Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties

Abstract

1. Introduction

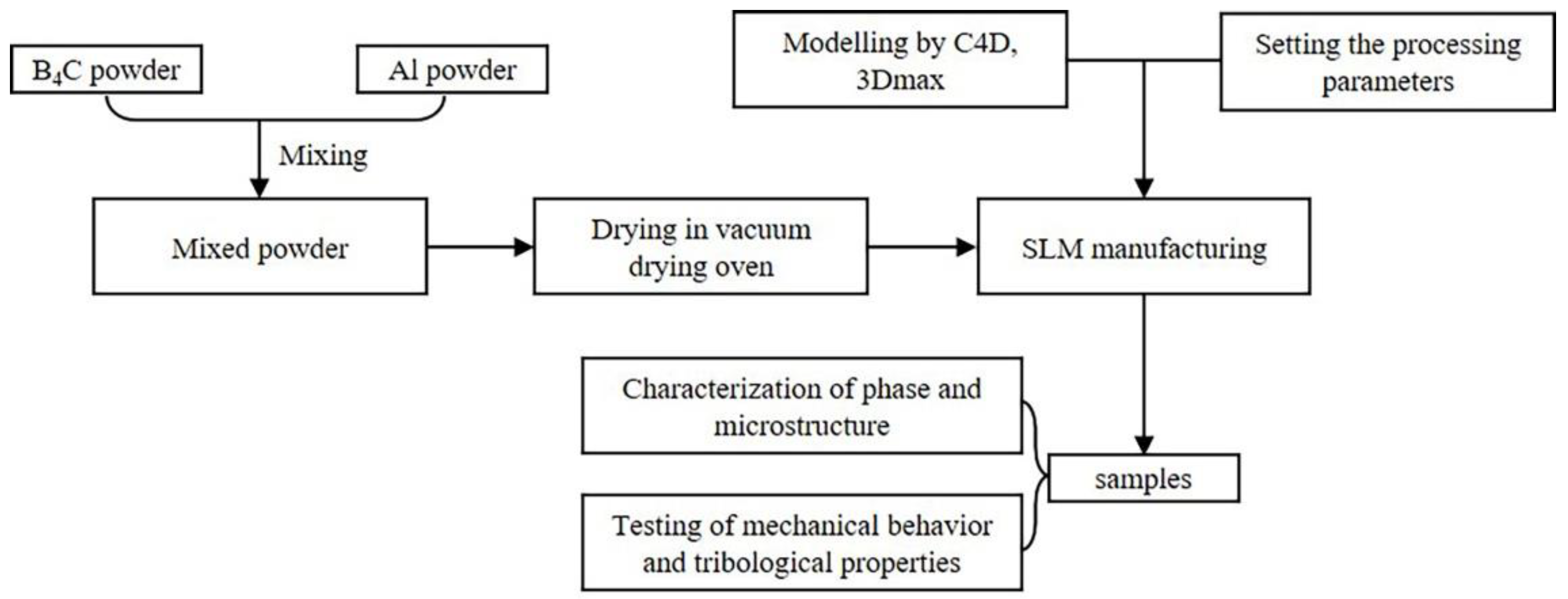

2. Experimental Procedure

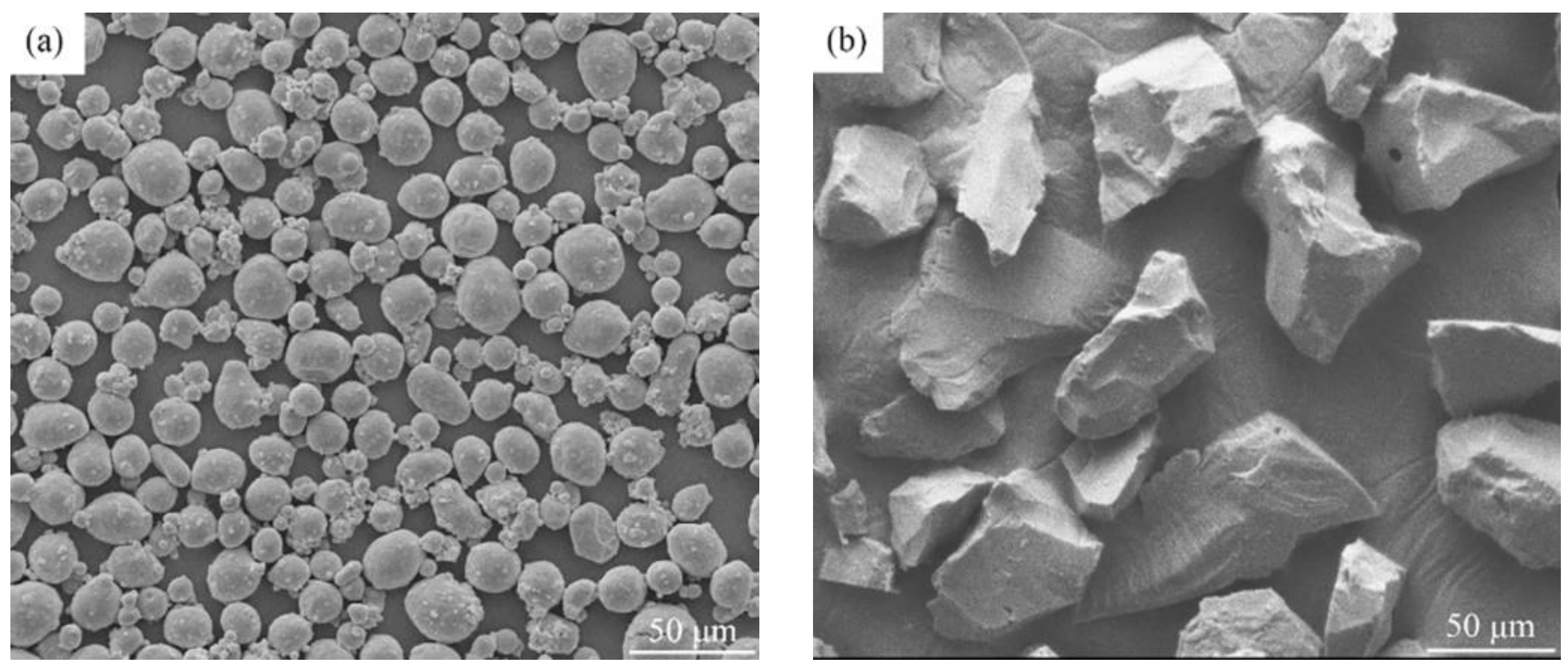

2.1. Raw Material Powder

2.2. SLM Processing

2.3. Phase and Microstructure

2.4. Mechanical Behaviour

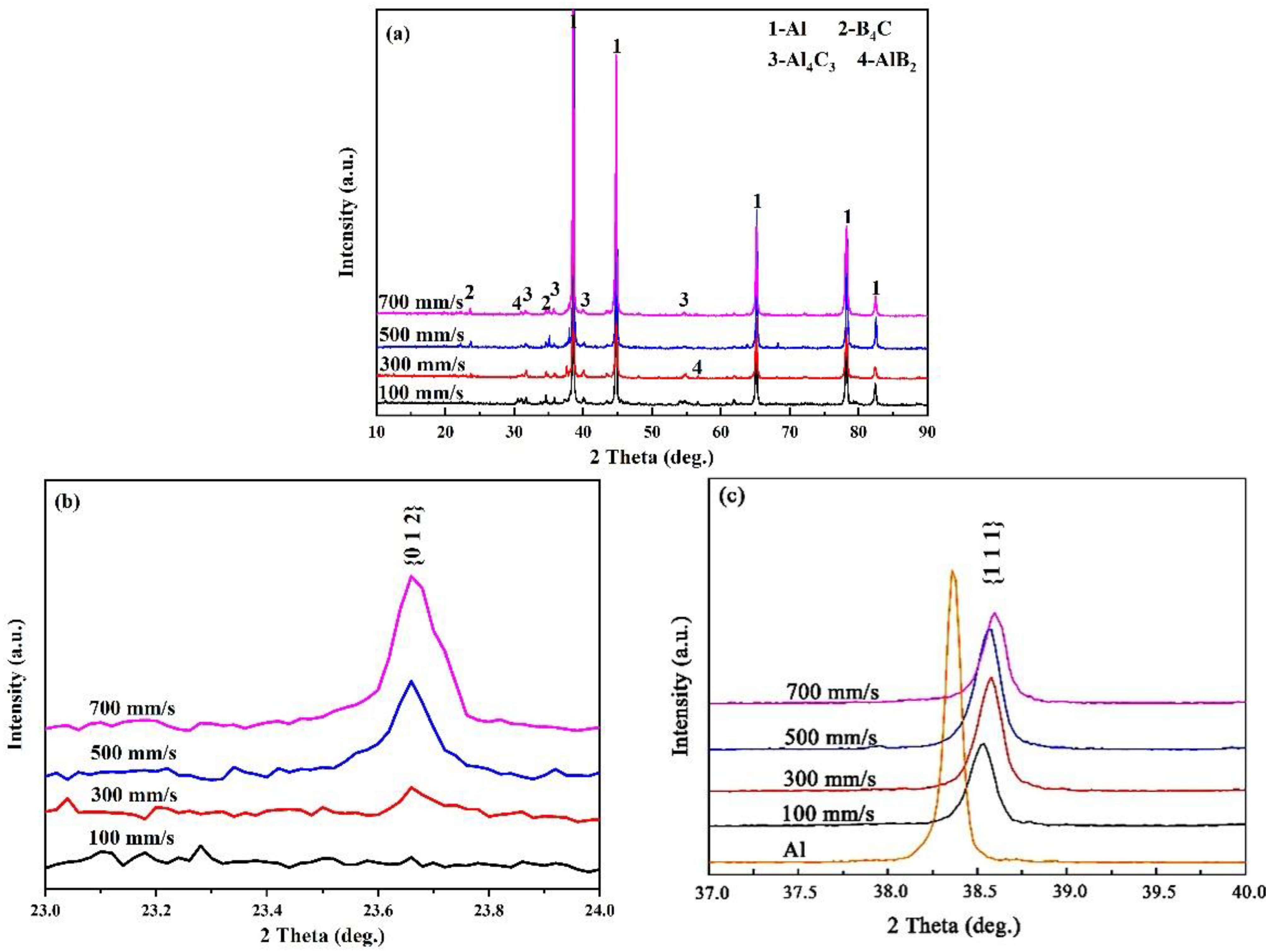

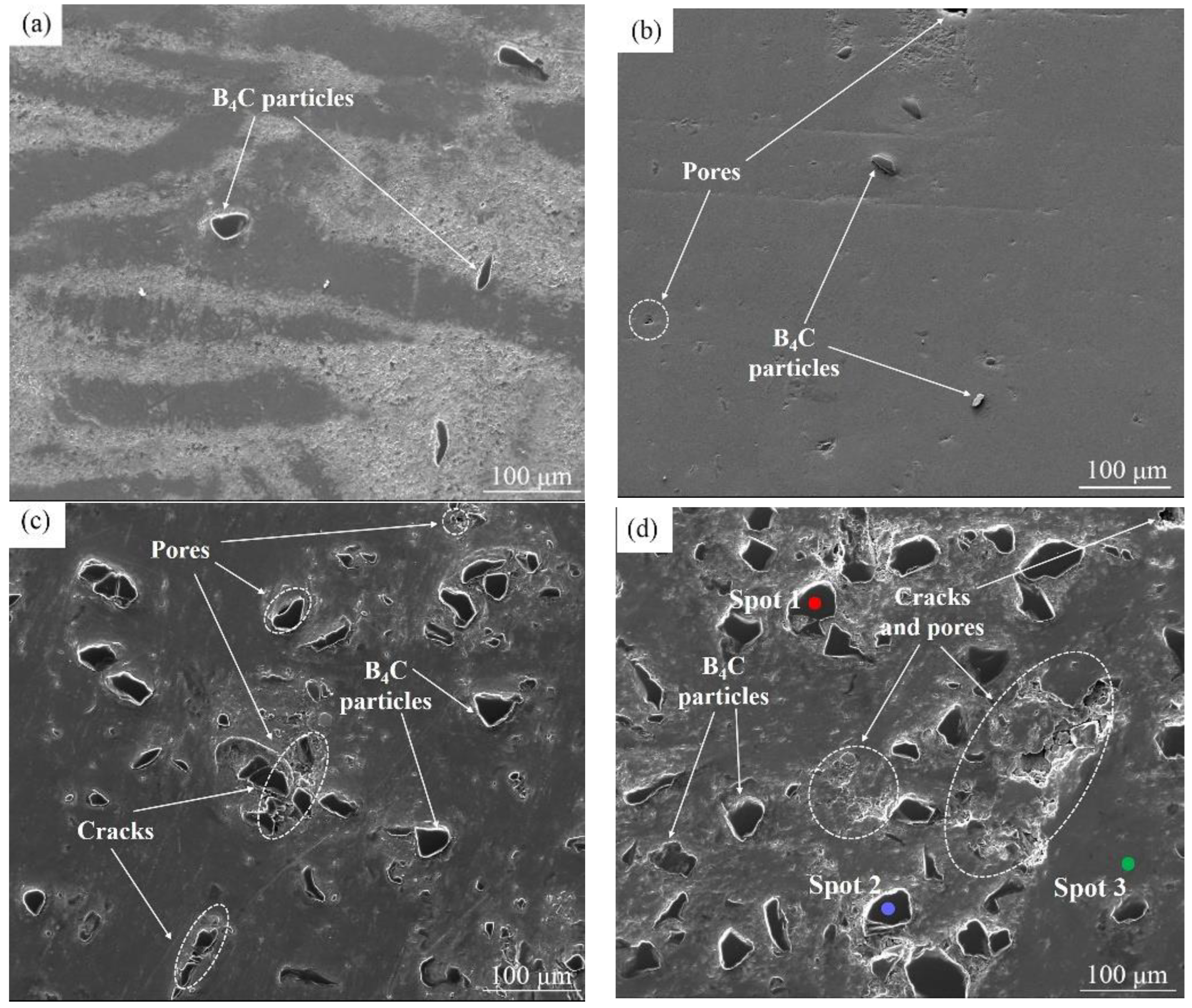

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Najafi, A.; Golestani-Fard, F.; Rezaie, H.R. Sol-gel synthesis and characterization of B4C nanopowder. Ceram. Int. 2018, 44, 21386–21394. [Google Scholar] [CrossRef]

