Recrystallization Behavior of a Mg-5Zn Alloy Influenced by Minor SiCp during Hot Compression

Abstract

:1. Introduction

2. Experimental Procedures

3. Results

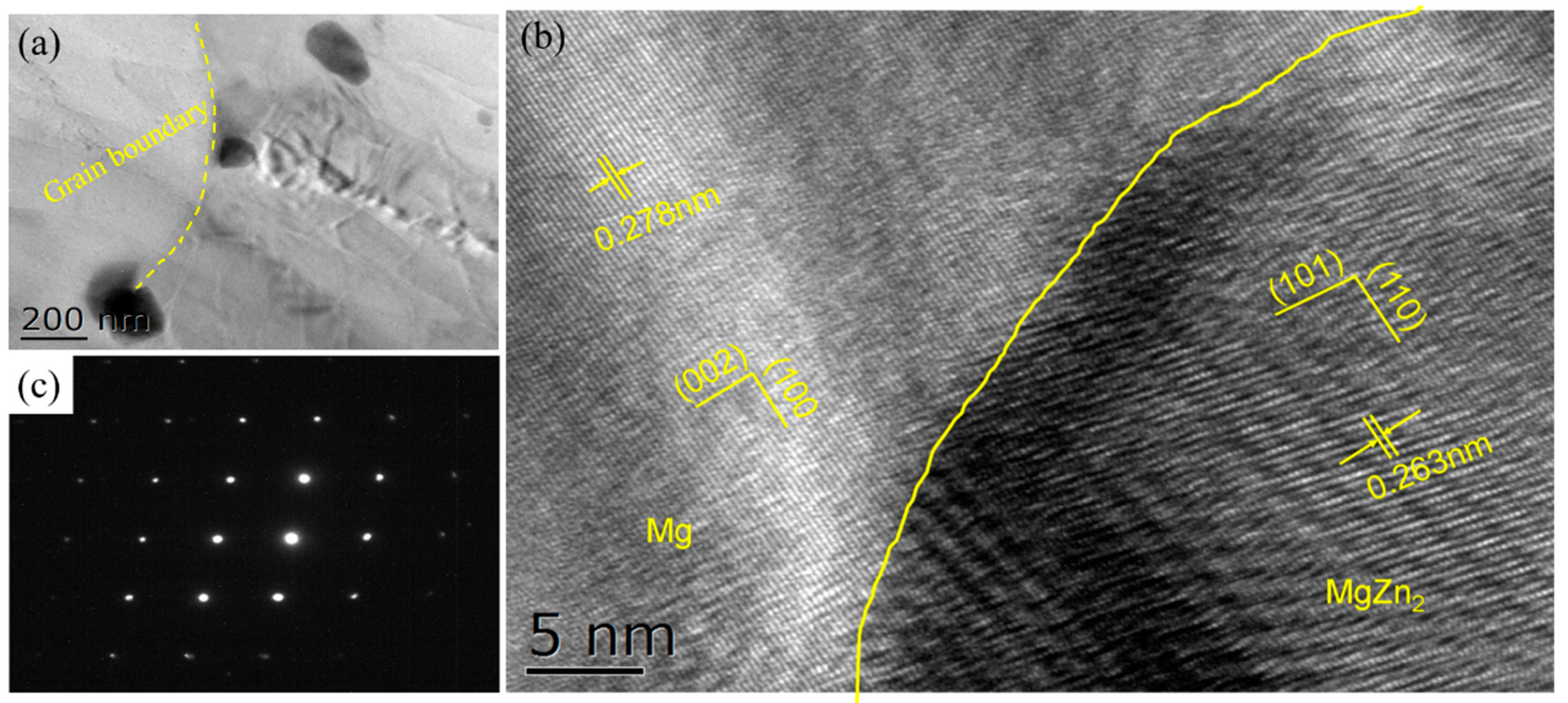

3.1. Microstructure of As-Homogenized Materials

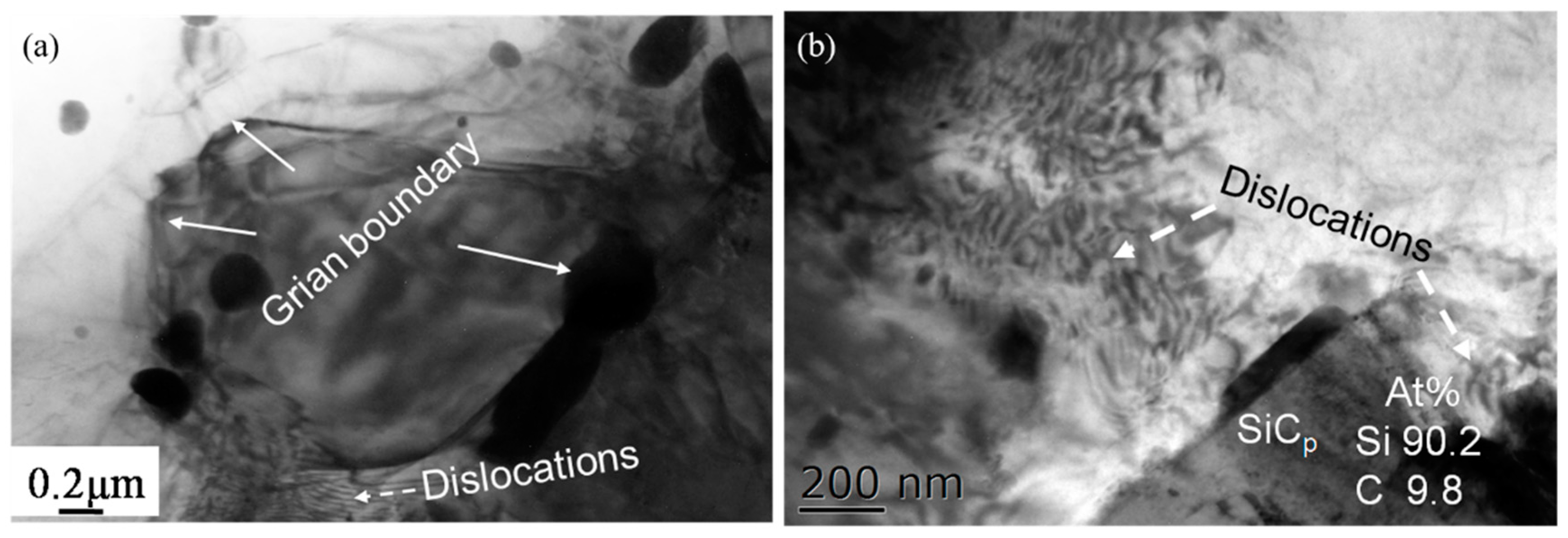

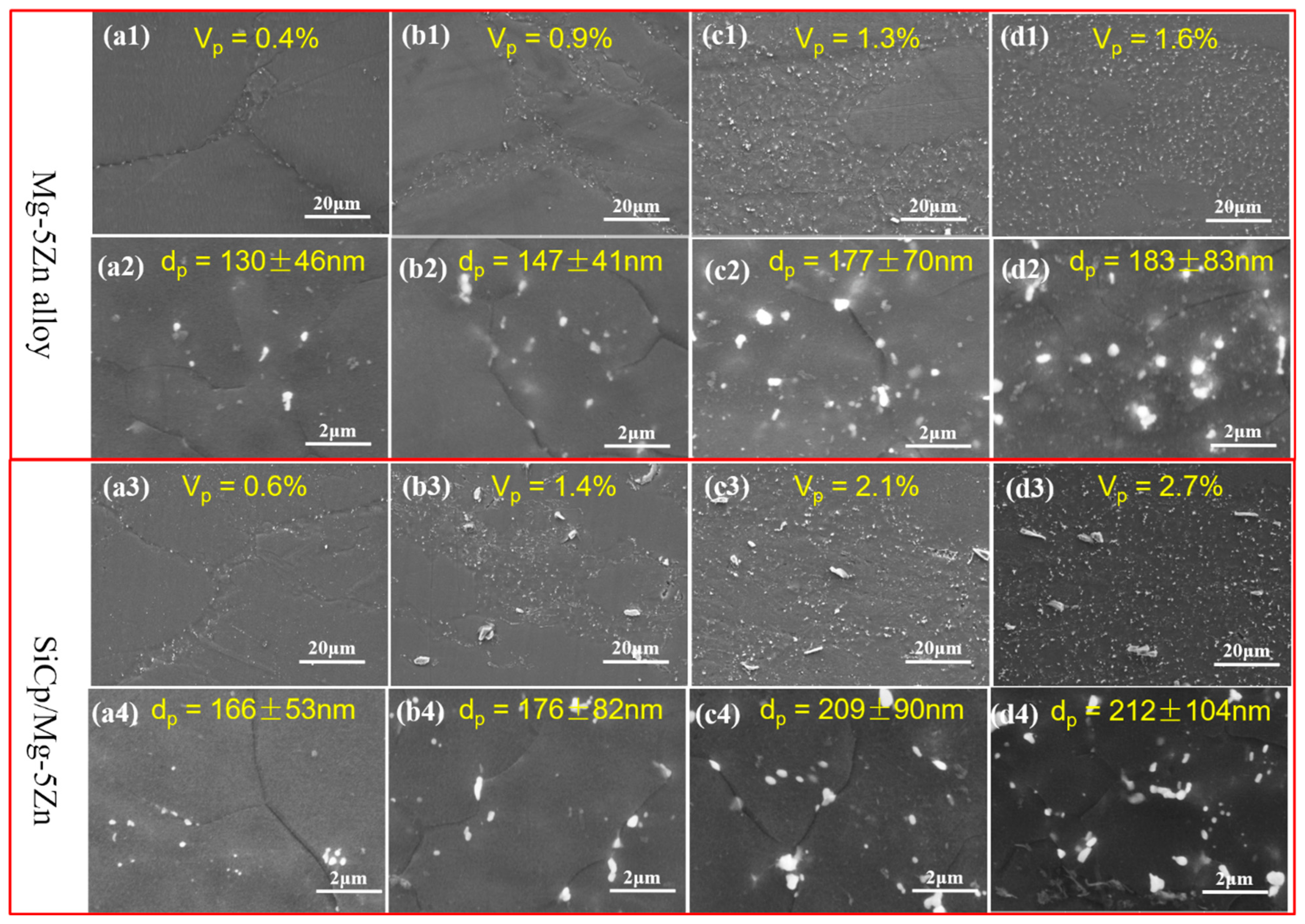

3.2. DRX Behavior

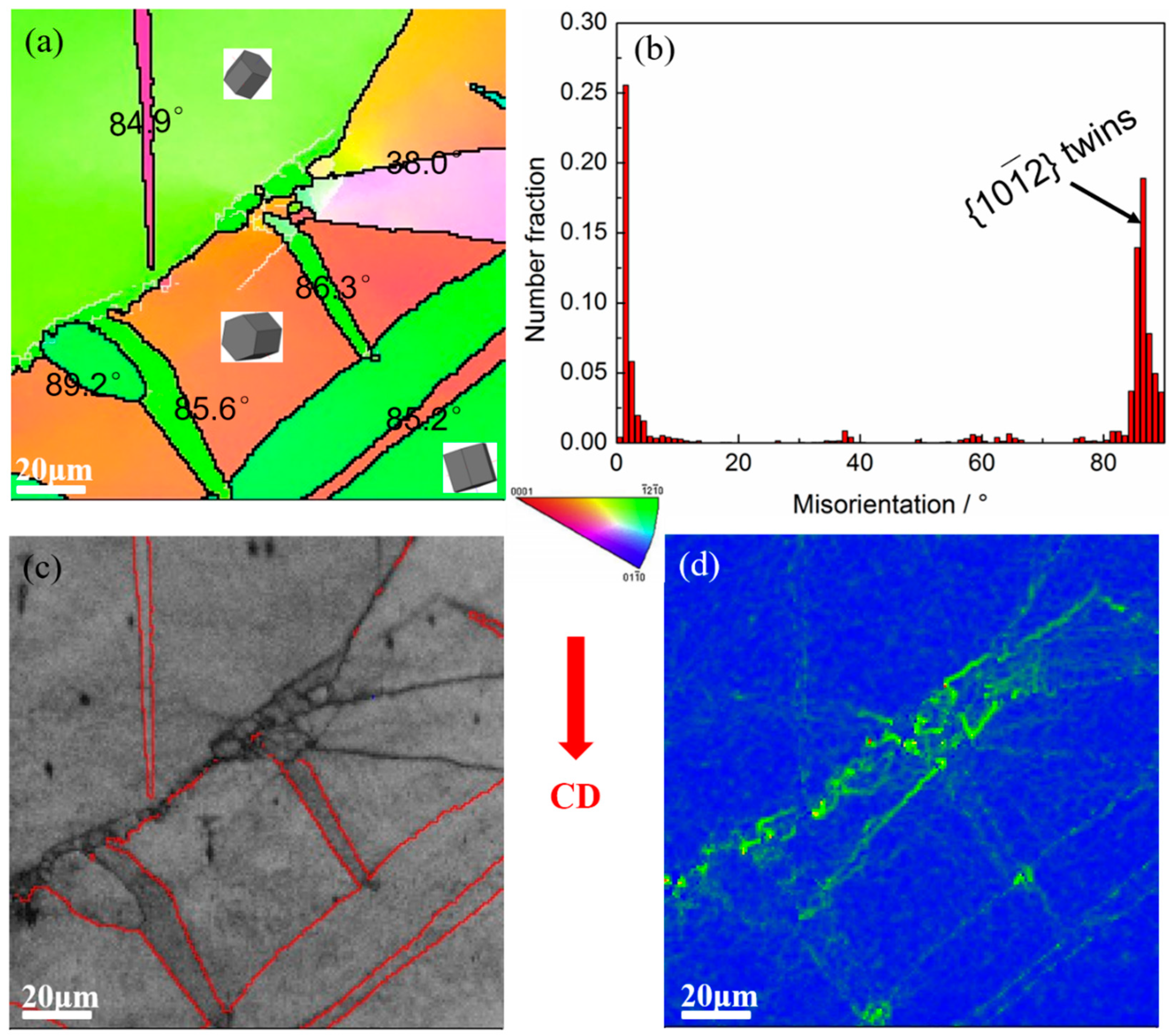

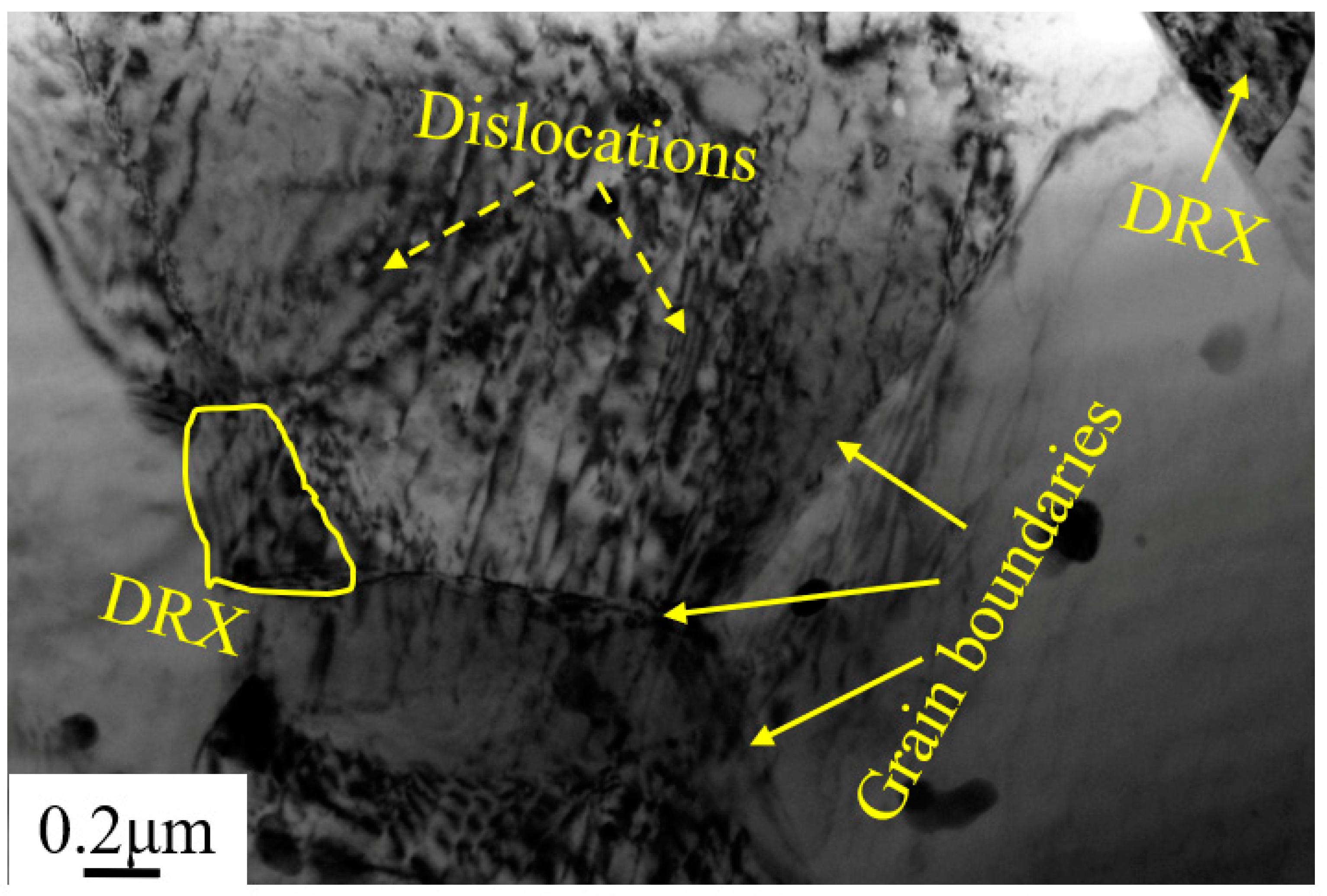

3.2.1. Mg-5Zn Alloy

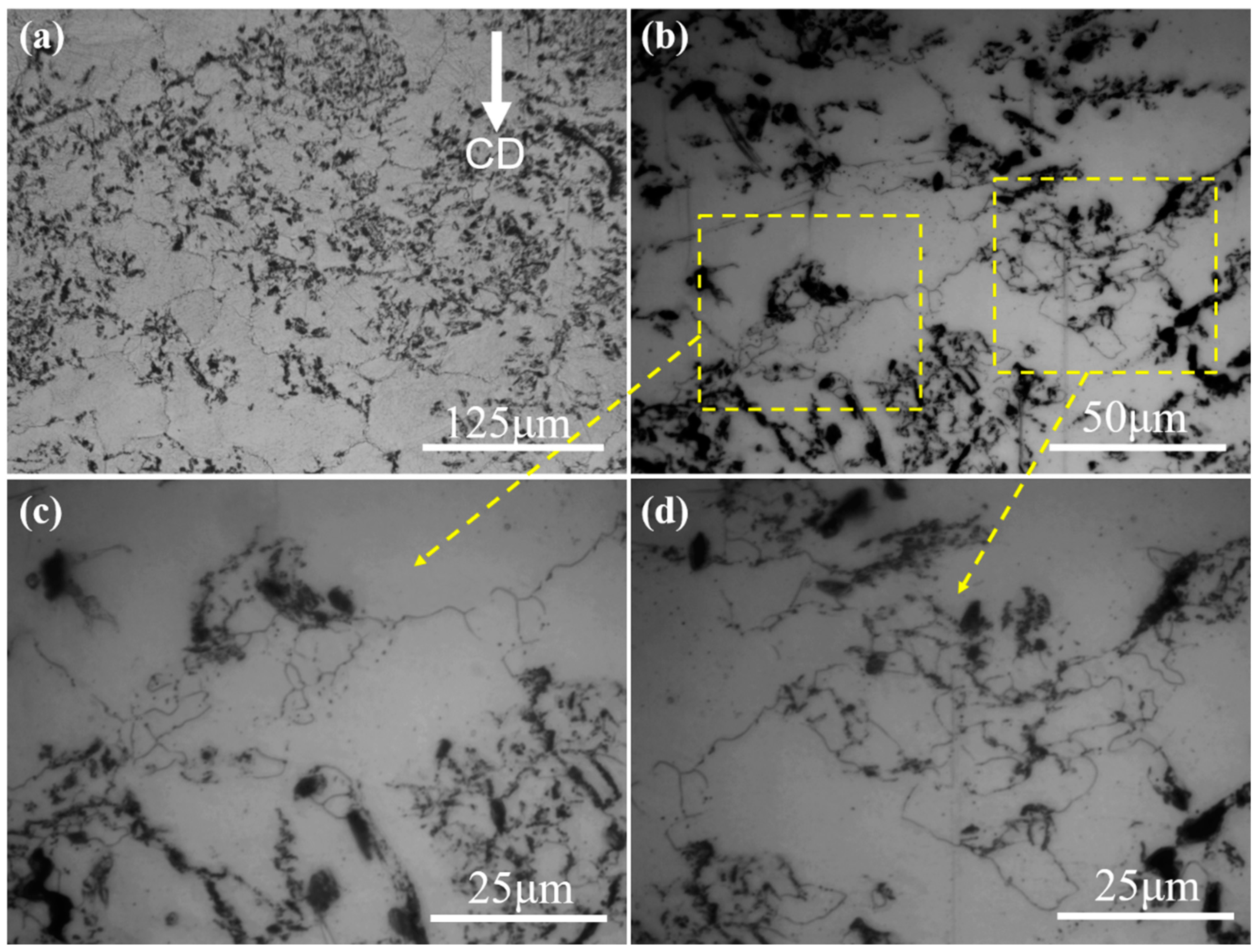

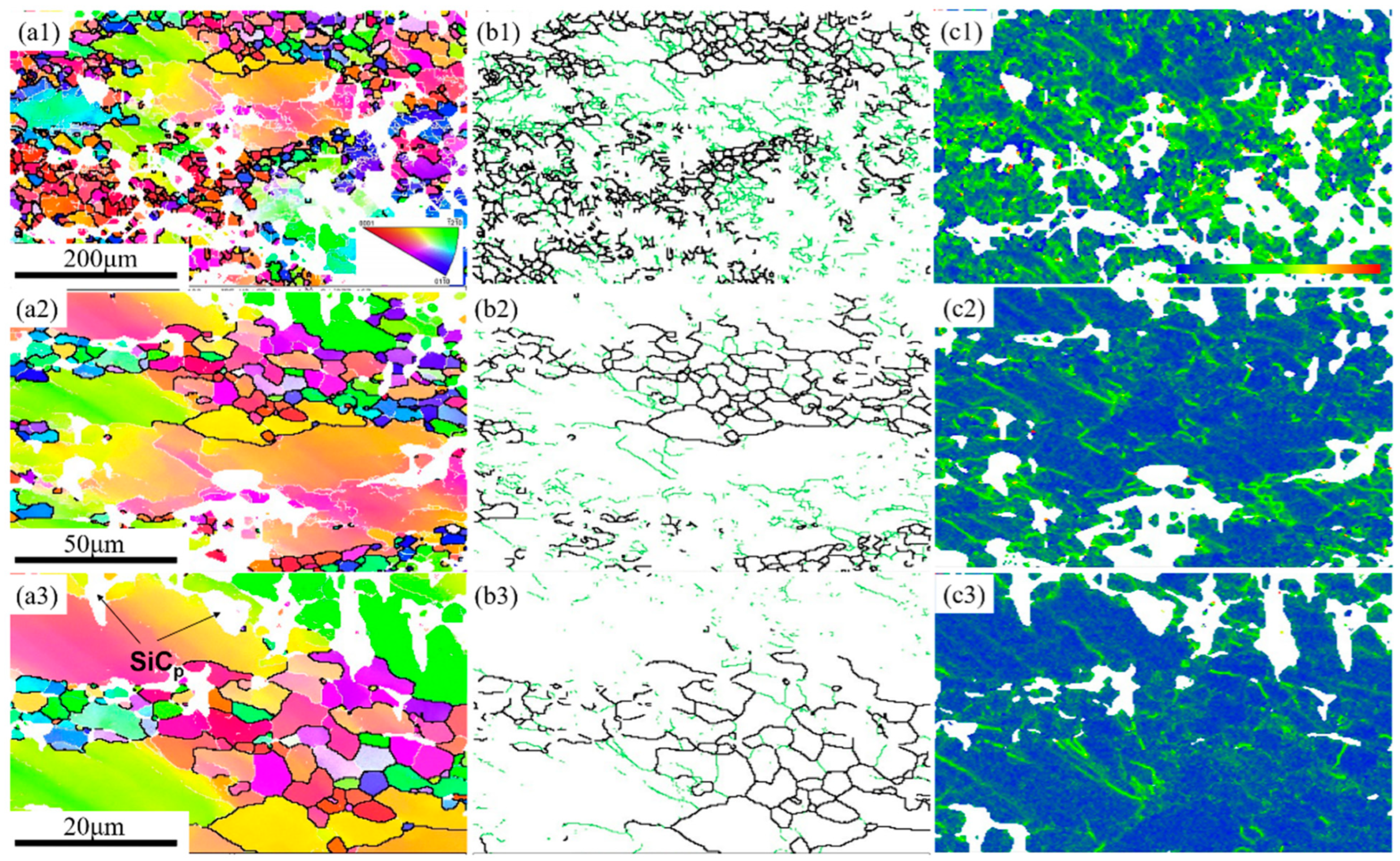

3.2.2. SiCp/Mg-5Zn Material

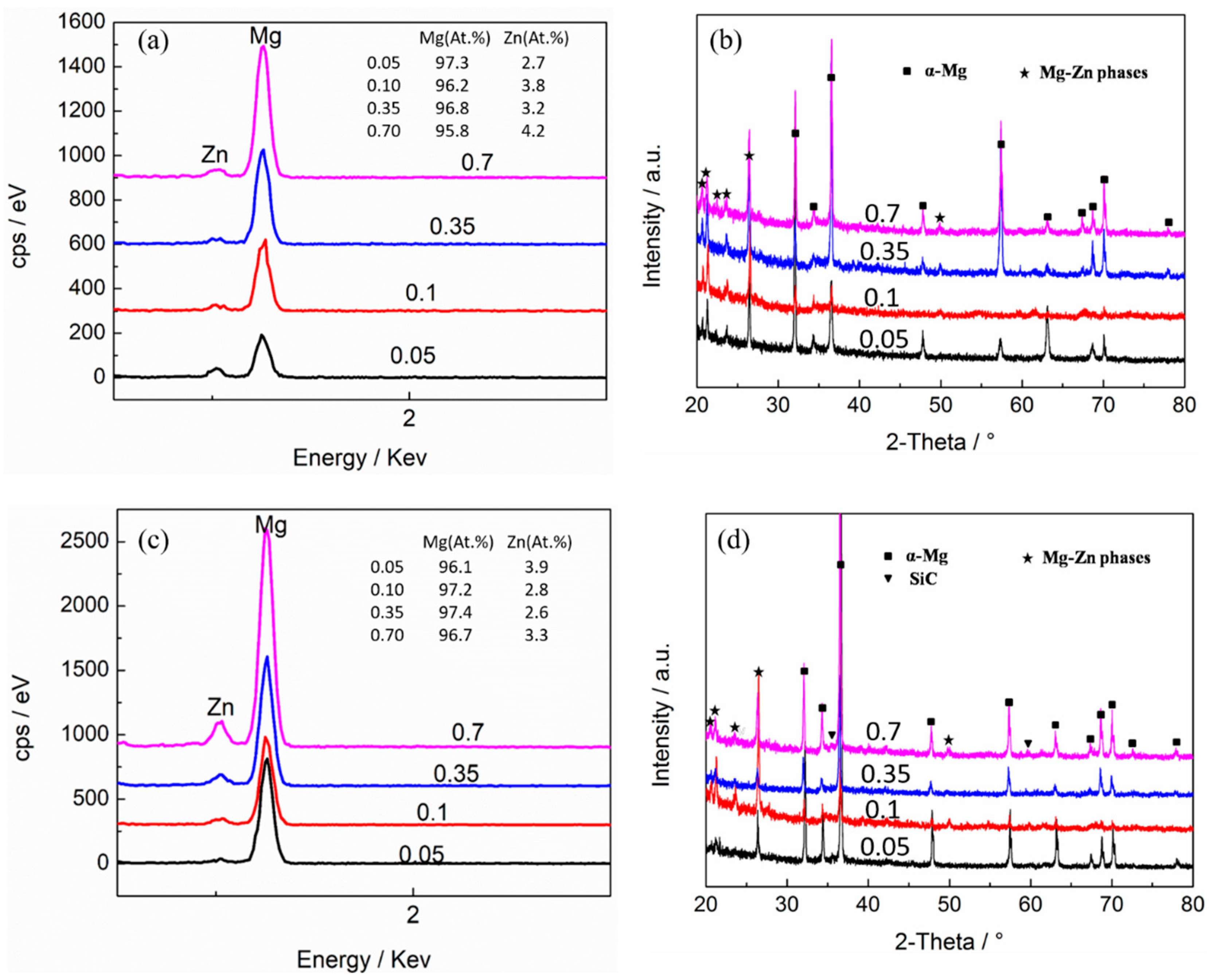

