Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy

Abstract

1. Introduction

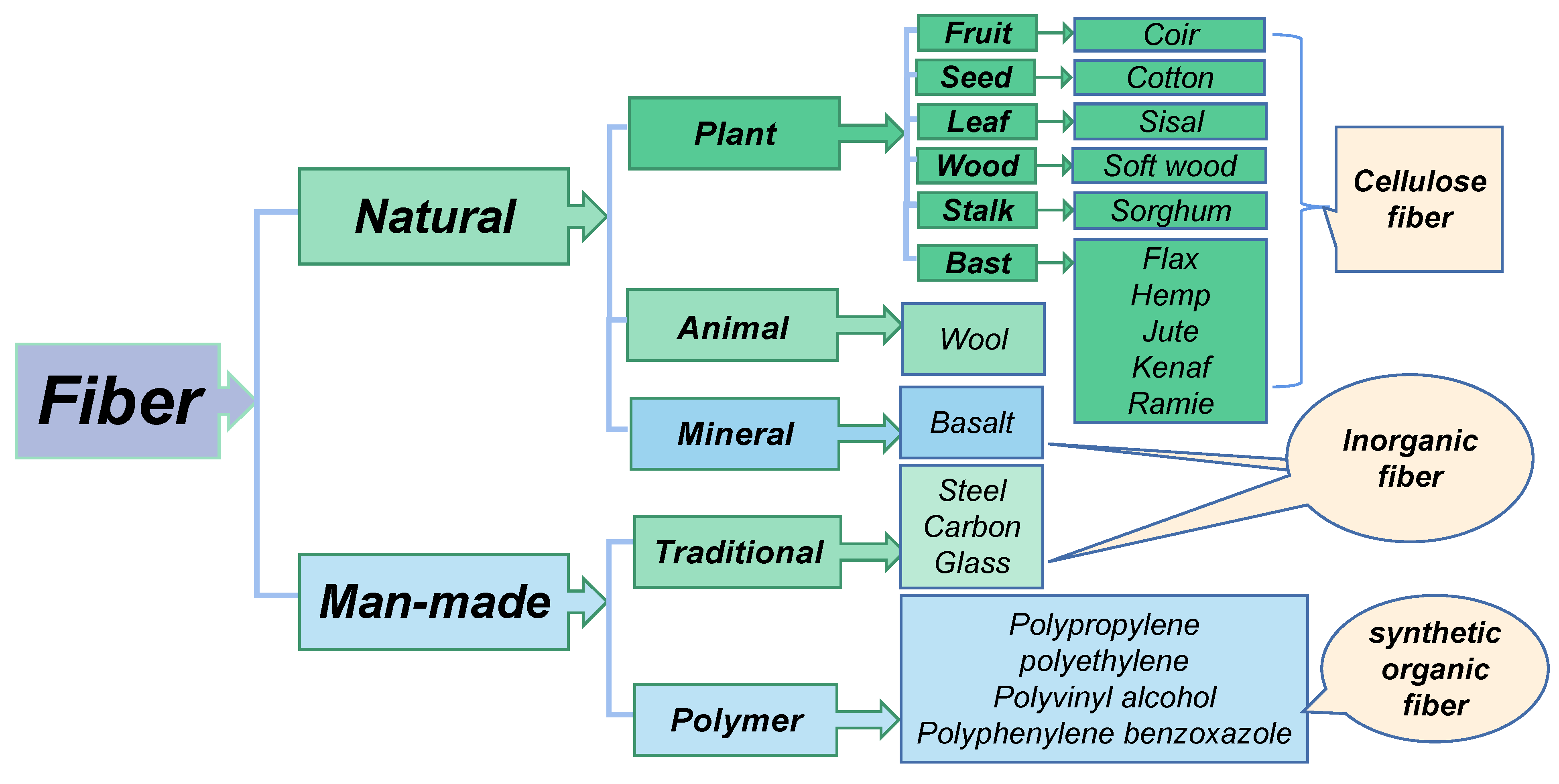

2. Reinforced Fibers of 3DPGs

3. Polymerization of Geopolymers

4. Effect of Fibers on Properties of Fresh 3DFRPGs Mixture

4.1. Formation of Weak Interlaminar Bonding and Anisotropy

4.2. Effects of Inorganic Fibers

4.3. Effects of PFs

4.4. Effects of Synthetic Organic Fibers

5. Effect of Fibers on Mechanical Properties of Hardened 3DFRPGs

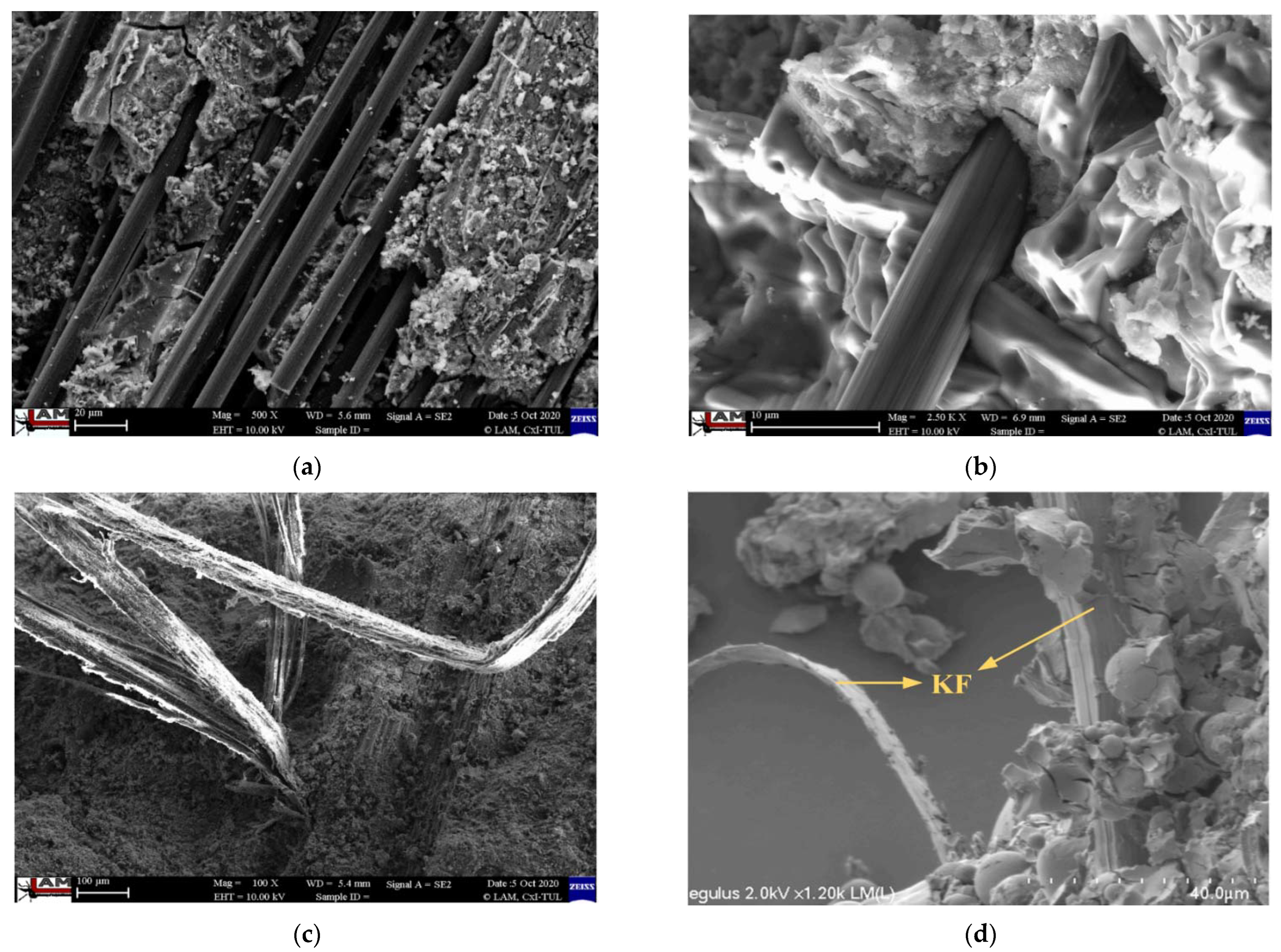

5.1. Effects of Inorganic Fibers

5.2. Effects of PFs

5.3. Effects of Synthetic Organic Fibers

5.3.1. Effect of PE Fibers

5.3.2. Effect of PP Fibers

5.3.3. Effect of PVA Fibers

5.4. Effects of Hybrid Fibers

6. Interlayer Bonding and Anisotropy of 3DFRPGs

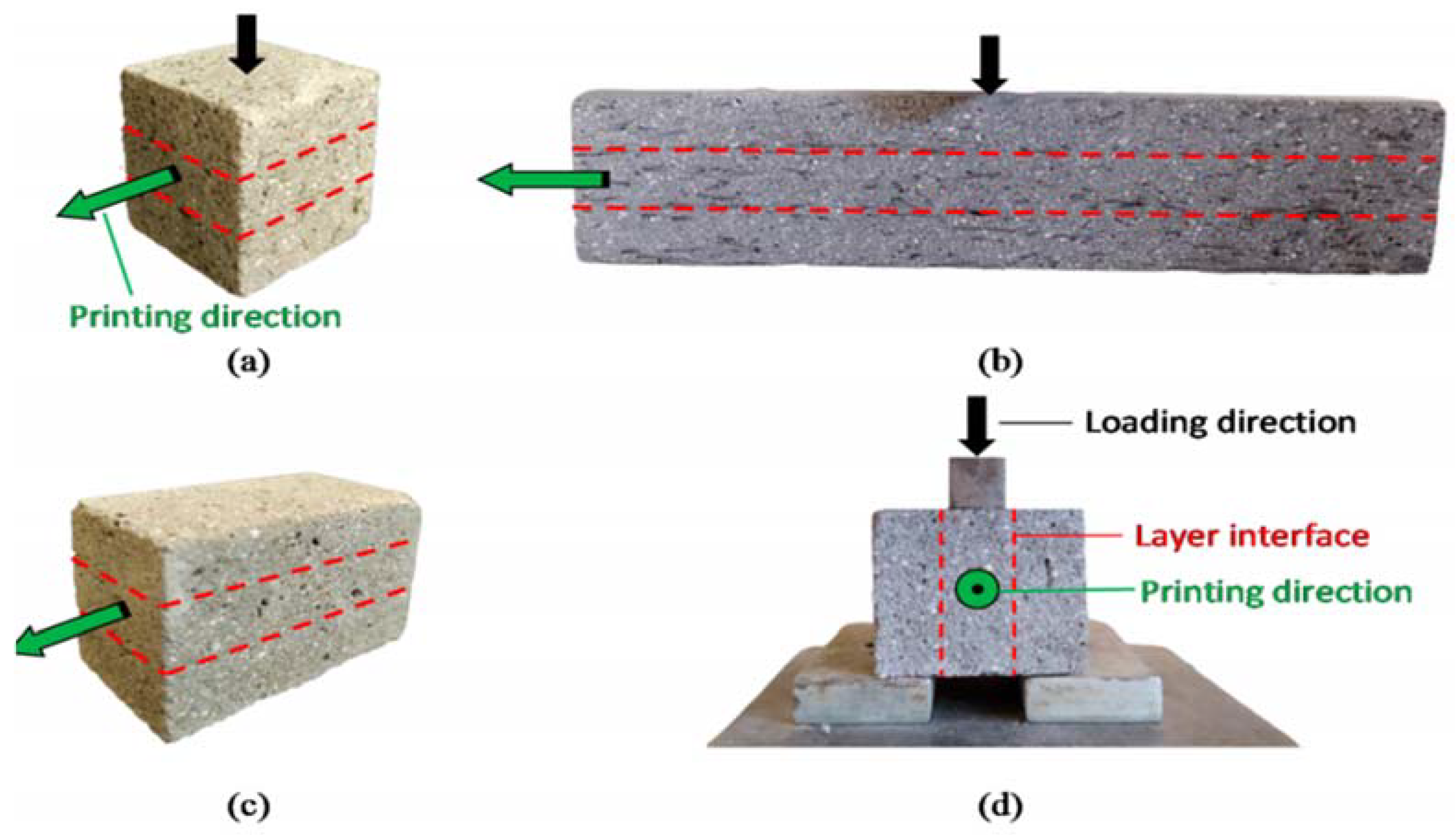

6.1. Interlayer Bonding Strength of 3DFRPGs

6.2. Anisotropy of 3DFRPGs

7. Improvement of Weak Interlayer Bonding

7.1. Good Material Formulation

7.2. Improving the Printing Process

7.3. Improving Compactness of Layer Interface

7.4. Adjustment of Printing Interval

7.5. Optimization of Printing Path

