Fatigue Characteristics of 7050-T7451 Aluminum Alloy Friction Stir Welding Joints and the Stress Ratio Effect

Abstract

:1. Introduction

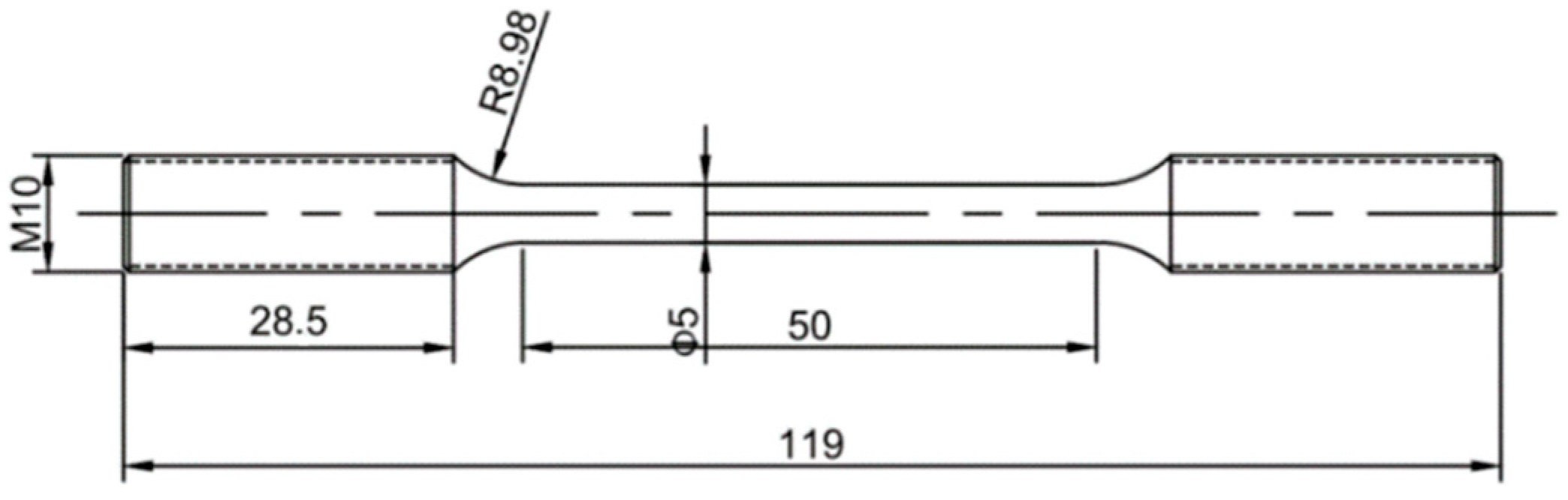

2. Materials and Methods

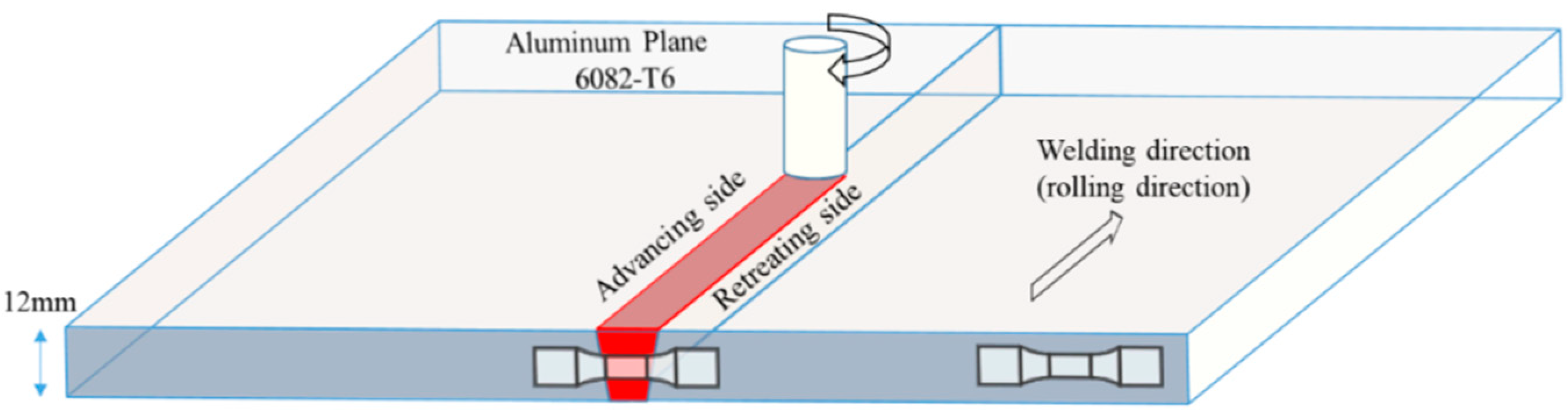

