Applicability of Pre-Plastic Deformation Method for Improving Mechanical Properties of Bulk Metallic Glasses

Abstract

1. Introduction

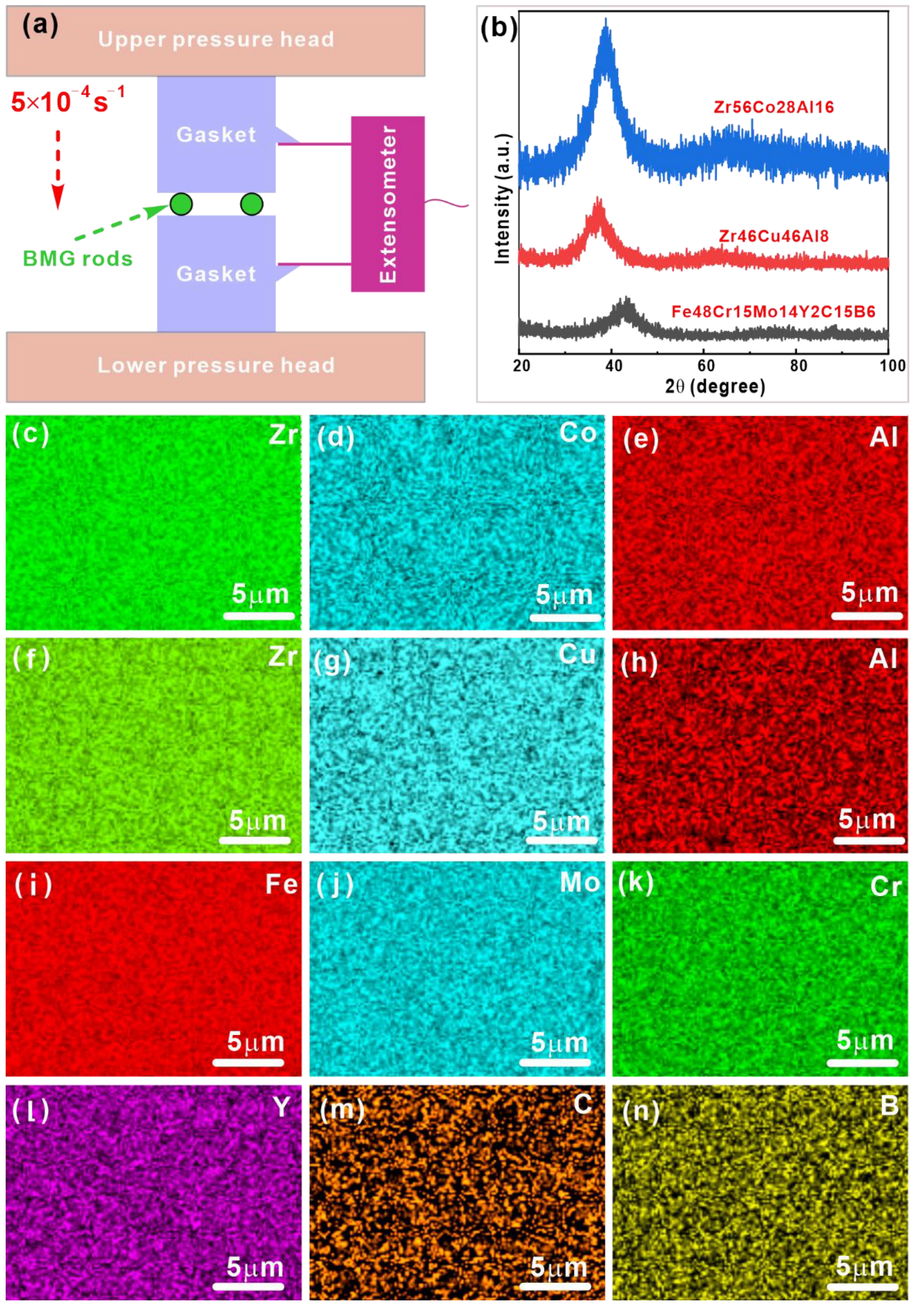

2. Materials and Methods

3. Results

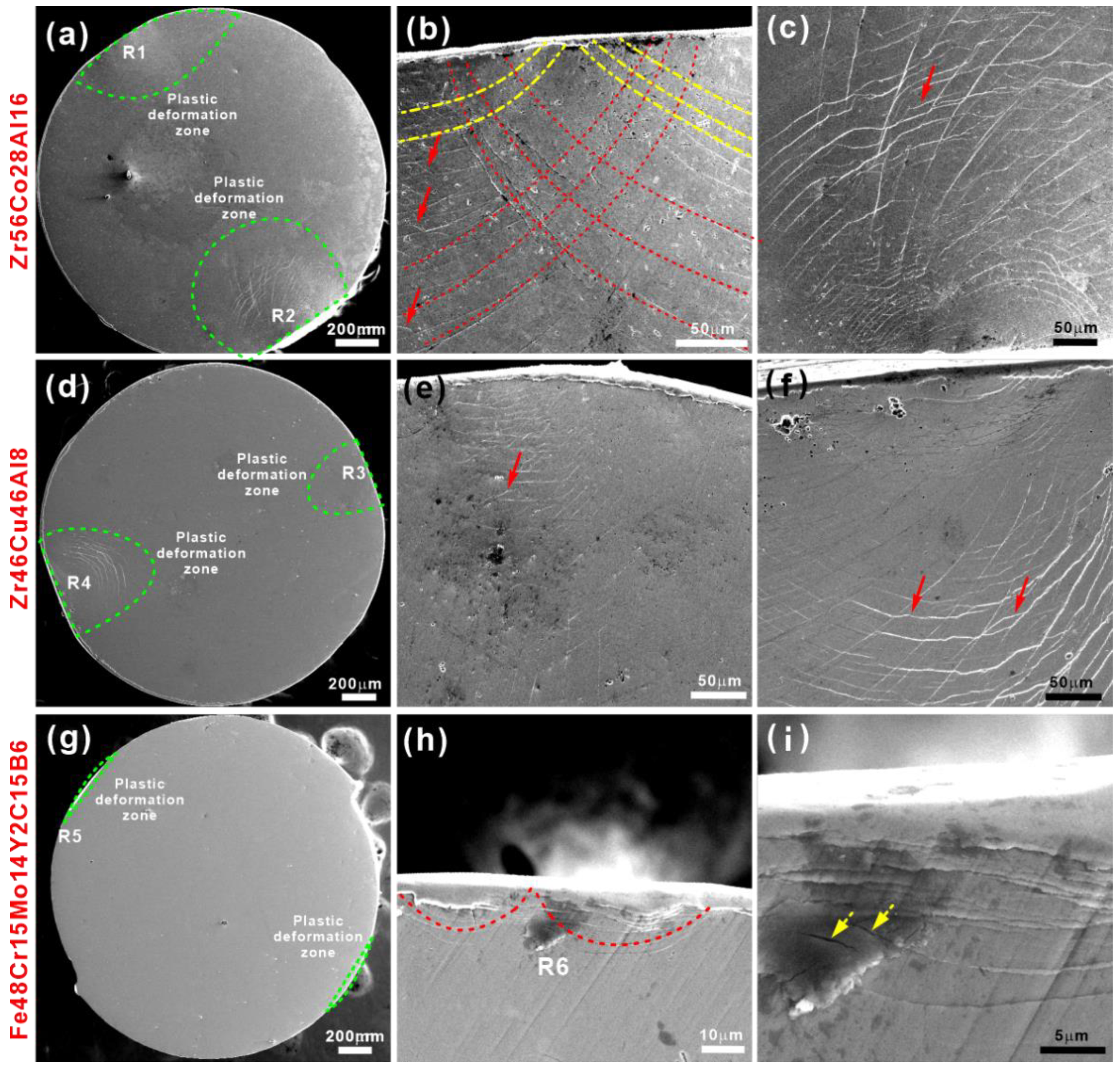

