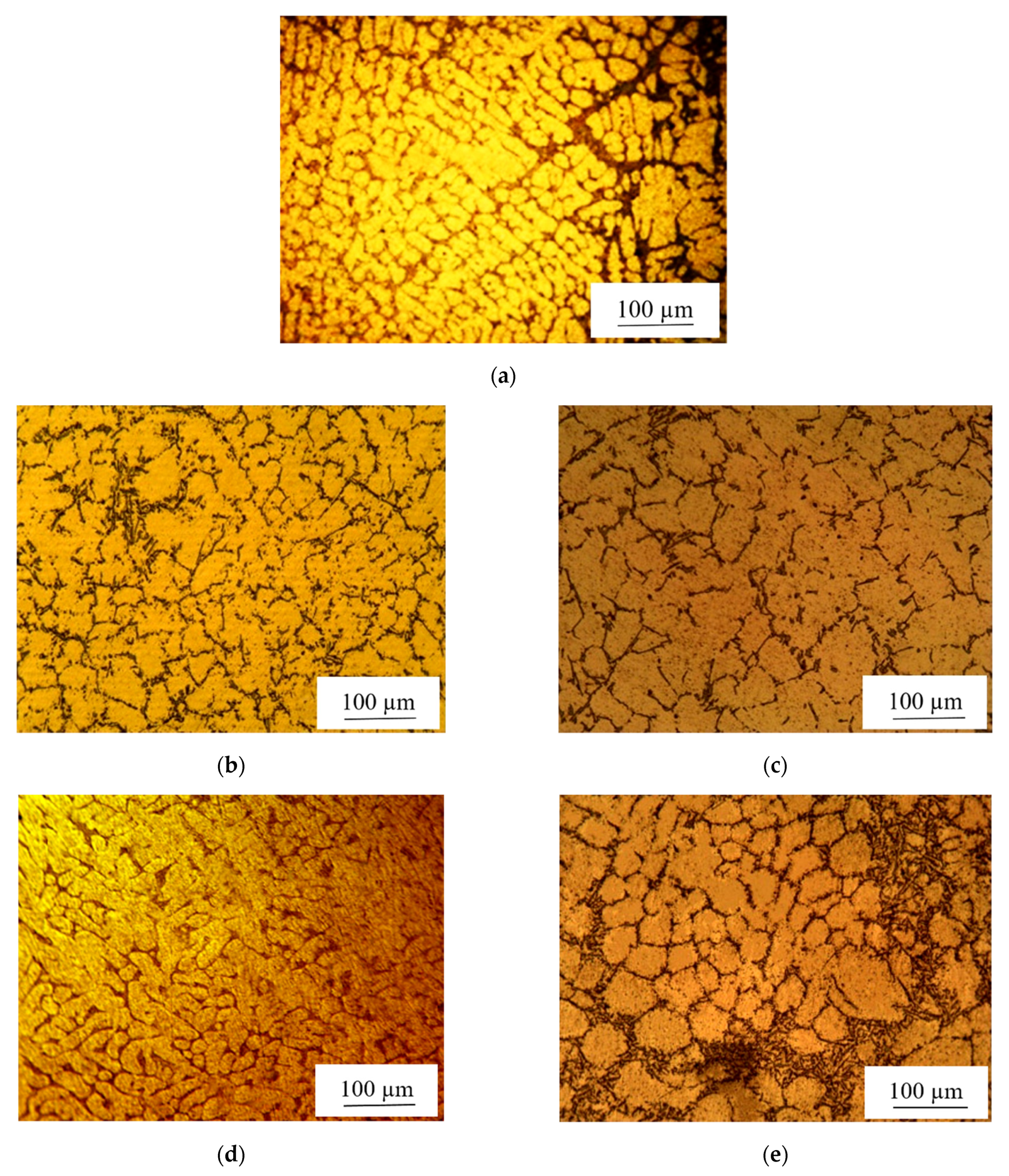

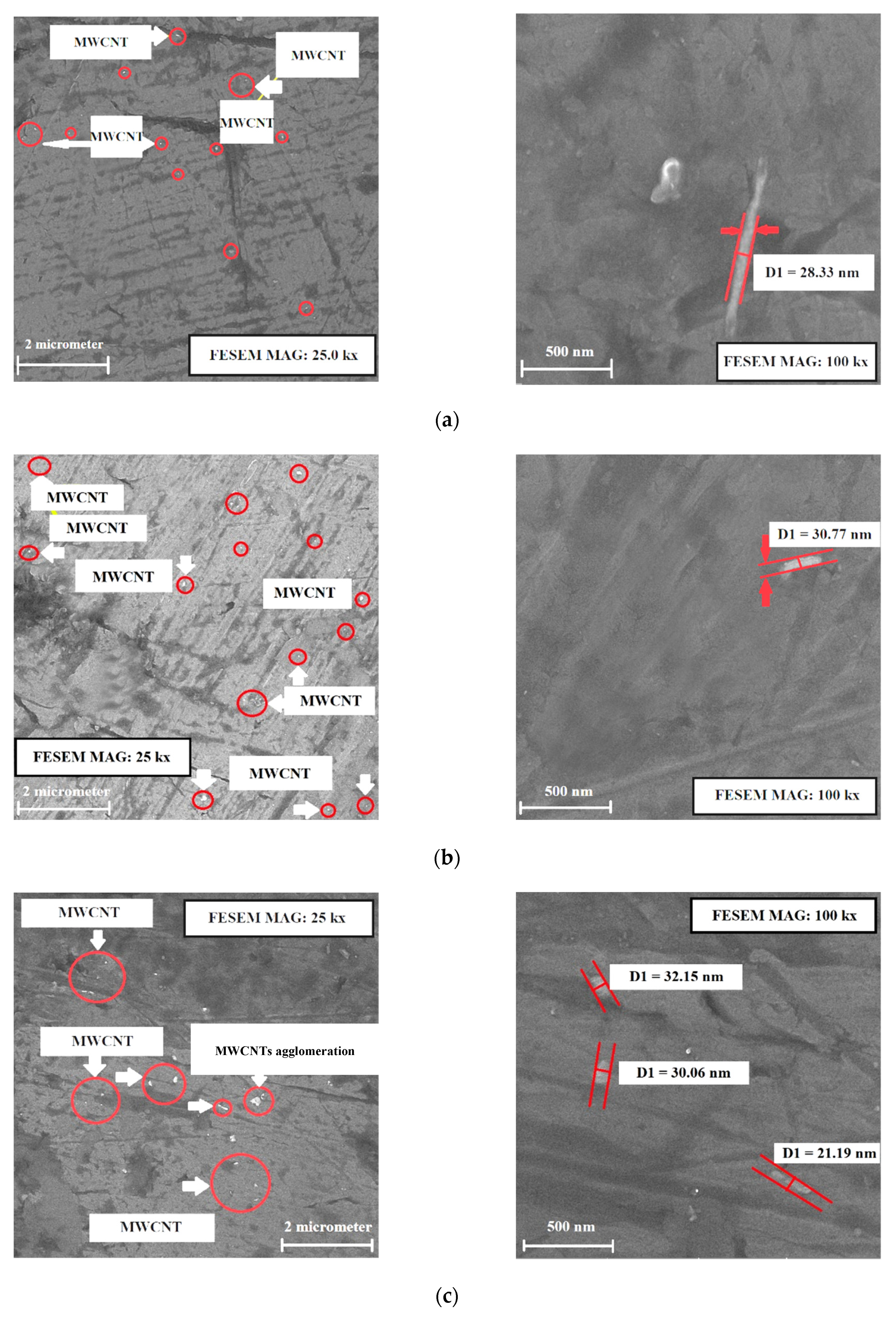

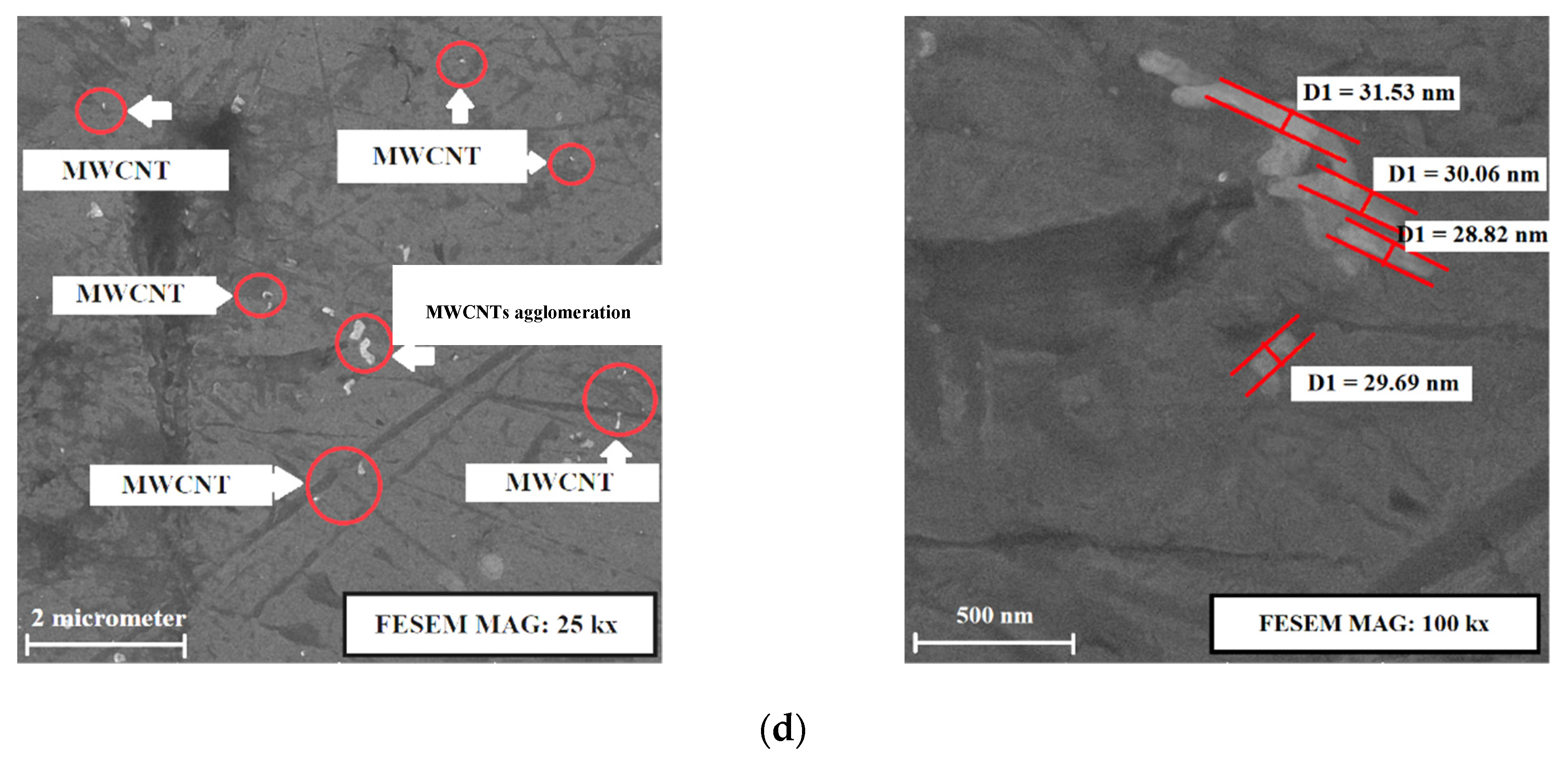

3. Results and Discussion

4. Conclusions

