Mid-Infrared Broadband Achromatic Metalens with Wide Field of View

Abstract

1. Introduction

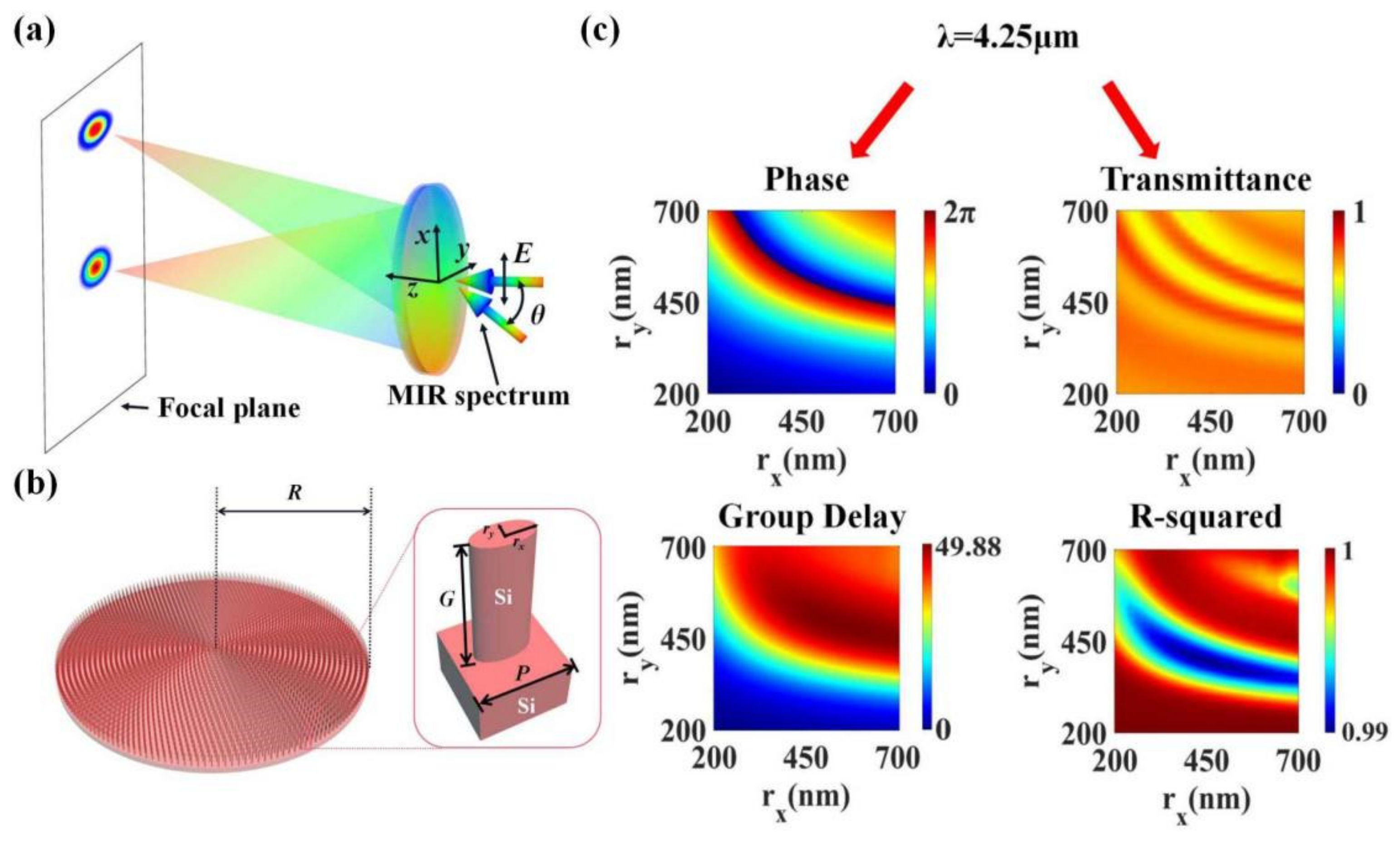

2. Principle and Design Method

2.1. Principle of Correcting Monochromatic Aberration of Metalens

2.2. Principle of Dispersion Compensation of Metalens

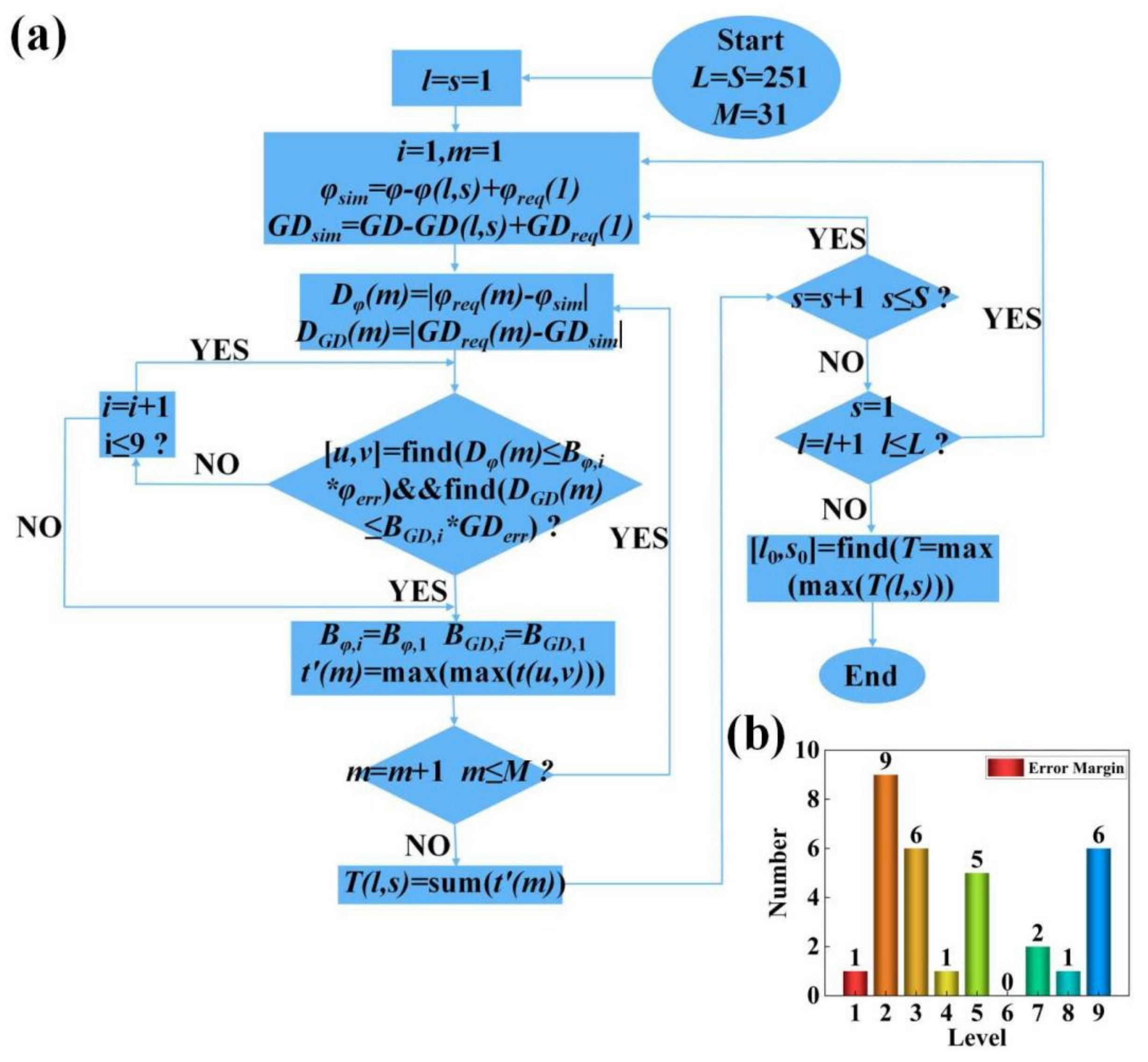

2.3. Design Method for Determining the Structure of Metalens

3. Simulation Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Li, J.; Zheng, C.; Yue, Z.; Wang, S.; Li, M.; Zhao, H.; Zhang, Y.; Yao, J. Active controllable spin-selective terahertz asymmetric transmission based on all-silicon metasurfaces. Appl. Phys. Lett. 2021, 118, 221110. [Google Scholar] [CrossRef]