- Najafi, A.; Golestani-Fard, F.; Rezaie, H.R.; Saeb, S.P. Sol-Gel synthesis and characterization of SiC–B4C nano powder. Ceram. Int. 2021, 47, 6376–6387. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Characterization of hybrid aluminum matrix composites for advanced applications—A review. J. Mater. Res. Technol. 2016, 5, 159–169. [Google Scholar] [CrossRef]

- Wu, H.B.; Zeng, F.H.; Yuan, T.; Zhang, F.Q.; Xiong, X. Wettability of 2519Al on B4C at 1000–1250 °C and mechanical properties of infiltrated B4C–2519Al composites. Ceram. Int. 2014, 40, 2073–2081. [Google Scholar] [CrossRef]

- Auradi, V.; Rajesh, G.L.; Kori, S.A. Preparation and evaluation of mechanical properties of 6061Al–B4Cp composites produced via two-stage melt stirring. Adv. Manuf. Process. 2014, 29, 194–200. [Google Scholar] [CrossRef]

- Chen, M.; Liu, Z. Ultrasound assisted casting method for fabricating B4Cp/Al composites with the addition of K2ZrF6. Mater. Lett. 2020, 280, 128545. [Google Scholar] [CrossRef]

- Karabulut, Y.; Ünal, R. Additive manufacturing of ceramic particle-reinforced aluminum-based metal matrix composites: A review. J. Mater. Sci. 2022, 57, 19212–19242. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Liu, J.; Zhou, Y.; Li, M.; Wen, S.F.; Wei, Q.S.; Yan, C.Z.; Shi, Y.S. Enhanced nanohardness and new insights into texture evolution and phase transformation of TiAl/TiB2 in-situ metal matrix composites prepared via selective laser melting. Acta. Mater. 2017, 136, 90–104. [Google Scholar] [CrossRef]

