High-Temperature Oxidation Behavior of TiB2-HfB2-Ni Cermet Material

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussions

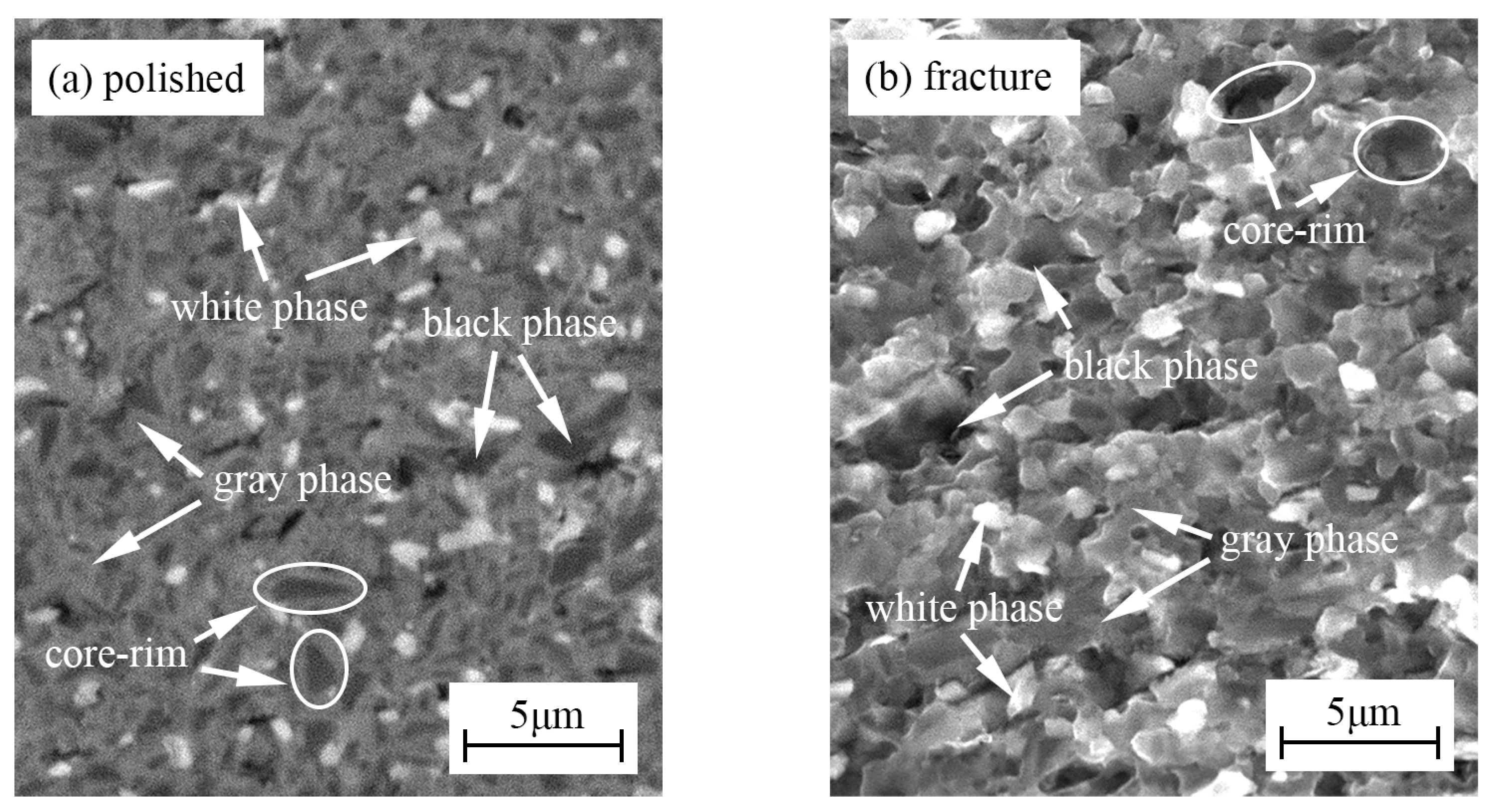

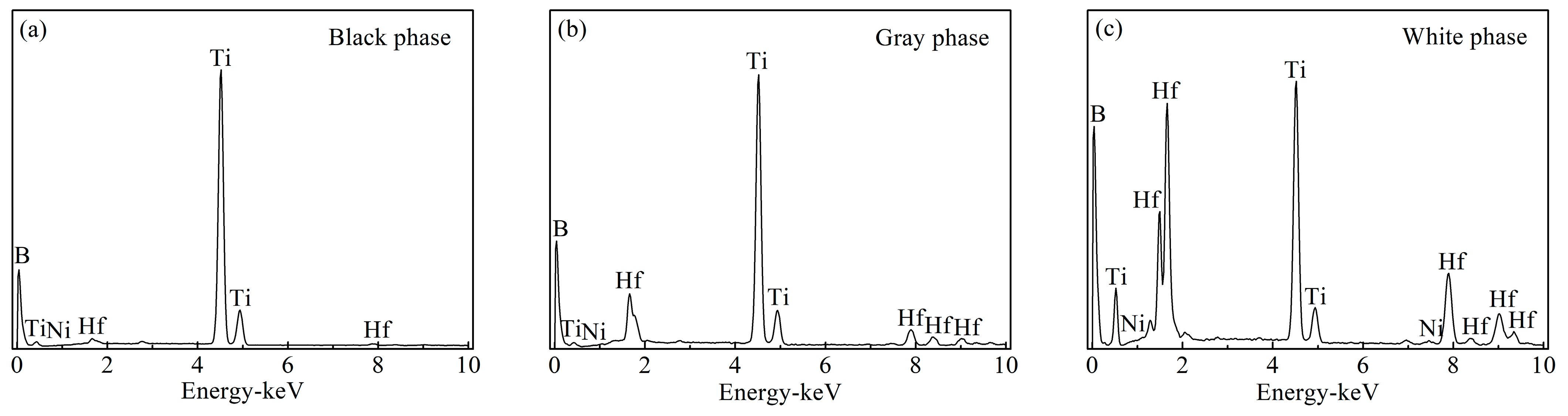

