Simulation of Far-Field Light Distribution of Micro-LED Based on Its Structural Parameters

Abstract

1. Introduction

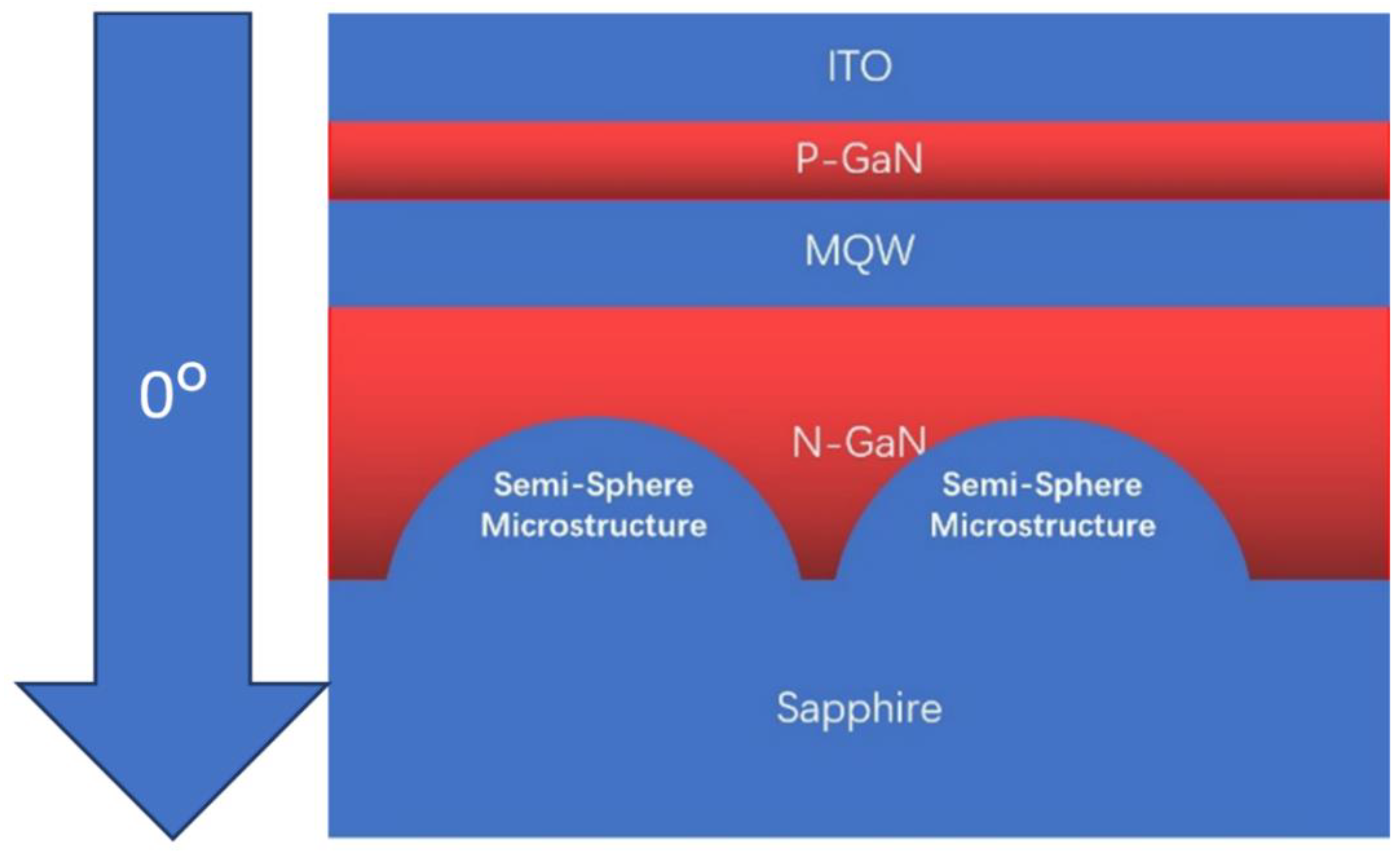

2. Design Concept

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hsiang, E.L.; Li, Y.; He, Z.; Zhan, T.; Zhang, C.; Lan, Y.F.; Dong, Y.; Wu, S.T. Enhancing the efficiency of color conversion micro-LED display with a patterned cholesteric liquid crystal polymer film. Nanomaterials 2020, 10, 2430. [Google Scholar] [CrossRef]