- Xi, L.; Wang, P.; Prashanth, K.G.; Li, H.; Prykhodko, H.V.; Scudino, S.; Kaban, I. Effect of TiB2 particles on microstructure and crystallographic texture of Al-12Si fabricated by selective laser melting. J. Alloys Compd. 2019, 786, 551–556. [Google Scholar] [CrossRef]

- Dan, C.Y.; Chen, Z.; Mathon, M.H.; Ji, G.; Li, L.W.; Wu, Y.; Brisset, F.; Guo, L.; Wang, H.W.; Ji, V. Cold rolling texture evolution of TiB2 particle reinforced Al-based composites by Neutron Diffraction and EBSD analysis. Mater. Charact. 2018, 136, 293–301. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium–titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Almangour, B.; Baek, M.S.; Grzesiak, D.; Lee, K.A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Li, W.; Sun, R.; Wang, P.; Li, X.L.; Sakai, T. Subsurface faceted cracking behavior of selective laser melting Ni-based superalloy under very high cycle fatigue. Scr. Mater. 2021, 194, 113613. [Google Scholar] [CrossRef]

- Nong, X.D.; Zhou, X.L.; Ren, Y.X. Fabrication and characterization of Fe-based metallic glasses by selective laser melting. Opt. Laser Technol. 2019, 109, 20. [Google Scholar] [CrossRef]

- Lamagna, L.; Paiella, A.; Masi, S.; Bottini, L.; Boschetto, A.; Veniali, F. Selective laser melting process of Al–based pyramidal horns for the W-band: Fabrication and testing. J. Infrared Millim. Terahertz Waves 2021, 42, 154–172. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Lober, L.; Wang, Z.; Chaubey, A.K.; Kuhn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Jue, J.; Gu, D.; Chang, K.; Dai, D. Microstructure evolution and mechanical properties of Al-Al2O3 composites fabricated by selective laser melting. Powder Technol. 2017, 310, 80–91. [Google Scholar] [CrossRef]

- Shang, Y.; Yuan, Y.; Li, D.; Li, Y.; Chen, J. Effects of scanning speed on in vitro biocompatibility of 316L stainless steel parts elaborated by selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 92, 4379–4385. [Google Scholar] [CrossRef]

- Ni, X.; Kong, D.; Wu, W.; Liang, Z.; Dong, C.; He, B.; Lin, L.; Wu, K.; Zhu, D. Corrosion behavior of 316L stainless steel fabricated by selective laser melting under different scanning speeds. J. Mater. Eng. Perform. 2018, 27, 3667–3677. [Google Scholar] [CrossRef]

- Lu, Y.; Gan, Y.; Lin, J.; Guo, S.; Wu, S.; Lin, J. Effect of laser speeds on the mechanical property and corrosion resistance of CoCrW alloy fabricated by SLM. Rapid. Prototyp. J. 2017, 23, 28. [Google Scholar] [CrossRef]

- Matras, A. Research and optimization of surface roughness in milling of SLM semi-finished parts manufactured by using the different laser scanning speed. Materials 2020, 13, 9. [Google Scholar] [CrossRef] [PubMed]

- Sadali, M.F.; Hassan, M.Z.; Ahmad, F.; Yahaya, H.; Rasid, Z.A. Influence of selective laser melting scanning speed parameter on the surface morphology, surface roughness, and micropores for manufactured Ti6Al4V parts. J. Mater. Res. 2020, 35, 2025–2035. [Google Scholar] [CrossRef]

- Xie, H.B.; Zhang, J.L.; Li, F.L.; Yuan, G.Q.; Zhu, Q.; Jia, Q.L.; Zhang, H.J.; Zhang, S.W. Selective laser melting of SiCp/Al composites: Densification, microstructure, and mechanical and tribological properties. Ceram. Int. 2021, 47, 30826–30837. [Google Scholar] [CrossRef]

- Viala, J.C.; Bouix, J.; Gonzalez, G.; Esnouf, C. Chemical reactivity of aluminium with boron carbide. J. Mater. Sci. 1997, 32, 4559–4573. [Google Scholar] [CrossRef]

- Tonelli, L.; Fortunato, A.; Ceschini, L. CoCr alloy processed by selective laser melting (SLM): Effect of laser energy density on microstructure, surface morphology, and hardness. J. Manuf. Process. 2020, 52, 106–119. [Google Scholar] [CrossRef]

- Fei, C.; Gu, D.; Dai, D.; Yuan, P. Selective laser melting of in-situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Almangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- Anthes, J.P.; Palmer, M.A.; Gusinow, M.A.; Matzen, M.K. Absorption of laser radiation by Al, Fe, and Au planar metallic targets. Appl. Phys. Lett. 1979, 34, 841. [Google Scholar] [CrossRef]

- Fischer, P.; Romano, V.; Weber, H.P.; Karapatis, N.P.; Boillit, E.; Glardon, R. Sintering of commercially pure titanium powder with a Nd:YAG laser source. Acta Mater. 2003, 51, 1651–1662. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Liao, Q.; Wei, W.; Zuo, H.; Li, X.; Wu, G. Interfacial bonding enhancement and properties improvement of carbon/copper composites based on nickel doping. Compos. Interfaces 2020, 28, 637–649. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Lee, S.K.; Kim, Y.; Cho, S. Experimental and thermodynamic study on interfacial reaction of B4C–Al6061 composites fabricated by stir casting process. J. Alloys Compd. 2020, 859, 157813. [Google Scholar] [CrossRef]