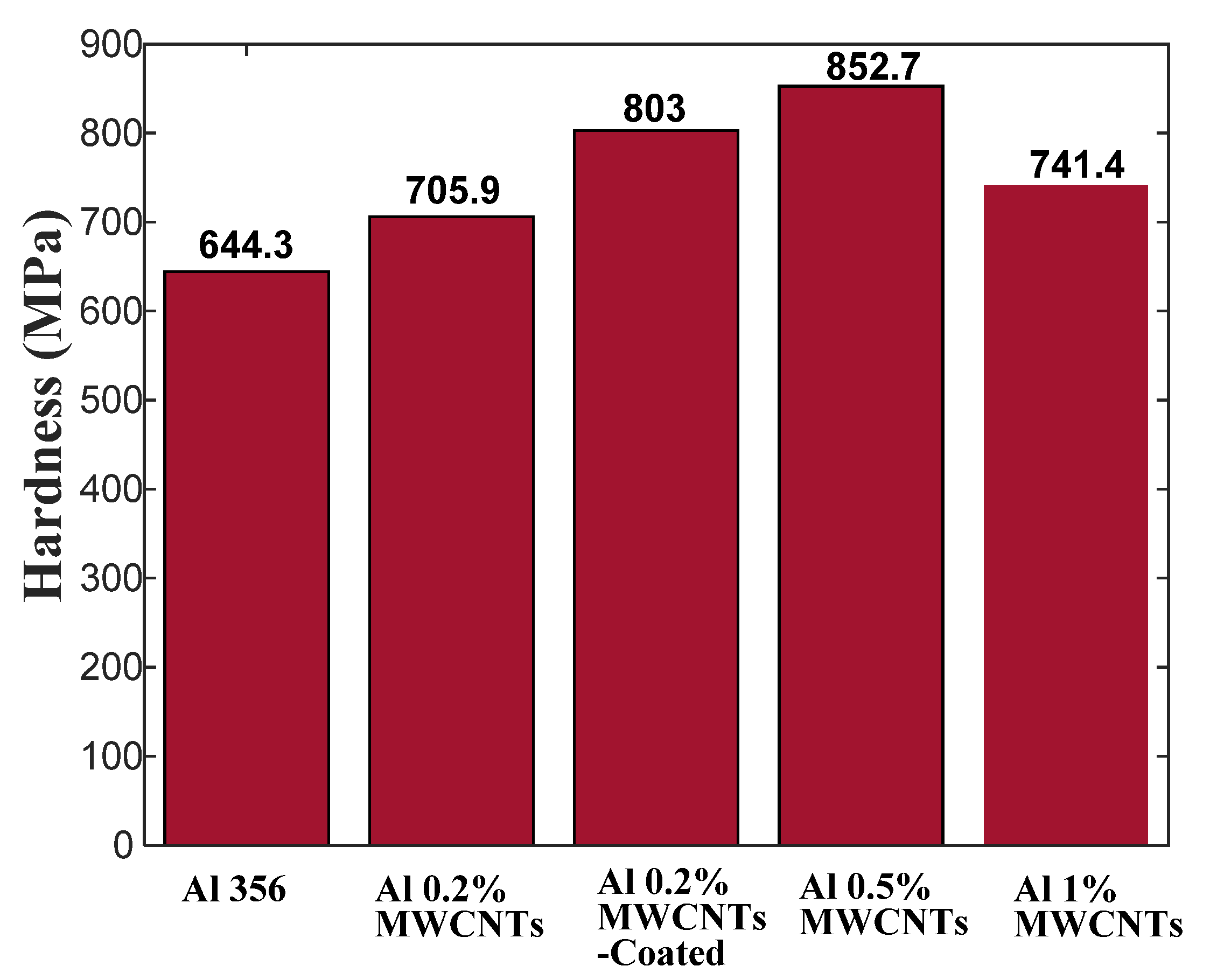

- The addition of MWCNTs enhances the hardness, and the maximum value achieved with 0.5% MWCNTs was 87 BHN, showing a 32% increase in comparison to the base alloy.

