Progress in the Development of Active-Matrix Quantum-Dot Light-Emitting Diodes Driven by Non-Si Thin-Film Transistors

Abstract

1. Introduction

2. Non-Si TFT Backplane Technology

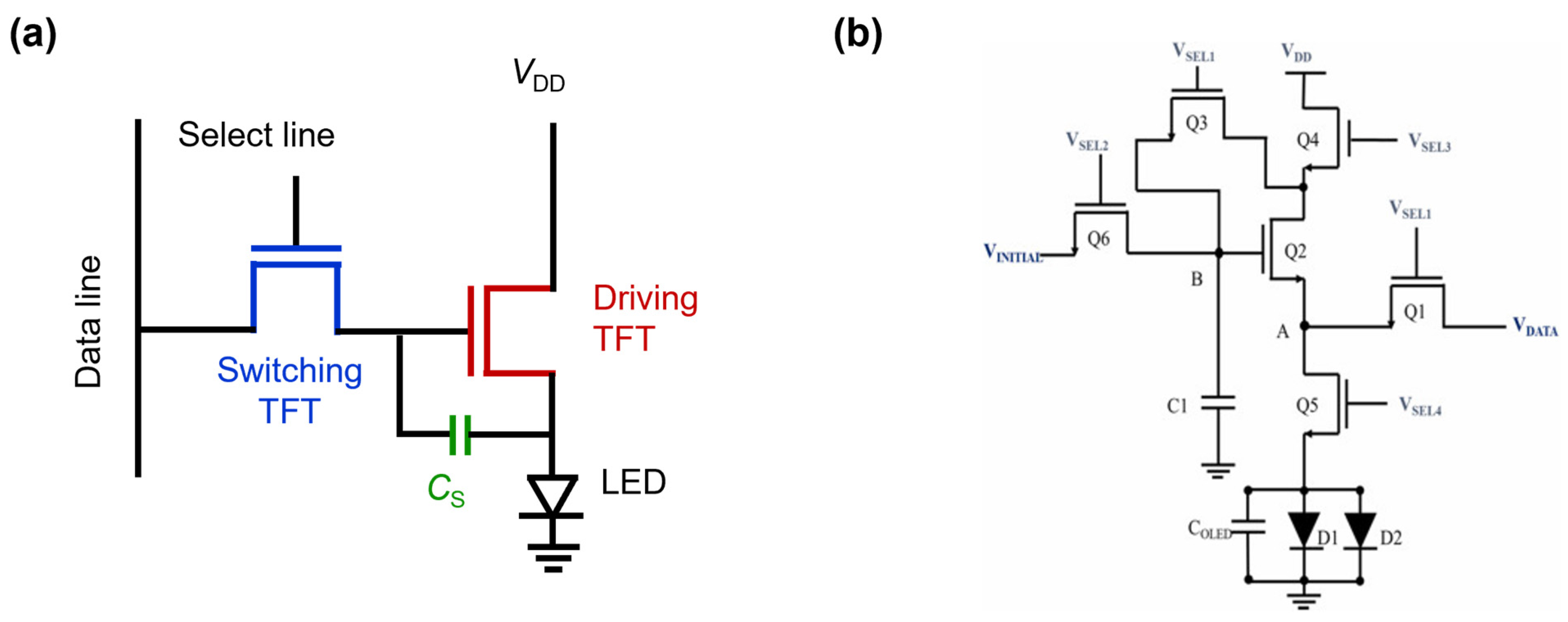

2.1. Circuits for AM Driving

2.2. Active Materials for Non-Si TFT Backplane

| Year | Channel Material | Type | Mobility (cm2 V−1 s−1) | Subthreshold Swing (V dec−1) | Ion/off Ratio | Threshold Voltage (V) | Reference |

