Interlaminar Microstructure and Mechanical Properties of Narrow Gap Laser Welding of 40-mm-Thick Ti-6Al-4V Alloy

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

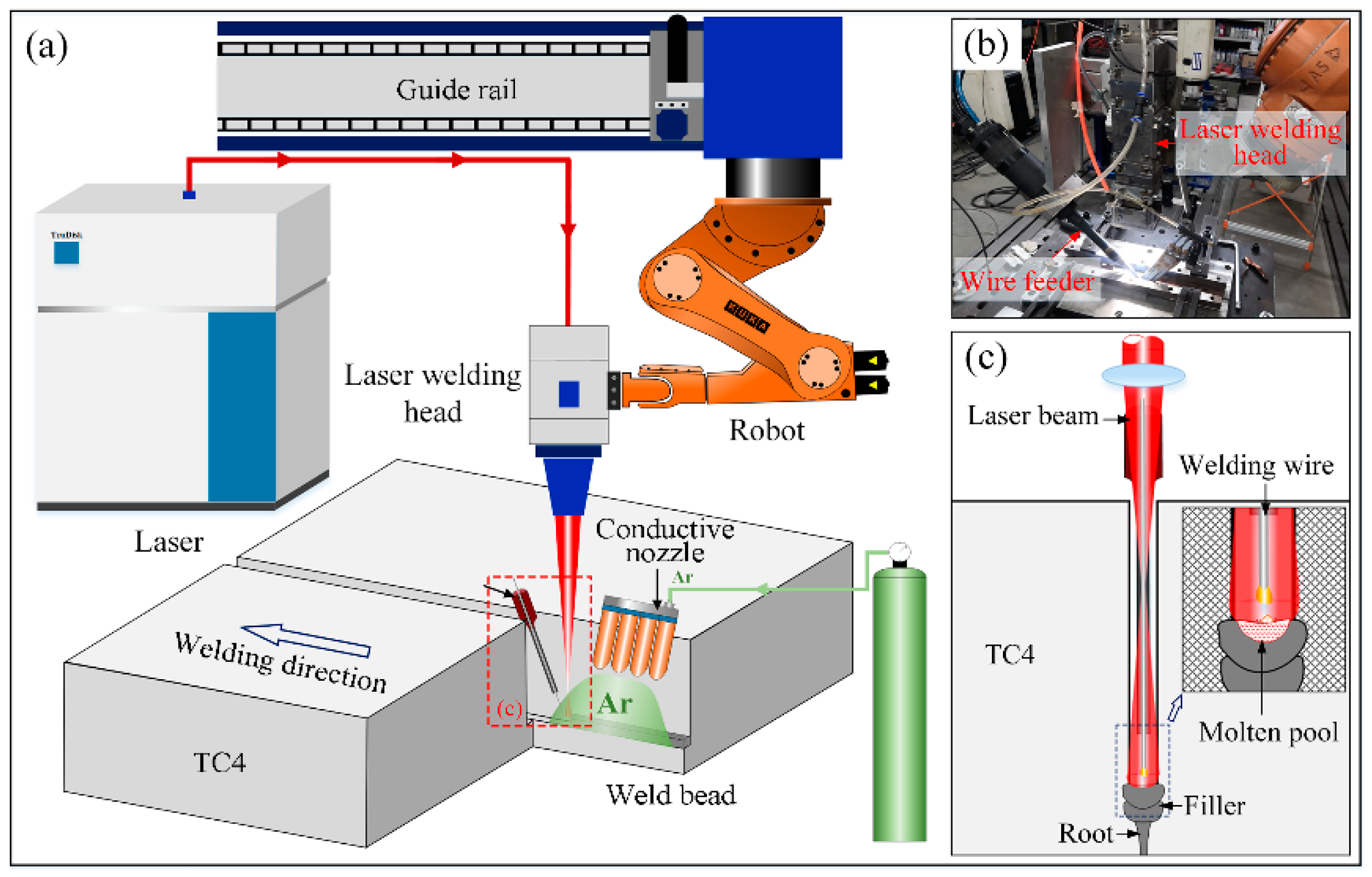

2.2. Experimental Setup

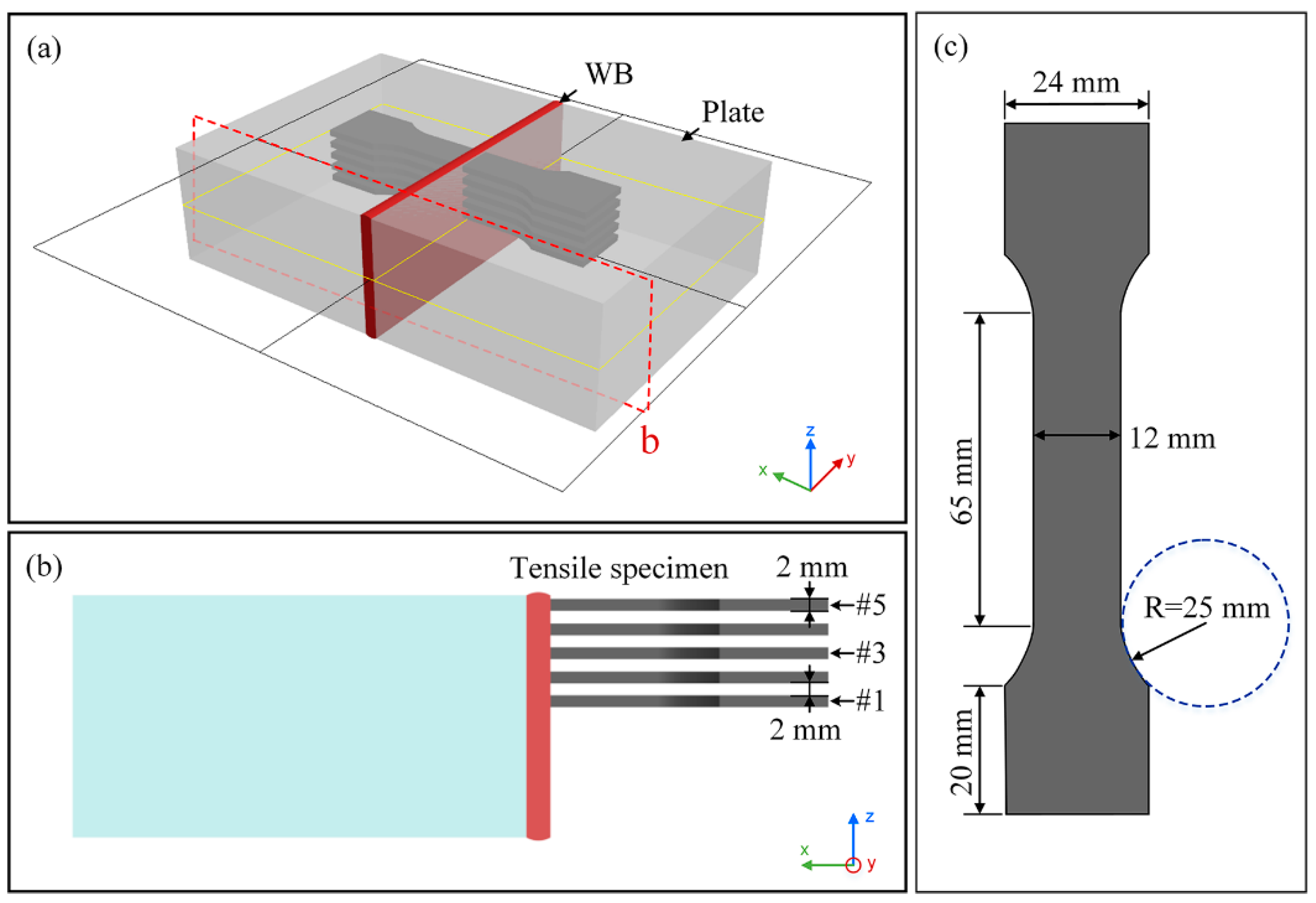

2.3. Analysis Method

3. Result and Discussion

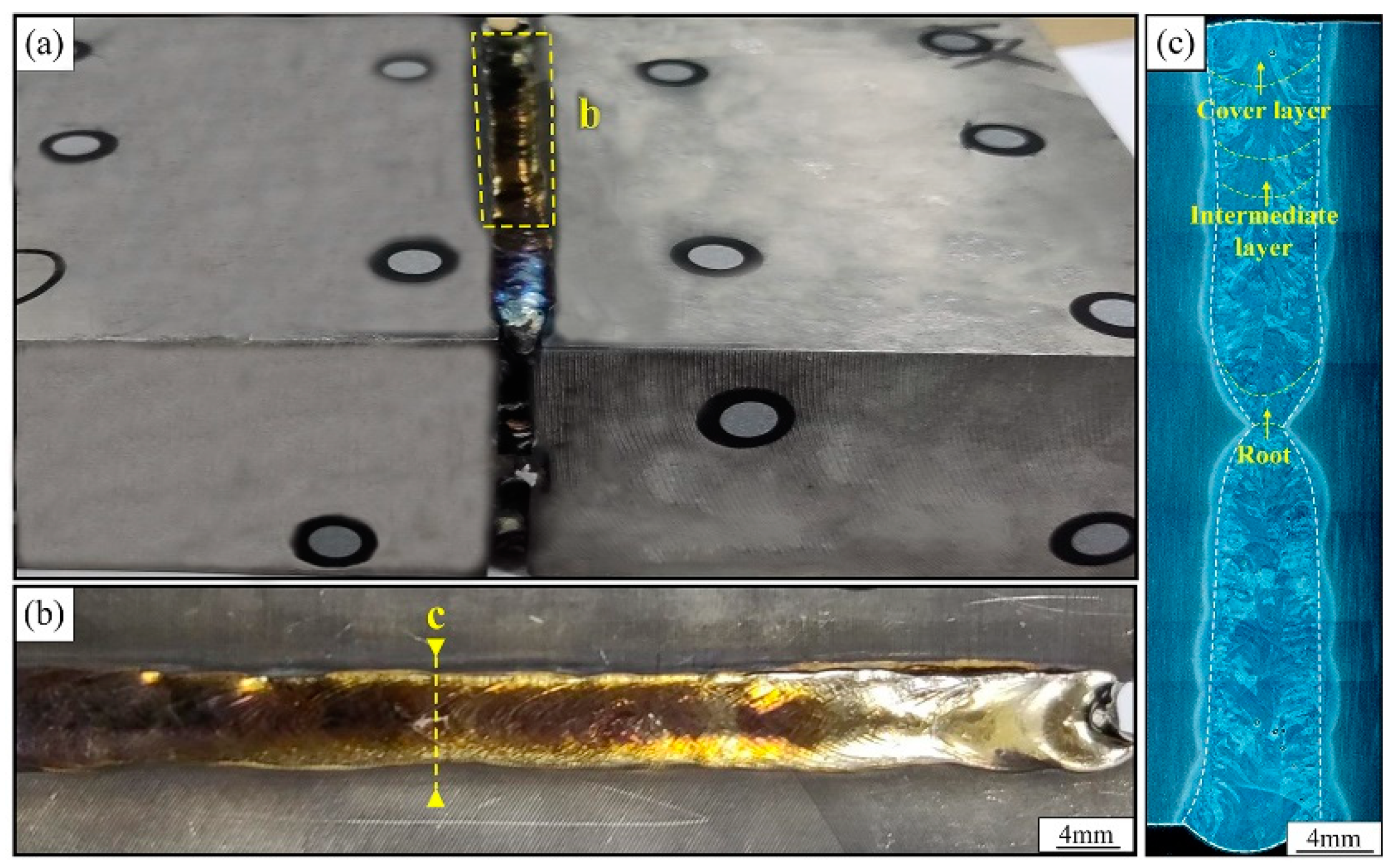

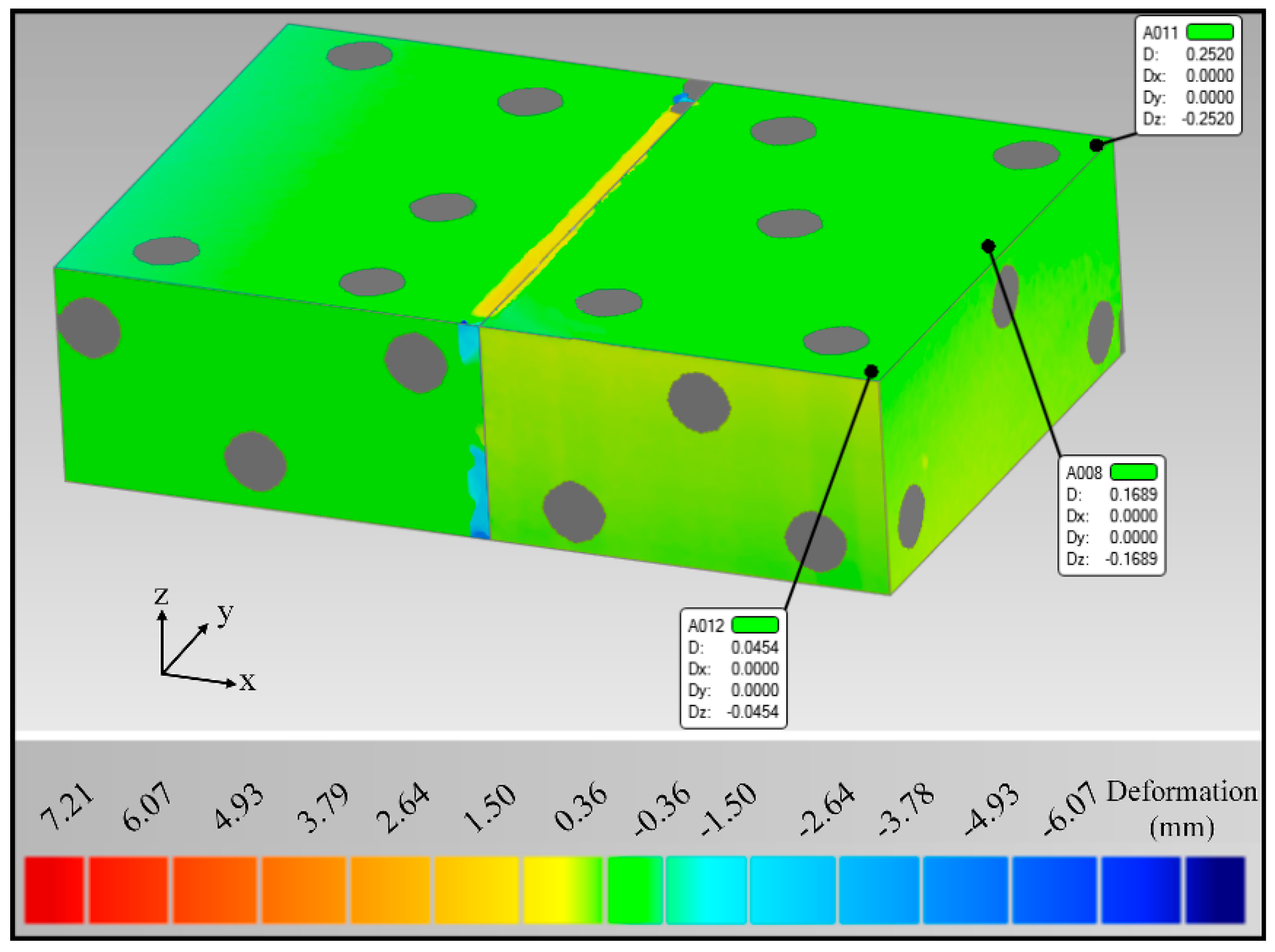

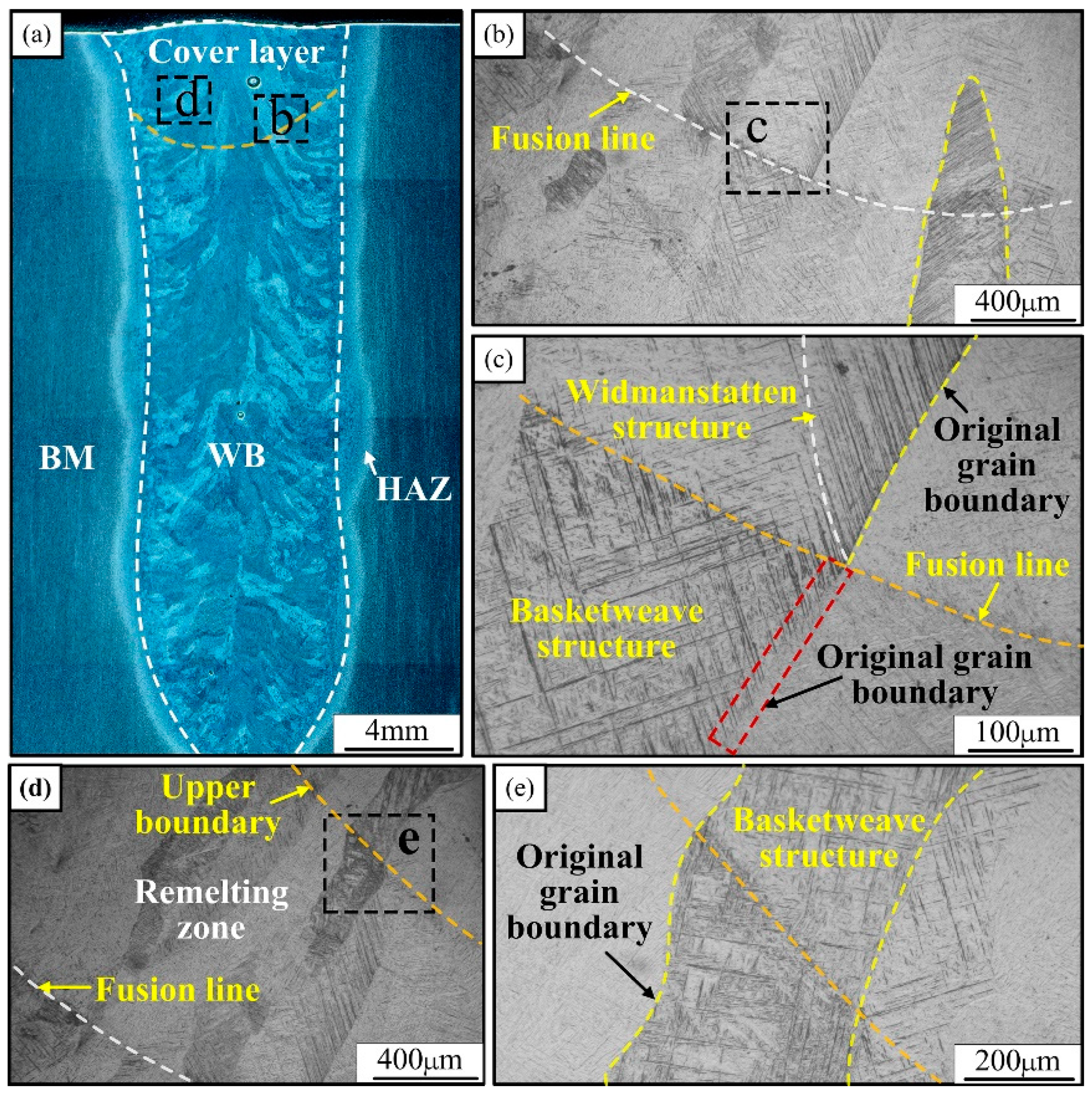

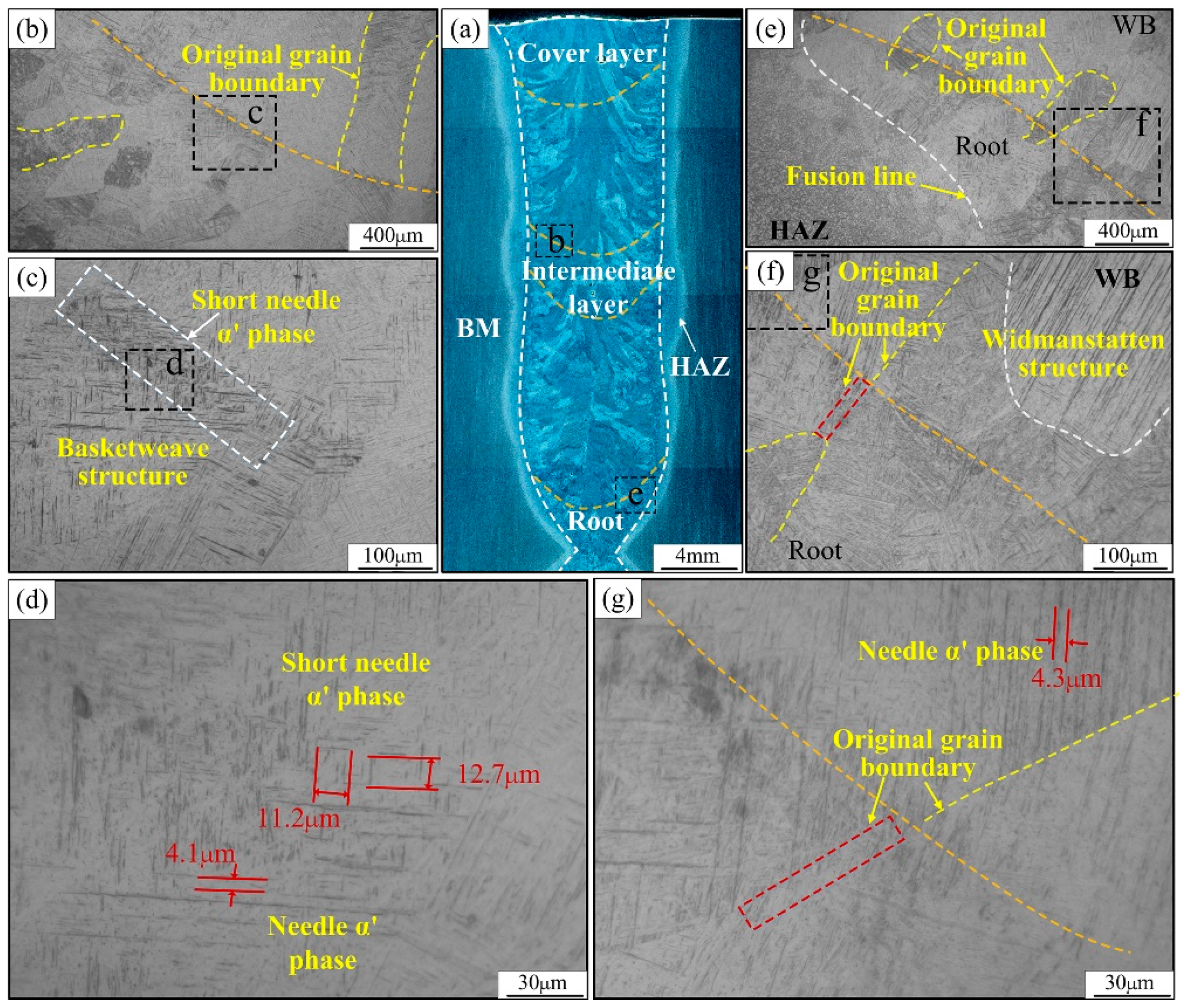

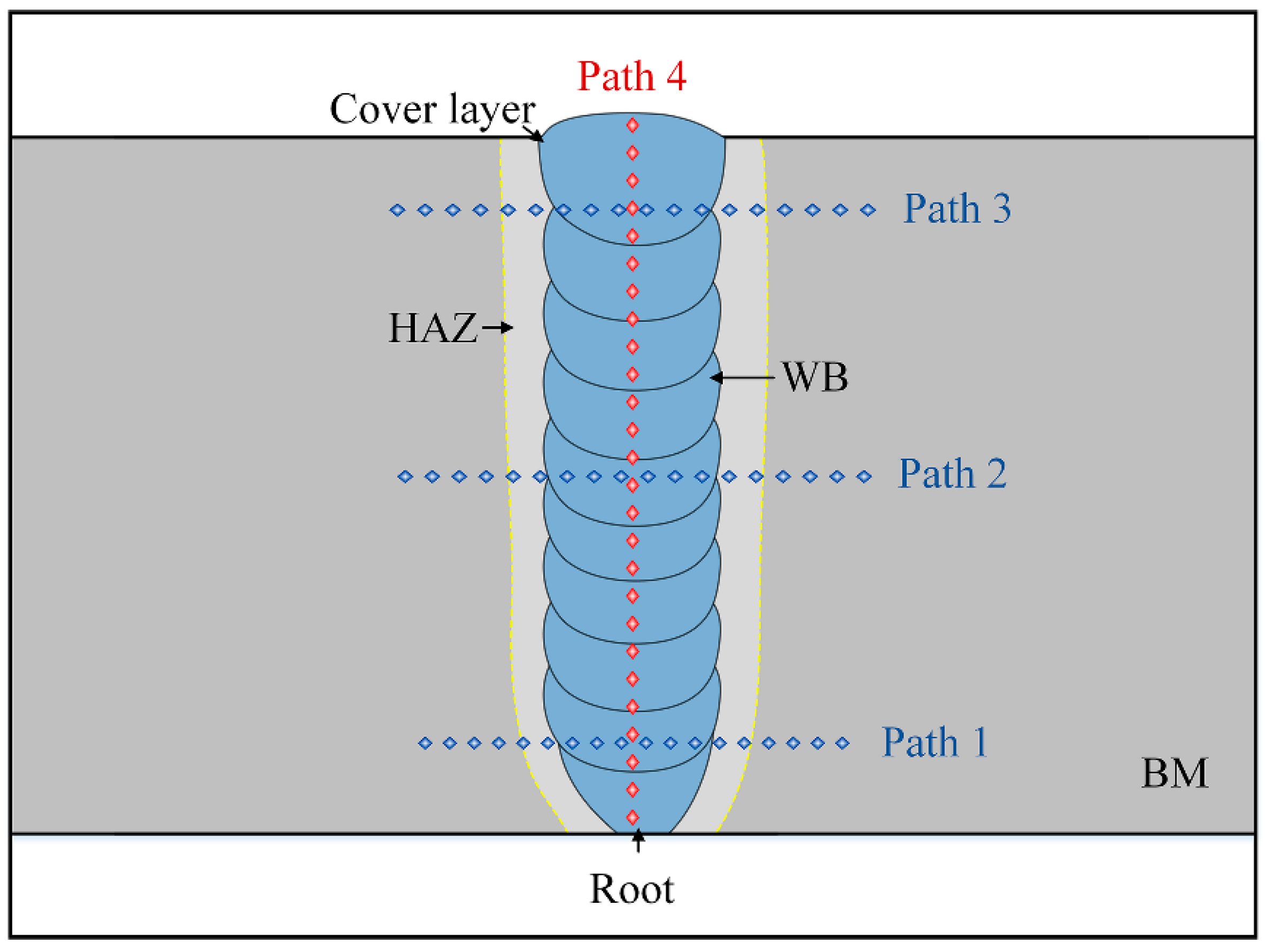