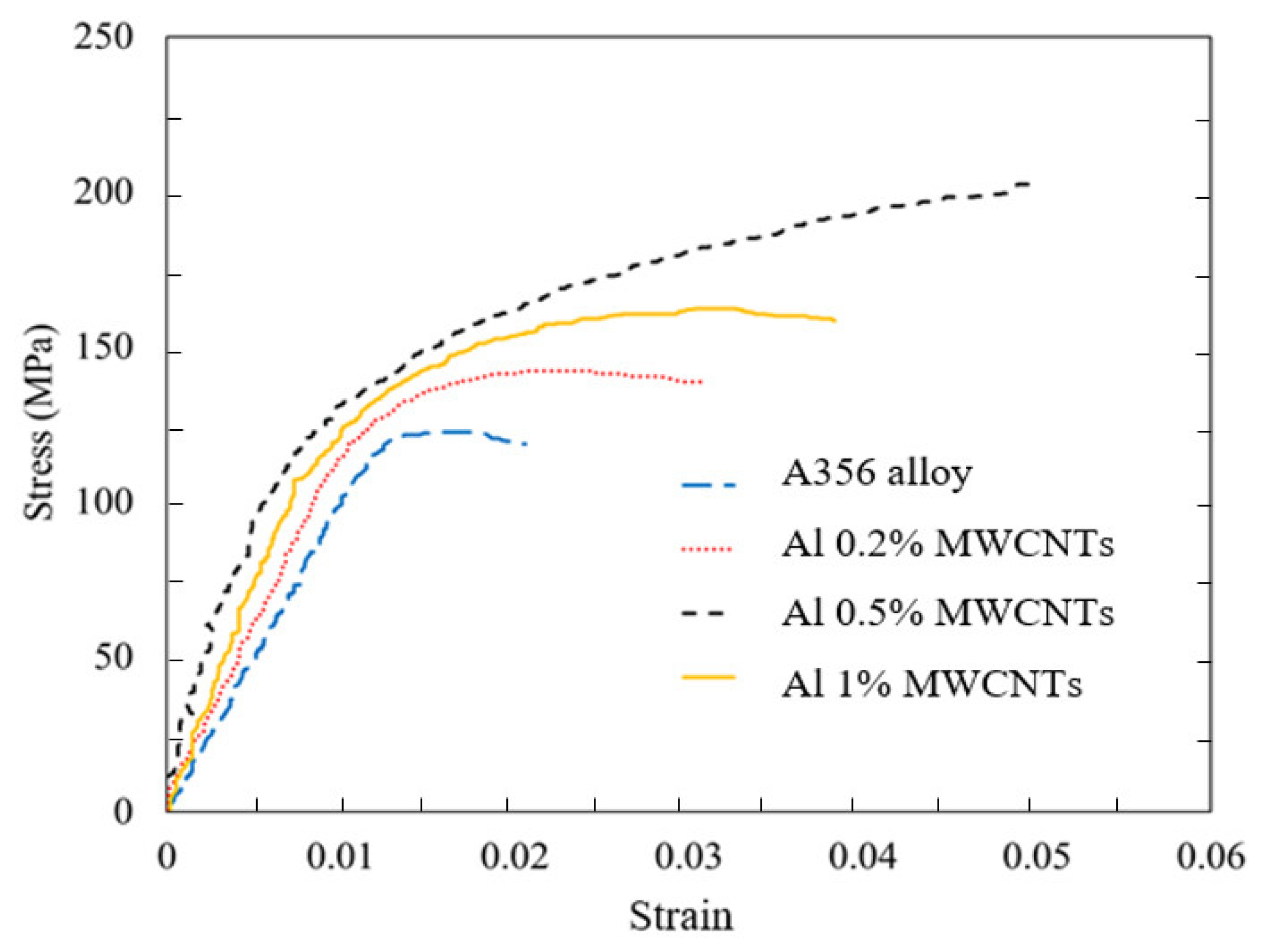

- When increasing the weight percentage from 0% to 0.5%, all the basic factors of mechanical performance such as ultimate stress, yield stress, elastic modulus, fracture strain, and toughness increase.

- The improvement in the mechanical and creep properties of nanocomposites with coated nanoparticles was more significant than that of uncoated nanoparticles. Furthermore, the yield stress increased by 37%, the ultimate tensile stress by 20%, the maximum hardness by 14%, and the maximum elongation by 16% in comparison to the uncoated nanoparticles.

- The nanocomposite with 0.5% MWCNTs had the highest yield stress, ultimate tensile stress, hardness, and elongation percentage compared with other specimens. In addition, the yield stress increased by 110%, the maximum ultimate tensile stress by 66%, the maximum hardness by 32%, and the maximum elongation by 110% compared with the base alloy.