- Fan, Z.Y.; Lin, J.Y.; Jiang, H.X. III-nitride micro-emitter arrays: Development and applications. J. Phys. D Appl. Phys. 2008, 41, 94001. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Huang Chen, S.-W.H.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and micro-LED: Promising candidates for the next generation display technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef]

- Huang, Y.; Tan, G.; Gou, F.; Li, M.-C.; Lee, S.-L.; Wu, S.-T. Prospects and challenges of mini-LED and micro-LED displays. J. Soc. Inf. Disp. 2019, 27, 387–401. [Google Scholar] [CrossRef]

- Park, H.J.; Cha, Y.J.; Kwak, J.S. Chip size-dependent light extraction efficiency for blue micro-LEDs. J. Korean Inst. Electr. Electron. Mater. Eng. 2019, 32, 47–52. [Google Scholar]

- Chang, K.; Yu, L.; Sang, J. P-5.13: Visual luminance uniformity and OD value calculation for direct type mini-LED backlight. SID Symp. Dig. Tech. Pap. 2019, 50 (Suppl. S1), 750–752. [Google Scholar] [CrossRef]

- Tan, G.; Huang, Y.; Li, M.C.; Lee, S.L.; Wu, S.T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584. [Google Scholar] [CrossRef]

- Deng, Z.; Zheng, B.; Zheng, J.; Wu, L.; Yang, W.; Lin, Z.; Shen, P.; Li, J. 74–5: Late-news paper: High dynamic range Incell LCD with excellent performance. SID Symp. Dig. Tech. Pap. 2018, 49, 996–998. [Google Scholar] [CrossRef]

- Chen, E.; Guo, J.; Jiang, Z.; Shen, Q.; Ye, Y.; Xu, S.; Sun, J.; Yan, Q.; Guo, T. Edge/direct-lit hybrid mini-LED backlight with U-grooved light guiding plates for local dimming. Opt. Express 2021, 29, 12179–12194. [Google Scholar] [CrossRef]

- Zhu, R.; Luo, Z.; Chen, H.; Dong, Y.; Wu, S.T. Realizing Rec. 2020 color gamut with quantum dot displays. Opt. Express 2015, 23, 23680–23693. [Google Scholar] [CrossRef]

- Chen, E.; Xie, H.; Huang, J.; Miu, H.; Shao, G.; Li, Y.; Guo, T.; Xu, S.; Ye, Y. Flexible/curved backlight module with quantum-dots microstructure array for liquid crystal displays. Opt. Express 2018, 26, 3466–3482. [Google Scholar] [CrossRef]

- Peng, F.; Chen, H.; Gou, F.; Lee, Y.H.; Wand, M.; Li, M.C.; Lee, S.L.; Wu, S.T. Analytical equation for the motion picture response time of display devices. J. Appl. Phys. 2017, 121, 023108. [Google Scholar] [CrossRef]

- Tsai, C.C.; Wu, S.T. Broadband wide-angle polarization converter for LCD backlight. Appl. Opt. 2008, 47, 2882–2887. [Google Scholar] [CrossRef]

- Lu, Z.Z.J.; Lee, J.W., III; Kim, J.M. Wide-angle film diffuser. J. Soc. Inf. Disp. 2007, 15, 565–570. [Google Scholar] [CrossRef]

- Li, Z.; Guo, L.; Dai, K.; Liao, Y.; Ma, R.; Li, C.; Wang, Z.; Shao, X. P-11.2: The analysis of light-leakage under the large viewing angle for LCD. SID Symp. Dig. Tech. Pap. 2019, 50 (Suppl. S1), 910–911. [Google Scholar] [CrossRef]