2.1. Materials and FSW Joints

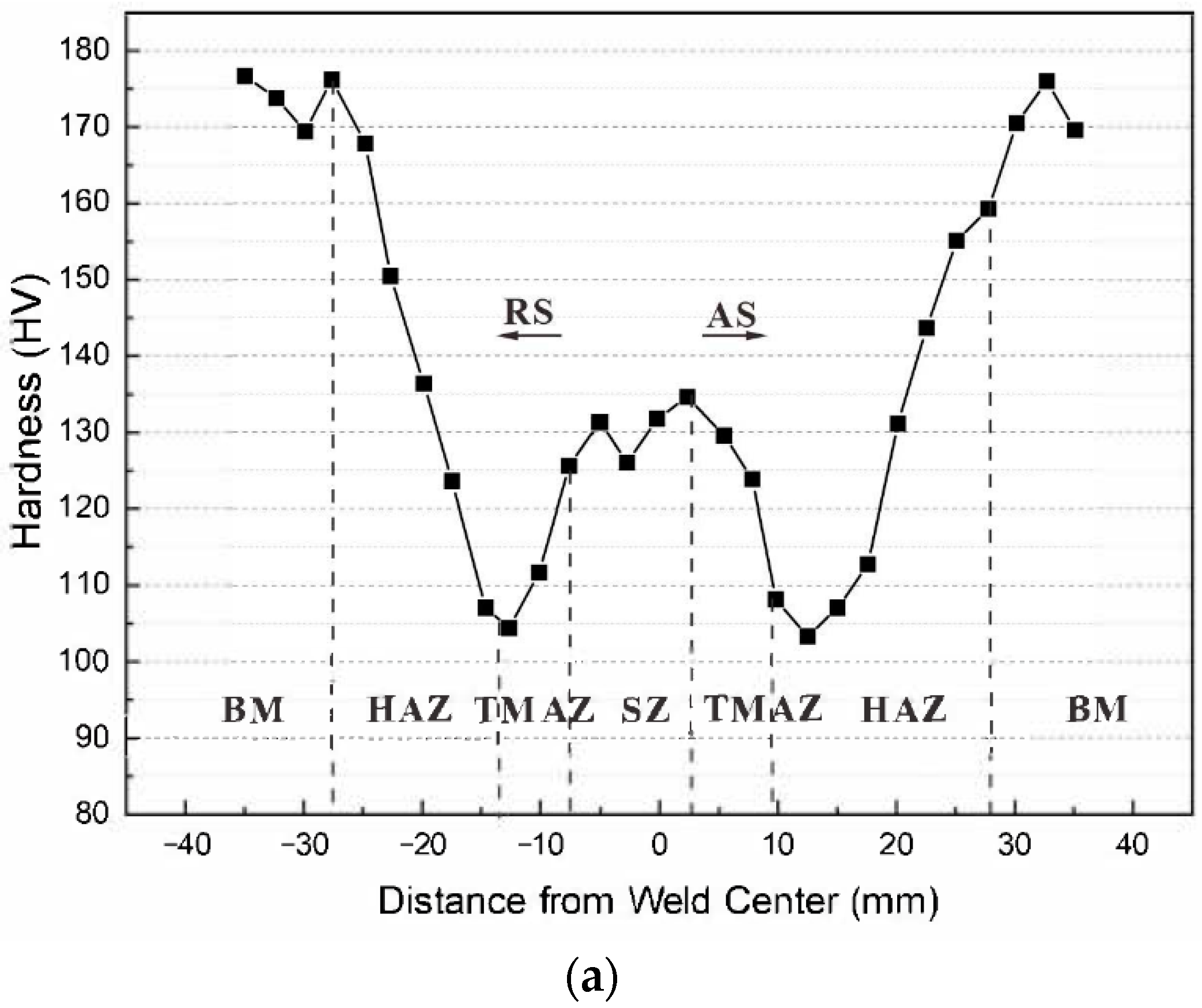

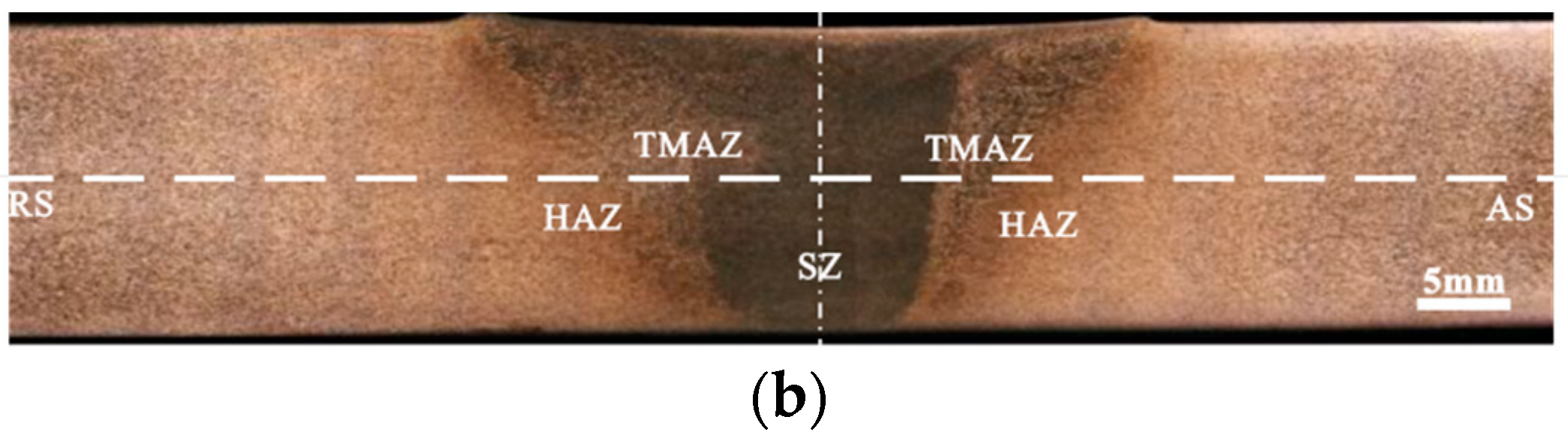

2.2. Hardness Test and Characteristic Areas

2.3. Fatigue Test

2.4. Metallography Preparation and Analysis

3. Results