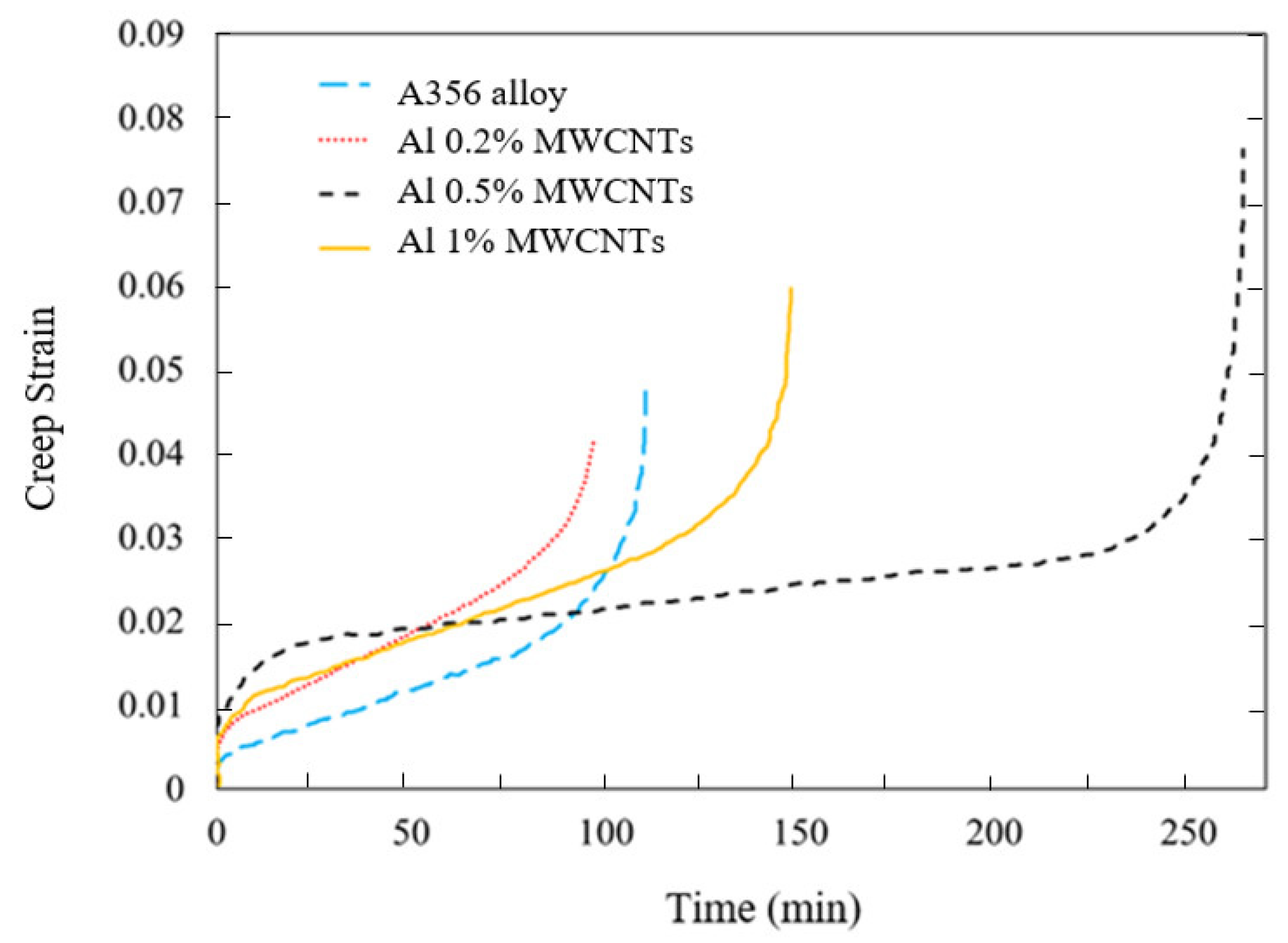

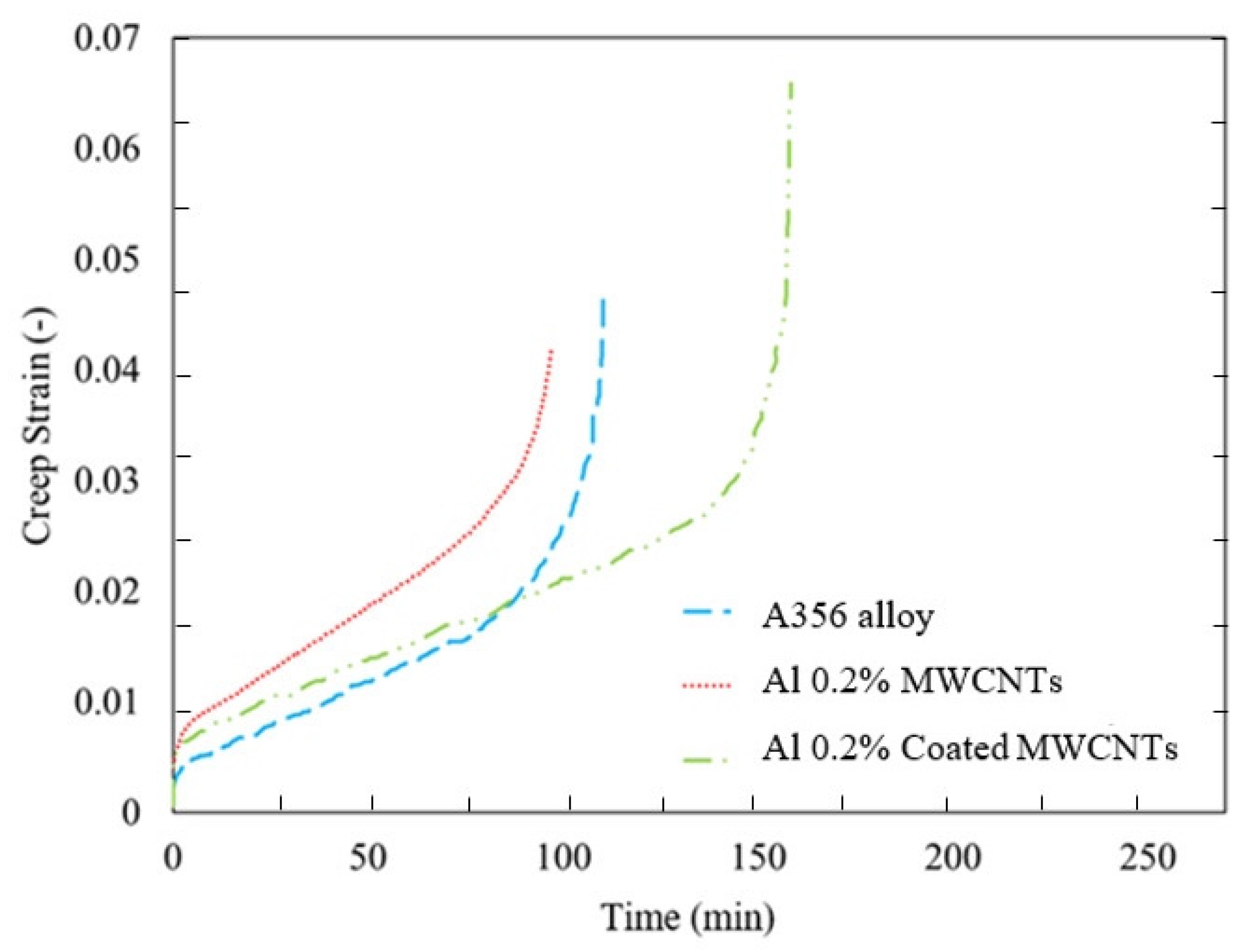

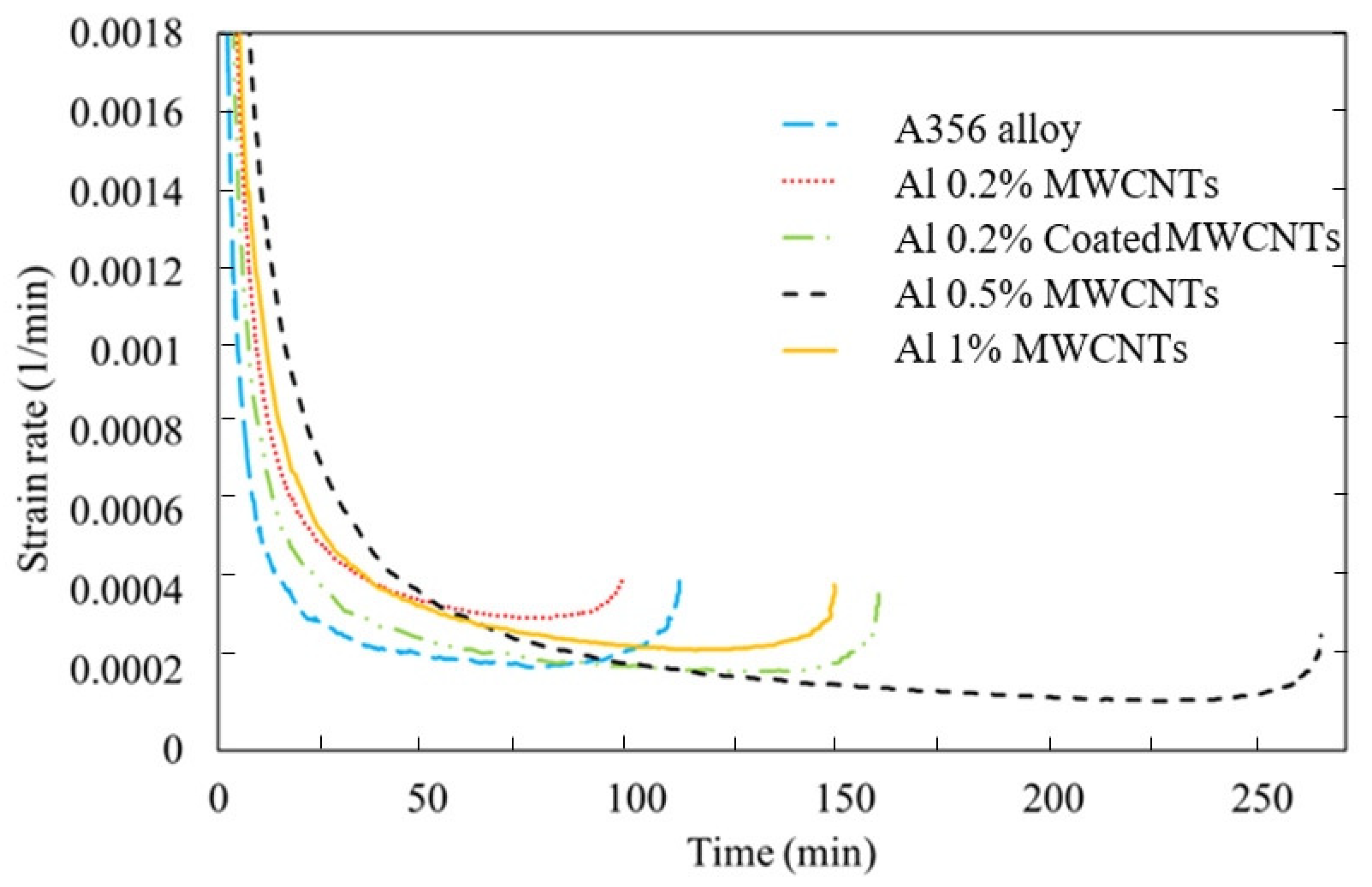

- The addition of MWCNTs with weight percentages of 0.5% and 1% improves the creep life by 139% and 34%, respectively. However, the addition of MWCNTs with 0.2% weight percentages reduced the creep life by 12%.

- The addition of MWCNTs with weight percentages of 0.5% and 1% significantly enhances the creep failure strain by 62% and 30% in comparison to the A356 aluminum alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azadi, M.; Zolfaghari, M.; Rezanezhad, S.; Azadi, M. Effects of SiO2 nano-particles on tribological and mechanical properties of aluminum matrix composites by different dispersion methods. Appl. Phys. A Mater. Sci. Process. 2018, 124, 377. [Google Scholar] [CrossRef]

- David, R.; Shrivastava, V.; Dasgupta, R.; Prasad, B.K.; Singh, I.B. Corrosion Investigation of Zinc–Aluminum Alloy (ZA-27) Matrix Reinforced with In Situ Synthesized Titanium Carbide Particle Composites. Journal of Materials Engineering and Performance. J. Mater. Eng. Perform. 2019, 28, 2356–2364. [Google Scholar] [CrossRef]

- Kannan, C.; Ramanujam, R. Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J. Adv. Res. 2017, 8, 309–319. [Google Scholar] [CrossRef]

- Tan, C.; Abe, Y.; Daodon, W.; Takahashi, N.; Mori, K.; Purbolaksono, J. Increase in ironing limit of aluminium alloy cups with lubricants containing nanoparticles. J. Mater. Process. Technol. 2016, 229, 804–813. [Google Scholar] [CrossRef]