- Gou, F.; Hsiang, E.L.; Tan, G.; Chou, P.T.; Li, Y.L.; Lan, Y.F.; Wu, S.T. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746–A757. [Google Scholar] [CrossRef]

- Lu, Z.; Tian, P.; Chen, H.; Baranowski, I.; Fu, H.; Huang, X.; Montes, J.; Fan, Y.; Wang, H.; Liu, X.; et al. Active tracking system for visible light communication using a GaN-based micro-LED and NRZ-OOK. Opt. Express 2017, 25, 17971–17981. [Google Scholar] [CrossRef]

- Han, H.V.; Lin, H.Y.; Lin, C.C.; Chong, W.C.; Li, J.R.; Chen, K.J.; Yu, P.; Chen, T.M.; Chen, H.M.; Lau, K.M.; et al. Resonant-enhanced full-color emission of quantum-dot-based micro LED display technology. Opt. Express 2015, 23, 32504–32515. [Google Scholar] [CrossRef]

- Gordon, J.; Harman, S. A graduated cylinder colorimeter: An investigation of path length and the Beer–Lambert law. J. Chem. Educ. 2002, 79, 611. [Google Scholar] [CrossRef]

- Zhu, L.; Ng, C.W.; Wong, N.; Wong, K.K.Y.; Lai, P.T.; Choi, H.W. Pixel-to-pixel fiber-coupled emissive micro-light-emitting diode arrays. IEEE Photonics J. 2009, 1, 1–8. [Google Scholar] [CrossRef][Green Version]

- Bayneva, I.I. Calculation and construction of optical elements of light devices. Dilemas Contemp. Educ. Política Valores 2019, 6, 58. [Google Scholar] [CrossRef]

- Guo, W.; Meng, H.; Chen, Y.; Sun, T.; Li, Y. Wafer-level monolithic integration of vertical micro-LEDs on glass. IEEE Photon. Technol. Lett. 2020, 32, 673–676. [Google Scholar] [CrossRef]

- Xu, F.F.; Tao, T.; Liu, B.; Wang, X.; Gong, M.G.; Zhi, T.; Pan, D.; Xie, Z.; Zhou, Y.; Zheng, Y.; et al. High-performance semi-polar inGaN/GaN green micro light-emitting-diodes. IEEE Photon. J. 2019, 12, 1–7. [Google Scholar] [CrossRef]

- Lelikov, Y.S.; Bochkareva, N.I.; Gorbunov, R.I.; Martynov, I.A.; Rebane, Y.T.; Tarkin, D.V.; Shreter, Y.G. Measurement of the absorption coefficient for light laterally propagating in light-emitting diode structures with In0. 2Ga0. 8N/GaN quantum wells. Semiconductors. 2008, 42, 1342–1345. [Google Scholar] [CrossRef]

- Du, Y.; Chang, B.; Fu, X.; Wang, X.; Wang, M. Electronic structure and optical properties of zinc-blende GaN. Optik 2012, 123, 2208–2212. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Ishikawa, H.; Jiang, H.; Egawa, T.; Jimbo, T.; Umeno, M. Optical absorption and photoluminescence studies of n-type GaN. Jpn. J. Appl. Phys. 1999, 38, L993–L995. [Google Scholar] [CrossRef]

- Yang, D.; Thomas, M.E.; Tropf, W.J. Infrared refractive index of sapphire as a function of temperature. Window Dome Technol. Mater. 1999, 3705, 60–69. [Google Scholar]

