Effect of Cellulose Nanofibrils on the Physical Properties and Frost Resistance of Pervious Concrete

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Mixture Proportions

2.2. Test Methods

2.2.1. Rheological Properties

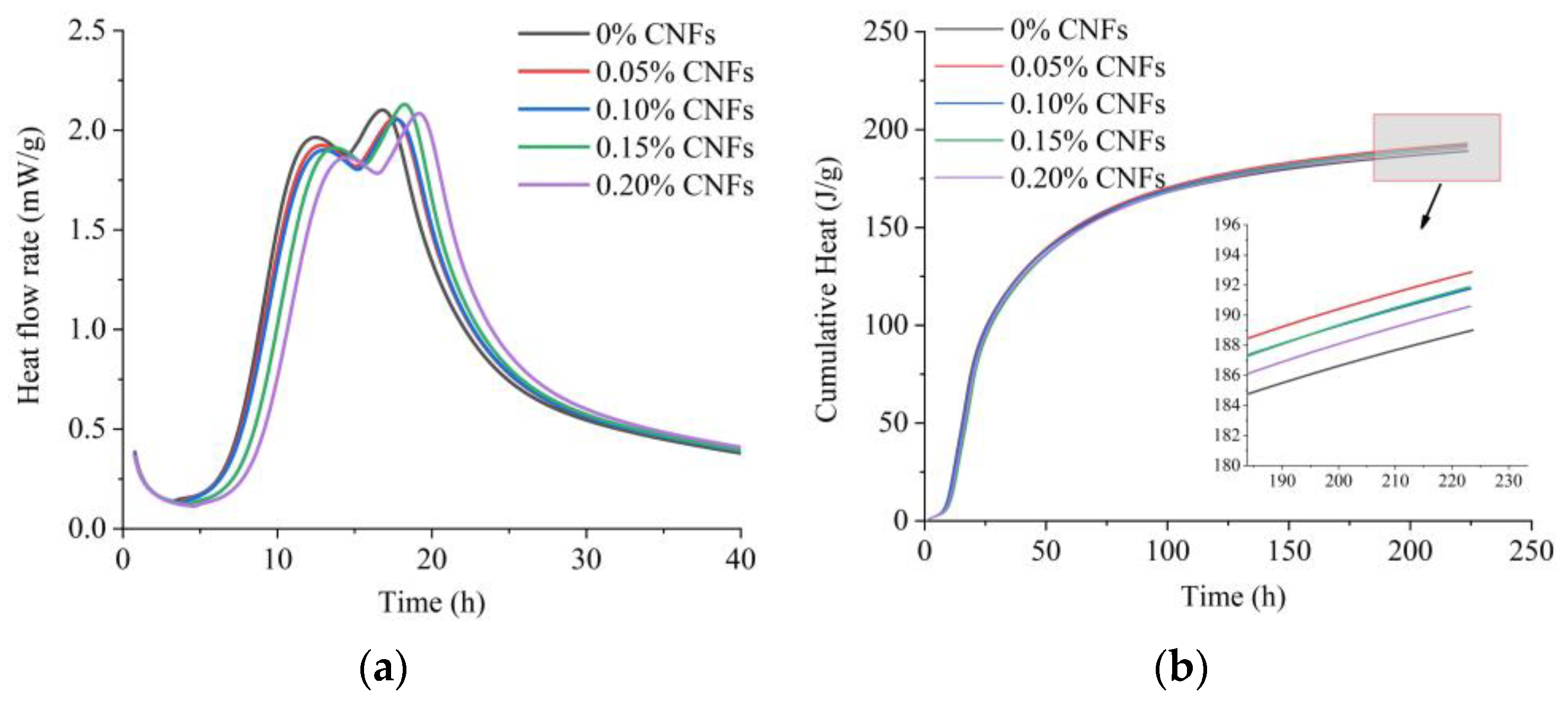

2.2.2. Isothermal Calorimetry

