Tuning the Curing Efficiency of Conventional Accelerated Sulfur System for Tailoring the Properties of Natural Rubber/Bromobutyl Rubber Blends

Abstract

1. Introduction

2. Materials

2.1. Compounding

2.2. Characterization

2.2.1. Cure Properties

2.2.2. Tensile Properties

2.2.3. Hardness Testing

2.2.4. Compression Set

3. Results and Discussion

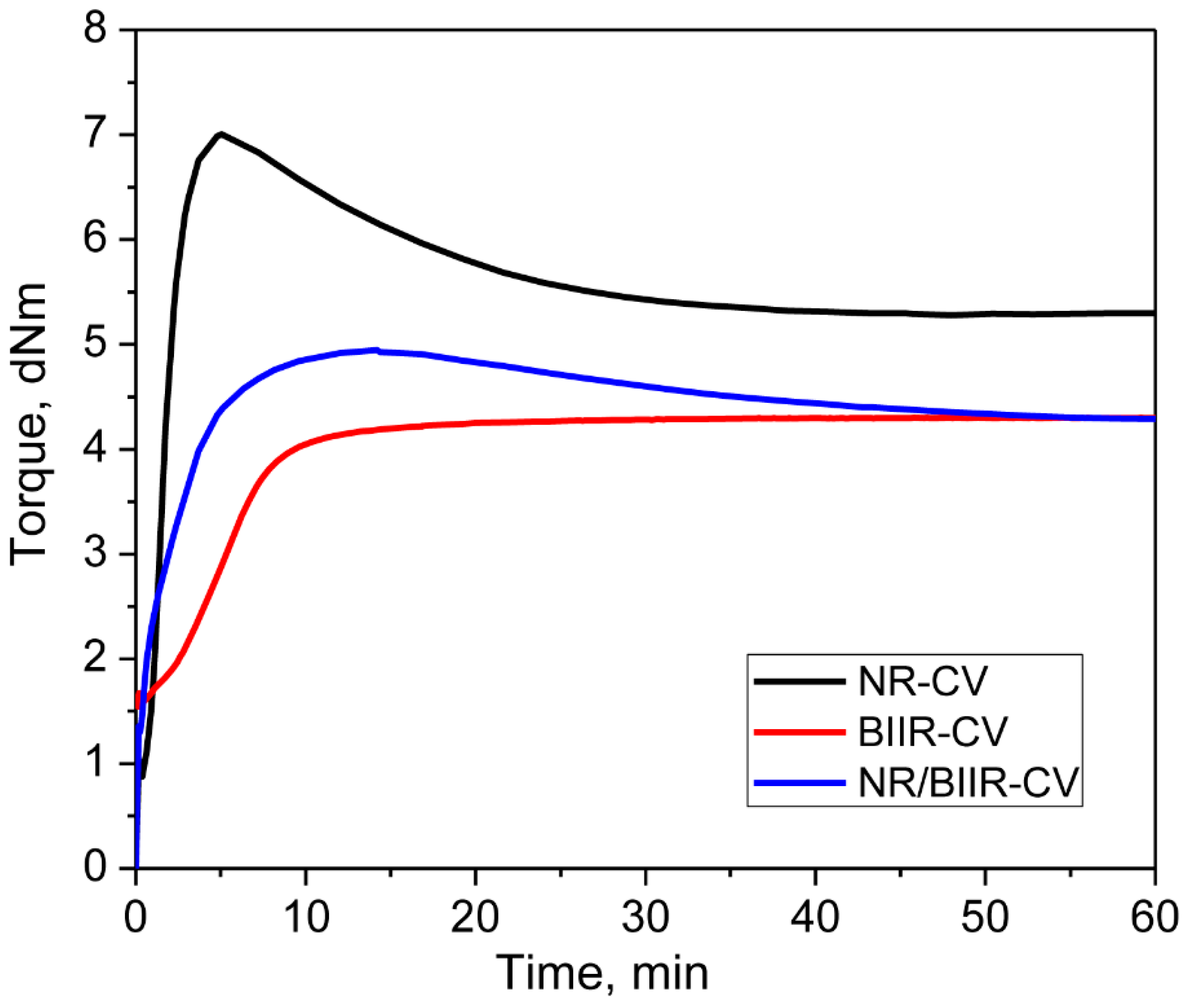

3.1. Curing Behavior and the Mechanical Properties of the NR, BIIR and NR/BIIR Blend with a CV System

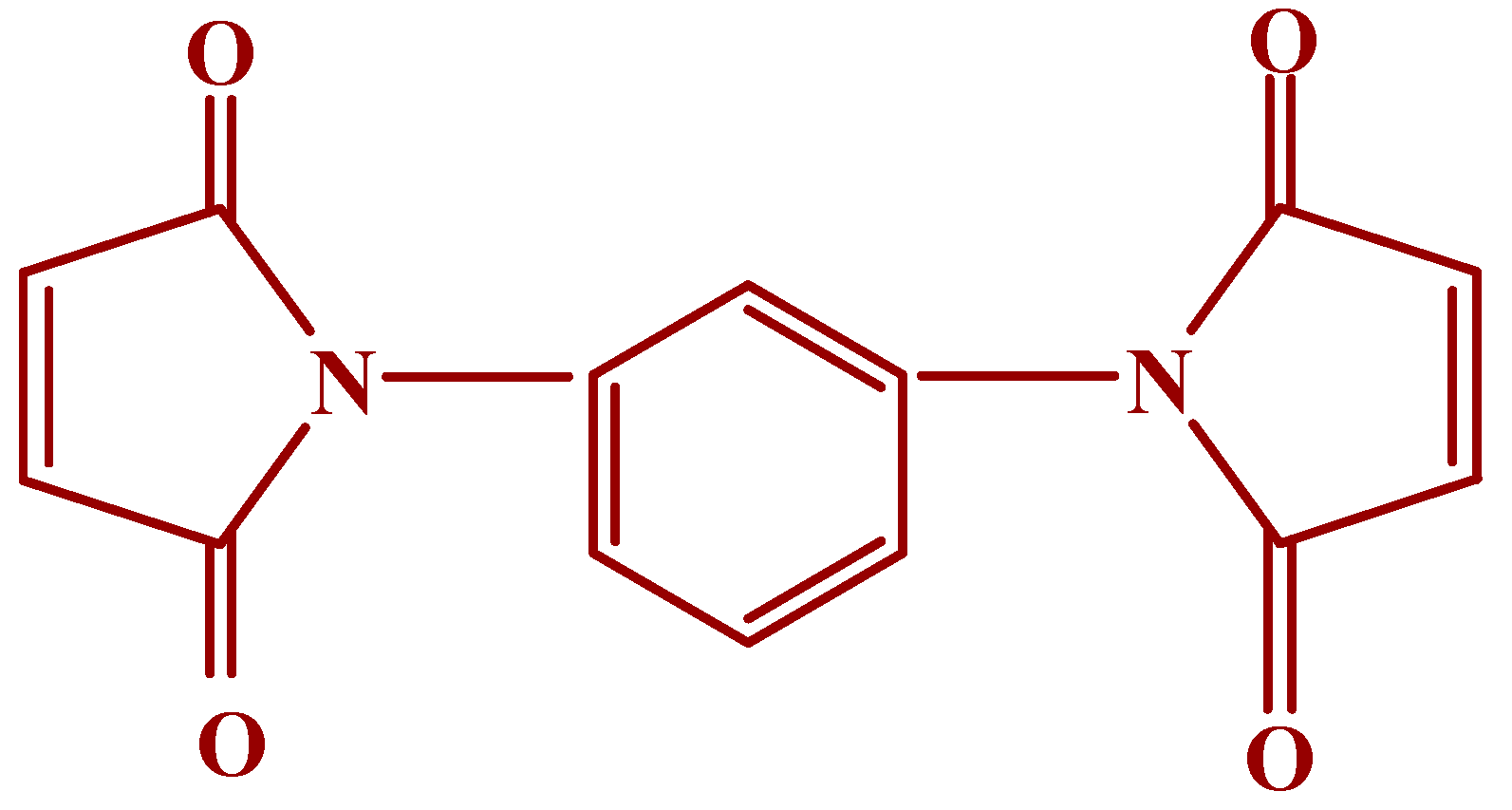

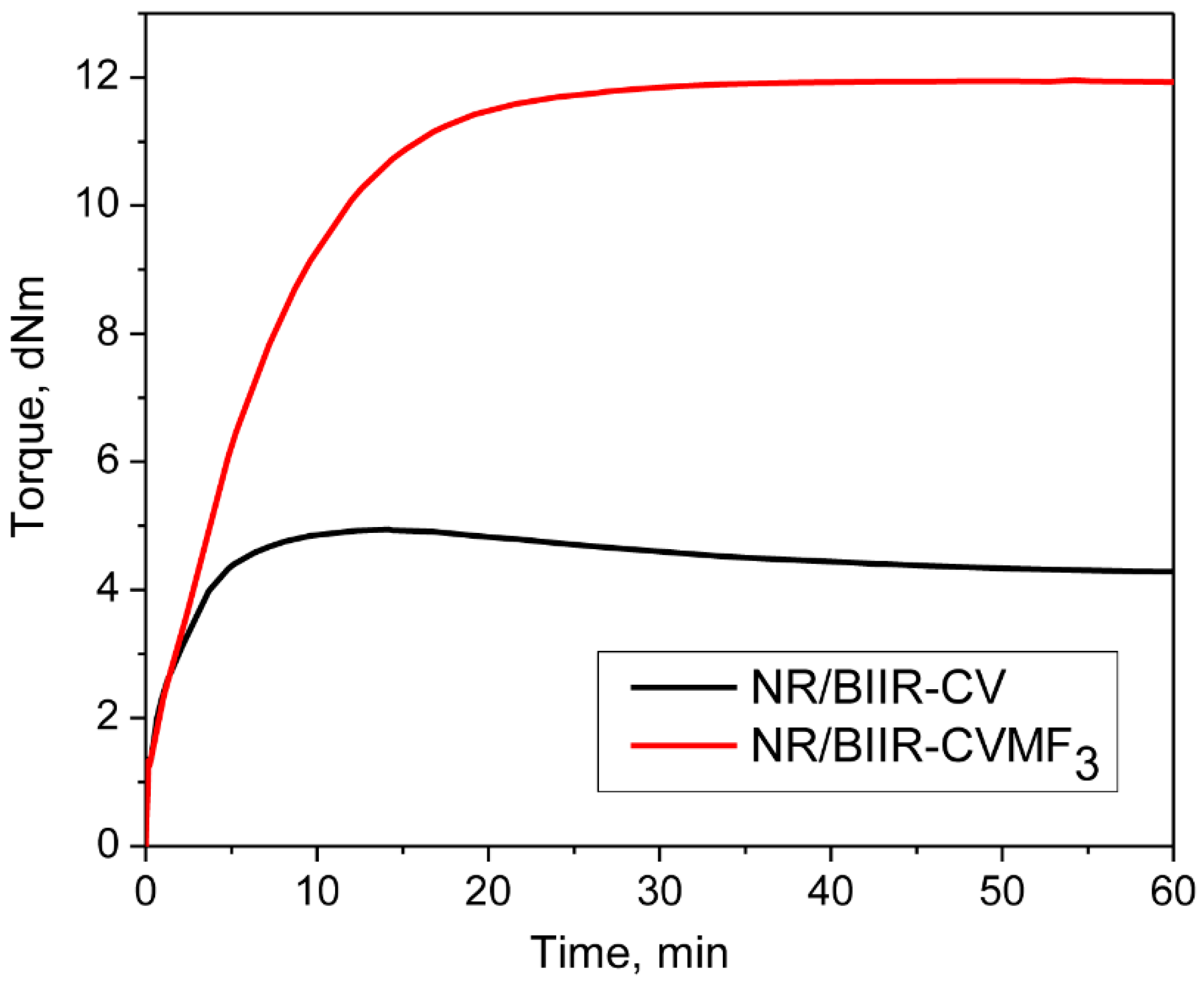

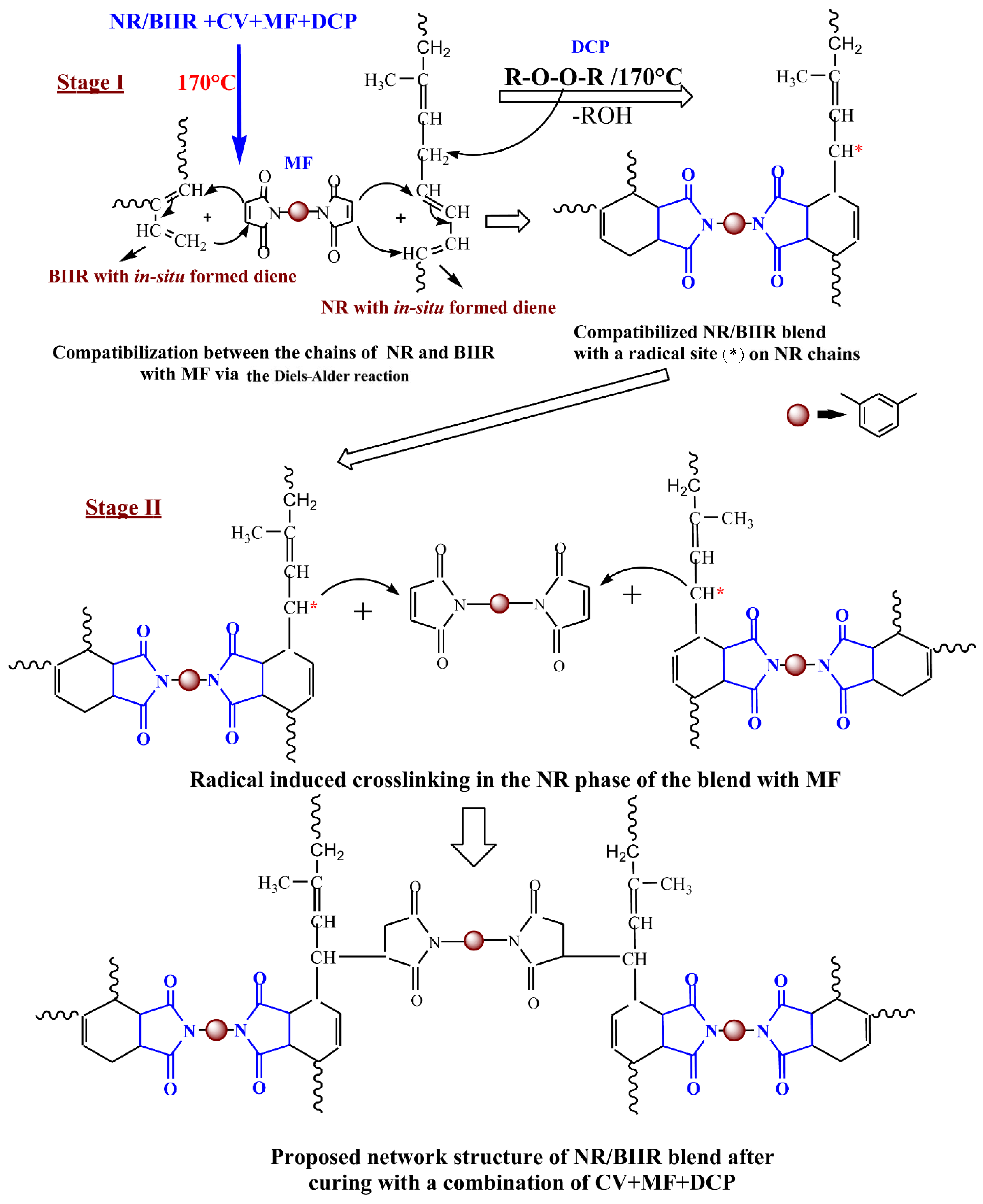

3.2. Curing Behavior and the Mechanical Properties of NR/BIIR-CV with Bismaleimide and Dicumyl Peroxide

