Temperature and Infill Density Effects on Thermal, Mechanical and Shape Memory Properties of Polylactic Acid/Poly(ε-caprolactone) Blends for 4D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation

2.2. Characterization

3. Results and Discussion

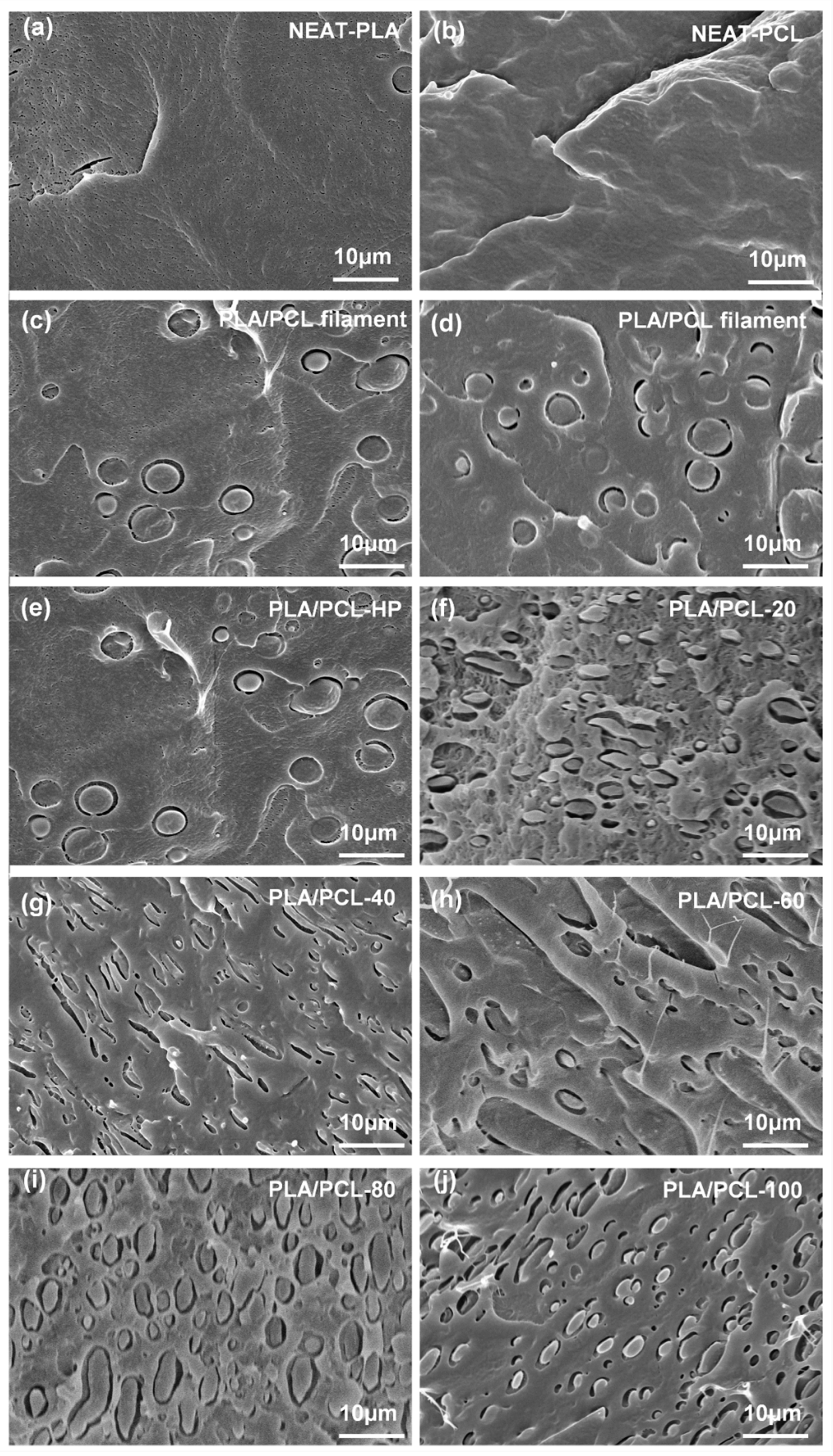

3.1. Microstructures

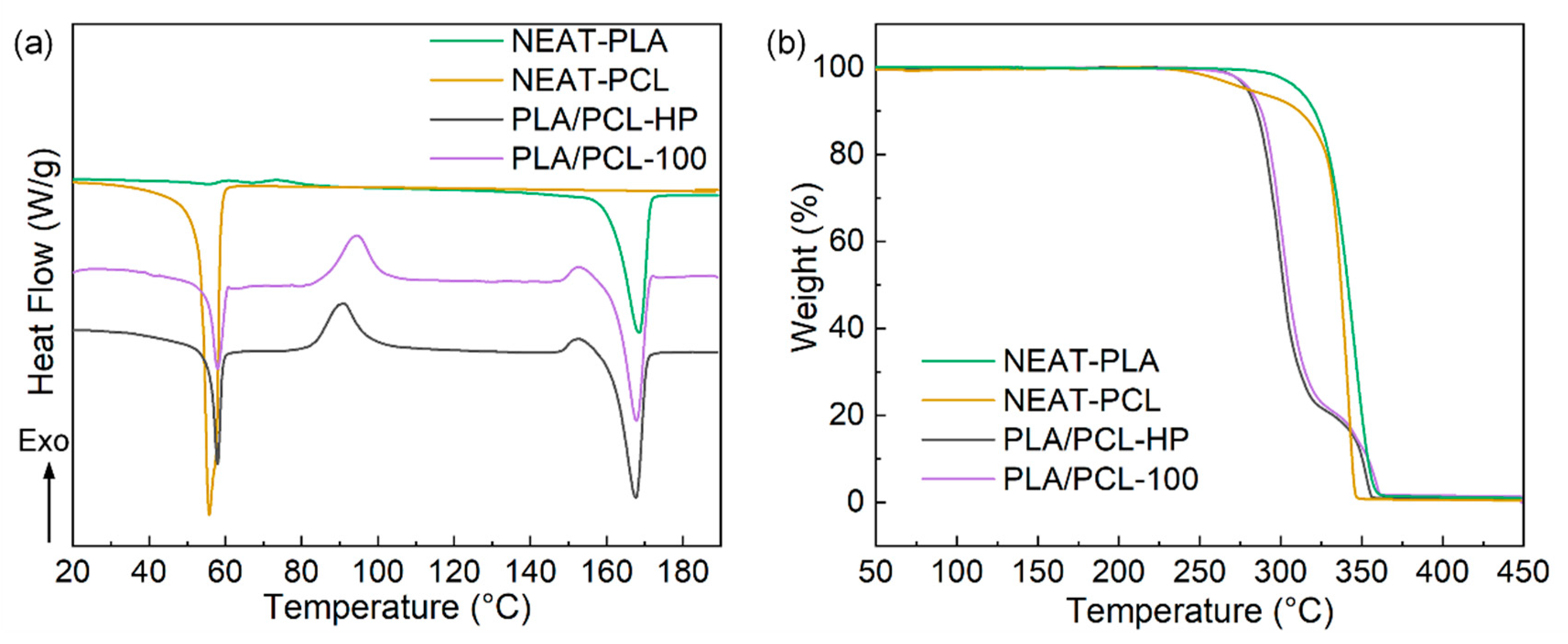

3.2. Thermal Properties

3.3. Mechanical Properties and Model