3.1. Pre-Existing Shear Bands in BMGs after PPD Treatments

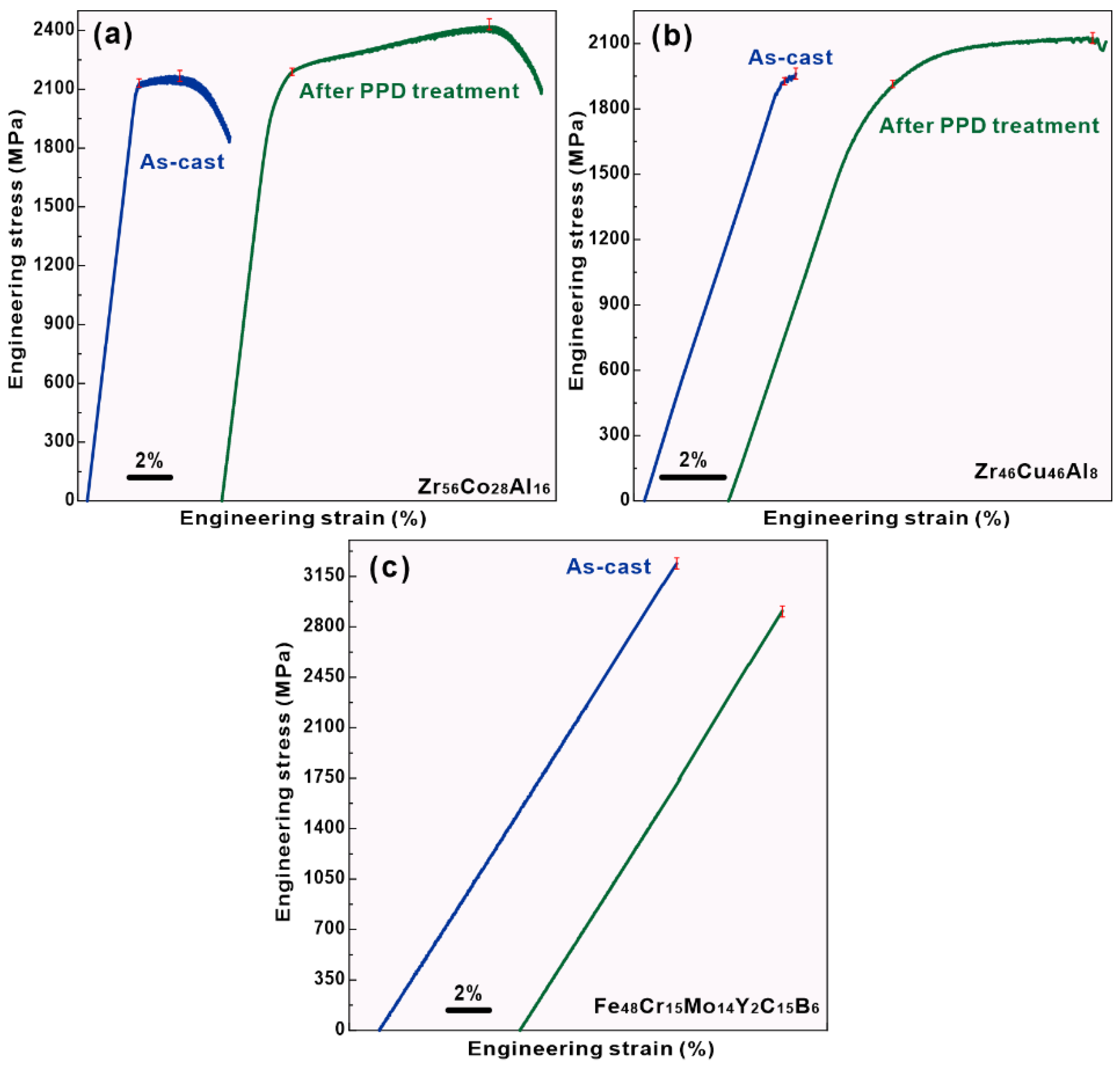

3.2. Mechanical Properties of BMGs in As-Cast States and after PPD Treatments

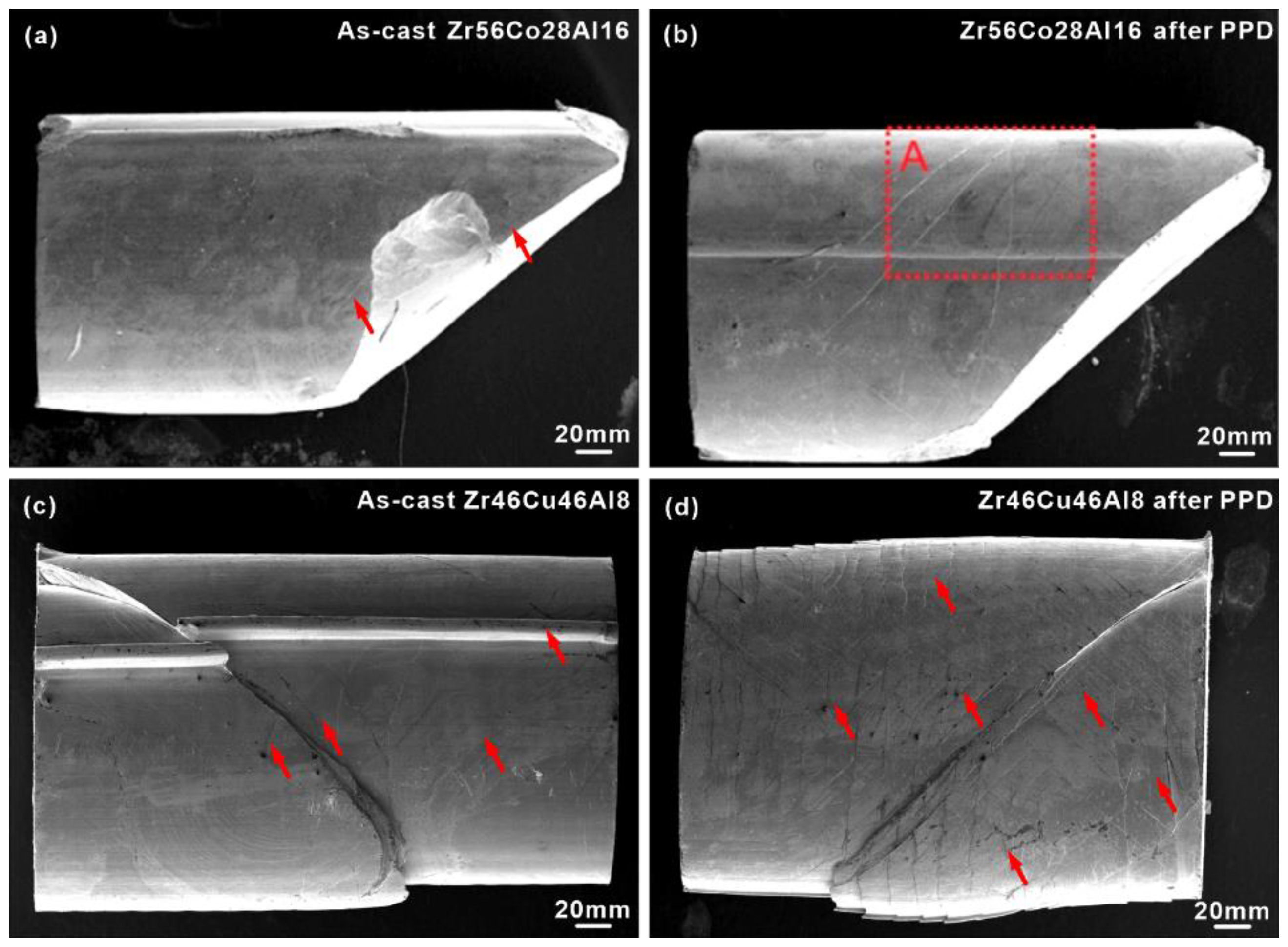

3.3. Fracture Morphologies

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Yang, G.N.; Shao, Y.; Yao, K.F. Understanding the fracture behaviors of metallic glasses—An overview. Appl. Sci. 2019, 9, 4277. [Google Scholar] [CrossRef]

- Sun, B.A.; Wang, W.H. The fracture of bulk metallic glasses. Prog. Mater. Sci. 2015, 74, 211–307. [Google Scholar] [CrossRef]