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amram, B.; Bokobza, L.; Queslel, J.P.; Monnerie, L. Fourier-transform infra-red dichroism study of molecular orientation in synthetic high cis-1,4-polyisoprene and in natural rubber. Polymer 1986, 27, 877–882. [Google Scholar] [CrossRef]

- Huneau, B. Strain induced crystallization of natural rubber. A review of X-ray diffraction investigations. Rubber Chem. Technol. 2011, 84, 425–452. [Google Scholar] [CrossRef]

- Gros, A.; Tosaka, M.; Huneau, B.; Verron, E.; Poompradub, S.; Senoo, K. Dominating factor of strain-induced crystallization in natural rubber. Polymer 2015, 76, 230–236. [Google Scholar] [CrossRef][Green Version]

- Mahendra, A.; Akhmad, A.; Dewi, K.A.; Eryanti, K.; Herri, S.; Ade, S.H.; Caroline, D.L. Properties of natural rubber/chloroprene rubber blend for rubber fender application: Effects of blend ratio. Macromol. Symp. 2020, 391, 1–5. [Google Scholar]

- Quang, N.T.; Hung, D.V.; Linh, N.P.D.; Chuong, B.; Duong, D.L. Detailed study on the mechanical properties and activation energy of natural rubber/chloroprene rubber blends during aging processes. J. Chem. 2020, 2020, 7064934. [Google Scholar]

- Hayeemasae, N.; Salleh, S.Z.; Ismail, H. Utilization of chloroprene rubber waste as blending components with natural rubber: Aspect on metal oxide contents. J. Mater. Cycles Waste Manag. 2019, 21, 1095–1105. [Google Scholar] [CrossRef]

- Siti, Z.S.; Hanafi, I.; Zulkifli, A. Study on the effect of virgin and recycled chloroprene rubber (vCR and rCR) on the properties of natural rubber/chloroprene rubber (NR/CR) blends. J. Polym. Eng. 2013, 33, 803–811. [Google Scholar]

- Marek, P.; Shibulal, G.S.; Radek, S.; Ondřej, K. Rheometer evidences for the co-curing effect of a bismaleimide in conjunction with the accelerated-sulfur on natural rubber/chloroprene rubber blends. Polymers 2021, 13, 1510–1520. [Google Scholar]

- Akiba, M.; Hashim, A.S. Vulcanization and crosslinking in elastomers. Prog. Polym. Sci. 1997, 22, 475–521. [Google Scholar] [CrossRef]

- Kruzelak, J.; Sykora, R.; Hudec, I. Sulfur and peroxide vulcanisation of rubber compounds-overview. Chem. Pap. 2016, 70, 1533–1555. [Google Scholar] [CrossRef]

- Rajesh, B.R.; Shibulal, G.S.; Chandra, A.K.; Naskar, K. Compounding and Vulcanization. In Advances in Elastomers I. Advanced Structured Materials; Springer: Berlin/Heidelberg, Germany, 2013; pp. 83–138. [Google Scholar]

- Vukov, R. Zinc oxide cross-linking chemistry of halobutyl elastomers—A model compound approach. Rubber Chem. Technol. 1984, 57, 284–290. [Google Scholar] [CrossRef]