- Krishnan, M.N.; Suresh, S.; Vettivel, S. Characterization, formability, various stresses and failure analysis on workability of sintered Mg-5%B4C composite under triaxial stress state condition. J. Alloys Compd. 2018, 747, 324–339. [Google Scholar] [CrossRef]

- Rajamohan, V.; Mathew, A.T. Material and Mechanical Characterization of Multi-Functional Carbon Nanotube Reinforced Hybrid Composite Materials. Exp. Tech. 2019, 43, 301–314. [Google Scholar] [CrossRef]

- Hu, W.; Huang, Z.; Wang, Y.; Li, X.; Zhai, H.; Zhou, Y.; Chen, L. Layered ternary MAX phases and their MX particulate derivative reinforced metal matrix composite: A review. J. Alloys Compd. 2021, 856, 157313. [Google Scholar] [CrossRef]

- Merad, L.; Benyoucef, B.; Abadie, M.; Charles, J. Characterization and mechanical properties of epoxy resin reinforced with TiO2 nanoparticles. Exp. Tech. 2014, 38, 59–66. [Google Scholar] [CrossRef]

- Azarniya, A.; Taheri, A.K.; Taheri, K.K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective. J. Alloys Compd. 2019, 781, 945–983. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Svec, P.; Orovcik, L. Industrially fabricated in-situ Al-AlN metal matrix composites (part A): Processing, thermal stability, and microstructure. J. Alloys Compd. 2021, 883, 160858. [Google Scholar] [CrossRef]

- Elhadari, H.; Patel, H.; Chen, D.; Kasprzak, W. Tensile and fatigue properties of a cast aluminum alloy with Ti, Zr and V additions. Mater. Sci. Eng. A 2011, 528, 8128–8138. [Google Scholar] [CrossRef]

