Investigation of Setting Time and Microstructural and Mechanical Properties of MK/GGBFS-Blended Geopolymer Pastes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Paste Synthesis

2.3. Characterizations

3. Results and Discussion

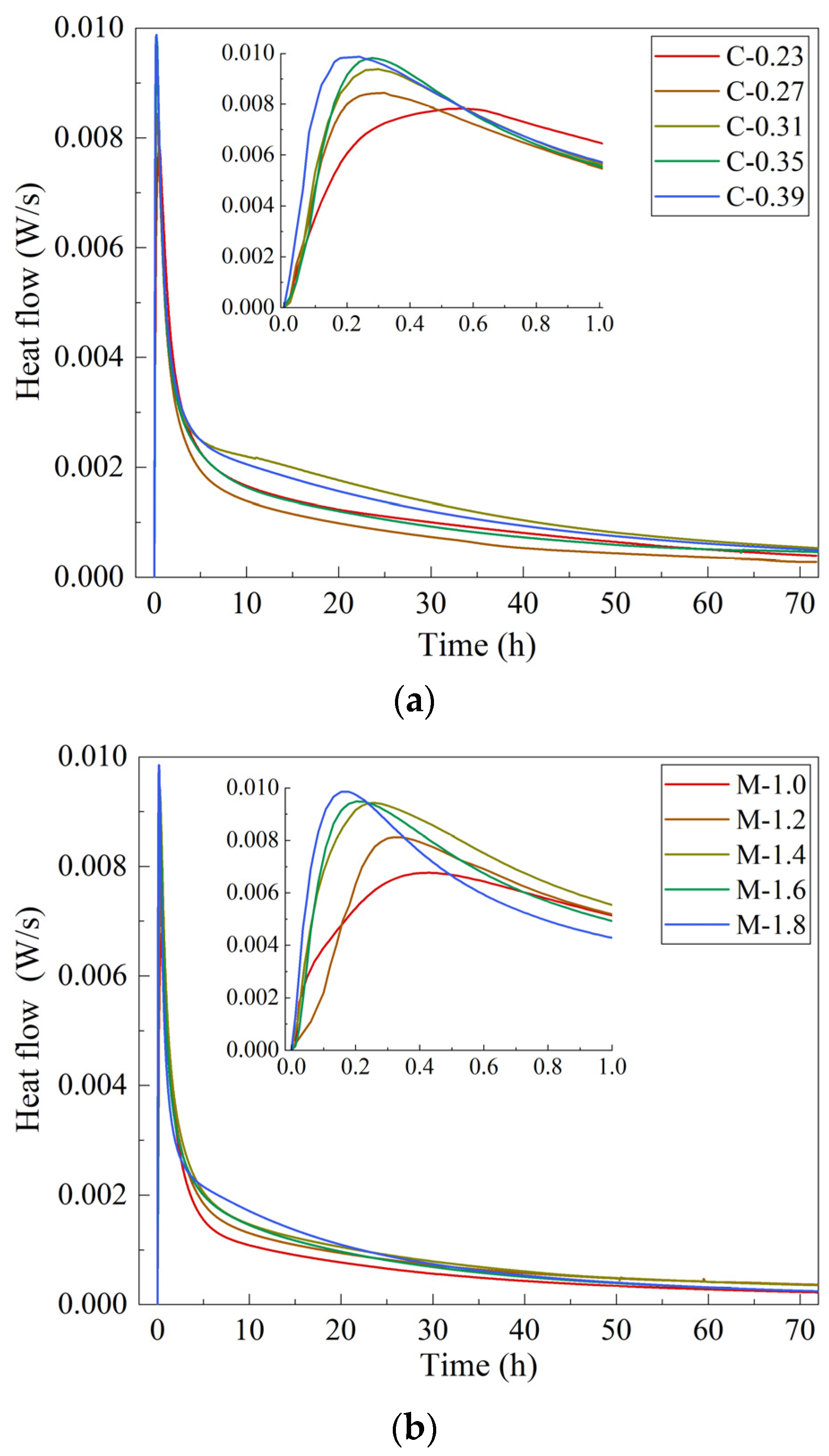

3.1. Isothermal Calorimetry

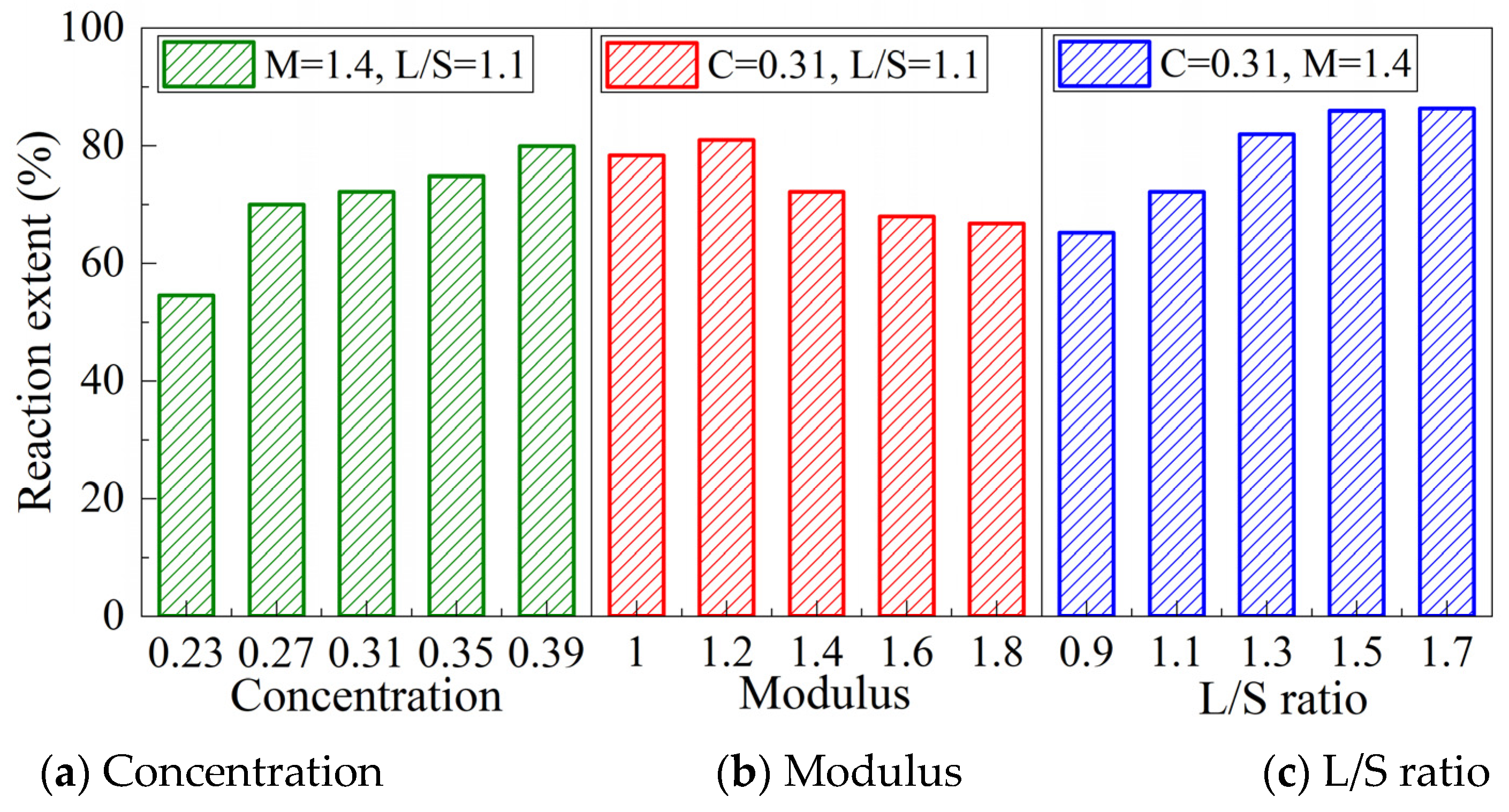