- Kuntz, I.; Zapp, R.L.; Pancirov, R.J. The chemistry of the zinc oxide cure of halobutyl. Rubber Chem. Technol. 1984, 57, 813–825. [Google Scholar] [CrossRef]

- Naba, K.D.; Tripathy, D.K. Miscibility studies in blends of bromobutyl rubber and natural rubber. J. Elastomers Plast. 1993, 25, 158–179. [Google Scholar]

- Sathi, S.G.; Jang, J.Y.; Jeong, K.U.; Nah, C. Thermally stable bromobutyl rubber with a high crosslinking density based on a 4,4′ bismaleimidodiphenylmethane curing agent. J. Appl. Polym. Sci. 2016, 133, 1–14. [Google Scholar] [CrossRef]

- Thomas, D.K. The degradation of polyisobutylene by dicumyl peroxide. Trans. Faraday Soc. 1961, 57, 511–517. [Google Scholar] [CrossRef]

- Sathi, S.G.; Stoček, R.; Kratina, O. Reversion free high-temperature vulcanization of cis-polybutadiene rubber with the accelerated-sulfur system. Express Polym. Lett. 2020, 14, 838–847. [Google Scholar]

- Sathi, S.G.; Jang, J.Y.; Yu, H.C.; Huh, Y.I.; Nah, C. Cure characteristics and physico-mechanical properties of a conventional sulfur-cured natural rubber with a novel anti-reversion agent. J. Polym. Res. 2016, 23, 237–248. [Google Scholar]

- Movahed, S.O.; Ansarifar, A.; Mirzaie, F. Effect of various efficient vulcanization cure systems on the compression set of a nitrile rubber filled with different fillers. J. Appl. Polym. Sci. 2015, 132, 1–10. [Google Scholar]

- Sathi, S.G.; Jeon, J.; Won, J.; Nah, C. Enhancing the efficiency of zinc oxide vulcanization in brominated poly (isobutylene-co-isoprene) rubber using structurally different bismaleimides. J. Polym. Res. 2018, 25, 108–121. [Google Scholar] [CrossRef]

- Marek, P.; Shibulal, G.S.; Radek, S. Identifying the co-curing effect of an accelerated-sulfur/bismaleimide combination on natural rubber/halogenated rubber blends using a rubber process analyzer. Polymers 2021, 13, 4329–4342. [Google Scholar]