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martinie, L.; Rossi, P.; Roussel, N. Rheology of fiber reinforced cementitious materials: Classification and prediction. Cem. Concr. Res. 2010, 40, 226–234. [Google Scholar] [CrossRef]

- Kan, L.; Wang, W.; Liu, W.; Wu, M. Development and characterization of fly ash based PVA fiber reinforced Engineered Geopolymer Composites incorporating metakaolin. Cem. Concr. Comp. 2020, 108, 103521. [Google Scholar] [CrossRef]

- Sathish Kumar, V.; Ganesan, N.; Indira, P.V. Shear Strength of Hybrid Fibre-Reinforced Ternary Blend Geopolymer Concrete Beams under Flexure. Materials 2021, 14, 6634. [Google Scholar] [CrossRef] [PubMed]

- Rabiaa, E.; Mohamed, R.A.S.; Sofi, W.H.; Taher, A.T. Developing geopolymer concrete properties by using nanomaterials and steel fibers. Adv. Mater. Sci. Eng. 2020, 21, 1–12. [Google Scholar] [CrossRef]

- Ibraheem, M.; Butt, F.; Waqas, R.M.; Hussain, K.; Tufail, R.F.; Ahmad, N.; Usanova, K.; Musarat, M.A. Mechanical and Microstructural Characterization of Quarry Rock Dust Incorporated Steel Fiber Reinforced Geopolymer Concrete and Residual Properties after Exposure to Elevated Temperatures. Materials 2021, 14, 6890. [Google Scholar] [CrossRef]

- Ma, P.; Xin, M.; Zhang, Y.; Ge, S.; Wang, D.; Jiang, C.; Zhang, L.; Cheng, X. Facile synthesis of novel dopamine-modified glass fibers for improving alkali resistance of fibers and flexural strength of fiber-reinforced cement. RSC Adv. 2021, 11, 18818–18826. [Google Scholar] [CrossRef]

- Zhang, P.; Han, X.; Zheng, Y.; Wan, J.; Hui, D. Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete. Rev. Adv. Mater. Sci. 2021, 60, 418–437. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, G. Resistance of fiber-reinforced fly ash-steel slag based geopolymer mortar to sulfate attack and drying-wetting cycles. Constr. Build. Mater. 2021, 269, 121326. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Chen, B.; Oderji, S.Y.; Haque, M.A.; Ahmad, M.R. Comparative study on the effect of fiber type and content on the performance of one-part alkali-activated mortar. Constr. Build. Mater. 2020, 243, 118221. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Properties of 3D-Printed Polymer Fiber-Reinforced Mortars: A Review. Polymers 2022, 14, 1315. [Google Scholar] [CrossRef]