3.1. Microstructure of TBHB before Oxidation

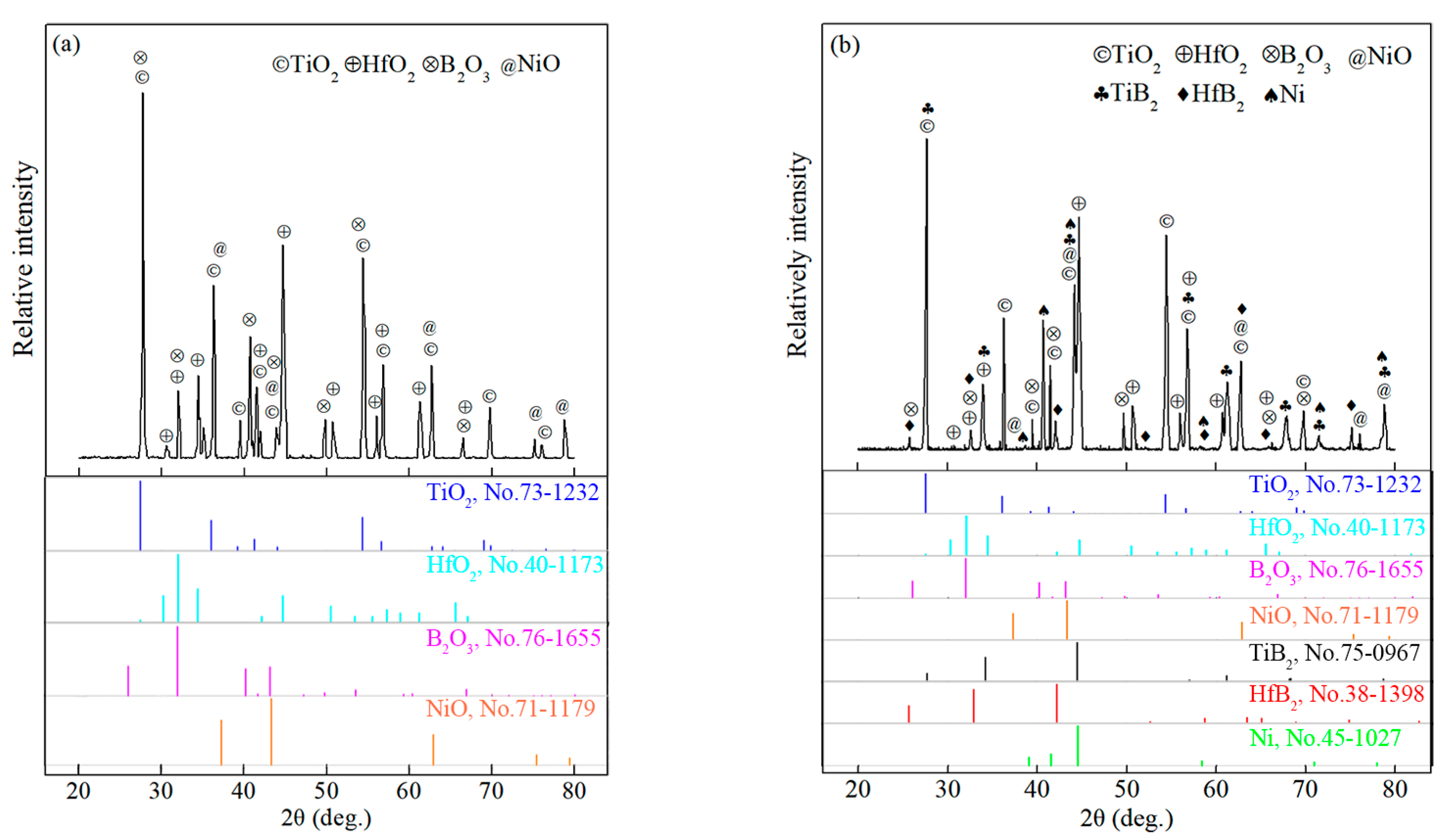

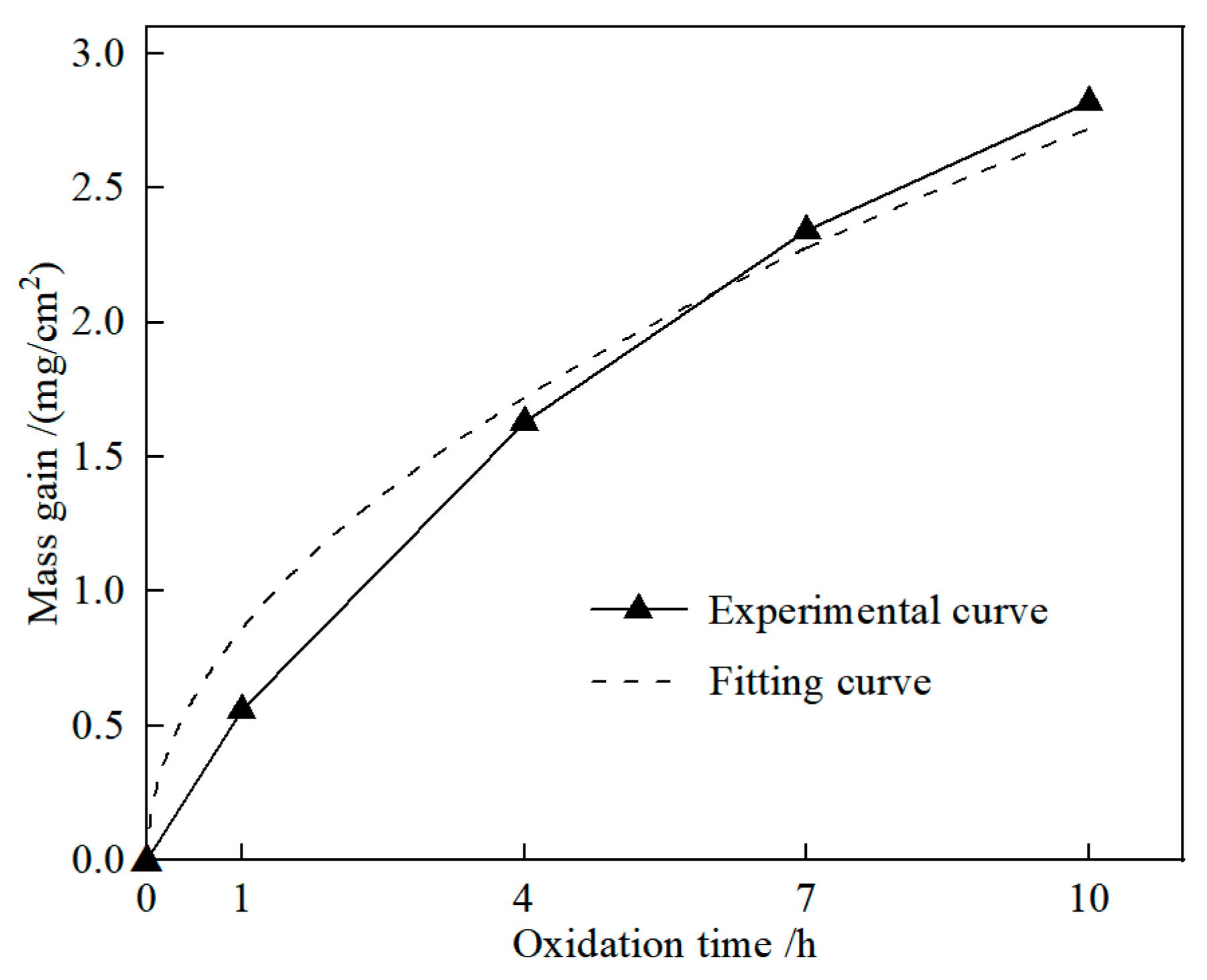

3.2. Oxides and Mass Gain in TBHB

3.3. Thermal Fracture of TBHB in the High-Temperature Oxidation Process

4. Conclusions

- (1)

- Before oxidation, TiB2-HfB2-Ni cermets, consisting of TiB2, HfB2, and Ni phases, had the core-rim structure. The core was TiB2 grain and the rim was composed of Ni and the solid solution (Ti, Hf)B2.