| Mix ID * | NR | BIIR | ZnO | St.Acid | Sulfur | CBS | MF | DCP |

|---|---|---|---|---|---|---|---|---|

| NR/BIIR-CV | 50 | 50 | 5 | 1 | 1.25 | 0.25 | - | - |

| NR-CV | 100 | - | 5 | 2 | 2.5 | 0.5 | - | - |

| NR-CVMF3 | 100 | - | 5 | 2 | 2.5 | 0.5 | 3 | - |

| BIIR-CV | - | 100 | 5 | - | 0.5 | 0.1 | - | - |

| BIIR-CVMF3 | - | 100 | 5 | - | 0.5 | 0.1 | 3 | - |

| NR/BIIR-CVMF3 | 50 | 50 | 5 | 1 | 1.25 | 0.25 | 3 | - |

| NR/BIIR-CVMF3-D0.25 | 50 | 50 | 5 | 1 | 1.25 | 0.25 | 3 | 0.25 |

| NR/BIIR-CVMF3-D0.5 | 50 | 50 | 5 | 1 | 1.25 | 0.25 | 3 | 0.5 |

| NR/BIIR-CVMF3-D1.0 | 50 | 50 | 5 | 1 | 1.25 | 0.25 | 3 | 1 |

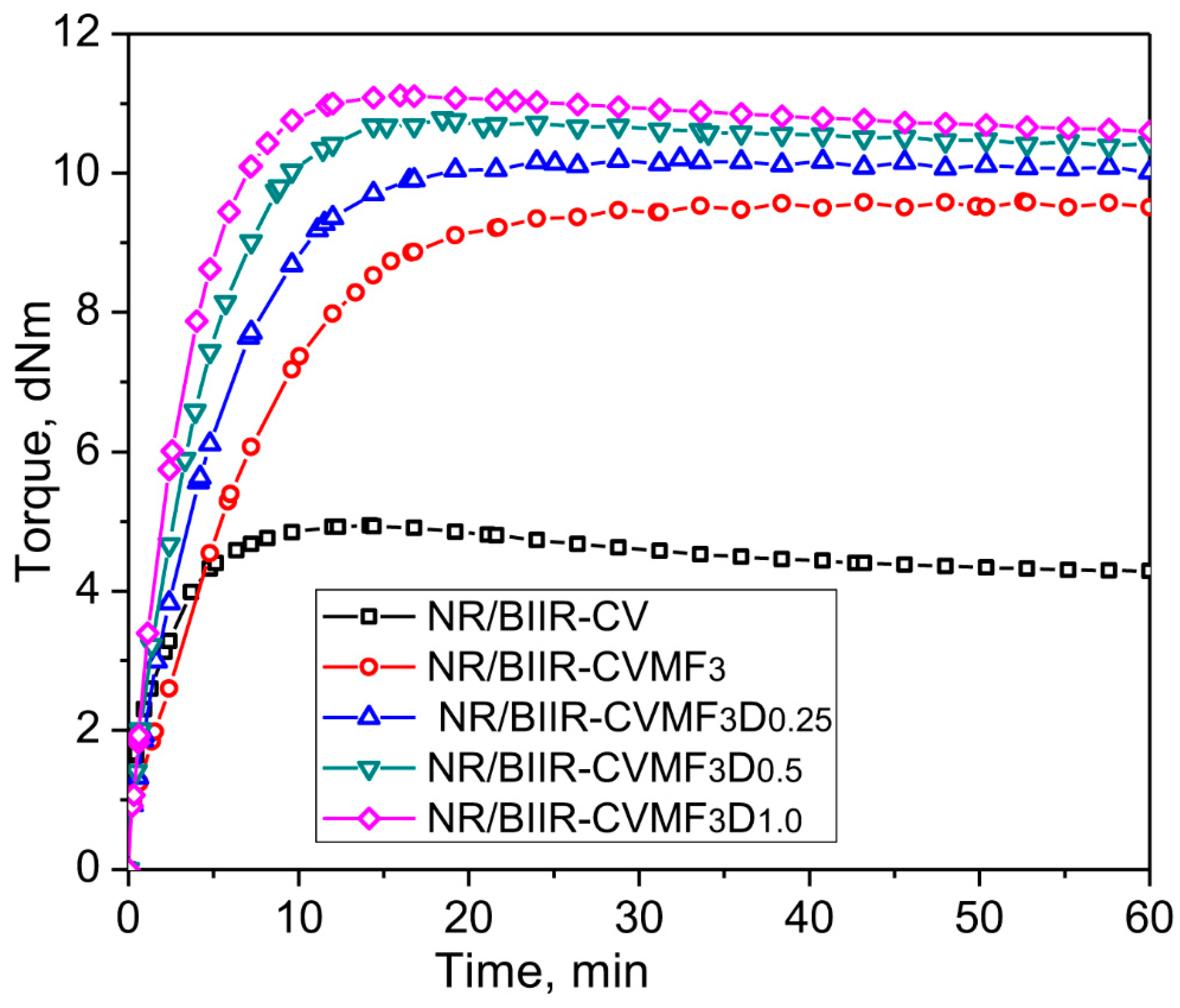

| Mix ID | ML (dNm) | MH (dNm) | ΔM (dNm) | TS2 (min) | T90 (min) | CRI (min−1) |