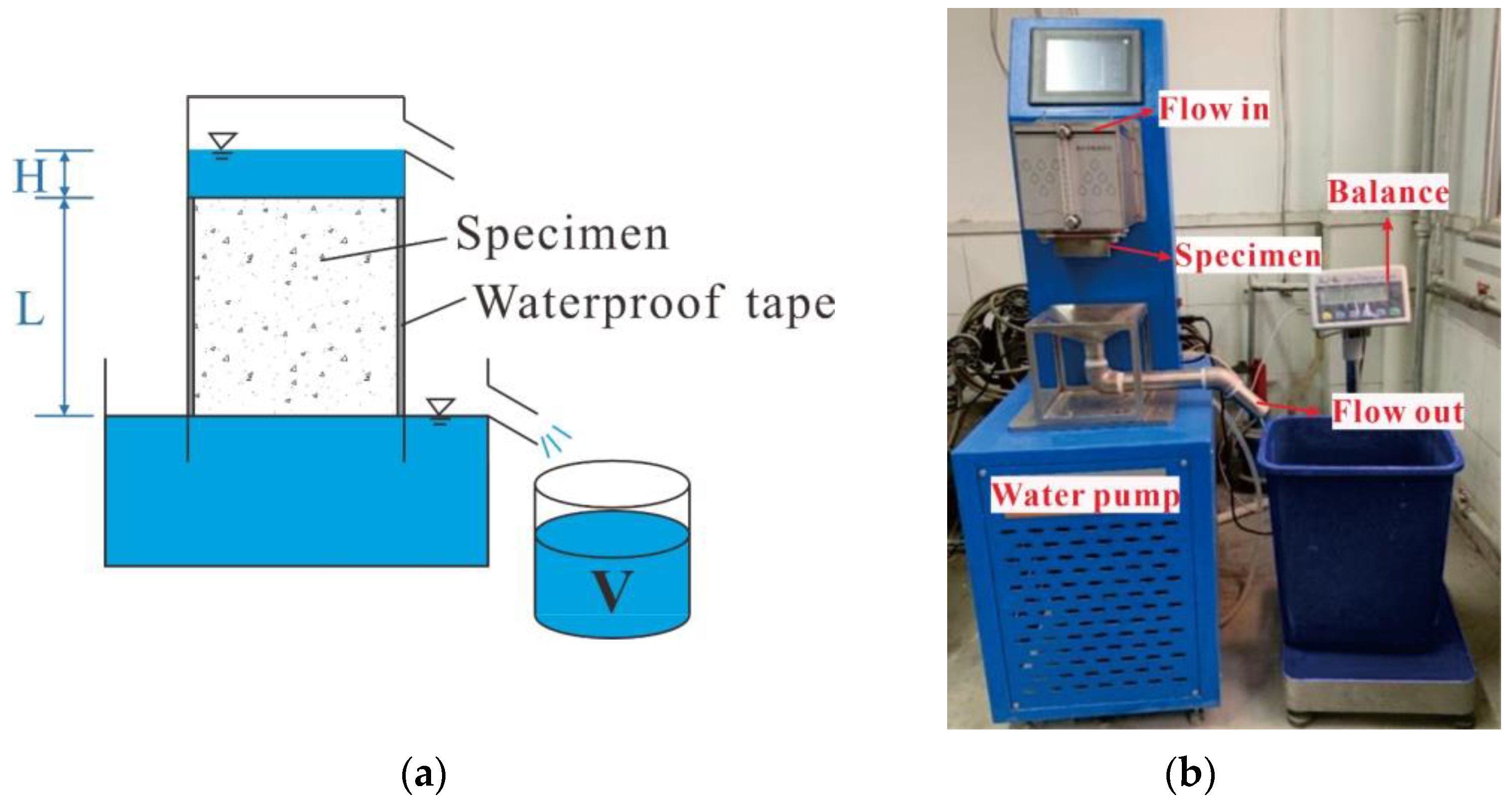

2.2.3. Porosity and Water Permeability

2.2.4. Mechanical Properties

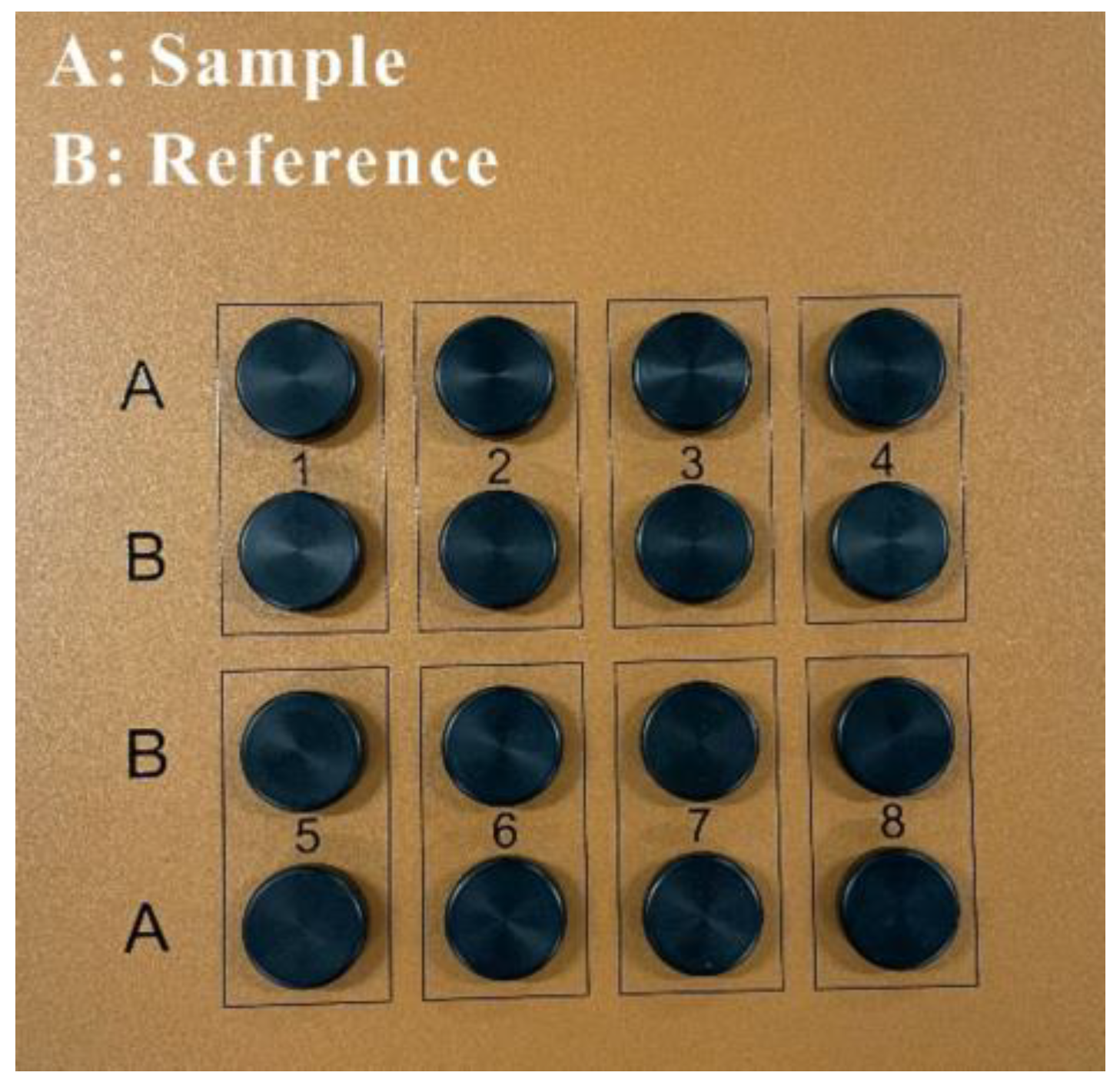