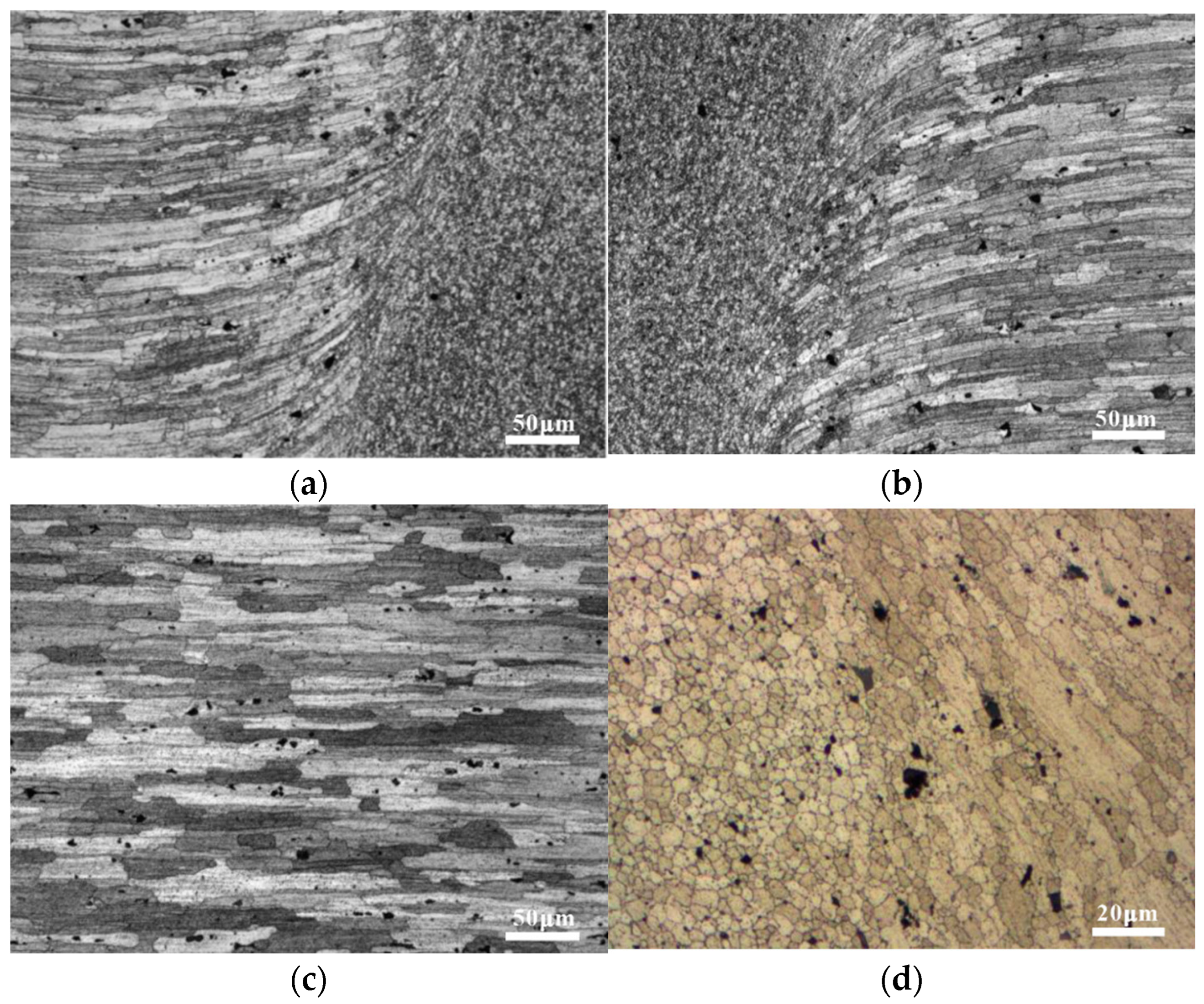

3.1. Microstructure Observations

3.1.1. Metallographic Analysis

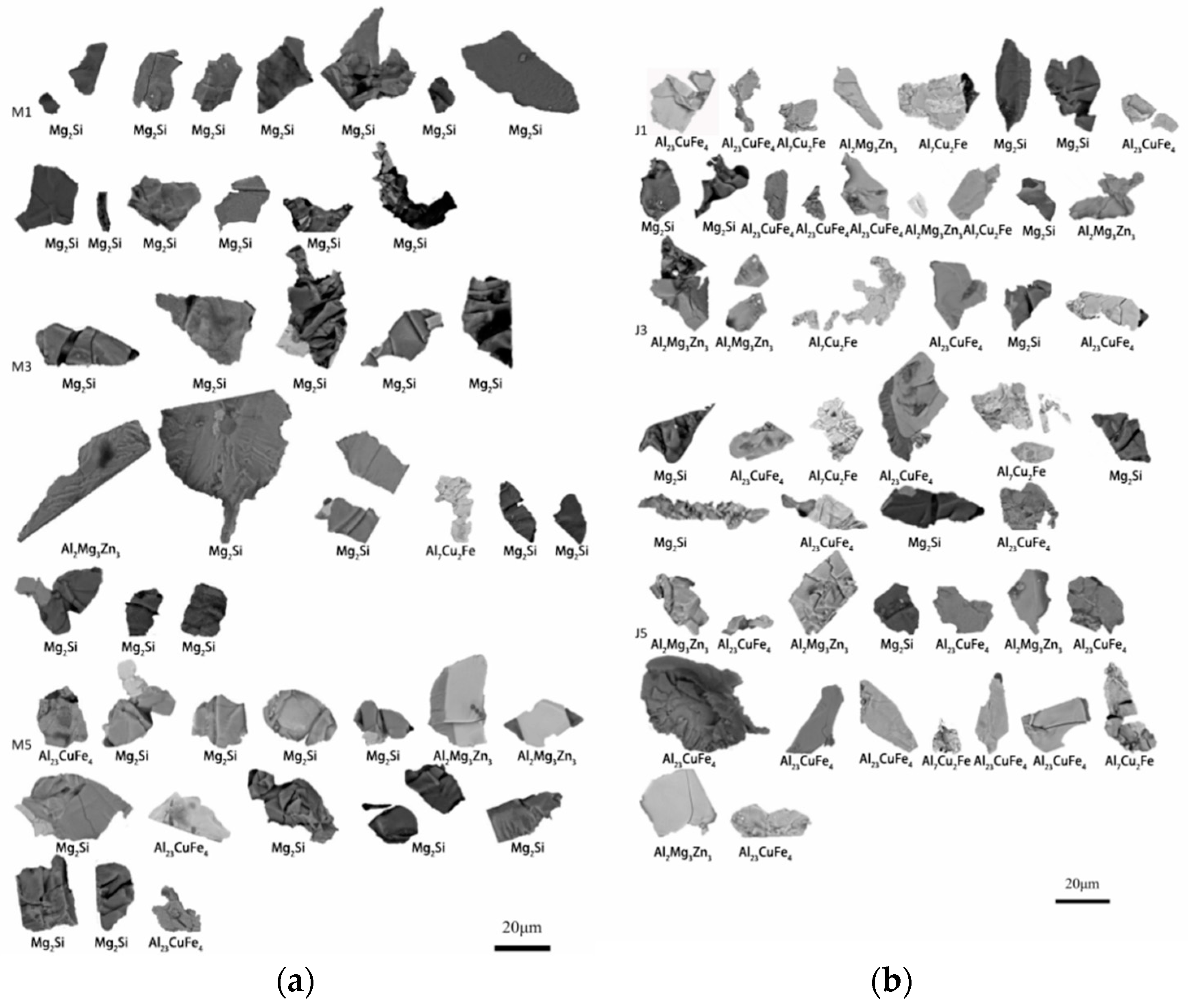

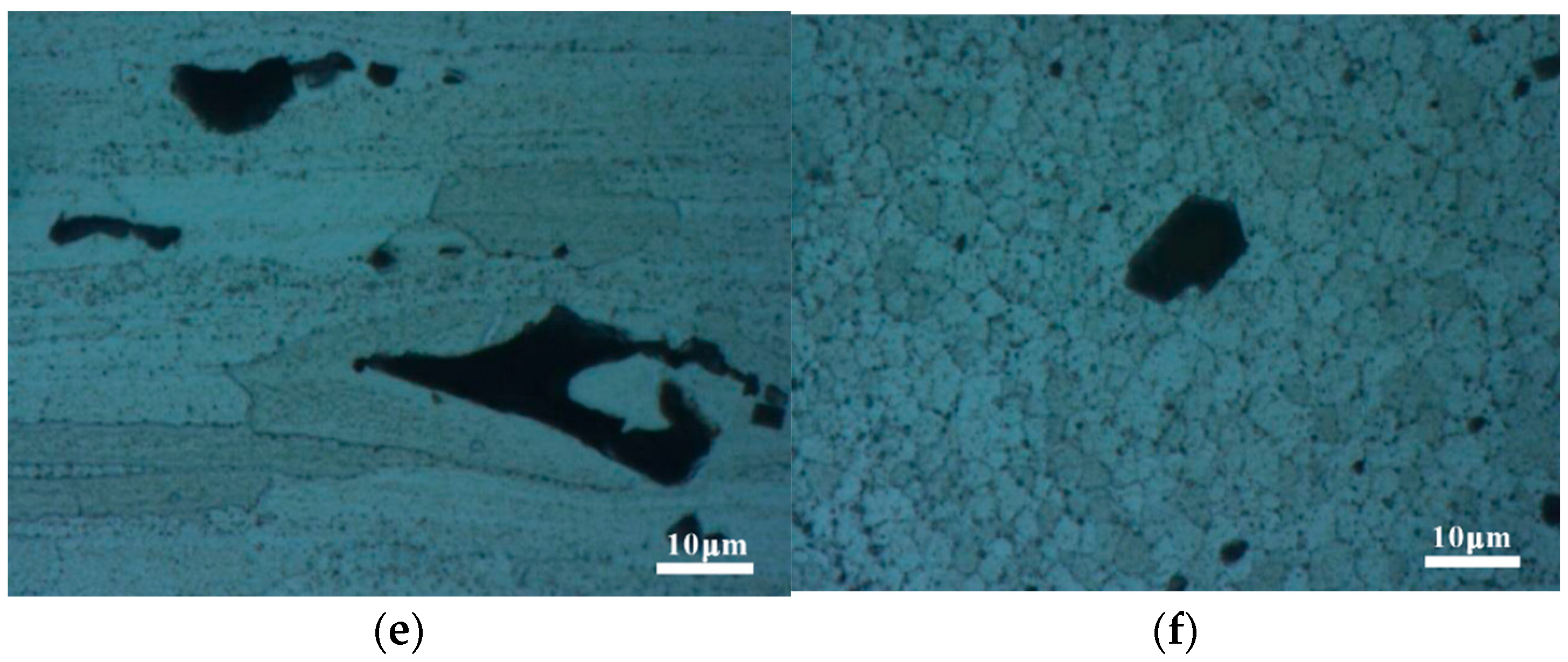

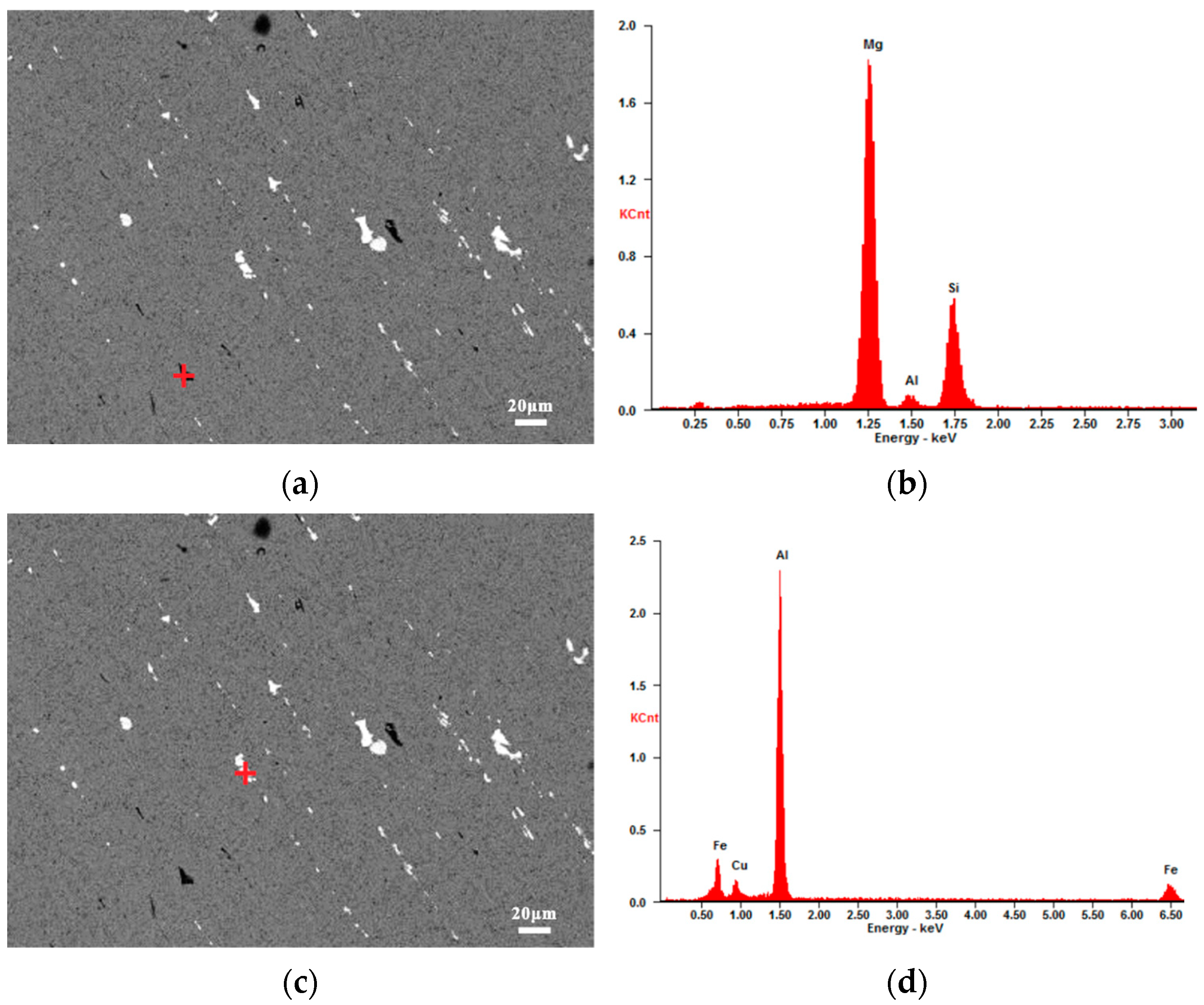