- (2)

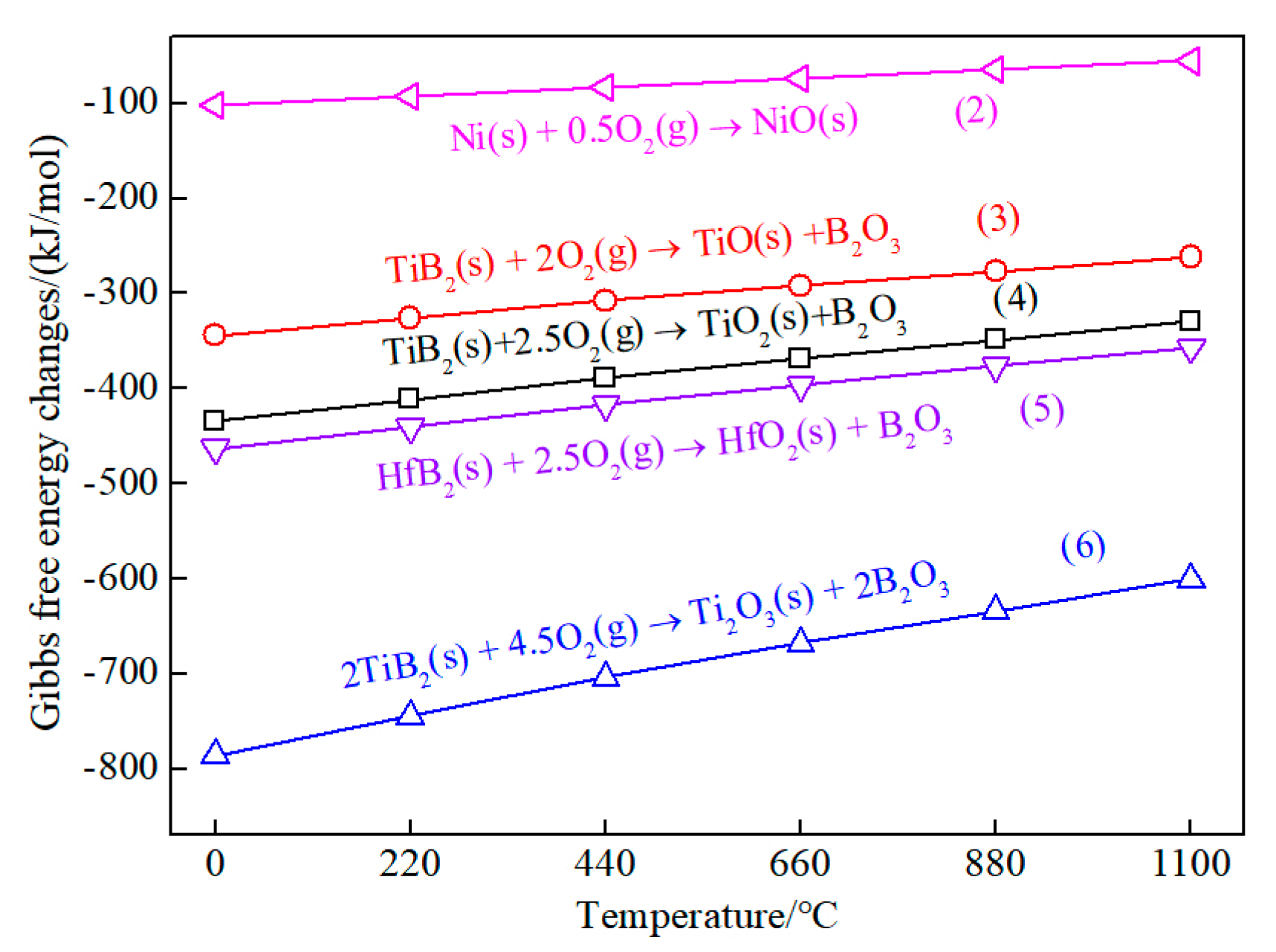

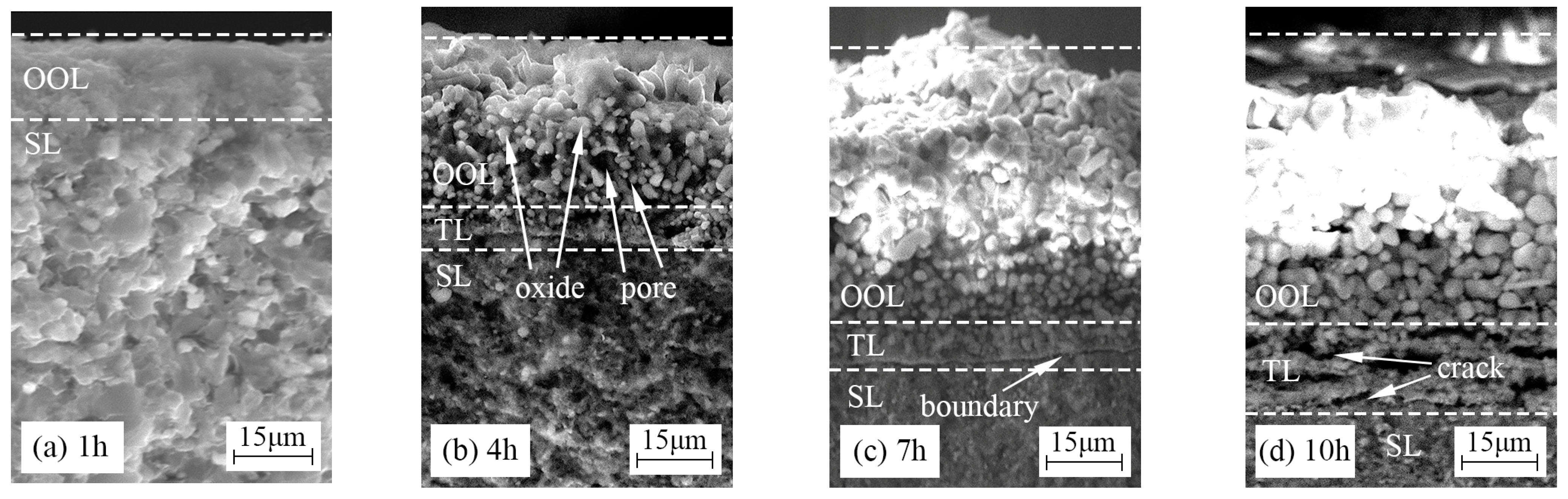

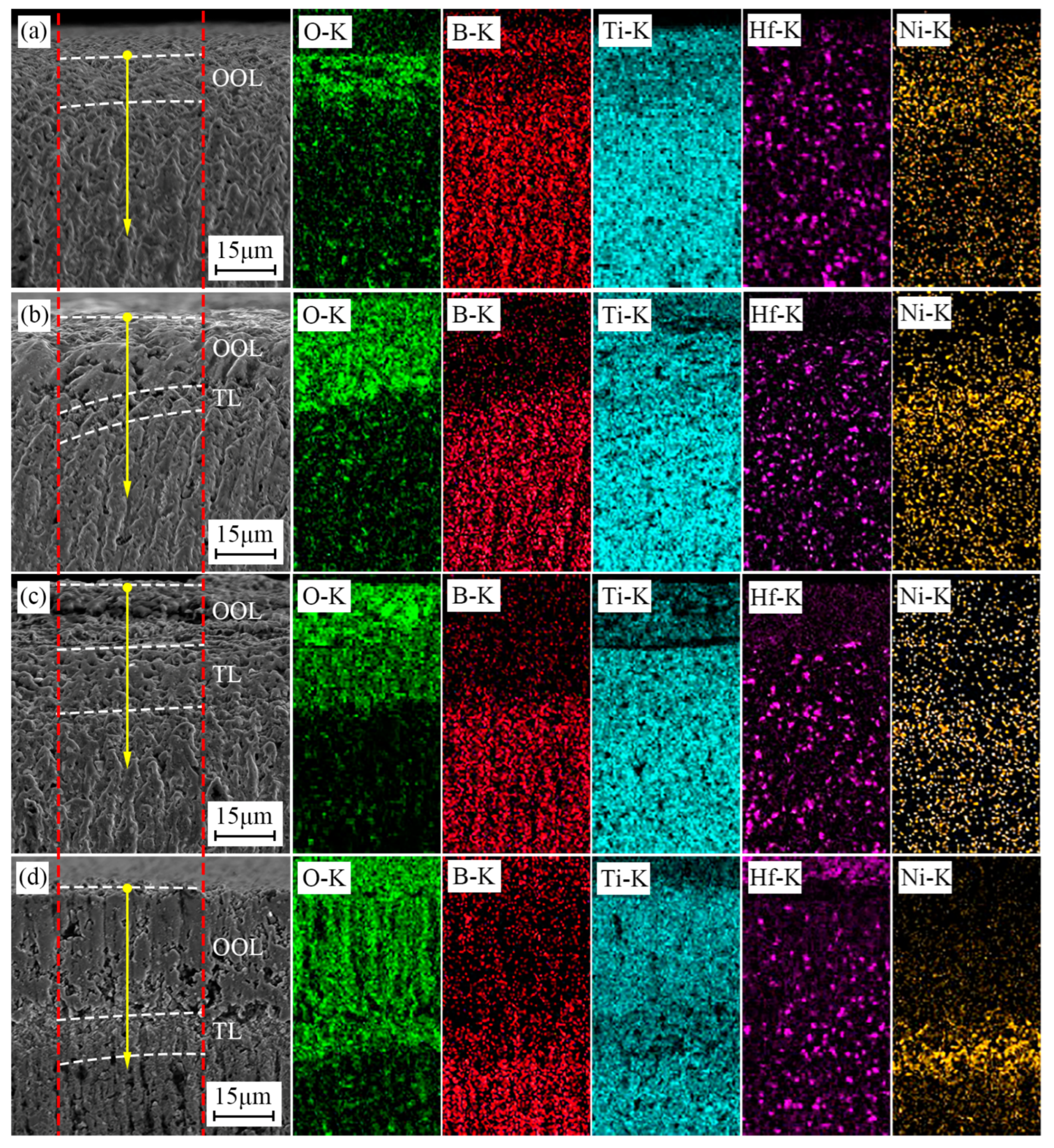

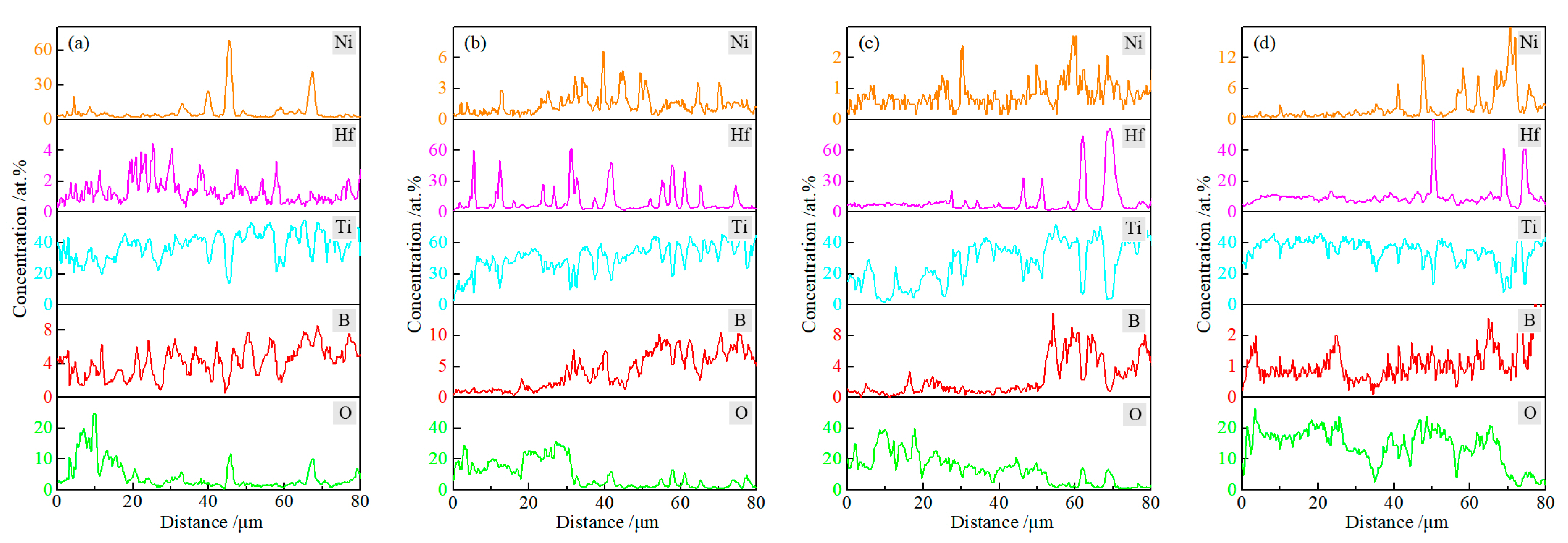

- After oxidation, the oxides of TiB2-HfB2-Ni cermet surface were TiO2, HfO2, B2O3, and NiO. Aside from the above oxides, there was TiB2, HfB2, and Ni on the cross-section. The values of mass gain at 1100 °C for 1, 4, 7, and 10 h were 0.56, 1.63, 2.34, and 2.82 mg/cm2, respectively. The oxide content reduced gradually from the outer to the inner of TiB2-HfB2-Ni cermet. With the oxidation time increasing from 1 h to 10 h, the oxidation of TiB2-HfB2-Ni cermet surface became more severe and the oxide layer became thicker.

- (3)

- The thicknesses of the oxide layers at 1100 °C for 1, 4, 7, and 10 h were about 15, 30, 50, and 70 μm, respectively. The oxide layer was thinner and dense at 1100 °C for 1 h. An obvious boundary was observed between the transition layer and the substrate layer at 1100 °C for 7 h. The thermal fracture occurred in contact regions of different layers at 1100 °C for 10 h. TBHB took place in oxidation at different levels from the outer to the inner, and there were some differences between the components of the outer oxide layer, transition layer, and substrate layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Balcı, Ö.; Burkhardt, U.; Schmidt, M.; Hennicke, J.; Yağcı, M.B.; Somer, M. Densification, microstructure and properties of TiB2 ceramics fabricated by spark plasma sintering. Mater. Charact. 2018, 145, 435–443. [Google Scholar] [CrossRef]