- Luo, Y.; Chu, C.H.; Vyas, S.; Kuo, H.Y.; Chia, Y.H.; Chen, M.K.; Shi, X.; Tanaka, T.; Misawa, H.; Huang, Y.-Y.; et al. Varifocal Metalens for Optical Sectioning Fluorescence Microscopy. Nano Lett. 2021, 21, 5133–5142. [Google Scholar] [PubMed]

- Cai, X.; Tang, R.; Zhou, H.; Li, Q.; Ma, S.; Wang, D.; Liu, T.; Ling, X.; Tan, W.; He, Q.; et al. Dynamically controlling terahertz wavefronts with cascaded metasurfaces. Adv. Photonics 2021, 3, 1–10. [Google Scholar] [CrossRef]

- Gric, T.; Hess, O. Investigation of Hyperbolic Metamaterials. Appl. Sci. 2018, 8, 1222. [Google Scholar] [CrossRef]

- Kim, I.; Yoon, G.; Jang, J.; Genevet, P.; Nam, K.T.; Rho, J. Outfitting Next Generation Displays with Optical Metasurfaces. ACS Photonics 2018, 5, 3876–3895. [Google Scholar] [CrossRef]

- Arbabi, A.; Horie, Y.; Ball, A.J.; Bagheri, M.; Faraon, A. Subwavelength-thick lenses with high numerical apertures and large efficiency based on high-contrast transmitarrays. Nat. Commun. 2015, 6, 7069. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, J.; Zheng, H.; An, S.; Lin, H.; Zheng, B.; Du, Q.; Yin, G.; Michon, J.; Zhang, Y.; et al. Ultra-thin high-efficiency mid-infrared transmissive Huygens meta-optics. Nat. Commun. 2018, 9, 1481. [Google Scholar]

- Zhan, A.; Colburn, S.; Trivedi, R.; Fryett, T.K.; Dodson, C.M.; Majumdar, A. Low-Contrast Dielectric Metasurface Optics. ACS Photonics 2016, 3, 209–214. [Google Scholar]

- Tan, H.; Deng, J.; Zhao, R.; Wu, X.; Li, G.; Huang, L.; Liu, J.; Cai, X. A Free-Space Orbital Angular Momentum Multiplexing Communication System Based on a Metasurface. Laser Photonics Rev. 2019, 13, 1800278. [Google Scholar]

- Yang, H.; Li, G.; Cao, G.; Zhao, Z.; Chen, J.; Ou, K.; Chen, X.; Lu, W. Broadband polarization resolving based on dielectric metalenses in the near-infrared. Opt. Express 2018, 26, 5632. [Google Scholar]

- Arbabi, A.; Arbabi, E.; Horie, Y.; Kamali, S.M.; Faraon, A. Planar metasurface retroreflector. Nat. Photonics 2017, 11, 415–420. [Google Scholar] [CrossRef]

- Chen, M.; Gao, W.; Liu, H.; Teng, C.; Deng, S.; Deng, H.; Yuan, L. Polarization controllable generation of flat superimposed OAM states based on metasurface. Opt. Express 2019, 27, 20133. [Google Scholar] [CrossRef]

- Yang, H.; Li, G.; Su, X.; Cao, G.; Zhao, Z.; Yu, F.; Chen, X.; Lu, W. Annihilating optical angular momentum and realizing a meta-waveplate with anomalous functionalities. Opt. Express 2017, 25, 16907. [Google Scholar]

- Engelberg, J.; Levy, U. Achromatic flat lens performance limits. Optica 2021, 8, 834–845. [Google Scholar] [CrossRef]

- Zhao, F.; Li, Z.; Li, S.; Dai, X.; Zhou, Y.; Liao, X.; Cao, J.C.; Liang, G.; Shang, Z.; Zhang, Z.; et al. Terahertz metalens of hyper-dispersion. Photonics Res. 2022, 10, 886–895. [Google Scholar] [CrossRef]

- Ou, K.; Yu, F.; Li, G.; Wang, W.; Chen, J.; Miroshnichenko, A.E.; Huang, L.; Li, T.; Li, Z.; Chen, X.; et al. Broadband Achromatic Metalens in Mid-Wavelength Infrared. Laser Photonics Rev. 2021, 15, 2100020. [Google Scholar] [CrossRef]