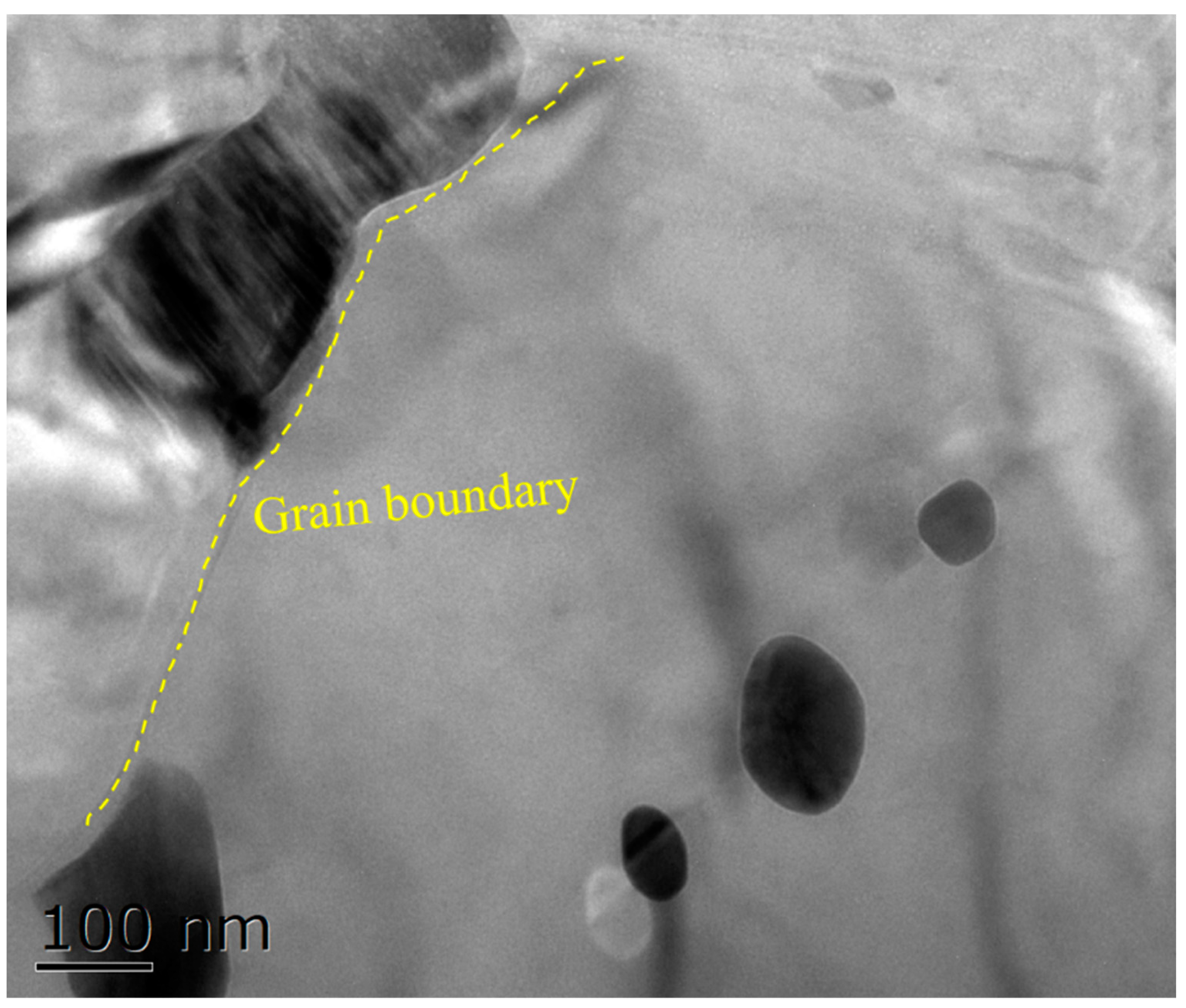

3.3. Precipitation Behavior

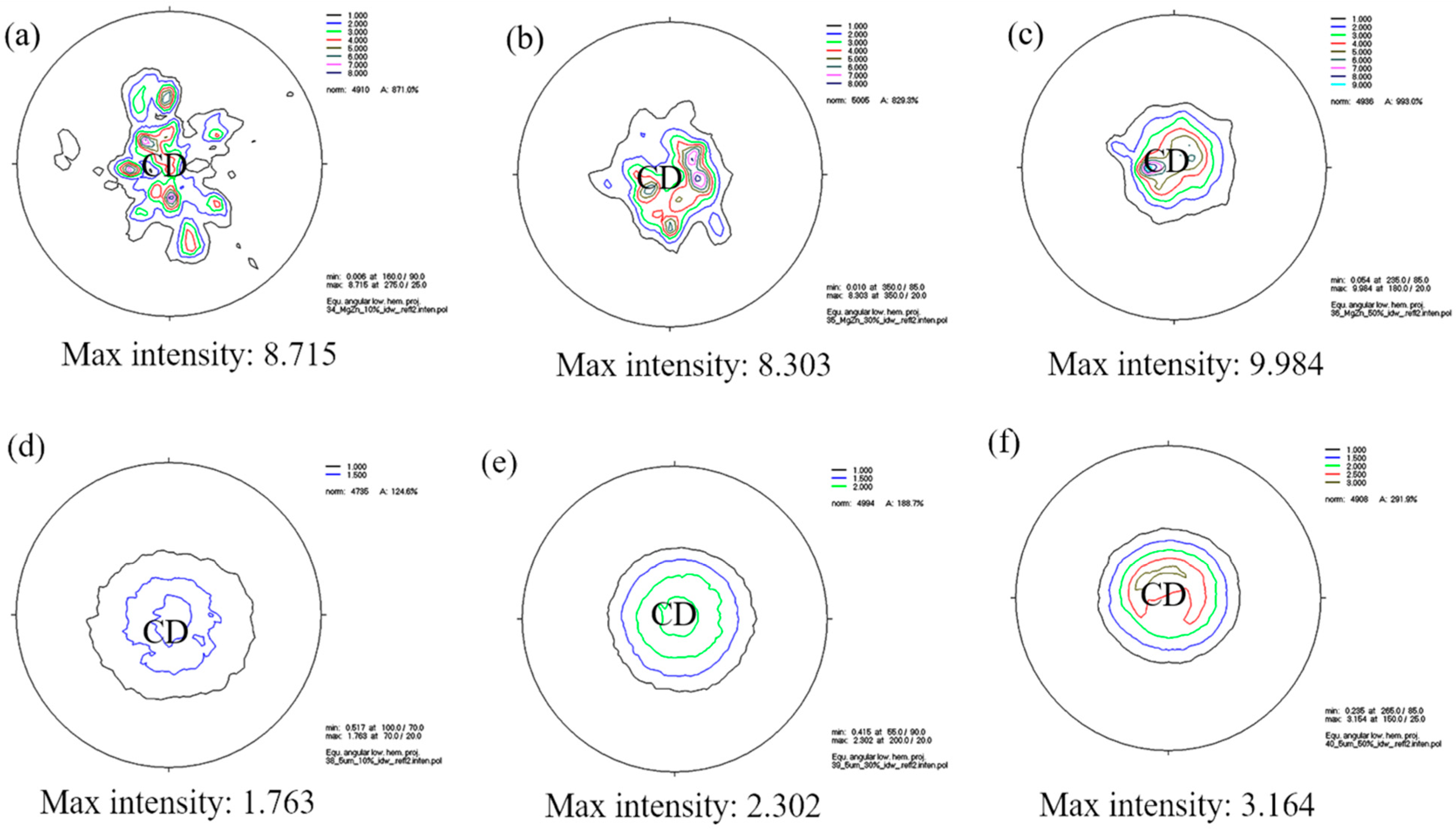

3.4. Texture Distribution

4. Discussion

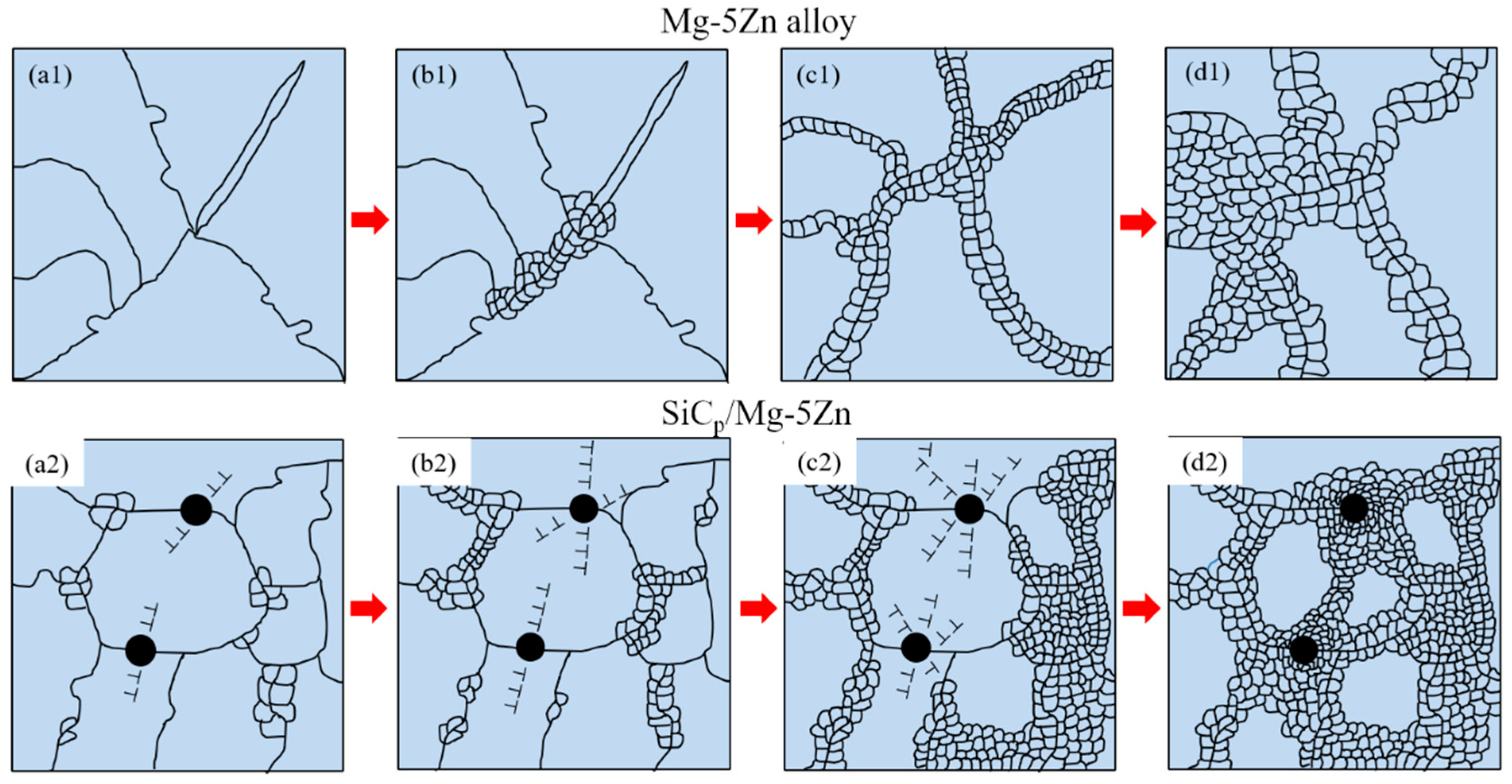

4.1. Effect of SiCp on DRX Behavior

4.2. Effect of SiCp on Precipitation Behavior

5. Conclusions

- (1)

- DRXed grains were mainly formed in the Mg-5Zn alloy by the “bulging” nucleation mechanism of the original grain boundary during compression. Moreover, the formation of twins also induced the formation of DRXed grains. The volume fraction and average DRXed grain size of Mg-5Zn alloy increased with the increment of compression strain;