|---|---|---|---|---|---|---|---|

| 2018 | IGZO | n | 61.3 | 0.08 | ~106 | 0.78 | [68] |

| MoS2 | n | 260 | - | ~106 | - | [69] | |

| SWNT | n | 10 | - | ~108 | - | [70] | |

| 2019 | IGZO | n | 74 | 0.21 | ~108 | −1.3 | [41] |

| MoS2 | n | 170 | - | ~106 | - | [71] | |

| SWNT | p | 20.9 | 0.2 | ~104 | 0.4 | [72] | |

| 2020 | ZnON | n | 147 | 0.21 | ~104 | −0.72 | [40] |

| MoS2 | n | 107 | - | ~106 | - | [73] | |

| SWNT | p | 16 | - | - | - | [74] | |

| MoTe2 | p | 178.7 | - | ~107 | −22 | [75] | |

| 2021 | IGTO * | n | 116.5 | 0.13 | ~109 | 0.47 | [76] |

| MoS2 | n | 44.6 | 0.36 | ~105 | - | [77] | |

| SWNT | p | 10.92 | 0.4 | ~105 | 0.48 | [78] | |

| MoTe2 | p | 12.6 | 0.26 | ~104 | 0.87 | [79] | |

| 2022 | In2O3:H | n | 139.2 | 0.19 | - | 0.2 | [43] |

| MoS2 | n | 12.3 | - | ~109 | - | [80] | |

| SWNT | p | 496 | - | ~108 | - | [81] | |

| MoTe2 | p | 30 | - | ~106 | −20 | [82] |

3. QLED Frontplane Technology

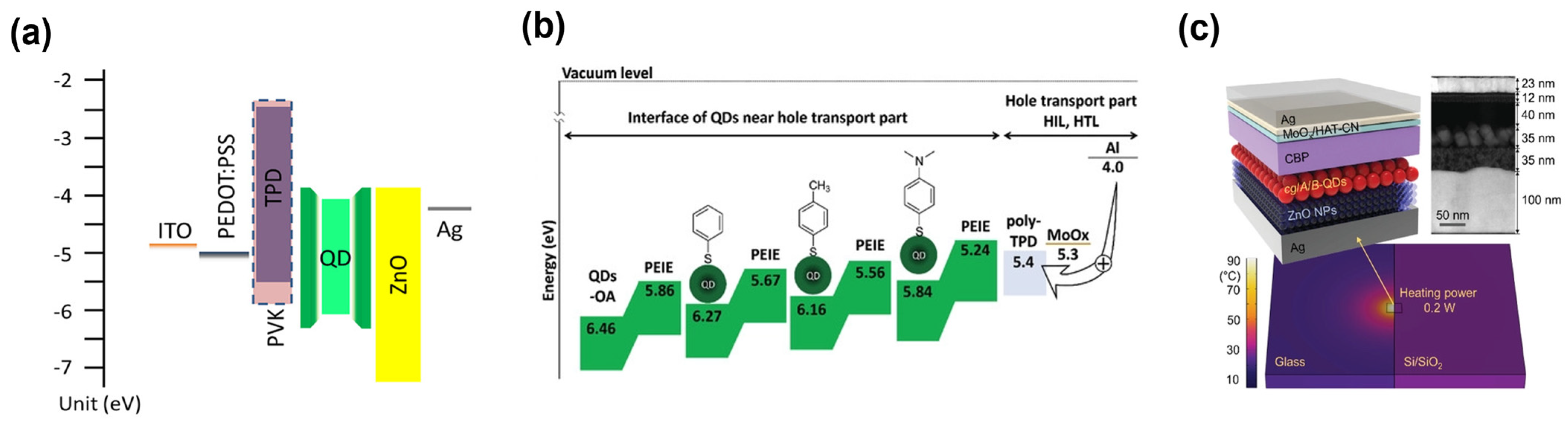

3.1. Device Architecture for QLEDs

3.2. High-Performance QLEDs Based on Device Engineering

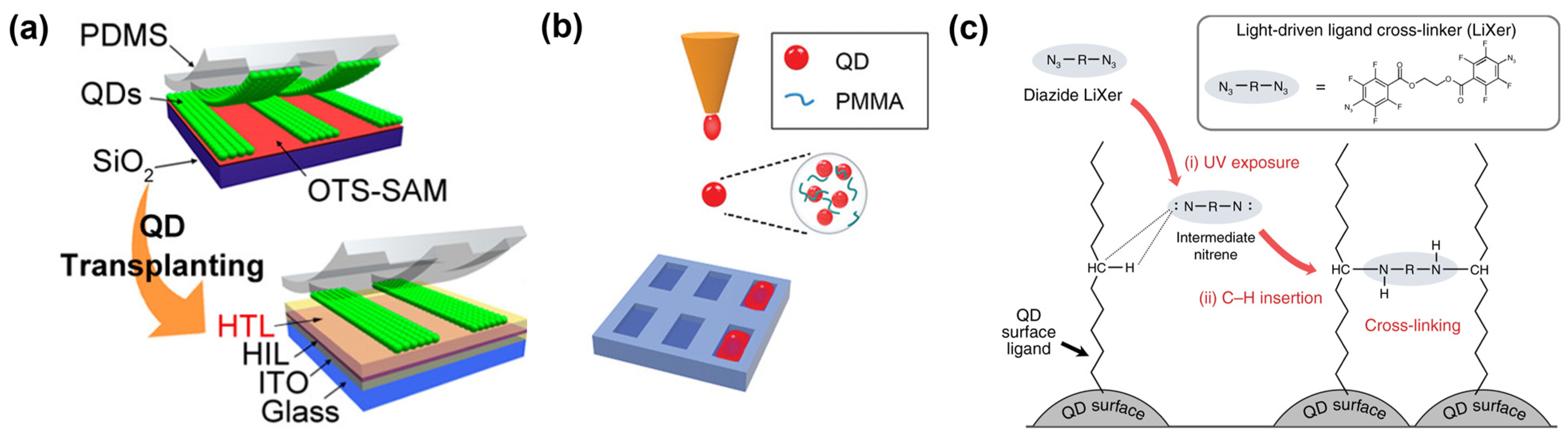

3.3. QD Patterning Technologies

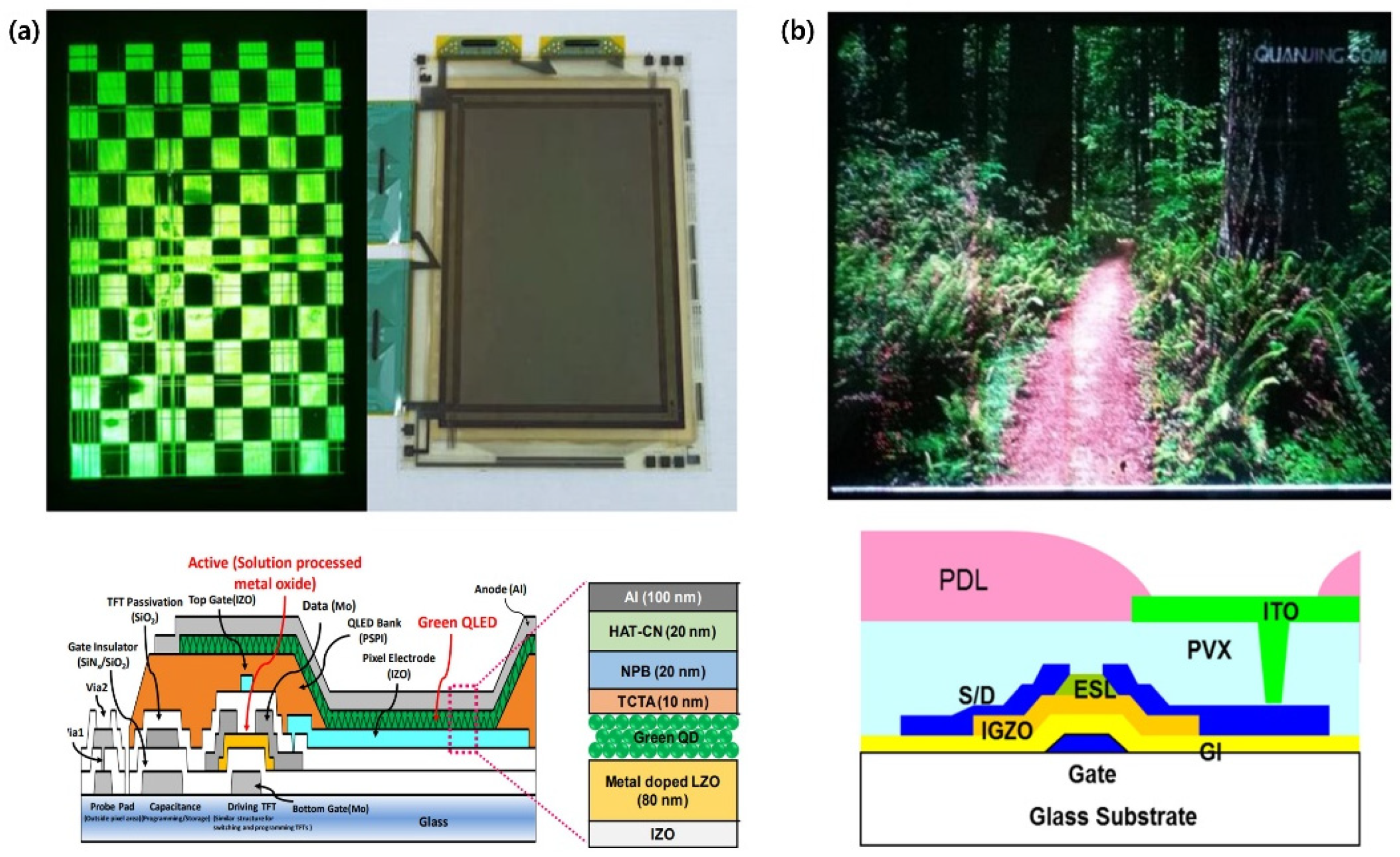

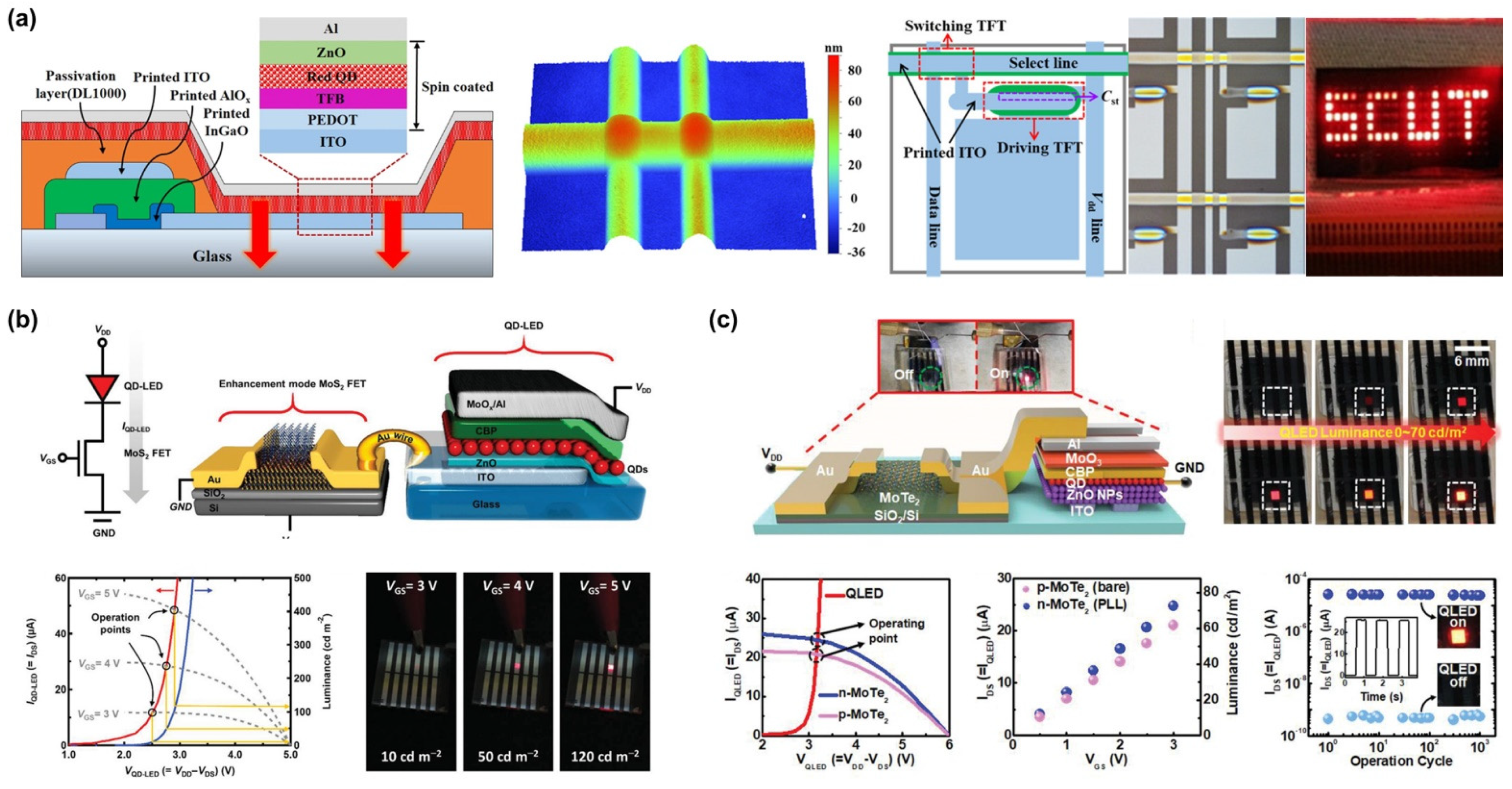

4. Monolithically Integrated TFT–QLED Devices

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aroutiounian, V.; Petrosyan, S.; Khachatryan, A.; Touryan, K. Quantum Dot Solar Cells. J. Appl. Phys. 2001, 89, 2268–2271. [Google Scholar] [CrossRef]