- Shayesteh, F.; Delbari, S.A.; Ahmadi, Z.; Shokouhimehr, M.; Asl, M.S. Influence of TiN dopant on microstructure of TiB2 ceramic sintered by spark plasma. Ceram. Int. 2019, 45, 5306–5311. [Google Scholar] [CrossRef]

- Grigoriev, S.; Pristinskiy, Y.; Soe, T.; Malakhinsky, A.; Mosyanov, M.; Podrabinnik, P.; Smirnov, A.; Pinargote, N.S. Processing and Characterization of Spark Plasma Sintered SiC-TiB2-TiC Powders. Materials 2022, 15, 1946–1961. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Hamidzadeh Mahaseni, Z.; Dashti Germi, M.; Delbari, S.A.; Le, Q.V.; Ahmadi, Z.; Shokouhimehr, M.; Shahedi Asl, M.; Namini, A.S. Densification behavior and microstructure development in TiB2 ceramics doped with h-BN. Ceram. Int. 2020, 46, 18970–18975. [Google Scholar] [CrossRef]

- Song, J.; Huang, C.; Zou, B.; Liu, H.; Liu, L.; Wang, J. Effects of sintering additives on microstructure and mechanical properties of TiB2–WC ceramic–metal composite tool materials. Int. J. Refract. Met. Hard Mater. 2012, 30, 91–95. [Google Scholar] [CrossRef]

- Song, J.; Xie, J.; Lv, M.; Gao, J.; An, J. Microstructure and Mechanical Properties of TiB2-HfC Ceramic Tool Materials. JOM 2018, 70, 2544–2554. [Google Scholar] [CrossRef]

- Ramesh, B.; Showman, E.; Abraar, S.A.M.; Saxena, K.K.; Tharwan, M.Y.; Alsaadi, N.; Al Sofyani, S.; Elsheikh, A.H. Microstructure, Mechanical Characteristics, and Wear Performance of Spark Plasma Sintered TiB2-Si3N4 as Affected by B4N Doping. Materials 2022, 15, 7096–7113. [Google Scholar] [CrossRef]

- Song, J.; Huang, C.; Lv, M.; Zou, B.; Wang, S.; Wang, J.; An, J. Effects of TiC content and melt phase on microstructure and mechanical properties of ternary TiB2-based ceramic cutting tool materials. Mater. Sci. Eng. A 2014, 605, 137–143. [Google Scholar] [CrossRef]

- Vaferi, K.; Nekahi, S.; Vajdi, M.; Sadegh Moghanlou, F.; Shokouhimehr, M.; Motallebzadeh, A.; Sha, J.; Asl, M.S. Heat transfer, thermal stress and failure analyses in a TiB2 gas turbine stator blade. Ceram. Int. 2019, 45, 19331–19339. [Google Scholar] [CrossRef]

- Qiu, X.-L.; He, C.-Y.; Zhao, P.; Liu, B.-H.; Guo, H.-X.; Liu, G.; Gao, X.-H. Reinforcement optical performance and thermal tolerance in a TiB2-HfB2-based double-layer spectral selective absorber via a pre-annealing strategy. Mater. Today Phys. 2022, 24, 100690–100698. [Google Scholar] [CrossRef]

- Vajdi, M.; Sadegh Moghanlou, F.; Ahmadi, Z.; Motallebzadeh, A.; Shahedi Asl, M. Thermal diffusivity and microstructure of spark plasma sintered TiB2-SiC-Ti composite. Ceram. Int. 2019, 45, 8333–8344. [Google Scholar] [CrossRef]

- Jinpeng, S.; Shaowei, L.; Ahmad, R.; Jiaojiao, G.; Ming, L. Tribological behaviour of TiB2 -HfC ceramic tool material under dry sliding condition. Ceram. Int. 2020, 46, 20320–20327. [Google Scholar] [CrossRef]

- Andrievskii, R.A.; Shul’ga, Y.M.; Volkova, L.S.; Korobov, I.I.; Dremova, N.N.; Kabachkov, E.N.; Kalinnikov, G.V.; Shilkin, S.P. Oxidation behavior of TiB2 micro- and nanoparticles. Inorg. Mater. 2016, 52, 686–693. [Google Scholar] [CrossRef]

- Ni, C.; Tang, Y.; Abdellatif, H.R.S.; Huang, X.; Xie, D.; Ni, J. Boron-Doped TiO2 from Anodization of TiB2 for Efficient Photocatalysis. J. Electrochem. Soc. 2020, 167, 126505–126512. [Google Scholar] [CrossRef]

- Yang, Y.; Kang, Y.; Liu, G.; Cheng, H.-M. Homogeneous boron doping in a TiO2 shell supported on a TiB2 core for enhanced photocatalytic water oxidation. Chin. J. Catal. 2018, 39, 431–437. [Google Scholar] [CrossRef]