2.2.5. Frost Resistance

2.2.6. Scanning Electron Microscopy

3. Results

3.1. Rheological Properties

3.2. Isothermal Calorimetry

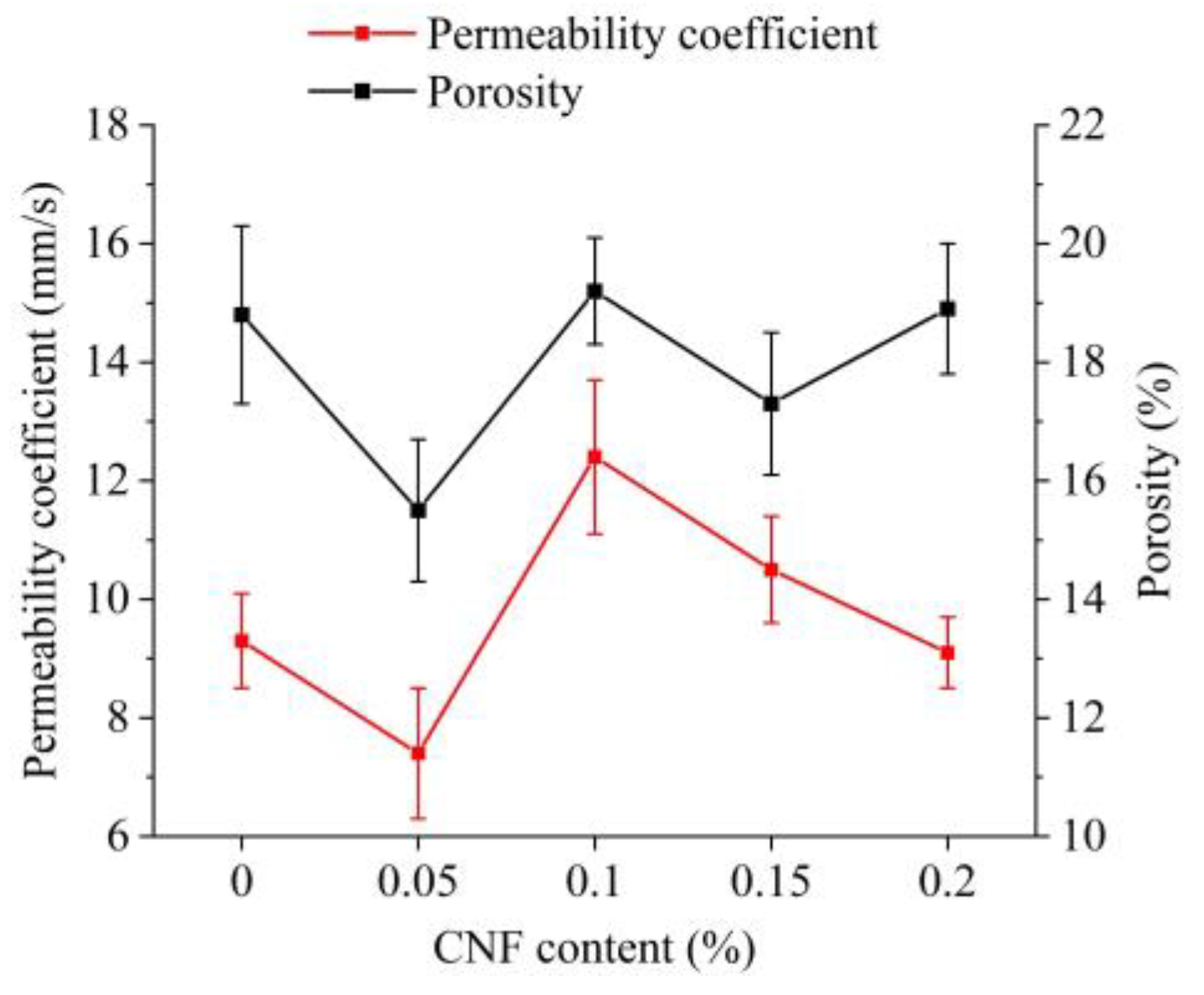