- Nozik, A.J. Quantum Dot Solar Cells. Phys. E Low-Dimens. Syst. Nanostruct. 2002, 14, 115–120. [Google Scholar] [CrossRef]

- Semonin, O.E.; Nozik, A.J.; Beard, M.C. In a Quantum Dot Solar Cell. Science 2013, 1530, 1530–1534. [Google Scholar]

- Shirasaki, Y.; Supran, G.J.; Bawendi, M.G.; Bulović, V. Emergence of Colloidal Quantum-Dot Light-Emitting Technologies. Nat. Photonics 2013, 7, 13–23. [Google Scholar] [CrossRef]

- Kim, M.R.; Ma, D. Quantum-Dot-Based Solar Cells: Recent Advances, Strategies, and Challenges. J. Phys. Chem. Lett. 2015, 6, 85–99. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, C.S.; Kim, S.; Hur, J.; Lee, S.; Shin, K.W.; Yoon, Y.Z.; Choi, M.K.; Yang, J.; Kim, D.H.; et al. Fully Stretchable Optoelectronic Sensors Based on Colloidal Quantum Dots for Sensing Photoplethysmographic Signals. ACS Nano 2017, 11, 5992–6003. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Shim, H.J.; Yang, J.; Choi, M.K.; Kim, D.C.; Kim, J.; Hyeon, T.; Kim, D.H. Ultrathin Quantum Dot Display Integrated with Wearable Electronics. Adv. Mater. 2017, 29, 1700217. [Google Scholar] [CrossRef]

- Song, J.; Wang, O.; Shen, H.; Lin, Q.; Li, Z.; Wang, L.; Zhang, X.; Li, L.S. Over 30% External Quantum Efficiency Light-Emitting Diodes by Engineering Quantum Dot-Assisted Energy Level Match for Hole Transport Layer. Adv. Funct. Mater. 2019, 29, 1808377. [Google Scholar] [CrossRef]

- Livache, C.; Martinez, B.; Goubet, N.; Gréboval, C.; Qu, J.; Chu, A.; Royer, S.; Ithurria, S.; Silly, M.G.; Dubertret, B.; et al. A Colloidal Quantum Dot Infrared Photodetector and Its Use for Intraband Detection. Nat. Commun. 2019, 10, 2125. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, C.; Guo, Y.; Yang, Y.; Xing, Y.; Que, W. PbS QD-based photodetectors: Future-oriented near-infrared detection technology. J. Mater. Chem. C 2021, 9, 417–438. [Google Scholar] [CrossRef]

- Li, Z.; Hu, Y.; Shen, H.; Lin, Q.; Wang, L.; Wang, H.; Zhao, W.; Li, L.S. Efficient and Long-Life Green Light-Emitting Diodes Comprising Tridentate Thiol Capped Quantum Dots. Laser Photonics Rev. 2017, 11, 1600227. [Google Scholar] [CrossRef]

- Sun, Y.; Su, Q.; Zhang, H.; Wang, F.; Zhang, S.; Chen, S. Investigation on Thermally Induced Efficiency Roll-Off: Toward Ef-ficient and Ultrabright Quantum-Dot Light-Emitting Diodes. ACS Nano 2019, 13, 11433–11442. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.F.; Chou, S.Y.; Huang, P.; Xiao, C.; Liu, X.; Xie, Y.; Zhao, F.; Huang, Y.; Feng, J.; Zhong, H.; et al. Stretchable Organometal-Halide-Perovskite Quantum-Dot Light-Emitting Diodes. Adv. Mater. 2019, 31, 1807516. [Google Scholar] [CrossRef]

- Kim, T.; Kim, K.H.; Kim, S.; Choi, S.M.; Jang, H.; Seo, H.K.; Lee, H.; Chung, D.Y.; Jang, E. Efficient and stable blue quantum dot light-emitting diode. Nature 2020, 586, 385–389. [Google Scholar] [CrossRef]

- Jia, S.; Tang, H.; Ma, J.; Ding, S.; Qu, X.; Xu, B.; Wu, Z.; Li, G.; Liu, P.; Wang, K.; et al. High Performance Inkjet-Printed Quantum-Dot Light-Emitting Diodes with High Operational Stability. Adv. Opt. Mater. 2021, 9, 2101069. [Google Scholar] [CrossRef]

- Chao, W.C.; Chiang, T.H.; Liu, Y.C.; Huang, Z.X.; Liao, C.C.; Chu, C.H.; Wang, C.H.; Tseng, H.W.; Hung, W.Y.; Chou, P.T. High efficiency green InP quantum dot light-emitting diodes by balancing electron and hole mobility. Commun. Mater. 2021, 2, 96. [Google Scholar] [CrossRef]

- Cho, K.S.; Lee, E.K.; Joo, W.J.; Jang, E.; Kim, T.H.; Lee, S.J.; Kwon, S.J.; Han, J.Y.; Kim, B.K.; Choi, B.L.; et al. High-performance crosslinked colloidal quantum-dot light-emitting diodes. Nat. Photonics 2009, 3, 341–345. [Google Scholar] [CrossRef]

- Kim, T.H.; Cho, K.S.; Lee, E.K.; Lee, S.J.; Chae, J.; Kim, J.W.; Kim, D.H.; Kwon, J.Y.; Amaratunga, G.; Lee, S.Y.; et al. Full-colour quantum dot displays fabricated by transfer printing. Nat. Photonics 2011, 5, 176–182. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, Y.; Cao, W.; Titov, A.; Hyvonen, J.; Manders, J.R.; Xue, J.; Holloway, P.H.; Qian, L. High-efficiency light-emitting devices based on quantum dots with tailored nanostructures. Nat. Photonics 2015, 9, 259–265. [Google Scholar] [CrossRef]

- Lai, K.Y.; Yang, S.; Tsai, T.C.; Yao, I.A.; Yang, C.L.; Chang, C.C.; Chen, H.S. Top-Emitting Active-Matrix Quantum Dot Light-Emitting Diode Array with Optical Microcavity for Micro QLED Display. Nanomaterials 2022, 12, 2683. [Google Scholar] [CrossRef]

- Jiang, C.; Mu, L.; Zou, J.; He, Z.; Zhong, Z.; Wang, L.; Xu, M.; Wang, J.; Peng, J.; Cao, Y. Full-Color Quantum Dots Active Matrix Display Fabricated by Ink-Jet Printing. Sci. China Chem. 2017, 60, 1349–1355. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Kristal, B.; Zhang, Y.; Li, D.; Yu, G.; Wang, X.; Wang, L.; Shi, Y.; Wang, Z.; et al. Developing AMQLED Technology for Display Applications. SID Int. Symp. Dig. Tech. Pap. 2018, 49, 1076–1079. [Google Scholar] [CrossRef]

- Roh, J.; Ryu, J.H.; Baek, G.W.; Jung, H.; Seo, S.G.; An, K.; Jeong, B.G.; Lee, D.C.; Hong, B.H.; Bae, W.K.; et al. Threshold Voltage Control of Multilayered MoS2 Field-Effect Transistors via Octadecyltrichlorosilane and Their Applications to Active Matrixed Quantum Dot Displays Driven by Enhancement-Mode Logic Gates. Small 2019, 15, 1803852. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; He, P.; Chen, S.; Lan, L.; Dai, X.; Peng, J. Inkjet-Printed Oxide Thin-Film Transistors Based on Nanopore-Free Aqueous-Processed Dielectric for Active-Matrix Quantum-Dot Light-Emitting Diode Displays. ACS Appl. Mater. Interfaces 2019, 11, 28052–28059. [Google Scholar] [CrossRef]

- Baek, G.W.; Seo, S.G.; Hahm, D.; Bae, W.K.; Kwak, J.; Jin, S.H. Highly Efficient, Surface Ligand Modified Quantum Dot Light-Emitting Diodes Driven by Type-Controllable MoTe2 Thin Film Transistors via Electron Charge Enhancer. Adv. Electron. Mater. 2021, 7, 2100535. [Google Scholar] [CrossRef]