- O’Mahony, D.; Hossain, M.N.; Justice, J.; Pelucchi, E.; O’Riordan, A. High index contrast optical platform using gallium phosphide on sapphire: An alternative to SOI. Silicon Photonics Photonic Integr. Circuits 2012, 8431, 294–301. [Google Scholar]

| Material | Thickness | Refractive Index | Absorption Index [mm−1] |

|---|---|---|---|

| Semi-sphere micro-structure | Φ 3 µm | 1.70 | 0.004 |

| Sapphire | 5 µm | 1.70 | 0.004 |

| ITO | 300 nm | 1.50 | 0 |

| p-GaN | 150 nm | 2.45 | 2.300 |

| Active layer (MQW) | 100 nm | 2.54 | 25 |

| n-GaN | 6.75 µm | 2.45 | 2.3 |

| Material | Thickness (µm) | Refractive Index | Absorption Index [mm−1] |

|---|---|---|---|

| Semi-sphere micro-structure | Φ1–4 | 1.70 | 0.004 |

| Material | Thickness | Refractive Index | Absorption Index [mm−1] |

|---|---|---|---|

| Semi-sphere micro-structure | Φ3 µm | 1.70 | 0.004 |

| Al2O3 | 10–50 µm | 1.70 | 0.004 |

| ITO | 300 nm | 1.50 | 0 |

| p-GaN | 150 nm | 2.45 | 2.300 |

| Active layer | 100 nm | 2.54 | 25 |

| n-GaN | 6.75 µm | 2.45 | 2.300 |