3.3. Water Permeability

3.4. Mechanical Properties

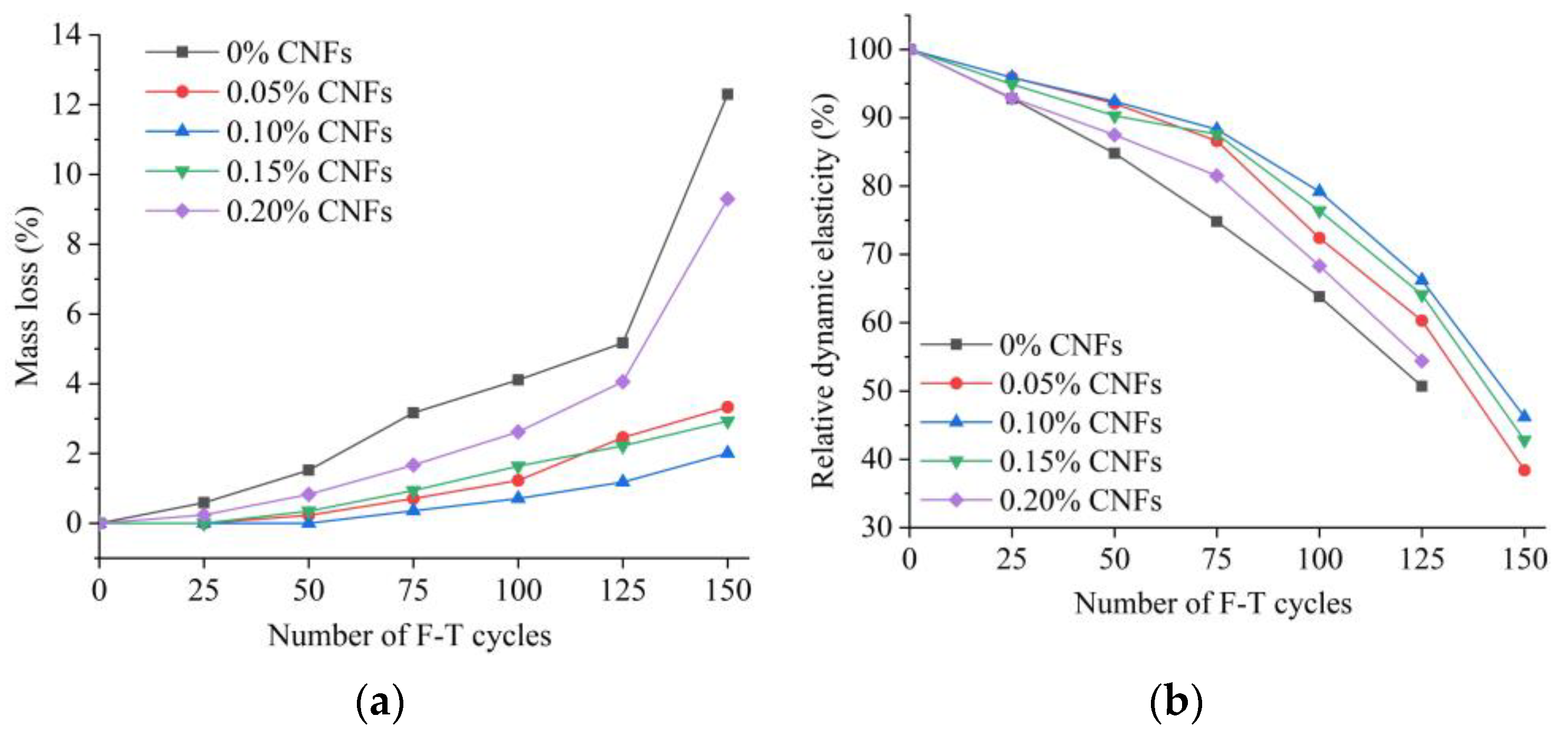

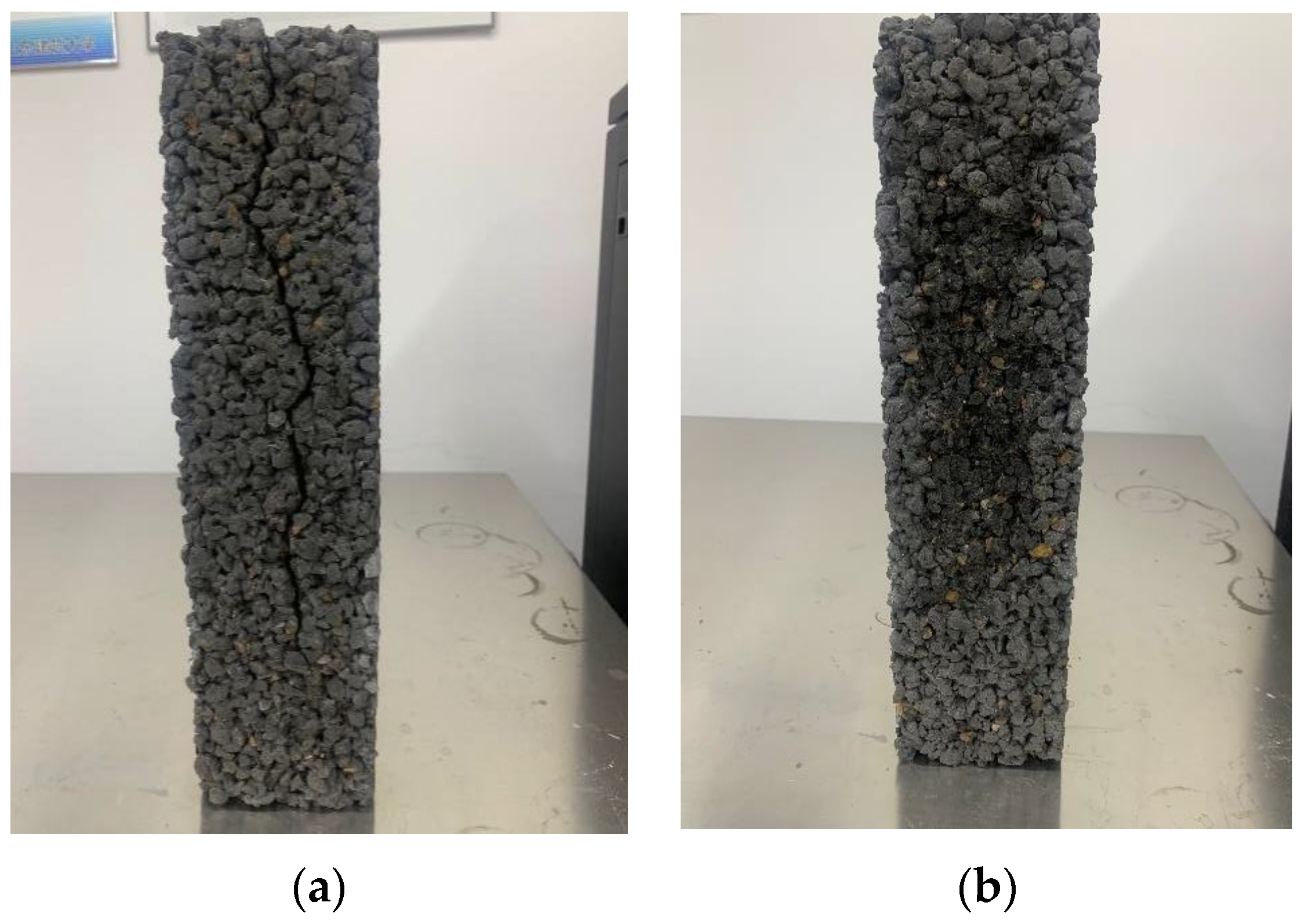

