Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties

Abstract

1. Introduction

Study Significance

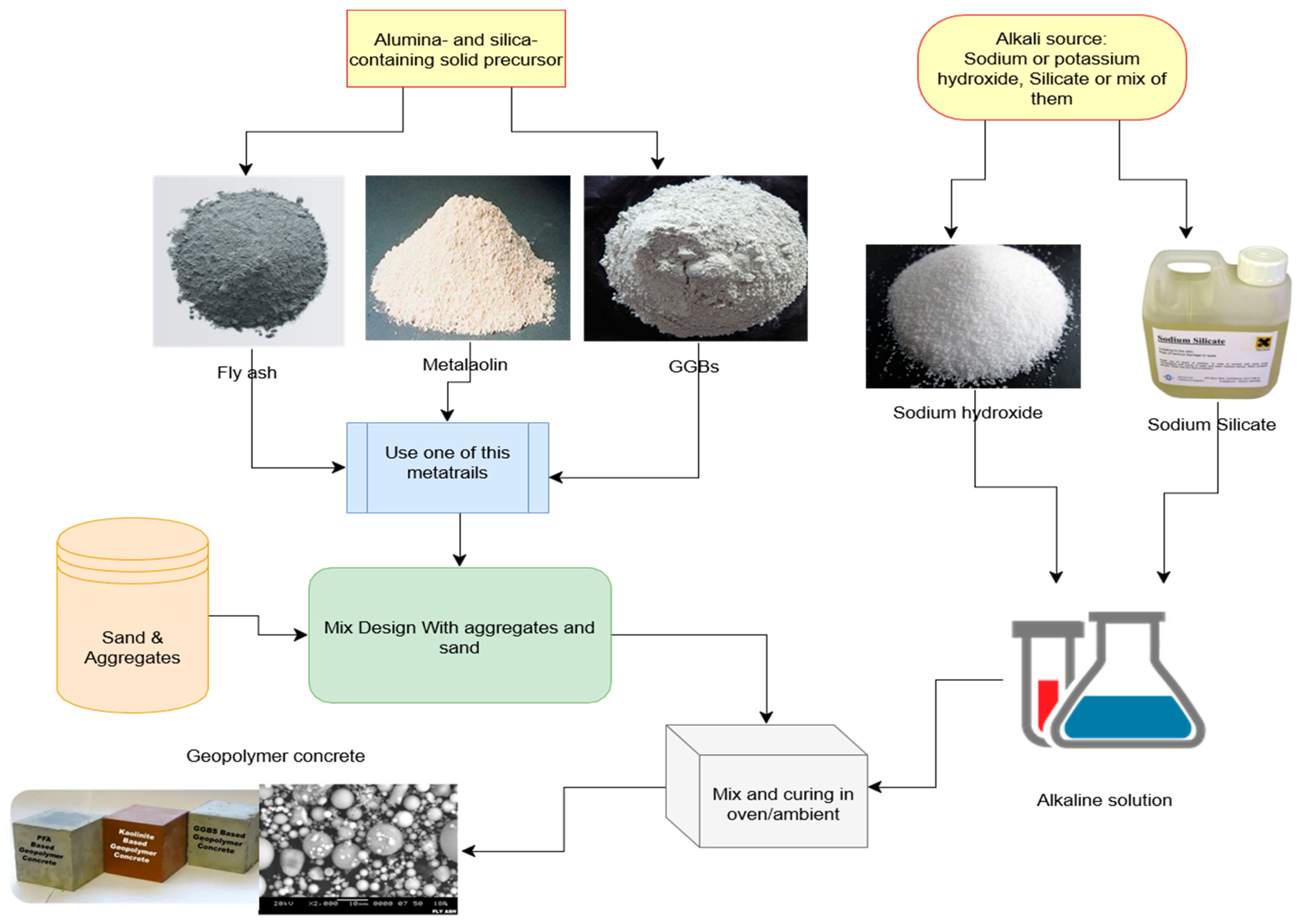

2. Geopolymer Mortar (GPM)

2.1. Fresh Geopolymer Mortar Properties

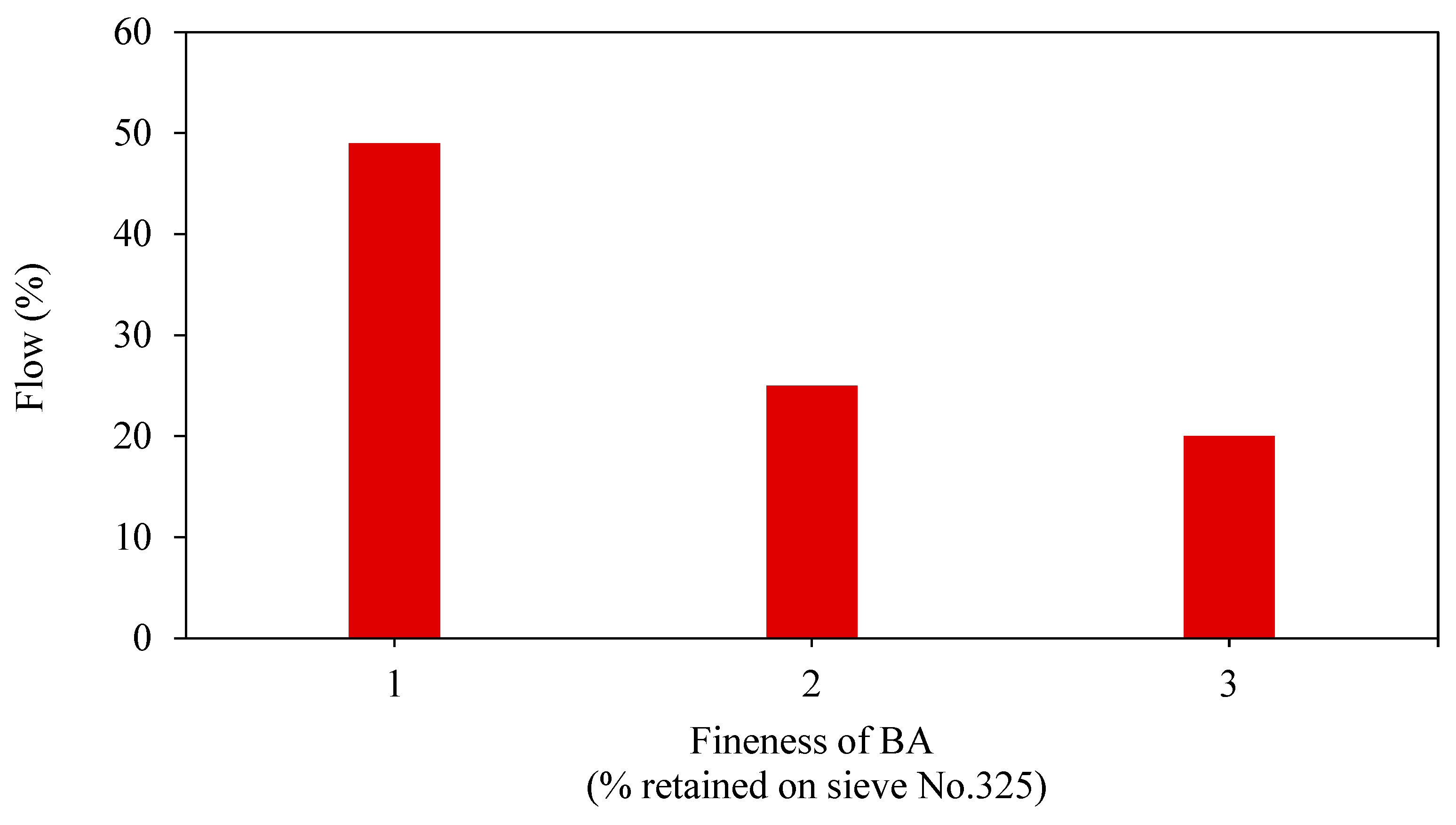

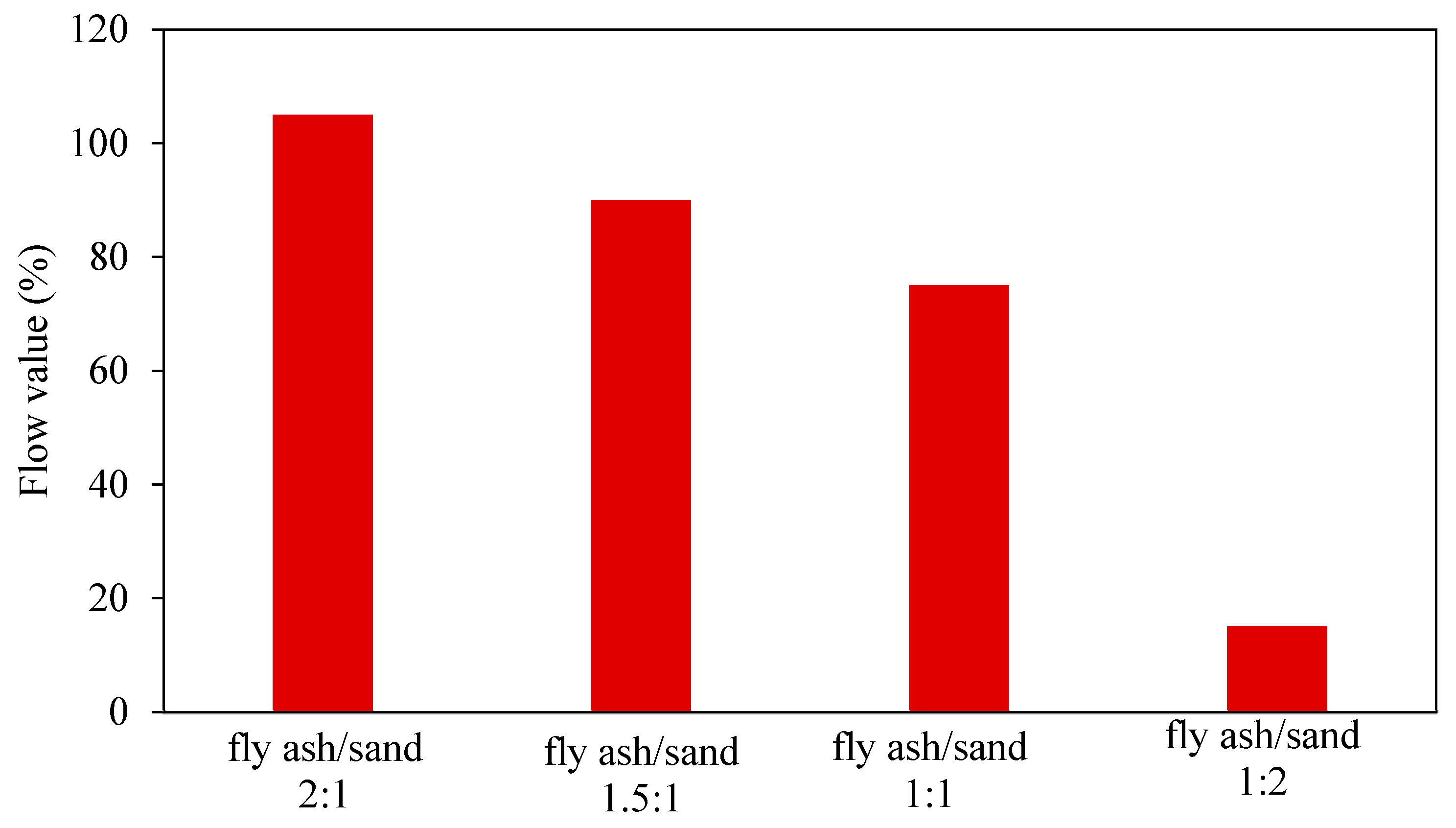

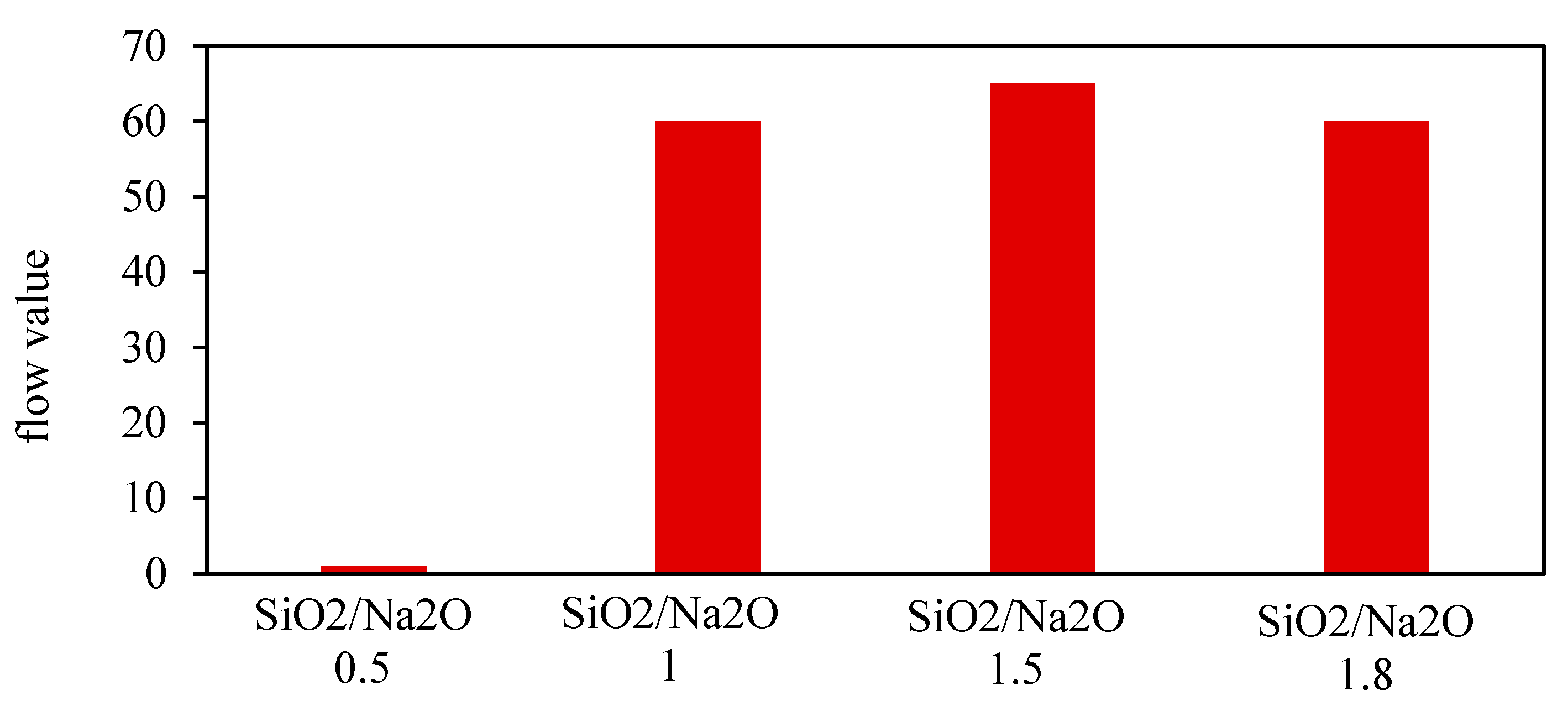

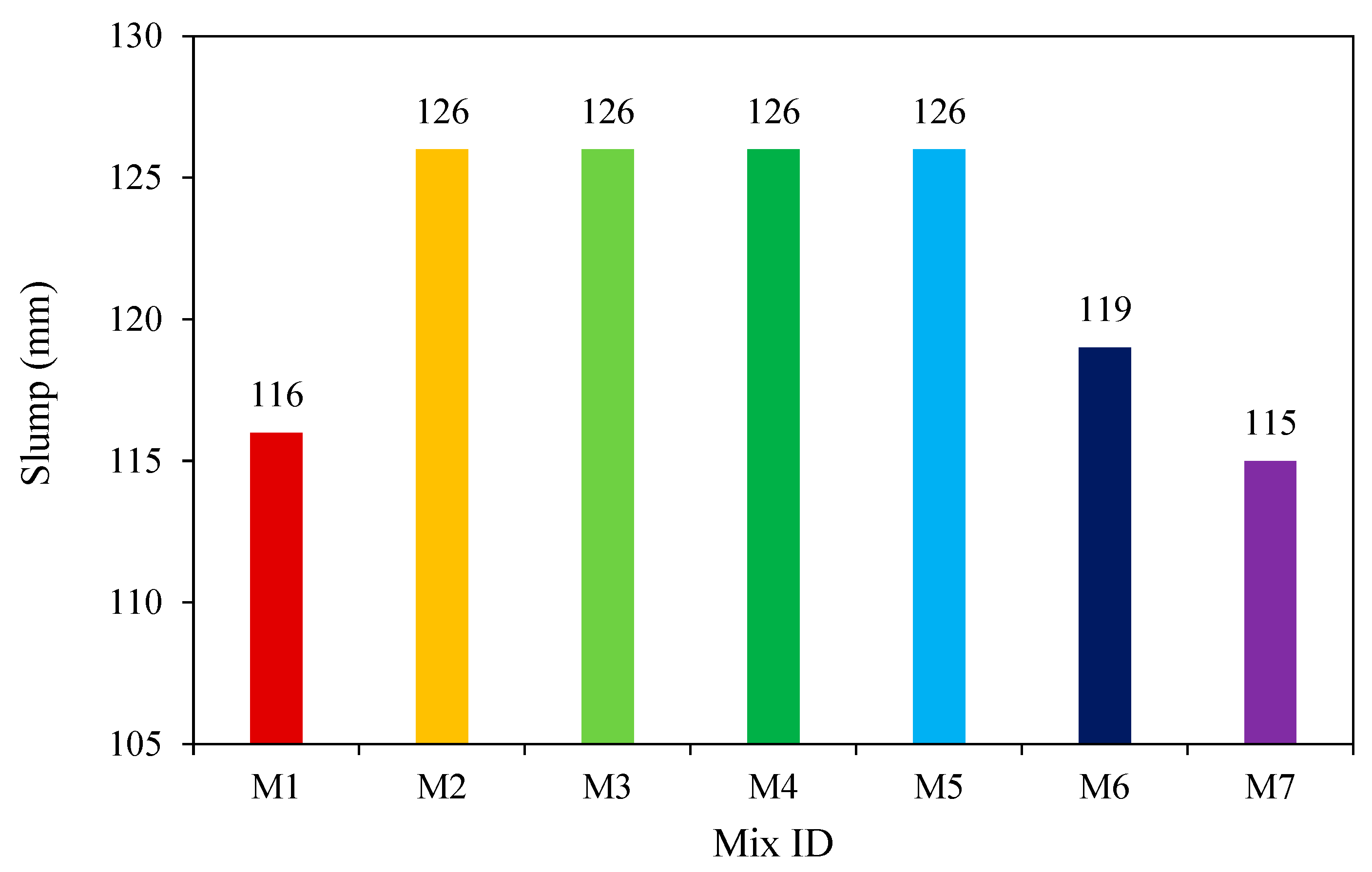

2.1.1. Fresh Geopolymer Mortar Workability

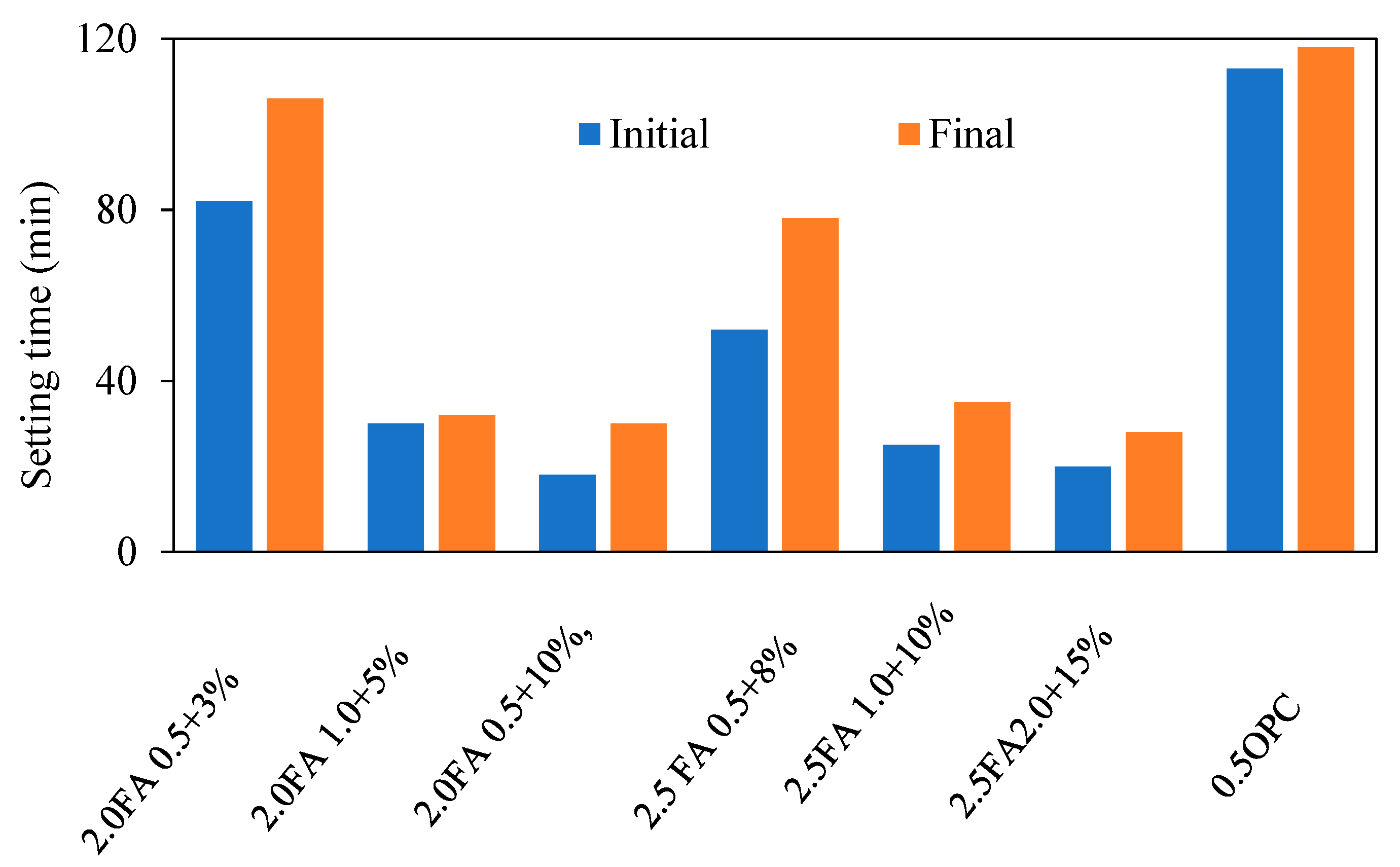

2.1.2. Fresh Geopolymer Mortar Setting Time

2.2. Geopolymer Mortar Mechanical Properties

2.2.1. Geopolymer Mortar Compressive Strength

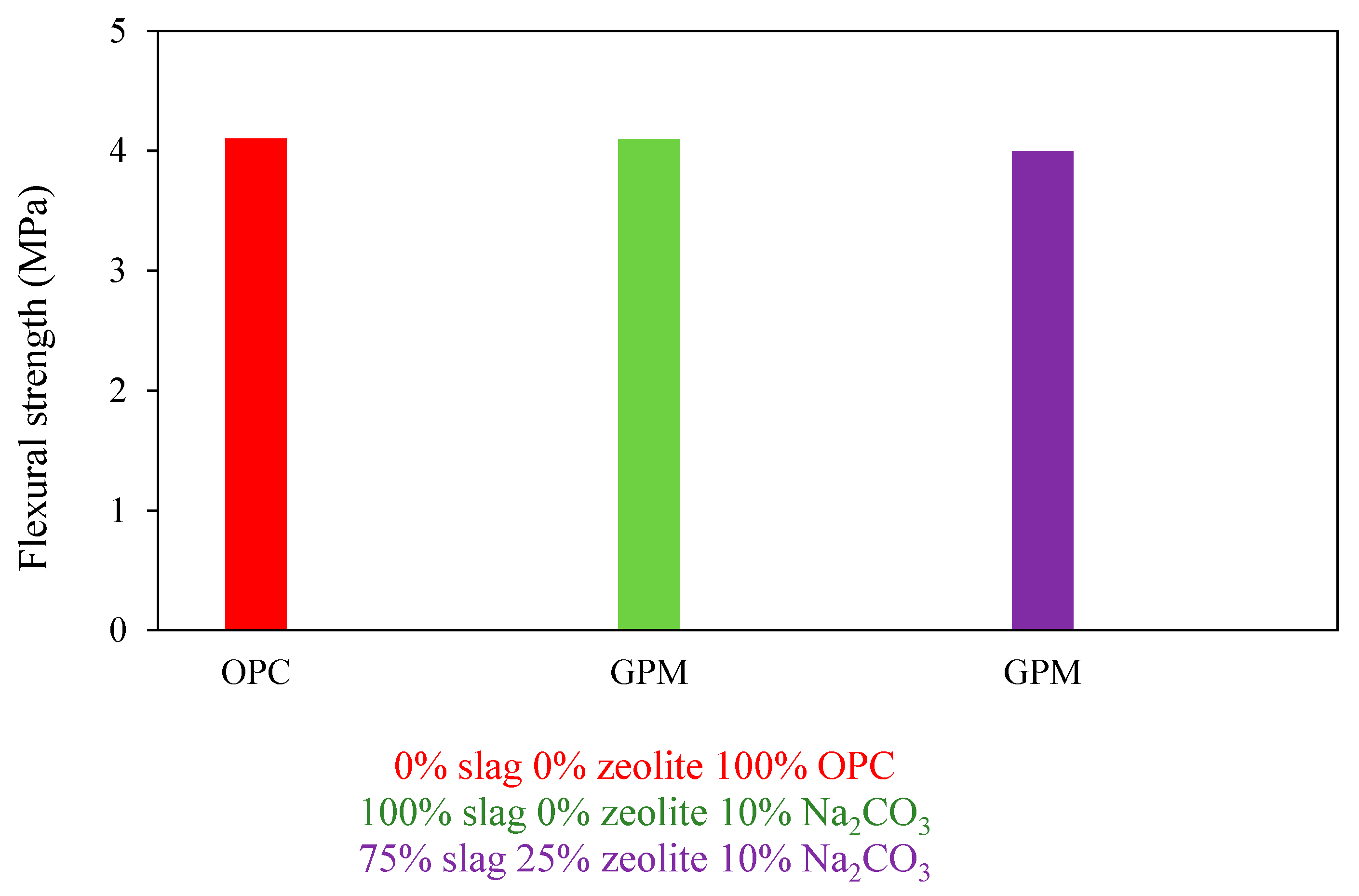

2.2.2. Geopolymer Mortar Flexural Strength

3. Geopolymer Concrete (GPC)

3.1. Fresh Properties of Geopolymer Concrete

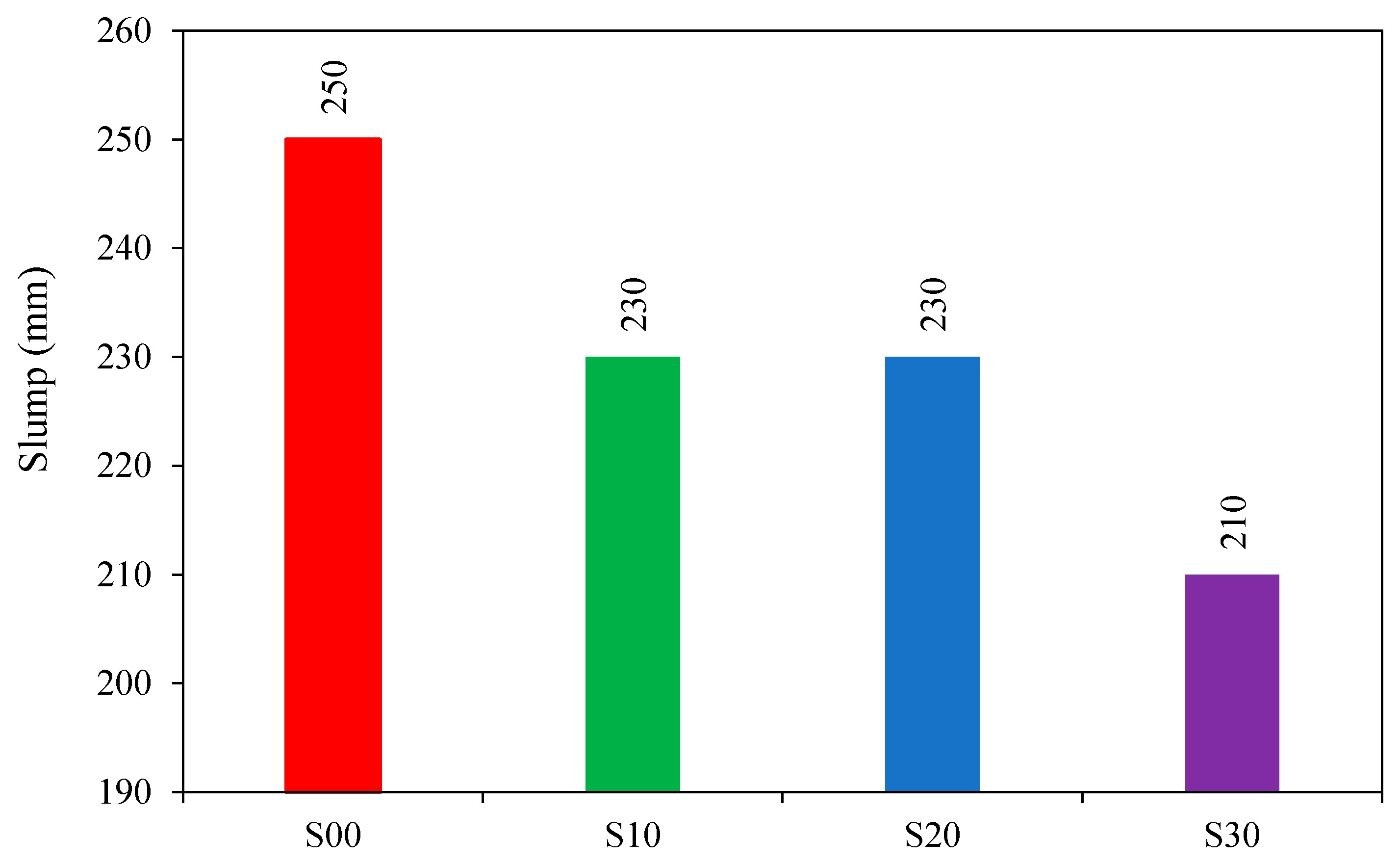

3.1.1. Geopolymer Concrete Workability

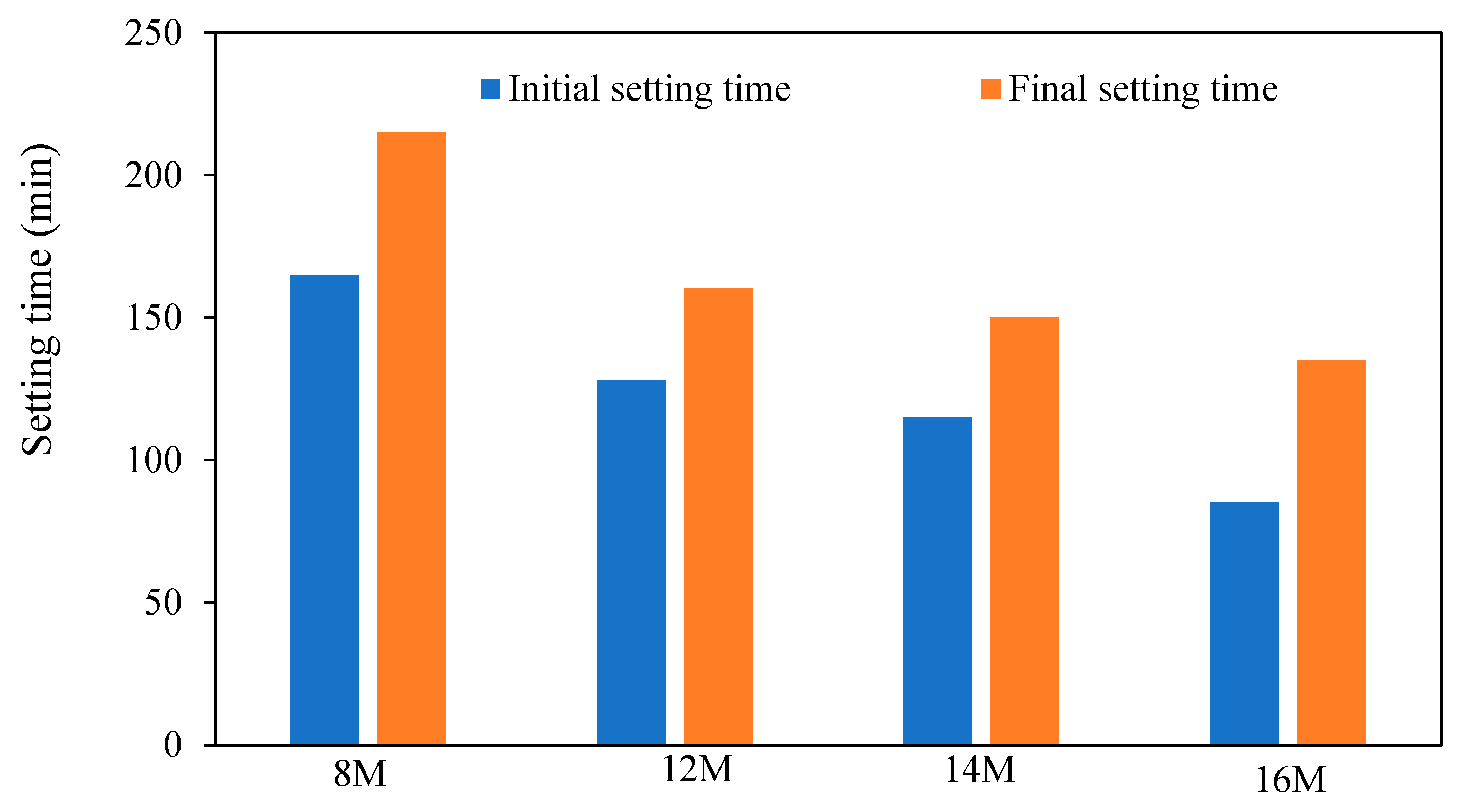

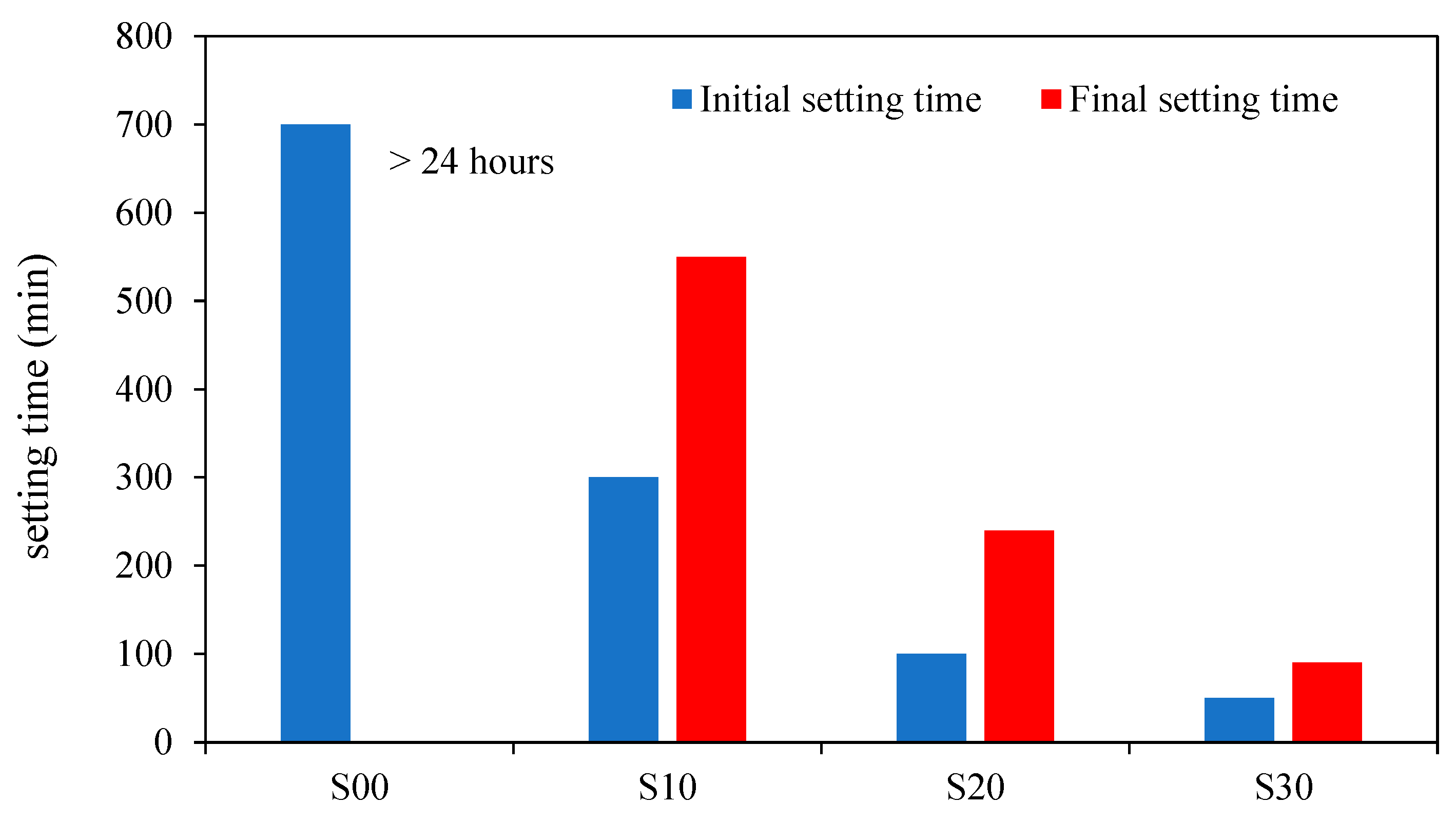

3.1.2. Geopolymer Concrete Setting Time

