Investigation of the Effect of Supersonic Flow of Dissociated Nitrogen on ZrB2–HfB2–SiC Ceramics Doped with 10 vol.% Carbon Nanotubes

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

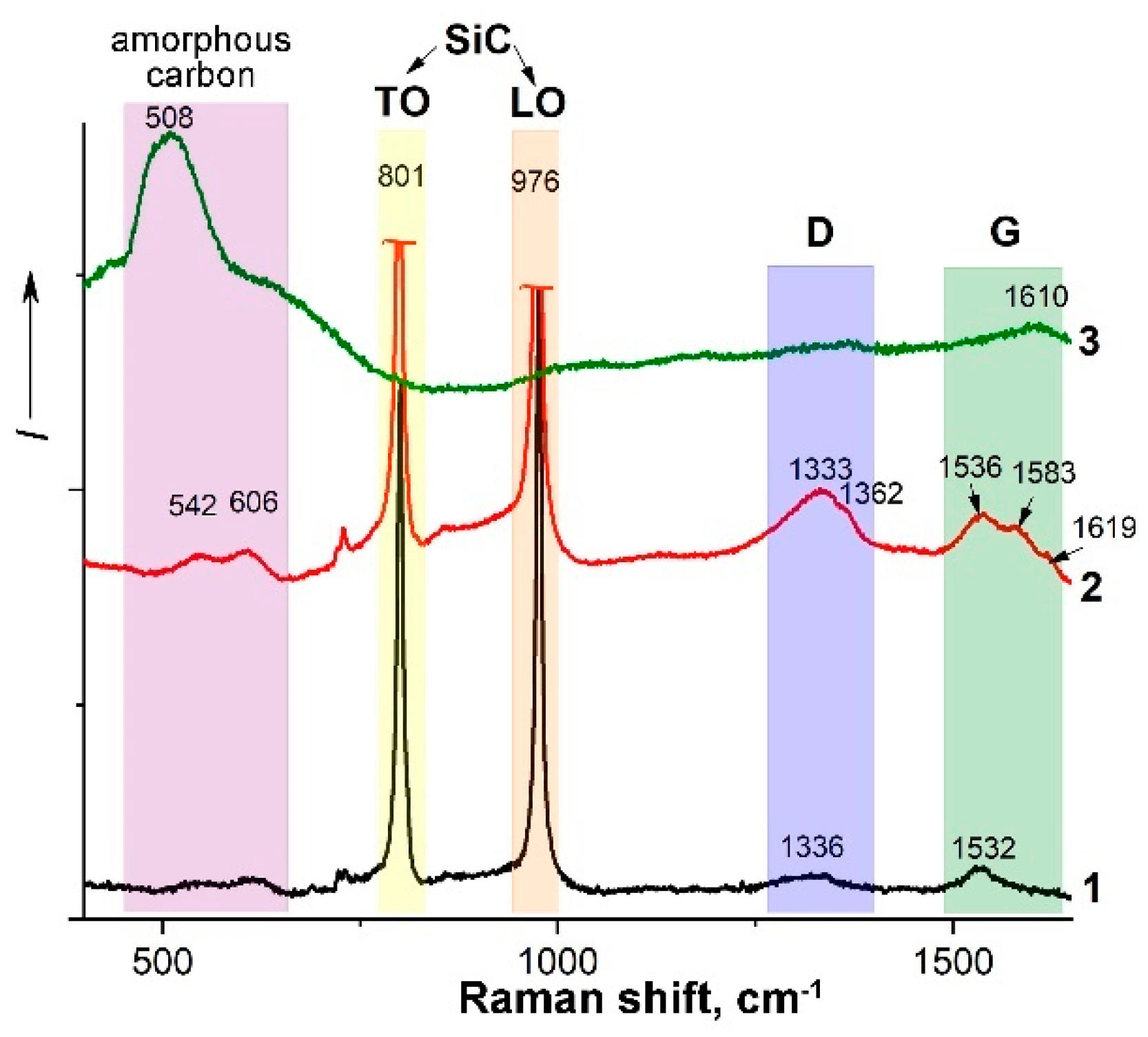

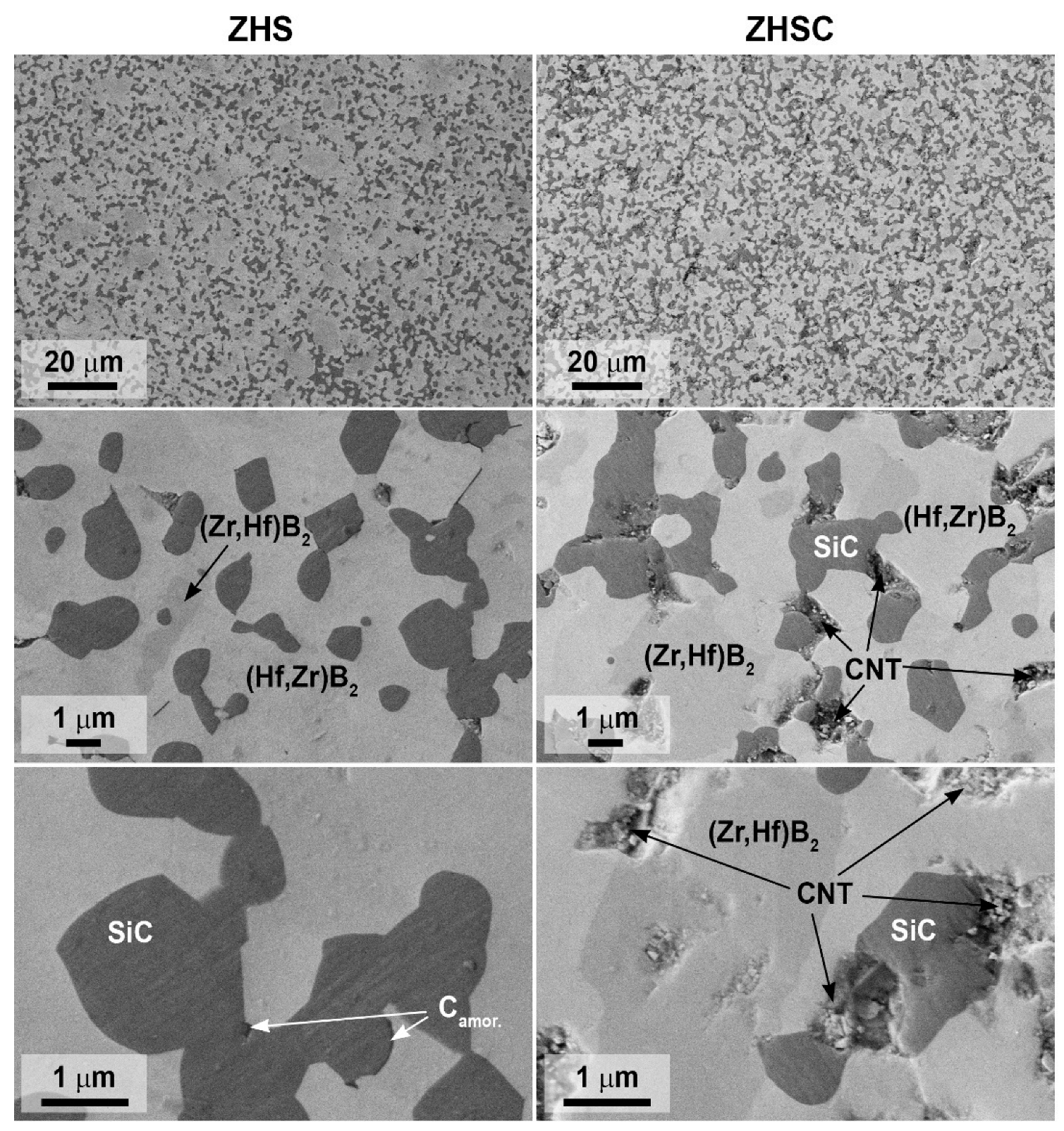

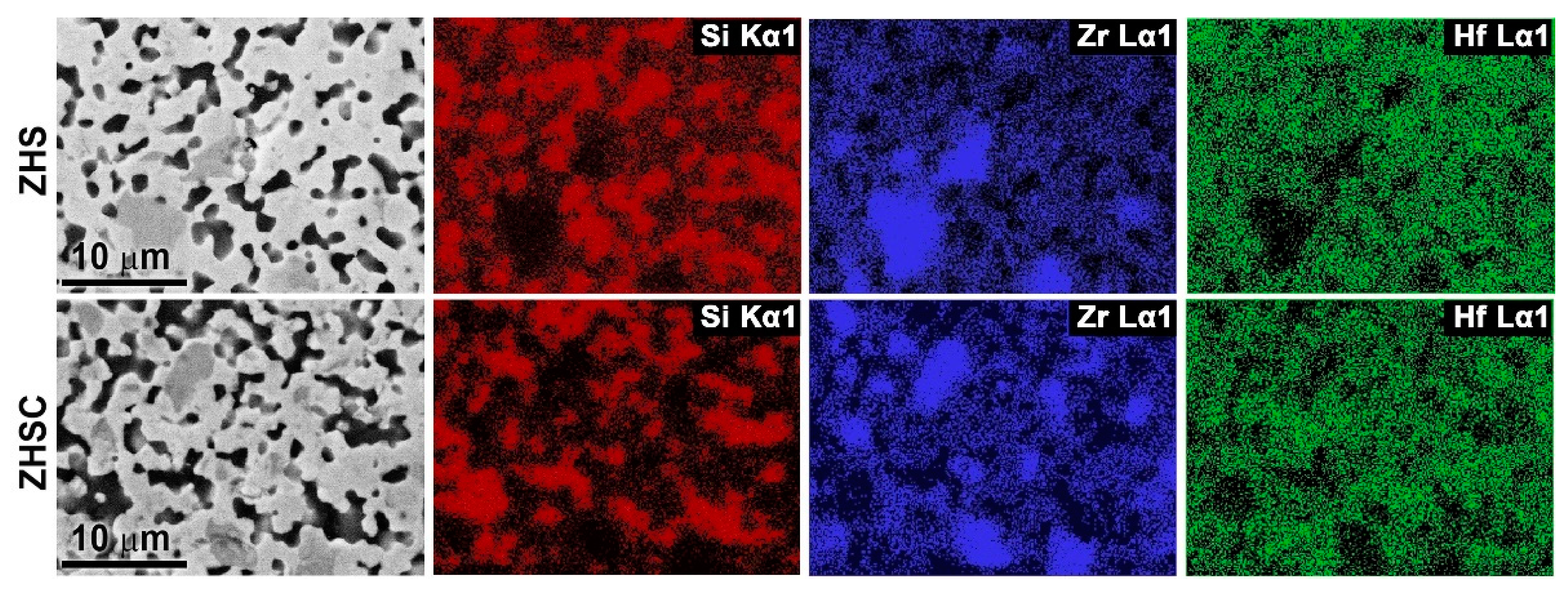

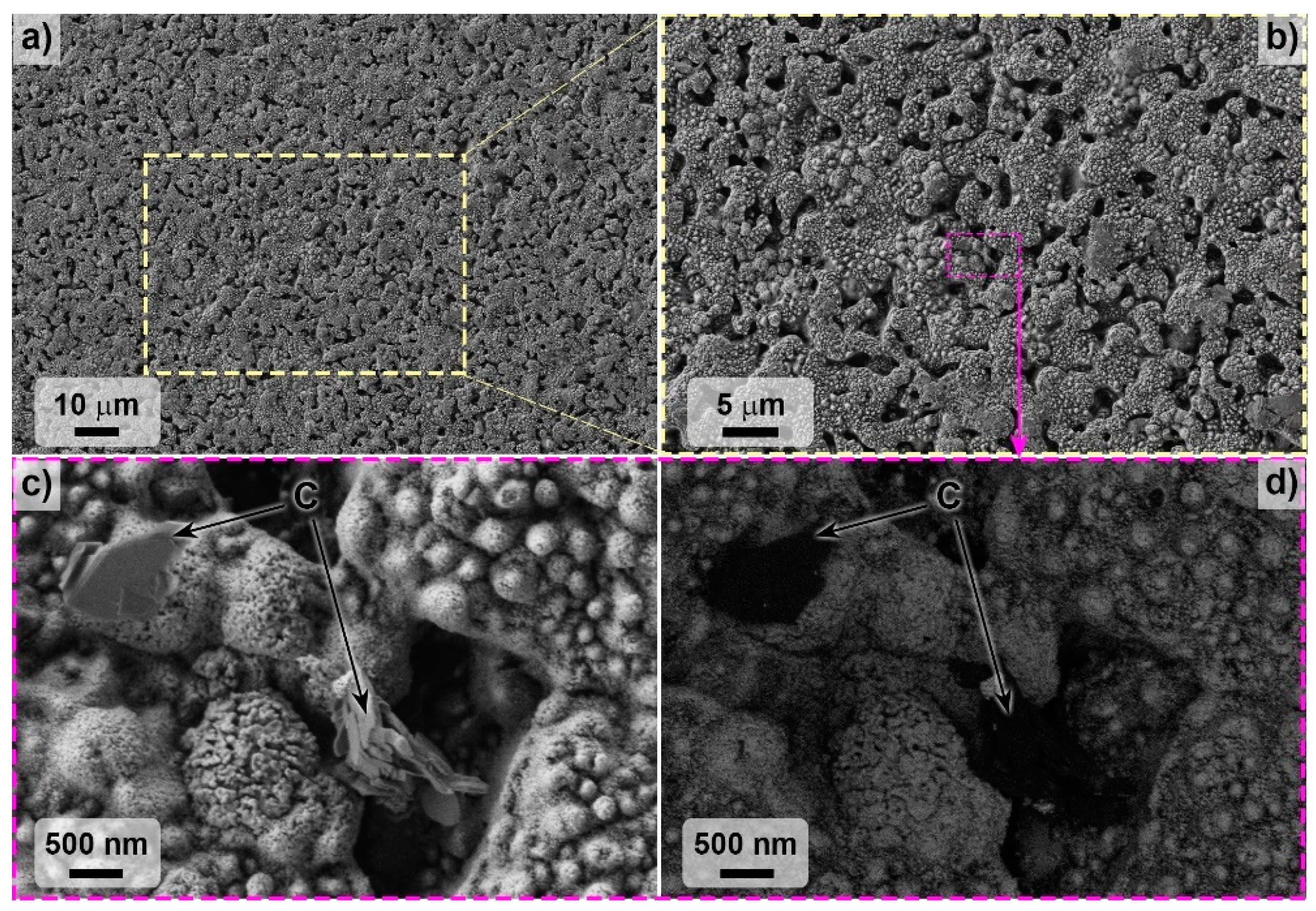

3.1. Obtaining ZHS and ZHSC Ceramic Materials

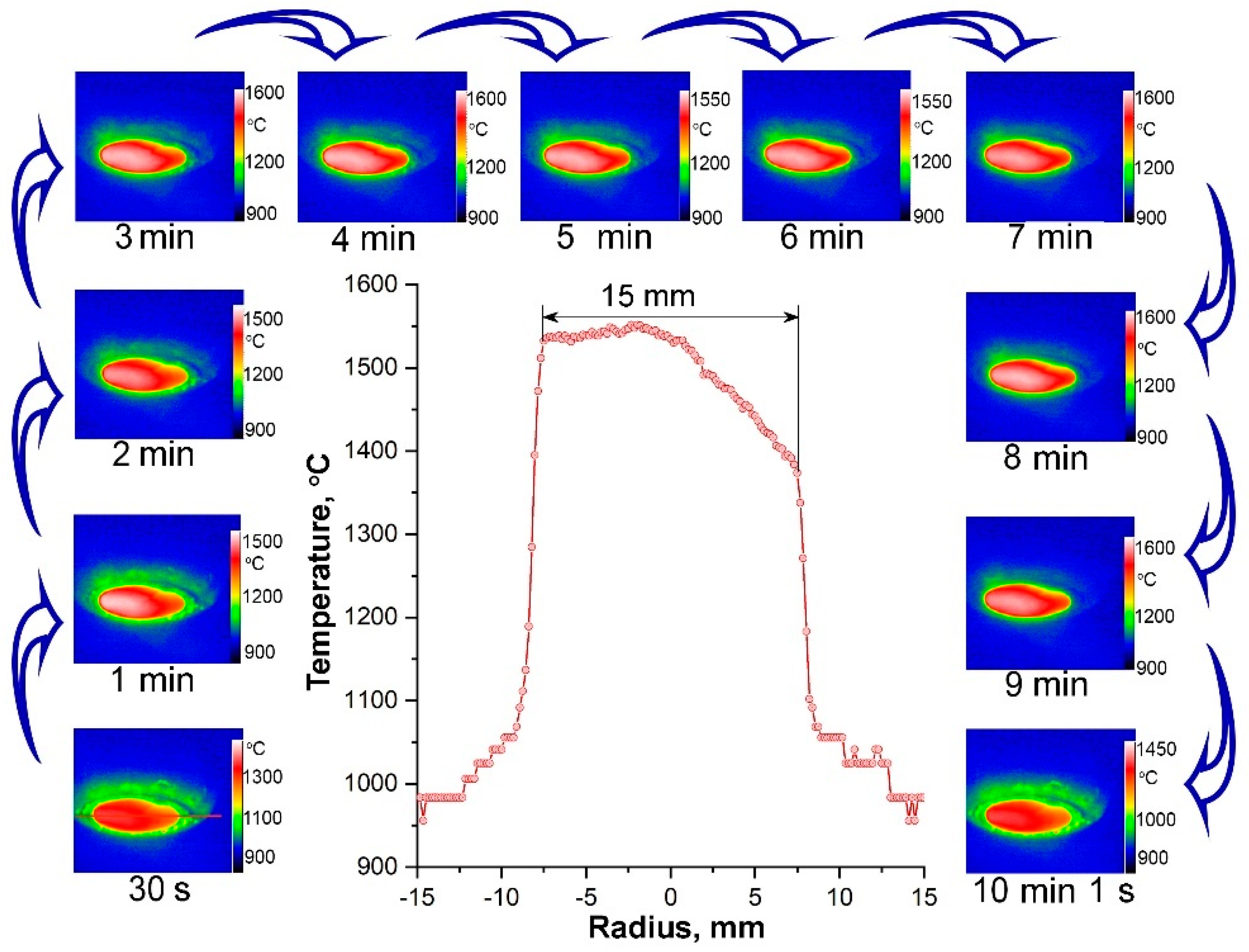

3.2. The Study of the Behaviour of ZHSC Ceramic Material under the Influence of the Supersonic Flow of Dissociated Nitrogen

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simonenko, E.P.; Sevast’yanov, D.V.; Simonenko, N.P.; Sevast’yanov, V.G.; Kuznetsov, N.T. Promising Ultra-High-Temperature Ceramic Materials for Aerospace Applications. Russ. J. Inorg. Chem. 2013, 58, 1669–1693. [Google Scholar] [CrossRef]