- El-Kady, O.; Fathy, A. Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater. Des. 2014, 54, 348–353. [Google Scholar] [CrossRef]

- Yang, H.Y.; Wang, Z.; Chen, L.Y.; Shu, S.L.; Zhang, L.C. Interface formation and bonding control in high-volume-fraction (TiC+TiB2)/Al composites and their roles in enhancing properties. Compos. Part B Eng. 2021, 209, 108605. [Google Scholar] [CrossRef]

- Laorden, L.M.; Rodrigo, P.; Torres, B.; Rams, J. Modification of microstructure and superficial properties of A356 and A356/10%SiCp by selective laser surface melting (SLSM). Surf. Coat. Technol. 2017, 309, 1001–1009. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, G.; Yang, C.; Zhou, W.; Sun, B. Novel selective laser melting processed in-situ TiC particle-reinforced Ni matrix composite with excellent processability and mechanical properties. Mater. Sci. Eng. A 2020, 797, 140145. [Google Scholar] [CrossRef]

- Wilson, S.; Alpas, A.T. Thermal effects on mild wear transitions in dry sliding of an aluminum alloy. Wear 1999, 225–229, 440–449. [Google Scholar] [CrossRef]

- Aleksander, J.P.; Beaman, D.R. Al-B-C phase development and effects on mechanical properties of B4C/Al-Derived composites. J. Am. Ceram. Soc. 1995, 78, 305–312. [Google Scholar] [CrossRef]

- Peng, Z.; Li, Y.; Wang, W.; Gao, Z.; Wang, B. The design, fabrication and properties of B4C/Al neutron absorbers. J. Nucl. Mater. 2013, 437, 350–358. [Google Scholar] [CrossRef]

- Chen, H.S.; Wang, W.X.; Li, Y.L.; Zhou, J.; Nie, H.H.; Wu, Q.C. The design, microstructure and mechanical properties of B4C/6061Al neutron absorber composites fabricated by SPS. Mater. Des. 2016, 94, 360–367. [Google Scholar] [CrossRef]

- Li, Y.Z.; Wang, Q.Z.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Interfacial reaction mechanism between matrix and reinforcement in B4C/6061Al composites. Mater. Chem. Phys. 2015, 154, 107–117. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Perumal, A.E. Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos. Part B Eng. 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Sufizadeh, A.R.; Emamy, M. The effect of strontium on the microstructure and wear properties of A356–10%B4C cast composites. Mater. Des. 2010, 31, 2187–2195. [Google Scholar] [CrossRef]

- Canakci, A. Microstructure and abrasive wear behaviour of B4C particle reinforced 2014 Al matrix composites. J. Mater. Sci. 2008, 46, 2805–2813. [Google Scholar] [CrossRef]

- Tang, F.; Wu, X.; Ge, S.; Ye, J.; Zhu, H.; Hagiwara, M.; Schoenung, J.M. Dry sliding friction and wear properties of B4C particulate-reinforced Al-5083 matrix composites. Wear 2008, 264, 555–561. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Meratian, M.; Emadi, R.; Najarian, A.R. Comparison of microstructural and mechanical properties of Al–TiC, Al–B4C and Al–TiC–B4C composites prepared by casting techniques. Mater. Sci. Eng. A 2013, 560, 278–287. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Haseeb, A.S.M.A.; Celis, J.P. Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear 2006, 261, 634–641. [Google Scholar] [CrossRef]