- Sainz-Aja, J.A.; Sanchez, M.; Gonzalez, L.; Tamayo, P.; Garcia del Angel, G.; Aghajanian, A.; Diego, S.; Thomas, C. Recycled Polyethylene Fibres for Structural Concrete. Appl. Sci. 2022, 12, 2867. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Research progress on durability of cellulose fiber-reinforced cement-based composites. Int. J. Polym. Sci. 2021, 2021, 1014531. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Durability of Cellulosic-Fiber-Reinforced Geopolymers: A Review. Molecules 2022, 27, 796. [Google Scholar] [CrossRef]

- Ogura, H.; Nerella, V.N.; Mechtcherine, V. Developing and Testing of Strain-Hardening Cement-Based Composites (SHCC) in the Context of 3D-Printing. Materials 2018, 11, 1375. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.A.G.; Tan, M.J.; Gibson, I.; Campbell, R.I.; Campbell, R.I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Wu, Z.; Memari, A.M.; Duarte, J.P. State of the Art Review of Reinforcement Strategies and Technologies for 3D Printing of Concrete. Energies 2022, 15, 360. [Google Scholar] [CrossRef]

- Kaszyńska, M.; Skibicki, S.; Hoffmann, M. 3D Concrete Printing for Sustainable Construction. Energies 2020, 13, 6351. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J. Method of formulating geopolymer for 3D printing for construction applications. Mater. Design 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Hoffmann, M.; Skibicki, S.; Pankratow, P.; Zieliński, A.; Pajor, M.; Techman, M. Automation in the Construction of a 3D-Printed Concrete Wall with the Use of a Lintel Gripper. Materials 2020, 13, 1800. [Google Scholar] [CrossRef] [PubMed]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butlera, M.; Mechtcherinea, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Comp. 2018, 95, 260–270. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China 2018, 61, 475–495. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswel, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Chou, S.Y.; Lin, W.T.; Mikuła, J.; Mierzwi’nski, D.; Cheng, A.; Hebda, M. A Comparative Study of Mechanical Properties of Fly Ash-Based Geopolymer Made by Casted and 3D Printing Methods. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012005. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- Marczyk, J.; Ziejewska, C.; Gądek, S.; Korniejenko, K.; Łach, M.; Góra, M.; Kurek, I.; Doğan-Sağlamtimur, N.; Hebda, M.; Szechyńska-Hebda, M. Hybrid Materials Based on Fly Ash, Metakaolin, and Cement for 3D Printing. Materials 2021, 14, 6874. [Google Scholar] [CrossRef]

- Parathi, S.; Nagarajan, P.; Pallikkara, S.A. Ecofriendly geopolymer concrete: A comprehensive review. Clean Technol. Environ. Policy 2021, 23, 1701–1713. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef]

- Favier, A.; Hot, J.; Habert, G.; Roussela, N.; Lacaillerie, J. Flow properties of mk-based geopolymer pastes. a comparative study with standard portland cement pastes. Soft Matter 2013, 10, 1134–1141. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Gong, L.; Pan, Y.; Li, C.; Zhou, T.; Cheng, X. Facile construction of the aerogel/geopolymer composite with ultra-low thermal conductivity and high mechanical performance. RSC Adv. 2018, 8, 2350–2356. [Google Scholar] [CrossRef] [PubMed]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Guo, G.; Lv, C.; Liu, J.; Wang, L. Properties of Fiber-Reinforced One-Part Geopolymers: A Review. Polymers 2022, 14, 3333. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.; Abdullah, M.; Vizureanu, P.; Tahir, M. Geopolymers and Their Uses: Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012019. [Google Scholar] [CrossRef]

- Mahesh, K.; Komal, K.; Manjunath, G.S. Workability and strength study on fiber reinforced geopolymer concrete. IUP J. Struct. Eng. 2018, 11, 41–57. [Google Scholar]

- Rashad, A.M. The effect of polypropylene, polyvinyl-alcohol, carbon and glass fibres on geopolymers properties. Mater. Sci. Technol. 2019, 35, 127–146. [Google Scholar] [CrossRef]

- Zhuang, X.; Chen, L.; Komarneni, S.; Zhou, C.; Tong, D.; Yang, H.; Yu, W.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Raj, S.D. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J.; Guo, G.; Zhang, Y. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022, 14, 4134. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [PubMed]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Effect of Type of Fiber on Inter-Layer Bond and Flexural Strengths of Extrusion-Based 3D Printed Geopolymer. Mater. Sci. Forum 2018, 939, 155–162. [Google Scholar] [CrossRef]

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dong, F. Effect of polyethylene fiber content on workability and mechanical-anisotropic properties of 3D printed ultra-high ductile concrete. Constr. Build. Mater. 2021, 281, 122586. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable Reinforced Geopolymer Composite for Extrusion-based 3D Printing. Mater. Lett. 2018, 9, 159. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J.; Pan, J. Properties of 3D-Printable Ductile Fibre-Reinforced Geopolymer Composite for Digital Construction Applications. In Rheology and Processing of Construction Materials; Mechtcherine, V., Khayat, K., Secrieru, E., Eds.; Springer: Cham, Switzerland, 2020; Volume 23. [Google Scholar] [CrossRef]