- Chen, C.; Su, S.; Zhang, S.; Chen, S. Al Reaction-Induced Conductive a-InGaZnO as Pixel Electrode for Active-Matrix Quantum-Dot LED Displays. IEEE Electron Device Lett. 2022, 43, 749–752. [Google Scholar] [CrossRef]

- Jin, S.H.; Kang, S.K.; Cho, I.T.; Han, S.Y.; Chung, H.U.; Lee, D.J.; Shin, J.; Baek, G.W.; Kim, T.; Lee, J.H.; et al. Water-Soluble Thin Film Transistors and Circuits Based on Amorphous Indium-Gallium-Zinc Oxide. ACS Appl. Mater. Interfaces 2015, 7, 8268–8274. [Google Scholar] [CrossRef]

- Ryu, J.H.; Baek, G.W.; Yu, S.J.; Seo, S.G.; Jin, S.H. Photosensitive Full-Swing Multi-Layer MoS2 inverters with Light Shielding Layers. IEEE Electron Device Lett. 2017, 38, 67–70. [Google Scholar] [CrossRef]

- Choi, M.; Park, Y.J.; Sharma, B.K.; Bae, S.R.; Kim, S.Y.; Ahn, J.H. Flexible Active-Matrix Organic Light-Emitting Diode Display Enabled by MoS2 Thin-Film Transistor. Sci. Adv. 2018, 4, eaas8721. [Google Scholar] [CrossRef]

- Choi, M.; Bae, S.R.; Hu, L.; Hoang, A.T.; Kim, S.Y.; Ahn, J.H. Full-Color Active-Matrix Organic Light-Emitting Diode Display on Human Skin Based on a Large-Area MoS2 backplane. Sci. Adv. 2020, 6, eabb5898. [Google Scholar] [CrossRef]

- Khan, M.I.; Baek, G.W.; Kim, K.; Jin, S.H. Simultaneous Detection of Dopamine and Uric Acid on Indium Tin Oxides Modified with Cost-Effective Gas-Phase Synthesized Single Walled Carbon Nanotubes. Electroanalysis 2017, 29, 1925–1933. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Jang, J. AMQLED Display with Solution-Processed Oxide TFT Backplane. SID Int. Symp. Dig. Tech. Pap. 2018, 49, 1080–1083. [Google Scholar] [CrossRef]

- Srivastava, A.; Dubey, D.; Goswami, M.; Kandpal, K. Mechanical Strain and Bias-Stress Compensated, 6T-1C Pixel Circuit for Flexible AMOLED Displays. Microelectron. J. 2021, 117, 105266. [Google Scholar] [CrossRef]

- Wu, W.J.; Zhou, L.; Yao, R.H.; Peng, J.B. A New Voltage-Programmed Pixel Circuit for Enhancing the Uniformity of AMOLED Displays. IEEE Electron Device Lett. 2011, 32, 931–933. [Google Scholar] [CrossRef]

- Bang, J.S.; Kim, H.S.; Kim, K.D.; Kwon, O.J.; Shin, C.S.; Lee, J.; Cho, G.H. A Hybrid AMOLED Driver IC for Real-Time TFT Nonuniformity Compensation. IEEE J. Solid-State Circuits 2016, 51, 966–978. [Google Scholar]

- Lin, C.L.; Chang, W.Y.; Hung, C.C. Compensating Pixel Circuit Driving AMOLED Display with A-IGZO TFTs. IEEE Electron Device Lett. 2013, 34, 1166–1168. [Google Scholar] [CrossRef]

- Park, J.H.; Seok, H.J.; Kim, C.H.; Jung, S.H.; Cho, H.K.; Kim, H.K. Compositional Engineering of Hf-Doped InZnSnO Films for High-Performance and Stability Amorphous Oxide Semiconductor Thin Film Transistors. Adv. Electron. Mater. 2021, 7, 2001216. [Google Scholar] [CrossRef]

- Jeong, H.J.; Lee, H.M.; Ryu, C.H.; Park, E.J.; Han, K.L.; Hwang, H.J.; Ok, K.C.; Kim, H.S.; Park, J.S. Ultra-High-Speed Intense Pulsed-Light Irradiation Technique for High-Performance Zinc Oxynitride Thin-Film Transistors. ACS Appl. Mater. Interfaces 2019, 11, 4152–4158. [Google Scholar] [CrossRef]

- Chung, J.; Tak, Y.J.; Kim, W.G.; Park, J.W.; Kim, T.S.; Lim, J.H.; Kim, H.J. Low-Temperature Fabrication of Solution-Processed Hafnium Oxide Gate Insulator Films Using a Thermally Purified Solution Process. J. Mater. Chem. C 2018, 6, 4928–4935. [Google Scholar] [CrossRef]

- Park, E.J.; Lee, H.M.; Kim, Y.S.; Jeong, H.J.; Park, J.; Park, J.S. Transparent Flexible High Mobility TFTs Based on ZnON Semiconductor with Dual Gate Structure. IEEE Electron Device Lett. 2020, 41, 401–404. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Wu, Q.; Dussarrat, C.; Qi, J.; Zhu, W.; Ding, X.; Zhang, J. High-Performance 1-V ZnO Thin-Film Transistors with Ultrathin, ALD-Processed ZrO2 Gate Dielectric. IEEE Trans. Electron Devices 2019, 66, 3382–3386. [Google Scholar] [CrossRef]

- Ren, J.; Li, K.; Yang, J.; Lin, D.; Kang, H.; Shao, J.; Fu, R.; Zhang, Q. Solution-Processed Amorphous Gallium-Tin Oxide Thin Film for Low-Voltage, High-Performance Transistors. Sci. China Mater. 2019, 62, 803–812. [Google Scholar] [CrossRef]

- Magari, Y.; Kataoka, T.; Yeh, W.; Furuta, M. High-Mobility Hydrogenated Polycrystalline In2O3 (In2O3:H) Thin-Film Transistors. Nat. Commun. 2022, 13, 1078. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, C.; Wang, G.; Pei, Y. Investigation of Solution Combustion- Processed Nickel Oxide p-Channel Thin Film Transistors. Semicond. Sci. Technol. 2017, 32, 085004. [Google Scholar] [CrossRef]

- Liang, L.Y.; Liu, Z.M.; Cao, H.T.; Yu, Z.; Shi, Y.Y.; Chen, A.H.; Zhang, H.Z.; Fang, Y.Q.; Sun, X.L. Phase and Optical Characterizations of Annealed SnO Thin Films and Their P-Type TFT Application. J. Electrochem. Soc. 2010, 157, H598. [Google Scholar] [CrossRef]

- Sanal, K.C.; Vikas, L.S.; Jayaraj, M.K. Room Temperature Deposited Transparent P-Channel CuO Thin Film Transistors. Appl. Surf. Sci. 2014, 297, 153–157. [Google Scholar] [CrossRef]

- Ryu, J.H.; Baek, G.W.; Kim, S.Y.; Kwon, H.I.; Jin, S.H. Spray-Coated Single Walled Carbon Nanotubes as Source and Drain Electrodes in SnO Thin-Film Transistors. Semicond. Sci. Technol. 2018, 33, 075013. [Google Scholar] [CrossRef]

- Liu, N.; Baek, J.; Kim, S.M.; Hong, S.; Hong, Y.K.; Kim, Y.S.; Kim, H.S.; Kim, S.; Park, J. Improving the Stability of High-Performance Multilayer MoS2 Field-Effect Transistors. ACS Appl. Mater. Interfaces 2017, 9, 42943–42950. [Google Scholar] [CrossRef]

- Li, N.; Wang, Q.; Shen, C.; Wei, Z.; Yu, H.; Zhao, J.; Lu, X.; Wang, G.; He, C.; Xie, L.; et al. Large-Scale Flexible and Transparent Electronics Based on Monolayer Molybdenum Disulfide Field-Effect Transistors. Nat. Electron. 2020, 3, 711–717. [Google Scholar] [CrossRef]

- Zhu, K.; Wen, C.; Aljarb, A.A.; Xue, F.; Xu, X.; Tung, V.; Zhang, X.; Alshareef, H.N.; Lanza, M. The Development of Integrated Circuits Based on Two-Dimensional Materials. Nat. Electron. 2021, 4, 775–785. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, Y.; Hu, Z.; Wang, W.; Chang, Z.; Zhang, Y.; Lu, Q.; Wu, H.; Liao, J.; Zou, W.; et al. Large-Area Transfer of Two-Dimensional Materials Free of Cracks, Contamination and Wrinkles via Controllable Conformal Contact. Nat. Commun. 2022, 13, 4409. [Google Scholar] [CrossRef] [PubMed]

