Ultrafine Grain Ferrite Transformed from Fine Austenite Grains Produced by Dynamic Reversal Transformation

Abstract

1. Introduction

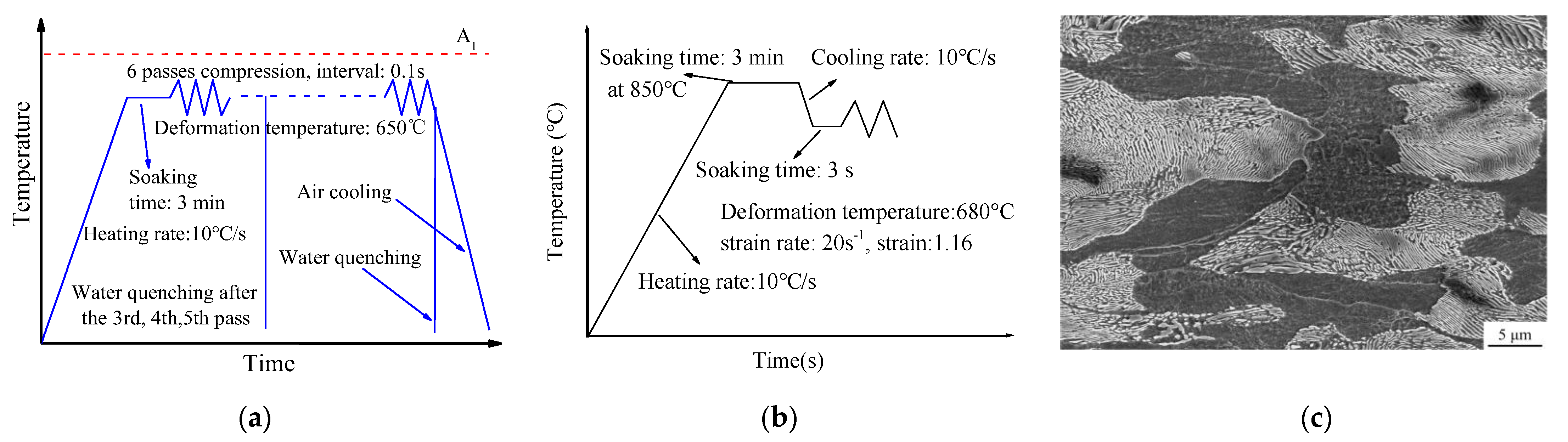

2. Materials and Methods

3. Results

3.1. Variation of Follow Stress and Temperature

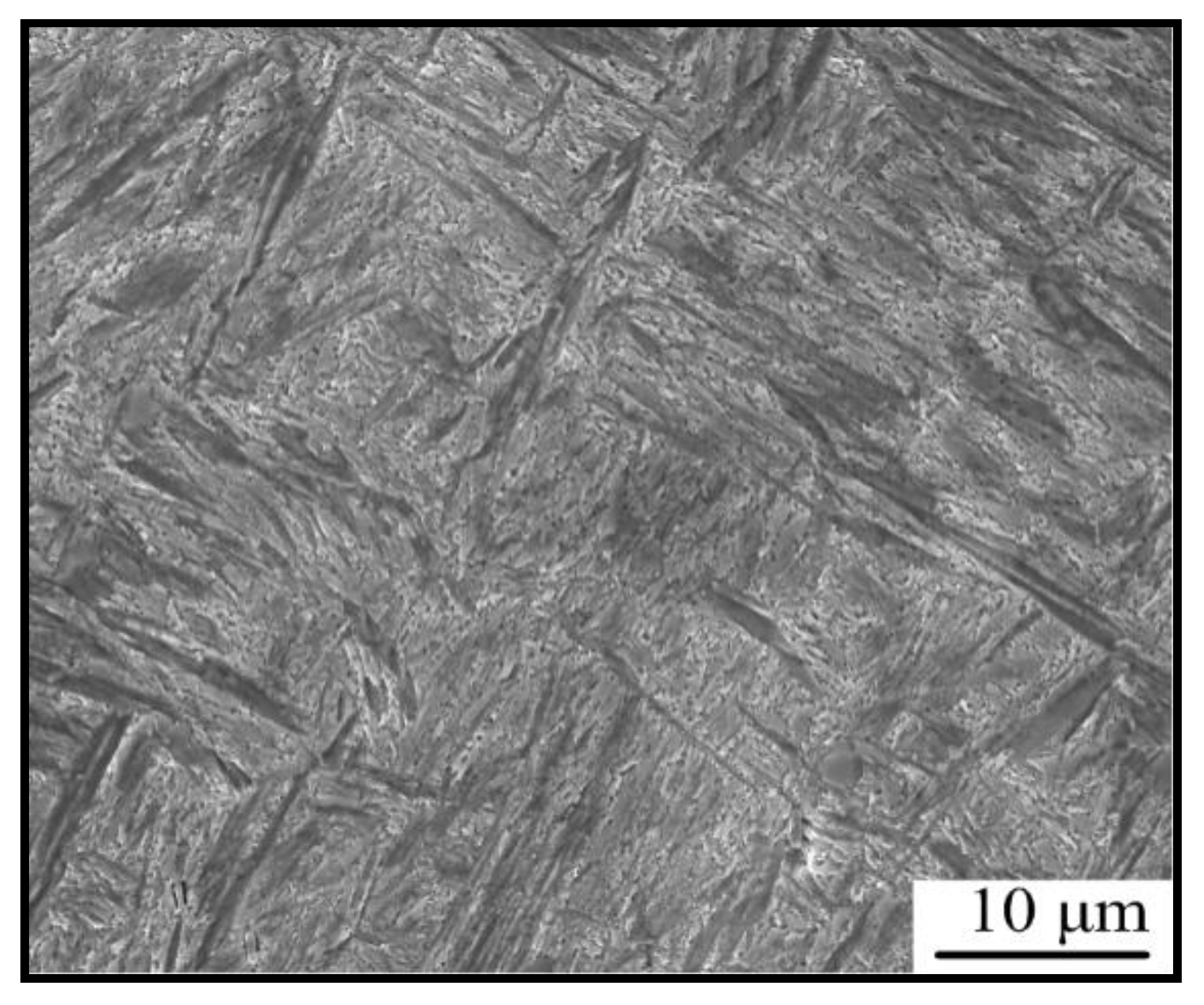

3.2. Variation of Microstructure during Multi Passes Compression

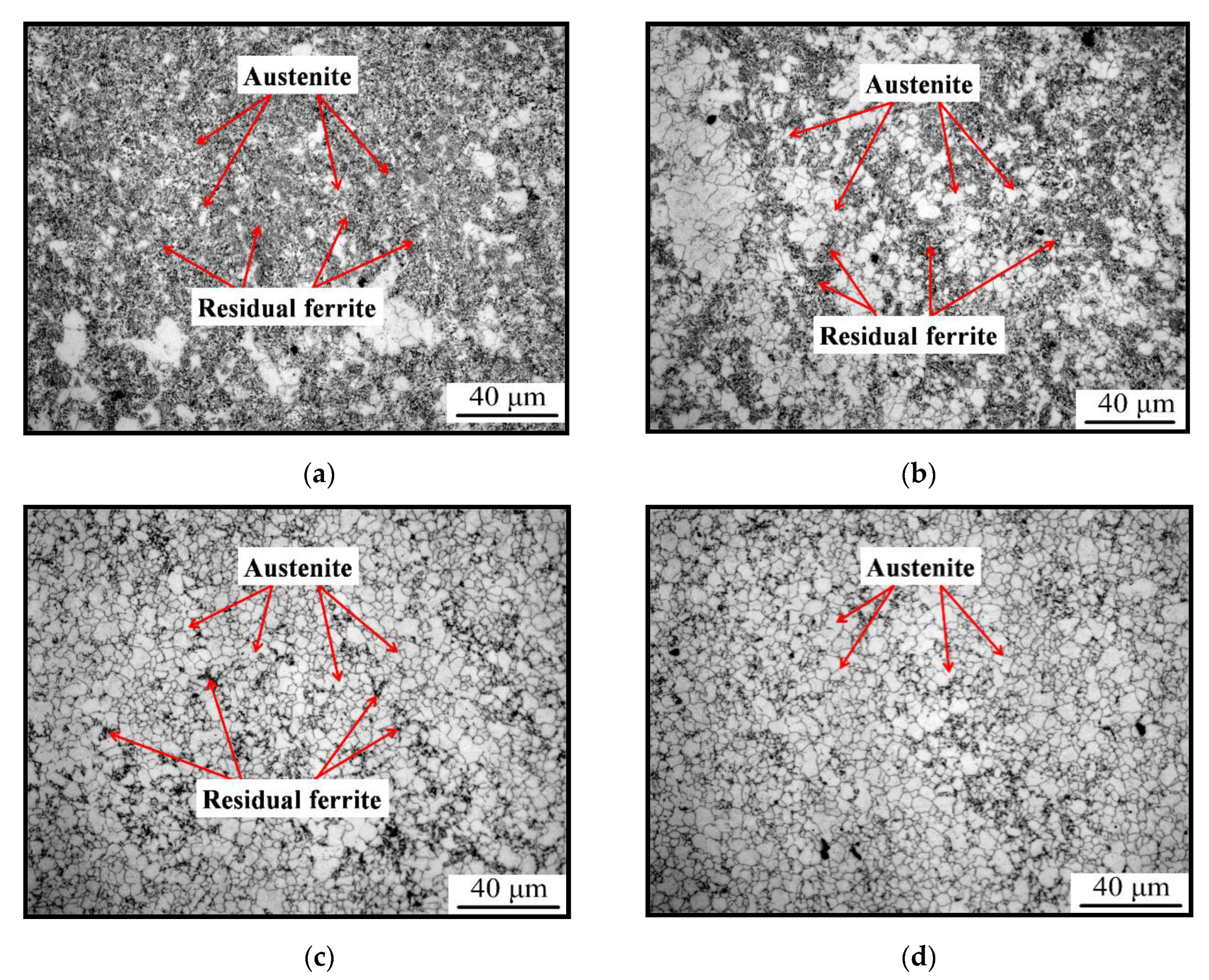

3.3. Variation of Microstructure during Air Cooling after Multi-Pass Compression

4. Discussions

4.1. Analysis of Multi-Pass Compression

4.2. Thermodynamic Analysis of DRT