- Aslani, F.; Ryan, D.; Hamidi, F.; Valizadeh, A. Mechanical and shrinkage performance of 3D-printed rubberised engineered cementitious composites. Constr. Build. Mater. 2022, 339, 127665. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.; Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Chou, S.Y.; Lin, W.T.; Cheng, A.; Hebdowska-Krupa, M.; Gądek, S.; Mikuła, J. Mechanical Properties of Short Fiber-Reinforced Geopolymers Made by Casted and 3D Printing Methods: A Comparative Study. Materials 2020, 13, 579. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Wang, F.; Sanjayan, J. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3d printing. Constr. Build. Mater. 2019, 202, 770–783. [Google Scholar] [CrossRef]

- Bohuchval, M.; Sonebi, M.; Amziane, S.; Perrot, A. Effect of metakaolin and natural fibres on three-dimensional printing mortar. Proc. Inst. Civil. Eng.-Constr. Mater. 2021, 174, 115–128. [Google Scholar] [CrossRef]

- Kornejenko, K.; Ach, M.; Salamtmur, N.D.; Furtos, G.; Mkua, J. The overview of mechanical properties of short natural fiber reinforced geopolymer composites. Environ. Res. Technol. 2020, 3, 21–32. [Google Scholar] [CrossRef]

- Lim, J.; Panda, B.; Pham, Q. Improving flexural characteristics of 3D printed geopolymer composites with improcess steel cable reinforcemen. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Lesovik, V.; Fediuk, R.; Amran, M.; Alaskhanov, A.; Volodchenko, A.; Murali, G.; Uvarov, V.; Elistratkin, M. 3D-Printed Mortars with Combined Steel and Polypropylene Fibers. Fibers 2021, 9, 79. [Google Scholar] [CrossRef]

- Bos, H.L.; Oever, M.; Peters, O. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part1-fibres as reinforcements.Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Mustafa, A.; Abdollah, M.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using weighted decision matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid) (pla) composites: A comparative study. Compos. Sci. Technol. 2015, 66, 1813–1824. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of microwave heating on interlayer bonding and buildability of geopolymer 3D concrete printing, Construct. Build. Mater. 2020, 265, 120786. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Giacobello, F.; Ielo, I.; Belhamdi, H.; Plutino, M.R. Geopolymers and Functionalization Strategies for the Development of Sustainable Materials in Construction Industry and Cultural Heritage Applications: A Review. Materials 2022, 15, 1725. [Google Scholar] [CrossRef] [PubMed]

- Sambucci, M.; Sibai, A.; Valente, M. Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review. J. Comp. Sci. 2021, 5, 109. [Google Scholar]

- Duxson, P.; Lukey, G.; Separovic, F.; Deventer, J. Effect of Alkali Cations on Aluminum Incorporation in Geopolymeric Gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef] [PubMed]

- Murcia, D.; Genedy, M.; Taha, M. Examining the significance of infill printing pattern on the anisotropy of 3D printed concrete. Constr. Build. Mater. 2020, 262, 120559. [Google Scholar] [CrossRef]

- Yalçınkaya, Ç. Influence of Hydroxypropyl Methylcellulose Dosage on the Mechanical Properties of 3D Printable Mortars with and without Fiber Reinforcement. Buildings 2022, 12, 360. [Google Scholar] [CrossRef]

- Ma, S.; Yang, H.; Zhao, S.; He, P.; Zhang, Z.; Duan, X.; Yang, Z.; Jia, D.; Zhou, Y. 3D-printing of architectured short carbon fiber-geopolymer composite. Compos. Part B 2021, 226, 109348. [Google Scholar] [CrossRef]

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Shaping of geopolymer composites by 3D printing. J. Build. Eng. 2021, 34, 101894. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D printing geopolymers: A review. Cem. Concr. Comp. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Kong, X.; Dai, L.; Wang, Y.; Qiao, D.; Hou, S.; Wang, S. Influence of kenaf stalk on printability and performance of 3D printed industrial tailings based geopolymer. Constr. Build. Mater. 2022, 315, 125787. [Google Scholar] [CrossRef]

- Long, W.; Tao, J.; Lin, X.; Gu, Y.; Mei, L.; Duan, H.; Xing, F. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. J. Clean. Prod. 2019, 239, 118054. [Google Scholar] [CrossRef]

- Sinka, M.; Zorica, J.; Bajare, D.; Sahmenko, G.; Korjakins, A. Fast Setting Binders for Application in 3D Printing of Bio-Based Building Materials. Sustainability 2020, 12, 8838. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Comp. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Sanjayan, J. Development of 3d printable engineered cementitious composites with ultra-high tensile ductility for digital construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, J.; Wang, Q.; Shi, J.; Wang, H. PVA fifibre reinforced high-strength cementitious composite for 3D printing: Mechanical properties and durability. Addit. Manuf. 2022, 49, 102500. [Google Scholar]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Malaszkiewicz, D. Influence of polymer fibers on rheological properties of cement mortars. Open Eng. 2017, 7, 228–236. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswe, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kejzlar, P.; Louda, P. The Influence of the Material Structure on the Mechanical Properties of Geopolymer Composites Reinforced with Short Fibers Obtained with Additive Technologies. Int. J. Mol. Sci. 2022, 23, 2023. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, Q.; Li, J. Shrinkage and mechanical properties optimization of spray-based 3D printed concrete by PVA fiber. Mater. Lett. 2022, 319, 132253. [Google Scholar] [CrossRef]