- Tans, S.J.; Verschueren, A.R.M.; Dekker, C. Room-Temperature Transistor Based on a Single Carbon Nanotube. Nature 1998, 393, 49–52. [Google Scholar] [CrossRef]

- Artukovic, E.; Kaempgen, M.; Hecht, D.S.; Roth, S.; Grüner, G. Transparent and Flexible Carbon Nanotube Transistors. Nano Lett. 2005, 5, 757–760. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Timmermans, M.Y.; Tian, Y.; Nasibulin, A.G.; Kauppinen, E.I.; Kishimoto, S.; Mizutani, T.; Ohno, Y. Flexible High-Performance Carbon Nanotube Integrated Circuits. Nat. Nanotechnol. 2011, 6, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Liu, C.; Ren, W.; Cheng, H. A Review of Carbon Nanotube- and Graphene-Based Flexible Thin-Film Transistors. Small 2013, 9, 1188–1205. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Nishide, D.; Tanaka, T.; Kataura, H. Large-Scale Single-Chirality Separation of Single-Wall Carbon Nanotubes by Simple Gel Chromatography. Nat. Commun. 2011, 2, 309. [Google Scholar] [CrossRef]

- Tanaka, T.; Liu, H.; Fujii, S.; Kataura, H. From Metal/Semiconductor Separation to Single-chirality Separation of Single-wall Carbon Nanotubes Using Gel. Phys. Status Solidi-Rapid Res. Lett. 2011, 5, 301–306. [Google Scholar] [CrossRef]

- Rojas, W.A.G.; Hersam, M.C. Chirality-Enriched Carbon Nanotubes for Next-Generation Computing. Adv. Mater. 2020, 32, 1905654. [Google Scholar] [CrossRef]

- Tu, X.; Zheng, M. A DNA-Based Approach to the Carbon Nanotube Sorting Problem. Nano Res. 2008, 1, 185–194. [Google Scholar] [CrossRef]

- Asada, Y.; Miyata, Y.; Ohno, Y.; Kitaura, R.; Sugai, T.; Mizutani, T.; Shinohara, H. High-Performance Thin-Film Transistors with DNA-Assisted Solution Processing of Isolated Single-Walled Carbon Nanotubes. Adv. Mater. 2010, 22, 2698–2701. [Google Scholar] [CrossRef]

- Gomulya, W.; Gao, J.; Loi, M.A. Conjugated Polymer-Wrapped Carbon Nanotubes: Physical Properties and Device Applications. Eur. Phys. J. B 2013, 86, 404. [Google Scholar] [CrossRef]

- Samanta, S.K.; Fritsch, M.; Scherf, U.; Gomulya, W.; Bisri, S.Z.; Loi, M.A. Conjugated Polymer-Assisted Dispersion of Single-Wall Carbon Nanotubes: The Power of Polymer Wrapping. Acc. Chem. Res. 2014, 47, 2446–2456. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Xing, X.; Zhu, M.; Cao, J.; Ali, M.U.; Li, A.; He, Y.; Meng, H. Low-Voltage, High-Performance Flexible Organic Field-Effect Transistors Based on Ultrathin Single-Crystal Microribbons. ACS Appl. Mater. Interfaces 2019, 11, 34188–34195. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Ji, X.; Jiao, X.; Chu, M.; Liu, J.; Li, Y.; Chen, M.; Zhou, Z.; Zhang, C.; Miao, Q.; et al. A Transfer Method for High-Mobility, Bias-Stable, and Flexible Organic Field-Effect Transistors. Adv. Mater. Technol. 2020, 5, 2000169. [Google Scholar] [CrossRef]

- Han, M.J.; Lee, D.W.; Lee, E.K.; Kim, J.Y.; Jung, J.Y.; Kang, H.; Ahn, H.; Shin, T.J.; Yoon, D.K.; Park, J. Il Molecular Orientation Control of Liquid Crystal Organic Semiconductor for High-Performance Organic Field-Effect Transistors. ACS Appl. Mater. Interfaces 2021, 13, 11125–11133. [Google Scholar] [CrossRef]

- Haase, K.; Teixeira da Rocha, C.; Hauenstein, C.; Zheng, Y.; Hambsch, M.; Mannsfeld, S.C.B. High-Mobility, Solution-Processed Organic Field-Effect Transistors from C8-BTBT:Polystyrene Blends. Adv. Electron. Mater. 2018, 4, 1800076. [Google Scholar] [CrossRef]

- Fu, B.; Sun, L.; Liu, L.; Ji, D.; Zhang, X.; Yang, F.; Hu, W. Low-Power High-Mobility Organic Single-Crystal Field-Effect Transistor. Sci. China Mater. 2022, 65, 2779–2785. [Google Scholar] [CrossRef]

- Xia, G.; Zhang, Q.; Wang, S. High-Mobility IGZO TFTs by Infrared Radiation Activated Low-Temperature Solution Process. IEEE Electron Device Lett. 2018, 39, 1868–1871. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Zhu, E.; Liao, L.; Lee, S.-J.; Ding, M.; Shakir, I.; Gambin, V.; Huang, Y.; Duan, X. Approaching the Schottky–Mott Limit in van Der Waals Metal–Semiconductor Junctions. Nature 2018, 557, 696–700. [Google Scholar] [CrossRef]

- Schneider, S.; Brohmann, M.; Lorenz, R.; Hofstetter, Y.J.; Rother, M.; Sauter, E.; Zharnikov, M.; Vaynzof, Y.; Himmel, H.-J.; Zaumseil, J. Efficient n-Doping and Hole Blocking in Single-Walled Carbon Nanotube Transistors with 1,2,4,5Tetrakis(Tetramethylguanidino)Ben-Zene. ACS Nano 2018, 12, 5895–5902. [Google Scholar] [CrossRef]

- Wang, Y.; Kim, J.C.; Wu, R.J.; Martinez, J.; Song, X.; Yang, J.; Zhao, F.; Mkhoyan, A.; Jeong, H.Y.; Chhowalla, M. Van Der Waals Contacts between Three-Dimensional Metals and Two-Dimensional Semiconductors. Nature 2019, 568, 70–74. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, M.; Du, C.; Li, L.; Chang, K.-C. Improving Performance of All-Carbon-Nanotube Thin-Film Transistors by Low Temperature Supercritical CO2 Fluid Activation. IEEE Electron Device Lett. 2019, 40, 921–924. [Google Scholar] [CrossRef]

- Sanjay, S.; Sahoo, K.; Bhat, N. Alcohol-Based Sulfur Treatment for Improved Performance and Yield in Local Back-Gated and Channel-Length-Scaled MoS₂ FETs. IEEE Trans. Electron Devices 2020, 67, 3711–3715. [Google Scholar] [CrossRef]

- Salazar-Rios, J.M.; Sengrian, A.A.; Talsma, W.; Duim, H.; Abdu-Aguye, M.; Jung, S.; Fröhlich, N.; Allard, S.; Scherf, U.; Loi, M.A. Customizing the Polarity of Single-Walled Carbon-Nanotube Field-Effect Transistors Using Solution-Based Additives. Adv. Electron. Mater. 2020, 6, 1900789. [Google Scholar] [CrossRef]

- Iqbal, M.W.; Elahi, E.; Amin, A.; Aftab, S.; Aslam, I.; Hussain, G.; Shehzad, M.A. A Facile Route to Enhance the Mobility of MoTe2 Field Effect Transistor via Chemical Doping. Superlattices Microstruct. 2020, 147, 106698. [Google Scholar] [CrossRef]

- Kim, B.K.; On, N.; Choi, C.H.; Kim, M.J.; Kang, S.; Lim, J.H.; Jeong, J.K. Polycrystalline Indium Gallium Tin Oxide Thin-Film Transistors with High Mobility Exceeding 100 cm2/Vs. IEEE Electron Device Lett. 2021, 42, 347–350. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, A.; Tomar, M.; Gupta, V. Realization of Low-Power and High Mobility Thin Film Transistors Based on MoS2 Layers Grown by PLD Technique. Mater. Sci. Eng. B 2021, 266, 115047. [Google Scholar] [CrossRef]

- Kim, S.; Baek, G.W.; Jeong, J.; Seo, S.G.; Jin, S.H. Scalable and Selective N-Type Conversion for Carbon Nanotube Transistors via Patternable Polyvinyl Alcohol Stacked with Hydrophobic Layers and Their Application to Complementary Logic Circuits. J. Mater. Res. Technol. 2021, 12, 243–256. [Google Scholar] [CrossRef]