- Justin, J.-F.; Julian-Jankowiak, A.; Guérineau, V.; Mathivet, V.; Debarre, A. Ultra-High Temperature Ceramics Developments for Hypersonic Applications. CEAS Aeronaut. J. 2020, 11, 651–664. [Google Scholar] [CrossRef]

- Pellegrini, C.; Balat-Pichelin, M.; Rapaud, O.; Bêche, E. Oxidation Resistance of Zr- and Hf-Diboride Composites Containing SiC in Air Plasma up to 2600 K for Aerospace Applications. Ceram. Int. 2022, 48, 2177–2190. [Google Scholar] [CrossRef]

- Nisar, A.; Hassan, R.; Agarwal, A.; Balani, K. Ultra-High Temperature Ceramics: Aspiration to Overcome Challenges in Thermal Protection Systems. Ceram. Int. 2022, 48, 8852–8881. [Google Scholar] [CrossRef]

- Guérineau, V.; Vilmart, G.; Dorval, N.; Julian-Jankowiak, A. Comparison of ZrB2-SiC, HfB2-SiC and HfB2-SiC-Y2O3 Oxidation Mechanisms in Air Using LIF of BO2(G). Corros. Sci. 2020, 163, 108278. [Google Scholar] [CrossRef]

- Shapkin, N.P.; Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Simonenko, E.P.; Simonenko, N.P.; Zavjalov, A.P.; Belov, A.A.; Portnyagin, A.S.; Gerasimenko, A.V.; et al. Spark Plasma Sintering-Reactive Synthesis of SiC and SiC–HfB2 Ceramics Based on Natural Renewable Raw Materials. Russ. J. Inorg. Chem. 2021, 66, 629–637. [Google Scholar] [CrossRef]

- Qiu, X.-L.; Gao, X.-H.; He, C.-Y.; Liu, G. Optical Design, Thermal Shock Resistance and Failure Mechanism of a Novel Multilayer Spectrally Selective Absorber Coating Based on HfB2 and ZrB2. Sol. Energy Mater. Sol. Cells 2020, 211, 110533. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Z.; Luo, Y.; Wu, Z.; Liu, Y.; Hou, S.; Liu, X.; Zhang, Q.; Cao, F. High-Performance Spectrally Selective Absorber Using the ZrB 2 -Based All-Ceramic Coatings. ACS Appl. Mater. Interfaces 2021, 13, 40522–40530. [Google Scholar] [CrossRef]

- Azzali, N.; Meucci, M.; Di Rosa, D.; Mercatelli, L.; Silvestroni, L.; Sciti, D.; Sani, E. Spectral Emittance of Ceramics for High Temperature Solar Receivers. Sol. Energy 2021, 222, 74–83. [Google Scholar] [CrossRef]

- Zoli, L.; Sciti, D.; Sani, E. Zirconium Diboride-Based Nanofluids for Solar Energy Applications. J. Mol. Liq. 2021, 322, 114981. [Google Scholar] [CrossRef]