|---|---|---|---|---|---|---|

| NR/BIIR-CV | 1.30 | 4.94 | 3.64 | 0.93 | 6.33 | 18.51 |

| NR-CV | 0.88 | 7.00 | 6.12 | 1.07 | 3.08 | 49.75 |

| NR-CVMF3 | 0.75 | 11.33 | 10.58 | 1.29 | 6.44 | 19.41 |

| BIIR-CV | 1.59 | 4.30 | 2.71 | 4.28 | 9.72 | 18.38 |

| BIIR-CVMF3 | 1.69 | 8.21 | 5.76 | 2.28 | 8.30 | 16.61 |

| NR/BIIR-CVMF3 | 0.98 | 9.33 | 8.35 | 1.54 | 15.70 | 7.06 |

| NR/BIIR-CVMF3-D0.25 | 0.93 | 10.22 | 9.29 | 0.90 | 11.05 | 9.85 |

| NR/BIIR-CVMF3-D0.5 | 1.00 | 10.78 | 9.78 | 0.72 | 8.88 | 12.25 |

| NR/BIIR-CVMF3-D1.0 | 0.91 | 11.11 | 10.20 | 0.52 | 7.15 | 15.08 |

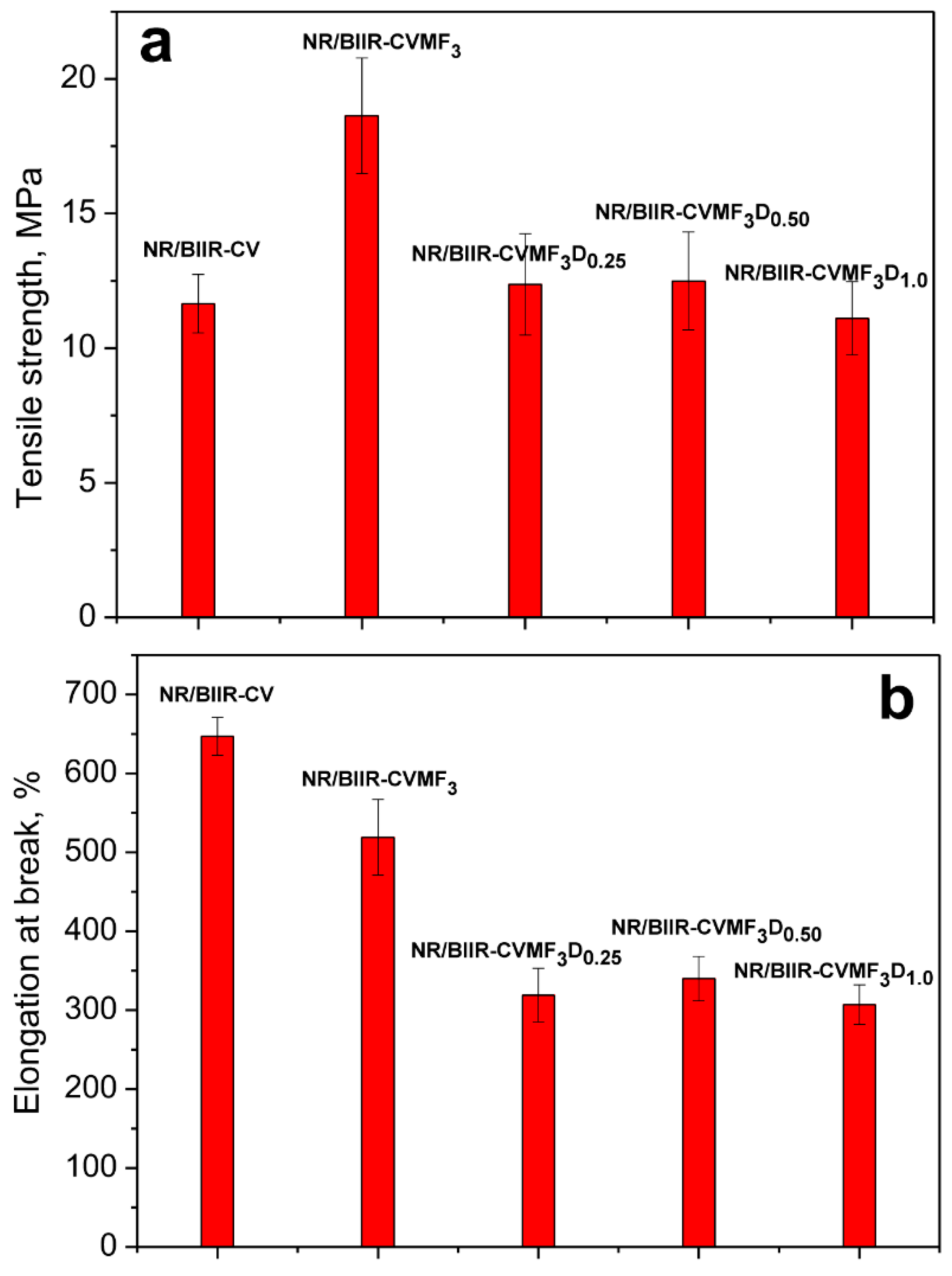

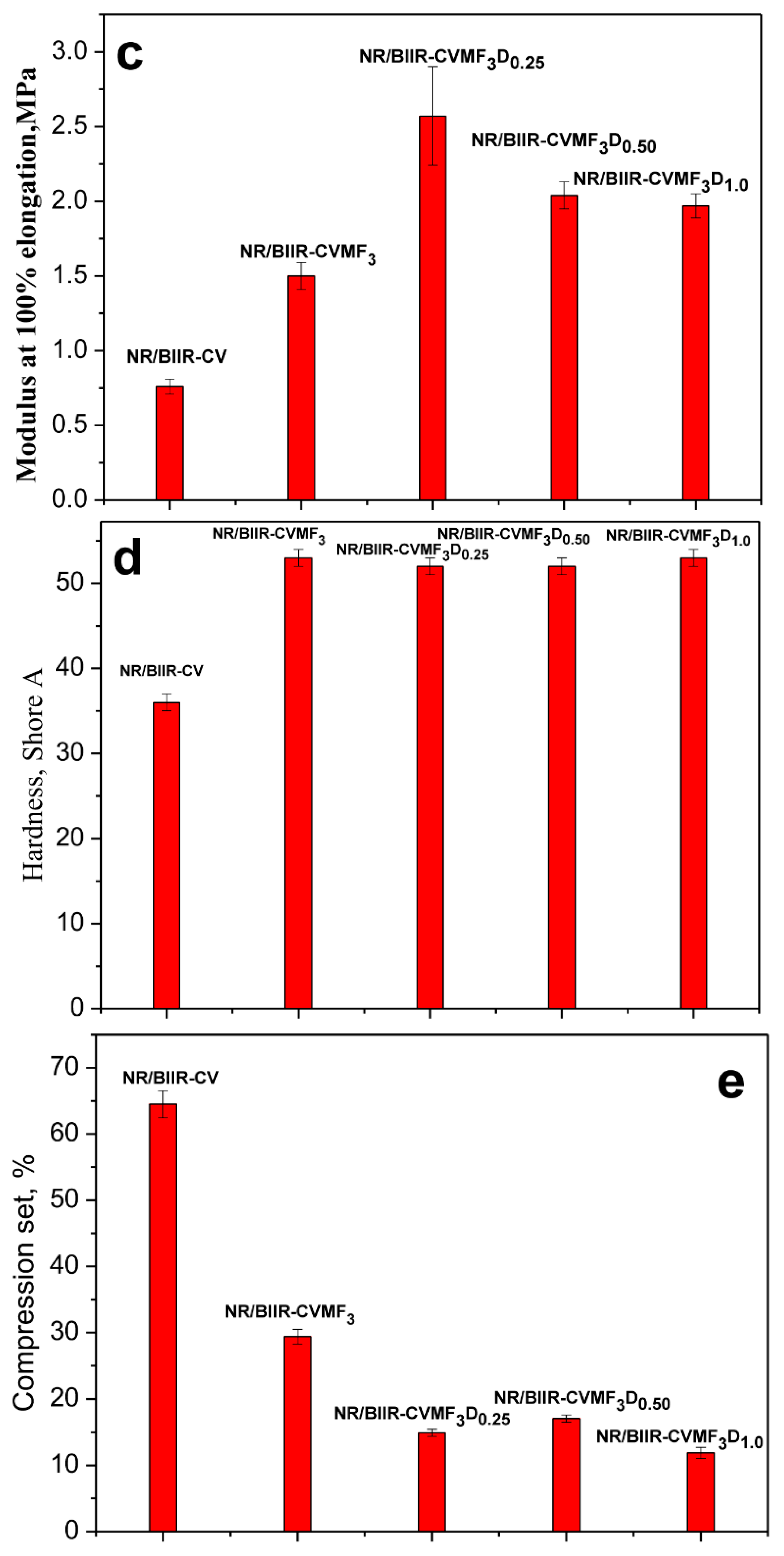

| Sample ID | Tensile Strength (MPa) | Elongation at Break (MPa) | Modulus at 100% (MPa) | Hardness (Shore A) |

|---|---|---|---|---|

| NR/BIIR-CV | 11.65 ± 1.09 | 647 ± 24 | 0.76 ± 0.05 | 36 ± 1 |

| NR-CV | 17.81 ± 1.71 | 653 ± 61 | 0.84 ± 0.08 | 38 ± 1 |

| BIIR-CV | 14.62 ± 1.26 | 834 ± 33 | 0.86 ± 0.39 | 35 ± 1 |

| NR/BIIR-CVMF3 | 18.63 ± 2.14 | 519 ± 48 | 1.50 ± 0.09 | 53 ± 1 |

| Sample ID | Curing Time (min) | Compression Set (%) |

|---|---|---|

| NR/BIIR-CV | T90 + 5 | 64.5 ± 2.05 |

| 45 | 47.9 ± 3.16 | |

| NR-CV | T90 + 5 | 61.6 ± 0.25 |

| 45 | 48.4 ± 1.42 | |