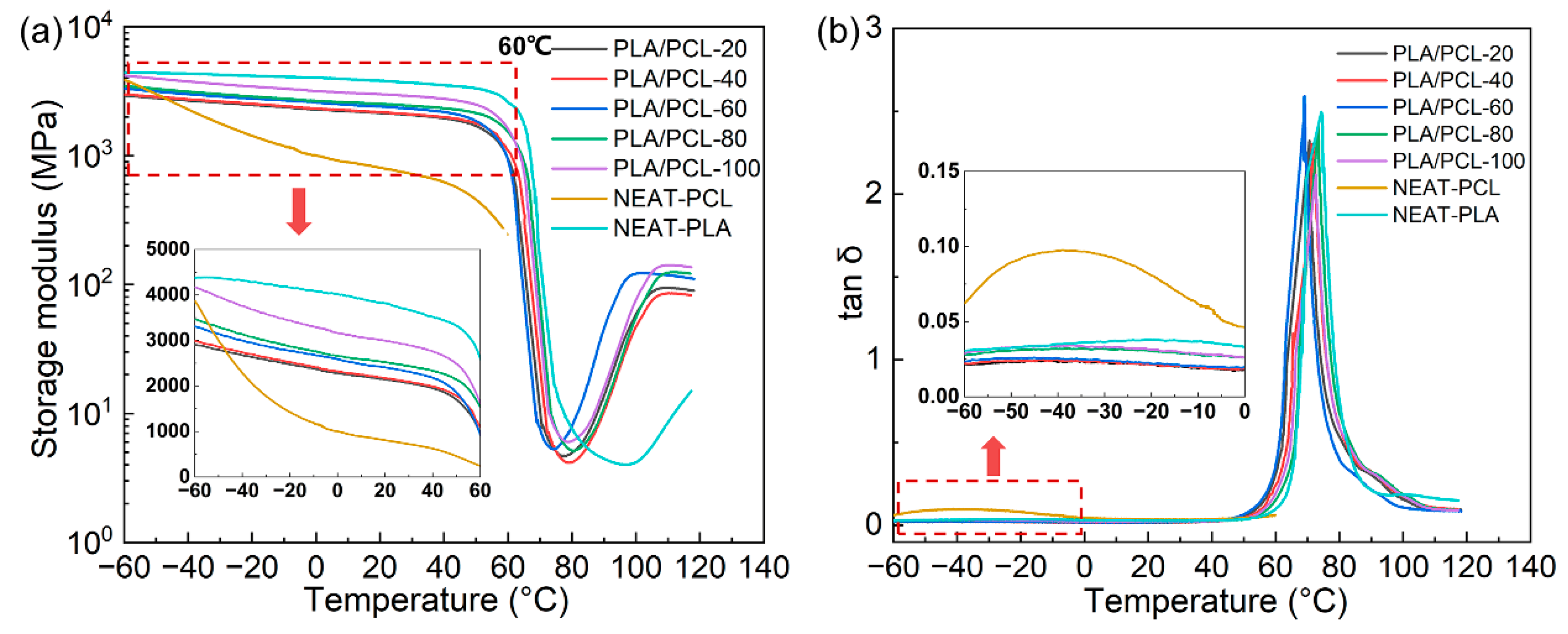

3.3.1. Dynamic Mechanical Properties

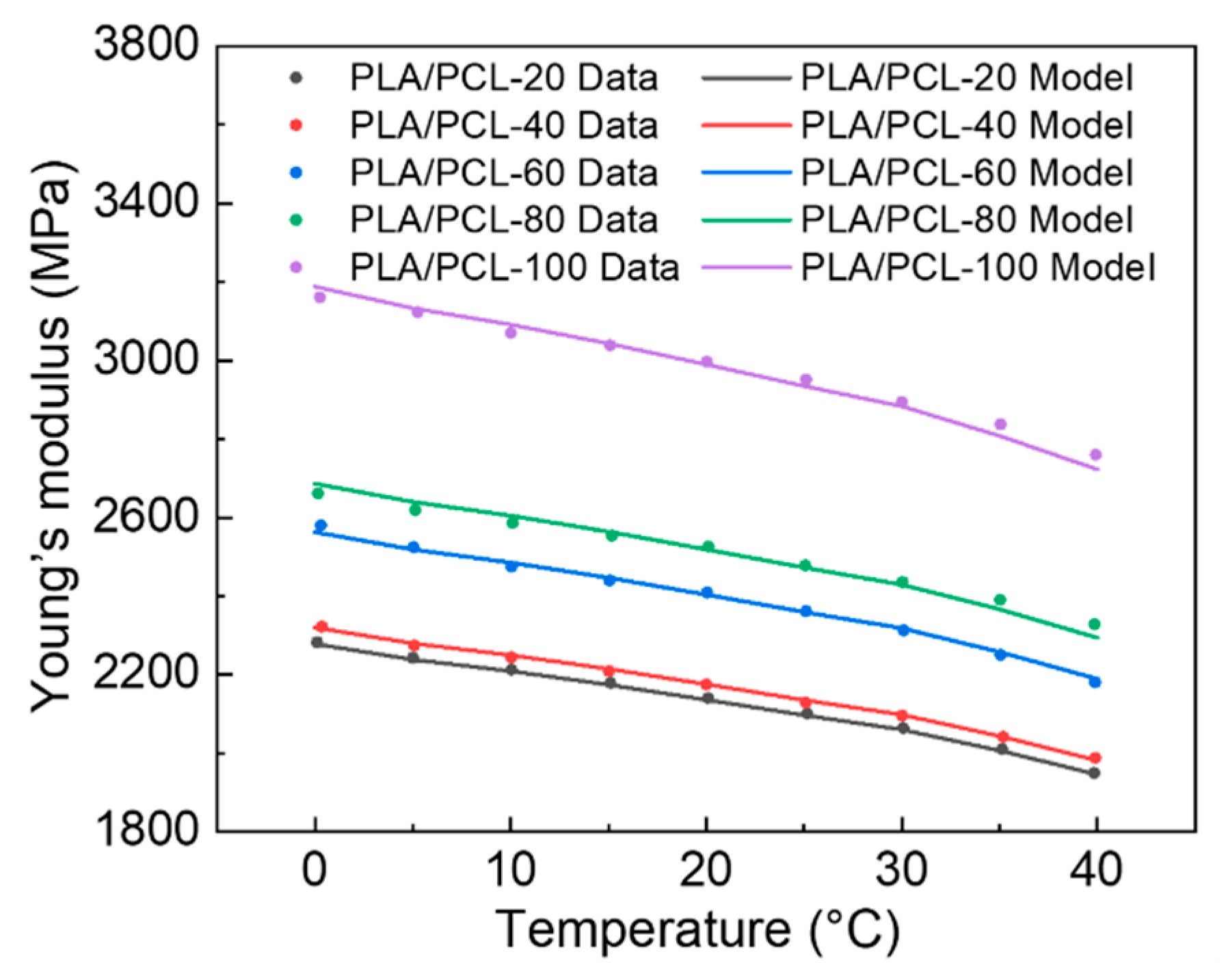

3.3.2. Theoretical Prediction Model

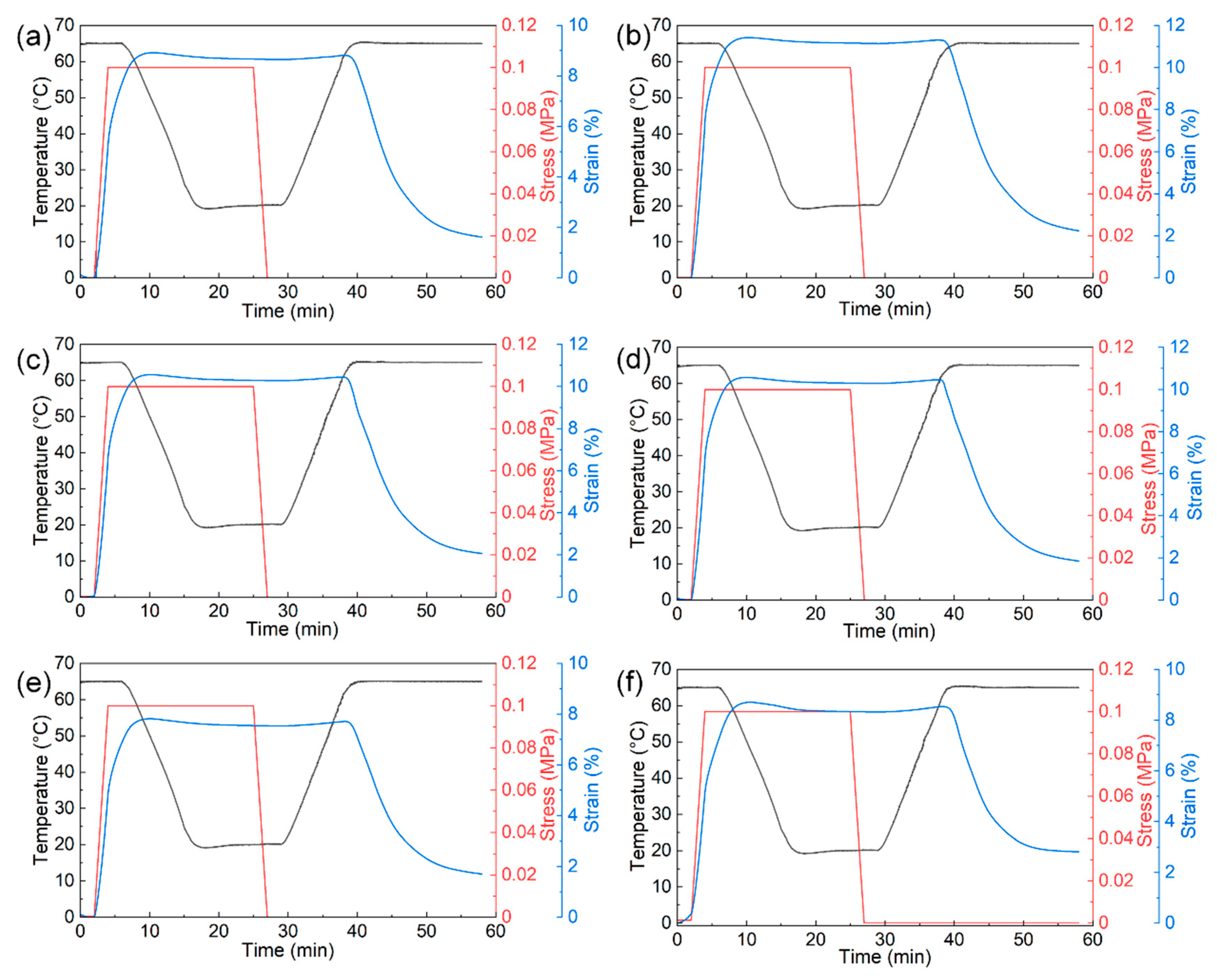

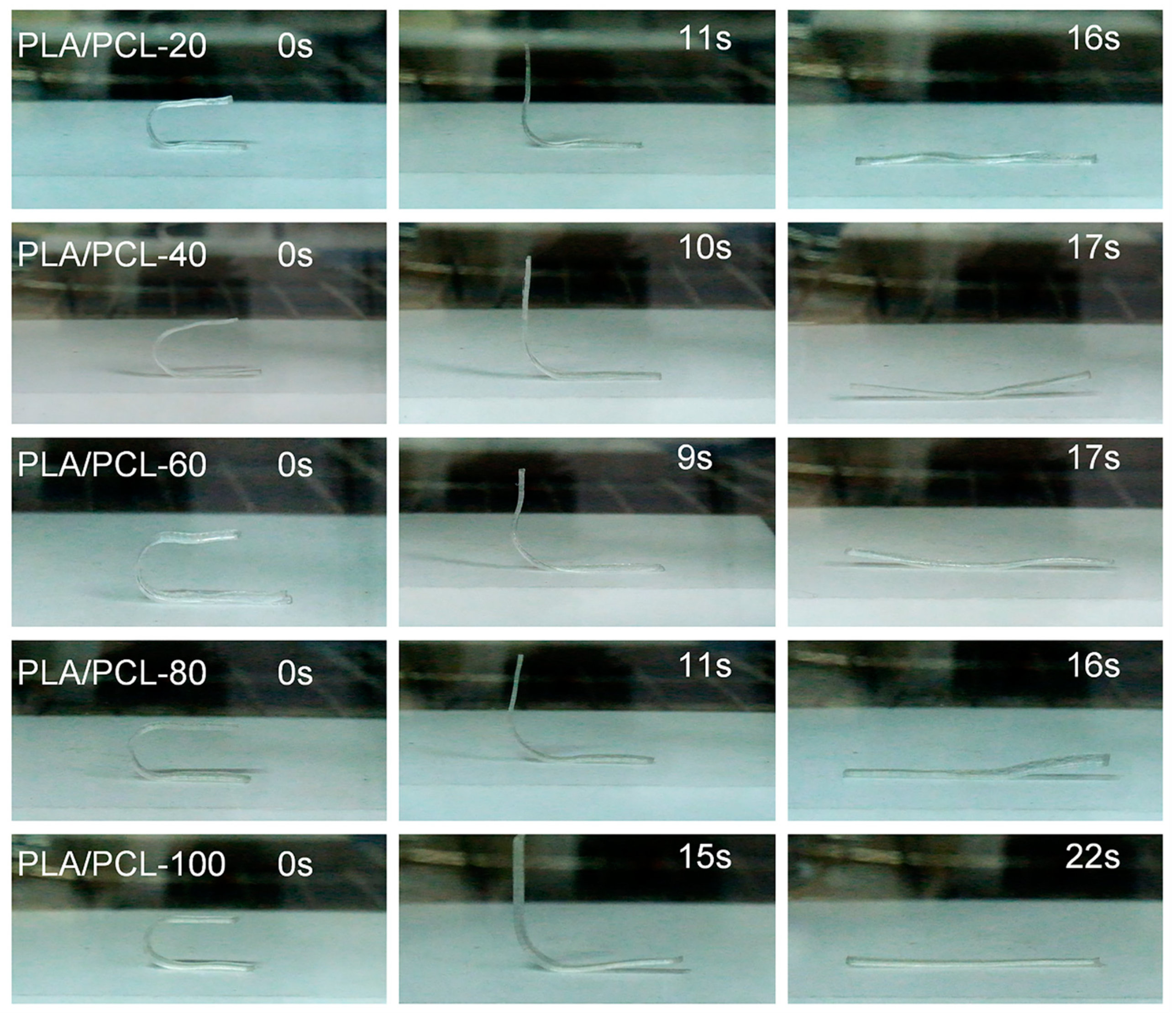

3.4. Shape Memory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B-Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wu, S.; Zeng, T.; Liu, Z.; Ma, G.; Xiong, Z.; Zuo, L.; Zhou, Z. 3D Printing