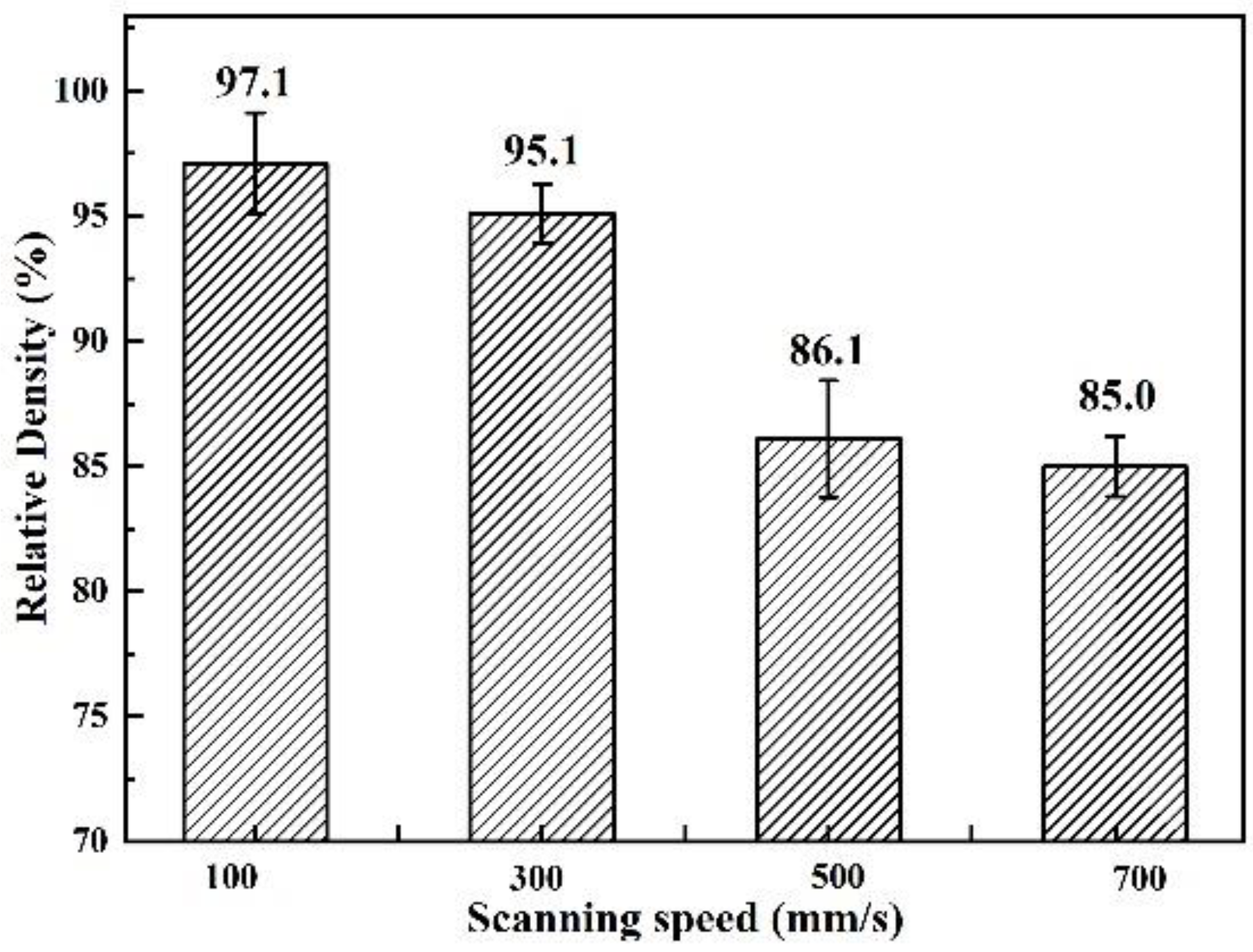

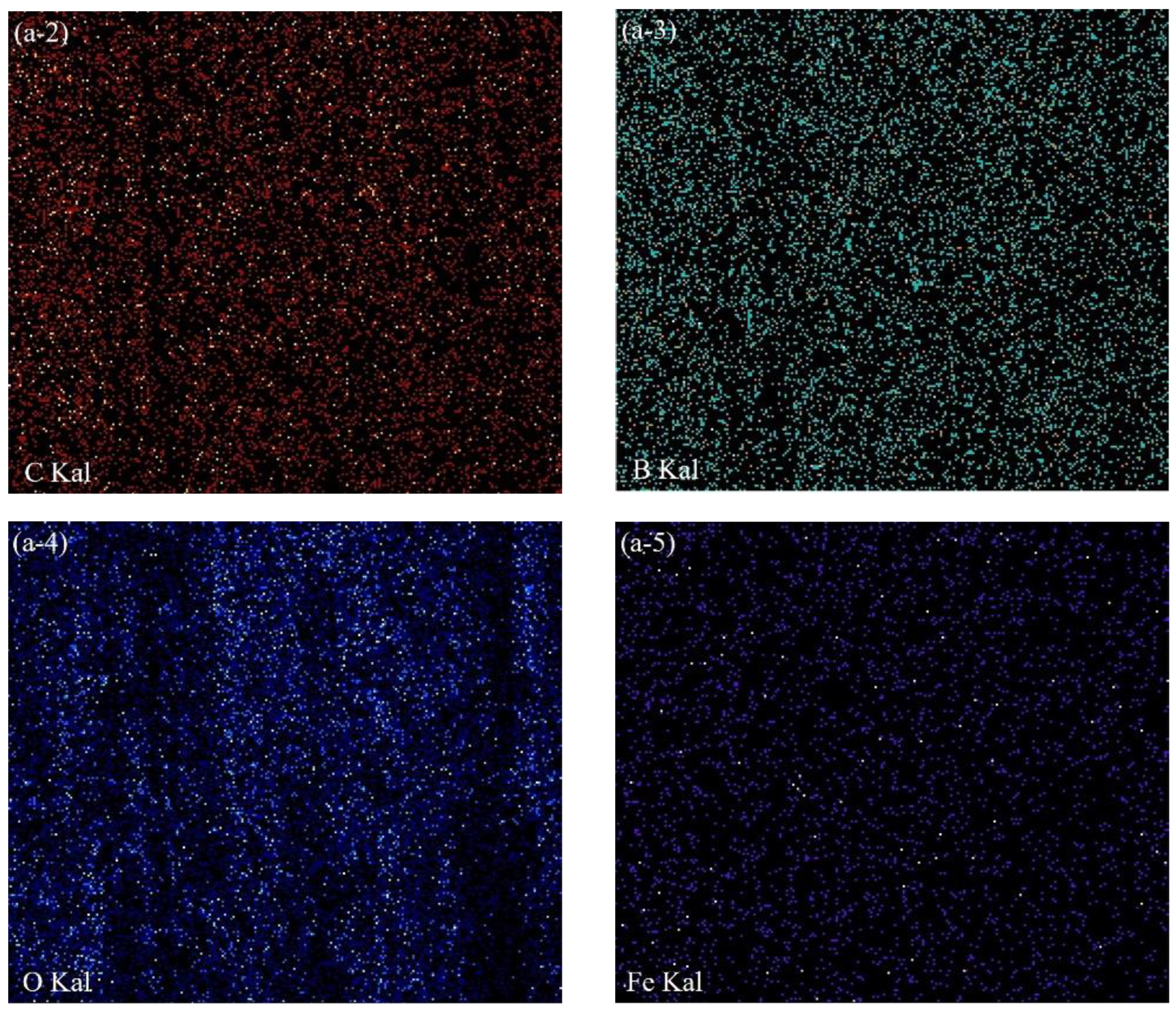

| No. | Laser Power [W] | Scanning Speed [mm/s] | Hatch Space [mm] | Layer Thickness [mm] | Energy Density [J/mm3] |