- Qiu, X.-L.; Gao, X.-H.; He, C.-Y.; Liu, G. Enhanced Thermal Stability of the TiB2–ZrB2 Composite Ceramic Based High Temperature Spectrally Selective Absorber Coatings: Optical Properties, Failure Analysis and Chromaticity Investigation. Opt. Mater. 2020, 100, 109666. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Kolesnikov, A.F.; Chaplygin, A.V.; Lysenkov, A.S.; Nagornov, I.A.; Simonenko, T.L.; Gubin, S.P.; Sevastyanov, V.G.; Kuznetsov, N.T. Oxidation of Graphene-Modified HfB2-SiC Ceramics by Supersonic Dissociated Air Flow. J. Eur. Ceram. Soc. 2022, 42, 30–42. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolenikov, A.F.; Lysenkov, A.S.; Nagornov, I.A.; Kurlov, V.N.; Ershov, A.E.; Sevastyanov, V.G.; Kuznetsov, N.T. Behavior of the Ultra-High Temperature Ceramic Material HfB2-SiC-Y3Al5O12 under the Influence of the Supersonic Dissociated Air Flow. Russ. J. Inorg. Chem. 2020, 65, 1596–1605. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Papynov, E.K.; Shichalin, O.O.; Kolesnikov, A.F.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Study of the Thermal Behavior of Wedge-Shaped Samples of HfB2–45 Vol % SiC Ultra-High-Temperature Composite in a High-Enthalpy Air Flow. Russ. J. Inorg. Chem. 2018, 63, 421–432. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolesnikov, A.F.; Lysenkov, A.S.; Nagornov, I.A.; Sevastyanov, V.G.; Kuznetsov, N.T. The Effects of Subsonic and Supersonic Dissociated Air Flow on the Surface of Ultra-High-Temperature HfB2-30 Vol% SiC Ceramics Obtained Using the Sol-Gel Method. J. Eur. Ceram. Soc. 2020, 40, 1093–1102. [Google Scholar] [CrossRef]

- Lynam, A.; Romero, A.R.; Xu, F.; Wellman, R.W.; Hussain, T. Thermal Spraying of Ultra-High Temperature Ceramics: A Review on Processing Routes and Performance. J. Therm. Spray Technol. 2022, 31, 745–779. [Google Scholar] [CrossRef]

- Monteverde, F.; Savino, R. ZrB2-SiC Sharp Leading Edges in High Enthalpy Supersonic Flows. J. Am. Ceram. Soc. 2012, 95, 2282–2289. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, P.; Han, J.; Meng, S. Ablation Behavior of ZrB2–SiC Ultra High Temperature Ceramics under Simulated Atmospheric Re-Entry Conditions. Compos. Sci. Technol. 2008, 68, 1718–1726. [Google Scholar] [CrossRef]

- Parthasarathy, T.A.; Petry, M.D.; Cinibulk, M.K.; Mathur, T.; Gruber, M.R. Thermal and Oxidation Response of UHTC Leading Edge Samples Exposed to Simulated Hypersonic Flight Conditions. J. Am. Ceram. Soc. 2013, 96, 907–915. [Google Scholar] [CrossRef]

- Balat-Pichelin, M.; Bêche, E.; Sciti, D.; Alfano, D. Emissivity, Catalycity and Microstructural Characterization of ZrB2–SiCfiber Based UHTC at High Temperature in a Non-Equilibrium Air Plasma Flow. Ceram. Int. 2014, 40, 9731–9742. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, S.; Liu, Y.; Liu, L.; Ma, Z. Enthalpy Driving Force and Chemical Bond Weakening: The Solid-Solution Formation Mechanism and Densification Behavior of High-Entropy Diborides (Hf1−x/4Zr1−x/4Nb1−x/4Ta1−x/4Scx)B2. J. Eur. Ceram. Soc. 2022, 42, 3685–3698. [Google Scholar] [CrossRef]

- Kong, Q.; Huo, S.; Chen, L.; Wang, Y.; Ouyang, J.; Zhou, Y. Novel (Zr, Ti)B2-(Zr, Ti)C-SiC Ceramics via Reactive Hot Pressing. J. Eur. Ceram. Soc. 2022, 42, 4045–4052. [Google Scholar] [CrossRef]

- Kirnbauer, A.; Wagner, A.; Moraes, V.; Primetzhofer, D.; Hans, M.; Schneider, J.M.; Polcik, P.; Mayrhofer, P.H. Thermal Stability and Mechanical Properties of Sputtered (Hf,Ta,V,W,Zr)-Diborides. Acta Mater. 2020, 200, 559–569. [Google Scholar] [CrossRef]

- Jafari, S.; Bavand-Vandchali, M.; Mashhadi, M.; Nemati, A. Effects of HfB2 Addition on Pressureless Sintering Behavior and Microstructure of ZrB2-SiC Composites. Int. J. Refract. Met. Hard Mater. 2021, 94, 105371. [Google Scholar] [CrossRef]

- Dodi, E.; Balak, Z.; Kafashan, H. HfB2-Doped ZrB2-30 Vol.% SiC Composites: Oxidation Resistance Behavior. Mater. Res. Express 2021, 8, 045605. [Google Scholar] [CrossRef]

- Jafari, S.; Bavand-Vandchali, M.; Mashhadi, M.; Nemati, A. Synthesis Mechanism and Microstructure Characterization of ZrB2–ZrC–SiC Nanocomposite Synthesized via Magnesium Boro/Carbothermal Reduction at Low Temperatures. Mater. Chem. Phys. 2022, 280, 125830. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Sun, D.; Zhang, Y.; Liu, B.; Hu, Q.; Zhou, A. Synthesis and Thermal Stability of Two-Dimensional Carbide MXene Ti3C2. Mater. Sci. Eng. B 2015, 191, 33–40. [Google Scholar] [CrossRef]