Technology for Smart Clothing: A Topic Review. Materials 2022, 15, 7391. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, A.; Lafont, U.; Holynska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49–50, 79–120. [Google Scholar] [CrossRef]

- Hu, J.L.; Zhu, Y.; Huang, H.H.; Lu, J. Recent advances in shape-memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Leng, J.S.; Lan, X.; Liu, Y.J.; Du, S.Y. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Pan, H.M. Advanced Materials in 3D/4D Printing Technology. Polymers 2022, 14, 3255. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, N.B.; Hingorani, H.; Ding, N.Y.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.Y.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Melocchi, A.; Uboldi, M.; Inverardi, N.; Briatico-Vangosa, F.; Baldi, F.; Pandini, S.; Scalet, G.; Auricchio, F.; Cerea, M.; Foppoli, A.; et al. Expandable drug delivery system for gastric retention based on shape memory polymers: Development via 4D printing and extrusion. Int. J. Pharm. 2019, 571, 118700. [Google Scholar] [CrossRef]

- Zare, M.; Prabhakaran, M.P.; Parvin, N.; Ramakrishna, S. Thermally-induced two-way shape memory polymers: Mechanisms, structures, and applications. Chem. Eng. J. 2019, 374, 706–720. [Google Scholar] [CrossRef]