3.2. Reaction Extent

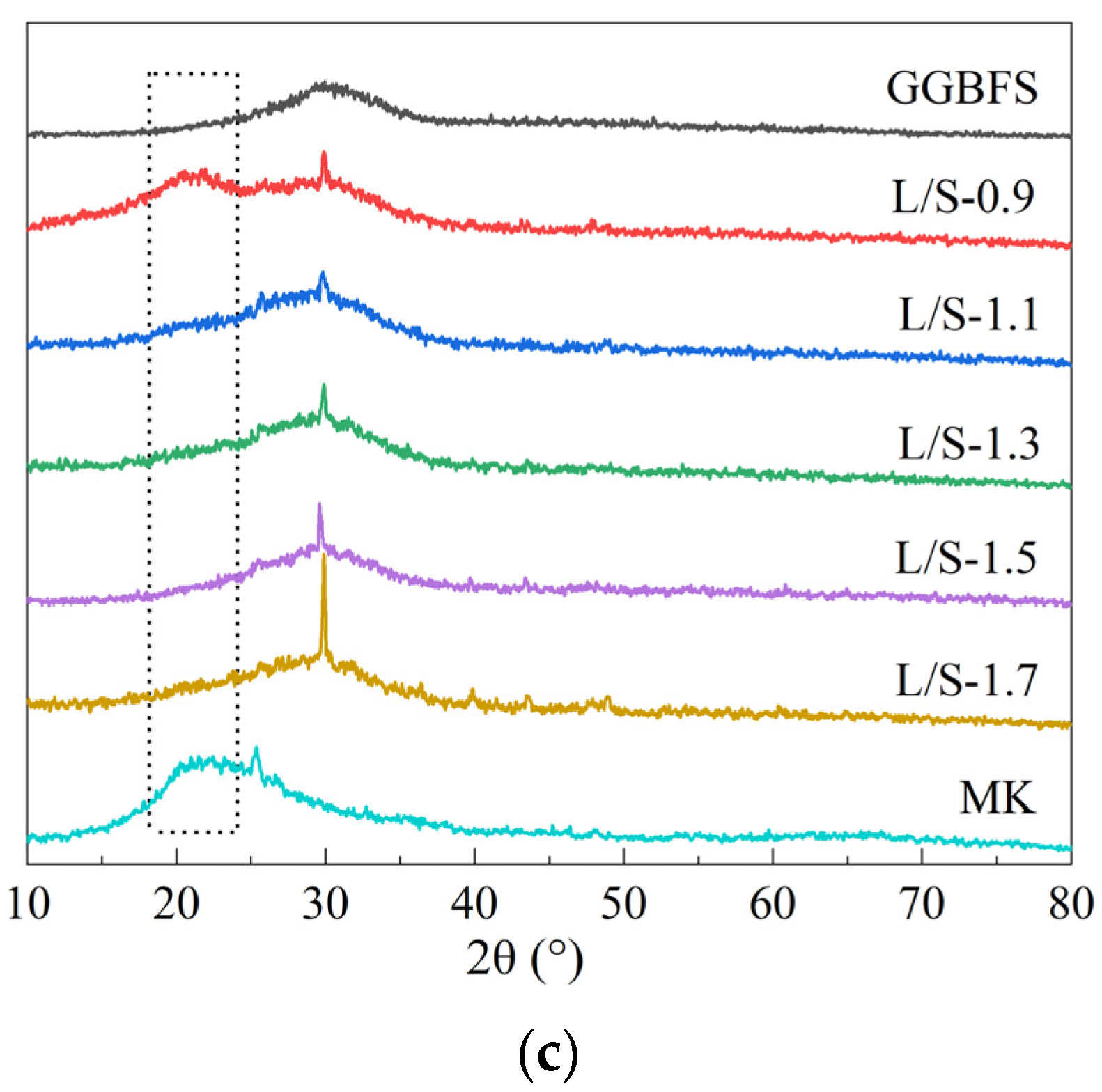

3.3. Phase Composition

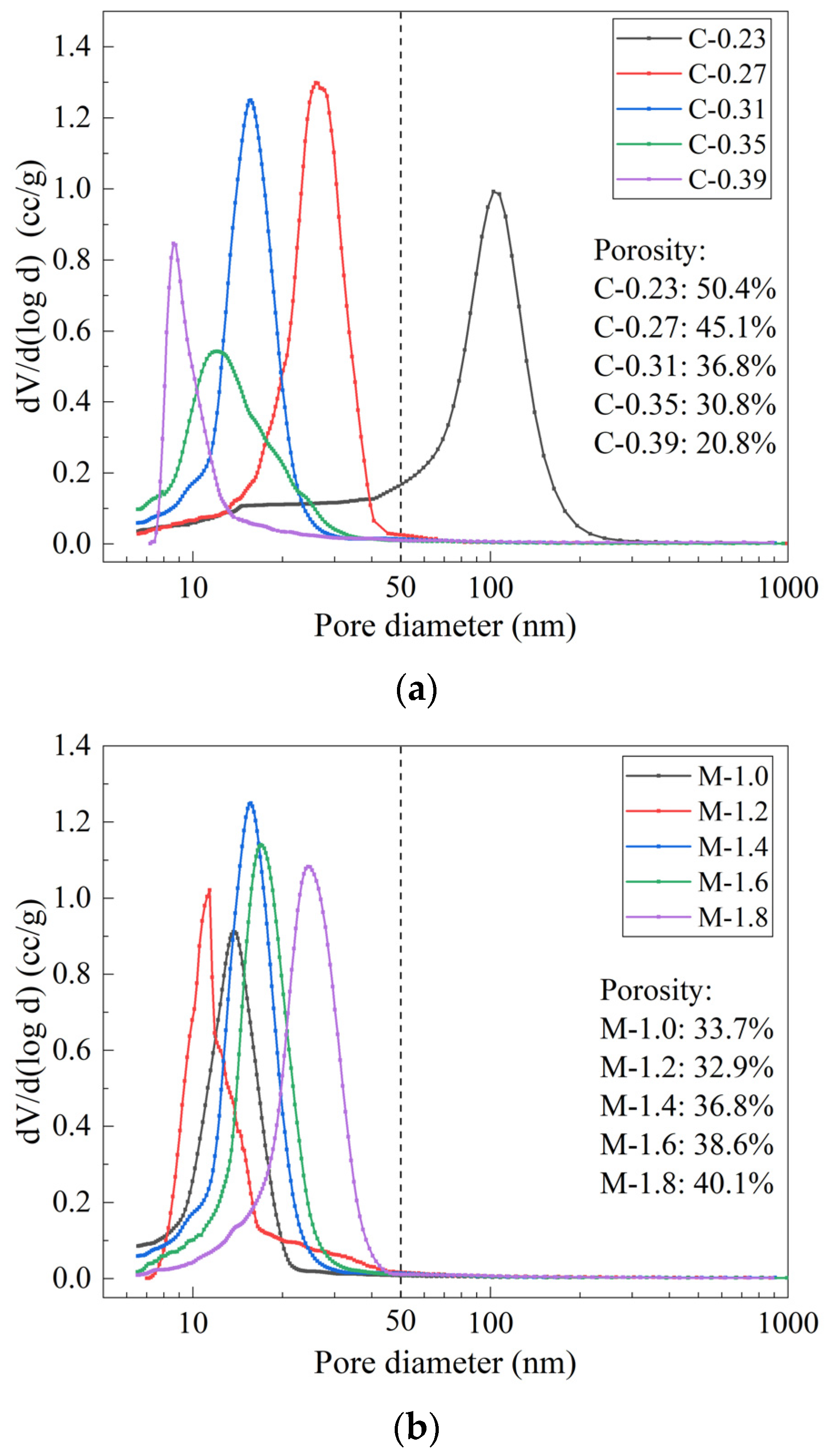

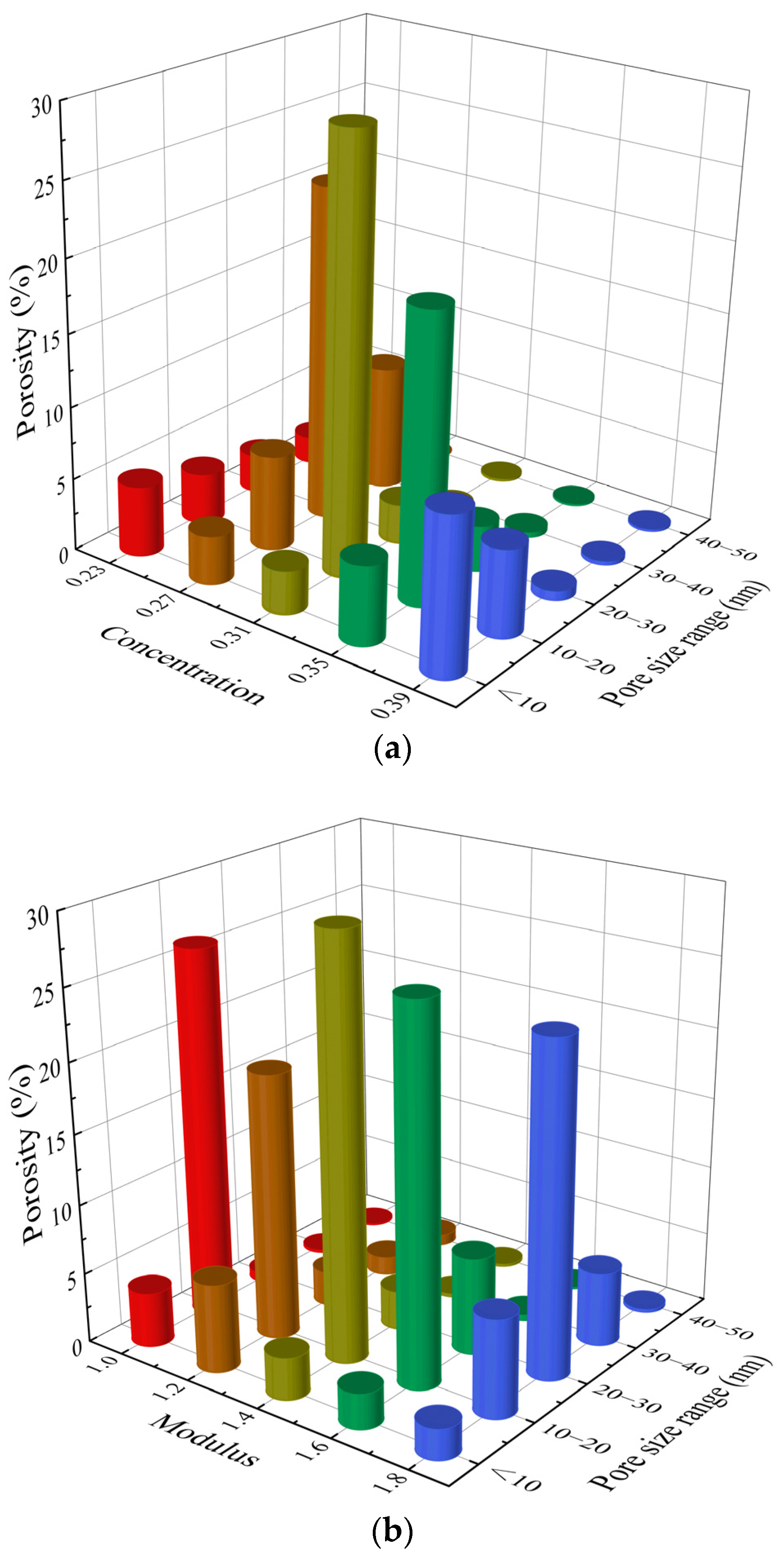

3.4. Pore Structure

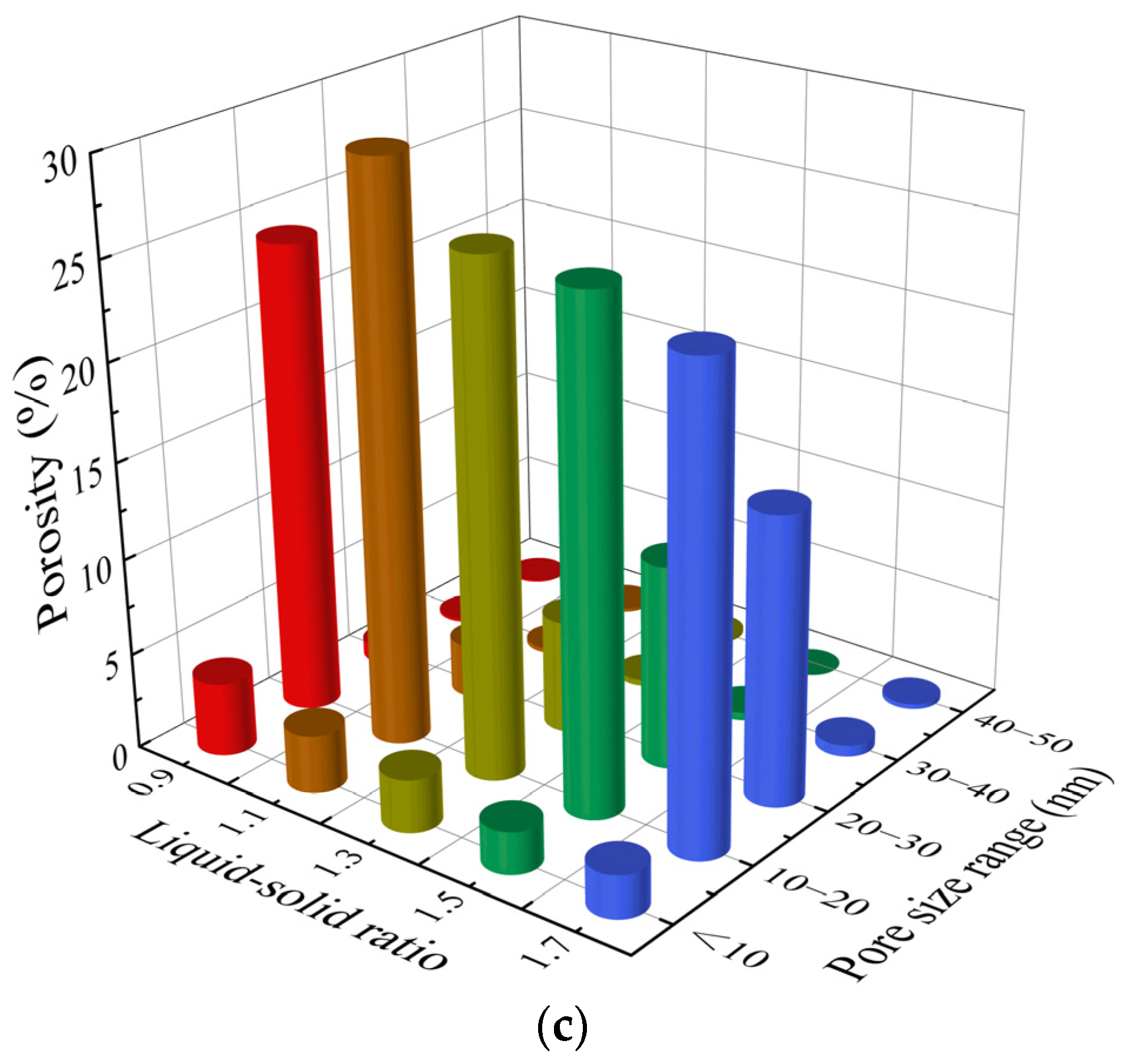

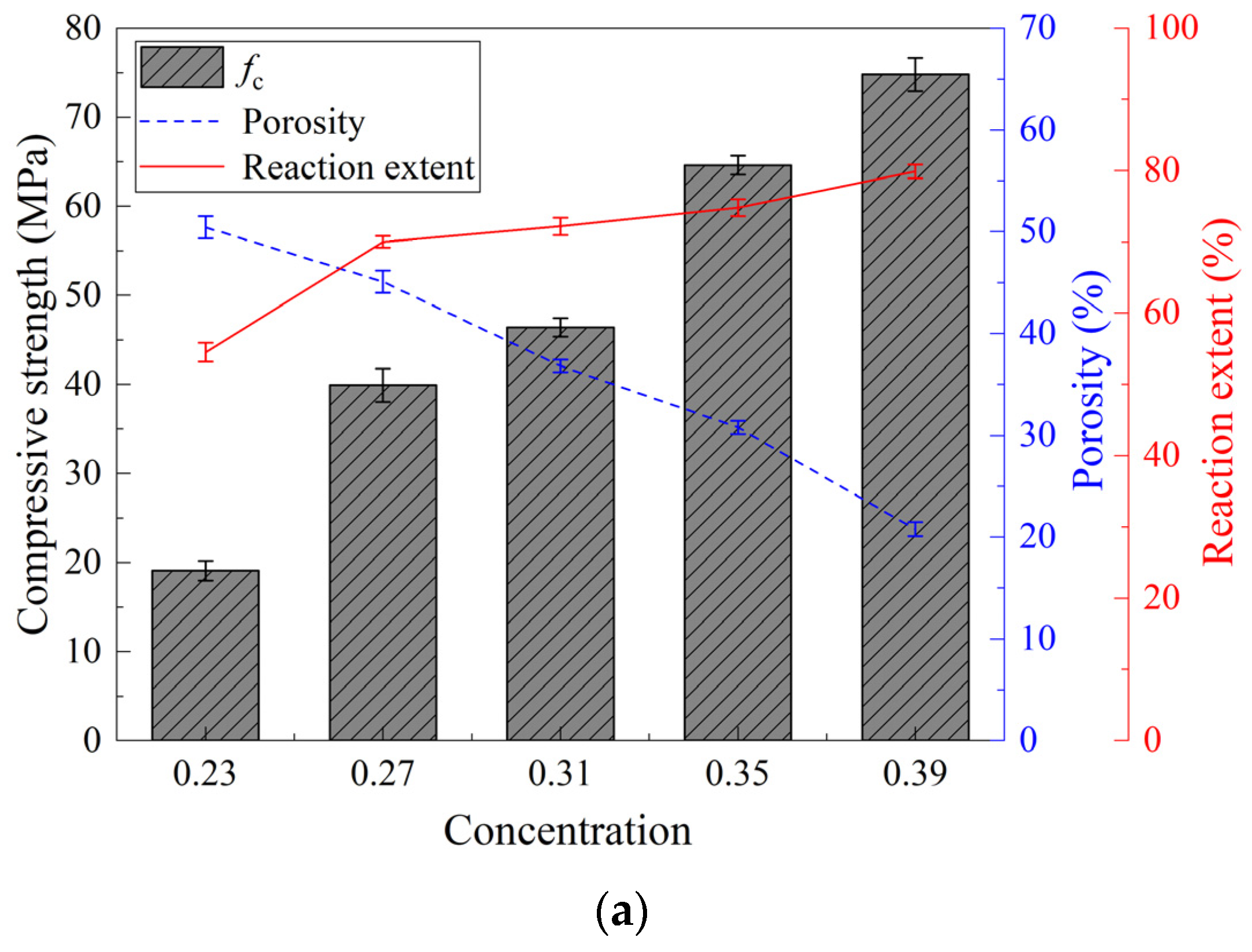

3.5. Morphology Analysis

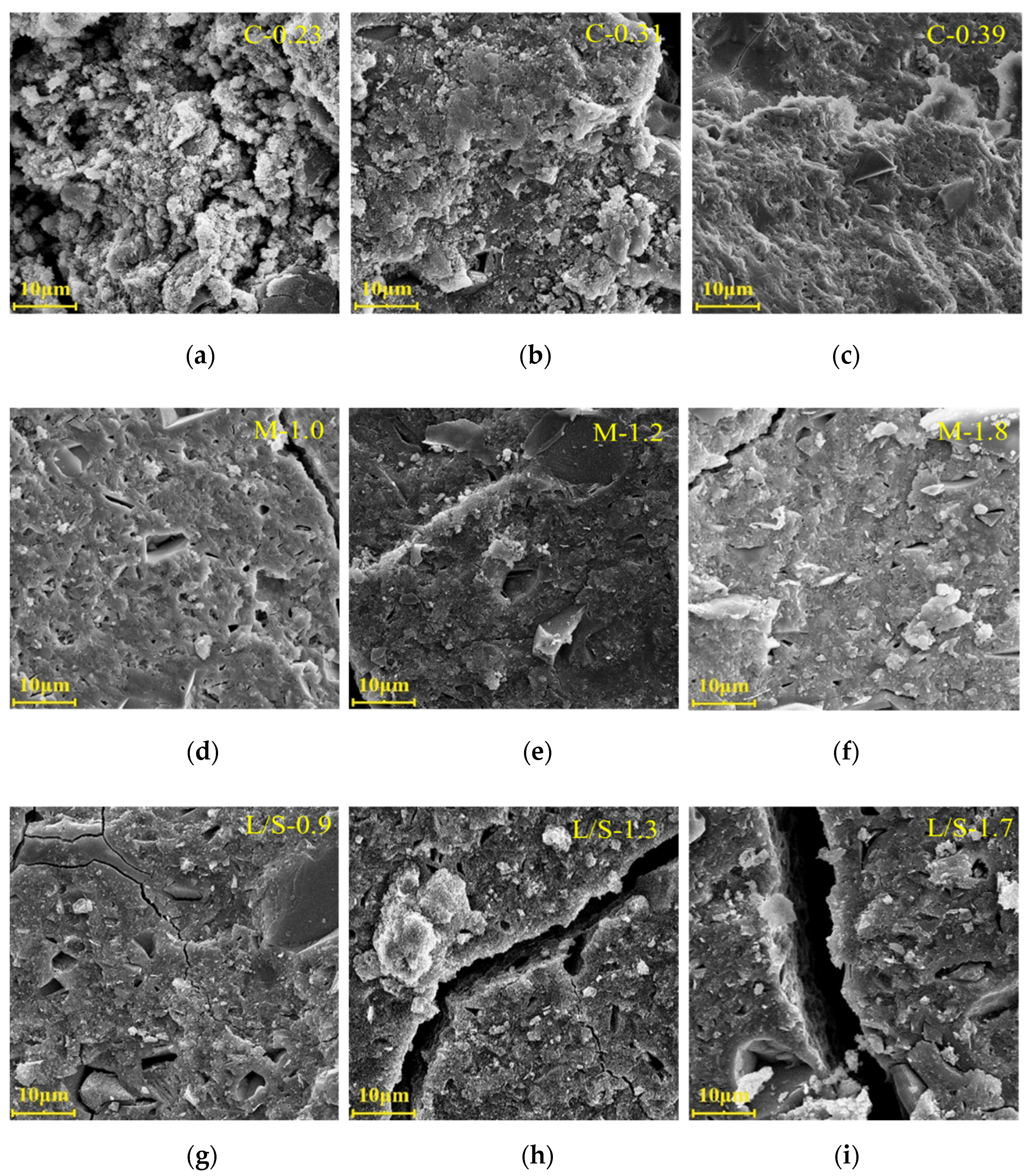