- Wang, X.; Wu, S.; Qu, R.; Zhang, Z. Shear band evolution under cyclic loading and fatigue property in metallic glasses: A brief review. Materials 2021, 14, 3595. [Google Scholar] [CrossRef]

- Sharma, A.; Zadorozhnyy, V. Review of the recent development in metallic glass and its composites. Metals 2021, 11, 1933. [Google Scholar] [CrossRef]

- Wang, X.J.; Lu, Y.Z.; Lu, X.; Huo, J.T.; Wang, Y.J.; Wang, W.H.; Dai, L.H.; Jiang, M.Q. Elastic criterion for shear-banding instability in amorphous solids. Phys. Rev. E 2022, 105, 045003. [Google Scholar] [CrossRef] [PubMed]

- Tao, K.; Li, F.C.; Liu, Y.H.; Pineda, E.; Song, K.K.; Qiao, J.C. Unraveling the microstructural heterogeneity and plasticity of Zr50Cu40Al10 bulk metallic glass by nanoindentation. Int. J. Plast. 2022, 154, 103305. [Google Scholar] [CrossRef]

- He, J.; Kaban, I.; Mattern, N.; Song, K.; Sun, B.; Zhao, J.; Kim, D.H.; Eckert, J.; Greer, A.L. Local microstructure evolution at shear bands in metallic glasses with nanoscale phase separation. Sci. Rep. 2016, 6, 25832. [Google Scholar] [CrossRef]

- Pan, J.; Duan, F. Rejuvenation behaviors in metallic glasses. Acta Metall. Sin. 2021, 57, 439–452. [Google Scholar]

- Zhang, K.; Wang, Y.; Zhang, W.; Hu, Z.; Wei, B.; Feng, Y. Crystallization behavior and mechanical response of metallic glass induced by ion irradiation at elevated temperature. J. Nucl. Mater. 2021, 545, 152618. [Google Scholar] [CrossRef]

- Luo, Y.; Xing, L.; Jiang, Y.; Li, R.; Lu, C.; Zeng, R.; Luo, J.; Zhang, P.; Liu, W. Additive manufactured marge Zr-based bulk metallic glass composites with desired deformation ability and corrosion resistance. Materials 2020, 13, 597. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.; Ke, H.; Sun, B.; Zhu, Z.; Wang, Y.; Li, H.; Wang, A.; Zhang, H. On low-temperature strength and tensile ductility of bulk metallic glass composites containing stable or shape memory β-Ti crystals. Acta Mater. 2022, 222, 117444. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, C.; Jiang, J.Z. Bulk metallic glass composites containing B2 phase. Prog. Mater. Sci. 2021, 121, 100799. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.F.; Li, C.J.; Yuan, Q.; Wu, Z.X.; Tan, J.; Gao, P.; You, X.; Yi, J.H. Effect of Al content on the mechanical properties and toughening mechanism of Zr-Co-Al alloys prepared by rapid solidification. Mater. Sci. Eng. A 2022, 831, 142237. [Google Scholar] [CrossRef]

- Şopu, D.; Yuan, X.; Moitzi, F.; Stoica, M.; Eckert, J. Structure-property relationships in shape memory metallic glass composites. Materials 2019, 12, 1419. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.; Chen, G.; Liu, C.T.; Lu, Z. Bulk metallic glass composites with transformation-mediated work-hardening and ductility. Adv. Mater. 2010, 22, 2770–2773. [Google Scholar] [CrossRef]

- Shao, H.; Xu, Y.; Shi, B.; Yu, C.; Hahn, H.; Gleiter, H.; Li, J. High density of shear bands and enhanced free volume induced in Zr70Cu20Ni10 metallic glass by high-energy ball milling. J. Alloys Compd. 2013, 548, 77–81. [Google Scholar] [CrossRef]

- Qu, R.T.; Calin, M.; Eckert, J.; Zhang, Z.F. Metallic glasses: Notch-insensitive materials. Scr. Mater. 2012, 66, 733–736. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, M.Q.; Dai, L.H. Collective evolution dynamics of multiple shear bands in bulk metallic glasses. Int. J. Plast. 2013, 50, 18–36. [Google Scholar] [CrossRef]

- Sieber, H.; Wilde, G.; Sagel, A.; Perepezko, J.H. Amorphous phase formation during cold rolling of Al-Sm and Zr-Cu-Ni-Al multilayer structures. J. Non-Cryst. Solids 1999, 250–252, 616–620. [Google Scholar] [CrossRef]

- Atzmon, M.; Unruh, K.M.; Johnson, W.L. Formation and characterization of amorphous erbium-ased alloys prepared by near-sothermal cold-rolling of elemental composites. J. Appl. Phys. 1985, 58, 3865–3870. [Google Scholar] [CrossRef][Green Version]

- Hagiwara, M.; Inoue, A.; Masumoto, T. Production of amorphous CoSiB and CoMSiB (M = Group IV–VIII transition metals) wires by a method employing melt spinning into rotating water and some properties of the wires. Mater. Sci. Eng. 1982, 54, 197–207. [Google Scholar] [CrossRef]

- Masumoto, T.; Maddin, R. Structural stability and mechanical properties of amorphous metals. Mater. Sci. Eng. 1975, 19, 1–24. [Google Scholar] [CrossRef]

- Yokoyama, Y.; Yamano, K.; Fukaura, K.; Sunada, H.; Inoue, A. Ductility improvement of Zr55Cu30Al10Ni5 bulk amorphous alloy. Scr. Mater. 2001, 44, 1529–1533. [Google Scholar] [CrossRef]