- Huang, Z.; Qin, M.; Guo, X.; Yang, C.; Li, S. Achromatic and wide-field metalens in the visible region. Opt. Express 2021, 29, 13542–13551. [Google Scholar] [CrossRef]

- Li, H.; Xiao, X.; Fang, B.; Gao, S.; Wang, Z.; Chen, C.; Zhao, Y.; Zhu, S.; Li, T. Bandpass-filter-integrated multiwavelength achromatic metalens. Photonics Res. 2021, 9, 1384–1390. [Google Scholar] [CrossRef]

- Chen, W.T.; Zhu, A.Y.; Sanjeev, V.; Khorasaninejad, M.; Shi, Z.; Lee, E.; Capasso, F. A broadband achromatic metalens for focusing and imaging in the visible. Nat. Nanotechnol. 2018, 13, 220–226. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Shi, Z.; Zhu, A.Y.; Chen, W.T.; Sanjeev, V.; Zaidi, A.; Capasso, F. Achromatic Metalens over 60 nm Bandwidth in the Visible and Metalens with Reverse Chromatic Dispersion. Nano Lett. 2017, 17, 1819–1824. [Google Scholar]

- Chen, W.T.; Zhu, A.Y.; Sisler, J.; Bharwani, Z.; Capasso, F. A broadband achromatic polarization-insensitive metalens consisting of anisotropic nanostructures. Nat. Commun. 2019, 10, 355. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, S.; Overvig, A.C.; Lu, M.; Stein, A.; Yu, N. Broadband achromatic dielectric metalenses. Light Sci. Appl. 2018, 7, 85. [Google Scholar] [CrossRef] [PubMed]

- Ou, K.; Yu, F.; Li, G.; Wang, W.; Miroshnichenko, A.E.; Huang, L.; Wang, P.; Li, T.; Li, Z.; Chen, X.; et al. Mid-infrared polarization-controlled broadband achromatic metadevice. Sci. Adv. 2020, 6, eabc0711. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Li, Z.; Dai, X.; Liao, X.; Li, S.; Cao, J.; Shang, Z.; Zhang, Z.; Liang, G.; Chen, G.; et al. Broadband Achromatic Sub-Diffraction Focusing by an Amplitude-Modulated Terahertz Metalens. Adv. Opt. Mater. 2020, 8, 2000842. [Google Scholar] [CrossRef]

- Arbabi, A.; Arbabi, E.; Kamali, S.M.; Horie, Y.; Han, S.; Faraon, A. Miniature optical planar camera based on a wide-angle metasurface doublet corrected for monochromatic aberrations. Nat. Commun. 2016, 7, 13682. [Google Scholar] [CrossRef]

- Groever, B.; Chen, W.T.; Capasso, F. Meta-lens doublet in the visible region. Nano Lett. 2017, 17, 4902–4907. [Google Scholar] [CrossRef]

- Fu, R.; Li, Z.; Zheng, G.; Chen, M.; Yang, Y.; Tao, J.; Wu, L.; Deng, Q. Reconfigurable step-zoom metalens without optical and mechanical compensations. Opt. Express 2019, 27, 12221. [Google Scholar] [CrossRef]

- Aieta, F.; Genevet, P.; Kats, M.; Capasso, F. Aberrations of flat lenses and aplanatic metasurfaces. Opt. Express 2013, 21, 31530. [Google Scholar] [CrossRef]

- Kamali, S.M.; Arbabi, A.; Arbabi, E.; Horie, Y.; Faraon, A. Decoupling optical function and geometrical form using conformal flexible dielectric metasurfaces. Nat. Commun. 2016, 7, 11618. [Google Scholar] [CrossRef]

- Sawant, R.; Andrén, D.; Martins, R.J.; Khadir, S.; Verre, R.; Käll, M.; Genevet, P. Aberration-corrected large-scale hybrid metalenses. Optica 2021, 8, 1405–1411. [Google Scholar]

- Yang, F.; An, S.; Shalaginov, M.Y.; Zhang, H.; Rivero-Baleine, C.; Hu, J.; Gu, T. Design of broadband and wide-field-of-view metalenses. Opt. Lett. 2021, 46, 5735. [Google Scholar]