- Murthy, T.S.R.C.; Sonber, J.K.; Subramanian, C.; Hubli, R.C.; Suri, A.K. Densification, characterization and oxidation studies of TiB2-WSi2 composite. Int. J. Refract. Met. Hard Mater. 2012, 33, 10–21. [Google Scholar] [CrossRef]

- Murthy, T.S.R.C.; Sonber, J.K.; Vishwanadh, B.; Nagaraj, A.; Sairam, K.; Bedse, R.D.; Chakravartty, J.K. Densification, characterization and oxidation studies of novel TiB2+EuB6 compounds. J. Alloys Compd. 2016, 670, 85–95. [Google Scholar] [CrossRef]

- Murthy, T.S.R.C.; Sonber, J.K.; Subramanian, C.; Hubli, R.C.; Krishnamurthy, N.; Suri, A.K. Densification and oxidation behavior of a novel TiB2–MoSi2–CrB2 composite. Int. J. Refract. Met. Hard Mater. 2013, 36, 243–253. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y.; Cheng, X.; Xie, S. Microstructural evolution and oxidation behavior of TiB2-SiC-B4C composite fabricated by reactive spark plasma sintering. J. Alloys Compd. 2018, 765, 158–165. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, X.; Ge, C.; Liu, G.; Xu, S.; Zhong, D.; Qiao, G. Oxidation behavior of in situ synthesized (TiB + TiC)/Ti–6Al–4V composites from Ti–B4C–C and Ti–TiB2–TiC systems. J. Mater. Res. 2019, 34, 1762–1772. [Google Scholar] [CrossRef]

- Huang, X.; Sun, S.; Tu, G. Investigation of mechanical properties and oxidation resistance of CVD TiB2 ceramic coating on molybdenum. J. Mater. Res. Technol. 2020, 9, 282–290. [Google Scholar] [CrossRef]

- Murthy, T.S.R.C.; Balasubramaniam, R.; Basu, B.; Suri, A.K.; Mungole, M.N. Oxidation of monolithic TiB2 and TiB2–20 wt.% MoSi2 composite at 850 °C. J. Eur. Ceram. Soc. 2006, 26, 187–192. [Google Scholar] [CrossRef]

- An, J.; Song, J.; Liang, G.; Gao, J.; Xie, J.; Cao, L.; Wang, S.; Lv, M.; Agrawal, D. Effects of HfB2 and HfN Additions on the Microstructures and Mechanical Properties of TiB2-Based Ceramic Tool Materials. Materials 2017, 10, 461–471. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Huang, C.; Zou, B.; Liu, H.; Wang, J. Microstructure and mechanical properties of TiB2–TiC–WC composite ceramic tool materials. Mater. Des. 2012, 36, 69–74. [Google Scholar] [CrossRef]

- Ma, K.; Zhang, R.; Sun, J.; Liu, C. Oxidation Mechanism of Biomedical Titanium Alloy Surface and Experiment. Int. J. Corros. 2020, 167, 1678615–1678623. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Oxidation studies on TaC based ultra-high temperature ceramic composites under plasma arc jet exposure. Corros. Sci. 2016, 109, 50–61. [Google Scholar] [CrossRef]

- Xu, L.; Yang, Y.; Wang, S.; Li, M.; Xu, J.; Qian, Y.; Zuo, J.; Zhang, D. Improved both mechanical and anti-oxidation performances of ZrB2-SiC ceramics with molybdenum disilicide addition. Mater. Chem. Phys. 2019, 223, 53–59. [Google Scholar] [CrossRef]

- Astapov, A.N.; Pogozhev, Y.S.; Prokofiev, M.V.; Lifanov, I.P.; Potanin, A.Y.; Levashov, E.A.; Vershinnikov, V.I. Kinetics and mechanism of high-temperature oxidation of the heterophase ZrSi2-MoSi2-ZrB2 ceramics. Ceram. Int. 2019, 45, 6392–6404. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Gao, J.; Song, J. High-Temperature Oxidation Behavior of TiB2-HfB2-Ni Cermet Material. Materials 2022, 15, 8860. https://doi.org/10.3390/ma15248860

Wang Z, Gao J, Song J. High-Temperature Oxidation Behavior of TiB2-HfB2-Ni Cermet Material. Materials. 2022; 15(24):8860. https://doi.org/10.3390/ma15248860

Chicago/Turabian StyleWang, Zhuo, Jiaojiao Gao, and Jinpeng Song. 2022. "High-Temperature Oxidation Behavior of TiB2-HfB2-Ni Cermet Material" Materials 15, no. 24: 8860. https://doi.org/10.3390/ma15248860

APA StyleWang, Z., Gao, J., & Song, J. (2022). High-Temperature Oxidation Behavior of TiB2-HfB2-Ni Cermet Material. Materials, 15(24), 8860. https://doi.org/10.3390/ma15248860