- Jin, H.J.; Zhou, F.; Wang, L.B.; Lu, K. Effect of plastic deformation on thermal stability in metallic glasses. Scr. Mater. 2001, 44, 1083–1087. [Google Scholar] [CrossRef]

- Cao, Q.P.; Liu, J.W.; Yang, K.J.; Xu, F.; Yao, Z.Q.; Minkow, A.; Fecht, H.J.; Ivanisenko, J.; Chen, L.Y.; Wang, X.D.; et al. Effect of pre-existing shear bands on the tensile mechanical properties of a bulk metallic glass. Acta Mater. 2010, 58, 1276–1292. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, J.; Shek, C.H.; Yan, J. Effects of pre-compression deformation on nanoindentation response of Zr65Cu15Al10Ni10 bulk metallic glass. J. Alloys Compd. 2016, 674, 223–228. [Google Scholar] [CrossRef]

- Scudino, S. Mechanism of shear banding during cold rolling of a bulk metallic glass. J. Alloys Compd. 2019, 773, 883–889. [Google Scholar] [CrossRef]

- Li, B.; Scudino, S.; Gludovatz, B.; Kruzic, J.J. Role of pre-existing shear band morphology in controlling the fracture behavior of a Zr-Ti-Cu-Ni-Al bulk metallic glass. Mater. Sci. Eng. A 2020, 786, 139396. [Google Scholar] [CrossRef]

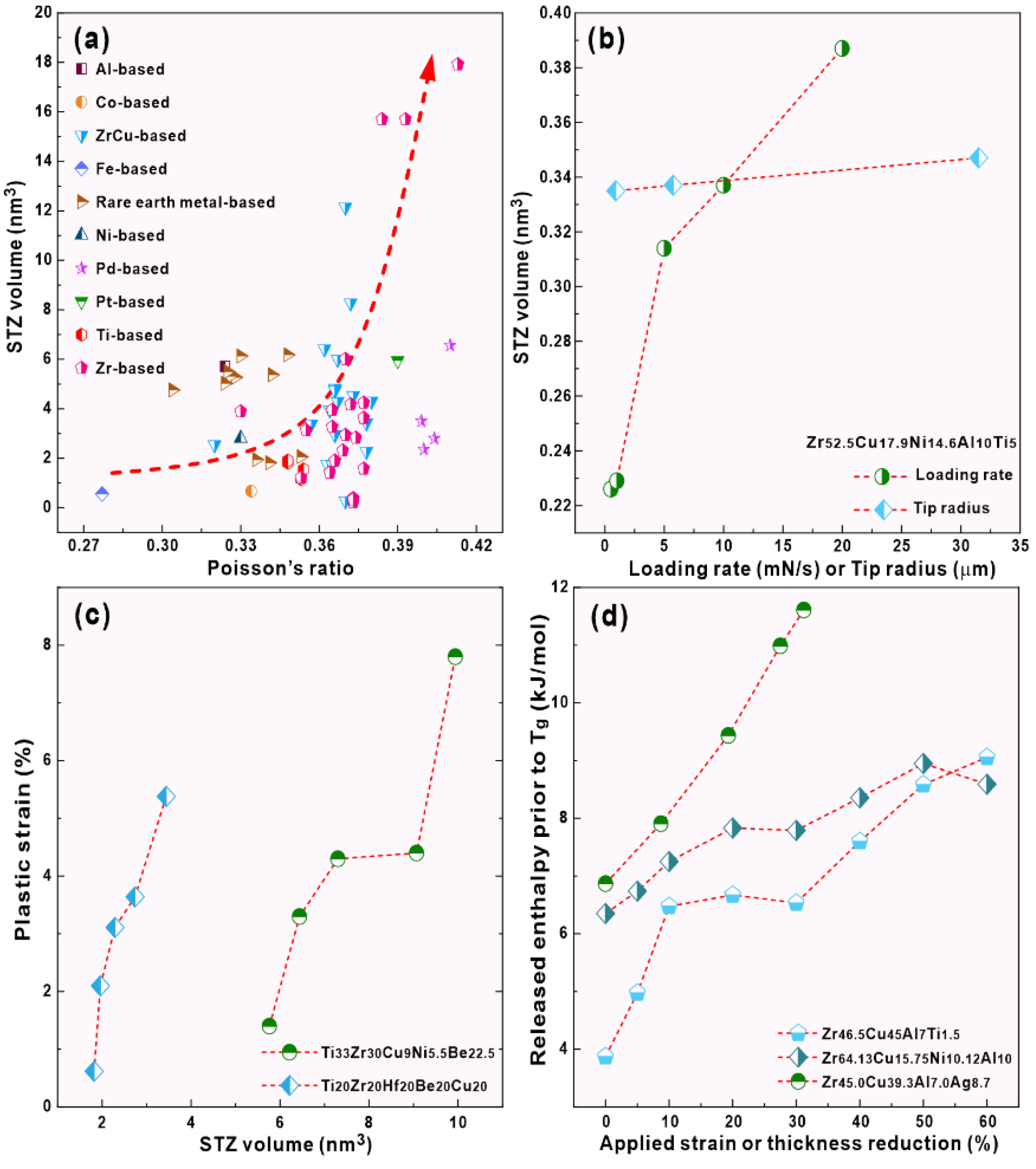

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Madge, S.V.; Louzguine-Luzgin, D.V.; Lewandowski, J.J.; Greer, A.L. Toughness, extrinsic effects and Poisson’s ratio of bulk metallic glasses. Acta Mater. 2012, 60, 4800–4809. [Google Scholar] [CrossRef]