3.2. Mechanical Properties of Hardened Geopolymer Concrete

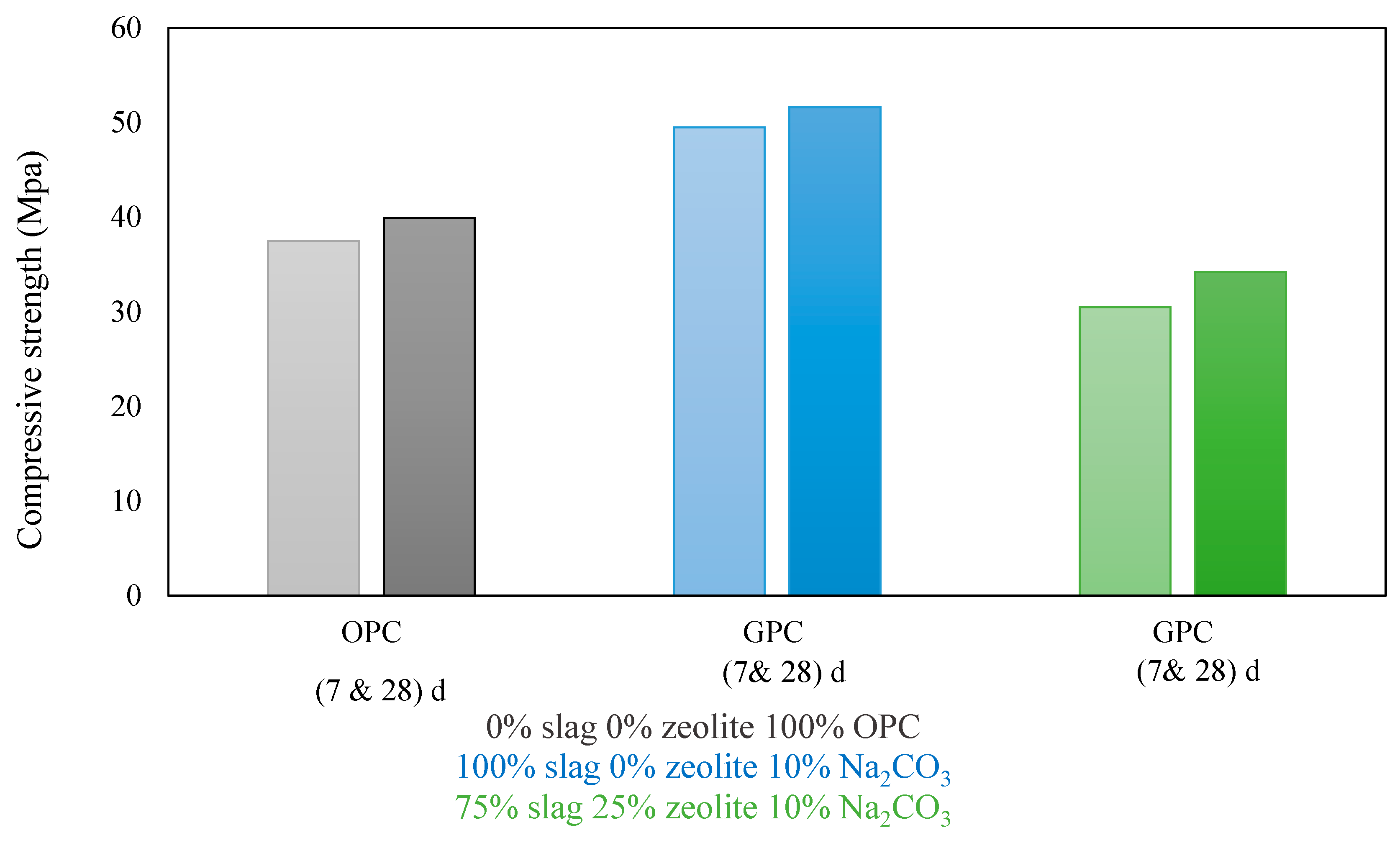

3.2.1. Compressive Strength

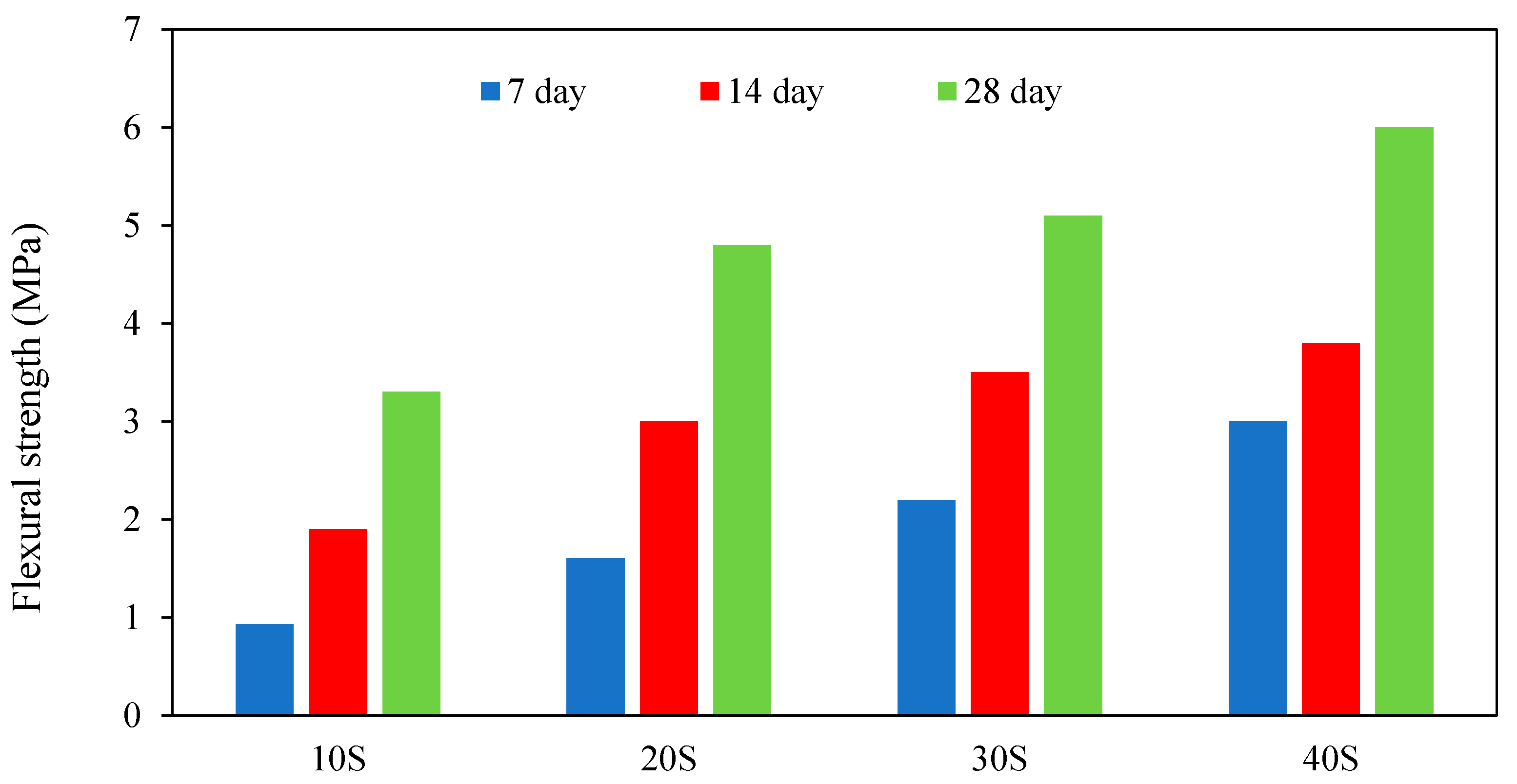

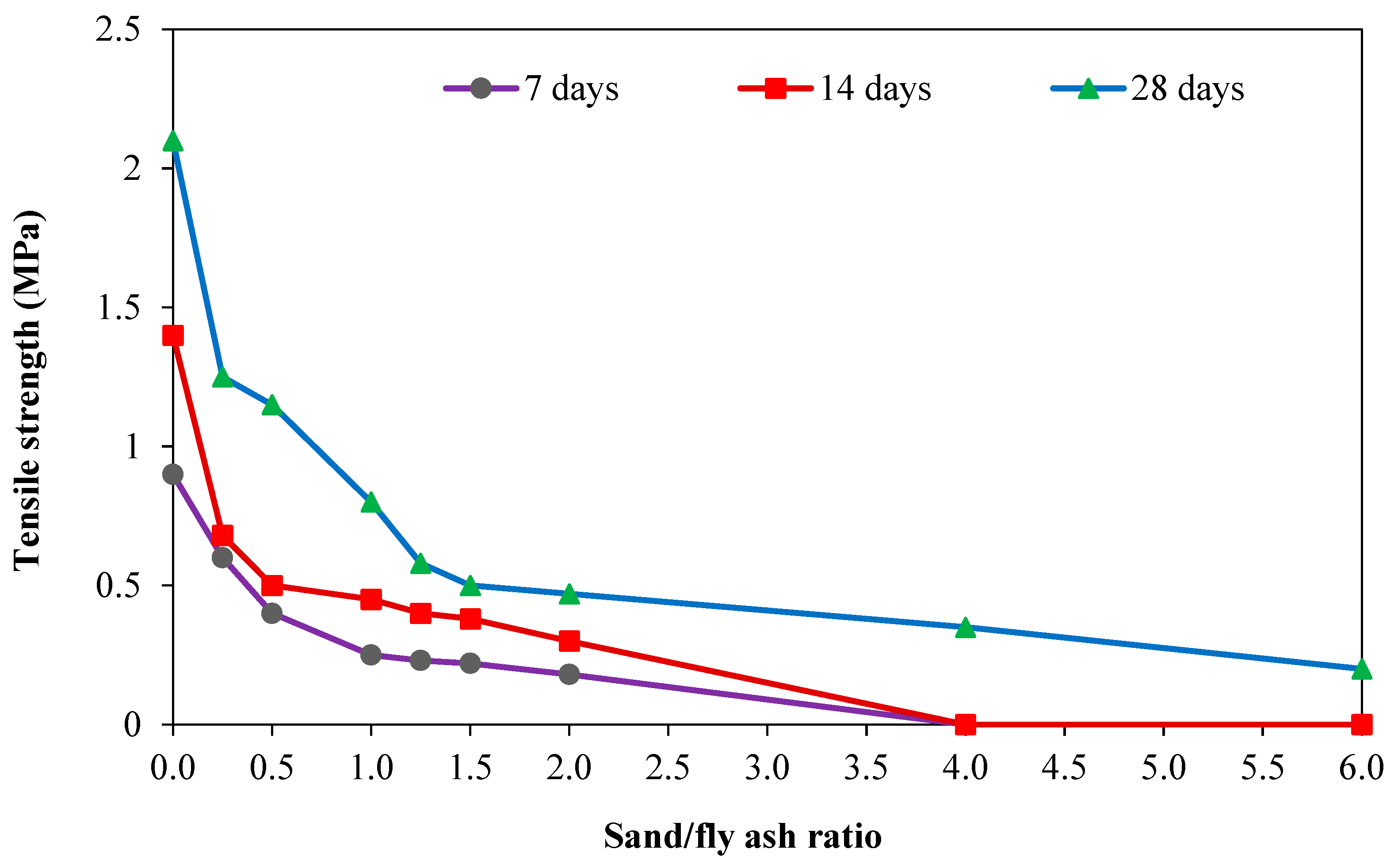

3.2.2. Tensile Strength and Flexural Strength

3.3. Microstructural Properties of Hardened GPC

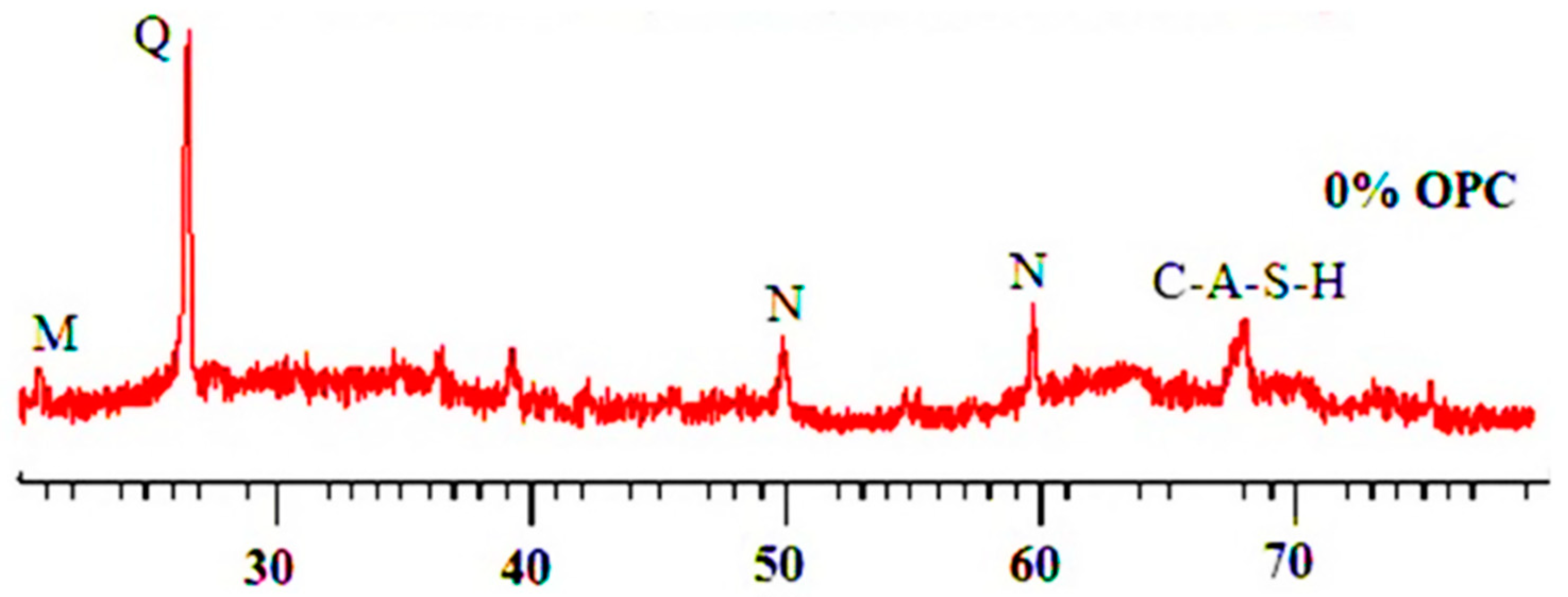

3.3.1. X-ray Diffraction (XRD)

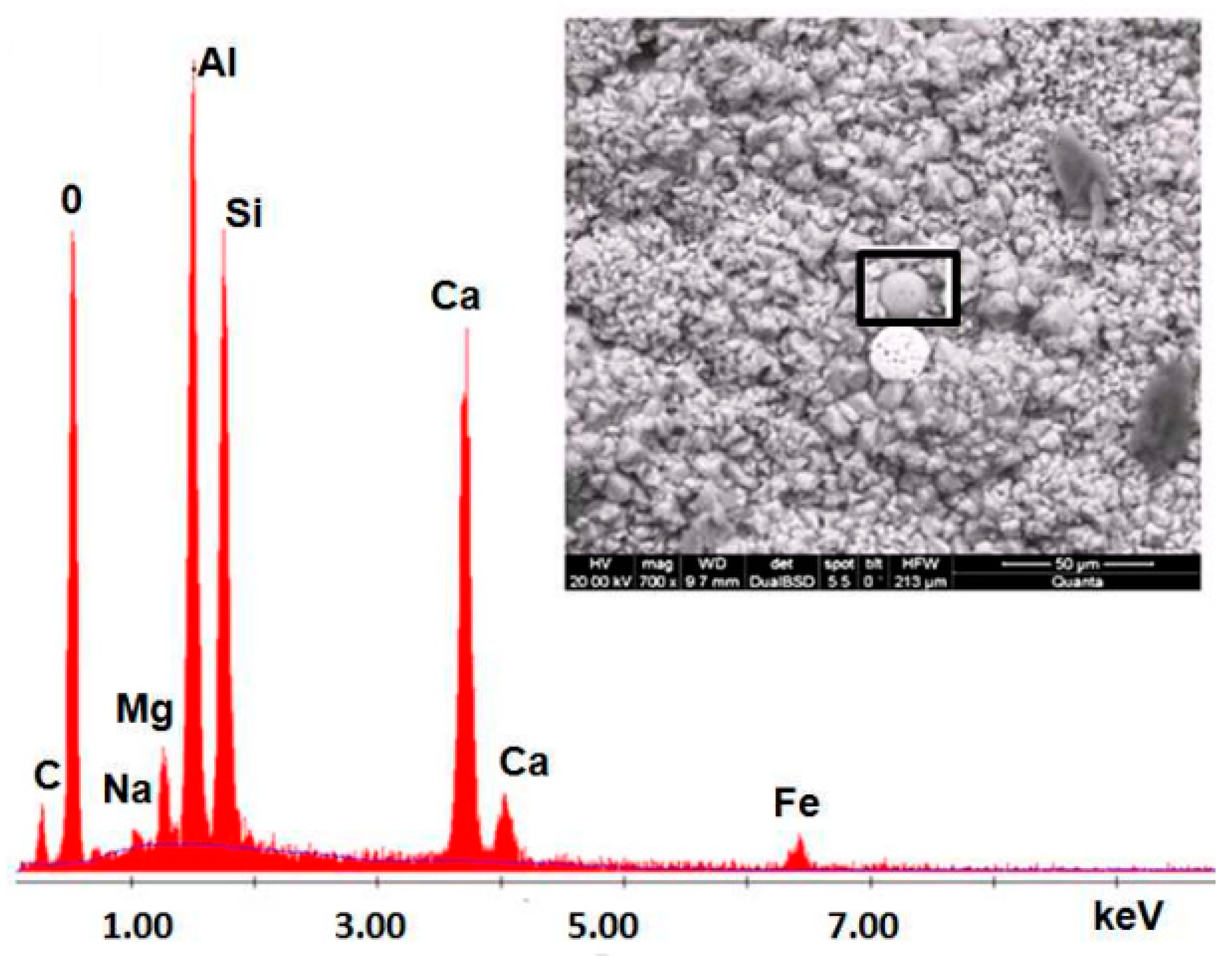

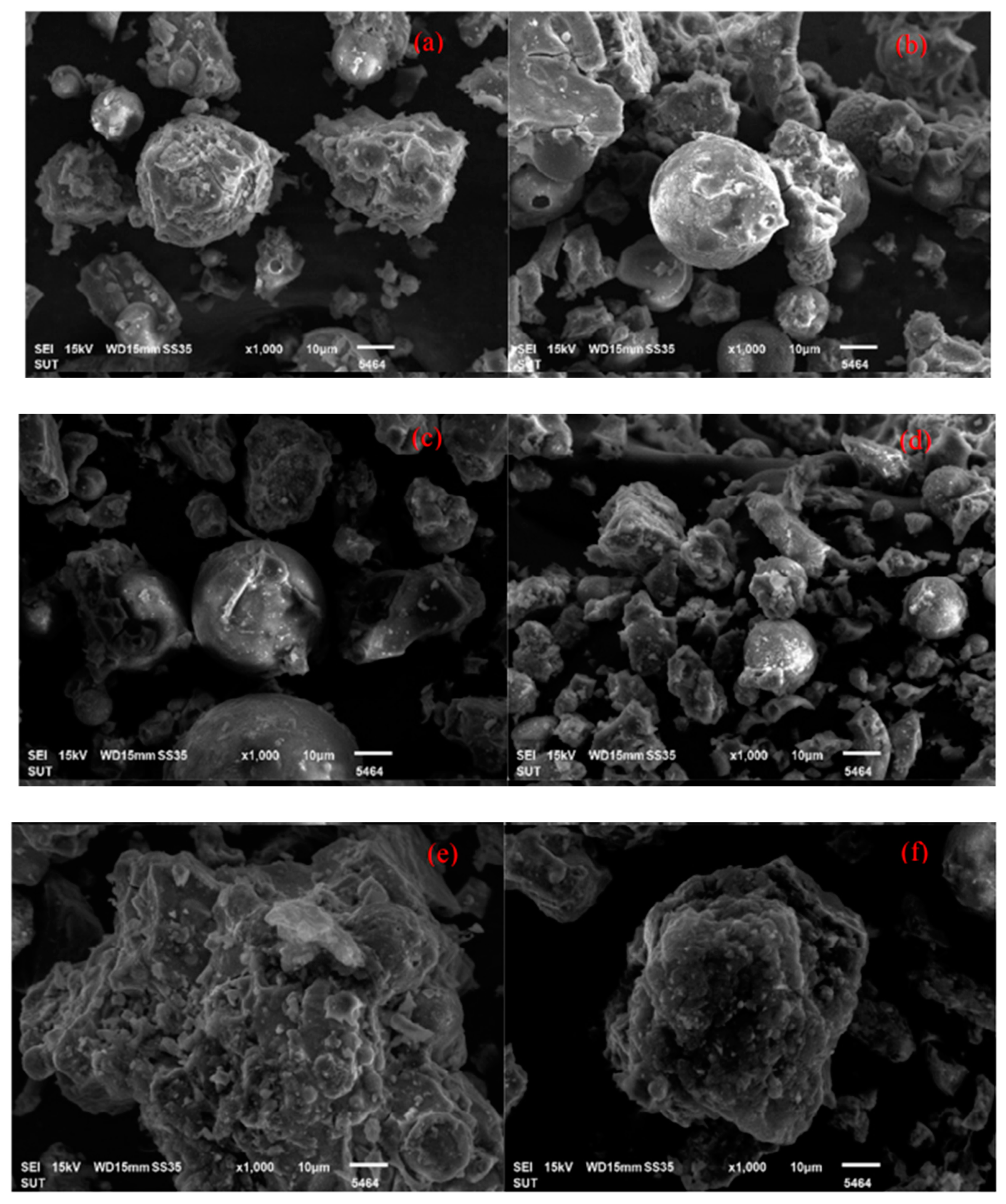

3.3.2. Scanning Electron Micrograph (SEM) and Energy Dispersive X-ray (EDX)

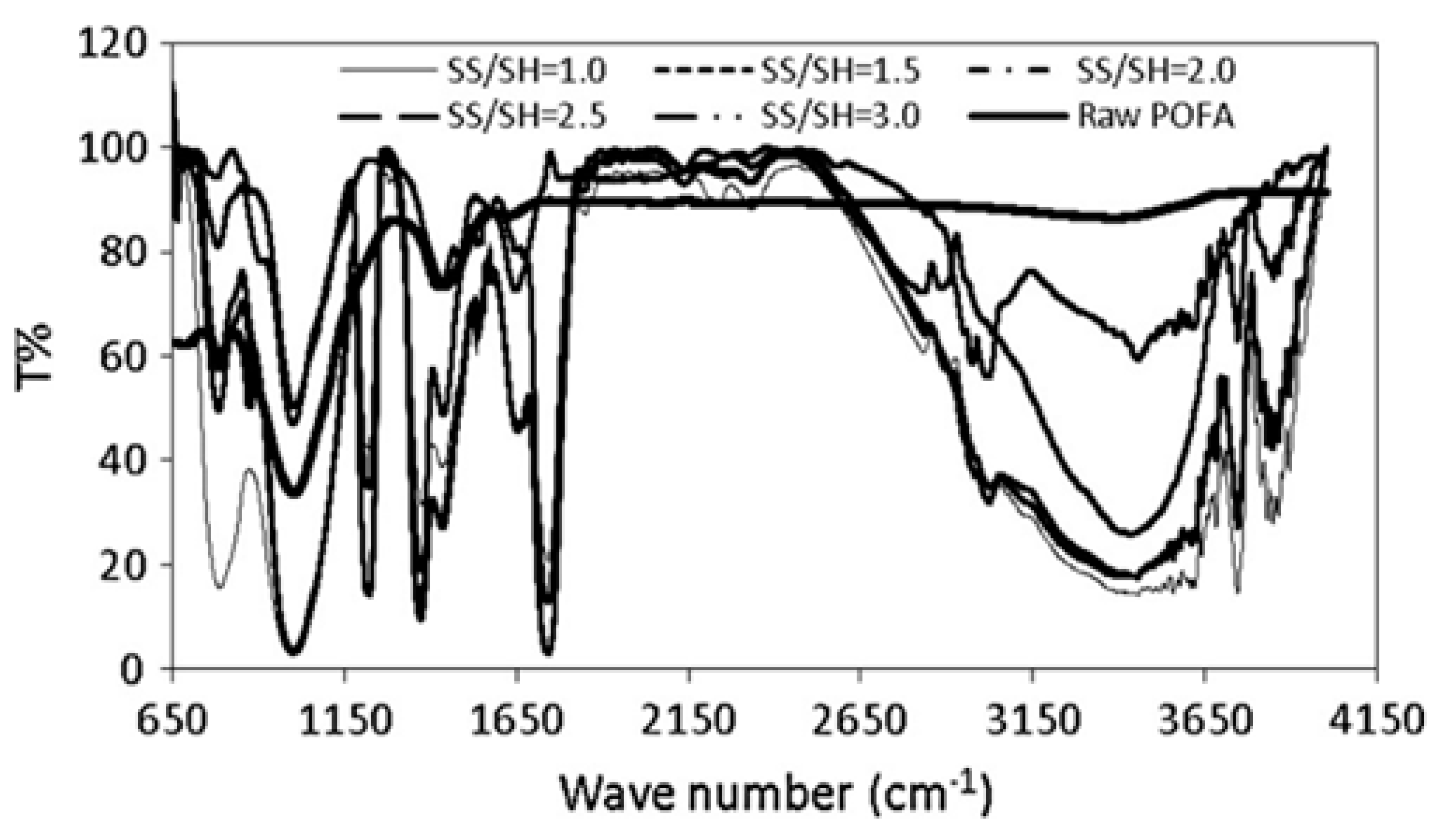

3.3.3. Fourier Transform Infrared Spectroscopy (FTIR)

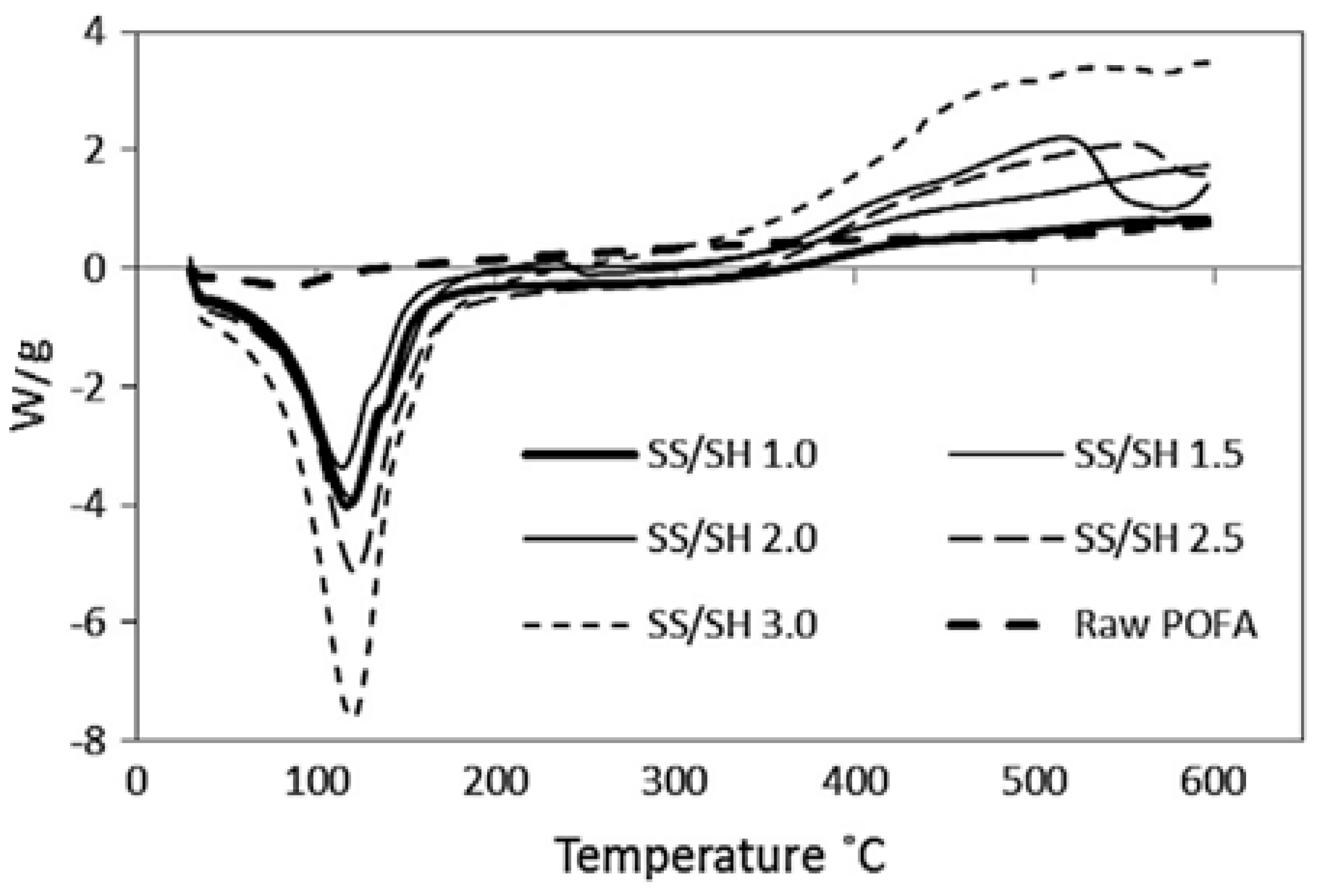

3.3.4. Differential Scanning Calorimetry (DSC)

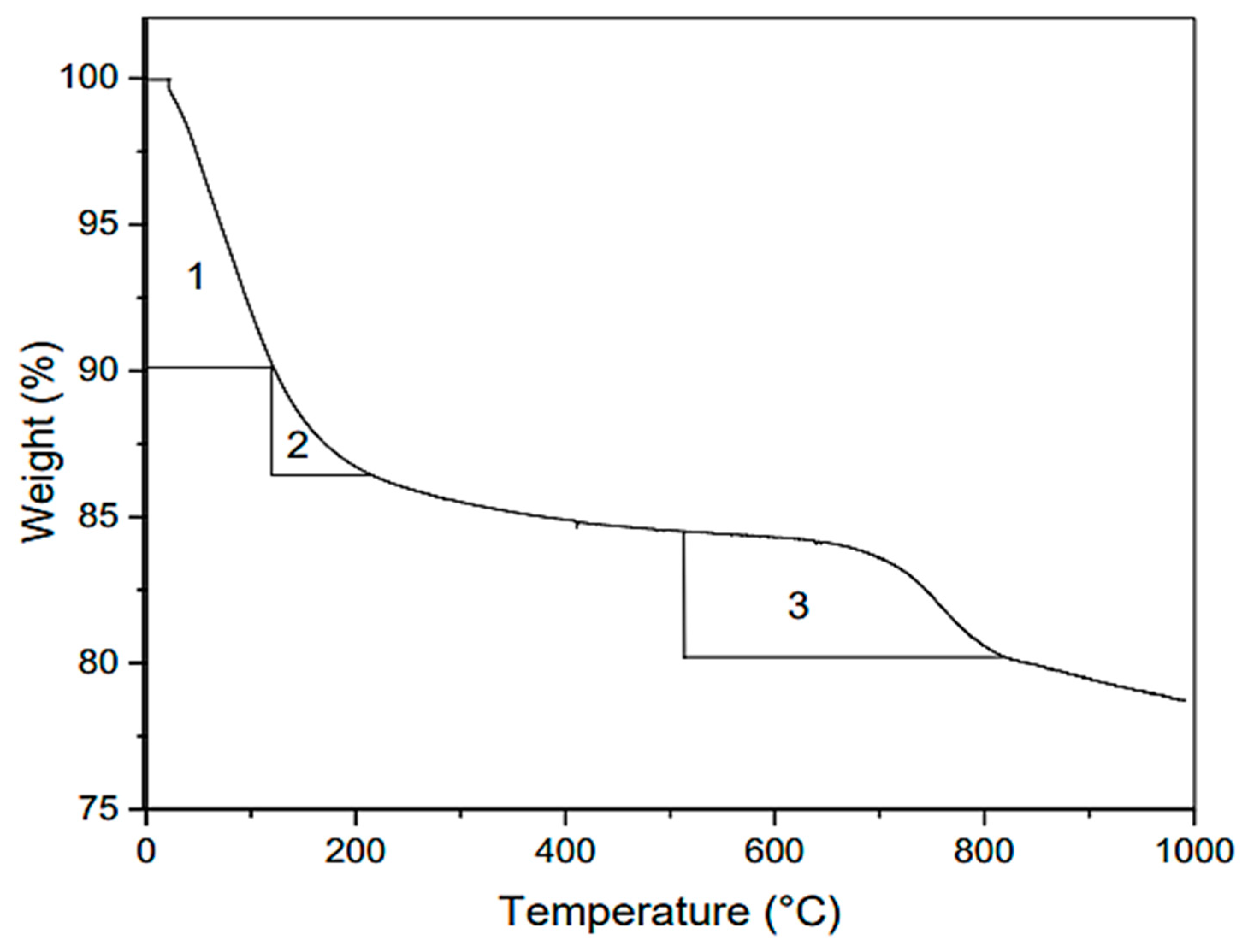

3.3.5. Thermal Gravimetric Analysis (TGA)

4. Scope and Future Research Work

5. Conclusions

- Construction with geopolymer concrete is more durable and stronger than with PC concrete;