3.5. Frost Resistance

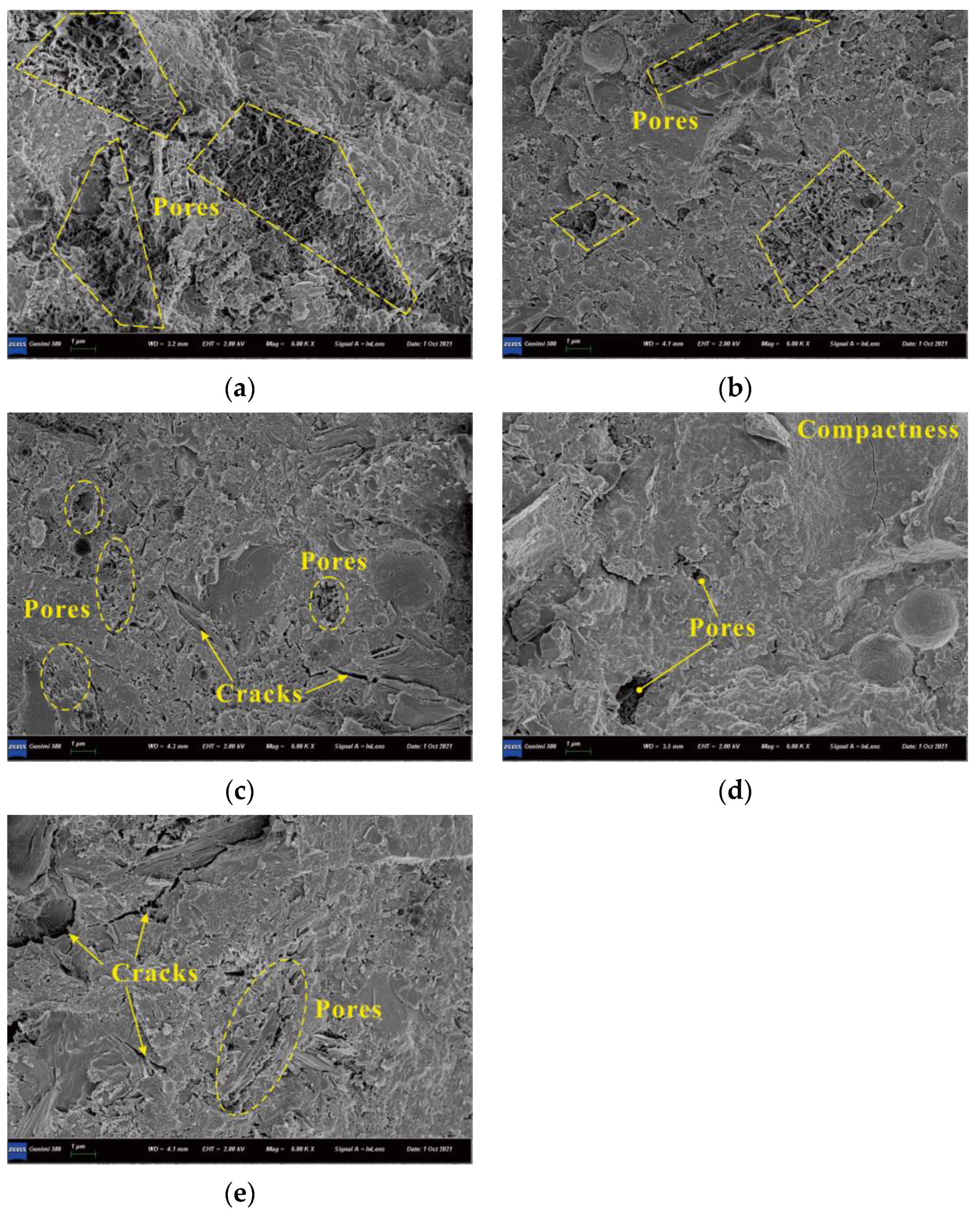

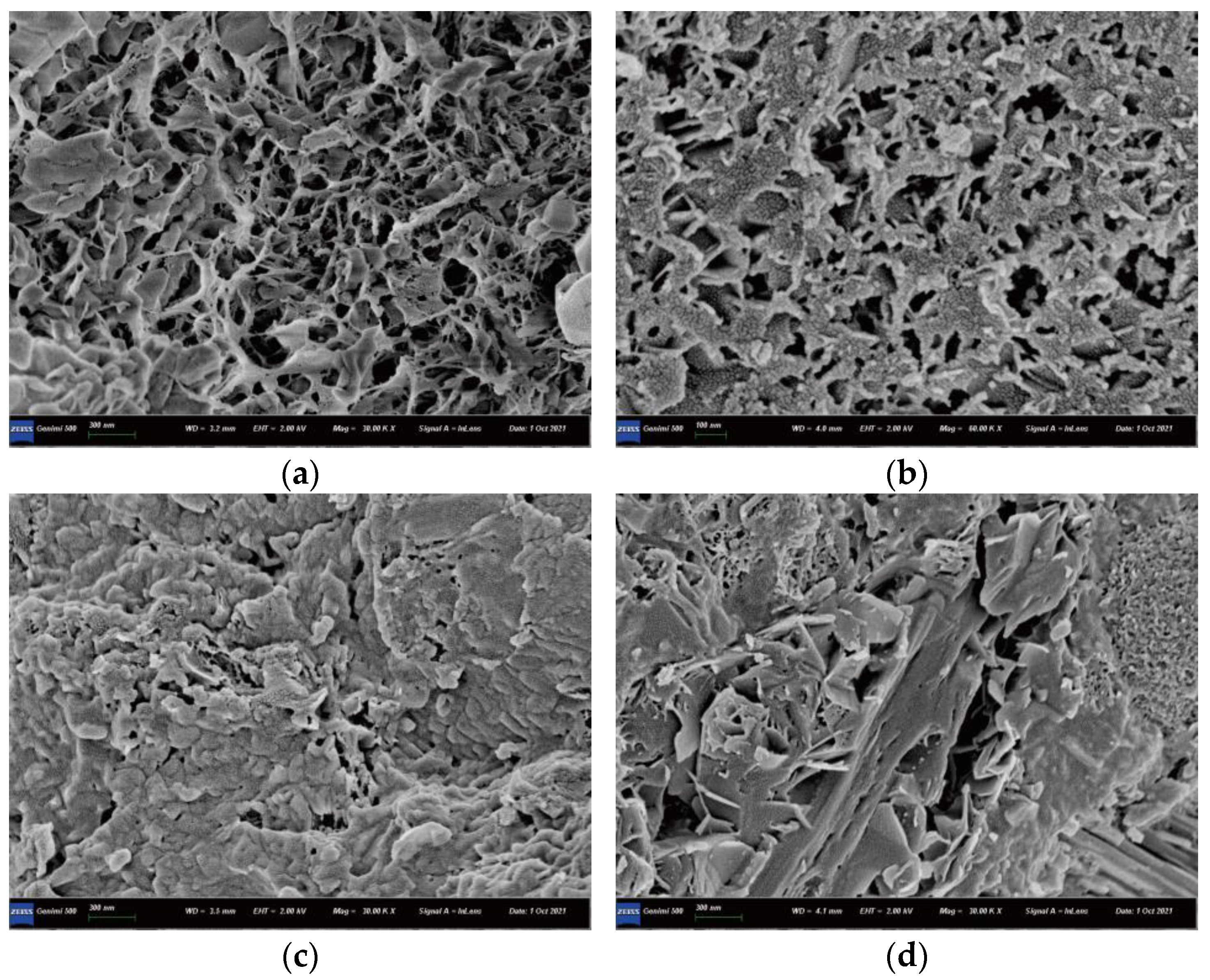

3.6. SEM Observations

4. Conclusions

- 1.