- Heshmati, M.; Astinchap, B.; Heshmati, M.; Yas, M.H.; Amini, Y. An integrated numerical–experimental study on the optimum utilization of carbon nanotubes in laminated composites. J. Sandw. Struct. Mater. 2015, 19, 231–258. [Google Scholar] [CrossRef]

- Patra, A.K.; Mitra, N. Mixed-mode fracture of sandwich composites: Performance improvement with multiwalled carbon nanotube sonicated resin. J. Sandw. Struct. Mater. 2017, 20, 379–395. [Google Scholar] [CrossRef]

- Ajoku, C.A. Mechanical properties of aluminum foam reinforced with recycled ceramic aggregates. Niger. J. Technol. 2019, 38, 315–325. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature effect on the axial quasi-static compressive behavior of ex-situ aluminum foam-filled tubes. Compos. Struct. 2017, 180, 709–722. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloys Compound. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Prakash, D.S.; Balaji, V.; Rajesh, D.; Anand, P.; Karthick, M. Experimental investigation of nano reinforced aluminium based metal matrix composites. Mater. Today Proc. 2021, 54, 852–857. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Park, B.; Jo, I.; Lee, S.-K.; Kim, Y.; Lee, S.-B.; Cho, S. Mechanical and Thermal Neutron Absorbing Properties of B4C/Aluminum Alloy Composites Fabricated by Stir Casting and Hot Rolling Process. Metals 2021, 11, 413. [Google Scholar] [CrossRef]