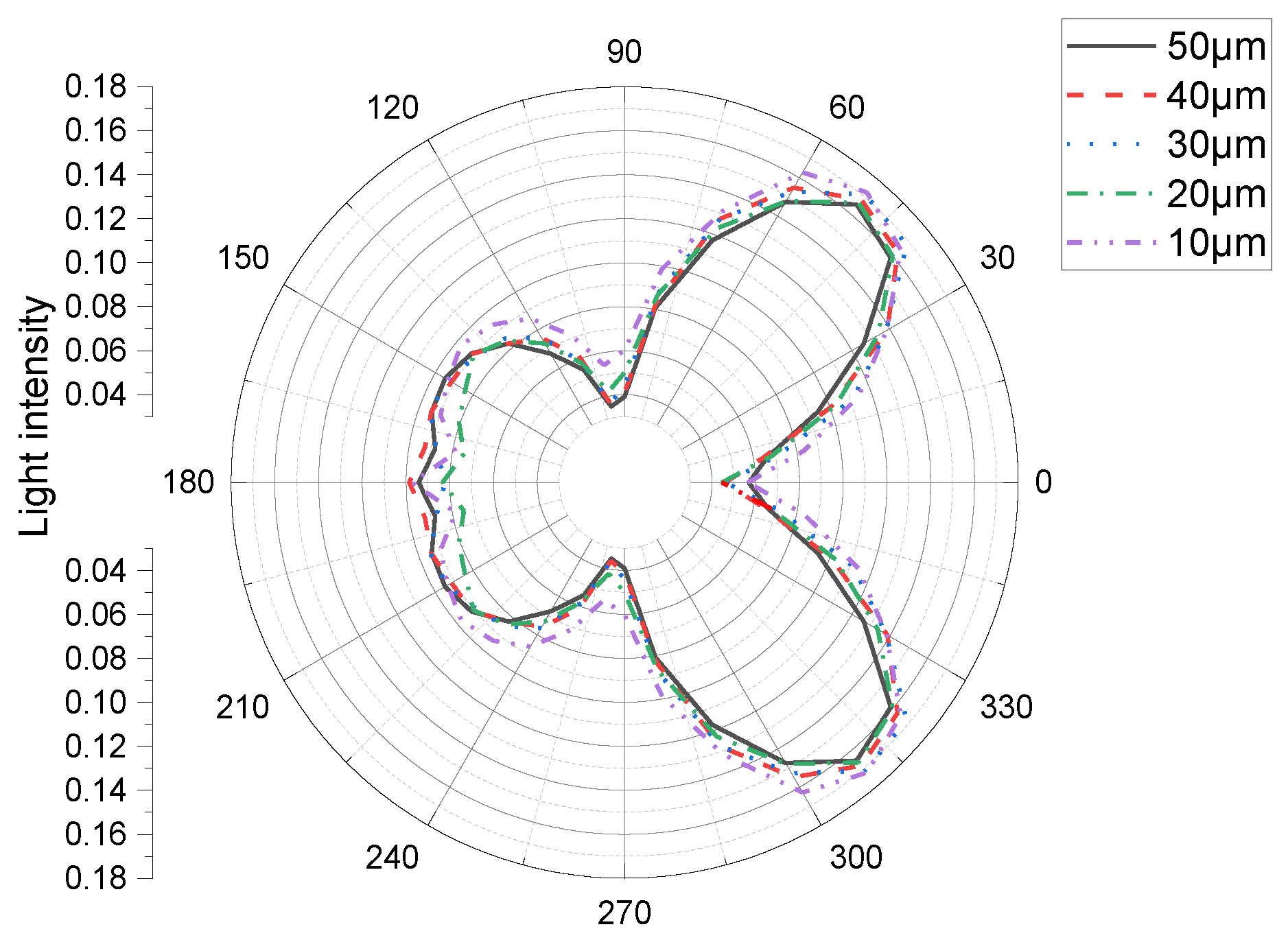

| Chip Size [μm] | Light Efficiency |

|---|---|

| 10 | 0.653 |

| 20 | 0.590 |

| 30 | 0.605 |

| 40 | 0.597 |

| 50 | 0.572 |

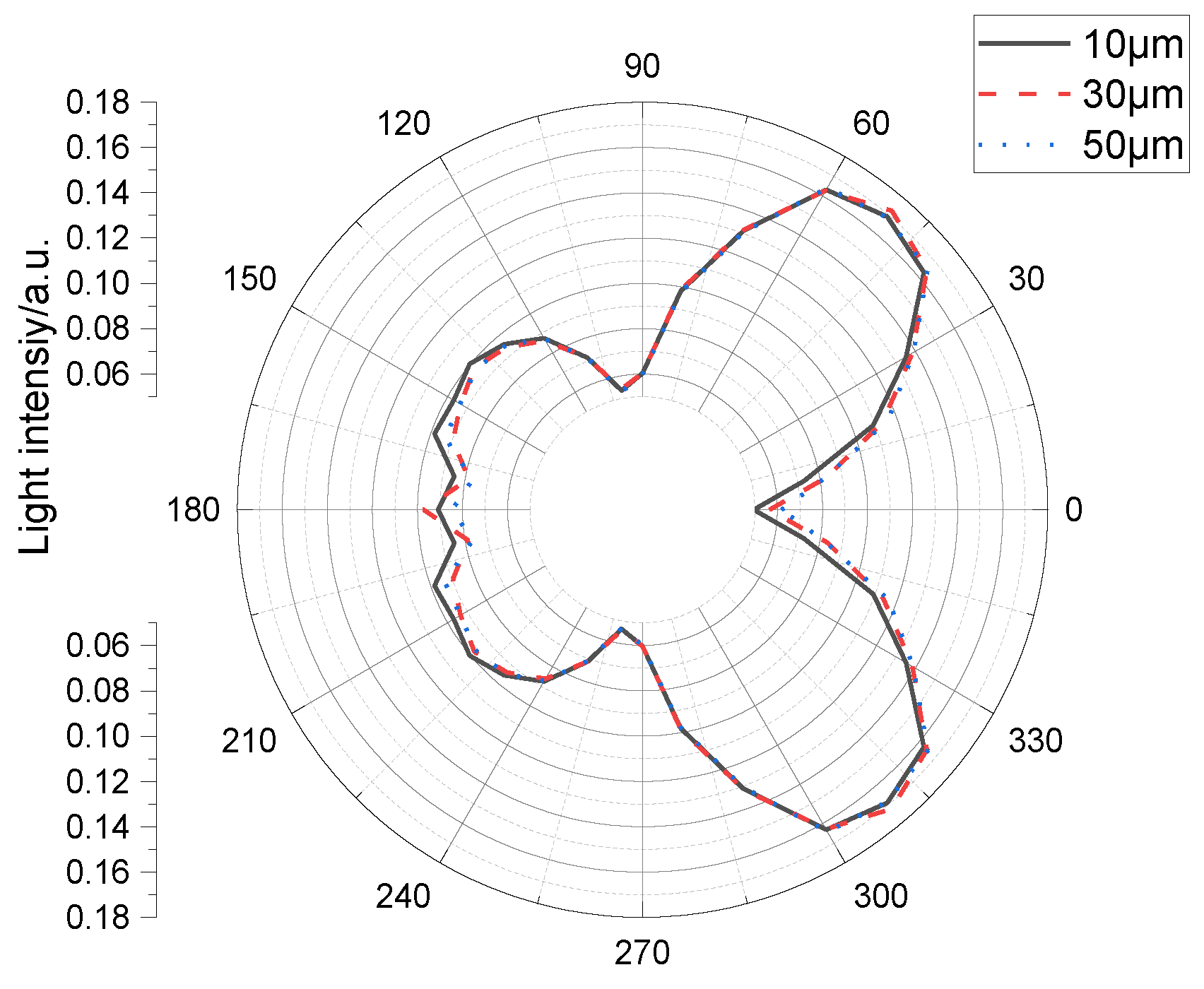

| Semi-Diameter of the Semi-Sphere Micro-Structure at a 10-μm-Thick (Al2O3)2 Film | Light Efficiency | Semi-Diameter of the Semi-Sphere Micro-Structure at a 30-μm-Thick (Al2O3)2 Film | Light Efficiency |

|---|---|---|---|

| 0.5 | 0.543 | 0.5 | 0.633 |

| 1 | 0.518 | 1 | 0.656 |

| 1.5 | 0.653 | 1.5 | 0.653 |

| 2 | 0.644 | 2 | 0.644 |

| (Al2O3)2 Film Thickness at a 0.5-μm Semi-Diameter of the Semi-Sphere Micro-Structure | Light Efficiency | (Al2O3)2 Film Thickness at a 1-μm Semi-Diameter of the Semi-Sphere Micro-Structure | Light Efficiency | (Al2O3)2 Film Thickness at a 1.5-μm Semi-Diameter of the Semi-Sphere Micro-Structure | Light Efficiency | (Al2O3)2 Film Thickness at a 2-μm Semi-Diameter of the Semi-Sphere Micro-Structure | Light Efficiency |

|---|---|---|---|---|---|---|---|

| 10 | 0.543 | 10 | 0.518 | 10 | 0.653 | 10 | 0.644 |