- (2)

- The introduction of SiCp improved the DRXed ratio of the Mg-5Zn matrix, but DRXed grains in SiCp/Mg-5Zn material were still mainly formed by the mechanism of “bulging” nucleation under low strain. However, there were obviously DRXed grains around the particles under higher strain, and the DRXed grains near the particles were smaller than those far away from the particles, which was credited to the PSN effect of particle;

- (3)

- The addition of SiCp enhanced the volume fraction and size of precipitates in the Mg-5Zn alloy. Meanwhile, the addition of SiCp had little effect on the texture type of the Mg-5Zn alloy but decreased the maximum intensity of (0002) basal texture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nie, J.F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2011, 43, 3891–3939. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Xu, D.; Wang, S.; Sheng, L.; Zeng, R.-C.; Han, E.-H. Influence of solution treatment on the corrosion fatigue behavior of an as-forged Mg-Zn-Y-Zr alloy. Int. J. Fatigue 2019, 120, 46–55. [Google Scholar] [CrossRef]

- Li, Y.; Hou, P.; Wu, Z.; Feng, Z.; Ren, Y.; Choo, H. Dynamic recrystallization of a wrought magnesium alloy: Grain size and texture maps and their application for mechanical behavior predictions. Mater. Des. 2021, 202, 109562. [Google Scholar] [CrossRef]

- Pan, H.; Kang, R.; Li, J.; Xie, H.; Zeng, Z.; Huang, Q.; Yang, C.; Ren, Y.; Qin, G. Mechanistic investigation of a low-alloy Mg-Ca based extrusion alloy with high strength-ductility synergy. Acta Mater. 2020, 186, 278–290. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Derazkola, H.A.; García Gil, E.; Murillo-Marrodán, A.; Méresse, D. Review on Dynamic Recrystallization of Martensitic Stainless Steels during Hot Deformation: Part I—Experimental Study. Metals 2021, 11, 572. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Li, W.J.; Deng, K.K.; Zhang, X.; Wang, C.J.; Kang, J.-W.; Nie, K.-B.; Liang, W. Microstructures, tensile properties and work hardening behavior of SiCp/Mg-Zn-Ca composites. J. Alloy. Compd. 2017, 695, 2215–2223. [Google Scholar] [CrossRef]

- Shi, Q.-X.; Deng, K.-K.; Nie, K.-B.; Zhang, W.-G.; Cao, M.; Liang, W. Significant Influence of Minor SiCp on Microstructure and Mechanical Properties of Pure Mg. J. Mater. Eng. Perform. 2020, 29, 1356–1365. [Google Scholar] [CrossRef]

- Nie, K.-B.; Zhu, Z.-H.; Munroe, P.; Deng, K.-K.; Guo, Y.-C. Microstructure and mechanical properties of TiC nanoparticle-reinforced Mg-Zn-Ca matrix nanocomposites processed by combining multidirectional forging and extrusion. Trans. Nonferrous Met. Soc. China 2020, 30, 2394–2412. [Google Scholar] [CrossRef]

- Sun, X.-F.; Wang, C.-J.; Deng, K.-K.; Nie, K.-B.; Zhang, X.-C.; Xiao, X.-Y. High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg 17 Al 12 phase. J. Alloy. Compd. 2018, 732, 328–335. [Google Scholar] [CrossRef]

- Wang, X.-J.; Hu, X.-S.; Nie, K.-B.; Wu, K.; Zheng, M.-Y. Hot extrusion of SiCp/AZ91 Mg matrix composites. Trans. Nonferrous Met. Soc. China 2012, 22, 1912–1917. [Google Scholar] [CrossRef]