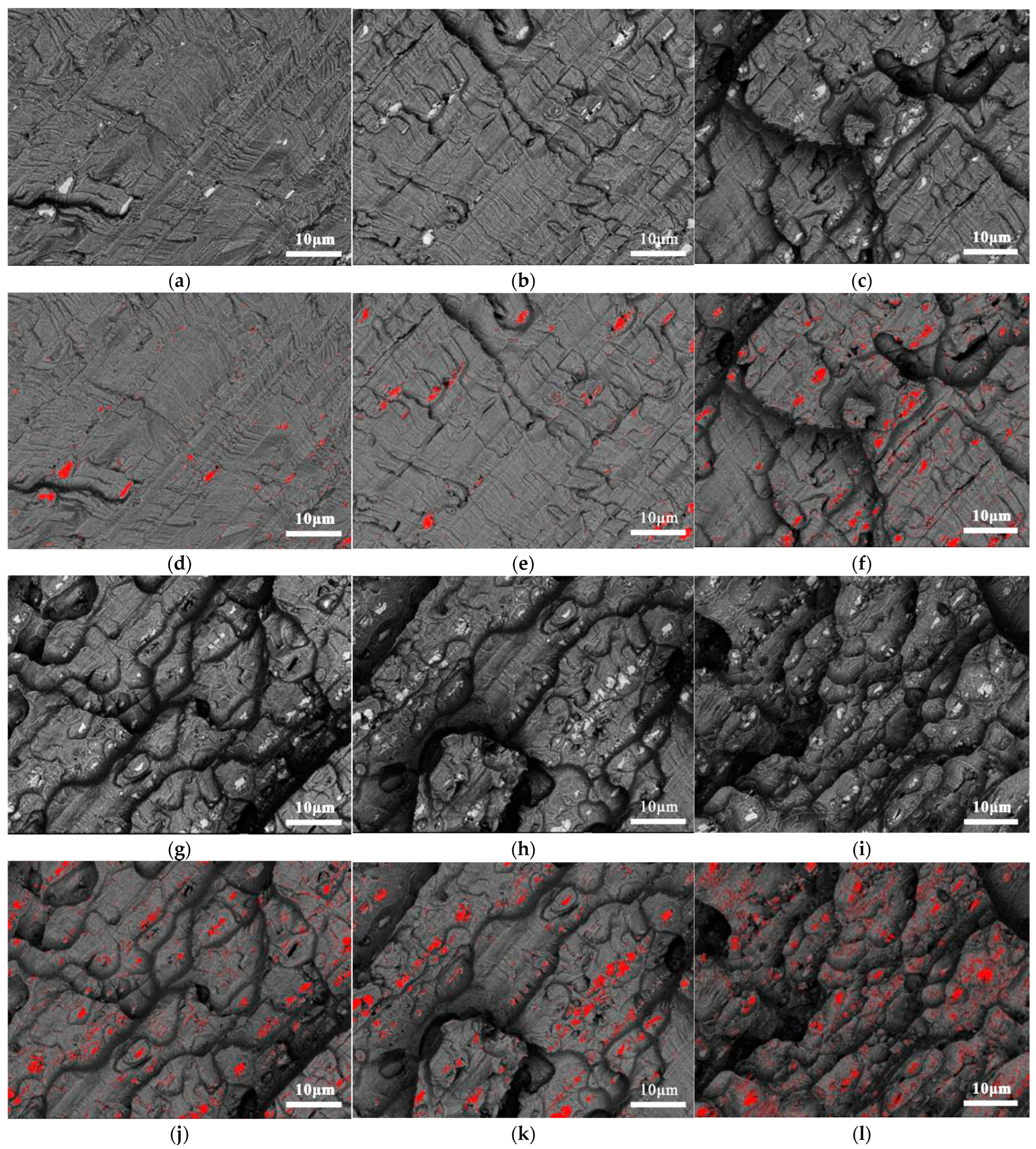

3.1.2. Coarse Secondary Phases

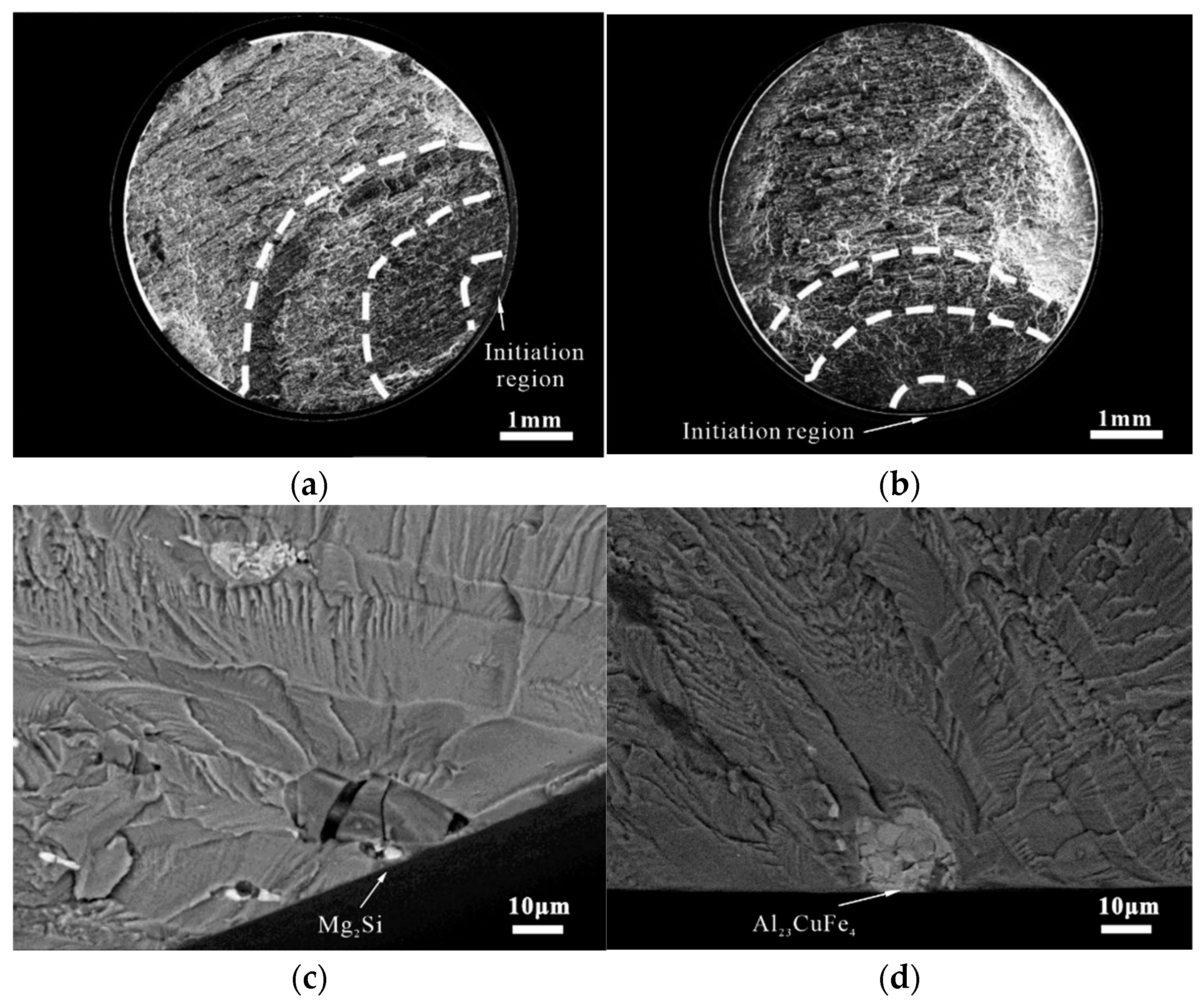

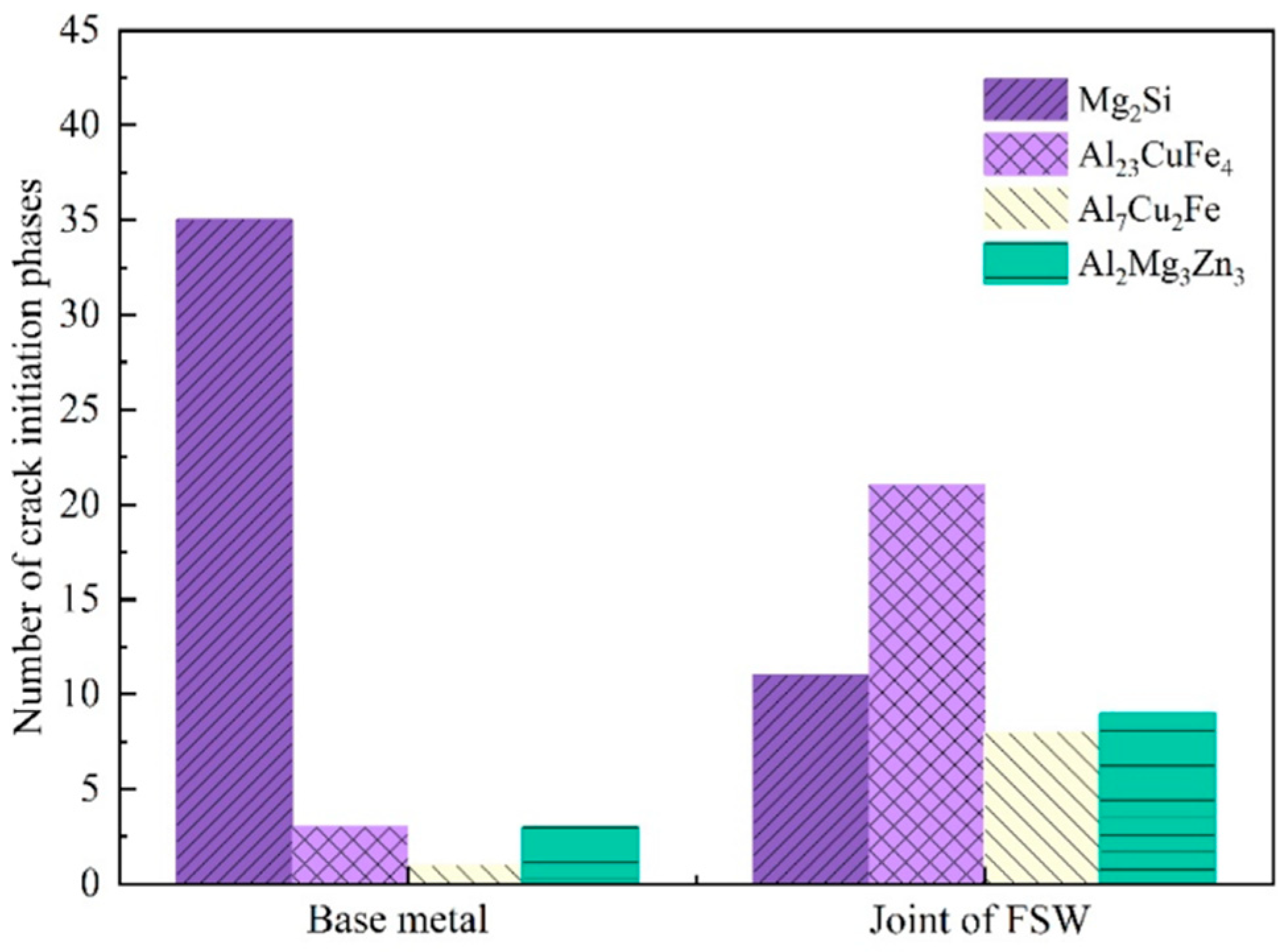

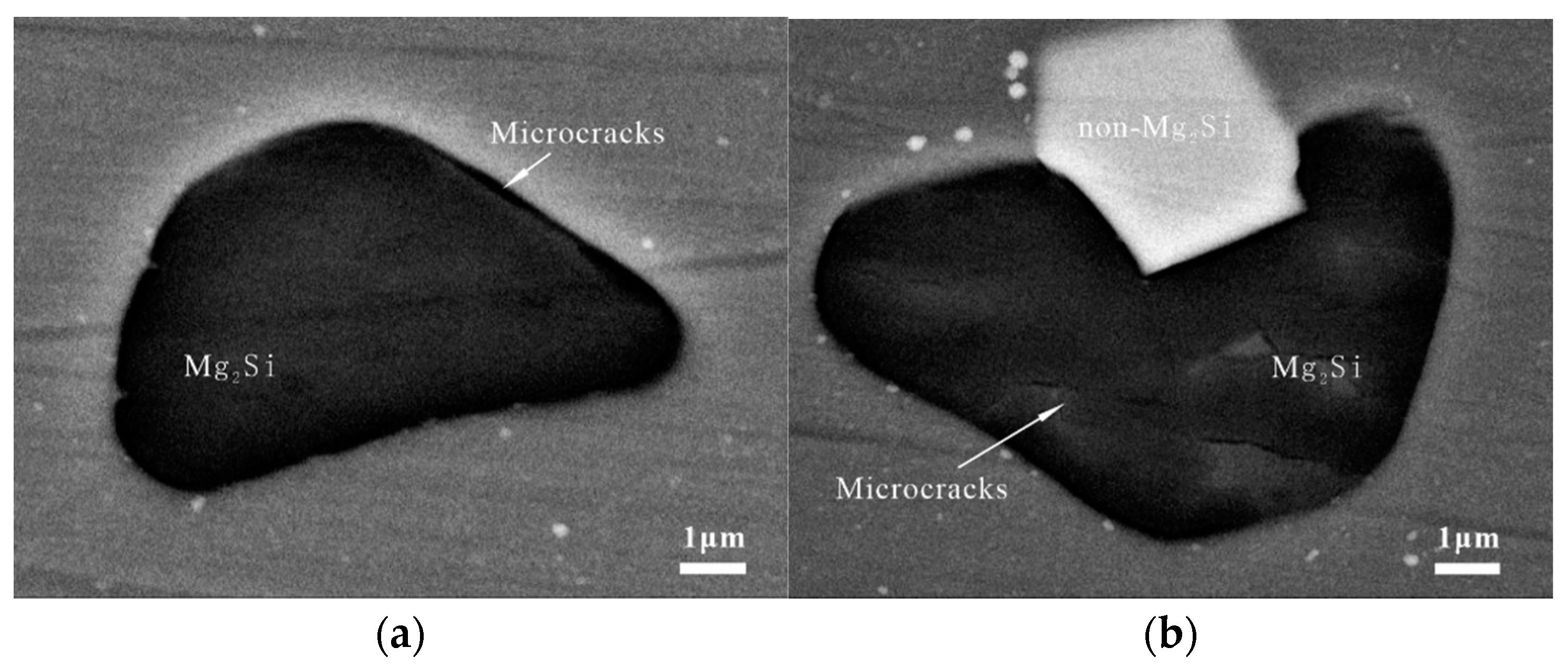

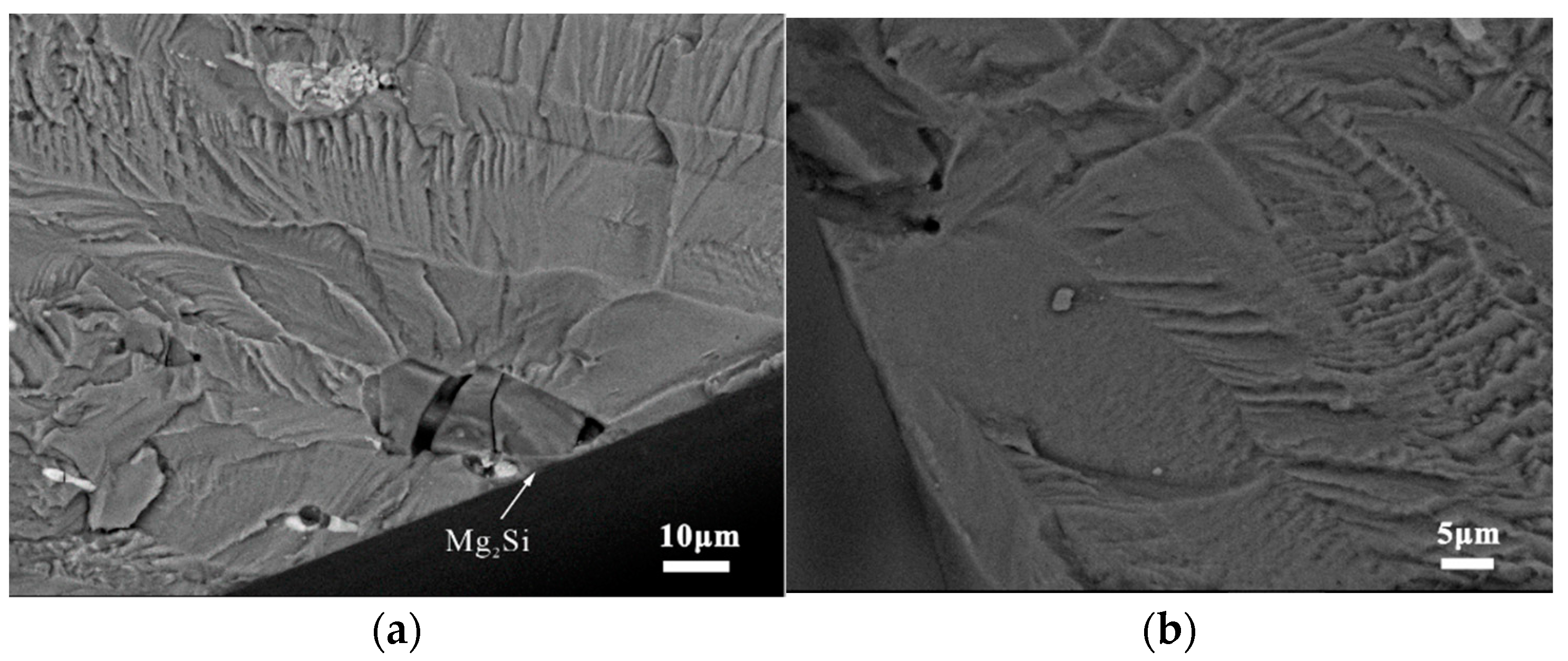