- Seo, S.G.; Jeong, J.; Kim, S.Y.; Kim, S.; Kim, K.; Kim, K.; Jin, S.H. Bias Stress Instability in Multilayered MoTe2 Field Effect Transistors under DC and Pulse-Mode Operation. Electron. Lett. 2021, 57, 193–195. [Google Scholar] [CrossRef]

- Hwangbo, S.; Hu, L.; Hoang, A.T.; Choi, J.Y.; Ahn, J.-H. Wafer-Scale Monolithic Integration of Full-Colour Micro-LED Display Using MoS2 Transistor. Nat. Nanotechnol. 2022, 17, 500–506. [Google Scholar] [CrossRef]

- Sun, Y.; Li, P.; Kauppinen, E.I.; Sun, D.-M.; Ohno, Y. Key Factors for Ultra-High on/off Ratio Thin-Film Transistors Using as-Grown Carbon Nanotube Networks. RSC Adv. 2022, 12, 16291–16295. [Google Scholar] [CrossRef] [PubMed]

- Huyen Nguyen, P.; Hieu Nguyen, D.; Kim, H.; Jeong, H.M.; Oh, H.M.; Jeong, M.S. Synergistic Hole-Doping on Ultrathin MoTe2 for Highly Stable Unipolar Field-Effect Transistor. Appl. Surf. Sci. 2022, 596, 153567. [Google Scholar] [CrossRef]

- Colvin, V.L.; Schlamp, M.C.; Alivisatos, A.P. Light-Emitting Diodes Made from Cadmium Selenide Nanocrystals and a Semiconducting Polymer. Nature 1994, 370, 354–357. [Google Scholar] [CrossRef]

- Jang, H.J.; Lee, J.Y.; Baek, G.W.; Kwak, J.; Park, J.-H. Progress in the development of the display performance of AR, VR, QLED and OLED devices in recent years. J. Inf. Disp. 2022, 23, 1–17. [Google Scholar] [CrossRef]

- Bae, W.K.; Kwak, J.; Lim, J.; Lee, D.; Nam, M.K.; Char, K.; Lee, C.; Lee, S. Multicolored light-emitting diodes based on all-quantum-dot multilayer films using layer-by-layer assembly method. Nano Lett. 2010, 10, 2368–2373. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.; Bae, W.K.; Lee, D.; Park, I.; Lim, J.; Park, M.; Cho, H.; Woo, H.; Yoon, D.Y.; Char, K.; et al. Bright and efficient full-color colloidal quantum dot light-emitting diodes using an inverted device structure. Nano Lett. 2012, 12, 2362–2366. [Google Scholar] [CrossRef]

- Qian, L.; Zheng, Y.; Choudhury, K.R.; Bera, D.; So, F.; Xue, J.; Holloway, P.H. Electroluminescence from Light-Emitting Polymer/ZnO Nanoparticle Heterojunctions at Sub-Bandgap Voltages. Nano Today 2010, 5, 384–389. [Google Scholar] [CrossRef]

- Qian, L.; Zheng, Y.; Xue, J.; Holloway, P.H. Stable and Efficient Quantum-Dot Light-Emitting Diodes Based on Solution-Processed Multilayer Structures. Nat. Photonics 2011, 5, 543–548. [Google Scholar] [CrossRef]

- Yang, X.; Mutlugun, E.; Dang, C.; Dev, K.; Gao, Y.; Tan, S.T.; Sun, X.W.; Demir, H.V. Highly flexible, electrically driven, top-emitting, quantum dot light-emitting stickers. ACS Nano 2014, 8, 8224–8231. [Google Scholar] [CrossRef]

- Ding, K.; Fang, Y.; Dong, S.; Chen, H.; Luo, B.; Jiang, K.; Gu, H.; Fan, L.; Liu, S.; Hu, B.; et al. 24.1% External Quantum Efficiency of Flexible Quantum Dot Light-Emitting Diodes by Light Extraction of Silver Nanowire Transparent Electrodes. Adv. Opt. Mater. 2018, 6, 1800347. [Google Scholar] [CrossRef]

- Li, D.; Feng, J.; Zhu, Y.; Lu, Z.; Pei, C.; Chen, Z.; Li, Y.; Li, X.; Xu, X. Enhanced efficiency of top-emission InP-based green quantum dot light-emitting diodes with optimized angular distribution. Nano Research 2021, 14, 4243–4249. [Google Scholar] [CrossRef]

- Chen, L.; Qin, Z.; Chen, S. Ultrahigh Resolution Pixelated Top-Emitting Quantum-Dot Light-Emitting Diodes Enabled by Color-Converting Cavities. Small Methods 2022, 6, 2101090. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhou, X.; Chen, S. Very bright and efficient microcavity top-emitting quantum dot light-emitting diodes with Ag electrodes. ACS Appl. Mater. Interfaces 2016, 8, 16768–16775. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Pan, T.; Zhang, J.; Zhang, L.; Liu, S.; Xie, W. Color-tunable, spectra-stable flexible white top-emitting organic light-emitting devices based on alternating current driven and dual-microcavity technology. ACS Photonics 2019, 6, 2350–2357. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, H.; Xu, M.; Zhang, J.; Feng, H.; Zhang, L.; Liu, S.; Xie, W. High-Efficiency, Large-Area, Flexible Top-Emitting Quantum-Dot Light-Emitting Diode. ACS Photonics 2022. [Google Scholar] [CrossRef]

- Shi, L.; Chen, S. Over 32.5% Efficient Top-Emitting Quantum-Dot LEDs with Angular-Independent Emission. ACS Appl. Mater. Interfaces 2022, 14, 30039–30045. [Google Scholar] [CrossRef]

- Kim, H.-M.; Lee, J.; Hwang, E.; Kim, J.; Jang, J. P-95: Inverted tandem architecture of quantum-dot light emitting diodes with solution processed charge generation layers. SID Int. Symp. Dig. Tech. Pap. 2016, 47, 1480–1483. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, X.; Chen, S. Over 100 cd A− 1 efficient quantum dot light-emitting diodes with inverted tandem structure. Adv. Funct. Mater. 2017, 27, 1700610. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, S.; Sun, X.W. Efficient red/green/blue tandem quantum-dot light-emitting diodes with external quantum efficiency exceeding 21%. ACS nano 2018, 12, 697–704. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, H.; Chen, S. Flexible and tandem quantum-dot light-emitting diodes with individually addressable red/green/blue emission. npj Flex. Electron. 2021, 5, 8. [Google Scholar] [CrossRef]

- Cho, S.-Y.; Oh, N.; Nam, S.; Jiang, Y.; Shim, M. Enhanced device lifetime of double-heterojunction nanorod light-emitting diodes. Nanoscale 2017, 9, 6103–6110. [Google Scholar] [CrossRef] [PubMed]

- Yun, J.; Kim, J.; Jung, B.J.; Kim, G.; Kwak, J. Enhanced efficiency and high temperature stability of hybrid quantum dot light-emitting diodes using molybdenum oxide doped hole transport layer. RSC Adv. 2019, 9, 16252–16257. [Google Scholar] [CrossRef] [PubMed]

- Bae, W.K.; Kwak, J.; Lim, J.; Lee, D.; Nam, M.K.; Char, K.; Lee, C.; Lee, S. Deep blue light-emitting diodes based on Cd1− xZnxS@ ZnS quantum dots. Nanotechnology 2009, 20, 075202. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hou, X.; Dai, X.; Yao, Z.; Lv, L.; Jin, Y.; Peng, X. Stoichiometry-controlled InP-based quantum dots: Synthesis, photoluminescence, and electroluminescence. J. Am. Chem. Soc. 2019, 141, 6448–6452. [Google Scholar] [CrossRef]

- Li, J.; Liang, Z.; Su, Q.; Jin, H.; Wang, K.; Xu, G.; Xu, X. Small molecule-modified hole transport layer targeting low turn-on-voltage, bright, and efficient full-color quantum dot light emitting diodes. ACS Appl. Mater. Interfaces 2018, 10, 3865–3873. [Google Scholar] [CrossRef]

- Hong, A.; Kim, J.; Kwak, J. Sunlike White Quantum Dot Light-Emitting Diodes with High Color Rendition Quality. Adv. Opt. Mater. 2020, 8, 2001051. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, L.; Kang, D.J.; Strahl, R.; Kraus, T. High-resolution inkjet printing of quantum dot light-emitting microdiode arrays. Adv. Opt. Mater. 2020, 8, 1901429. [Google Scholar] [CrossRef]