- Doherty, R.; Hughes, D.; Humphreys, F.; Jonas, J.; Jensen, D.; Kassner, M.; King, W.; McNelley, T.; McQueen, H.; Rollett, A. Current issues in recrystallization: A review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Deng, K.; Nie, K.B.; Wu, Y.; Wang, X.; Hu, X.; Zheng, M. Microstructure and mechanical properties of SiCp/AZ91 composite deformed through a combination of forging and extrusion process. Mater. Des. 2010, 31, 3929–3932. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Nie, K.B.; Deng, K.K.; Wu, K.; Zheng, M.Y. Dynamic recrystallization behavior of particle reinforced Mg matrix composites fabricated by stir casting. Mater. Sci. Eng. A 2012, 545, 38–43. [Google Scholar] [CrossRef]

- Shi, Q.-X.; Wang, C.-J.; Deng, K.-K.; Nie, K.-B.; Wu, Y.; Gan, W.-M.; Liang, W. Microstructure and mechanical behavior of Mg-5Zn matrix influenced by particle deformation zone. J. Mater. Sci. Technol. 2021, 60, 8–20. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, L.; Hu, L.; Sun, Y.; Gao, F.; Liu, W.; Yu, H. Effect of subgrain and the associated DRX behaviour on the texture modification of Mg-6.63Zn-0.56Zr alloy during hot tensile deformation. Mater. Sci. Eng. A 2021, 823, 141745. [Google Scholar] [CrossRef]

- Hu, G.X.; Cai, X.; Rong, Y.H. Fundamentals of Materials Science; Shanghai Jiaotong University Press: Shanghai, China, 2010. [Google Scholar]

- Xu, S.; Kamado, S.; Matsumoto, N.; Honma, T.; Kojima, Y. Recrystallization mechanism of as-cast AZ91 magnesium alloy during hot compressive deformation. Mater. Sci. Eng. A 2009, 527, 52–60. [Google Scholar] [CrossRef]

- Nie, H.; Hao, X.; Kang, X.; Chen, H.; Chi, C.; Liang, W. Strength and plasticity improvement of AZ31 sheet by pre-inducing large volume fraction of (10–12) tensile twins. Mater. Sci. Eng. A 2020, 776, 139045. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, B.; Xie, C.; Zhang, J.; Tang, C.; Chen, Y. Twinning, dynamic recrystallization, and crack in AZ31 magnesium alloy during high strain rate plane strain compression across a wide temperature. Mater. Sci. Eng. A 2018, 733, 98–107. [Google Scholar] [CrossRef]

- Liu, T.; Yang, Q.; Guo, N.; Lu, Y.; Song, B. Stability of twins in Mg alloys—A short review. J. Magn. Alloy. 2020, 8, 66–77. [Google Scholar] [CrossRef]

- Zhao, T.S.; Hu, Y.B.; Zhang, C.; He, B.; Zheng, T.X.; Tang, A.T.; Pan, F.S. Influence of extrusion conditions on microstructure and mechanical properties of Mg-2Gd-0.3Zr magnesium alloy. J. Magn. Alloy. 2022, 10, 387–399. [Google Scholar] [CrossRef]

- Tong, L.B.; Zheng, M.Y.; Cheng, L.R.; Kamado, S.; Zhang, H.J. Effect of extrusion ratio on microstructure, texture and mechanical properties of indirectly extruded Mg–Zn–Ca alloy. Mater. Sci. Eng. A 2013, 569, 48–53. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Yan, H.; Su, B.; Song, M.; Zhu, S. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 2016, 100, 58–66. [Google Scholar] [CrossRef]

- Shi, Q.-X.; Wang, C.-J.; Deng, K.-K.; Nie, K.-B.; Cao, M.; Gan, W.-M.; Liang, W. Work hardening and softening behavior of pure Mg influenced by Zn addition investigated via in-situ neutron diffraction. Mater. Sci. Eng. A 2020, 772, 138827. [Google Scholar] [CrossRef]

- Li, W.-J.; Deng, K.-K.; Zhang, X.; Nie, K.-B.; Xu, F.-J. Effect of ultra-slow extrusion speed on the microstructure and mechanical properties of Mg-4Zn-0.5Ca alloy. Mater. Sci. Eng. A 2016, 677, 367–375. [Google Scholar] [CrossRef]

- Du, Y.Z.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Xu, S.W. The microstructure, texture and mechanical properties of extruded Mg-5.3Zn-0.2Ca-0.5Ce (wt%) alloy. Mater. Sci. Eng. A 2015, 620, 164–171. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Chong, S.L. Role of {10–12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Chong, S.L. Strain path dependence of {10–12} twinning activity in a polycrystalline magnesium alloy. Scr. Mater. 2011, 64, 145–148. [Google Scholar] [CrossRef]

- Mendis, C.; Hono, K. Understanding precipitation processes in magnesium alloys. Fundament. Magnes. Alloy. Metall. 2013, 125–151. [Google Scholar]

- Guo, F.; Zhang, D.; Yang, X.; Jiang, L.; Pan, F. Strain-induced dynamic precipitation of Mg17Al12 phases in Mg–8Al alloys sheets rolled at 748K. Mater. Sci. Eng. A 2015, 636, 516–521. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Sanjari, M.; Su, J.; Jung, I.-H.; Yue, S. Effect of strain-induced precipitation on dynamic recrystallization in Mg–Al–Sn alloys. Mater. Sci. Eng. A 2014, 616, 252–259. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Q.; Wang, C.; Deng, K.; Nie, K.; Liang, W. Recrystallization Behavior of a Mg-5Zn Alloy Influenced by Minor SiCp during Hot Compression. Materials 2022, 15, 8498. https://doi.org/10.3390/ma15238498

Shi Q, Wang C, Deng K, Nie K, Liang W. Recrystallization Behavior of a Mg-5Zn Alloy Influenced by Minor SiCp during Hot Compression. Materials. 2022; 15(23):8498. https://doi.org/10.3390/ma15238498

Chicago/Turabian StyleShi, Quanxin, Cuiju Wang, Kunkun Deng, Kaibo Nie, and Wei Liang. 2022. "Recrystallization Behavior of a Mg-5Zn Alloy Influenced by Minor SiCp during Hot Compression" Materials 15, no. 23: 8498. https://doi.org/10.3390/ma15238498

APA StyleShi, Q., Wang, C., Deng, K., Nie, K., & Liang, W. (2022). Recrystallization Behavior of a Mg-5Zn Alloy Influenced by Minor SiCp during Hot Compression. Materials, 15(23), 8498. https://doi.org/10.3390/ma15238498