3.1. Weld Formation

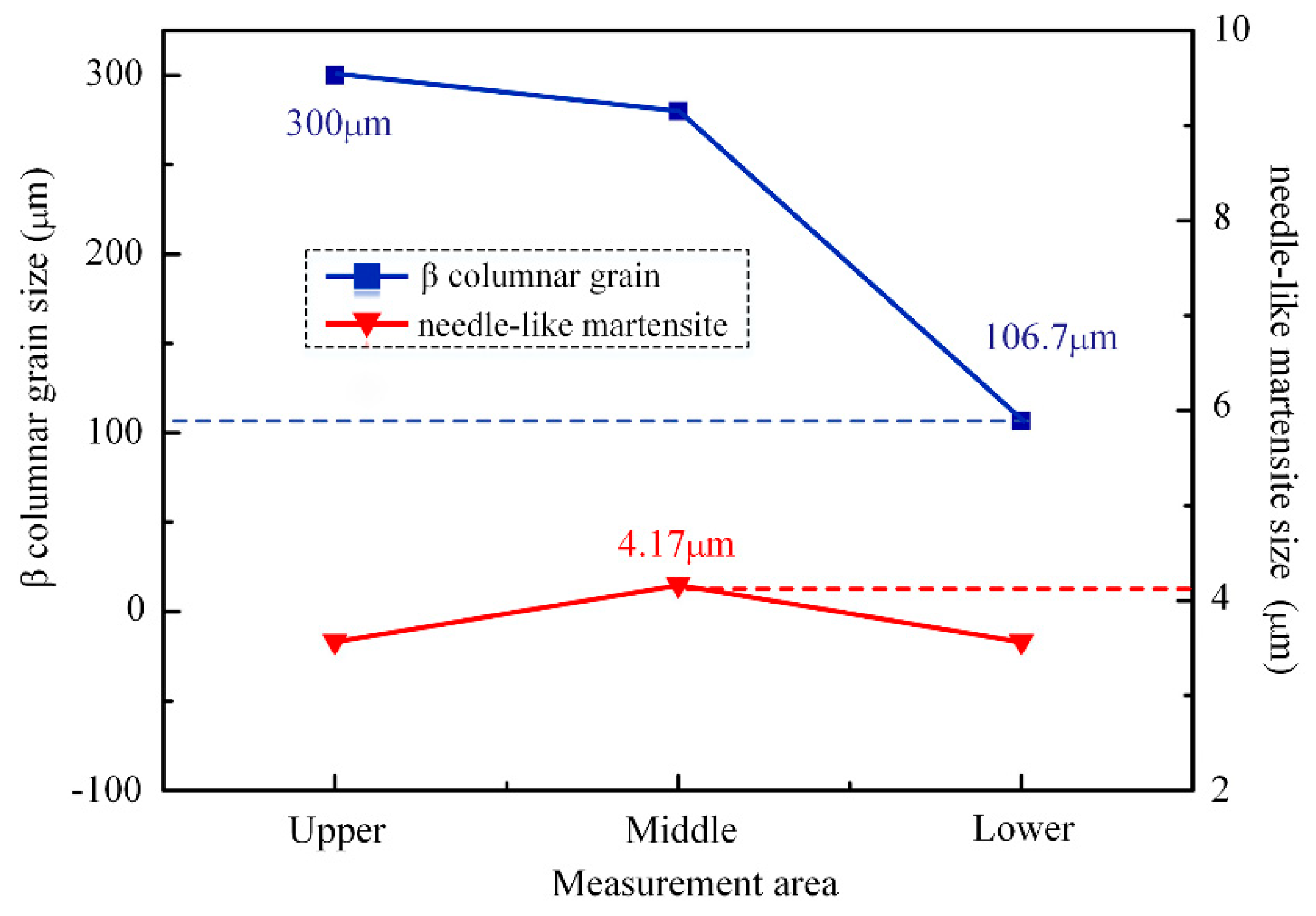

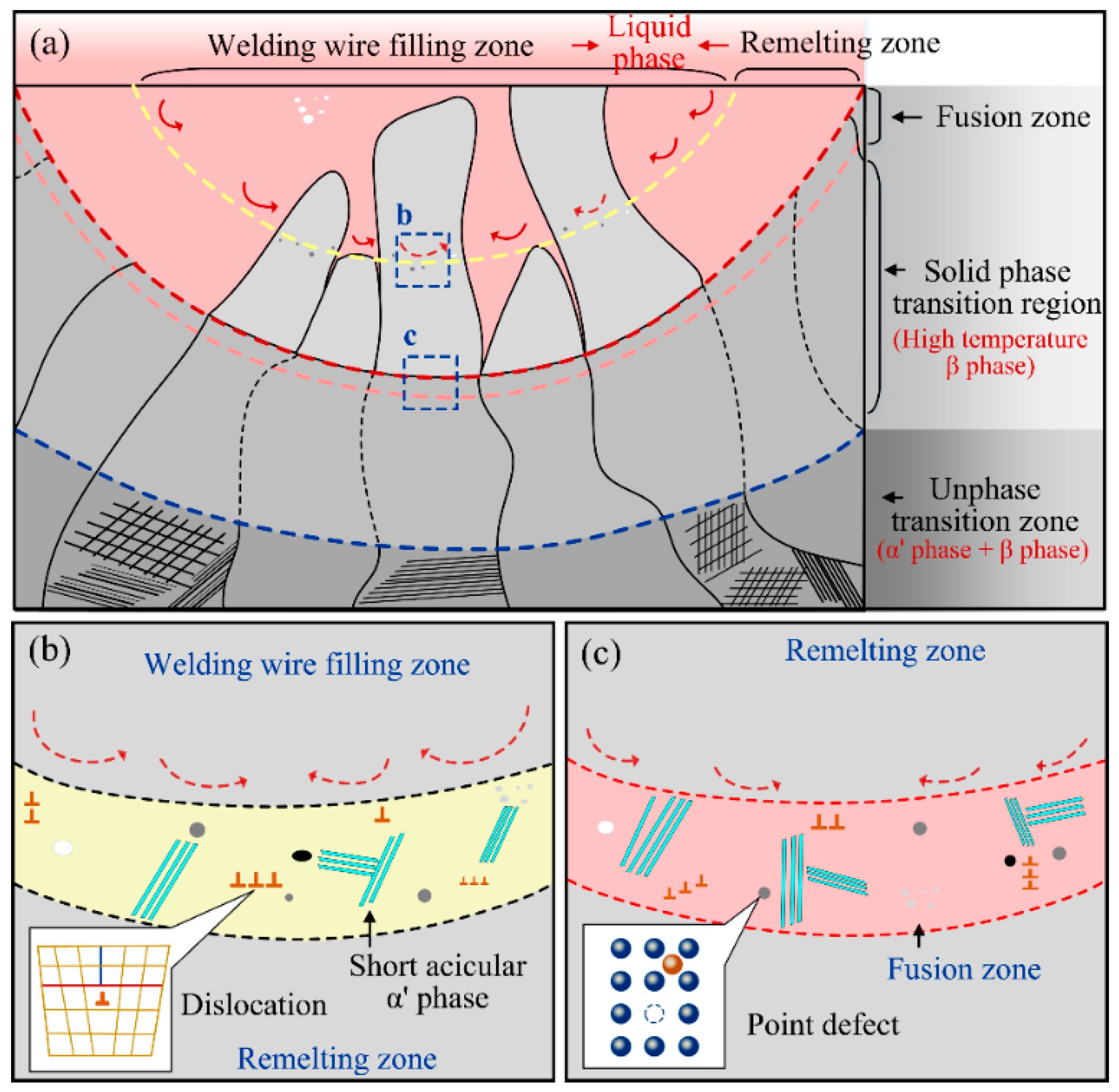

3.2. Microstructure Examination

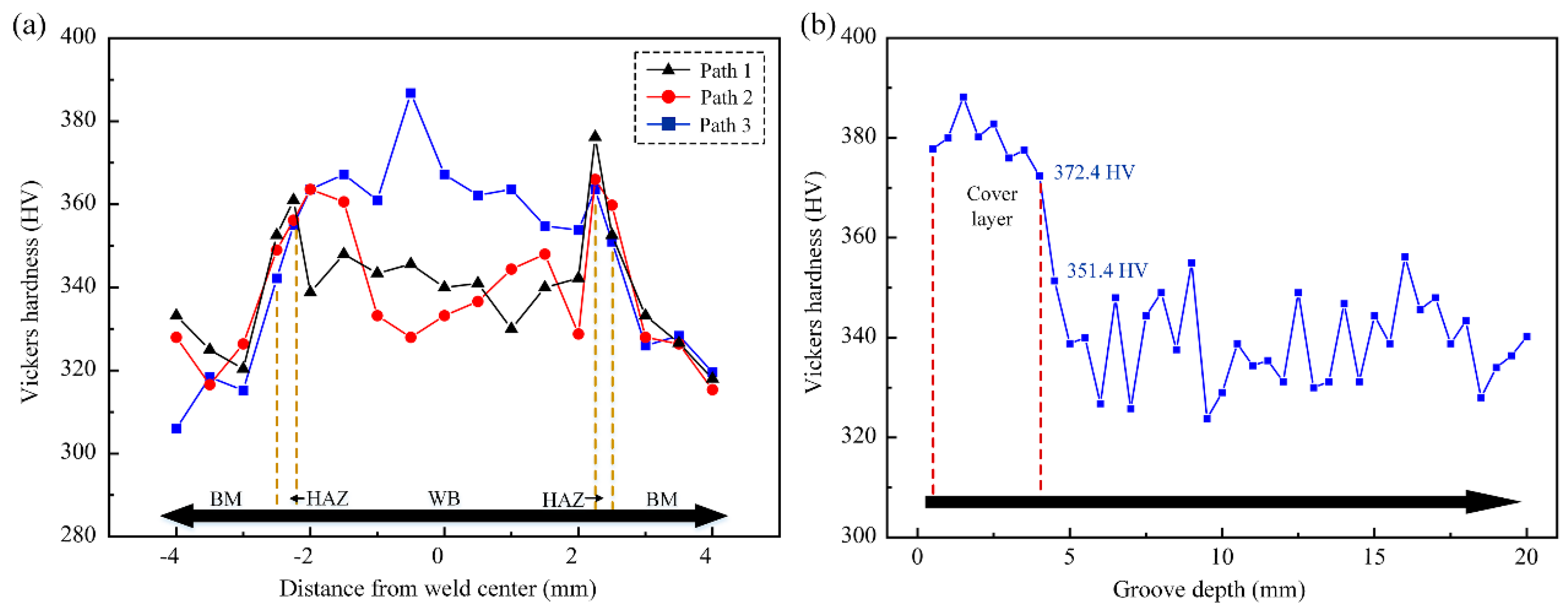

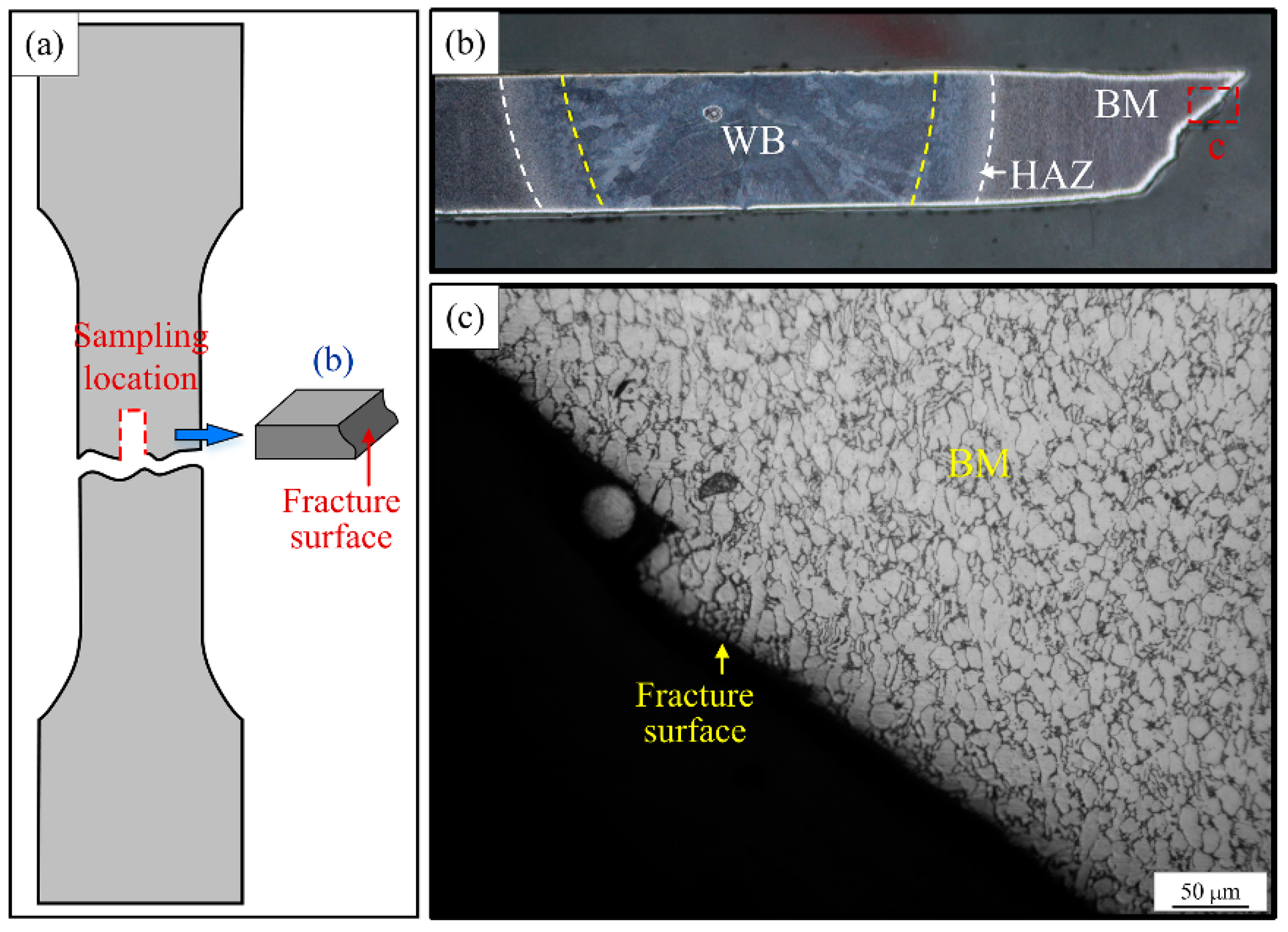

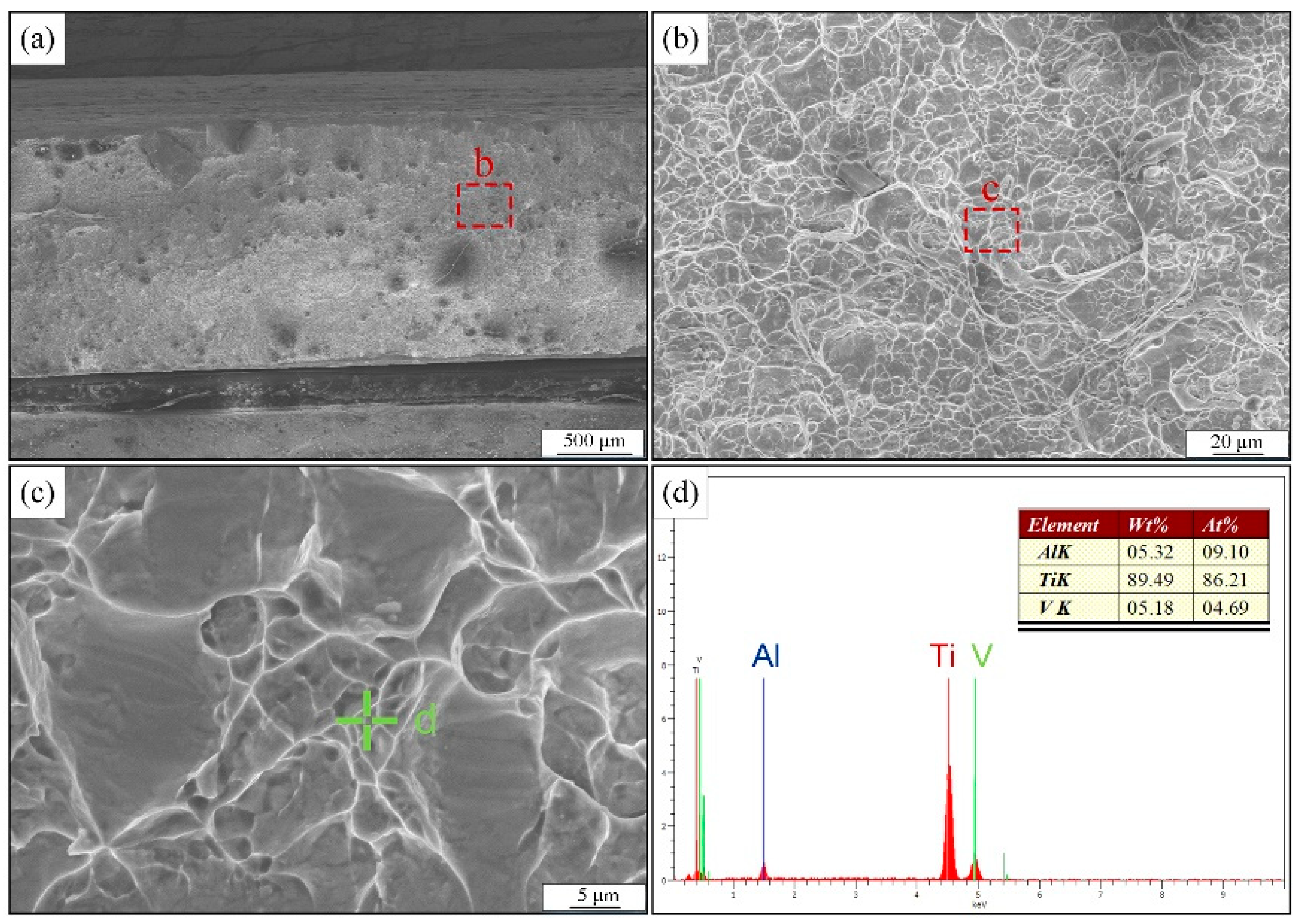

3.3. The Weld Joint Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.Q.; Zhao, Z.B.; Yu, B.B.; Liu, J.R.; Wang, Q.J.; Zhang, J.H.; Yang, R.; Li, J.W. Effect of Base Material on Microstructure and Texture Evolution of a Ti–6Al–4V Electron-Beam Welded Joint. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 499–504. [Google Scholar] [CrossRef]

- Akman, E.; Demir, A.; Canel, T.; Sınmazçelik, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Sato, Y.; Tsukamoto, M.; Yamashita, Y. Surface morphology of Ti-6Al-4V plate fabricated by vacuum selective laser melting. Appl. Phys. B-Lasers Opt. 2015, 119, 545–549. [Google Scholar] [CrossRef]

- Kumar, C.; Das, M.; Paul, C.P.; Bindra, K.S. Comparison of bead shape, microstructure and mechanical properties of fiber laser beam welding of 2 mm thick plates of Ti-6Al-4V alloy. Opt. Laser Technol. 2018, 105, 306–321. [Google Scholar] [CrossRef]

- Romero, J.; Attallah, M.M.; Preuss, M.; Karadge, M.; Bray, S.E. Effect of the forging pressure on the microstructure and residual stress development in Ti–6Al–4V linear friction welds. Acta Mater. 2009, 57, 5582–5592. [Google Scholar] [CrossRef]

- Schneider, A.; Gumenyuk, A.; Lammers, M.; Malletschek, A.; Rethmeier, M. Laser Beam Welding of Thick Titanium Sheets in the Field of Marine Technology. Phys. Procedia 2014, 56, 582–590. [Google Scholar] [CrossRef]

- Fu, P.; Mao, Z.; Zuo, C.; Wang, Y.; Wang, C. Microstructures and fatigue properties of electron beam welds with beam oscillation for heavy section TC4-DT alloy. Chin. J. Aeronaut. 2014, 27, 1015–1021. [Google Scholar] [CrossRef]

- Wu, M.; Xin, R.; Wang, Y.; Zhou, Y.; Wang, K.; Liu, Q. Microstructure, texture and mechanical properties of commercial high-purity thick titanium plates jointed by electron beam welding. Mater. Sci. Eng. A 2016, 677, 50–57. [Google Scholar] [CrossRef]

- Karimzadeh, F.; Heidarbeigy, M.; Saatchi, A. Effect of heat treatment on corrosion behavior of Ti–6Al–4V alloy weldments. J. Mater. Process. Technol. 2008, 206, 388–394. [Google Scholar] [CrossRef]

- Long, J.; Jia, J.-L.; Zhang, L.-J.; Zhuang, M.-X.; Wu, J.-H. Fatigue inhomogeneity of 140 mm thick TC4 titanium alloy double-sided electron beam welded joints. Int. J. Fatigue 2022, 165, 107214. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Feng, J.; Wang, S.; Zhao, H. Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation. Int. J. Adv. Manuf. Technol. 2017, 90, 413–420. [Google Scholar] [CrossRef]

- Guo, W.; Li, L.; Dong, S.; Crowther, D.; Thompson, A. Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt. Lasers Eng. 2017, 91, 1–15. [Google Scholar] [CrossRef]

- Li, L.; Wang, S.; Huang, W.; Jin, Y. Microstructure and mechanical properties of electron beam welded TC4/TA7 dissimilar titanium alloy joint. J. Manuf. Processes 2020, 50, 295–304. [Google Scholar] [CrossRef]