- Quiñonez, P.A.; Ugarte-Sanchez, L.; Bermudez, D.; Chinolla, P.; Dueck, R.; Cavender-Word, T.J.; Roberson, D.A. Design of Shape Memory Thermoplastic Material Systems for FDM-Type Additive Manufacturing. Materials 2021, 14, 4254. [Google Scholar] [CrossRef]

- Xia, Y.L.; He, Y.; Zhang, F.H.; Liu, Y.J.; Leng, J.S. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Herath, H.; Epaarachchi, J.A.; Islam, M.M.; Al-Azzawi, W.; Leng, J.; Zhang, F. Structural performance and photothermal recovery of carbon fibre reinforced shape memory polymer. Compos. Sci. Technol. 2018, 167, 206–214. [Google Scholar] [CrossRef]

- Liu, T.Z.; Liu, L.W.; Yu, M.; Li, Q.F.; Zeng, C.J.; Lan, X.; Liu, Y.J.; Leng, J.S. Integrative hinge based on shape memory polymer composites: Material, design, properties and application. Compos. Struct. 2018, 206, 164–176. [Google Scholar] [CrossRef]

- Lin, C.; Lv, J.X.; Li, Y.S.; Zhang, F.H.; Li, J.R.; Liu, Y.J.; Liu, L.W.; Leng, J.S. 4D-Printed Biodegradable and Remotely Controllable Shape Memory Occlusion Devices. Adv. Funct. Mater. 2019, 29, 1906569. [Google Scholar] [CrossRef]

- Kashyap, D.; Kumar, P.K.; Kanagaraj, S. 4D printed porous radiopaque shape memory polyurethane for endovascular embolization. Addit. Manuf. 2018, 24, 687–695. [Google Scholar] [CrossRef]

- Shin, S.H.; So, H.Y. Time-dependent motion of 3D-printed soft thermal actuators for switch application in electric circuits. Addit. Manuf. 2021, 39, 101893. [Google Scholar] [CrossRef]

- Bi, H.J.; Ye, G.Y.; Sun, H.; Ren, Z.C.; Gu, T.F.; Xu, M. Mechanically robust, shape memory, self-healing and 3D printable thermoreversible cross-linked polymer composites toward conductive and biomimetic skin devices applications. Addit. Manuf. 2022, 49, 102487. [Google Scholar] [CrossRef]

- He, Q.G.; Wang, Z.J.; Wang, Y.; Minori, A.; Tolley, M.T.; Cai, S.Q. Electrically controlled liquid crystal elastomer-based soft tubular actuator with multimodal actuation. Sci. Adv. 2019, 5, eaax5746. [Google Scholar] [CrossRef]

- Hann, S.Y.; Cui, H.T.; Nowicki, M.; Zhang, L.G. 4D printing soft robotics for biomedical applications. Addit. Manuf. 2020, 36, 101567. [Google Scholar] [CrossRef]

- Gonzalez-Henriquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Janbaz, S.; Darafsheh, A.; Mazur, T.R.; Ramakrishna, S. 4D printing of shape memory polylactic acid (PLA). Polymer 2021, 230, 124080. [Google Scholar] [CrossRef]

- Invernizzi, M.; Turri, S.; Levi, M.; Suriano, R. 4D printed thermally activated self-healing and shape memory polycaprolactone-based polymers. Eur. Polym. J. 2018, 101, 169–176. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- Molavi, F.K.; Ghasemi, I.; Messori, M.; Esfandeh, M. Nanocomposites based on poly(L-lactide)/poly(epsilon-caprolactone) blends with triple-shape memory behavior: Effect of the incorporation of graphene nanoplatelets (GNps). Compos. Sci. Technol. 2017, 151, 219–227. [Google Scholar] [CrossRef]

- Zhou, H.M.; Xia, Y.; Mu, G.Q.; Gao, Y.M.; Liang, S.; Li, G.Z.; Yang, Q.; Lin, X.J.; Qian, F. The preparation and characterization of biodegradable PCL/PLA shape memory blends. J. Macromol. Sci. Part A-Pure Appl. Chem. 2021, 58, 669–676. [Google Scholar] [CrossRef]

- Ma, S.Q.; Jiang, Z.Y.; Wang, M.; Zhang, L.; Liang, Y.H.; Zhang, Z.H.; Ren, L.; Ren, L.Q. 4D printing of PLA/PCL shape memory composites with controllable sequential deformation. Bio-Des. Manuf. 2021, 4, 867–878. [Google Scholar] [CrossRef]

- Wang, Y.M.; Wang, Y.N.; Wei, Q.H.; Zhang, J.; Lei, M.J.; Li, M.Y.; Li, D.H. Effects of the composition ratio on the properties of PCL/PLA blends: A kind of thermo-sensitive shape memory polymer composites. J. Polym. Res. 2021, 28, 451. [Google Scholar] [CrossRef]