- Many factors, including curing conditions, the ratio of alkaline to the binder, and the type of activator, have an important impact on the mechanical properties of geopolymer concrete. Consequently, a proper mix design is required to achieve the target strength;

- Geopolymer concrete possesses all the potential characteristics for future applications in civil engineering because it is a green material and requires strength and durability properties for all types of projects in the construction industry;

- Even though it is known that GPC could be used as a replacement material and is a cleaner and more sustainable form of concrete, it is still not widely used in construction;

- Geopolymer concrete needs a standard code to be used more often in building structures;

- In terms of mechanical and microstructural performance, geopolymer concrete was better than PC concrete, especially after exposure to high temperatures;

- The effect of using geopolymer as a partial replacement for PC on the microstructure can be easily noticed; the microstructure has become significantly denser and more homogenous compared with the control specimen, while the number of voids has decreased;

- C-S-H gel and geopolymer gel enhance the mechanical and microstructural properties of precursors that are either high in Ca or contain a combination of Ca components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Basha, S.M.; Reddy, C.B.; Vasugi, K. Strength behaviour of geopolymer concrete replacing fine aggregates by M-sand and E-waste. Int. J. Eng. Trends Technol. 2016, 40, 401–407. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Zanotti, C.; Banthia, N. Pull-out behavior of different fibers in geopolymer mortars: Effects of alkaline solution concentration and curing. Mater. Struct. 2017, 50, 80. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.; Ng, T.; Sanjayan, J.; Gilbert, R. Creep and drying shrinkage of a blended slag and low calcium fly ash geopolymer Concrete. Mater. Struct. 2016, 49, 1619–1628. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mahmood, L.J.; Muhammad, M.A.; Faraj, R.H.; Qaidi, S.M.A.; Sor, N.H.; Mohammed, A.S.; Mohammed, A.A. Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 2022, 5, 100111. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Isleem, H.F.; de Azevedo, A.R.G.; Ahmed, H.U.; Emad, W. Sustainable utilisation of red mud waste (bauxite residue) and slag for the production of geopolymer composites: A review, Case Studies in Construction. Materials 2022, 16, e00994. [Google Scholar]

- IEA. Global Cement Production, 2010–2019; IEA: Paris, France, 2020. [Google Scholar]

- Chowdhury, S.; Mohapatra, S.; Gaur, A.; Dwivedi, G.; Soni, A. Study of various properties of geopolymer concrete–A review. Mater. Today Proc. 2021, 46, 5687–5695. [Google Scholar] [CrossRef]

- Mohajerani, A.; Suter, D.; Jeffrey-Bailey, T.; Song, T.; Arulrajah, A.; Horpibulsuk, S.; Law, D. Recycling waste materials in geopolymer concrete. Clean Technol. Environ. Policy 2019, 21, 493–515. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Qaidi, S.M.A.; Faraj, R.H.; Sor, N.H.; Mohammed, A.A. Compressive strength of geopolymer concrete composites: A systematic comprehensive review, analysis and modeling. Eur. J. Environ. Civ. Eng. 2022, 1–46. [Google Scholar] [CrossRef]

- Ahmed, S.N.; Sor, N.H.; Ahmed, M.A.; Qaidi, S.M.A. Thermal conductivity and hardened behavior of eco-friendly concrete incorporating waste polypropylene as fine aggregate. Mater. Today Proc. 2022, 57, 818–823. [Google Scholar] [CrossRef]

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.H.; Qaidi, S.M.A.; de Prado Gil, J.; Martínez-García, R. Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct. Concr. 2022. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Sreevidya, V. Investigations on the Flexural Behaviour of Ferro Geopolymer Composite Slabs. 2014. Available online: https://www.researchgate.net/publication/321050166_INVESTIGATIONS_ON_THE_FLEXURAL_BEHAVIOUR_OF_FERRO_GEOPOLYMER_COMPOSITE_SLABS (accessed on 1 September 2022).