- Ahmadi, Z.; Shahedi Asl, M.; Zakeri, M.; Farvizi, M. On the Reactive Spark Plasma Sinterability of ZrB2–SiC–TiN Composite. J. Alloys Compd. 2022, 909, 164611. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Ma, X.; Liu, L.; Wu, Y.; Li, D.; Wang, P.; Duan, X. Mechanical and Ablation Properties of Laminated ZrB2-SiC Ceramics with Si3N4 Whisker Interface. Corros. Sci. 2022, 197, 110051. [Google Scholar] [CrossRef]

- Ouyang, G.; Besser, M.F.; Kramer, M.J.; Akinc, M.; Ray, P.K. Designing Oxidation Resistant Ultra-High Temperature Ceramics through the Development of an Adherent Native Thermal Barrier. J. Alloys Compd. 2019, 790, 1119–1126. [Google Scholar] [CrossRef]

- Liégaut, C.; Bertrand, P.; Maillé, L.; Rebillat, F. UHTC-Based Matrix as Protection for Cf/C Composites: Original Manufacturing, Microstructural Characterisation and Oxidation Behaviour at Temperature above 2000 °C. J. Eur. Ceram. Soc. 2022, 42, 3168–3182. [Google Scholar] [CrossRef]

- Shanbhog, N.; Arunachalam, N.; Bakshi, S.R. Effect of Graphene Nanoplatelets Reinforcement on Grindability of Zirconium Diboride Ceramics. J. Manuf. Sci. Eng. 2022, 144, 071007. [Google Scholar] [CrossRef]

- Hu, P.; Gui, K.; Hong, W.; Zhang, X.; Dong, S. High-Performance ZrB2-SiC-C f Composite Prepared by Low-Temperature Hot Pressing Using Nanosized ZrB2 Powder. J. Eur. Ceram. Soc. 2017, 37, 2317–2324. [Google Scholar] [CrossRef]

- Cheng, Y.; Lyu, Y.; Han, W.; Hu, P.; Zhou, S.; Zhang, X. Multiscale Toughening of ZrB2-SiC-Graphene@ZrB2-SiC Dual Composite Ceramics. J. Am. Ceram. Soc. 2019, 102, 2041–2052. [Google Scholar] [CrossRef]

- Tian, W.-B.; Kan, Y.-M.; Zhang, G.-J.; Wang, P.-L. Effect of Carbon Nanotubes on the Properties of ZrB2–SiC Ceramics. Mater. Sci. Eng. A 2008, 487, 568–573. [Google Scholar] [CrossRef]

- Shahedi Asl, M.; Farahbakhsh, I.; Nayebi, B. Characteristics of Multi-Walled Carbon Nanotube Toughened ZrB2–SiC Ceramic Composite Prepared by Hot Pressing. Ceram. Int. 2016, 42, 1950–1958. [Google Scholar] [CrossRef]

- Nisar, A.; Khan, M.M.; Bajpai, S.; Balani, K. Processing, Microstructure and Mechanical Properties of HfB2-ZrB2-SiC Composites: Effect of B4C and Carbon Nanotube Reinforcements. Int. J. Refract. Met. Hard Mater. 2019, 81, 111–118. [Google Scholar] [CrossRef]

- Hassan, R.; Omar, S.; Balani, K. Solid Solutioning in ZrB2 with HfB2: Effect on Densification and Oxidation Resistance. Int. J. Refract. Met. Hard Mater. 2019, 84, 105041. [Google Scholar] [CrossRef]

- Lin, J.; Huang, Y.; Zhang, H.; Yang, Y.; Li, N. Microstructure and Mechanical Properties of Spark Plasma Sintered ZrB2–SiC–MWCNT Composites. Ceram. Int. 2015, 41, 15261–15265. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Balani, K. Establishing Microstructure-Mechanical Property Correlation in ZrB2-Based Ultra-High Temperature Ceramic Composites. Ceram. Int. 2017, 43, 13483–13492. [Google Scholar] [CrossRef]

- Nisar, A.; Balani, K. Phase and Microstructural Correlation of Spark Plasma Sintered HfB2-ZrB2 Based Ultra-High Temperature Ceramic Composites. Coatings 2017, 7, 110. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Effect of Carbon Nanotube on Processing, Microstructural, Mechanical and Ablation Behavior of ZrB2-20SiC Based Ultra-High Temperature Ceramic Composites. Carbon N. Y. 2017, 111, 269–282. [Google Scholar] [CrossRef]

- Dubey, S.; Awasthi, S.; Nisar, A.; Balani, K. Role of Interfaces in Damage Initiation and Tolerance of Carbon Nanotube-Reinforced HfB2-ZrB2 Ceramics. JOM 2020, 72, 2207–2218. [Google Scholar] [CrossRef]

- Nisar, A.; Bajpai, S.; Khan, M.M.; Balani, K. Wear Damage Tolerance and High Temperature Oxidation Behavior of HfB2:ZrB2–SiC Composites. Ceram. Int. 2020, 46, 21689–21698. [Google Scholar] [CrossRef]

- Popov, O.; Vleugels, J.; Zeynalov, E.; Vishnyakov, V. Reactive Hot Pressing Route for Dense ZrB2-SiC and ZrB2-SiC-CNT Ultra-High Temperature Ceramics. J. Eur. Ceram. Soc. 2020, 40, 5012–5019. [Google Scholar] [CrossRef]