- Divagar, S.; Vigneshwar, M.; Selvamani, S. Impacts of Nano Particles on Fatigue Strength of Aluminum Based Metal Matrix Composites for Aerospace. Mater. Today Proc. 2016, 3, 3734–3739. [Google Scholar] [CrossRef]

- Raju, P.R.M.; Rajesh, S.; Raju, K.S.R.; Raju, V.R. Evaluation of Fatigue Life of Al2024/Al2O3 Particulate Nano Composite Fabricated Using Stir Casting Technique. Mater. Today Proc. 2017, 4, 3188–3196. [Google Scholar] [CrossRef]

- Hemanth, J. Quartz (SiO2p) reinforced chilled metal matrix composite (CMMC) for automotive applications. Mater. Des. 2009, 30, 323–329. [Google Scholar] [CrossRef]

- Mazahery, A.; Abdizadeh, H.; Baharvandi, H. Development of high-performance A356/nano-Al2O3 composites. Mater. Sci. Eng. A 2009, 518, 61–64. [Google Scholar] [CrossRef]

- Smart, D.S.R.; Kumar, J.P.; Smart, J.J. High Temperature Mechanical and Creep Performance of AA7075/TaC/Si3N4/Ti Hybrid Metal Matrix Composites. Int. J. Manuf. Mater. Mech. Eng. 2021, 11, 50–62. [Google Scholar] [CrossRef]

- Tariq, F.; Uzair, M.; Shifa, M. Residual compressive strength of aluminum alloy honeycomb sandwich panel in the presence of multiple impact dents. J. Sandw. Struct. Mater. 2021, 24, 1189–1205. [Google Scholar] [CrossRef]

- Gosavi, S.V.; Jaybhaye, M. Microstructural studies on aluminium metal matrix composite (Al7075-SiC) fabricated through stir casting process. Mater. Today Proc. 2021, 39, 1412–1416. [Google Scholar] [CrossRef]

- Tang, P.; Yu, F.; Teng, X.; Peng, L. Microstructure and creep behavior of in situ SiO2/Al composites produced with different size precursors. Compos. Interfaces 2021, 28, 1257–1279. [Google Scholar] [CrossRef]

- Rohatgi, P.; Schultz, B.; Daoud, A.; Zhang, W. Tribological performance of A206 aluminum alloy containing silica sand particles. Tribol. Int. 2010, 43, 455–466. [Google Scholar] [CrossRef]

- Yar, A.A.; Montazerian, M.; Abdizadeh, H.; Baharvandi, H. Microstructure and mechanical properties of aluminum alloy matrix composite reinforced with nano-particle MgO. J. Alloys Compd. 2009, 484, 400–404. [Google Scholar] [CrossRef]

- Sajjadi, S.; Parizi, M.T.; Ezatpour, H.; Sedghi, A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J. Alloys Compd. 2012, 511, 226–231. [Google Scholar] [CrossRef]

- Sajjadi, S.; Ezatpour, H.; Beygi, H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Zhao, J.; Su, H.; Wu, C. The effect of ultrasonic vibration on stress-strain relations during compression tests of aluminum alloys. J. Mater. Res. Technol. 2020, 9, 14895–14906. [Google Scholar] [CrossRef]

- Bhowmik, A.; Dey, D.; Biswas, A. Characteristics Study of Physical, Mechanical and Tribological Behaviour of SiC/TiB2 Dispersed Aluminium Matrix Composite. Silicon 2021, 14, 1133–1146. [Google Scholar] [CrossRef]

- Panthglin, C.; Boontein, S.; Kajornchaiyakul, J.; Limmaneevichitr, C. Microstructure and Impression Creep Characteristics of A356–SiC Composites Containing Zr. Int. J. Met. 2021, 16, 783–797. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Li, Y.; Mao, D.; Wan, L.; Huang, Y. Insight into ultra-refined grains of aluminum matrix composites via deformation-driven metallurgy. Compos. Commun. 2021, 26, 100776. [Google Scholar] [CrossRef]

- Zhao, K.; Zhu, X.; Liu, J.; Wang, Y.; Chen, B.; Wei, Q.; An, L. Superb high-temperature strength of aluminum-based nanocomposite with supra-nano stacking faults/twins. Compos. Commun. 2021, 25, 100753. [Google Scholar] [CrossRef]

- Siddappa, P.; Shivakumar, B.; Yogesha, K. Synthesis and characterization of cold extruded Al/TiC metal matrix composite produced by stir casting technique. Mater. Today Proc. 2021, 46, 2534–2539. [Google Scholar] [CrossRef]

- Gupta, A.; Yadav, A.; Singh, G.; Kumar, S.; Kumar, A. Study of doping effect on properties of AlSiC composite: A review. Mater. Today Proc. 2021, 47, 4059–4061. [Google Scholar] [CrossRef]

- Senthil, S.; Raguraman, M.; Thamarai Manalan, D. Manufacturing processes & recent applications of aluminium metal matrix composite materials: A review. in: Mater. Today Proc. 2020, 45, 5934–5938. [Google Scholar] [CrossRef]

- Sankhla, A.; Patel, K.M. Metal Matrix Composites Fabricated by Stir Casting Process—A Review. Adv. Mater. Process. Technol. 2021, 8, 1270–1291. [Google Scholar] [CrossRef]

- Ajayan, P.M.; Tour, J.M. Nanotube composites. Nature 2007, 447, 1066–1068. [Google Scholar] [CrossRef]

- Sirichaivetkul, R.; Limmaneevichitr, C.; Tongsri, R.; Kajornchaiyakul, J. Isothermal Investigation and Deformation Behavior during Homogenization of 6063 Aluminum Alloy. J. Mater. Eng. Perform. 2022, 1–13. [Google Scholar] [CrossRef]

- Al-Furjan, M.S.; Hajmohammad, M.H.; Shen, X.; Rajak, D.K.; Kolahchi, R. Evaluation of tensile strength and elastic modulus of 7075-T6 aluminum alloy by adding SiC reinforcing particles using vortex casting method. J. Alloys Compd. 2021, 886, 161261. [Google Scholar] [CrossRef]

- Hamedan, A.D.; Shahmiri, M. Production of A356–1wt% SiC nanocomposite by the modified stir casting method. Mater. Sci. Eng. A 2012, 556, 921–926. [Google Scholar] [CrossRef]

- Ali, Z.; Muthuraman, V.; Rathnakumar, P.; Gurusamy, P.; Nagaral, M. Studies on mechanical properties of 3 wt% of 40 and 90 µm size B4C particulates reinforced A356 alloy composites. Mater. Today Proc. 2022, 52, 494–499. [Google Scholar] [CrossRef]

- ASTM Standard Specification B26/B26M-09; Standard Specification for Aluminum-Alloy Sand Castings. ASTM International: West Conshohocken, PA, USA, 2009.