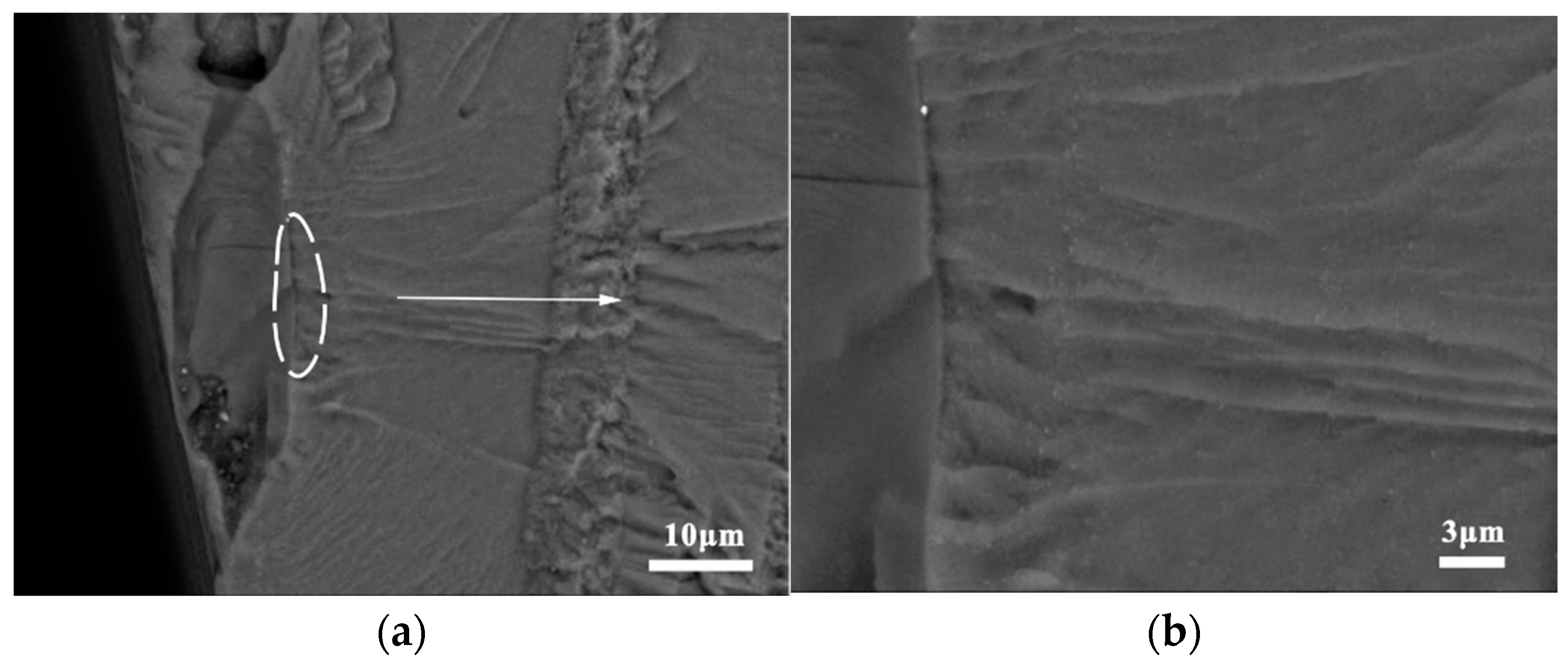

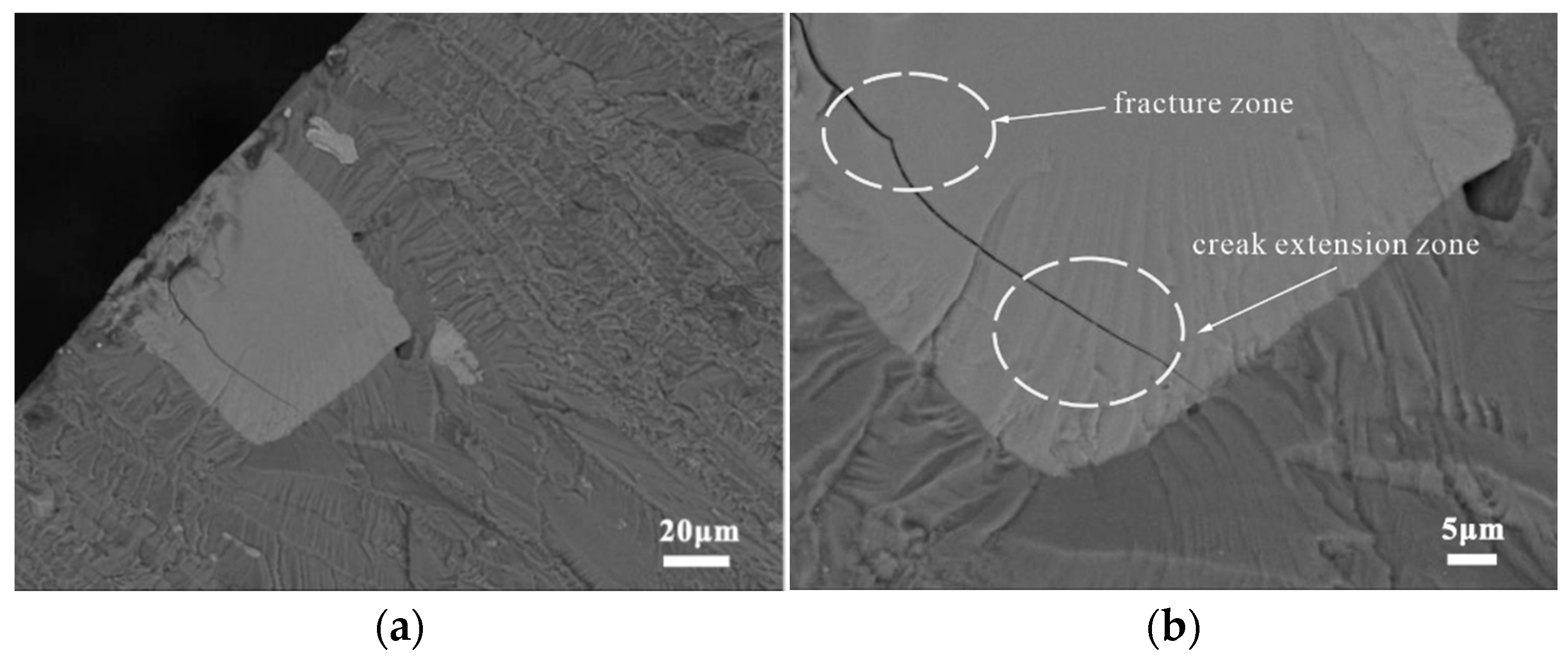

3.2. Fatigue Crack-Initiation Mechanism

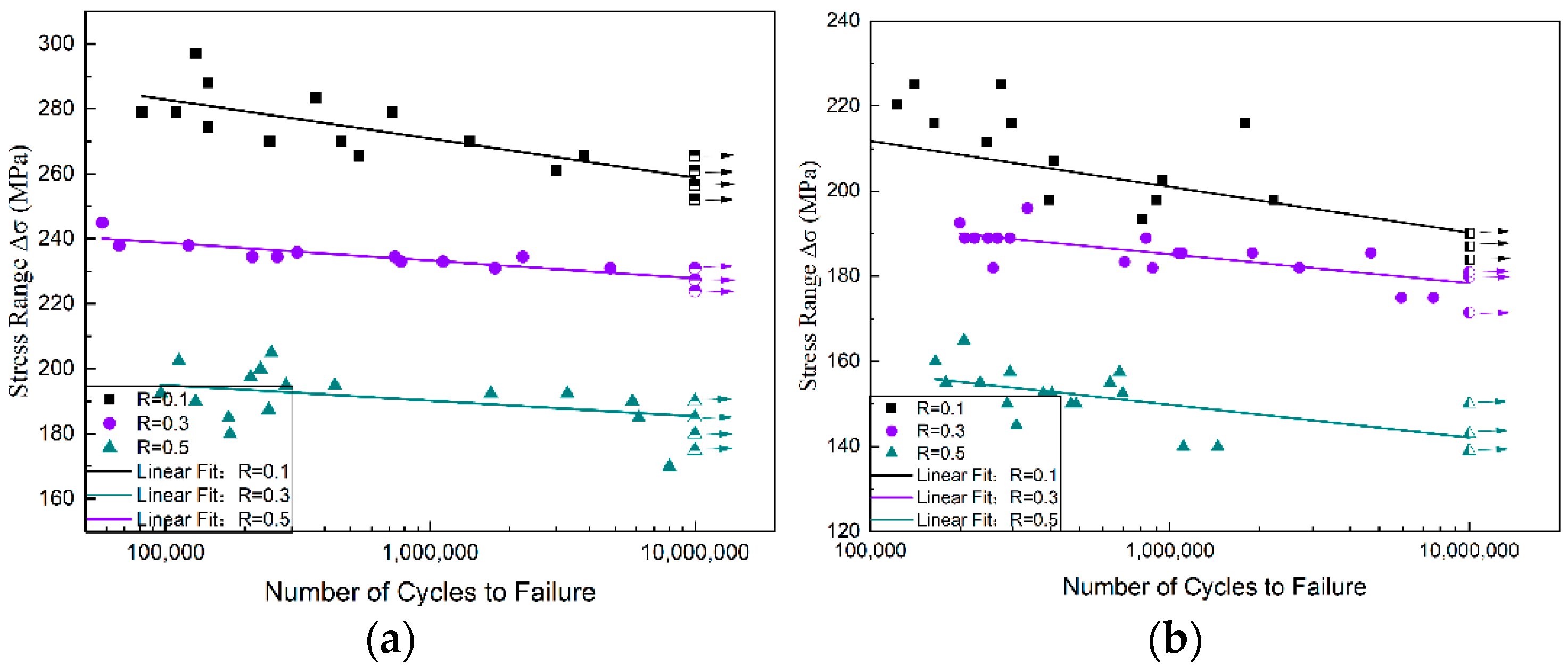

3.3. Effect of the Stress Ratio on the Fatigue Behavior