- Nisar, A.; Khan, M.M.; Balani, K. Enhanced Thermo-Mechanical Damage Tolerance of Functionally Graded ZrB2-20SiC Ceramic Reinforced with Carbon Nanotubes. Ceram. Int. 2019, 45, 6198–6208. [Google Scholar] [CrossRef]

- Gordeev, A.N.; Kolesnikov, A.F.; Sakharov, V.I. HF-Plasmatron Experiment and Numerical Simulation of Heat Transfer in Underexpanded Dissociated-Nitrogen Jets. Fluid Dyn. 2017, 52, 786–796. [Google Scholar] [CrossRef]

- Carandente, V.; Savino, R.; Esposito, A.; Zuppardi, G.; Caso, V. Experimental and Numerical Simulation, by an Arc-Jet Facility, of Hypersonic Flow in Titan’s Atmosphere. Exp. Therm. Fluid Sci. 2013, 48, 97–101. [Google Scholar] [CrossRef]

- Rini, P.; Kolesnikov, A.; Vasil’evskii, S.; Chazot, O.; Degrez, G. CO2 Stagnation Line Flow Simulation for Mars Entry Applications. In Proceedings of the 38th AIAA Thermophysics Conference, Toronto, ON, Canada, 6–9 June 2005; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar]

- Kolesnikov, A.F.; Gordeev, A.N.; Vasil’evskii, S.A. Effects of Catalytic Recombination on the Surface of Metals and Quartz for the Conditions of Entry into the Martian Atmosphere. High Temp. 2016, 54, 29–37. [Google Scholar] [CrossRef]

- Kolesnikov, A.F.; Sakharov, V.I. Correlation of the Conditions of Model Heat Transfer in Underexpanded Dissociated Carbon Dioxide Jets and in Hypersonic Flow Past a Sphere in the Martian Atmosphere. Fluid Dyn. 2015, 50, 578–584. [Google Scholar] [CrossRef]

- Paterna, D.; Monti, R.; Savino, R.; Esposito, A. Experimental and Numerical Investigation of Martian Atmosphere Entry. J. Spacecr. Rockets 2002, 39, 227–236. [Google Scholar] [CrossRef]

- Kolesnikov, A.F.; Lukomskii, I.V.; Sakharov, V.I.; Chaplygin, A.V. Experimental and Numerical Modeling of Heat Transfer to Graphite Surface in Underexpanded Dissociated-Nitrogen Jets. Fluid Dyn. 2021, 56, 897–905. [Google Scholar] [CrossRef]

- Kolesnikov, A.F.; Kuznetsov, N.T.; Murav’eva, T.I.; Nagornov, I.A.; Sakharov, V.I.; Sevastyanov, V.G.; Simonenko, E.P.; Simonenko, N.P.; Chaplygin, A.V.; Shcherbakova, O.O. Investigation of Heat Transfer to HfB2-SiC-Based Ceramics in Underexpanded Dissociated-Nitrogen Jets and Analysis of the Surface. Fluid Dyn. 2022, 57, 513–523. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Kolesnikov, A.F.; Chaplygin, A.V.; Lysenkov, A.S.; Nagornov, I.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Modification of HfB2–30% SiC UHTC with Graphene (1 Vol %) and Its Influence on the Behavior in a Supersonic Air Jet. Russ. J. Inorg. Chem. 2021, 66, 1405–1415. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolenikov, A.F.; Lysenkov, A.S.; Nagornov, I.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Oxidation of Porous HfB2–SiC Ultra-High Temperature Ceramic Materials Rich in Silicon Carbide (65 Vol %) by a Supersonic Air Flow. Russ. J. Inorg. Chem. 2020, 65, 606–615. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolesnikov, A.F.; Sevastyanov, V.G.; Kuznetsov, N.T. Behavior of HfB2–30 Vol% SiC UHTC Obtained by Sol–Gel Approach in the Supersonic Airflow. J. Sol.-Gel. Sci. Technol. 2019, 92, 386–397. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Papynov, E.K.; Gridasova, E.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Production of HfB2–SiC (10–65 Vol % SiC) Ultra-High-Temperature Ceramics by Hot Pressing of HfB2–(SiO2–C) Composite Powder Synthesized by the Sol–Gel Method. Russ. J. Inorg. Chem. 2018, 63, 1–15. [Google Scholar] [CrossRef]

- Lukomskii, I.V.; Chaplygin, A.V.; Kolesnikov, A.F. A Device for Measuring the Heat Flux to the Surface of a Material Heated in a Jet of High-Enthalpy Gas to a High Temperature. Patent RU 205572, 5 April 2021. [Google Scholar]

- Belov, G.V.; Iorish, V.S.; Yungman, V.S. IVTANTHERMO for Windows—Database on Thermodynamic Properties and Related Software. Calphad 1999, 23, 173–180. [Google Scholar] [CrossRef]

- Gurvich, L.V.; Iorish, V.S.; Yungman, V.S. IVTANTERMO. A Thermodynamic Database and Software System for the Personal Computer. User’s Guide; CRC Press. Inc.: Boca Raton, FL, USA, 1993. [Google Scholar]

- Gilman, J.J. Hardnesses of Carbides and Other Refractory Hard Metals. J. Appl. Phys. 1970, 41, 1664–1666. [Google Scholar] [CrossRef]

- Wong-Ng, W.; Hubbard, C.R. Standard Reference Materials for X-Ray Diffraction Part II. Calibration Using d-Spacing Standards. Powder Diffr. 1987, 2, 242–248. [Google Scholar] [CrossRef]

- Kawamura, T. Silicon Carbide Crystals Grown in Nitrogen Atmosphere. Mineral. J. 1965, 4, 333–355. [Google Scholar] [CrossRef]