- Yu, P.; Bai, H.Y. Poisson’s ratio and plasticity in CuZrAl bulk metallic glasses. Mater. Sci. Eng. A 2008, 485, 1–4. [Google Scholar] [CrossRef]

- Tan, J.; Zhang, Y.; Sun, B.; Stoica, M.; Li, C.; Song, K.; Kühn, U.; Pan, F.; Eckert, J. Correlation between internal states and plasticity in bulk metallic glass. Appl. Phys. Lett. 2011, 98, 151906. [Google Scholar]

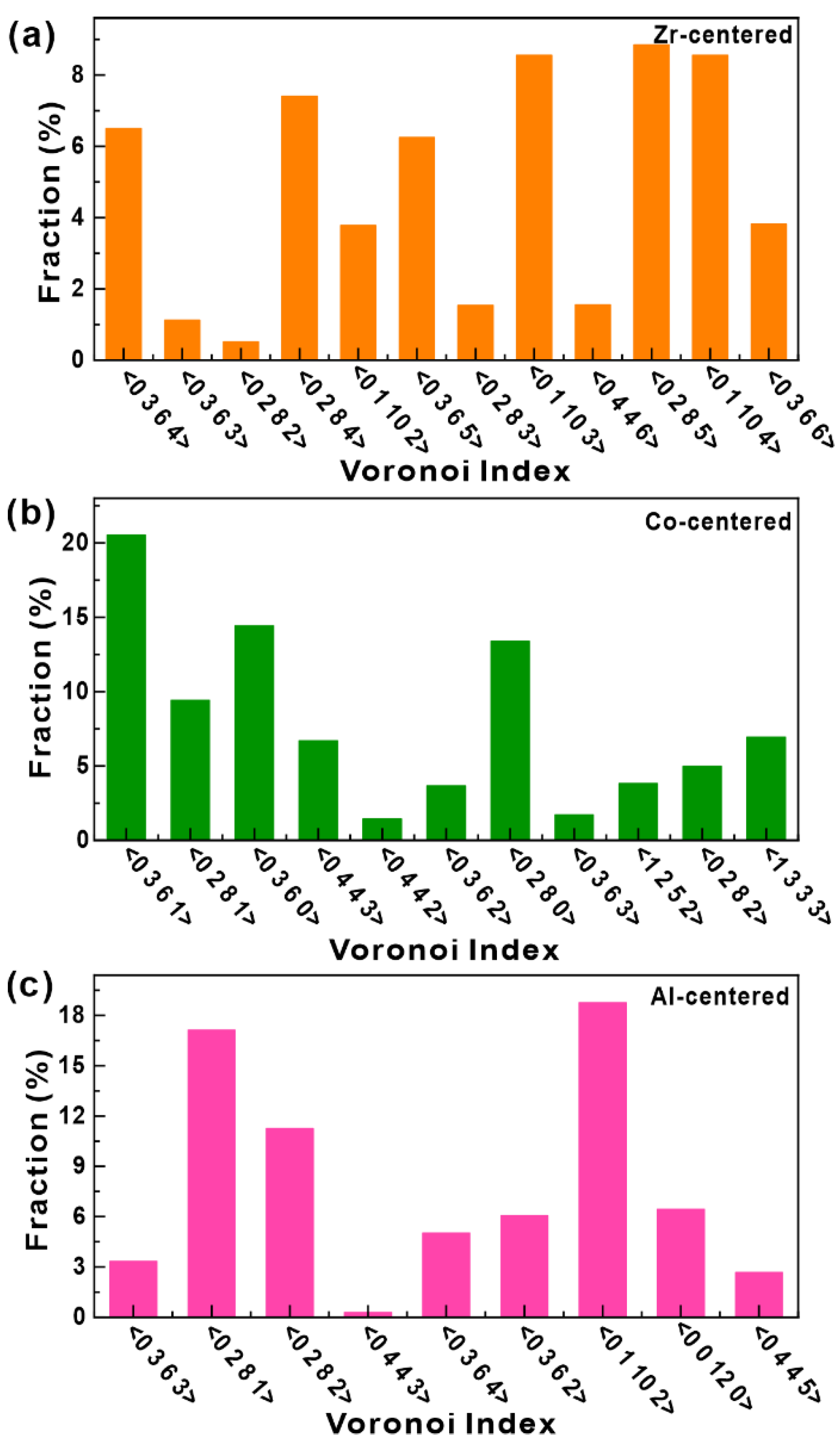

- Zhang, H.; Sun, H.; Pan, S.; Şopu, D.; Peng, C.; Zhao, K.; Song, K.; Yuan, S.; Qiao, J.; Wang, L.; et al. Origin of structural heterogeneity in Zr-Co-Al metallic glasses from the point of view of liquid structures. J. Non-Cryst. Solids 2021, 553, 120501. [Google Scholar] [CrossRef]

- Jana, S.; Bhowmick, R.; Kawamura, Y.; Chattopadhyay, K.; Ramamurty, U. Deformation morphology underneath the Vickers indent in a Zr-based bulk metallic glass. Intermetallics 2004, 12, 1097–1102. [Google Scholar] [CrossRef]

- Reddy, K.V.; Pal, S. Cold-rolling induced residual stress effect on the shock response of crystalline-metallic glass (Cu-CuZr) nanolaminates by molecular dynamics simulation. Mater. Chem. Phys. 2021, 272, 125010. [Google Scholar] [CrossRef]