- Davidovits, J. False values on CO2 emission for geopolymer cement/concrete published in scientific papers. Tech. Pap. 2015, 24, 1–9. [Google Scholar]

- Gollakota, A.R.K.; Volli, V.; Shu, C.-M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef] [PubMed]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of glass powder-based geopolymer stabilised road bases containing recycled waste glass aggregate. Transp. Res. Rec. 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Lukey, G.C. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Elhag, A.B.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.A.; Mohammed, A.A. Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 2022, 16, e01036. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment–A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Atrushi, D.S.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Najm, H.M. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A review of properties and behaviour of reinforced geopolymer concrete structural elements-A clean technology option for sustainable development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Habert, G.; D’Espinose De Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Umniati, B.S.; Risdanareni, P.; Zein, F.T.Z. Workability Enhancement of Geopolymer Concrete through the Use of Retarder. AIP Conf. Proc. 2017, 1887, 020033. [Google Scholar]

- Mehta, A.; Siddique, R. Properties of Low-Calcium Fly Ash Based Geopolymer Concrete Incorporating PC as Partial Re-placement of Fly Ash. Constr. Build. Mater. 2017, 150, 792–807. [Google Scholar] [CrossRef]

- Hassan, A. Experimental Study of Fly Ash Based Geopolymer Concrete. Int. J. Adv. Earth Sci. Eng. 2018, 7, 635–648. [Google Scholar] [CrossRef]

- Antoni, P.; Satria, J.; Sugiarto, A.; Hardjito, D. Effect of Variability of Fly Ash Obtained from the Same Source on the Characteristics of Geopolymer. MATEC Web Conf. 2017, 97, 01026. [Google Scholar] [CrossRef]

- Lakshmi, R.; Nagan, S. Utilization of Waste e Plastic Particles in Cementitious Mixtures. J. Struct. Eng. (Madras) 2011, 38, 26–35. [Google Scholar]

- Memon, F.A.; Nuruddin, M.F.; Demie, S.; Shafiq, N. Effect of Superplasticizer and Extra Water on Workability and Com-pressive Strength of Self-Compacting Geopolymer Concrete. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 407–414. [Google Scholar]

- Warid Wazien, A.Z.; Al Bakri Abdullah, M.M.; Abd Razak, R.; Mohd Remy Rozainy, M.A.Z.; Mohd Tahir, M.F.; Hussin, K. Potential of Geopolymer Mortar as Concrete Repairing Materials. Mater. Sci. Forum 2016, 857, 382–387. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and Strength of Lignite Bottom Ash Geopolymer Mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and Strength of Coarse High Calcium Fly Ash Geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- ASTM C 1437-07; Standard Test Methods for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2008.

- Bhowmick, A.; Ghosh, S. Effect of Synthesising Parameters on Workability and Compressive Strength of Fly Ash Based Geopolymer Mortar. Int. J. Struct. Civ. Eng. 2012, 3, 168–177. [Google Scholar]

- ASTM C1437-01; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2001.

- BS EN 480-5; Admixtures for Concrete, Mortar and Grout—Test Methods Part 5: Determination of Capillary Absorption. British Standard Institute: London, UK, 2005; Volume 3, pp. 480–485.

- Jumrat, S.; Chatveera, B.; Rattanadecho, P. Dielectric Properties and Temperature Profile of Fly Ash-Based Geopolymer Mortar. Int. Commun. Heat Mass Transf. 2011, 38, 242–248. [Google Scholar] [CrossRef]

- Saloma; Saggaff, A.; Hanafiah; Mawarni, A. Geopolymer Mortar with Fly Ash. MATEC Web Conf. 2016, 78, 01026. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Sata, V.; Hanjitsuwan, S.; Ridtirud, C.; Hatanaka, S.; Chindaprasirt, P. Compressive Strength, Bending and Fracture Characteristics of High Calcium Fly Ash Geopolymer Mortar Containing Portland Cement Cured at Ambient Temperature. Arab. J. Sci. Eng. 2016, 41, 1263–1271. [Google Scholar] [CrossRef]

- Erfanimanesh, A.; Sharbatdar, M.K. Mechanical and Microstructural Characteristics of Geopolymer Paste, Mortar, and Concrete Containing Local Zeolite and Slag Activated by Sodium Carbonate. J. Build. Eng. 2020, 32, 101781. [Google Scholar] [CrossRef]

- Yusuf, T.O.; Ismail, M.; Usman, J.; Noruzman, A.H. Impact of Blending on Strength Distribution of Ambient Cured Me-takaolin and Palm Oil Fuel Ash Based Geopolymer Mortar. Adv. Civ. Eng. 2014, 2014, 658067. [Google Scholar] [CrossRef]

- Ismail, M.; Yusuf, T.O.; Noruzman, A.H.; Hassan, I.O. Early Strength Characteristics of Palm Oil Fuel Ash and Metakaolin Blended Geopolymer Mortar. Adv. Mater. Res. 2013, 690, 1045–1048. [Google Scholar] [CrossRef]

- De Rossi, A.; Ribeiro, M.J.; Labrincha, J.A.; Novais, R.M.; Hotza, D.; Moreira, R.F.P.M. Effect of the Particle Size Range of Construction and Demolition Waste on the Fresh and Hardened-State Properties of Fly Ash-Based Geopolymer Mortars with Total Replacement of Sand. Process Saf. Environ. Prot. 2019, 129, 130–137. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of Inorganic Polymer (Geopolymer) Mortars Made of Glass Cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Hussin, M.W. Influence of Different Curing Temperatures and Alkali Activators on Properties of GBFS Geopolymer Mortars Containing Fly Ash and Palm-Oil Fuel Ash. Constr. Build. Mater. 2016, 125, 1229–1240. [Google Scholar] [CrossRef]

- Steinerova, M. Mechanical Properties of Geopolymer Mortars in Relation to Their Porous Structure. Ceram. Silik. 2011, 55, 362–372. [Google Scholar]

- Li, X.; Wang, Z.; Jiao, Z. Influence of Curing on the Strength Development of Calcium-Containing Geopolymer Mortar. Materials 2013, 6, 5069–5076. [Google Scholar] [CrossRef]

- Atiş, C.D.; Görür, E.B.; Karahan, O.; Bilim, C.; Ilkentapar, S.; Luga, E. Very High Strength (120 MPa) Class F Fly Ash Ge-opolymer Mortar Activated at Different NaOH Amount, Heat Curing Temperature and Heat Curing Duration. Constr. Build. Mater. 2015, 96, 673–678. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of Geopolymer Mortar under Ambient Temper-ature for in Situ Applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural Fiber Reinforced High Calcium Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Lloyd, N.A.; Rangan, B.V. Geopolymer Concrete with Fly Ash. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Patil, S.; Karikatti, V.; Chitawadagi, M. Granulated Blast-Furnace Slag (GGBS) based Geopolymer Concrete–Review. Int. J. Adv. Sci. Eng. 2018, 5, 879–885. [Google Scholar] [CrossRef]

- Rajarajeswari, A.; Dhinakaran, G. Compressive strength of GGBFS based GPC under thermal curing. Constr. Build. Mater. 2016, 126, 552–559. [Google Scholar] [CrossRef]

- Khater, H.M. Efect of fumed silica on the characterisation of the geopolymer materials. Int. J. Adv. Struct. Eng. 2013, 5, 12. [Google Scholar] [CrossRef]

- Brew, D.R.M.; MacKenzie, K.J.D. Geopolymer synthesis using fumed silica and sodium aluminate. J. Mater. Sci. 2007, 42, 3990–3993. [Google Scholar] [CrossRef]

- Bajpai, R.; Kailash, C.; Anshuman, S.; Kuldip, S.S.; Manpreet, S. Environmental impact assessment of fy ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Efects of steel fber and silica fume. Cem. Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Rangan, B.; Hardjito, D. Studies on Fly Ash-Based Geopolymer Concrete. Ph.D. Thesis, Curtin University of Technology, Bentley, Australia, 2005. [Google Scholar]

- Day, K.W. Properties of Concrete. In Concrete Mix Design, Quality Control and Specification; CRC Rress: Boca Raton, FL, USA, 2021. [Google Scholar]

- Ng, T.S.; Foster, S.J. Development of High Performance Geopolymer Conscrete. In Proceedings of the Futures in Mechanics of Structures and Materials—20th Australasian Conference on the Mechanics of Structures and Materials (ACMSM20), Toowoomba, Australia, 2–5 November 2008. [Google Scholar]

- Le, H.T.N.; Poh, L.H.; Wang, S.; Zhang, M.H. Critical Parameters for the Compressive Strength of High-Strength Concrete. Cem. Concr. Compos. 2017, 82, 202–216. [Google Scholar] [CrossRef]

- Demie, S.; Nuruddin, M.F.; Shafiq, N. Effects of micro-structure characteristics of interfacial transition zone on the compressive strength of self-compacting geopolymer concrete. Constr. Build. Mater. 2013, 41, 91–98. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Sata, V.; Hanjitsuwan, S.; Ridtirud, C.; Hatanaka, S.; Chindaprasirt, P. High calcium fly ash geopolymer mortar containing Portland cement for use as repair material. Constr. Build. Mater. 2015, 98, 482–488. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I. The development of compressive strength of ground granulated blast furnace slag-palm oil fuel ash-fly ash based geopolymer mortar. Mater. Des. 2014, 56, 833–841. [Google Scholar] [CrossRef]

- Li, Z.; Chen, R.; Zhang, L. Utilization of chitosan biopolymer to enhance fly ash-based geopolymer. J. Mater. Sci. 2013, 48, 7986–7993. [Google Scholar] [CrossRef]

- Yang, T.; Yao, X.; Zhang, Z.; Wang, H. Mechanical property and structure of alkali-activated fly ash and slag blends. J. Sustain. Cem. Mater. 2012, 1, 167–178. [Google Scholar] [CrossRef]

- Rattanasak, U.; Pankhet, K.; Chindaprasirt, P. Effect of chemical admixtures on properties of high-calcium fly ash geopolymer. Int. J. Miner. Met. Mater. 2011, 18, 364–369. [Google Scholar] [CrossRef]

- Nath, S.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Ding, Y.-C.; Cheng, T.-W.; Dai, Y.-S. Application of geopolymer paste for concrete repair. Struct. Concr. 2017, 18, 561–570. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, M.; Zhang, G.; Mann, D.; Lumsden, K.; Tao, M. Durability of red mud-fly ash based geopolymer and leaching behavior of heavy metals in sulfuric acid solutions and deionised water. Constr. Build. Mater. 2016, 124, 373–382. [Google Scholar] [CrossRef]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The effect of microwave incinerated rice husk ash on the compressive and bond strength of fly ash based geopolymer concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Rashad, A.M. Properties of alkali activated fly ash concrete blended with slag. Iran. J. Mater. Sci. Eng. 2013, 10, 57–64. [Google Scholar]

- Abhilash, P.; Sashidhar, C.; Reddy, I.R. Strength properties of Fly ash and GGBS based Geo-polymer Concrete. Int. J. ChemTech Res. 2016, 9, 350–356. [Google Scholar]

- Oderji, S.Y.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators. J. Clean. Prod. 2019, 225, 1–10. [Google Scholar] [CrossRef]

- Sarvanan, S.; Elavenil, S. Strength properties of geopolymer concrete using M-sand by assessing their mechanical characteristics. ARPN J. Eng. Appl. Sci. 2018, 13, 4028–4041. [Google Scholar]

- Partha, S.D.; Pradib, N.; Prabir, K.S. Strength and Permeation Properties of Slag Blended Fly Ash Based Geopolymer Concrete. Adv. Mater. Res. 2013, 651, 168–173. [Google Scholar] [CrossRef]

- Lee, B.; Kim, G.; Kim, R.; Cho, B.; Lee, S.; Chon, C.M. Strength Development Properties of Geopolymer Paste and Mortar with Respect to Amorphous Si/Al Ratio of Fly Ash. Constr. Build. Mater. 2017, 151, 512–519. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly Ash-Based Geopolymer: Clean Production, Properties and Applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Wong, L.S. Durability performance of geopolymer concrete: A review. Polymers 2022, 14, 868. [Google Scholar] [CrossRef]

- Alomayri, T. The microstructural and mechanical properties of geopolymer composites containing glass microfibres. Ceram. Int. 2017, 43, 4576–4582. [Google Scholar] [CrossRef]

- Pongsak, J.; Horpibulsuk, S. Physical and microstructure properties of geopolymer nanocomposite reinforced with carbon nanotubes. Mater. Today Proc. 2019, 17, 1682–1692. [Google Scholar]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, P.; Wu, J.; Jing, Y.; Zhang, D.; Zhang, T. Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2. Nanotechnol. Rev. 2022, 11, 1478–1498. [Google Scholar] [CrossRef]