- Burdick, C.L.; Owen, E.A. The Atomic Structure of Carborundum Determined by X-Rays. J. Am. Chem. Soc. 1918, 40, 1749–1759. [Google Scholar] [CrossRef]

- Kugai, L.N. Chemical Stability of Borides of Transition Metals of Groups IV-VI Inalkaline Solutions. Izv. Akad. Nauk Neorg. Mater. (Russ.) 1972, 8, 669–670. [Google Scholar]

- Holleck, H. Legierungsverhalten von HfB2 Mit Uran- Und Übergangsmetalldiboriden. J. Nucl. Mater. 1967, 21, 14–20. [Google Scholar] [CrossRef]

- Lipson, H.S.; Stokes, A.R. The Structure of Graphite. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1942, 181, 101–105. [Google Scholar] [CrossRef]

- Popov, O.; Vishnyakov, V.; Poperenko, L.; Yurgelevych, I.; Avramenko, T.; Ovcharenko, A. Reactively Sintered TiB2-Based Heteromodulus UHT Ceramics with in-Situ Formed Graphene for Machinable Concentrated Solar Light Absorbers. Ceram. Int. 2022, 48, 17828–17836. [Google Scholar] [CrossRef]

- Hassan, R.; Kundu, R.; Balani, K. Oxidation Behaviour of Coarse and Fine SiC Reinforced ZrB2 at Re-Entry and Atmospheric Oxygen Pressures. Ceram. Int. 2020, 46, 11056–11065. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, X.; Wang, W.; Liu, H.; Li, C.; Wu, H.; Hou, X. In-Situ Fabrication of ZrB2-ZrC-SiCnws Hybrid Nanopowders with Tuneable Morphology SiCnws. Ceram. Int. 2022, 48, 4055–4065. [Google Scholar] [CrossRef]

- Ma, H.-B.; Zhang, G.-J.; Liu, H.-L.; Liu, J.-X.; Lu, Y.; Xu, F.-F. Effect of WC or ZrC Addition on Thermal Residual Stresses in ZrB2SiC Ceramics. Mater. Des. 2016, 110, 340–345. [Google Scholar] [CrossRef]

- Ghosh, D.; Subhash, G.; Orlovskaya, N. Measurement of Scratch-Induced Residual Stress within SiC Grains in ZrB2–SiC Composite Using Micro-Raman Spectroscopy. Acta Mater. 2008, 56, 5345–5354. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, H.; Wang, A.; Wang, Q.; Ren, L.; Hu, P.; Sun, D. Achieving the Synergy of Superior Damage Tolerance and Oxidation Resistance of 2D Cf/ZrB2-SiC Composites via Fiber Heat Treatment. Appl. Surf. Sci. 2021, 556, 149807. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Jorio, A.; Hofmann, M.; Dresselhaus, G.; Saito, R. Perspectives on Carbon Nanotubes and Graphene Raman Spectroscopy. Nano Lett. 2010, 10, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Kieffer, R.; Nowotny, H.; Ettmayer, P.; Dufek, G. Neue Untersuchungen Uber Die Mischbarkeit von Ubergangsmetallnitriden Und -Karbiden. Metall 1972, 26, 701–708. [Google Scholar]

- Lengauer, W.; Binder, S.; Aigner, K.; Ettmayer, P.; Guillou, A.; Debuigne, J.; Groboth, G. Solid State Properties of Group IVb Carbonitrides. J. Alloys Compd. 1995, 217, 137–147. [Google Scholar] [CrossRef]

- Brager, A. An X-Ray Examination of the Structure of Boron Nitride. Acta Physicochim. 1937, 7, 699–706. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonenko, E.P.; Simonenko, N.P.; Kolesnikov, A.F.; Chaplygin, A.V.; Lysenkov, A.S.; Nagornov, I.A.; Mokrushin, A.S.; Kuznetsov, N.T. Investigation of the Effect of Supersonic Flow of Dissociated Nitrogen on ZrB2–HfB2–SiC Ceramics Doped with 10 vol.% Carbon Nanotubes. Materials 2022, 15, 8507. https://doi.org/10.3390/ma15238507

Simonenko EP, Simonenko NP, Kolesnikov AF, Chaplygin AV, Lysenkov AS, Nagornov IA, Mokrushin AS, Kuznetsov NT. Investigation of the Effect of Supersonic Flow of Dissociated Nitrogen on ZrB2–HfB2–SiC Ceramics Doped with 10 vol.% Carbon Nanotubes. Materials. 2022; 15(23):8507. https://doi.org/10.3390/ma15238507

Chicago/Turabian StyleSimonenko, Elizaveta P., Nikolay P. Simonenko, Anatoly F. Kolesnikov, Aleksey V. Chaplygin, Anton S. Lysenkov, Ilya A. Nagornov, Artem S. Mokrushin, and Nikolay T. Kuznetsov. 2022. "Investigation of the Effect of Supersonic Flow of Dissociated Nitrogen on ZrB2–HfB2–SiC Ceramics Doped with 10 vol.% Carbon Nanotubes" Materials 15, no. 23: 8507. https://doi.org/10.3390/ma15238507

APA StyleSimonenko, E. P., Simonenko, N. P., Kolesnikov, A. F., Chaplygin, A. V., Lysenkov, A. S., Nagornov, I. A., Mokrushin, A. S., & Kuznetsov, N. T. (2022). Investigation of the Effect of Supersonic Flow of Dissociated Nitrogen on ZrB2–HfB2–SiC Ceramics Doped with 10 vol.% Carbon Nanotubes. Materials, 15(23), 8507. https://doi.org/10.3390/ma15238507