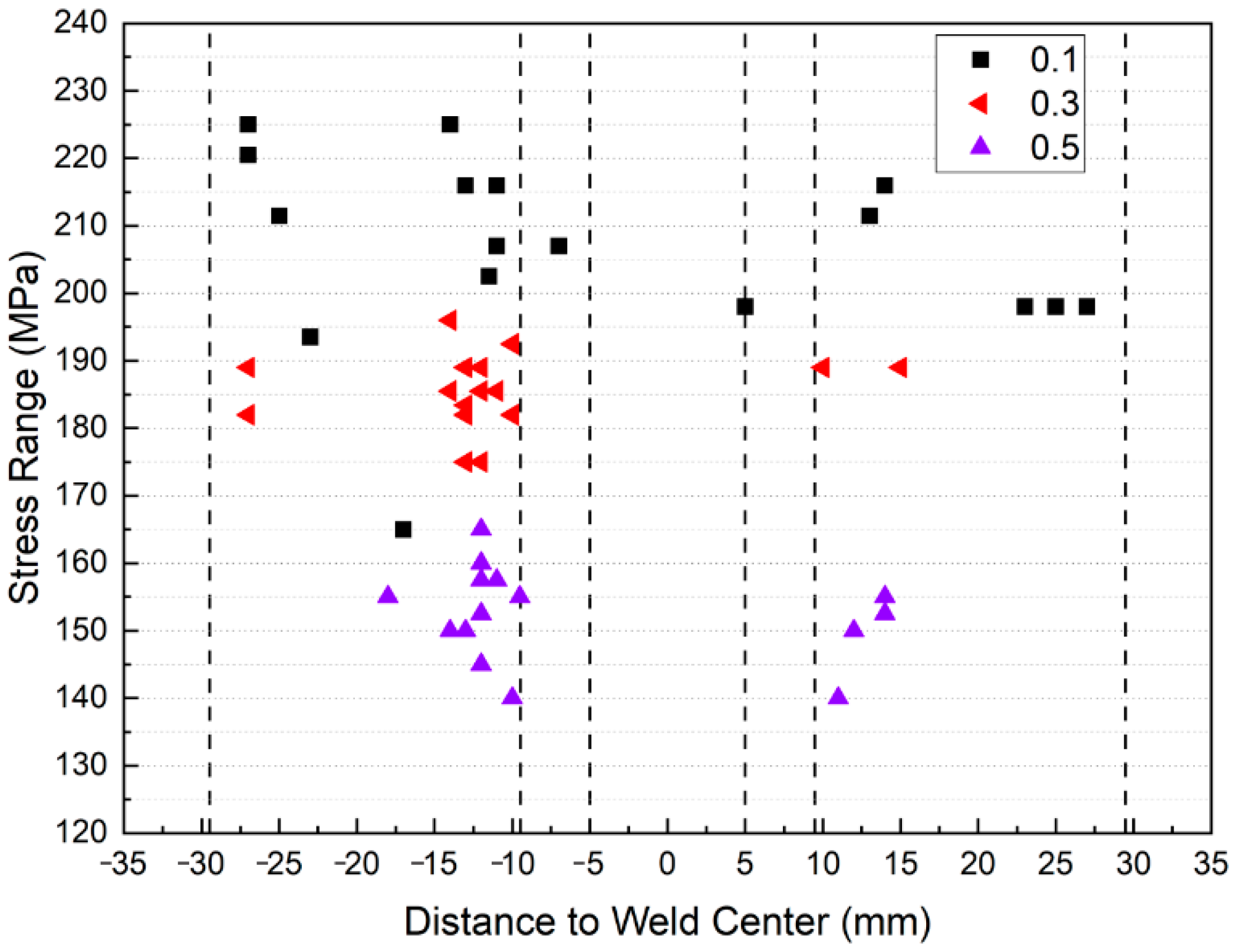

3.4. Effect of the Stress Ratio on the Fracture Location in Joint Specimens

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Specimen | σa (MPa) | σmax (MPa) | Fatigue Life (Cycles) | Result | Fracture Phase |