- Arafa, S.; Milad, A.; Yusoff, N.I.M.; Al-Ansari, N.; Yaseen, Z.M. Investigation into the permeability and strength of pervious geopolymer concrete containing coated biomass aggregate material. J. Mater. Res. Technol. 2021, 15, 2075–2087. [Google Scholar] [CrossRef]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S.; Md Yusoff, N.I. Utilisation of waste-based geopolymer in asphalt pavement modification and construction—A review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Toniolo, N.; Rincón, A.; Roether, J.A.; Ercole, P.; Bernardo, E.; Boccaccini, A.R. Extensive reuse of soda-lime waste glass in fly ash-based geopolymers. Constr. Build. Mater. 2018, 188, 1077–1084. [Google Scholar] [CrossRef]

- Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Gómez-Soberón, J.M.; Alamaral-Sánchez, J.L.; Corral-Higuera, R.; Chinchillas-Chinchillas MD, J.; Acuña-Agüero, O.H. Experimental study of XRD, FTIR and TGA techniques in geopolymeric materials. Int. J. Adv. Comput. Sci. Appl 2014, 4, 221–226. [Google Scholar]

- Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Nizar, I.K.; Rafiza, A.R.; Zarina, Y. The processing, characterisation, and properties of fly ash based geopolymer concrete. Rev. Adv. Mater. Sci. 2012, 30, 90–97. [Google Scholar]

- Xiao, S.; Cai, Y.; Guo, Y.; Lin, J.; Liu, G.; Lan, X.; Song, Y. Experimental Study on Axial Compressive Performance of Polyvinyl Alcohol Fibers Reinforced Fly Ash—Slag Geopolymer Composites. Polymers 2021, 14, 142. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kejzlar, P.; Louda, P. The Influence of the Material Structure on the Mechanical Properties of Geopolymer Composites Reinforced with Short Fibers Obtained with Additive Technologies. Int. J. Mol. Sci. 2022, 23, 2023. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, M.; Shen, W.; Zhu, G.; Ge, X. Mechanical properties and microstructure of metakaolin-based geopolymer compound-modified by polyacrylic emulsion and polypropylene fibers. Constr. Build. Mater. 2018, 190, 680–690. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Le, T.A.; Le, S.H.; Nguyen, T.N.; Nguyen, K.T. Assessment of the Rheological and Mechanical Properties of Geopolymer Concrete Comprising Fly Ash and Fluid Catalytic Cracking Residue as Aluminosilicate Precursor. Appl. Sci. 2021, 11, 3032. [Google Scholar] [CrossRef]

- Salih, M.A.; Ali AA, A.; Farzadnia, N. Characterization of mechanical and microstructural properties of palm oil fuel ash geopolymer cement paste. Constr. Build. Mater. 2014, 65, 592–603. [Google Scholar] [CrossRef]

- Rajini, B.; Rao, A.N.; Sashidhar, C. Micro-level studies of fly ash and GGBS–based geopolymer concrete using Fourier transform infra-red. Mater. Today Proc. 2021, 46, 586–589. [Google Scholar] [CrossRef]

- Frydrych, M.; Hýsek, Š.; Fridrichová, L.; Le Van, S.; Herclík, M.; Pechočiaková, M.; Le Chi, H.; Louda, P. Impact of Flax and Basalt Fibre Reinforcement on Selected Properties of Geopolymer Composites. Sustainability 2019, 12, 118. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of elevated temperature on mechanical properties of high-volume fly ash-based geopolymer concrete, mortar and paste cured at room temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Zeyad, A.M.; Agwa, I.S.; Amin, M. Effect of elevated temperatures on mechanical properties of lightweight geopolymer concrete. Case Stud. Constr. Mater. 2021, 15, e00673. [Google Scholar] [CrossRef]

- Vogt, O.; Ukrainczyk, N.; Ballschmiede, C.; Koenders, E. Reactivity and microstructure of metakaolin based geopolymers: Effect of fly Ash and liquid/solid contents. Materials 2019, 12, 3485. [Google Scholar] [CrossRef]

- Jamil, N.H.; Abdullah, M.M.A.B.; Pa, F.C.; Mohamad, H.; Ibrahim, W.M.A.W.; Amonpattaratkit, P.; Gondro, J.; Sochacki, W.; Ibrahim, N. Self-fluxing mechanism in geopolymerization for low-sintering temperature of ceramic. Materials 2021, 14, 1325. [Google Scholar] [CrossRef]

- Haruna, S.; Mohammed, B.S.; Wahab, M.M.A.; Kankia, M.U.; Amran, M.; Gora, A.U.M. Long-Term Strength Development of Fly Ash-Based One-Part Alkali-Activated Binders. Materials 2021, 14, 4160. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Long, T.; Sarker, P.K.; Shi, X.; Cai, G.; Wang, Q. The effect of ordinary portland cement substitution on the thermal stability of geopolymer concrete. Materials 2019, 12, 2501. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Vizureanu, P.; Sandu, A.V.; Burduhos Nergis, D.P.; Bejinariu, C. XRD and TG-DTA Study of New Phosphate-Based Geopolymers with Coal Ash or Metakaolin as Aluminosilicate Source and Mine Tailings Addition. Materials 2021, 15, 202. [Google Scholar] [CrossRef] [PubMed]

- Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. Sustainable utilisation of waste carbon black in alkali-activated mortar production. Case Stud. Constr. Mater. 2021, 15, e00743. [Google Scholar]

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt fibers in modified whisker reinforced cementitious composites. Period. Polytech. Civ. Eng. 2022, 66, 344–354. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Guan, J.; Liu, Z.; Khan, M. Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Compos. Part B Eng. 2021, 224, 109219. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M.; Ahmed, S. Effectiveness of Calcium Carbonate Whisker in Cementitious Composites. Period. Polytechnica. Civ. Eng. 2022, 64, 265. [Google Scholar] [CrossRef]

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2022, 319, 126130. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Doğan-Sağlamtimur, N.; Bilgil, A.; Tamer, A.; Günaydin, K. Process Development of Fly Ash-Based Geopolymer Mortars in View of the Mechanical Characteristics. Materials 2021, 14, 2935. [Google Scholar] [CrossRef]

- Kljajević, L.; Nenadović, M.; Ivanović, M.; Bučevac, D.; Mirković, M.; Mladenović Nikolić, N.; Nenadović, S. Heat Treatment of Geopolymer Samples Obtained by Varying Concentration of Sodium Hydroxide as Constituent of Alkali Activator. Gels 2022, 8, 333. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S.; Khan, R.A. Mechanical and Microstructural Analysis of Waste Ceramic Optimal Concrete Reinforced by Hybrid Fibers Materials: A Comprehensive Study. J. Archit. Environ. Struct. Eng. Res. 2022, 5, 11–33. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Ahmad, M.; Sabri Sabri, M.M. Mechanical Properties, Crack Width, and Propagation of Waste Ceramic Concrete Subjected to Elevated Temperatures: A Comprehensive Study. Materials 2022, 15, 2371. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Ahmad, M.; Sabri Sabri, M.M. Colour Change of Sustainable Concrete Containing Waste Ceramic and Hybrid Fibre: Effect of Temperature. Materials 2022, 15, 2174. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. Effect of Elevated Temperatures Exposure on the Mechanical Properties of Waste Ceramic Concrete Reinforced with Hybrid Fibers Materials. Sigma J. Eng. Nat. Sci. 2021; in press. [Google Scholar]

- Aksoylu, C.; Özkılıç, Y.O.; Hadzima-Nyarko, M.; Işık, E.; Arslan, M.H. Investigation improvement in shear performance of reinforced concrete beams produced with recycled steel wires from waste tyre. Sustainability 2022, 14, 13360. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. The Use of Waste Ceramic Optimal Concrete for A Cleaner and Sustainable Environment—A Case Study of Mechanical Properties. Civ. Environ. Eng. Rep. 2022, 32, 85–102. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in Bending Performance of Reinforced Concrete Beams Produced with Waste Lathe Scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S.; Submitter, Y. Artificial Neural Networks for Evaluation & Prediction of the Mechanical Properties of Waste Ceramic Optimal Concrete Exposed to Elevated Temperature. Available SSRN 2021, 4032028. [Google Scholar] [CrossRef]

- Hussein, O.H.; Ibrahim, A.M.; Abd, S.M.; Najm, H.M.; Shamim, S.; Sabri, M.M.S. Hybrid Effect of Steel Bars and PAN Textile Reinforcement on Ductility of One-Way Slab Subjected to Bending. Molecules 2022, 27, 5208. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. The effect of metallic and non-metallic fiber on the mechanical properties of waste ceramic concrete. Innov. Infrastruct. Solut. 2021, 6, 204. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Nanayakkara, O.; Najm, H.M.; Sabri, M.M.S. Effect of Using Steel Bar Reinforcement on Concrete Quality by Ultrasonic Pulse Velocity Measurements. Materials 2022, 15, 4565. [Google Scholar] [CrossRef] [PubMed]

| Strength (MPa) | Structural Member | Amount (m3) | Emission Factor (tCO2−e/m3) | Emissions (tCO2−e) |

|---|---|---|---|---|

| 15 32 32 40 40 | Blinding Footings Slabs In situ column and wall Precast walls | 589 489 1984 253 1067 | 0.20 0.24 0.27 0.27 0.33 | 119 119 533 63 351–1185 |

| Ref. | Additives | Remarks |

|---|---|---|

| Erfanimanesh et al. [45] | PC mortar, slag, and zeolite | The compressive strength of GPM increased by up to 48% in the first seven days compared to the cement mortar after 28 days. |

| Tanakorn Phoo [44] | NaOH dosages | A high NaOH dosage increases mortar compressive strengths. |

| Mohammad Ismail et al. [47] | palm oil fuel and ash metakaolin | The high volume of palm oil fuel and ash metakaolin replacement has been found to reduce compressive strength at an early curing age. |

| Yusuf et al. [46] | blending silica-rich MK and palm oil fuel ash | The Weibull distribution is suitable for analysing the blended GPM. |

| Ismail et al. [47] | sisal fibre (SF), coconut fibre (CF), and glass fibre (GF) | The compressive strengths of GPM reinforced with SF, CF and GF both dropped a lot more than those reinforced with SF. |

| De Rossi [48] | construction and demolition waste (CDW) | The mixed fraction had the highest strength values due to the maximum packing density. |

| Ref. | Additives | Remarks |

|---|---|---|

| Demie, S et al. [67] | Superplasticizer | A high superplasticiser dose increases CS. |

| Phoo-Ngernkham et al. [68] | Ground granulated BFS | Compressive strength improves when GBFS dosage is increased. |

| Phoo-Ngernkham et al. [69] | PC mortar | GP composites were developed that have a more uniform and dense structure than concrete. |

| Islam, A et al. [70] | Ground granulated BFS, palm oil fuel ash | A 67 MPa CS was achieved by combining 30% POFA with 70% GGBS in FA-GP concrete. |

| Li, Z et al. [71] | Chitosan biopolymer | N-carboxymethyl chitosan’s addition greatly enhanced strength and led to a slight boost in compressive strength. |

| Yang, T et al. [72] | Ground granulated BFS | The CS of GP mixtures can be increased through the addition of slag to the raw material, with a slag/FA dosage ratio of 0.8, resulting in the highest strength. |

| Rattanasak, U et al. [73] | Sulfate of calcium and sodium, calcium chloride, and sucrose | The final setting time is significantly prolonged by the presence of sugar. As a rule, admixtures boost CS quality. |

| Nath, S et al. [74] | GBFS, GCS | Partial replacement with GCS yielded a higher CS than partial replacement with GBFS. |

| Ding, Y.-C [75] | ground granulated BFS | 48 MPa CSs were achieved with an M ratio of 0.96 SiO2/Na2O and a raw material composition of 70% GGBFS and 30% FA. |

| Zhang, M et al. [76] | Red mud | There is a decline in CS after 120 days. Safe aggregation of metals where they cannot exceed safe limits. |

| Kusbiantoro, A et al. [77] | Incinerated rice husk ash | Compressive and bond strength were enhanced when rice husk ash was added at an optimum dosage of 7%. |

| Torres-Carrasco et al. [78] | Waste glass | Supplemental silicon causes a rise in CS concentration. Typically, 15 g/100 mL is what’s prescribed. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250. https://doi.org/10.3390/ma15228250

Saeed A, Najm HM, Hassan A, Sabri MMS, Qaidi S, Mashaan NS, Ansari K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials. 2022; 15(22):8250. https://doi.org/10.3390/ma15228250

Chicago/Turabian StyleSaeed, Ahmed, Hadee Mohammed Najm, Amer Hassan, Mohanad Muayad Sabri Sabri, Shaker Qaidi, Nuha S. Mashaan, and Khalid Ansari. 2022. "Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties" Materials 15, no. 22: 8250. https://doi.org/10.3390/ma15228250

APA StyleSaeed, A., Najm, H. M., Hassan, A., Sabri, M. M. S., Qaidi, S., Mashaan, N. S., & Ansari, K. (2022). Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials, 15(22), 8250. https://doi.org/10.3390/ma15228250