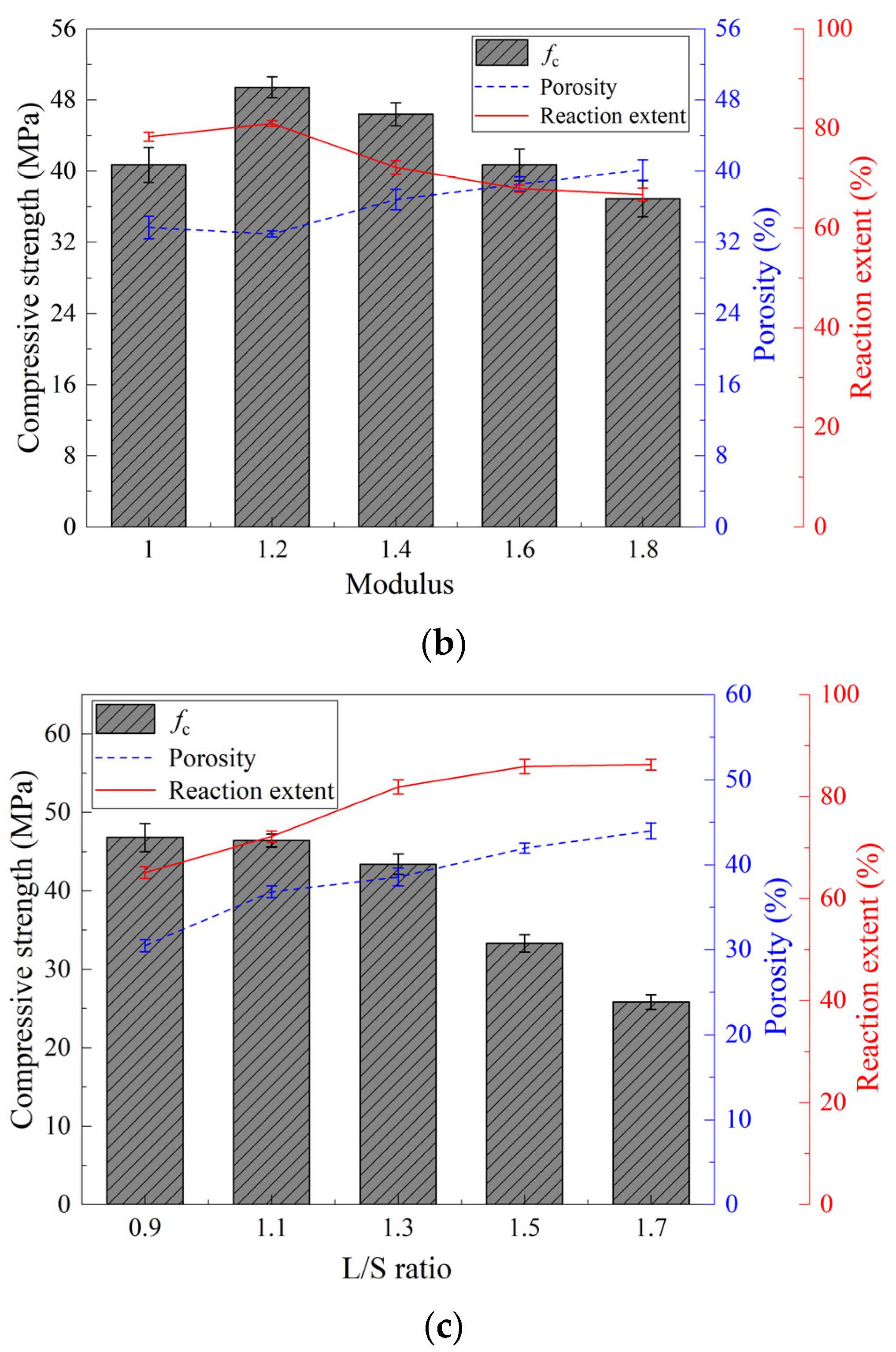

3.6. Setting Time and Compressive Strength

4. Conclusions

- The exothermic characteristics of geopolymerization in the fresh geopolymer paste are related to the alkali content, silicate content, and water content in the alkaline activator. With the increase in concentration, the alkali content increased, the time of exothermic peak appeared earlier, the peak value increased, and the heat production increased. With the increase in modulus, the silicate content increases, the time of exothermic peak appears earlier, and the peak value increases, but the heat production increases first and then decreases, and reaches the highest value when the modulus is 1.2, which is related to the high alkali content that hinders the continuous geopolymerization. As the L/S ratio increases, the alkali content and silicate content increase, and the heat production increases. However, as the water content also increases, the time when the exothermic peak appears is delayed and the peak value decreases.