- Chen, Y.; Yue, H.; Wang, X. Microstructure, texture and tensile property as a function of scanning speed of Ti-47Al-2Cr-2Nb alloy fabricated by selective electron beam melting. Mater. Sci. Eng. A 2018, 713, 195–205. [Google Scholar] [CrossRef]

- Keßler, B.; Brenner, B.; Dittrich, D.; Standfuß, J.; Beyer, E.; Leyens, C.; Maier, G. Laser Multi-Pass Narrow-Gap Welding—A Promising Technology for Joining Thick-Walled Components of Future Power Plants. MATEC Web Conf. 2019, 269, 02011. [Google Scholar] [CrossRef][Green Version]

- Sun, J.; Ren, W.; Nie, P.; Huang, J.; Zhang, K.; Li, Z. Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate using narrow gap laser welding method. Mater. Des. 2019, 175, 107823. [Google Scholar] [CrossRef]

- Yu, Y.C.; Yang, S.L.; Yin, Y.; Wang, C.M.; Hu, X.Y.; Meng, X.X.; Yu, S.F. Multi-pass laser welding of thick plate with filler wire by using a narrow gap joint configuration. J. Mech. Sci. Technol. 2013, 27, 2125–2131. [Google Scholar] [CrossRef]

- Shariff, T.; Cao, X.; Chromik, R.R.; Wanjara, P.; Cuddy, J.; Birur, A. Effect of joint gap on the quality of laser beam welded near-β Ti-5553 alloy with the addition of Ti–6Al–4V filler wire. J. Mater. Sci. 2012, 47, 866–875. [Google Scholar] [CrossRef]

- Long, J.; Zhang, L.-J.; Zhuang, M.-X.; Bai, L.-a.; Na, S.-J. Narrow-gap laser welding with beam wobbling and filler wire and microstructural performance of joints of thick TC4 titanium alloy plates. Opt. Laser Technol. 2022, 152, 108089. [Google Scholar] [CrossRef]

- Yang, W.; Xin, J.; Fang, C.; Dai, W.; Wei, J.; Wu, J.; Song, Y. Microstructure and mechanical properties of ultra-narrow gap laser weld joint of 100 mm-thick SUS304 steel plates. J. Mater. Process. Technol. 2019, 265, 130–137. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.Y.; Snis, A.; Lai, Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 2012, 65, 8–15. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Zhang, L.-J.; Liu, J.-Z.; Ning, J.; Zhang, J.-X.; Na, S.-J.; Zhu, L. Microstructures and performances of the butt joint of TA1/Q235B bimetallic sheet with addition of a Mo interlayer by using narrow gap laser welding with filler wire. J. Mater. Res. Technol. 2020, 9, 10498–10510. [Google Scholar] [CrossRef]

- Jiang, L.; Shi, L.; Lu, Y.; Xiang, Y.; Zhang, C.; Gao, M. Effects of sidewall grain growth on pore formation in narrow gap oscillating laser welding. Opt. Laser Technol. 2022, 156, 108483. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, Y.; Huang, S.; Youssef, S.S.; Qi, M.; Wang, H.; Qiu, J.; Lei, J.; Yang, R. Temperature-gradient induced microstructure evolution in heat-affected zone of electron beam welded Ti-6Al-4V titanium alloy. J. Mater. Sci. Technol. 2019, 35, 1681–1690. [Google Scholar] [CrossRef]

- Haghdadi, N.; DeMott, R.; Stephenson, P.L.; Liao, X.Z.; Ringer, S.P.; Primig, S. Five-parameter characterization of intervariant boundaries in additively manufactured Ti-6Al-4V. Mater. Des. 2020, 196, 109177. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Li, L. Process-parameter interactions in ultra-narrow gap laser welding of high strength steels. Int. J. Adv. Manuf. Technol. 2016, 84, 2547–2566. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, G.; Zhou, Y.; Li, S. Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kW fiber laser. Opt. Express 2013, 21, 19997–20004. [Google Scholar] [CrossRef]

- Becker, T.; Dhansay, N.; Ter Haar, G.; Vanmeensel, K. Near-Threshold Fatigue Crack Growth Rates of Laser Powder Bed Fusion Produced Ti-6Al-4V. Acta Mater. 2020, 197, 269–282. [Google Scholar] [CrossRef]

- Maawad, E.; Gan, W.; Hofmann, M.; Ventzke, V.; Riekehr, S.; Brokmeier, H.-G.; Kashaev, N.; Müller, M. Influence of crystallographic texture on the microstructure, tensile properties and residual stress state of laser-welded titanium joints. Mater. Des. 2016, 101, 137–145. [Google Scholar] [CrossRef]

- Leitao, C.; Leal, R.M.; Rodrigues, D.M.; Loureiro, A.; Vilaça, P. Mechanical behaviour of similar and dissimilar AA5182-H111 and AA6016-T4 thin friction stir welds. Mater. Des. 2009, 30, 101–108. [Google Scholar] [CrossRef]

- Zhang, Y.; Bi, Y.; Zhou, J.; Sun, D.; Li, H. Microstructure and mechanical property improvement of Ti alloy and stainless steel joint based on a hybrid connection mechanism. Mater. Lett. 2020, 274, 128012. [Google Scholar] [CrossRef]

| Composition | Fe | C | H | O | N | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| wt.% | ≤0.30 | ≤0.10 | ≤0.015 | ≤0.20 | ≤0.05 | 5.5–6.8 | 3.5–4.5 | Balance |

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Ti6Al4V alloy | 980 | 938 | 14.6 |

| Process Parameters | Amount |

|---|---|

| Laser power (kW) | 4.5 |

| Welding speed (m/min) | 0.9 |

| Wire feeding speed (m/min) | 9 |

| Defocusing (mm) | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Ling, W.; Li, Y.; Wang, J.; Zhan, X. Interlaminar Microstructure and Mechanical Properties of Narrow Gap Laser Welding of 40-mm-Thick Ti-6Al-4V Alloy. Materials 2022, 15, 7742. https://doi.org/10.3390/ma15217742

Liu X, Ling W, Li Y, Wang J, Zhan X. Interlaminar Microstructure and Mechanical Properties of Narrow Gap Laser Welding of 40-mm-Thick Ti-6Al-4V Alloy. Materials. 2022; 15(21):7742. https://doi.org/10.3390/ma15217742

Chicago/Turabian StyleLiu, Xing, Wanli Ling, Yue Li, Jianfeng Wang, and Xiaohong Zhan. 2022. "Interlaminar Microstructure and Mechanical Properties of Narrow Gap Laser Welding of 40-mm-Thick Ti-6Al-4V Alloy" Materials 15, no. 21: 7742. https://doi.org/10.3390/ma15217742

APA StyleLiu, X., Ling, W., Li, Y., Wang, J., & Zhan, X. (2022). Interlaminar Microstructure and Mechanical Properties of Narrow Gap Laser Welding of 40-mm-Thick Ti-6Al-4V Alloy. Materials, 15(21), 7742. https://doi.org/10.3390/ma15217742