- The effects of the CNF addition on the porosity and permeability of pervious concrete were significant. The addition of 0.1% and 0.15% CNFs increased the permeability coefficient from 9.3 mm/s to 12.4 mm/s and from 9.3 mm/s to 10.5 mm/s, respectively, corresponding to increases of 33.3% and 12.9%. These increases were attributed to the increased mixture stability and homogeneity. This case could be explained by the corresponding optimal variation of plastic viscosity and yield stress of unadulterated matrices.

- 2.

- Although the addition of 0.05–0.2% CNFs significantly delayed the heat flow peak at 0–24 h, cumulative heat increased until 200 h. The cumulative heat for the 0.05–0.15% CNF additions was greater than that for the 0.2% CNF addition.

- 3.

- The addition of 0.05–0.2% CNFs increased compressive strength by 9.7–26.6% and flexural strength by 6.5–25.8%; the 0.15% CNF addition showed the maximum increase in both indicators.

- 4.

- When the CNF addition was 0.05%–0.15%, frost resistance of pervious concrete increased with the addition of CNFs, and mass loss was significantly reduced by 73.2%–83.7%; however, with the 0.2% CNF addition, care should be taken to avoid a significant mass loss close to the 0% CNF addition.

- 5.

- The SEM results showed that the CNF addition changed the morphology and porosity of the hydration products in the matrices and ITZs. The addition of the 0.05–0.15% CNFs increased hydration products and reduced the number of pores, resulting in denser matrices and stronger ITZs. When increased strengths and frost resistance were also considered, additions of 0.1% and 0.15% CNFs could be regarded as optimal.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Agar-Ozbek, A.S.; Weerheijm, J.; Schlangen, E.; Van Breugel, K. Investigating porous concrete with improved strength: Testing at different scales. Constr. Build. Mater. 2013, 41, 480–490. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Liu, G.; Peng, X. Preparation and performance evaluation of an innovative pervious concrete pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar] [CrossRef]

- Tabatabaeian, M.; Khaloo, A.; Khaloo, H. An innovative high performance pervious concrete with polyester and epoxy resins. Constr. Build. Mater. 2019, 228, 116820. [Google Scholar] [CrossRef]

- Montes, F.; Fu, T.; Youngblood, J.P.; Weiss, J. Rheological Impact of Using Cellulose Nanocrystals (CNC) in Cement Pastes. Constr. Build. Mater. 2020, 235, 117497. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Basic, N.; Omran, A.F.; Tagnit-Hamou, A. Feasibility of Using Cellulose Filaments as a Viscosity Modifying Agent in Self-Consolidating Concrete. Cem. Concr. Compos. 2018, 94, 327–340. [Google Scholar] [CrossRef]

- Liang, L.; Zhang, X.; Liu, Q.; Li, X.; Shang, X. Cellulose Nanofibrils for the Performance Improvement of Ultra-High Ductility Cementitious Composites. Cellulose 2022, 29, 1705–1725. [Google Scholar] [CrossRef]

- Liang, L.; Yang, J.; Lv, G.; Lei, Z.; Li, X.; Liu, Q. Surface-Functionalized Nanocelluloses as Viscosity-Modifying Agents in Engineered Cementitious Composites. Front. Mater. 2021, 8, 783176. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The Influence of Cellulose Nanocrystal Additions on the Performance of Cement Paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Szymańska-Chargot, M.; Jarosz-Hadam, M.; Łagód, G. Effect of cellulose nanofibrils and nanocrystals on physical properties of concrete. Constr. Build. Mater. 2019, 223, 1–11. [Google Scholar] [CrossRef]

- Bakkari, M.E.; Bindiganavile, V.; Goncalves, J.; Boluk, Y. Preparation of Cellulose Nanofibers by TEMPO-Oxidation of Bleached Chemi-Thermomechanical Pulp for Cement Applications. Carbohydr. Polym. 2019, 203, 238–245. [Google Scholar] [CrossRef]

- Cengiz, A.; Kaya, M.; Pekel Bayramgil, N. Flexural stress enhancement of concrete by incorporation of algal cellulose nanofibers. Constr. Build. Mater. 2017, 149, 289–295. [Google Scholar] [CrossRef]

- Takasi, P. A Laboratory Investigation of Cement Based Materials with Cellulose Nanofibers. Doctoral Degree, The University of Maine, Orono, ME, USA, 2019. [Google Scholar]

- Goncalves, J.; El-Bakkari, M.; Boluk, Y.; Bindiganavile, V. Cellulose nanofibres (CNF) for sulphate resistance in cement based systems. Cem. Concr. Compos. 2019, 99, 100–111. [Google Scholar] [CrossRef]

- Benselfelt, T.; Pettersson, T.; Wågberg, L. Influence of surface charge density and morphology on the formation of polyelectrolyte multilayers on smooth charged cellulose surfaces. Langmuir 2017, 33, 968–979. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Zhang, T.; Wang, C.; Yang, Y.; Bogush, A.; Khayrulina, E.; Huang, Z.; Wei, J.; Yu, Q. Mixture proportion design of pervious concrete based on the relationships between fundamental properties and skeleton structures. Cem. Concr. Compos. 2020, 113, 103693. [Google Scholar] [CrossRef]