- Yamanaka, S.; Amiya, K.; Saotome, Y. Effects of residual stress on elastic plastic behavior of metallic glass bolts formed by cold thread rolling. J. Mater. Process. Technol. 2014, 214, 2593–2599. [Google Scholar] [CrossRef]

- Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 1977, 25, 407–415. [Google Scholar] [CrossRef]

- Argon, A.S. Plastic deformation in metallic glasses. Acta Metall. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Schuh, C.A.; Argon, A.S.; Nieh, T.G.; Wadsworth, J. The transition from localized to homogeneous plasticity during nanoindentation of an amorphous metal. Philos. Mag. 2003, 83, 2585–2597. [Google Scholar] [CrossRef]

- Dubach, A.; Dalla Torre, F.H.; Löffler, J.F. Constitutive model for inhomogeneous flow in bulk metallic glasses. Acta Mater. 2009, 57, 881–892. [Google Scholar] [CrossRef]

- Liu, S.T.; Wang, Z.; Peng, H.L.; Yu, H.B.; Wang, W.H. The activation energy and volume of flow units of metallic glasses. Scr. Mater. 2012, 67, 9–12. [Google Scholar] [CrossRef]

- Choi, I.C.; Zhao, Y.; Kim, Y.J.; Yoo, B.G.; Suh, J.Y.; Ramamurty, U.; Jang, J.I. Indentation size effect and shear transformation zone size in a bulk metallic glass in two different structural states. Acta Mater. 2012, 60, 6862–6868. [Google Scholar] [CrossRef]

- Johnson, W.L.; Samwer, K. A Universal Criterion for Plastic Yielding of Metallic Glasses with a (T/Tg)2/3 Temperature Dependence. Phys. Rev. Lett. 2005, 95, 195501. [Google Scholar] [CrossRef]

- Jiang, S.S.; Gan, K.F.; Huang, Y.J.; Xue, P.; Ning, Z.L.; Sun, J.F.; Ngan, A.H.W. Stochastic deformation and shear transformation zones of the glassy matrix in CuZr-based metallic-glass composites. Int. J. Plast. 2020, 125, 52–62. [Google Scholar] [CrossRef]

- Dong, F.; He, M.; Zhang, Y.; Wang, B.; Luo, L.; Su, Y.; Yang, H.; Yuan, X. Investigation of shear transformation zone and ductility of Zr-based bulk metallic glass after plasma-assisted hydrogenation. Mater. Sci. Eng. A 2019, 759, 105–111. [Google Scholar] [CrossRef]

- Pan, D.; Yokoyama, Y.; Fujita, T.; Liu, Y.H.; Kohara, S.; Inoue, A.; Chen, M.W. Correlation between structural relaxation and shear transformation zone volume of a bulk metallic glass. Appl. Phys. Lett. 2009, 95, 141909. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Wang, W.H.; Greer, A.L. Intrinsic plasticity or brittleness of metallic glasses. Philos. Mag. Lett. 2005, 85, 77–87. [Google Scholar] [CrossRef]

- Pan, D.; Inoue, A.; Sakurai, T.; Chen, M.W. Experimental characterization of shear transformation zones for plastic flow of bulk metallic glasses. Proc. Natl. Acad. Sci. USA 2008, 105, 14769–14772. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, M.; Jin, X.; Yang, H.; Jia, L.; Qiao, J. Effect of deep cryogenic cycling treatment on shear transformation zone volume and size of Zr-based metallic glass. J. Mater. Res. 2021, 36, 2047–2055. [Google Scholar] [CrossRef]

- Zhou, W.H.; Duan, F.H.; Meng, Y.H.; Zheng, C.C.; Chen, H.M.; Huang, A.G.; Wang, Y.X.; Li, Y. Effect of alloying oxygen on the microstructure and mechanical properties of Zr-based bulk metallic glass. Acta Mater. 2021, 220, 117345. [Google Scholar] [CrossRef]

- Ghodki, N.; Sadeghilaridjani, M.; Mukherjee, S. Time-dependent deformation mechanism of metallic glass in different structural states at different temperatures. J. Non-Cryst. Solids 2022, 576, 121221. [Google Scholar] [CrossRef]

- Perepezko, J.H.; Imhoff, S.D.; Chen, M.W.; Wang, J.Q.; Gonzalez, S. Nucleation of shear bands in amorphous alloys. Proc. Natl. Acad. Sci. USA 2014, 111, 3938–3942. [Google Scholar] [CrossRef]

- Choi, I.C.; Zhao, Y.; Yoo, B.G.; Kim, Y.J.; Suh, J.Y.; Ramamurty, U.; Jang, J.I. Estimation of the shear transformation zone size in a bulk metallic glass through statistical analysis of the first pop-in stresses during spherical nanoindentation. Scr. Mater. 2012, 66, 923–926. [Google Scholar] [CrossRef]

- Lv, J.W.; Wang, F.L.; Yin, D.W.; Zhang, S.; Cai, Z.Q.; Shi, Z.L.; Ma, M.Z.; Zhang, X.Y. Effect of deep cryogenic cycling treatment on the microstructure and mechanical properties of Ti-based bulk metallic glass. J. Alloys Compd. 2021, 887, 161386. [Google Scholar] [CrossRef]

- Fan, H.; Wang, N.; He, C.; Huang, Y.; Ning, Z.; Sun, J. Effect of pre-straining on the structure and nano-mechanical properties of a CuZrAl bulk metallic glass. J. Alloys Compd. 2022, 918, 165635. [Google Scholar] [CrossRef]