- Park, S.J.; Park, S.J.; Son, Y.; Ahn, I. Reducing anisotropy of a part fabricated by material extrusion via warm isostatic pressure (WIP) process. Addit. Manuf. 2022, 55, 102841. [Google Scholar] [CrossRef]

- Wang, S.; D’hooge, D.; Ragaert, K.; De Clerck, K.; Cardon, L. Recent Advances in Extrusion based Additive Manufacturing Material Developments. In Proceedings of the Polymer Engineering International/10th UK-China AMRI Research Workshop, Bradford, UK, 18–20 September 2018. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B-Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Huang, B. Favorable Thermoresponsive Shape Memory Effects of 3D Printed Poly(Lactic Acid)/Poly(epsilon-Caprolactone) Blends Fabricated by Fused Deposition Modeling. Macromol. Mater. Eng. 2020, 305, 2000295. [Google Scholar] [CrossRef]

- Cheng, C.Y.; Xie, H.; Xu, Z.Y.; Li, L.; Jiang, M.N.; Tang, L.; Yang, K.K.; Wang, Y.Z. 4D printing of shape memory aliphatic copolyester via UV-assisted FDM strategy for medical protective devices. Chem. Eng. J. 2020, 396, 125242. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B-Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Lin, X.; Gao, J.; Wang, J.; Wang, R.G.; Gong, M.; Zhang, L.; Lu, Y.L.; Wang, D.R.; Zhang, L.Q. Desktop printing of 3D thermoplastic polyurethane parts with enhanced mechanical performance using filaments with varying stiffness. Addit. Manuf. 2021, 47, 102267. [Google Scholar] [CrossRef]

- Li, P.; Fernandez, P.K.; Spintzyk, S.; Schmidt, F.; Beuer, F.; Unkovskiy, A. Effect of additive manufacturing method and build angle on surface characteristics and Candida albicans adhesion to 3D printed denture base polymers. J. Dent. 2022, 116, 103889. [Google Scholar] [CrossRef] [PubMed]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Non-Destructive and Destructive Testing to Analyse the Effects of Processing Parameters on the Tensile and Flexural Properties of FFF-Printed Graphene-Enhanced PLA. J. Compos. Sci. 2022, 6, 148. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A Variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. On some variational principles in anisotropic and nonhomogeneous elasticity. J. Mech. Phys. Solids 1962, 10, 335–342. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Affdl, J.C.H.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Liu, T.Z.; Liu, L.W.; Zeng, C.J.; Liu, Y.J.; Leng, J.S. 4D printed anisotropic structures with tailored mechanical behaviors and shape memory effects. Compos. Sci. Technol. 2020, 186, 107935. [Google Scholar] [CrossRef]

- Yao, T.Y.; Deng, Z.C.; Zhang, K.; Li, S.M. A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos. Part B-Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Yang, P.P.; Hu, N.; Guo, X.J.; Dong, L.T.; Chen, Y.; Guo, Z.Y. An ultra-simple universal model for the effective elastic properties of isotropic 3D closed-cell porous materials. Compos. Struct. 2020, 249, 112531. [Google Scholar] [CrossRef]

- Gonabadi, H.; Chen, Y.; Yadav, A.; Bull, S. Investigation of the effect of raster angle, build orientation, and infill density on the elastic response of 3D printed parts using finite element microstructural modeling and homogenization techniques. Int. J. Adv. Manuf. Technol. 2022, 118, 1485–1510. [Google Scholar] [CrossRef]

- Kozlov, V.I.; Zinchuk, L.P.; Karnaukhova, T.V. Nonlinear Vibrations and Dissipative Heating of Laminated Shells of Piezoelectric Viscoelastic Materials with Shear Strains. Int. Appl. Mech. 2021, 57, 669–686. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef]

- Li, W.; Qiao, X.Y.; Sun, K.; Chen, X.D. Effect of Electron Beam Irradiation on the Silk Fibroin Fiber/Poly(epsilon-caprolactone) Composite. J. Appl. Polym. Sci. 2009, 113, 1063–1069. [Google Scholar] [CrossRef]

- Lopez-Rodriguez, N.; Lopez-Arraiza, A.; Meaurio, E.; Sarasua, J.R. Crystallization, morphology, and mechanical behavior of polylactide/poly(epsilon-caprolactone) blends. Polym. Eng. Sci. 2006, 46, 1299–1308. [Google Scholar] [CrossRef]

- Urquijo, J.; Guerrica-Echevarria, G.; Ignacio Eguiazabal, J. Melt processed PLA/PCL blends: Effect of processing method on phase structure, morphology, and mechanical properties. J. Appl. Polym. Sci. 2015, 132, 42641. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J. A review of shape memory polymer composites and blends. Compos. Part A-Appl. Sci. Manuf. 2009, 40, 1661–1672. [Google Scholar] [CrossRef]