- Chen, M.; Xie, L.; Wei, C.; Yi, Y.-Q.-Q.; Chen, X.; Yang, J.; Zhuang, J.; Li, F.; Su, W.; Cui, Z. High performance inkjet-printed QLEDs with 18.3% EQE: Improving interfacial contact by novel halogen-free binary solvent system. Nano Res. 2021, 14, 4125–4131. [Google Scholar] [CrossRef]

- Han, M.G.; Lee, Y.; Kwon, H.-i.; Lee, H.; Kim, T.; Won, Y.-H.; Jang, E. InP-based quantum dot light-emitting diode with a blended emissive layer. ACS Energy Lett. 2021, 6, 1577–1585. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Wang, F.; Lin, Q.; Zhao, M. To improve the performance of green light-emitting devices by enhancing hole injection efficiency. Chem. Eng. J. Adv. 2021, 5, 100082. [Google Scholar] [CrossRef]

- Lee, S.; Hahm, D.; Yoon, S.-Y.; Yang, H.; Bae, W.K.; Kwak, J. Quantum-dot and organic hybrid light-emitting diodes employing a blue common layer for simple fabrication of full-color displays. Nano Res. 2022, 15, 6477–6482. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.-B.; Fan, F.; Levina, L.; Liu, M.; Quintero-Bermudez, R.; Gong, X.; Quan, L.N.; Fan, J.; Yang, Z. Bright colloidal quantum dot light-emitting diodes enabled by efficient chlorination. Nat. Photonics 2018, 12, 159–164. [Google Scholar] [CrossRef]

- Won, Y.-H.; Cho, O.; Kim, T.; Chung, D.-Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Alexandrov, A.; Zvaigzne, M.; Lypenko, D.; Nabiev, I.; Samokhvalov, P. Al-, Ga-, Mg-, or Li-doped zinc oxide nanoparticles as electron transport layers for quantum dot light-emitting diodes. Sci. Rep. 2020, 10, 7496. [Google Scholar] [CrossRef] [PubMed]

- Moon, H.; Lee, W.; Kim, J.; Lee, D.; Cha, S.; Shin, S.; Chae, H. Composition-tailored ZnMgO nanoparticles for electron transport layers of highly efficient and bright InP-based quantum dot light emitting diodes. Chem. Commun. 2019, 55, 13299–13302. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, Z.; Jin, Y.; Niu, Y.; Cao, H.; Liang, X.; Chen, L.; Wang, J.; Peng, X. Solution-processed, high-performance light-emitting diodes based on quantum dots. Nature 2014, 515, 96–99. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, L.; Li, Z.; Shen, H.; Guo, L.; Kuang, Y.; Wang, H.; Li, L.S. Nonblinking quantum-dot-based blue light-emitting diodes with high efficiency and a balanced charge-injection process. ACS Photonics 2018, 5, 939–946. [Google Scholar] [CrossRef]

- Kim, D.; Fu, Y.; Kim, S.; Lee, W.; Lee, K.H.; Chung, H.K.; Lee, H.J.; Yang, H.; Chae, H. Polyethylenimine ethoxylated-mediated all-solution-processed high-performance flexible inverted quantum dot-light-emitting device. ACS Nano 2017, 11, 1982–1990. [Google Scholar] [CrossRef]

- Lee, T.; Hahm, D.; Kim, K.; Bae, W.K.; Lee, C.; Kwak, J. Highly efficient and bright inverted top-emitting InP quantum dot light-emitting diodes introducing a hole-suppressing interlayer. Small 2019, 15, 1905162. [Google Scholar] [CrossRef]

- Li, D.; Bai, J.; Zhang, T.; Chang, C.; Jin, X.; Huang, Z.; Xu, B.; Li, Q. Blue quantum dot light-emitting diodes with high luminance by improving the charge transfer balance. Chem. Commun. 2019, 55, 3501–3504. [Google Scholar] [CrossRef]

- Rhee, S.; Chang, J.H.; Hahm, D.; Jeong, B.G.; Kim, J.; Lee, H.; Lim, J.; Hwang, E.; Kwak, J.; Bae, W.K. Tailoring the electronic landscape of quantum dot light-emitting diodes for high brightness and stable operation. ACS Nano 2020, 14, 17496–17504. [Google Scholar] [CrossRef] [PubMed]

- Moon, H.; Chae, H. Efficiency enhancement of all-solution-processed inverted-structure green quantum dot light-emitting diodes via partial ligand exchange with thiophenol derivatives having negative dipole moment. Adv. Opt. Mater. 2020, 8, 1901314. [Google Scholar] [CrossRef]

- Lee, T.; Kim, B.J.; Lee, H.; Hahm, D.; Bae, W.K.; Lim, J.; Kwak, J. Bright and Stable Quantum Dot Light-Emitting Diodes. Adv. Mater. 2022, 34, 2106276. [Google Scholar] [CrossRef] [PubMed]

- Rhee, S.; Hahm, D.; Seok, H.-J.; Chang, J.H.; Jung, D.; Park, M.; Hwang, E.; Lee, D.C.; Park, Y.-S.; Kim, H.-K. Steering Interface Dipoles for Bright and Efficient All-Inorganic Quantum Dot Based Light-Emitting Diodes. ACS Nano 2021, 15, 20332–20340. [Google Scholar] [CrossRef]

- Kang, B.-H.; Lee, J.-S.; Lee, S.-W.; Kim, S.-W.; Lee, J.-W.; Gopalan, S.-A.; Park, J.-S.; Kwon, D.-H.; Bae, J.-H.; Kim, H.-R. Efficient exciton generation in atomic passivated CdSe/ZnS quantum dots light-emitting devices. Sci. Rep. 2016, 6, 34659. [Google Scholar] [CrossRef]

- Bae, W.K.; Lim, J.; Zorn, M.; Kwak, J.; Park, Y.-S.; Lee, D.; Lee, S.; Char, K.; Zentel, R.; Lee, C. Reduced efficiency roll-off in light-emitting diodes enabled by quantum dot–conducting polymer nanohybrids. J. Mater. Chem. C 2014, 2, 4974–4979. [Google Scholar] [CrossRef]

- Park, Y.; Klöckner, B.; Hahm, D.; Kim, J.; Lee, T.; Kim, J.; Bae, W.K.; Zentel, R.; Kwak, J. Origin of enhanced efficiency and stability in diblock copolymer-grafted Cd-free quantum dot-based light-emitting diodes. J. Mater. Chem. C 2021, 9, 10398–10405. [Google Scholar] [CrossRef]

- Kim, L.A.; Anikeeva, P.O.; Coe-Sullivan, S.A.; Steckel, J.S.; Bawendi, M.G.; Bulović, V. Contact Printing of Quantum Dot Light-Emitting Devices. Nano Lett. 2008, 8, 4513–4517. [Google Scholar] [CrossRef]

- Cho, H.; Kwak, J.; Lim, J.; Park, M.; Lee, D.; Bae, W.K.; Kim, Y.S.; Char, K.; Lee, S.; Lee, C. Soft Contact Transplanted Nanocrystal Quantum Dots for Light-Emitting Diodes: Effect of Surface Energy on Device Performance. ACS Appl. Mater. Interfaces 2015, 7, 10828–10833. [Google Scholar] [CrossRef]

- Roh, H.; Ko, D.; Shin, D.Y.; Chang, J.H.; Hahm, D.; Bae, W.K.; Lee, C.; Kim, J.Y.; Kwak, J. Enhanced Performance of Pixelated Quantum Dot Light-Emitting Diodes by Inkjet Printing of Quantum Dot–Polymer Composites. Adv. Opt. Mater. 2021, 9, 2002129. [Google Scholar] [CrossRef]

- Yang, J.; Hahm, D.; Kim, K.; Rhee, S.; Lee, M.; Kim, S.; Chang, J.H.; Park, H.W.; Lim, J.; Lee, M.; et al. High-Resolution Patterning of Colloidal Quantum Dots via Non-Destructive, Light-Driven Ligand Crosslinking. Nat. Commun. 2020, 11, 2874. [Google Scholar] [CrossRef] [PubMed]

- Wood, V.; Panzer, M.J.; Chen, J.; Bradley, M.S.; Halpert, J.E.; Bawendi, M.C.; Bulović, V. Inkjet-Printed Quantum Dot-Polymer Composites for Full-Color AC-Driven Displays. Adv. Mater. 2009, 21, 2151–2155. [Google Scholar] [CrossRef]

- Haverinen, H.M.; Myllylä, R.A.; Jabbour, G.E. Inkjet Printing of Light Emitting Quantum Dots. Appl. Phys. Lett. 2009, 94, 073108. [Google Scholar] [CrossRef]