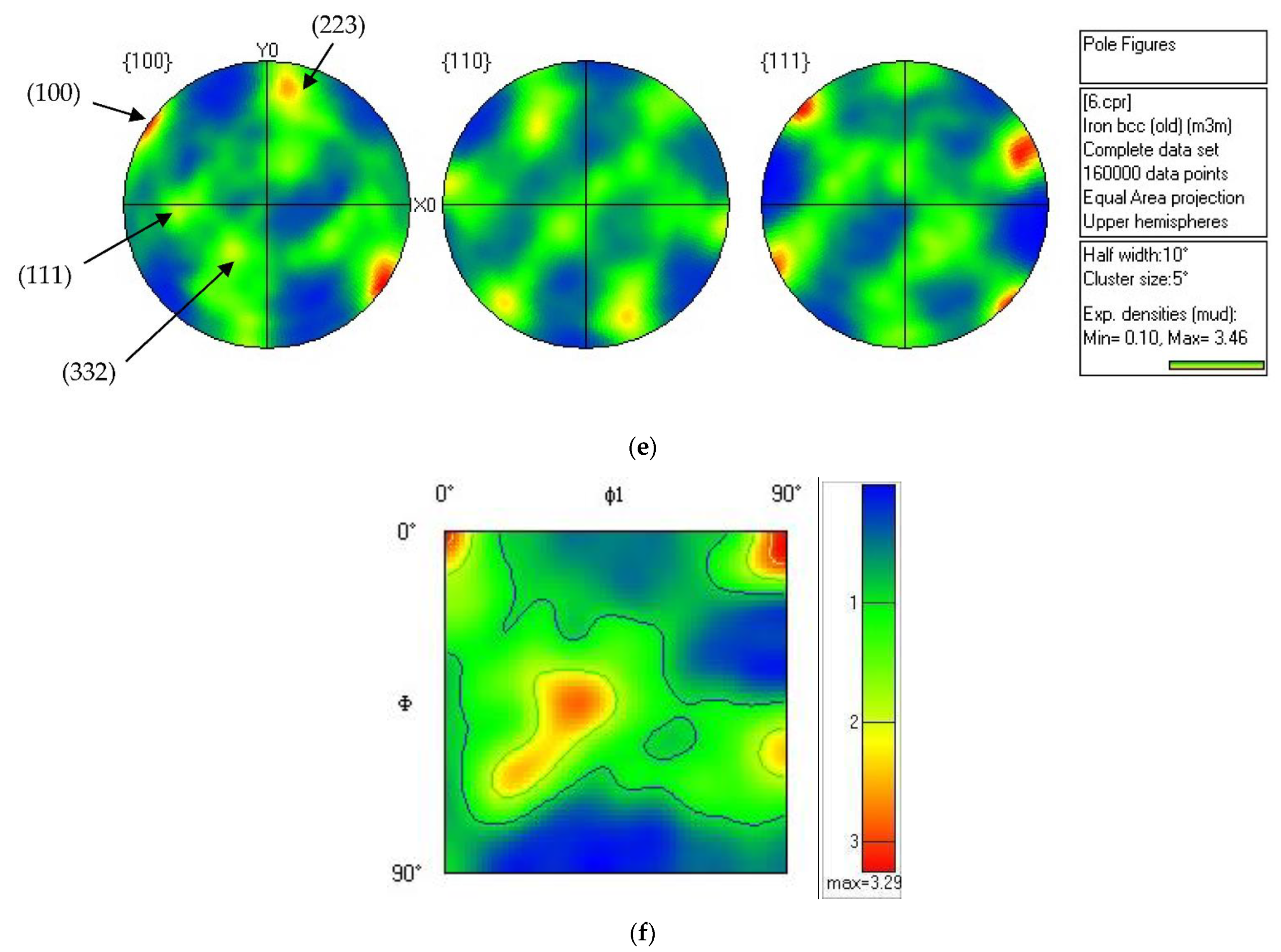

4.3. Analysis of Microstructure Transformation from Fine Austenite to Ferrite during Air Cooling

5. Conclusions

- Austenite DRT occurred during medium carbon steel warm deformation at 650 °C with high strain rate multi-pass compression.

- Fine austenite grains were obtained from the DRT, and the size of the austenite grains was about 3.4 μm at the total strain 2.67.

- Ultrafine ferrite grain was obtained and the size was approximately 0.62 μm. Additionally, the ferrite texture was characterized by good, deep drawing properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhang, H.; Pradeep, K.G.; Mandal, S.; Ponge, D.; Springer, H.; Raabe, D. Dynamic strain-induced transformation: A atomic scale investigation. Scr. Mater. 2015, 109, 23–27. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Sergueeva, A.V.; Mukherjee, A.K. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scripta Mater. 2003, 49, 669–674. [Google Scholar] [CrossRef]

- Miyajima, Y.; Homma, T.; Takenaka, S.; Watanabe, C.; Adachi, H.; Ishikawa, K. High strength and low electrical resistivity of Al-0.1 at%Ni alloys produced by accumulative roll bonding. Mater. Today 2022, 33, 104587. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Asl, F.G.; Mirabad, H.M.; Kim, H.S. Microstructural characterization and enhanced tensile and tribological properties of Cu–SiC nanocomposites developed by high-pressure torsion. J. Mater. Res. Technol. 2022, 20, 4038–4051. [Google Scholar] [CrossRef]

- Rui, B.; Sakaguchi, N.; Nakada, N. Mechanism of austenite recrystallization induced by martensitic reversion in super invar cast alloy. Materialia 2021, 15, 100995. [Google Scholar] [CrossRef]