|---|---|---|---|---|---|

| 1 | 250 | 100 | 0.05 | 0.05 | 1000 |

| 2 | 300 | 333 | |||

| 3 | 500 | 200 | |||

| 4 | 700 | 143 |

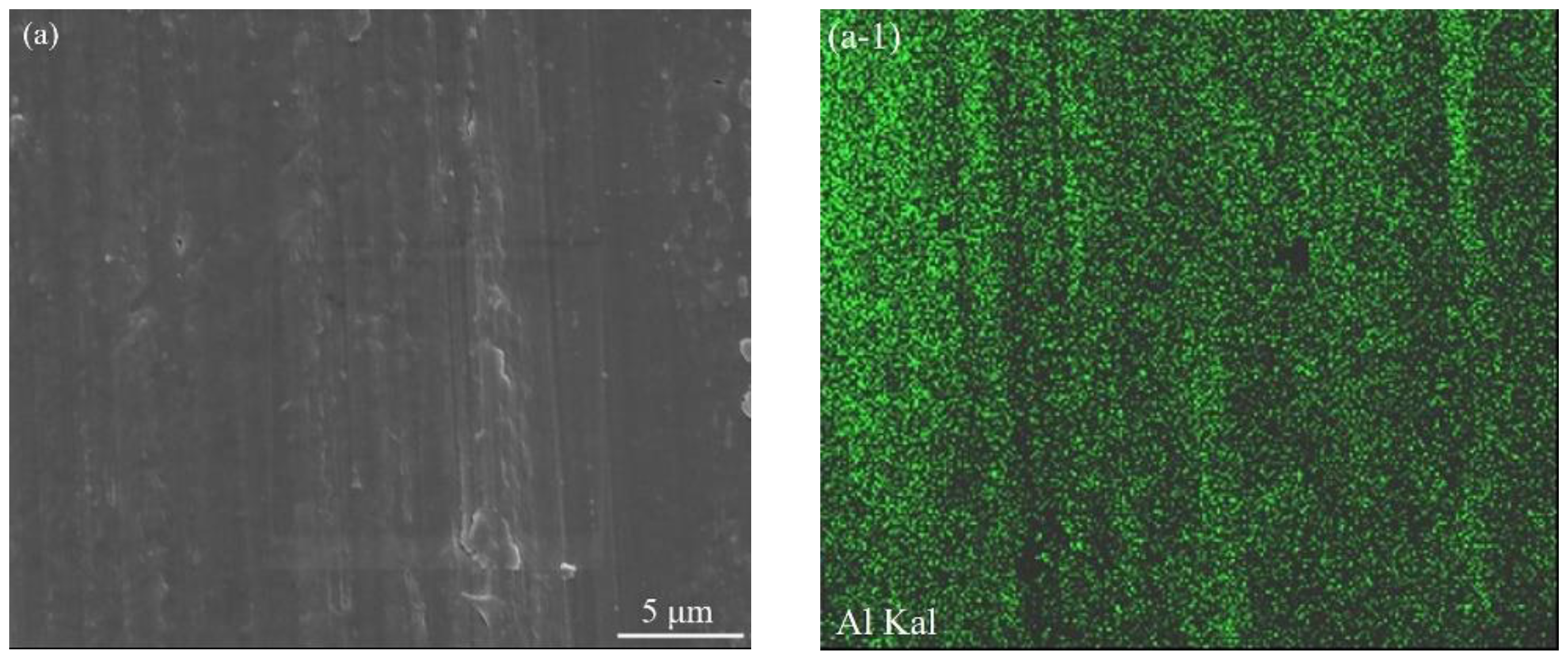

| Spot No. | Atomic Content/% | |||

|---|---|---|---|---|

| B | C | Al | O | |

| Spot 1 | 79.3 | 18.2 | 2.5 | 0 |

| Spot 2 | 78.5 | 19.0 | 2.5 | 0 |

| Spot 3 | 0 | 0 | 89.1 | 10.9 |

| Method | Matrix | B4C Fraction | Relative Density | Hardness | Wear Rate | Friction Coefficient | Ref. |

|---|---|---|---|---|---|---|---|

| Post densification heat treatment | Pure Al | 70 vol.% | N/A | 81 HRA | N/A | N/A | [38] |

| Hot-press infiltrate | 6061Al alloy | 30 wt.% | 98% | 123.6 HV0.5 | N/A | N/A | [39] |

| Spark plasma sintering | 6061Al alloy | 20 vol.% | 99.32% | 146 HV1 | N/A | N/A | [40] |

| Powder metallurgy technique | 6061Al alloy | 20 wt.% | N/A | 40 HRB | N/A | N/A | [41] |

| Casting technique | AA7075 alloy | 10 vol.% | N/A | 175 BHN | 7 × 10−6 g/m | 0.327 | [42] |

| Stir-casting technique | A356 alloy | 10 vol.% | N/A | N/A | 2.1 × 10−3 mg/m | N/A | [43] |

| Stir-casting technique | AA2014 alloy | 12 vol.% | 91.75% | 107 BHN | N/A | N/A | [44] |

| Hot isostatic pressing | AA5083 alloy | 10 wt.% | N/A | N/A | N/A | 0.41 | [45] |

| Squeeze-casting technique | Pure Al | 10 vol.% | N/A | 51 ± 3 HV5 | N/A | 0.31 | [46] |

| Stir-casting technique | Pure Al | 13 vol.% | 91.75% | N/A | 4.23 × 10−4 mm3/m | N/A | [47] |