- Haverinen, H.M.; Myllylä, R.A.; Jabbour, G.E.; Cheng, M. Inkjet Printed RGB Quantum Dot-Hybrid LED. J. Disp. Technol. 2010, 6, 87–89. [Google Scholar] [CrossRef]

- Still, T.; Yunker, P.J.; Yodh, A.G. Surfactant-Induced Marangoni Eddies Alter the Coffee-Rings of Evaporating Colloidal Drops. Langmuir 2012, 28, 4984–4988. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Zhong, Z.; Liu, B.; He, Z.; Zou, J.; Wang, L.; Wang, J.; Peng, J.; Cao, Y. Coffee-Ring-Free Quantum Dot Thin Film Using Inkjet Printing from a Mixed-Solvent System on Modified ZnO Transport Layer for Light-Emitting Devices. ACS Appl. Mater. Interfaces 2016, 8, 26162–26168. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Dong, T.; Zhong, Z.; Zheng, H.; Xu, W.; Ying, L.; Wang, J.; Peng, J.; Cao, Y. Uniform Inkjet-Printed Films with Single Solvent. Thin Solid Films 2018, 667, 21–27. [Google Scholar] [CrossRef]

- Yu, X.; Xing, R.; Peng, Z.; Lin, Y.; Du, Z.; Ding, J.; Wang, L.; Han, Y. To Inhibit Coffee Ring Effect in Inkjet Printing of Light-Emitting Polymer Films by Decreasing Capillary Force. Chin. Chem. Lett. 2019, 30, 135–138. [Google Scholar] [CrossRef]

- Li, H.; Duan, Y.; Shao, Z.; Zhang, G.; Li, H.; Huang, Y.; Yin, Z. QLEDs: High-Resolution Pixelated Light Emitting Diodes Based on Electrohydrodynamic Printing and Coffee-Ring-Free Quantum Dot Film. Adv. Mater. Technol. 2020, 5, 2000401. [Google Scholar] [CrossRef]

- Xiang, C.; Wu, L.; Lu, Z.; Li, M.; Wen, Y.; Yang, Y.; Liu, W.; Zhang, T.; Cao, W.; Tsang, S.W.; et al. High Efficiency and Stability of Ink-Jet Printed Quantum Dot Light Emitting Diodes. Nat. Commun. 2020, 11, 1646. [Google Scholar] [CrossRef]

- Xie, L.; Yang, J.; Zhao, W.; Yi, Y.Q.Q.; Liu, Y.; Su, W.; Li, Q.; Lei, W.; Cui, Z. High-Performance Inkjet-Printed Blue QLED Enabled by Crosslinked and Intertwined Hole Transport Layer. Adv. Opt. Mater. 2022, 10, 2200935. [Google Scholar] [CrossRef]

- Mei, W.; Zhang, Z.; Zhang, A.; Li, D.; Zhang, X.; Wang, H.; Chen, Z.; Li, Y.; Li, X.; Xu, X. High-Resolution, Full-Color Quantum Dot Light-Emitting Diode Display Fabricated via Photolithography Approach. Nano Res. 2020, 13, 2485–2491. [Google Scholar] [CrossRef]

- Myeong, S.; Chon, B.; Kumar, S.; Son, H.J.; Kang, S.O.; Seo, S. Quantum Dot Photolithography Using a Quantum Dot Photoresist Composed of an Organic-Inorganic Hybrid Coating Layer. Nanoscale Adv. 2022, 4, 1080–1087. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Fedin, I.; Zhang, H.; Talapin, D.V. Direct Optical Lithography of Functional Inorganic Nanomaterials. Science 2017, 357, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pan, J.A.; Wu, H.; Talapin, D.V. Direct Wavelength-Selective Optical and Electron-Beam Lithography of Functional Inorganic Nanomaterials. ACS Nano 2019, 13, 13917–13931. [Google Scholar] [CrossRef]

- Cho, H.; Pan, J.A.; Wu, H.; Lan, X.; Coropceanu, I.; Wang, Y.; Cho, W.; Hill, E.A.; Anderson, J.S.; Talapin, D.V. Direct Optical Patterning of Quantum Dot Light-Emitting Diodes via In Situ Ligand Exchange. Adv. Mater. 2020, 32, 2003805. [Google Scholar] [CrossRef]

- Park, J.S.; Kyhm, J.; Kim, H.H.; Jeong, S.; Kang, J.; Lee, S.E.; Lee, K.T.; Park, K.; Barange, N.; Han, J.; et al. Alternative Patterning Process for Realization of Large-Area, Full-Color, Active Quantum Dot Display. Nano Lett. 2016, 16, 6946–6953. [Google Scholar] [CrossRef]

- Hahm, D.; Lim, J.; Kim, H.; Shin, J.W.; Hwang, S.; Rhee, S.; Chang, J.H.; Yang, J.; Lim, C.H.; Jo, H.; et al. Direct Patterning of Colloidal Quantum Dots with Adaptable Dual-Ligand Surface. Nat. Nanotechnol. 2022, 17, 952–958. [Google Scholar] [CrossRef]

- Kong, Y.L.; Tamargo, I.A.; Kim, H.; Johnson, B.N.; Gupta, M.K.; Koh, T.W.; Chin, H.A.; Steingart, D.A.; Rand, B.P.; McAlpine, M.C. 3D Printed Quantum Dot Light-Emitting Diodes. Nano Lett. 2014, 14, 7017–7023. [Google Scholar] [CrossRef]

- Bae, J.; Lee, S.; Ahn, J.; Kim, J.H.; Wajahat, M.; Chang, W.S.; Yoon, S.Y.; Kim, J.T.; Seol, S.K.; Pyo, J. 3D-Printed Quantum Dot Nanopixels. ACS Nano 2020, 14, 10993–11001. [Google Scholar] [CrossRef]

- Kim, B.H.; Onses, M.S.; Lim, J.B.; Nam, S.; Oh, N.; Kim, H.; Yu, K.J.; Lee, J.W.; Kim, J.H.; Kang, S.K.; et al. High-Resolution Patterns of Quantum Dots Formed by Electrohydrodynamic Jet Printing for Light-Emitting Diodes. Nano Lett. 2015, 15, 969–973. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Moffitt, M.G. “Smart” Self-Assembled Quantum Dots Regulate and Stabilize Structure in Phase-Separated Polymer Blends. Chem. Mater. 2007, 19, 6581–6587. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, L.; Li, D.; Shi, Z.; Liu, P.; Yao, Z.; Yang, H.; Zou, T.; Zhao, B.; Zhang, X.; et al. Large-Area Patterning of Full-Color Quantum Dot Arrays beyond 1000 Pixels per Inch by Selective Electrophoretic Deposition. Nat. Commun. 2021, 12, 4603. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.L.; Kang, J.; Won, J.K.; Jung, S.M.; Kim, J.; Park, C.H.; Ju, B.K.; Kim, M.G.; Park, S.K. Spatial Light Patterning of Full Color Quantum Dot Displays Enabled by Locally Controlled Surface Tailoring. Adv. Opt. Mater. 2018, 6, 1701335. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, G.W.; Kim, Y.J.; Lee, M.; Kwon, Y.; Chun, B.; Park, G.; Seo, H.; Yang, H.; Kwak, J. Progress in the Development of Active-Matrix Quantum-Dot Light-Emitting Diodes Driven by Non-Si Thin-Film Transistors. Materials 2022, 15, 8511. https://doi.org/10.3390/ma15238511

Baek GW, Kim YJ, Lee M, Kwon Y, Chun B, Park G, Seo H, Yang H, Kwak J. Progress in the Development of Active-Matrix Quantum-Dot Light-Emitting Diodes Driven by Non-Si Thin-Film Transistors. Materials. 2022; 15(23):8511. https://doi.org/10.3390/ma15238511

Chicago/Turabian StyleBaek, Geun Woo, Yeon Jun Kim, Minhyung Lee, Yeunwoo Kwon, Beomsoo Chun, Ganghyun Park, Hansol Seo, Heesun Yang, and Jeonghun Kwak. 2022. "Progress in the Development of Active-Matrix Quantum-Dot Light-Emitting Diodes Driven by Non-Si Thin-Film Transistors" Materials 15, no. 23: 8511. https://doi.org/10.3390/ma15238511

APA StyleBaek, G. W., Kim, Y. J., Lee, M., Kwon, Y., Chun, B., Park, G., Seo, H., Yang, H., & Kwak, J. (2022). Progress in the Development of Active-Matrix Quantum-Dot Light-Emitting Diodes Driven by Non-Si Thin-Film Transistors. Materials, 15(23), 8511. https://doi.org/10.3390/ma15238511