- The change law of the reaction extent of geopolymer paste with the three influencing factors is consistent with the heat production of geopolymerization, but the fresh geopolymer paste with large heat production does not necessarily have a higher reaction extent, which is related to whether there is a difference in the amount of silicate in the paste. There is a maximum reaction extent of geopolymer paste, and the maximum value is 86.3% under the experimental conditions in this paper. The variation of porosity and the most probable pore size with the three influencing factors is opposite to the heat production. The difference of the total porosity caused by the different influencing factors is mainly related to the porosity with pore size less than or equal to 30 nm.

- The initial setting time of geopolymer paste mainly depends on the time and peak value of the exothermic peak of the geopolymerization. The earlier the exothermic peak appears, the greater the peak value, the faster the rate of geopolymerization, the more intense the degree, the shorter the initial setting time of the geopolymer paste.

- The compressive strength of the geopolymer paste increases with the increase in concentration. With the increase in modulus, the compressive strength increases first and then decreases, reaching a maximum of 49.4 MPa when the modulus is 1.2. The variation of compressive strength with concentration or modulus is the same as that of the reaction extent, which is opposite to the total porosity. The compressive strength decreases with the increase in the L/S ratio. When the L/S ratio changes, the compressive strength is positively correlated with the reaction extent and negatively correlated with total porosity. The total porosity and reaction extent jointly determine the compressive strength of the geopolymer paste.

- In this paper, the reaction extent and the total porosity of the geopolymer paste jointly determine the compressive strength. In the future, further tests can be carried out to clarify when the reaction degree or porosity plays a leading role. The microstructure of the geopolymer paste with different mixing ratios was observed by SEM. In the future, EDS can be used to analyze the specific products in the paste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement. A Review; Technical report for Geopolymer Science and Technics; Geopolymer Institute Library: Saint-Quentin, France, 2013; pp. 1–11. [Google Scholar]

- Assi, L.N.; Deaver, E.E.; ElBatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef]

- Saavedra, W.G.V.; de Gutiérrez, R.M. Performance of geopolymer concrete composed of fly ash after exposure to elevated temperatures. Constr. Build. Mater. 2017, 154, 229–235. [Google Scholar] [CrossRef]

- Albitar, M.; Ali, M.S.M.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Priyadharshini, P.; Ramamurthy, K.; Robinson, R. Excavated soil waste as fine aggregate in fly ash based geopolymer mortar. Appl. Clay Sci. 2017, 146, 81–91. [Google Scholar] [CrossRef]

- Tennakoon, C.; Nicolas, R.S.; Sanjayan, J.G.; Shayan, A. Thermal effects of activators on the setting time and rate of workability loss of geopolymers. Ceram. Int. 2016, 42, 19257–19268. [Google Scholar] [CrossRef]

- Sitarz, M.; Figiela, B.; Łach, M.; Korniejenko, K.; Mróz, K.; Castro-Gomes, J.; Hager, I. Mechanical Response of Geopolymer Foams to Heating—Managing Coal Gangue in Fire-Resistant Materials Technology. Energies 2022, 15, 3363. [Google Scholar] [CrossRef]

- Figiela, B.; Brudny, K.; Lin, W.T.; Korniejenko, K. Investigation of mechanical properties and microstructure of construction-and demolition-waste-based geopolymers. J. Compos. Sci. 2022, 6, 191. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Heath, A.; Paine, K.; McManus, M. Minimising the global warming potential of clay based geopolymers. J. Clean. Prod. 2014, 78, 75–83. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, H.; Zhou, C.; Wang, H. Geopolymer from kaolin in China: An overview. Appl. Clay Sci. 2016, 119, 31–41. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of curing schedule on the integrity of geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Zanotti, C.; Borges, P.H.; Bhutta, A.; Banthia, N. Bond strength between concrete substrate and metakaolin geopolymer repair mortar: Effect of curing regime and PVA fiber reinforcement. Cem. Concr. Compos. 2017, 80, 307–316. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. A review of the influence of source material’s oxide composition on the compressive strength of geopolymer concrete. Microporous Mesoporous Mater. 2016, 234. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.; Ariffin, M.A.M. Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain Shams Eng. J. 2018, 9, 1557–1566. [Google Scholar] [CrossRef]

- Bernal, S.A. Effect of the activator dose on the compressive strength and accelerated carbonation resistance of alkali silicate-activated slag/metakaolin blended materials. Constr. Build. Mater. 2015, 98, 217–226. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Van Deventer, J.S.J. The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem. Concr. Res. 2005, 35, 1688–1697. [Google Scholar] [CrossRef]

- Peng, H.; Cui, C.; Liu, Z.; Cai, C.S.; Liu, Y. Synthesis and Reaction Mechanism of an Alkali-Activated Metakaolin-Slag Composite System at Room Temperature. J. Mater. Civ. Eng. 2019, 31, 04018345. [Google Scholar] [CrossRef]

- Buchwald, A.; Tatarin, R.; Stephan, D. Reaction progress of alkaline-activated metakaolin-ground granulated blast furnace slag blends. J. Mater. Sci. 2009, 44, 5609–5617. [Google Scholar] [CrossRef]

- Puertas, F.; Jimenez, A.M.F. Mineralogical and microstructural characterisation of alkali-activated fly ash/slag pastes. Cem. Concr. Compos. 2003, 25, 287–292. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; de Gutiérrez, R.M.; Gordillo, M.; Provis, J.L. Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/slag blends. J. Mater. Sci. 2011, 46, 5477–5486. [Google Scholar] [CrossRef]

- El Moustapha, B.; Bonnet, S.; Khelidj, A.; Leklou, N.; Froelich, D.; Babah, I.A.; Charbuillet, C.; Khalifa, A. Compensation of the negative effects of micro-encapsulated phase change materials by incorporating metakaolin in geopolymers based on blast furnace slag. Constr. Build. Mater. 2022, 314, 125556. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Provis, J.L.; van Deventer, J.S. Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 2008, 38, 554–564. [Google Scholar] [CrossRef]

- Khalil, M.G.; Elgabbas, F.; El-Feky, M.S.; El-Shafie, H. Performance of geopolymer mortar cured under ambient temperature. Constr. Build. Mater. 2020, 242, 118090. [Google Scholar] [CrossRef]

- Burciaga-Díaz, O.; Magallanes-Rivera, R.; Escalante-García, J. Alkali-activated slag-metakaolin pastes: Strength, structural, and microstructural characterization. J. Sustain. Cem. Mater. 2013, 2, 111–127. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Optimization approach of granulated blast furnace slag and metakaolin based geopolymer mortars. Constr. Build. Mater. 2019, 198, 10–26. [Google Scholar] [CrossRef]

- Guo, X.L.; Shi, H.S.; Lin, M.S. Gradient Acid Dissolving Test Study and Identification of Geopolymer and Cement Hydration Products. J. Tongji Univ. Nat. Sci. 2013, 41, 547–550. [Google Scholar] [CrossRef]

- Lecomte, I.; Henrist, C.; Liégeois, M.; Maseri, F.; Rulmont, A.; Cloots, R. (Micro)-structural comparison between geopolymers, alkali-activated slag cement and Portland cement. J. Eur. Ceram. Soc. 2006, 26, 3789–3797. [Google Scholar] [CrossRef]