- Mohamadizadeh, A.; Zarei-Hanzaki, A.; Heshmati-Manesh, S.; Imandoust, A. The effect of strain induced ferrite transformation on the microstructural evolutions and mechanical properties of a TRIP-assisted steel. Mater. Sci. Engin. A 2014, 607, 621–629. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.Y.; Meng, Q.W.; Wang, L.Y.; Li, Y.Z.; Xu, W. Tailoring retained austenite and mechanical property improvement in Al–Si–V containing medium Mn steel via direct intercritical rolling. Mater. Sci. Engin. A 2022, 855, 143904. [Google Scholar] [CrossRef]

- Shen, X.J.; Tang, S.; Chen, J.; Liu, Z.Y.; Misra, R.D.K.; Wang, G.D. The effect of warm deforming and reversal austenization on the microstructure and mechanical properties of a microallyed steel. Mater. Sci. Eng. A 2016, 671, 182–189. [Google Scholar] [CrossRef]

- Yao, S.J.; Du, L.X.; Liu, X.H.; Wang, G.D. Influencing factors for obtaining ultrafine austenite grains with initial microstructure of warm-rolled ferrite/pearlite. Acta Metal. Sin. (Engl. Lett.) 2008, 21, 391–398. [Google Scholar] [CrossRef]

- Sun, J.J.; Jiang, T.; Wang, Y.J.; Guo, S.W.; Liu, Y.N. Effect of grain refinement on high-carbon martensite transformation and its mechanical properties. Mater. Sci. Eng. A 2018, 726, 342–349. [Google Scholar] [CrossRef]

- Yang, G.W.; Li, Z.D.; Sun, X.J.; Yong, X.; Yong, Q.L. Ultrafine grained austenite in a low carbon vanadium miroalloyed steel. J. Iron Steel Res. Int. 2013, 20, 64–69. [Google Scholar] [CrossRef]

- Ghosh, C.; Aranas, C., Jr.; Jonas, J.J. Dynamic transformation of deformed austenite at temperatures above Ae3. Prog. Mater. Sci. 2016, 82, 151–223. [Google Scholar] [CrossRef]

- Li, H.B.; Feng, Y.L.; Yan, T.; Yu, E.L. Constitutive Model of Warm Deformation Behavior of Medium Carbon Steel. J. Iron Steel Res. Int. 2016, 23, 940–948. [Google Scholar] [CrossRef]

- Trzaska, J.; Dobrzanski, L.A. Modeling of CCT diagrams for engineering and constructional steels. J. Mater. Proc. Tech. 2007, 192–193, 504–510. [Google Scholar] [CrossRef]

- Aranas, C., Jr.; Nguyen-Minh, T.; Grewal, R.; Jonas, J.J. Flow Softening-based Formation of Widmanstätten Ferrite in a 0.06%C Steel Deformed Above the Ae3. ISIJ Int. 2015, 55, 300–307. [Google Scholar] [CrossRef]

- Jonas, J.J.; Ghosh, C. Role of mechanical activation in the dynamic transformation of austenite. Acta Mater. 2013, 61, 6125–6131. [Google Scholar] [CrossRef]

- Aranas, C., Jr.; Foul, A.; Guo, B.Q.; Fall, A.; Jahazi, M.; Jonas, J.J. Determination of the critical stress for the initiation of dynamic transformation in commercially pure titanium. Scr. Mater. 2017, 133, 83–85. [Google Scholar] [CrossRef]

- Pang, J.C.; Yang, W.F.; Wang, G.D.; Zheng, S.J.; Misra, R.D.K.; Yi, H.L. Divorced eutectoid transformation in high-Al added steels due to heterogenous nucleation of κ-carbide. Scr. Mater. 2022, 209, 114395. [Google Scholar] [CrossRef]

- Verhoeven, J.D.; Gibson, E.D. The divorced eutectoid transformation in steel. Metall. Mater. Trans. A 1998, 29, 1181–1189. [Google Scholar] [CrossRef]

- Li, B.; Liu, Q.Y.; Jia, S.J.; Ren, Y.; Wang, B. Fabricating ultrafine grain by advanced thermomechanical processing onlow-carbon microalloyed steel. Scr. Mater. 2018, 152, 132–136. [Google Scholar] [CrossRef]