- Bradbury, C.R.; Gomon, J.-K.; Kollo, L.; Kwon, H.; Leparoux, M. Hardness of Multi Wall Carbon Nanotubes reinforced aluminium matrix composites. J. Alloys Compd. 2014, 585, 362–367. [Google Scholar] [CrossRef]

- Issa, H.K.; Taherizadeh, A.; Maleki, A.; Ghaei, A. Development of an aluminum/amorphous nano-SiO2 composite using powder metallurgy and hot extrusion processes. Ceram. Int. 2017, 43, 14582–14592. [Google Scholar] [CrossRef]

- Inegbenebor, A.O.; Bolu, C.; Babalola, O.; Fayomi, O.S.I. Aluminum Silicon Carbide Particulate Metal Matrix Composite Development Via Stir Casting Processing. Silicon 2016, 10, 343–347. [Google Scholar] [CrossRef]

- Fullman, R.L.; Carreker, R.P.; Fisher, J.C. Simple Devices for Approximating Constant Stress During Tensile Creep Tests. JOM 1953, 5, 657–659. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Yamdagni Strengthening in carbon nanotube/aluminum (CNT/Al)composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Paramsothy, M.; Gupta, M.; Chan, J.; Kwok, R. Carbon nanotube addition to simultaneously enhance strength and ductility of hybrid AZ31/AA5083 alloy. Mater. Sci. Appl. 2011, 2, 20–29. [Google Scholar] [CrossRef][Green Version]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Simultaneous enhancement in strength and ductility by reinforcing magnesium with carbon nanotubes. Mater. Sci. Eng. A 2006, 423, 153–156. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; Wiley, Cop.: New York, NY, USA, 2001. [Google Scholar]

- Abdizadeh, H.; Baghchesara, M.A. Investigation on mechanical properties and fracture behavior of A356 aluminum alloy based ZrO2 particle reinforced metal-matrix composite. Ceram. Int. 2013, 39, 2045–2050. [Google Scholar] [CrossRef]

- Rawat, A.; Kumar, A.; Agrawal, A.P. Investigation of mechanical properties of heat-treated A356/SiC composite fabricated through stir casting technique. Mater. Today Proc. 2022, 62, 203–208. [Google Scholar] [CrossRef]

| C% | Al% | Cl% | Co% | S% |

|---|---|---|---|---|

| 97.46 | 0.19 | 1.02 | 1.09 | 0.24 |

| Al | Si | Mg | Fe | Cu | Mn | Ti |

|---|---|---|---|---|---|---|

| Base | 7.03% | 0.37% | 0.15% | 0.01% | 0.02% | 0.13% |

| ASTM standard | 6.5–7.5% | 0.25–0.45% | <0.2% | <0.2% | <0.1% | <0.2% |

| Alloy | Yield Stress (MPa) | Ultimate Tensile Strength (MPa) | Hardness (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| A356 | 61 | 124 | 644 ± 66 | 2.0 |

| Al 0.2% MWCNTs | 82 | 148 | 705.9 ± 72 | 3.1 |

| Al 0.2% MWCNT-Coated | 112 | 178 | 803 ± 82 | 3.6 |

| Al 0.5% MWCNTs | 128 | 206 | 852.7 ± 87 | 4.2 |

| Al 1% MWCNTs | 90 | 159 | 741.4 ± 76 | 3.4 |

| Alloys Compared with the Base Alloy | Yield Stress (%) | Ultimate Tensile Strength (%) | Hardness (%) | Elongation at Break (%) |

|---|---|---|---|---|

| Al 0.2% MWCNTs | 34 | 19 | 9 | 55 |

| Al 0.2% MWCNT-Coated | 84 | 44 | 24 | 80 |

| Al 0.5% MWCNTs | 110 | 66 | 32 | 110 |

| Al 1% MWCNTs | 48 | 28 | 15 | 70 |

| Alloy | A356 | Al 0.2% MWCNTs | Al 0.2% MWCNT-Coated | Al 0.5% MWCNTs | Al 1% MWCNTs |

|---|---|---|---|---|---|

| Creep Failure Strain (mm/mm) | 0.0473 | 0.0417 | 0.0695 | 0.0762 | 0.0610 |

| Creep lifetime (min) | 110.4 | 97 | 158.4 | 264 | 147.4 |

| Alloy | A356 | Al 0.2% MWCNTs | Al 0.2% Coated-MWCNTs | Al 0.5% MWCNTs | Al 1% MWCNTs |

|---|---|---|---|---|---|

| Minimum Creep Strain Rate (min−1) | 0.000428 | 0.000430 | 0.000416 | 0.000288 | 0.000414 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, L.; Tan, C.Y.; Shen, X.; Ramesh, S.; Kolahchi, R.; Hajmohammad, M.H.; Rajak, D.K. Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting. Materials 2022, 15, 8959. https://doi.org/10.3390/ma15248959

Shan L, Tan CY, Shen X, Ramesh S, Kolahchi R, Hajmohammad MH, Rajak DK. Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting. Materials. 2022; 15(24):8959. https://doi.org/10.3390/ma15248959

Chicago/Turabian StyleShan, L., C. Y. Tan, X. Shen, S. Ramesh, R. Kolahchi, M. H. Hajmohammad, and D. K. Rajak. 2022. "Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting" Materials 15, no. 24: 8959. https://doi.org/10.3390/ma15248959

APA StyleShan, L., Tan, C. Y., Shen, X., Ramesh, S., Kolahchi, R., Hajmohammad, M. H., & Rajak, D. K. (2022). Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting. Materials, 15(24), 8959. https://doi.org/10.3390/ma15248959