- Alonso, S.; Palomo, A. Calorimetric study of alkaline activation of calcium hydroxide–metakaolin solid mixtures. Cem. Concr. Res. 2001, 31, 25–30. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Yan, F. Synthesis and mechanical properties of metakaolinite-based geopolymer. Colloids Surfaces A: Physicochem. Eng. Asp. 2005, 268, 1–6. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.; Rose, V.; De Gutierrez, R.M. Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cem. Concr. Compos. 2011, 33, 46–54. [Google Scholar] [CrossRef]

- Luukkonen, T.; Sreenivasan, H.; Abdollahnejad, Z.; Yliniemi, J.; Kantola, A.; Telkki, V.-V.; Kinnunen, P.; Illikainen, M. Influence of sodium silicate powder silica modulus for mechanical and chemical properties of dry-mix alkali-activated slag mortar. Constr. Build. Mater. 2020, 233, 117354. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Wang, X.; Hua, S. Effects of mix design parameters on heat of geopolymerization, set time, and compressive strength of high calcium fly ash geopolymer. Constr. Build. Mater. 2019, 228, 116763. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Provis, J.L.; Bullen, F.; Reid, A.; Zhu, Y. Quantitative kinetic and structural analysis of geopolymers. Part 1. The activation of metakaolin with sodium hydroxide. Thermochim. Acta 2012, 539, 23–33. [Google Scholar] [CrossRef]

- Shi, Z.; Shi, C.; Wan, S.; Zhang, Z. Effects of alkali dosage and silicate modulus on alkali-silica reaction in alkali-activated slag mortars. Cem. Concr. Res. 2018, 111, 104–115. [Google Scholar] [CrossRef]

- Zuhua, Z.; Xiao, Y.; Huajun, Z.; Yue, C. Role of water in the synthesis of calcined kaolin-based geopolymer. Appl. Clay Sci. 2009, 43, 218–223. [Google Scholar] [CrossRef]

- Reddy, K.C.; Gudur, C.; Subramaniam, K.V. Study on the influences of silica and sodium in the alkali-activation of ground granulated blast furnace slag. Constr. Build. Mater. 2020, 257, 119514. [Google Scholar] [CrossRef]

- Tian, X.; Zhang, H.; Zhang, T.; Fernández, C.A. Alkali-activated copper tailings-based pastes: Compressive strength and microstructural characterization. J. Mater. Res. Technol. 2020, 9, 6557–6567. [Google Scholar] [CrossRef]

- Tian, X.; Xu, W.; Song, S.; Rao, F.; Xia, L. Effects of curing temperature on the compressive strength and microstructure of copper tailing-based geopolymers. Chemosphere 2020, 253, 126754. [Google Scholar] [CrossRef] [PubMed]

- Lyu, S.-J.; Hsiao, Y.-H.; Wang, T.-T.; Cheng, T.-W.; Ueng, T.-H. Microstructure of geopolymer accounting for associated mechanical characteristics under various stress states. Cem. Concr. Res. 2013, 54, 199–207. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G.; Liu, Z.; Yang, L.; Zhang, M.; Zhang, Y. Numerical simulation of the effect of cement particle shapes on capillary pore structures in hardened cement pastes. Constr. Build. Mater. 2018, 173, 615–628. [Google Scholar] [CrossRef]

- Mehta, P.K. Studies on blended Portland cements containing Santorin earth. Cem. Concr. Res. 1981, 11, 507–518. [Google Scholar] [CrossRef]

- Álvarez-Ayuso, E.; Querol, X.; Plana, F.; Alastuey, A.; Moreno, N.; Izquierdo, M.; Font, O.; Moreno, T.; Diez, S.; Vázquez, E.; et al. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-)combustion fly ashes. J. Hazard. Mater. 2008, 154, 175–183. [Google Scholar] [CrossRef]

- Hu, X.; Shi, C.; Shi, Z.; Zhang, L. Compressive strength, pore structure and chloride transport properties of alkali-activated slag/fly ash mortars. Cem. Concr. Compos. 2019, 104, 103392. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, W.; Shi, Y. The effects of alkaline dosage and Si/Al ratio on the immobilization of heavy metals in municipal solid waste incineration fly ash-based geopolymer. Chemosphere 2010, 79, 665–671. [Google Scholar] [CrossRef]

- Borges, P.H.; Banthia, N.; Alcamand, H.A.; Vasconcelos, W.L.; Nunes, E.H. Performance of blended metakaolin/blastfurnace slag alkali-activated mortars. Cem. Concr. Compos. 2016, 71, 42–52. [Google Scholar] [CrossRef]

- Steins, P.; Poulesquen, A.; Frizon, F.; Diat, O.; Jestin, J.; Causse, J.; Lambertin, D.; Rossignol, S. Effect of aging and alkali activator on the porous structure of a geopolymer. J. Appl. Crystallogr. 2014, 47, 316–324. [Google Scholar] [CrossRef]

- Benavent, V.; Frizon, F.; Poulesquen, A. Effect of composition and aging on the porous structure of metakaolin-based geopolymers. J. Appl. Crystallogr. 2016, 49, 2116–2128. [Google Scholar] [CrossRef]

- Chotetanorm, C.; Chindaprasirt, P.; Sata, V.; Rukzon, S.; Sathonsaowaphak, A. High-Calcium Bottom Ash Geopolymer: Sorptivity, Pore Size, and Resistance to Sodium Sulfate Attack. J. Mater. Civ. Eng. 2013, 25, 105–111. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L.; Zhang, J. Effects of activator type/concentration and curing temperature on alkali-activated binder based on copper mine tailings. J. Mater. Sci. 2012, 47, 5933–5945. [Google Scholar] [CrossRef]

- Liang, J.J. Effect of the Activator Modulus and Slag Content on Alkali Activated Fly Ash/Slag Blended System. Master’s Thesis, Guangzhou University, Guangzhou, China, 2017. [Google Scholar]

- Wan, Q.; Zhang, Y.; Zhang, R. The effect of pore behavior and gel structure on the mechanical property at different initial water content. Constr. Build. Mater. 2021, 309, 125146. [Google Scholar] [CrossRef]

| Component | SiO2 | Al2O3 | CaO | MgO | SO3 | TiO2 | K2O | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| MK | 52.53 | 45.42 | 0.26 | - | 0.04 | 0.97 | 0.18 | - |

| GGBFS | 30.23 | 13.72 | 44.06 | 5.58 | 3.16 | 1.79 | 0.50 | 0.41 |

| No. | Concentration | Modulus | L/S | GGBFS (g) | MK (g) | Sodium Silicate Solution (g) | H2O (g) | NaOH (g) |