- Raju, B.; Hiremath, S.R.; Mahapatra, D.R. A review of micromechanics based models for effective elastic properties of reinforced polymer matrix composites. Compos. Struct. 2018, 204, 607–619. [Google Scholar] [CrossRef]

- Alasfar, R.H.; Ahzi, S.; Barth, N.; Kochkodan, V.; Khraisheh, M.; Koc, M. A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity. Polymers 2022, 14, 360. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F. The mechanics of 3-dimensional cellular materials. Proc. R. Soc. Lond. Ser. A-Math. Phys. Eng. Sci. 1982, 382, 43–59. [Google Scholar] [CrossRef]

- Blaker, J.J.; Maquet, V.; Jerome, R.; Boccaccini, A.R.; Nazhat, S.N. Mechanical properties of highly porous PDLLA/Bioglass (R) composite foams as scaffolds for bone tissue engineering. Acta Biomater. 2005, 1, 643–652. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular solids. MRS Bull. 2003, 28, 270–271. [Google Scholar] [CrossRef]

- Roberts, A.P.; Garboczi, E.J. Elastic moduli of model random three-dimensional closed-cell cellular solids. Acta Mater. 2001, 49, 189–197. [Google Scholar] [CrossRef]

- Choren, J.A.; Heinrich, S.M.; Silver-Thorn, M.B. Young’s modulus and volume porosity relationships for additive manufacturing applications. J. Mater. Sci. 2013, 48, 5103–5112. [Google Scholar] [CrossRef]

- Nam, S.; Pei, E. The Influence of Shape Changing Behaviors from 4D Printing through Material Extrusion Print Patterns and Infill Densities. Materials 2020, 13, 3754. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Nozzle temperature | 190 °C |

| Platform temperature | 50 °C |

| Printing speed | 30 mm s−1 |

| Layer thickness | 0.2 |

| Top/Bottom layers | 1 |

| Infill density | 20/40/60/80/100% |

| Infill pattern | Hexagon for 20–80%, Lines for 100% |

| E11 | E11f | Em | 2(l/d) |

| E22 | E22f | Em | 2 |

| G12 | G12f | Gm | 1 |

| Samples | Confidence Bounds of [95%] | ||||

|---|---|---|---|---|---|

| PLA/PCL-20 | 3 | 41.01% | 1 | 0.6681 | (0.6569, 0.6794) |

| PLA/PCL-40 | 3 | 38.51% | 1 | 0.6876 | (0.6820, 0.6932) |

| PLA/PCL-60 | 3 | 30.16% | 1 | 0.6538 | (0.6376, 0.6701) |

| PLA/PCL-80 | 3 | 23.48% | 1 | 0.7019 | (0.6586, 0.7453) |

| PLA/PCL-100 | 3 | 13.47% | 1 | 0.1150 | (0.0401, 0.1900) |

| Samples | Method | ||

|---|---|---|---|

| PLA/PCL-20 | ME | 97.20 | 81.84 |

| PLA/PCL-40 | ME | 97.72 | 80.37 |

| PLA/PCL-60 | ME | 97.45 | 80.42 |

| PLA/PCL-80 | ME | 97.45 | 82.49 |

| PLA/PCL-100 | ME | 96.58 | 78.18 |

| PLA/PCL-HP | Hot-pressing | 95.80 | 67.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, A.; Chen, X.-G.; Zhang, L.-Y.; Zhang, Y.-F. Temperature and Infill Density Effects on Thermal, Mechanical and Shape Memory Properties of Polylactic Acid/Poly(ε-caprolactone) Blends for 4D Printing. Materials 2022, 15, 8838. https://doi.org/10.3390/ma15248838

Li A, Chen X-G, Zhang L-Y, Zhang Y-F. Temperature and Infill Density Effects on Thermal, Mechanical and Shape Memory Properties of Polylactic Acid/Poly(ε-caprolactone) Blends for 4D Printing. Materials. 2022; 15(24):8838. https://doi.org/10.3390/ma15248838

Chicago/Turabian StyleLi, Ang, Xin-Gang Chen, Lan-Ying Zhang, and Yang-Fei Zhang. 2022. "Temperature and Infill Density Effects on Thermal, Mechanical and Shape Memory Properties of Polylactic Acid/Poly(ε-caprolactone) Blends for 4D Printing" Materials 15, no. 24: 8838. https://doi.org/10.3390/ma15248838

APA StyleLi, A., Chen, X.-G., Zhang, L.-Y., & Zhang, Y.-F. (2022). Temperature and Infill Density Effects on Thermal, Mechanical and Shape Memory Properties of Polylactic Acid/Poly(ε-caprolactone) Blends for 4D Printing. Materials, 15(24), 8838. https://doi.org/10.3390/ma15248838