- Weng, Y.; Lu, B.; Li, M.; Liu, Z.; Tan, M.; Qian, S. Empirical models to predict rheological properties of fiber reinforced cementitious composites for 3d printing. Constr. Build. Mater. 2018, 189, 676–685. [Google Scholar] [CrossRef]

- Tosun-Felekoglu, K.; Felekoglu, B. Effects of fibre hybridization on multiple cracking potential of cement-based composites under flexural loading. Constr. Build. Mater. 2013, 41, 15–20. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Z.; Wang, L. Interlayer Bond Strength of 3D Printing Cement Paste by Cross-Bonded Method. J. Chin. Ceram. Soc. 2019, 47, 648–652. [Google Scholar]

- Ye, J.; Cui, C.; Yu, J. Fresh and anisotropic-mechanical properties of 3D printable ultra-high ductile concrete with crumb rubber. Compos. Part B Eng. 2021, 211, 108639. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Chaves Figueiredo, S.; Romero Rodríguez, C.; Ahmed, Z.Y.; Bos, D.H.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials 2020, 13, 2253. [Google Scholar] [CrossRef] [PubMed]

- Zareiyana, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Bond properties of reinforcing bar penetrations in 3D concrete printing. Autom. Constr. 2020, 120, 103394. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Method for the enhancement of buildability and bending resistance of 3D printable tailing mortar. Int. J. Concr. Struct. M. 2018, 12, 37–48. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Automat. Constr. 2011, 21, 262–268. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Zhou, X. Anisotropic behavior in bending of 3D printed concrete reinforced with fibers. Compos. Struct. 2020, 254, 112808. [Google Scholar] [CrossRef]

- Oxman, N.; Tsai, E.; Firstenberg, M. Digital anisotropy: A variable elasticity rapid prototyping platform: This paper proposes and demonstrates a digital anisotropic fabrication approach by employing a multi-material printing platform to fabricate materials with controlled gradient properties. Virtual Phys. Prototyp. 2012, 7, 261–274. [Google Scholar] [CrossRef]

- Souza, M.T.; Ferreira, I.M.; Guzi, M.E. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Ma, G.; Salman, N.M.; Wang, L. A novel additive mortar leveraging internal curing for enhancing interlayer bonding of cementitious composite for 3D printing. Constr. Build. Mater. 2020, 244, 118305. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Z.; Ma, G. Interlayer bonding improvement of 3D printed concrete with polymer modified mortar: Experiments and molecular dynamics studies. Cem. Concr. Comp. 2020, 110, 103571. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J.; Xia, M. Method of enhancing interlayer bond strength in construction scale 3D printing with mortar by effective bond area amplification. Mater. Design 2019, 169, 107684. [Google Scholar]

- Hosseini, E.; Zakertabrizi, M.; Korayem, A.H.; Xu, G. A novel method to enhance the interlayer bonding of 3D printing concrete: An experimental and computational investigation. Cem. Concr. Comp. 2019, 99, 112–119. [Google Scholar] [CrossRef]

- Vaganov, V.; Popov, M.; Korjakins, A.; Šahmenko, G. Effect of CNT on Microstructure and Minearological Composition of Lightweight Concrete with Granulated Foam Glass. Procedia Eng. 2017, 172, 1204–1211. [Google Scholar] [CrossRef]

- Jeevanagoudar, Y.V.; Krishna, R.H.; Gowda, R.; Preetham, R.; Prabhakara, R. Improved mechanical properties and piezoresistive sensitivity evaluation of MWCNTs reinforced cement mortars. Constr. Build. Mater. 2017, 144, 188–194. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Falara, M.G.; Nitodas, S.F. Fresh and mechanical properties, and strain sensing of nanomodified cement mortars: The effects of MWCNT aspect ratio, density and functionalization. Cem. Concr. Comp. 2017, 82, 137–151. [Google Scholar] [CrossRef]

- Ghazizadeh, S.; Duffour, P.; Skipper, N.T.; Bai, Y. Understanding the behaviour of graphene oxide in Portland cement paste. Cem. Concr. Res. 2018, 111, 169–182. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, H.; Zhang, C. Effect of graphene on mechanical properties and microstructure of cement paste. J. Harbin Inst. Technol. 2015, 47, 26–30. [Google Scholar]

- Cao, M.; Xu, L.; Zhang, C. Rheological and mechanical properties of hybrid fiber reinforced cement mortar. Constr. Build. Mater. 2018, 171, 736–742. [Google Scholar] [CrossRef]

- Fan, L.; Wang, L.; Ma, G. Enhanced compressive performance of concrete via 3D-printing reinforcement. J. Zhejiang Univ.-Sci. A 2019, 20, 675–684. [Google Scholar] [CrossRef]

- Van Der Putten, J.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Microstructural Characterization of 3D Printed Cementitious Materials. Materials 2019, 12, 2993. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 282–400. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Bos, F.P.; Ahmed, Z.Y.; Jutinov, E.R.; Salet, T.A.M. Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete. Materials 2017, 10, 1314. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal De Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Zhang, D.; Tan, M.; Qian, S. Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process. Cem. Concr. Res. 2021, 143, 106386. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J. Printability, accuracy and strength of geopolymer made using powder-based 3D printing for construction applications. Autom. Constr. 2019, 101, 179–189. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G. Modification of early strength parameters of concrete by the addition of fly ash and admixture of nano C-S-H for application in 3D printing. MATEC Web Conf. 2020, 323, 01016. [Google Scholar] [CrossRef]