- Okisu, Y.; Takata, N.; Tsuji, N. A new route to fabricate ultrafine-grained structures in carbon steels without severe plastic deformation. Scr. Mater. 2009, 60, 76–79. [Google Scholar] [CrossRef]

- Atefi, S.; Parsa, M.H.; Ahmadkhaniha, D.; Zanella, C.; Jafarian, H.R. A study on microstructure development and mechanical properties of pure copper subjected to severe plastic deformation by the ECAP-Conform process. J. Mater. Res. Technol. 2022, 21, 1614–1629. [Google Scholar] [CrossRef]

- Ahn, Y.K.; Kwon, S.B.; Cho, J.U.; Kim, T.Y.; Hwang, N.M. Fabrication of cube-on-face textured Fe-1wt%Si and Fe-2wt%Si-1wt%Ni electrical steel using surface nucleation during γ→α phase transformation. Mater. Character 2020, 170, 110724. [Google Scholar] [CrossRef]

- Ahn, Y.K.; Jeong, Y.K.; Kim, T.Y.; Cho, J.U.; Hwang, N.M. Texture evolution of non-oriented electrical steel analyzed by EBSD and in-situ XRD during the phase transformation from γ to α. Mater. Commun. 2020, 25, 101307. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J. Transformation textures in steels. Int. Mater. Rev. 1990, 35, 1–36. [Google Scholar] [CrossRef]

- Tóth, L.S.; Jonas, J.J.; Daniel, D.; Ray, R.K. Development of ferrite rolling textures in low- and extra low-carbon steels. Metall. Trans. A 1990, 21, 2985–3000. [Google Scholar] [CrossRef]

- Toshiaki, U.; Jonas, J.J. Modeling texture change during the recrystallization of an IF steel. ISIJ Int. 1994, 34, 435–442. [Google Scholar]

- Ray, R.K.; Jonas, J.J.; Butron-Guillen, M.P.; Savoie, J. Transformation texture in seels. ISIJ Int. 1990, 34, 927–942. [Google Scholar] [CrossRef]

| Pass | True Strain | Strain Rate (s−1) | Interval (s) |

|---|---|---|---|

| 1 | 0.39 | 20.00 | 0.1 |

| 2 | 0.53 | 20.00 | 0.1 |

| 3 | 0.52 | 20.00 | 0.1 |

| 4 | 0.49 | 20.00 | 0.1 |

| 5 | 0.47 | 20.00 | 0.1 |

| 6 | 0.27 | 20.00 | -- |

| Texture | (223)<142> | (111)<112> | (100)<110> | (332)<5-73> |

|---|---|---|---|---|

| Content | 17.1% | 9.47% | 5.31% | 14.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zheng, X.; Fan, L.; Xu, H.; Tian, Y.; Dai, X.; Chen, L. Ultrafine Grain Ferrite Transformed from Fine Austenite Grains Produced by Dynamic Reversal Transformation. Materials 2022, 15, 8727. https://doi.org/10.3390/ma15248727

Li H, Zheng X, Fan L, Xu H, Tian Y, Dai X, Chen L. Ultrafine Grain Ferrite Transformed from Fine Austenite Grains Produced by Dynamic Reversal Transformation. Materials. 2022; 15(24):8727. https://doi.org/10.3390/ma15248727

Chicago/Turabian StyleLi, Hongbin, Xiaoping Zheng, Lifeng Fan, Haiwei Xu, Yaqiang Tian, Xin Dai, and Liansheng Chen. 2022. "Ultrafine Grain Ferrite Transformed from Fine Austenite Grains Produced by Dynamic Reversal Transformation" Materials 15, no. 24: 8727. https://doi.org/10.3390/ma15248727

APA StyleLi, H., Zheng, X., Fan, L., Xu, H., Tian, Y., Dai, X., & Chen, L. (2022). Ultrafine Grain Ferrite Transformed from Fine Austenite Grains Produced by Dynamic Reversal Transformation. Materials, 15(24), 8727. https://doi.org/10.3390/ma15248727