|---|---|---|---|---|---|

| M-1-1 | 279 | 310 | 81,661 | fracture | Mg2Si |

| M-1-2 | 270 | 300 | 248,588 | fracture | Mg2Si |

| M-1-3 | 261 | 290 | 1.00 × 107 | run-out | - |

| M-1-4 | 265.5 | 295 | 3,802,212 | fracture | Mg2Si |

| M-1-5 | 265.5 | 295 | 537,795 | fracture | Mg2Si |

| M-1-6 | 261 | 290 | 1.00 × 107 | run-out | - |

| M-1-7 | 261 | 290 | 1,848,259 | fracture | Mg2Si |

| M-1-8 | 261 | 290 | 2,991,520 | fracture | Al-Zn-Mg-Cr |

| M-1-9 | 256.5 | 285 | 1.00 × 107 | run-out | - |

| M-1-10 | 252 | 280 | 1.00 × 107 | run-out | - |

| M-1-11 | 265.5 | 295 | 1.00 × 107 | run-out | - |

| M-1-12 | 283.5 | 315 | 369,837 | fracture | Mg2Si |

| M-1-13 | 279 | 310 | 721,061 | fracture | Mg2Si |

| M-1-14 | 279 | 310 | 109,807 | fracture | Mg2Si |

| M-1-15 | 270 | 300 | 463,907 | fracture | Mg2Si |

| M-1-16 | 274.5 | 305 | 145,084 | fracture | Mg2Si |

| M-1-17 | 270 | 300 | 1,409,672 | fracture | Mg2Si |

| M-1-18 | 297 | 330 | 130,704 | fracture | Mg2Si |

| M-1-19 | 288 | 320 | 145,273 | fracture | Mg2Si |

| M-3-1 | 231 | 330 | 88,763 | fracture | Mg2Si |

| M-3-2 | 112 | 224 | 1.00 × 107 | run-out | - |

| M-3-3 | 115.5 | 231 | 1,756,799 | fracture | Mg2Si |

| M-3-4 | 115.5 | 231 | 1.00 × 107 | run-out | - |

| M-3-5 | 122.5 | 245 | 57,674 | fracture | Mg2Si |

| M-3-6 | 119 | 238 | 66,955 | fracture | Mg2Si |

| M-3-7 | 119 | 238 | 122,346 | fracture | Mg2Si |

| M-3-8 | 117.25 | 234.5 | 2,234,893 | fracture | - |

| M-3-9 | 115.5 | 231 | 4,782,308 | fracture | Mg2Si |

| M-3-10 | 117.95 | 235.9 | 314,380 | fracture | Mg2Si |

| M-3-11 | 113.75 | 227.5 | 1.00 × 107 | run-out | - |

| M-3-12 | 117.25 | 234.5 | 213,222 | fracture | Al-Zn-Mg-Cr |

| M-3-13 | 117.25 | 234.5 | 264,515 | fracture | Al7Cu2Fe+Al-Fe-Si |

| M-3-14 | 116.55 | 233.1 | 1,117,538 | fracture | Mg2Si |

| M-3-15 | 116.55 | 233.1 | 774,904 | fracture | Mg2Si |

| M-3-16 | 117.25 | 234.5 | 735,718 | fracture | Mg2Si |

| M-3-17 | 119 | 238 | 2,172,459 | fracture | Mg2Si |

| M-3-18 | 126 | 252 | 151,447 | fracture | Mg2Si |

| M-3-19 | 120.75 | 241.5 | 407,688 | fracture | Mg2Si |

| M-5-1 | 155 | 310 | 1.00 × 107 | run-out | - |

| M-5-2 | 160 | 320 | 1.00 × 107 | run-out | - |

| M-5-3 | 170 | 340 | 8,000,998 | fracture | Al23CuFe4 |

| M-5-4 | 175 | 350 | 1.00 × 107 | run-out | - |

| M-5-5 | 180 | 360 | 175,588 | fracture | Mg2Si |

| M-5-6 | 165 | 330 | 1.00 × 107 | run-out | - |

| M-5-7 | 170 | 340 | 1.00 × 107 | run-out | - |

| M-5-8 | 190 | 380 | 5,801,306 | fracture | Mg2Si |

| M-5-9 | 192.5 | 385 | 96,353 | fracture | Mg2Si |

| M-5-10 | 195 | 390 | 436,398 | fracture | Mg2Si |

| M-5-11 | 192.5 | 385 | 1,694,327 | fracture | Al-Zn-Mg-Cr |

| M-5-12 | 190 | 380 | 129,967 | fracture | Al-Zn-Mg-Cr |

| M-5-13 | 187.5 | 375 | 245,626 | fracture | Mg2Si |

| M-5-14 | 180 | 360 | 1.00 × 107 | run-out | - |

| M-5-15 | 185 | 370 | 173,310 | fracture | Al23CuFe4 |

| M-5-16 | 185 | 370 | 6,137,276 | fracture | Al-Zn-Mg-Cr |

| M-5-17 | 185 | 370 | 1.00 × 107 | run-out | - |

| M-5-18 | 190 | 380 | 1.00 × 107 | run-out | - |

| M-5-19 | 192.5 | 385 | 1.00 × 107 | run-out | - |

| M-5-20 | 205 | 410 | 251,325 | fracture | Mg2Si |

| M-5-21 | 202.5 | 405 | 112,467 | fracture | Mg2Si |

| M-5-22 | 200 | 400 | 228,618 | fracture | Mg2Si |

| M-5-23 | 195 | 390 | 285,575 | fracture | Mg2Si |

| M-5-24 | 197.5 | 395 | 209,999 | fracture | Mg2Si |

| M-5-25 | 192.5 | 385 | 3,296,722 | fracture | Al23CuFe4+Mg2Si |

| Specimen | σa (MPa) | σmax (MPa) | Fatigue Life (Cycles) | Result | Fracture Position | Fracture Phase |