- Bong, S.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications. Materials 2019, 12, 902. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.V.P.B.; Unluer, C.; Tan, M.J. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Comp. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Alghamdi, H.; Nair, S.A.O.; Neithalath, N. Insights into material design, extrusion rheology, and properties of 3D-printable alkali-activated fly ash-based binders. Mater. Des. 2019, 167, 107634. [Google Scholar] [CrossRef]

- Tay, Y.; Ting, G.; Qian, Y.; Panda, B.; He, L.; Tan, M. Time gap effect on bond strength of 3D-printed Concrete. Virtual Phys. Prototyp. 2018, 14, 104–131. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.; Hui, L.; Tay, Y.; Tan, M. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Beushausen, H.; Alexander, M. Bond strength development between concretes of different ages. Mag. Concr. Res. 2008, 60, 65–74. [Google Scholar] [CrossRef]

- Sun, X.; Gao, C.; Wang, H. Bond performance between BFRP bars and 3d printed concrete. Constr. Build. Mater. 2021, 269, 121325. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Method of enhancing interlayer bond strength in 3D concrete printing. RILEM Bookseries 2019, 19, 148–156. [Google Scholar]

- Panda, B.; Paul, S.; Mohamed, N.; Tay, Y.; Tan, M. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2017, 113, 108–116. [Google Scholar] [CrossRef]

- Sakka, F.; Assaad, J.; Hamzeh, F.; Nakhoul, C. Thixotropy and interfacial bond strengths of polymer-modified printed mortars. Mater. Struct. 2019, 52, 79–95. [Google Scholar] [CrossRef]

- Sun, X.; Le, K.; Wang, H.; Zhang, Z.; Chen, L. Influence of Extruded Strip Shape and Dimension on the Mechanical Properties of 3D Printed Concrete. J. Build. Mater. 2020, 23, 1313–1320. [Google Scholar]

| Fiber | Fiber Content /% | Type of Binder | Binder | Fine Aggregate/% | Additive /% | Ref. |

|---|---|---|---|---|---|---|

| polypropylene | 0.25–1.00 | GP | 100 (FA) | 150.00 | 2–0.40(CMC) | [41] |

| 0.25 | GP | 100 (FA) | 108.70 | 0.24(CMC) | [42] | |

| 1.00, 1.50, 2.00 | OPC + GP | 18 (FA), 38 (SF) | 92.07 | - | [43] | |

| 0.56 | GP | 64 (FA), 25 (GGBS), 11 (SF) | 120.00 | (HEC) | [44] | |

| 0.5 | GP | 100 (FA) | 100.00 | - | [27] | |

| polyvinyl alcohol | 0.25 | GP | 100 (FA) | 108.70 | 0.52(CMC) | [42] |

| 2.00 | GP | 50 (FA), 50 (GGBS) | 100.00 | 0.20(CMC) | [45] | |

| 1.75 | OPC + GP | 55 (GGBS), 5(SF) | 36.00 | 0.6 (SP) | [46] | |

| Polyphenylene benzoxazole | 0.25 | GP | 100 (FA) | 108.70 | 0.10(CMC) | [42] |

| Steel | 1.00 | GP | 100 (FA) | 100.00 | - | [27] |

| Glass | 0.25, 0.5, 0.75, 1.00 | OPC + GP | 23 (FA),5 (GGBS), 3 (SF) | 47.00 | 2.00(HPMC) | [47] |

| Carbon | 1.00 | GP | 100 (FA) | 100.00 | - | [48] |

| Basalt | 0.10, 0.30, 0.50, 0.70 | OPC + GP | 29 (FA), 14 (SF) | 171.00 | [49] | |

| Flax | 1.00 | GP | 100 (FA) | 100.00 | - | [48] |

| Sisal | 0.60, 1.00 | OPC + GP | 22(FA), 12(MTK) | 188.00 | 0.60 (SP) | [50] |

| Fiber Type | Fiber Name | Density /g/cm3 | Tensile Strength/MPa | Specific Strength | Tensile Modulus/GPa | Specific Modulus | Elongation at Break/% | Ref. |

|---|---|---|---|---|---|---|---|---|

| Synthetic organic | Polypropylene | 0.90 | 880 | 978 | 13.2 | 14.7 | 17.6 | [41] |

| Polyvinyl alcohol | 1.30 | 1600 | 1231 | 37 | 28.5 | 6.0 | [42] | |

| Polyphenylene benzoxazole | 1.56 | 5800 | 3718 | 270 | 173.1 | 2.5 | [42] | |

| Inorganic | Carbon | 1.60 | 5000 | 3125 | 230 | 143.8 | 1–1.5 | [48] |

| SUS304 | 7.90 | 515 | 65 | 193 | 24.4 | 40 | [52] | |

| Steel | 7.80 | 800 | 103 | 200 | 25.6 | 1.2 | [53] | |

| Basalt | 2.55 | 2180 | 855 | 87.2 | 34.2 | 2.55 | [50] | |

| Plant | Flax | 1.50 | 800–1500 | 535–1000 | 27.6–80 | 18.4–53 | 1.2–3.2 | [54] |