|---|---|---|---|---|---|---|---|---|

| C-0.23 | 0.23 | 1.4 | 1.1 | 40 | 60 | 55.1 | 47.0 | 7.9 |

| C-0.27 | 0.27 | 40 | 60 | 64.7 | 36.0 | 9.3 | ||

| C-0.31 | 0.31 | 40 | 60 | 74.3 | 25.1 | 10.7 | ||

| C-0.35 | 0.35 | 40 | 60 | 83.8 | 14.1 | 12.0 | ||

| C-0.39 | 0.39 | 40 | 60 | 93.4 | 3.1 | 13.4 | ||

| M-1.0 | 0.31 | 1.0 | 1.1 | 40 | 60 | 63.5 | 31.0 | 15.5 |

| M-1.2 | 1.2 | 40 | 60 | 69.4 | 27.8 | 12.9 | ||

| M-1.4 | 1.4 | 40 | 60 | 74.3 | 25.1 | 10.7 | ||

| M-1.6 | 1.6 | 40 | 60 | 78.4 | 22.8 | 8.8 | ||

| M-1.8 | 1.8 | 40 | 60 | 82.0 | 20.8 | 7.2 | ||

| L/S-0.9 | 0.31 | 1.4 | 0.9 | 40 | 60 | 60.8 | 20.5 | 8.7 |

| L/S-1.1 | 1.1 | 40 | 60 | 74.3 | 25.1 | 10.7 | ||

| L/S-1.3 | 1.3 | 40 | 60 | 87.8 | 29.6 | 12.6 | ||

| L/S-1.5 | 1.5 | 40 | 60 | 101.2 | 34.1 | 14.5 | ||

| L/S-1.7 | 1.7 | 40 | 60 | 114.8 | 38.7 | 16.5 |

| Code | Total Heat Released (J) | Average | Standard Deviation | ||

|---|---|---|---|---|---|

| C-0.23 | 179.3 | 176.2 | 168.6 | 174.7 | 5.51 |

| C-0.27 | 196.0 | 193.0 | 184.0 | 191.0 | 6.24 |

| C-0.31 | 235.0 | 228.6 | 224.3 | 229.3 | 5.38 |

| C-0.35 | 260.0 | 257.4 | 247.9 | 255.1 | 6.37 |

| C-0.39 | 290.5 | 287.2 | 280.3 | 286.0 | 5.20 |

| M-1.0 | 179.3 | 176.2 | 168.6 | 243.0 | 6.51 |

| M-1.2 | 196.0 | 193.0 | 184.0 | 259.0 | 5.99 |

| M-1.4 | 235.0 | 228.6 | 224.3 | 229.3 | 6.38 |

| M-1.6 | 260.0 | 257.4 | 247.9 | 209.5 | 6.41 |

| M-1.8 | 290.5 | 287.2 | 280.3 | 181.5 | 3.63 |

| L/S-0.9 | 216.2 | 210.8 | 209.9 | 212.3 | 3.41 |

| L/S-1.1 | 234.6 | 227.2 | 226.1 | 229.3 | 4.62 |

| L/S-1.3 | 238.5 | 232.6 | 232.1 | 234.4 | 3.56 |

| L/S-1.5 | 256.3 | 248.3 | 249.6 | 251.4 | 4.29 |

| L/S-1.7 | 273.5 | 265.8 | 267.7 | 269.0 | 4.01 |

| No. | The Most Probable Pore Sizes/nm | Total Porosity/% | The Porosity of the Different Pore Sizes/% | |||

|---|---|---|---|---|---|---|

| <10 nm | 10–100 nm | 100–1000 nm | >1000 nm | |||

| C-0.23 | 102.6 | 50.4 | 4.9 | 23.3 | 20.6 | 1.6 |

| C-0.27 | 26.0 | 45.1 | 3.4 | 39.4 | 0.6 | 1.7 |

| C-0.31 | 15.7 | 36.8 | 3.0 | 33.2 | 0.4 | 0.2 |

| C-0.35 | 12.1 | 30.8 | 5.5 | 23.9 | 0.2 | 1.2 |

| C-0.39 | 8.6 | 20.8 | 10.8 | 7.6 | 0.7 | 1.7 |

| M-1.0 | 13.5 | 33.7 | 3.9 | 27.5 | 0.4 | 1.9 |

| M-1.2 | 11.4 | 32.9 | 6.3 | 24.0 | 0.6 | 2.0 |

| M-1.4 | 15.7 | 36.8 | 3.0 | 33.2 | 0.4 | 0.2 |

| M-1.6 | 17.0 | 38.6 | 2.5 | 34.4 | 0.4 | 1.3 |

| M-1.8 | 24.4 | 40.1 | 2.2 | 36.5 | 0.4 | 1.0 |

| L/S-0.9 | 13.4 | 30.5 | 3.8 | 25.7 | 0.2 | 0.8 |

| L/S-1.1 | 15.7 | 36.8 | 3.0 | 33.2 | 0.4 | 0.2 |

| L/S-1.3 | 16.9 | 38.6 | 2.8 | 33.1 | 0.3 | 2.4 |

| L/S-1.5 | 18.1 | 42.0 | 2.2 | 37.6 | 0.3 | 1.9 |

| L/S-1.7 | 18.7 | 44.0 | 2.2 | 40.4 | 0.2 | 1.2 |

| No. | Ti 1(min) | Tf 2(min) | 28d fc 3(MPa) |

|---|---|---|---|

| C-0.23 | 116 | 121 | 19.1 |

| C-0.27 | 106 | 110 | 39.9 |

| C-0.31 | 91 | 100 | 46.4 |

| C-0.35 | 89 | 95 | 64.6 |

| C-0.39 | 85 | 90 | 74.8 |

| M-1.0 | 120 | 124 | 40.7 |

| M-1.2 | 104 | 108 | 49.4 |

| M-1.4 | 91 | 100 | 46.4 |

| M-1.6 | 88 | 92 | 40.7 |

| M-1.8 | 85 | 90 | 36.9 |

| L/S-0.9 | 68 | 73 | 46.8 |

| L/S-1.1 | 91 | 100 | 46.4 |

| L/S-1.3 | 115 | 121 | 43.4 |

| L/S-1.5 | 118 | 128 | 33.3 |

| L/S-1.7 | 226 | 230 | 25.8 |

| Code | L/S-1.7 (C-0.31, M-1.2) | C-0.27 (L/S-1.1, M-1.2) |

|---|---|---|

| Porosity (%) | 43.97 | 45.08 |

| Reaction extent (%) | 86.31 | 70.01 |

| Compressive strength (MPa) | 25.08 | 39.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, Q.; Tian, X.; Xie, G.; Luo, X.; Peng, H. Investigation of Setting Time and Microstructural and Mechanical Properties of MK/GGBFS-Blended Geopolymer Pastes. Materials 2022, 15, 8431. https://doi.org/10.3390/ma15238431

Zhong Q, Tian X, Xie G, Luo X, Peng H. Investigation of Setting Time and Microstructural and Mechanical Properties of MK/GGBFS-Blended Geopolymer Pastes. Materials. 2022; 15(23):8431. https://doi.org/10.3390/ma15238431

Chicago/Turabian StyleZhong, Qingyu, Xiang Tian, Guolun Xie, Xi Luo, and Hui Peng. 2022. "Investigation of Setting Time and Microstructural and Mechanical Properties of MK/GGBFS-Blended Geopolymer Pastes" Materials 15, no. 23: 8431. https://doi.org/10.3390/ma15238431

APA StyleZhong, Q., Tian, X., Xie, G., Luo, X., & Peng, H. (2022). Investigation of Setting Time and Microstructural and Mechanical Properties of MK/GGBFS-Blended Geopolymer Pastes. Materials, 15(23), 8431. https://doi.org/10.3390/ma15238431