- Tseng, E.; Colburn, S.; Whitehead, J.; Huang, L.; Baek, S.H.; Majumdar, A.; Heide, F. Neural nano-optics for high-quality thin lens imaging. Nat. Commun. 2021, 12, 6493. [Google Scholar] [CrossRef]

- Wojszvzyk, L.; Nguyen, A.; Coutrot, A.L.; Zhang, C.; Vest, B.; Greffet, J.J. An incandescent metasurface for quasimonochromatic polarized mid-wave infrared emission modulated beyond 10 MHz. Nat. Commun. 2021, 12, 1492. [Google Scholar]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef] [PubMed]

- Dorgan, V.E.; Bae, M.H.; Pop, E. Mobility and saturation velocity in graphene on SiO2. Appl. Phys. Lett. 2010, 97, 082112. [Google Scholar] [CrossRef]

- Katz, M. Aspherical surfaces used to minimize oblique astigmatic error, power error, and distortion of some high positive and negative power ophthalmic lenses. Appl. Opt. 1982, 21, 2982–2991. [Google Scholar]

- Liu, Z.; Du, Z.; Hu, B.; Liu, W.; Liu, J.; Wang, Y. Wide-angle Moiré metalens with continuous zooming. J. Opt. Soc. Am. B 2019, 36, 2810–2816. [Google Scholar]

- Chandler-Horowitz, D.; Amirtharaj, P.M. High-accuracy, midinfrared (450 cm−1 ≤ ω ≤ 4000 cm−1) refractive index values of silicon. J. Appl. Phys. 2005, 97, 123526. [Google Scholar]

- Huang, J.; Guan, H.; Hu, B.; Wang, G.; Liu, W.; Wang, Z.; Liu, J.; Zhang, Y.; Wang, Y. Enhanced terahertz focusing for a graphene-enabled active metalens. Opt. Express 2020, 28, 35179. [Google Scholar] [CrossRef]

- Yang, Q.; Gu, J.; Wang, D.; Zhang, X.; Tian, Z.; Ouyang, C.; Singh, R.; Han, J.; Zhang, W. Efficient flat metasurface lens for terahertz imaging. Opt. Express 2014, 22, 25931. [Google Scholar] [CrossRef]

- Wang, S.; Wu, P.C.; Su, V.C.; Lai, Y.C.; Hung Chu, C.; Chen, J.W.; Lu, S.H.; Chen, J.; Xu, B.; Kuan, C.H.; et al. Broadband achromatic optical metasurface devices. Nat. Commun. 2017, 8, 187. [Google Scholar] [CrossRef] [PubMed]

- Perrin, M.D.; Sivaramakrishnan, A.; Makidon, R.B.; Oppenheimer, B.R.; Graham, J.R. The Structure of High Strehl Ratio Point-Spread Functions. Astrophys. J. 2003, 596, 702–712. [Google Scholar] [CrossRef]

| 1 | 2 | |

|---|---|---|

| 1/0.199707 | 1/0.620348 | |

| −0.706966 | 115.017417 | |

| 0 | 0 | |

| 393.991442 | 471.989551 | |

| 1.870081 × 104 | 2.363506 × 104 | |

| 3.710574 × 106 | 5.501649 × 106 | |

| 3.882496 × 108 | 3.882496 × 108 |

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Bφ, i | 0.0001 | 0.001 | 0.002 | 0.003 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| BGD, i | 0.0001 | 0.001 | 0.002 | 0.003 | 0.005 | 0.01 | 0.02 | 0.03 | 0.05 |

| The Metalens Parameters | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Incident light wavelength () | 3.7–5 μm | ||||||||||

| Radius of monocrystalline silicon substrate (R) | 50.5 μm | ||||||||||

| Monocrystalline silicon nanopillar height (H) | 4.5 μm | ||||||||||

| Long axis radius (rx) and short axis radius (ry) of monocrystalline silicon nanopillar | 200 nm ≤ ry,ry ≤ 700 nm | ||||||||||

| Design focal length (L) | 200 μm | ||||||||||

| Lattice period (P) | 1650 nm | ||||||||||

| Achromatic Lens | |||||||||||

| m | rx (nm) | ry (nm) | Rm (μm) | m | rx (nm) | ry (nm) | Rm (μm) | m | rx (nm) | ry (nm) | Rm (μm) |