|---|---|---|---|---|---|---|

| J-1-1 | 165 | 290 | 80,671 | fracture | −17 | Al23CuFe4 |

| J-1-2 | 216 | 240 | 1,791,005 | fracture | −13 | Al23CuFe4 |

| J-1-3 | 207 | 230 | 1.00 × 107 | run-out | - | - |

| J-1-4 | 225 | 250 | 140,232 | fracture | −27 | Al-Fe-Cu-Si |

| J-1-5 | 225 | 250 | 274,147 | fracture | −14 | Al-Zn-Mg+Mg2Si |

| J-1-6 | 220.5 | 245 | 122,771 | fracture | −27 | Al7Cu2Fe |

| J-1-7 | 216 | 240 | 295,384 | fracture | −11 | Mg2Si |

| J-1-8 | 216 | 240 | 163,309 | fracture | 14 | Mg2Si |

| J-1-9 | 211.5 | 235 | 245,078 | fracture | 13 | Al23CuFe4 |

| J-1-10 | 202.5 | 225 | 943,366 | fracture | −11.5 | Mg2Si |

| J-1-11 | 198 | 220 | 902,891 | fracture | 27 | Mg2Si |

| J-1-12 | 198 | 220 | 2,219,198 | fracture | 23 | Al-Fe-Cu-Si |

| J-1-13 | 198 | 220 | 396,098 | fracture | 5 | Al23CuFe4+ Mg2Si |

| J-1-14 | 184.5 | 205 | 1.00 × 107 | run-out | - | - |

| J-1-15 | 193.5 | 215 | 811,127 | fracture | −23 | Al23CuFe4 |

| J-1-16 | 207 | 230 | 410,635 | fracture | −7 | Al-Fe-Cu-Si |

| J-1-17 | 207 | 230 | 990,881 | fracture | −11 | Al-Fe-Si |

| J-1-18 | 211.5 | 235 | 396,522 | fracture | −25 | Mg2Si |

| J-1-19 | 198 | 220 | 2,100,583 | fracture | 25 | Al-Zn-Mg-Cr |

| J-3-1 | 196 | 280 | 334,717 | fracture | −14 | Al-Zn-Mg |

| J-3-2 | 192.5 | 275 | 199,185 | fracture | −10 | Al-Zn-Mg |

| J-3-3 | 185.5 | 265 | 1,066,377 | fracture | −12 | Al7Cu2Fe |

| J-3-4 | 178.5 | 255 | 1.00 × 107 | run-out | - | - |

| J-3-5 | 182 | 260 | 2,710,786 | fracture | −10 | Al23CuFe4 |

| J-3-6 | 179.9 | 257 | 1.00 × 107 | run-out | - | - |

| J-3-7 | 183.4 | 262 | 1.00 × 107 | run-out | - | - |

| J-3-8 | 185.5 | 265 | 1,100,065 | fracture | −12 | Mg2Si |

| J-3-9 | 182 | 260 | 875,146 | fracture | −13 | Al-Fe-Si |

| J-3-10 | 175 | 250 | 7,592,429 | fracture | −13 | Mg2Si |

| J-3-11 | 175 | 250 | 5,932,497 | fracture | −12 | Al23CuFe4 |

| J-3-12 | 171.5 | 245 | 1.00 × 107 | run-out | - | - |

| J-3-13 | 189 | 270 | 831,811 | fracture | 15 | Al7Cu2Fe |

| J-3-14 | 183.4 | 262 | 706,717 | fracture | −13 | Al23CuFe4 |

| J-3-15 | 182 | 260 | 256,803 | fracture | −27 | Al23CuFe4 |

| J-3-16 | 182 | 260 | 1.00 × 107 | run-out | - | - |

| J-3-17 | 189 | 270 | 265,966 | fracture | −12 | Mg2Si |

| J-3-18 | 185.5 | 265 | 4,698,011 | fracture | −11 | Mg2Si |

| J-3-19 | 185.5 | 270 | 1,886,146 | fracture | −14 | Al-Fe-Cu-Si |

| J-3-20 | 189 | 270 | 292,650 | fracture | 10 | Al-Fe-Cu-Si |

| J-3-21 | 189 | 270 | 222,860 | fracture | 15 | Mg2Si |

| J-3-22 | 189 | 270 | 206,630 | fracture | −13 | |

| J-3-23 | 189 | 270 | 247,085 | fracture | −27 | Al23CuFe4 |

| J-5-1 | 165 | 330 | 205,727 | fracture | −12 | Al-Zn-Mg-Cr |

| J-5-2 | 160 | 320 | 165,198 | fracture | −12 | Al23CuFe4 |

| J-5-3 | 145 | 290 | 1.00 × 107 | run-out | - | - |

| J-5-4 | 150 | 300 | 1.00 × 107 | run-out | - | - |

| J-5-5 | 157.5 | 315 | 680,000 | fracture | −11 | Al-Zn-Mg |

| J-5-6 | 155 | 310 | 1.00 × 107 | run-out | - | - |

| J-5-7 | 157.5 | 315 | 293,075 | fracture | −12 | Mg2Si |

| J-5-8 | 152.5 | 305 | 696,085 | fracture | −12 | Al23CuFe4 |

| J-5-9 | 150 | 300 | 487,210 | fracture | −14 | Al-Zn-Mg-Cr |

| J-5-10 | 145 | 290 | 308,020 | fracture | −12 | Al23CuFe4 |

| J-5-11 | 135 | 270 | 1.00 × 107 | run-out | - | - |

| J-5-12 | 140 | 280 | 1,110,861 | fracture | 11 | Al-Fe-Cu-Si |

| J-5-13 | 140 | 280 | 1,448,751 | fracture | −10 | Al-Fe-Cu-Si |

| J-5-14 | 138.5 | 277 | 1.00 × 107 | run-out | - | - |

| J-5-15 | 150 | 300 | 468,549 | fracture | 12 | Al-Fe-Cu-Si |

| J-5-16 | 155 | 310 | 632,045 | fracture | −18 | Al7Cu2Fe |

| J-5-17 | 152.5 | 305 | 404,556 | fracture | 14 | Al-Fe-Cu-Si |

| J-5-18 | 152.5 | 305 | 377,823 | fracture | 14 | Al-Fe-Cu-Si |

| J-5-19 | 150 | 300 | 287,060 | fracture | −13 | Al23CuFe4 |

| J-5-20 | 155 | 310 | 178,972 | fracture | 14 | Al-Zn-Mg |

| J-5-21 | 155 | 310 | 233,045 | fracture | −9.5 | Al-Fe-Cu-Si |

Appendix B

References

- Çam, G.; Ipekoğlu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Wang, D.; Feng, J.; Guo, D.; Sun, C.; Luan, G.; Guo, H. Process of friction-stir welding high-strength aluminum alloy and mechanical properties of joint. China Weld 2004, 13, 159–162. [Google Scholar]

- Ma, Z.Y.; Feng, A.H.; Chen, D.L.; Shen, J. Recent Advances in Friction Stir Welding/Processing of Aluminum Alloys: Microstructural Evolution and Mechanical Properties. Crit. Rev. Solid State Mater. Sci. 2018, 43, 269–333. [Google Scholar] [CrossRef]

- Sun, G.; Wang, C.; Wei, X.; Shang, D.; Chen, S. Study on small fatigue crack initiation and growth for friction stir welded joints. Mater. Sci. Eng. A 2019, 739, 71–85. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Chen, Y.Y.; Zhong, L.P. Initiation and propagation behavior of fatigue crack in 2524-T34 alloy. Chin. J. Nonferrous Met. 2010, 1, 43–48. [Google Scholar]

- Payne, J.; Welsh, G.; Christ, R.J., Jr.; Nardiello, J.; Papazian, J.M. Observations of fatigue crack initiation in 7075-T651. Int. J. Fatigue 2010, 32, 247–255. [Google Scholar] [CrossRef]

- Harlow, D.; Nardiello, J.; Payne, J. The effect of constituent particles in aluminum alloys on fatigue damage evolution: Statistical observations. Int. J. Fatigue 2010, 32, 505–511. [Google Scholar] [CrossRef]

- Singh, S.S.; Schwartzstein, C.; Williams, J.J.; Xiao, X.; De Carlo, F.; Chawla, N. 3D microstructural characterization and mechanical properties of constituent particles in Al 7075 alloys using X-ray synchrotron tomography and nanoindentation. J. Alloys Compd. 2014, 602, 163–174. [Google Scholar] [CrossRef]

- Jin, Y.; Cai, P.; Wen, W.; Nagaumi, H.; Xu, B.; Zhang, Y.; Zhai, T. The anisotropy of fatigue crack nucleation in an AA7075 T651 Al alloy plate. Mater. Sci. Eng. A 2015, 622, 7–15. [Google Scholar] [CrossRef]

- Deng, C.; Han, Q.; Gong, B.; Gao, R. Effects of the heterogeneous microstructure of a 7050-T7451 aluminum alloy FSW joint on fatigue behavior under different stress ratios. Mater. Res. Express A 2019, 6, 126583. [Google Scholar] [CrossRef]

- Ma, M.; Wang, B.; Liu, H.; Yi, D.; Shen, F.; Zhai, T. Investigation of fatigue crack propagation behavior of 5083 aluminum alloy under various stress ratios: Role of grain boundary and Schmid factor. Mater. Sci. Eng. A 2020, 773, 138871. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Lu, Z.; Chen, D. Cyclic deformation of dissimilar welded joints between Ti–6Al–4V and Ti17 alloys: Effect of strain ratio. Mater. Sci. Eng. A 2014, 598, 122–134. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Met. Mater. Trans. A 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Besel, M.; Besel, Y.; Mercado, U.A.; Kakiuchi, T.; Uematsu, Y. Fatigue behavior of friction stir welded Al–Mg–Sc alloy. Int. J. Fatigue 2015, 77, 1–11. [Google Scholar] [CrossRef]

- Sillapasa, K.; Surapunt, S.; Miyashita, Y.; Mutoh, Y.; Seo, N. Tensile and fatigue behavior of SZ, HAZ and BM in friction stir welded joint of rolled 6N01 aluminum alloy plate. Int. J. Fatigue 2014, 63, 162–170. [Google Scholar] [CrossRef]

- White, B.; White, R.; Jordon, J.; Allison, P.; Rushing, T.; Garcia, L. The effect of tensile pre-straining on fatigue crack initiation mechanisms and mechanical behavior of AA7050 friction stir welds. Mater. Sci. Eng. A 2018, 736, 228–238. [Google Scholar] [CrossRef]

- Hassan, K.A.; Prangnell, P.B.; Norman, A.F.; Price, D.A.; Williams, S.W. Effect of welding parameters on nugget zone microstructure and properties in high strength aluminum alloy friction stir welds. Sci. Technol. Weld. Join. 2003, 8, 257–268. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Loder, B.; Safyari, M.; Willidal, T.; Hojo, T.; Mori, G. Hydrogen trapping and desorption affected by ferrite grain boundary types in shielded metal and flux-cored arc weldments with Ni addition. Int. J. Hydrogen Energy 2022, 47, 20676–20683. [Google Scholar] [CrossRef]

- Laz, P.J.; Hillberry, B.M. Fatigue life prediction from inclusion initiated cracks. Int. J. Fatigue 1998, 20, 263–270. [Google Scholar] [CrossRef]

- Frommeyer, G.; Beer, S.; Oldenburg, K.V. Microstructure and Mechanical Properties of Mechanically Alloyed Intermetallic Mg2Si Al Alloys. Z. Met. 1994, 85, 372–377. [Google Scholar]

- Liu, Y.; Deng, C.; Gong, B.; Bai, Y. Effects of heterogeneity and coarse secondary phases on mechanical properties of 7050-T7451 aluminum alloy friction stir welding joint. Mater. Sci. Eng. A 2019, 764, 138223. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Fe | Si | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|

| 5.89 | 2.59 | 1.98 | 0.29 | 0.10 | 0.10 | 0.05 | Remaining |

| ReL/MPa | Rm/MPa | A (%) | HV |

|---|---|---|---|

| 492 | 560 | 12 | 150 |

| Spinning Speed /r·min−1 | Welding Speed /mm·min−1 | Inclination /° | Depression /mm |

|---|---|---|---|

| 300 | 80 | 2.5 | 0.1 |

| Crack Initiation Phase | BM Specimen | FSW Specimen | ||||

|---|---|---|---|---|---|---|

| R = 0.1 | R = 0.3 | R = 0.5 | R = 0.1 | R = 0.3 | R = 0.5 | |

| Mg2Si | 13 | 12 | 10 | 5 | 5 | 1 |

| Al23CuFe4 | 0 | 0 | 3 | 6 | 6 | 9 |

| Al7Cu2Fe | 0 | 1 | 0 | 3 | 3 | 2 |

| Al2Mg3Zn3 | 0 | 1 | 2 | 3 | 2 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Lacidogna, G.; Deng, C.; Gong, B.; Liu, F. Fatigue Characteristics of 7050-T7451 Aluminum Alloy Friction Stir Welding Joints and the Stress Ratio Effect. Materials 2022, 15, 8010. https://doi.org/10.3390/ma15228010

Zhu H, Lacidogna G, Deng C, Gong B, Liu F. Fatigue Characteristics of 7050-T7451 Aluminum Alloy Friction Stir Welding Joints and the Stress Ratio Effect. Materials. 2022; 15(22):8010. https://doi.org/10.3390/ma15228010

Chicago/Turabian StyleZhu, Hanji, Giuseppe Lacidogna, Caiyan Deng, Baoming Gong, and Fei Liu. 2022. "Fatigue Characteristics of 7050-T7451 Aluminum Alloy Friction Stir Welding Joints and the Stress Ratio Effect" Materials 15, no. 22: 8010. https://doi.org/10.3390/ma15228010

APA StyleZhu, H., Lacidogna, G., Deng, C., Gong, B., & Liu, F. (2022). Fatigue Characteristics of 7050-T7451 Aluminum Alloy Friction Stir Welding Joints and the Stress Ratio Effect. Materials, 15(22), 8010. https://doi.org/10.3390/ma15228010