| 30 | 0.633 | 30 | 0.656 | 30 | 0.653 | 30 | 0.644 |

| 50 | 0.617 | 50 | 0.655 | 50 | 0.652 | 50 | 0.644 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Chen, Y.; Wang, C.; Peng, X.; Tang, T.; Chen, Z. Simulation of Far-Field Light Distribution of Micro-LED Based on Its Structural Parameters. Materials 2022, 15, 8854. https://doi.org/10.3390/ma15248854

Wei W, Chen Y, Wang C, Peng X, Tang T, Chen Z. Simulation of Far-Field Light Distribution of Micro-LED Based on Its Structural Parameters. Materials. 2022; 15(24):8854. https://doi.org/10.3390/ma15248854

Chicago/Turabian StyleWei, Wei, Yiying Chen, Chenxi Wang, Xing Peng, Tang Tang, and Zhizhong Chen. 2022. "Simulation of Far-Field Light Distribution of Micro-LED Based on Its Structural Parameters" Materials 15, no. 24: 8854. https://doi.org/10.3390/ma15248854

APA StyleWei, W., Chen, Y., Wang, C., Peng, X., Tang, T., & Chen, Z. (2022). Simulation of Far-Field Light Distribution of Micro-LED Based on Its Structural Parameters. Materials, 15(24), 8854. https://doi.org/10.3390/ma15248854