| 1 | 532 | 648 | 0 | 11 | 696 | 330 | 16.50 | 21 | 682 | 232 | 33.00 |

| 2 | 526 | 666 | 1.65 | 12 | 698 | 320 | 18.15 | 22 | 682 | 686 | 34.65 |

| 3 | 520 | 680 | 3.30 | 13 | 700 | 310 | 19.80 | 23 | 642 | 230 | 36.30 |

| 4 | 574 | 532 | 4.95 | 14 | 698 | 302 | 21.45 | 24 | 618 | 232 | 37.95 |

| 5 | 592 | 492 | 6.60 | 15 | 700 | 292 | 23.10 | 25 | 592 | 238 | 39.60 |

| 6 | 612 | 454 | 8.25 | 16 | 700 | 282 | 24.75 | 26 | 568 | 244 | 41.25 |

| 7 | 634 | 418 | 9.90 | 17 | 698 | 272 | 26.40 | 27 | 536 | 258 | 42.90 |

| 8 | 652 | 390 | 11.55 | 18 | 696 | 262 | 28.05 | 28 | 504 | 278 | 44.55 |

| 9 | 670 | 366 | 13.20 | 19 | 700 | 248 | 29.70 | 29 | 368 | 582 | 46.20 |

| 10 | 682 | 348 | 14.85 | 20 | 698 | 236 | 31.35 | 30 | 400 | 438 | 47.85 |

| 31 | 400 | 420 | 49.50 | ||||||||

| Chromatic Lens | |||||||||||

| m | rx (nm) | ry (nm) | Rm (μm) | m | rx (nm) | ry (nm) | Rm (μm) | m | rx (nm) | ry (nm) | Rm (μm) |

| 1 | 620 | 648 | 0 | 11 | 662 | 460 | 16.50 | 21 | 516 | 454 | 33.00 |

| 2 | 602 | 690 | 1.65 | 12 | 618 | 498 | 18.15 | 22 | 626 | 294 | 34.65 |

| 3 | 650 | 582 | 3.30 | 13 | 534 | 654 | 19.80 | 23 | 478 | 468 | 36.30 |

| 4 | 604 | 672 | 4.95 | 14 | 526 | 642 | 21.45 | 24 | 600 | 272 | 37.95 |

| 5 | 606 | 656 | 6.60 | 15 | 502 | 682 | 23.10 | 25 | 680 | 212 | 39.60 |

| 6 | 600 | 656 | 8.25 | 16 | 520 | 586 | 24.75 | 26 | 388 | 640 | 41.25 |

| 7 | 622 | 592 | 9.90 | 17 | 490 | 652 | 26.40 | 27 | 432 | 426 | 42.90 |

| 8 | 572 | 692 | 11.55 | 18 | 480 | 652 | 28.05 | 28 | 488 | 286 | 44.55 |

| 9 | 562 | 696 | 13.20 | 19 | 468 | 662 | 29.70 | 29 | 512 | 224 | 46.20 |

| 10 | 556 | 686 | 14.85 | 20 | 474 | 600 | 31.35 | 30 | 308 | 670 | 47.85 |

| 31 | 374 | 290 | 49.50 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Cui, C.; Zhao, J.; Hu, B. Mid-Infrared Broadband Achromatic Metalens with Wide Field of View. Materials 2022, 15, 7587. https://doi.org/10.3390/ma15217587

Jiang Y, Cui C, Zhao J, Hu B. Mid-Infrared Broadband Achromatic Metalens with Wide Field of View. Materials. 2022; 15(21):7587. https://doi.org/10.3390/ma15217587

Chicago/Turabian StyleJiang, Yurong, Cheng Cui, Jinmin Zhao, and Bin Hu. 2022. "Mid-Infrared Broadband Achromatic Metalens with Wide Field of View" Materials 15, no. 21: 7587. https://doi.org/10.3390/ma15217587

APA StyleJiang, Y., Cui, C., Zhao, J., & Hu, B. (2022). Mid-Infrared Broadband Achromatic Metalens with Wide Field of View. Materials, 15(21), 7587. https://doi.org/10.3390/ma15217587