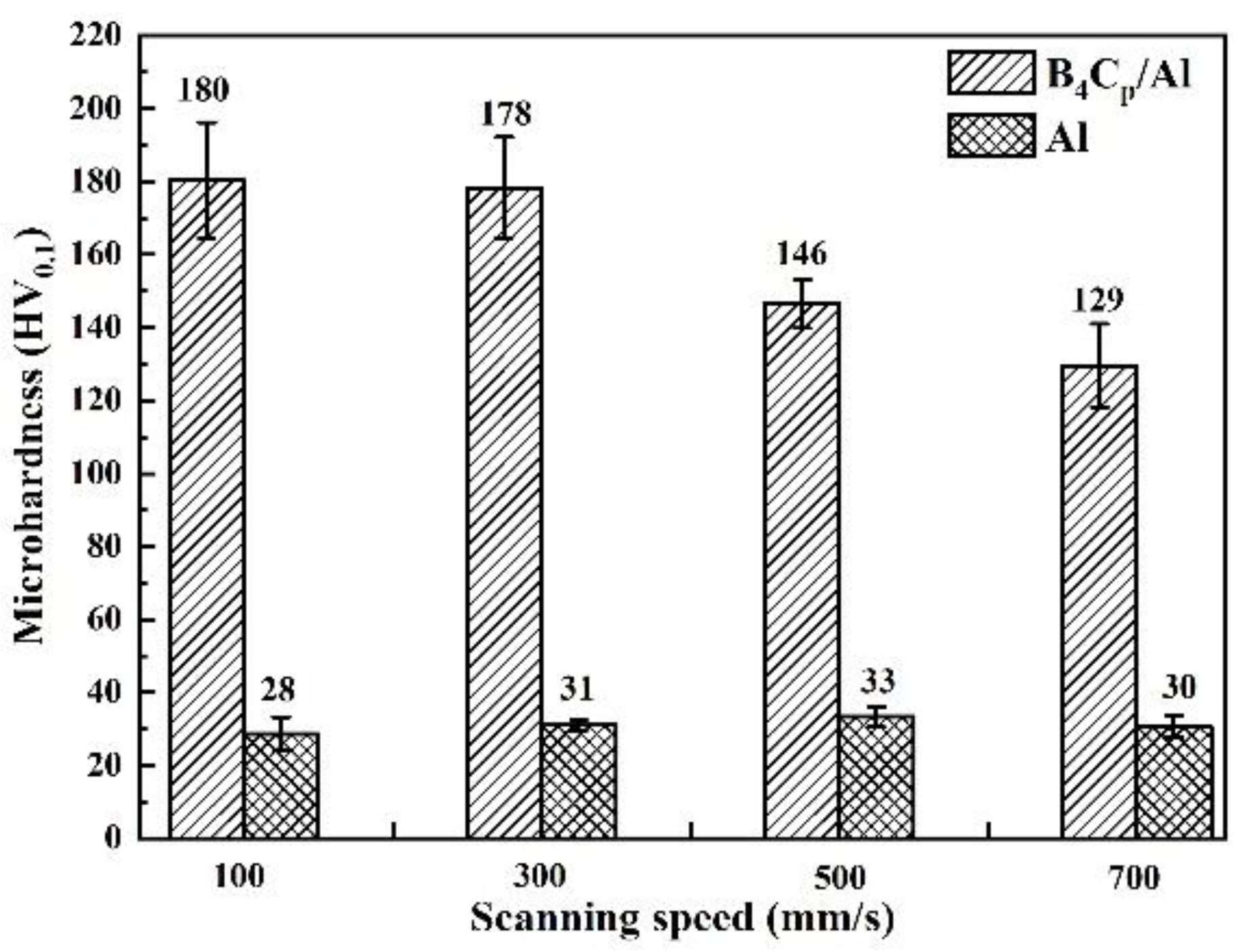

| SLM | Pure Al | 20 wt.% | 97.1% | 180 HV0.1 | 4.2 × 10−5 mm3/(N m) | 0.41 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Zhang, J.; Xie, H.; Li, F.; Huang, Z.; Yuan, G.; Zhang, J.; Jia, Q.; Zhang, H.; Yeprem, H.A.; et al. Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties. Materials 2022, 15, 8340. https://doi.org/10.3390/ma15238340

Yang G, Zhang J, Xie H, Li F, Huang Z, Yuan G, Zhang J, Jia Q, Zhang H, Yeprem HA, et al. Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties. Materials. 2022; 15(23):8340. https://doi.org/10.3390/ma15238340

Chicago/Turabian StyleYang, Guodong, Jialian Zhang, Houbo Xie, Faliang Li, Zhong Huang, Gaoqian Yuan, Jingzhe Zhang, Quanli Jia, Haijun Zhang, Hasibe Aygul Yeprem, and et al. 2022. "Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties" Materials 15, no. 23: 8340. https://doi.org/10.3390/ma15238340

APA StyleYang, G., Zhang, J., Xie, H., Li, F., Huang, Z., Yuan, G., Zhang, J., Jia, Q., Zhang, H., Yeprem, H. A., & Zhang, S. (2022). Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties. Materials, 15(23), 8340. https://doi.org/10.3390/ma15238340