| Hemp | 1.48 | 550–900 | 372–608 | 70 | 47.3 | 2–4 | [55] | |

| Jute | 1.46 | 393–800 | 269–548 | 10–30 | 6.85–20.6 | 1.5–1.8 | [56] | |

| Kenaf | 1.45 | 930 | 641 | 53 | 36.55 | 1.6 | [57] | |

| Sisal | 1.45 | 530–640 | 366–441 | 9.4–22 | 6.5–15.2 | 3–7 | [41] | |

| Cotton | 1.60 | 287–597 | 179–373 | 5.5–12.6 | 3.44–7.9 | 7–8 | [58] | |

| Coir | 1.20 | 175 | 146 | 4–6 | 3.3–5 | 30 | [41] | |

| Wood | 1.50 | 1000 | 667 | 40 | 26.67 | 4.4 | [58] |

| Binder/% | Activator | A/B | Fiber Content /% | Aspect Ratio | Property Measurement | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| FA | GGBS | SF | ||||||

| 80 | 15 | 5 | K2SiO3 | 0.45 | 0.5 (PVA) | 5714 | Thixotropic, flexural, microstructure | [52] |

| 50 | 50 | - | Na2SiO3 (Anhydrous) | 0.40 | 1.0 (PVA) | 231 | Thixotropic, deformation, stiffness, interlayer strength, microstructure | [59] |

| 74 | 16 | 10 | K2SiO3 | 0.65 | 0.25–1.0 (Glass) | 3, 6, 8 a | Compressive, flexural, and tensile strength | [47] |

| 100 | - | - | NaOH + Na2SiO3 (D grade) | 0.52 | 0.5 (PP) | 227 | Buildability, flexural strength | [27] |

| 1.0 (Steel) | 65 | |||||||

| 64 | 25 | 11 | Na2SiO3⋅5H2O | 0.31 | 0.8 (Stainless steel cable) | 1200 b | Flexural behavior | [44] |

| 64 | 25 | 11 | Na2SiO3⋅5H2O | 0.31 | 0.8 (Stainless steel cable) | 1200 b | Compressive, tensile, shear, and pull-out behavior | [60] |

| 50 | 50 | - | Na2SiO3 (Anhydrous) | 0.28 | 2.0 (PVA) | 200 | Density, porosity, compressive, and flexural strength | [55] |

| 87.7 | 4.6 | 7.7 | NaOH + K2SiO3 | 0.49 | 0.25 (Glass) | 4 a | Static yield stress, thixotropic, shape retention ability, deformation | [61] |

| 83.1 | 9.2 | 7.7 | ||||||

| 78.5 | 13.8 | 7.7 | ||||||

| Author | Nozzle Dimension (mm) | Printer Speed (mm/s) | Layer Height (mm) | Layer Width (mm) | Time Interval (min) | Curing Conditions | Ref. |

|---|---|---|---|---|---|---|---|

| Nematollahi et al. | 15 × 25 | - | 15 | 25 | 15 | Ambient | [41] |

| Aslani et al. | 20 | 10–100 | - | - | - | Standard moist | [46] |

| Panda et al. | 40 × 10 | - | 10 | 40 | 0.13 | laboratory temperature | [47] |

| Lim et al. | 13 × 30 | 60 | 13 | 30 | - | Ambient | [52] |

| Sanjayan et al. | 15 × 25 | 12 | 25 | 15 | 10, 20, 30 | Moist and temperature (23 ± 3 °C) | [87] |

| Chaves et al. | 10 × 50 | 100 | 10 | 50 | 3, 2, 4.5 | (20 ± 2)°C and relative humidity of (98 ± 2)% | [92] |

| Panda et al. | 40 × 10 | 90 | 30 | 1 | Ambient | [121] | |

| Weng et al. | 15 × 30 | 14.5–66.7 | 15 | 30 | - | Air; Water; Standard | [117] |

| Panda et al. | 30 × 15/20 × 20 | 70–110 | 20 | 20 | 1–360 | Ambient | [122] |

| Tay et al. | 30 × 15 | 80 | 15 | 30 | 1, 5, 10, 20 | Temperature (23 ± 2 °C) and relative humidity at 60%. | [124] |

| Panda et al. | 15 × 7 | 120 | 7 | 15 | 5–20 | Ambient | [125] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, C.; Shen, H.; Liu, J.; Wu, D.; Qu, E.; Liu, S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials 2022, 15, 8032. https://doi.org/10.3390/ma15228032

Lv C, Shen H, Liu J, Wu D, Qu E, Liu S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials. 2022; 15(22):8032. https://doi.org/10.3390/ma15228032

Chicago/Turabian StyleLv, Chun, Hongtao Shen, Jie Liu, Dan Wu, Enxiang Qu, and Shuang Liu. 2022. "Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy" Materials 15, no. 22: 8032. https://doi.org/10.3390/ma15228032

APA StyleLv, C., Shen, H., Liu, J., Wu, D., Qu, E., & Liu, S. (2022). Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials, 15(22), 8032. https://doi.org/10.3390/ma15228032