- Bentz, D.P. Influence of water-to-cement ratio on hydration kinetics: Simple models based on spatial considerations. Cem. Concr. Res. 2006, 36, 238–244. [Google Scholar] [CrossRef]

- Wu, J.; Guo, L.; Cao, Y.; Lyu, B. Mechanical and fiber/matrix interfacial behavior of ultra-high-strength and high-ductility cementitious composites incorporating waste glass powder. Cem. Concr. Compos. 2022, 126, 104371. [Google Scholar] [CrossRef]

- Haque, M.I.; Ashraf, W.; Khan, R.I.; Shah, S. A comparative investigation on the effects of nanocellulose from bacteria and plant-based sources for cementitious composites. Cem. Concr. Compos. 2022, 125, 104316. [Google Scholar] [CrossRef]

- Kamasamudram, K.S.; Ashraf, W.; Landis, E.N. Cellulose nanofibrils with and without nanosilica for the performance enhancement of Portland cement systems. Constr. Build. Mater. 2021, 285, 121547. [Google Scholar] [CrossRef]

- Golewski, G.L. Evaluation of morphology and size of cracks of the Interfacial Transition Zone (ITZ) in concrete containing fly ash (FA). J. Hazard. Mater. 2018, 357, 298–304. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.; Zheng, B.; Shi, T.; Ma, C.; Liu, Y.; Zhao, Z. Crack resistance property of carbon nanotubes-modified concrete. Mag. Concr. Res. 2022, 74, 1165–1175. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Zhao, X.; Wang, J.; Zhao, Z.; Corr, D.J.; Shah, S.P. Study on mechanical properties of the interfacial transition zone in carbon nanofiber-reinforced cement mortar based on the PeakForce tapping mode of atomic force microscope. J. Build. Eng. 2022, 61, 105248. [Google Scholar] [CrossRef]

- Sun, X.; Wu, Q.; Lee, S.; Qing, Y.; Wu, Y. Cellulose Nanofibers as a Modifier for Rheology, Curing and Mechanical Performance of Oil Well Cement. Sci. Rep. 2016, 6, 31654. [Google Scholar] [CrossRef]

| Raw Materials | Chemical Composition (wt%) | OPC | ||||||

|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Special Surface Area (m2/kg) | 28 d Compressive Strength (MPa) | Flexural Strength (MPa) | |

| OPC | 63.6 | 21.2 | 3.2 | 3.0 | 1.0 | 353 | 47.8 | 7.9 |

| FA | 8.1 | 53.4 | 24.2 | 4.4 | 0.8 | |||

| SF | 0.4 | 98.2 | 1.5 | 0.8 | 1.1 | |||

| Properties | Length (mm) | Diameter (mm) | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| CNF | 10–50 | 500–1000 | 0.7 | 8000–10,000 | 100–200 |

| Group ID | OPC | FA | SF | CA | HRWRA | Water | CNF |

|---|---|---|---|---|---|---|---|

| CNF-1 | 357 | 42 | 21 | 1470 | 0.42 | 117.6 | 0 |

| CNF-2 | 357 | 42 | 21 | 1470 | 0.42 | 117.6 | 0.21 |

| CNF-3 | 357 | 42 | 21 | 1470 | 0.42 | 117.6 | 0.42 |

| CNF-4 | 357 | 42 | 21 | 1470 | 0.42 | 117.6 | 0.63 |

| CNF-5 | 357 | 42 | 21 | 1470 | 0.42 | 117.6 | 0.84 |

| CNF Content (%) | τ0 (Pa) | μ (Pa·s) | c | R2 |

|---|---|---|---|---|

| 0 | 6.85 | 1.39 | −0.003 | 0.999 |

| 0.05 | 5.99 | 0.80 | −0.001 | 0.999 |

| 0.1 | 19.50 | 1.39 | −0.003 | 0.999 |

| 0.15 | 28.37 | 1.76 | −0.004 | 0.999 |

| 0.2 | 38.04 | 2.36 | −0.006 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Lei, C.; Li, Z.; Zhang, A.; Zhao, W.; Zhang, W.; Xu, J.; Guo, P. Effect of Cellulose Nanofibrils on the Physical Properties and Frost Resistance of Pervious Concrete. Materials 2022, 15, 7906. https://doi.org/10.3390/ma15227906

Zhang X, Lei C, Li Z, Zhang A, Zhao W, Zhang W, Xu J, Guo P. Effect of Cellulose Nanofibrils on the Physical Properties and Frost Resistance of Pervious Concrete. Materials. 2022; 15(22):7906. https://doi.org/10.3390/ma15227906

Chicago/Turabian StyleZhang, Xu, Chengbang Lei, Zhi Li, Aiqin Zhang, Wanfeng Zhao, Wei Zhang, Jiarong Xu, and Panpan Guo. 2022. "Effect of Cellulose Nanofibrils on the Physical Properties and Frost Resistance of Pervious Concrete" Materials 15, no. 22: 7906. https://doi.org/10.3390/ma15227906

APA StyleZhang, X., Lei, C., Li, Z., Zhang, A., Zhao, W., Zhang, W., Xu, J., & Guo, P. (2022). Effect of Cellulose Nanofibrils on the Physical Properties and Frost Resistance of Pervious Concrete. Materials, 15(22), 7906. https://doi.org/10.3390/ma15227906