| NR-CVMF3 | T90 + 5 | 37.7 ± 0.75 |

| BIIR-CV | T90 + 5 | 23.5 ± 0.78 |

| 45 | 18.8 ± 0.70 | |

| BIIR-CVMF3 | T90 + 5 | 11.7 ± 0.70 |

| NR/BIIR-CVMF3 | T90 + 5 | 29.4 ± 1.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pöschl, M.; Sathi, S.G.; Stoček, R. Tuning the Curing Efficiency of Conventional Accelerated Sulfur System for Tailoring the Properties of Natural Rubber/Bromobutyl Rubber Blends. Materials 2022, 15, 8466. https://doi.org/10.3390/ma15238466

Pöschl M, Sathi SG, Stoček R. Tuning the Curing Efficiency of Conventional Accelerated Sulfur System for Tailoring the Properties of Natural Rubber/Bromobutyl Rubber Blends. Materials. 2022; 15(23):8466. https://doi.org/10.3390/ma15238466

Chicago/Turabian StylePöschl, Marek, Shibulal Gopi Sathi, and Radek Stoček. 2022. "Tuning the Curing Efficiency of Conventional Accelerated Sulfur System for Tailoring the Properties of Natural Rubber/Bromobutyl Rubber Blends" Materials 15, no. 23: 8466. https://doi.org/10.3390/ma15238466

APA StylePöschl, M., Sathi, S. G., & Stoček, R. (2022). Tuning the Curing Efficiency of Conventional Accelerated Sulfur System for Tailoring the Properties of Natural Rubber/Bromobutyl Rubber Blends. Materials, 15(23), 8466. https://doi.org/10.3390/ma15238466