- Tong, Y.; Qiao, J.C.; Pelletier, J.M.; Yao, Y. Rate-dependent plastic deformation of TiZrHfCuNiBe high entropy bulk metallic glass. J. Alloys Compd. 2019, 785, 542–552. [Google Scholar] [CrossRef]

- Limbach, R.; Kosiba, K.; Pauly, S.; Kühn, U.; Wondraczek, L. Serrated flow of CuZr-based bulk metallic glasses probed by nanoindentation: Role of the activation barrier, size and distribution of shear transformation zones. J. Non-Cryst. Solids 2017, 459, 130–141. [Google Scholar] [CrossRef]

- Dubach, A.; Eswar Prasad, K.; Raghavan, R.; Löffler, J.F.; Michler, J.; Ramamurty, U. Free-volume dependent pressure sensitivity of Zr-based bulk metallic glass. J. Mater. Res. 2009, 24, 2697–2704. [Google Scholar] [CrossRef][Green Version]

- Gong, P.; Yin, G.; Jamili-Shirvan, Z.; Ding, H.; Wang, X.; Jin, J. Influence of deep cryogenic cycling on the rejuvenation and plasticization of TiZrHfBeCu high-entropy bulk metallic glass. Mater. Sci. Eng. A 2020, 797, 140078. [Google Scholar] [CrossRef]

- Liu, J.W.; Cao, Q.P.; Chen, L.Y.; Wang, X.D.; Jiang, J.Z. Shear band evolution and hardness change in cold-rolled bulk metallic glasses. Acta Mater. 2010, 58, 4827–4840. [Google Scholar] [CrossRef]

- Zhang, Y.; Hahn, H. Quantification of the free volume in Zr45.0Cu39.3Al7.0Ag8.7 bulk metallic glasses subjected to plastic deformation by calorimetric and dilatometric measurements. J. Alloys Compd. 2009, 488, 65–71. [Google Scholar] [CrossRef]

- Şopu, D.; Moitzi, F.; Mousseau, N.; Eckert, J. An atomic-level perspective of shear band formation and interaction in monolithic metallic glasses. Appl. Mater. Today 2020, 21, 100828. [Google Scholar] [CrossRef]

- Fang, H.Z.; Hui, X.; Chen, G.L.; Liu, Z.K. Al-centered icosahedral ordering in Cu46Zr46Al8 bulk metallic glass. Appl. Phys. Lett. 2009, 94, 091904. [Google Scholar] [CrossRef]

- Zhao, Y.; Choi, I.C.; Seok, M.Y.; Kim, M.H.; Kim, D.H.; Ramamurty, U.; Suh, J.Y.; Jang, J.I. Effect of hydrogen on the yielding behavior and shear transformation zone volume in metallic glass ribbons. Acta Mater. 2014, 78, 213–221. [Google Scholar] [CrossRef]

- Liu, S.; Chang, Z.; Fu, Y.; Liu, Y.; Lin, M.; Ren, X.; Wang, W.; Zhang, Z.; He, J. Nanoscale creep behavior and its size dependency of a Zr-based bulk metallic glass manufactured by selective laser melting. Mater. Des. 2022, 218, 110723. [Google Scholar] [CrossRef]

- Zhao, X.N.; Cao, Q.P.; Wang, C.; Wang, X.D.; Zhang, D.X.; Qu, S.X.; Jiang, J.Z. Dependence of room-temperature nanoindentation creep behavior and shear transformation zone on the glass transition temperature in bulk metallic glasses. J. Non-Cryst. Solids 2016, 445–446, 19–29. [Google Scholar] [CrossRef]

- Pan, D.; Guo, H.; Zhang, W.; Inoue, A.; Chen, M.W. Temperature-induced anomalous brittle-to-ductile transition of bulk metallic glasses. Proc. Natl. Acad. Sci. U.S.A. 2011, 99, 241907. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Huang, L.; Huang, P.; Xu, K.W.; Wang, F.; Lu, T.J. Clarification on shear transformation zone size and its correlation with plasticity for Zr-based bulk metallic glass in different structural states. Mater. Sci. Eng. A 2016, 677, 349–355. [Google Scholar] [CrossRef]

- Zhao, S.F.; Yang, G.N.; Ding, H.Y.; Yao, K.F. A quinary Ti-Zr-Hf-Be-Cu high entropy bulk metallic glass with a critical size of 12 mm. Intermetallics 2015, 61, 47–50. [Google Scholar] [CrossRef]

- Cao, Q.P.; Jin, J.B.; Ma, Y.; Cao, X.Z.; Wang, B.Y.; Qu, S.X.; Wang, X.D.; Zhang, D.X.; Jiang, J.Z. Enhanced plasticity in Zr-Cu-Ag-Al-Be bulk metallic glasses. J. Non-Cryst. Solids 2015, 412, 35–44. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, P.; Wang, F. The correlation between β relaxation and shear transformation zone in LaNiAl bulk metallic glasses: The effect of cryogenic thermal cycling treatment. J. Alloys Compd. 2021, 865, 158993. [Google Scholar] [CrossRef]

- Li, Y.H.; Zhang, W.; Dong, C.; Qiang, J.B.; Yubuta, K.; Makino, A.; Inoue, A. Unusual compressive plasticity of a centimeter-diameter Zr-based bulk metallic glass with high Zr content. J. Alloys Compd. 2010, 504, S2–S5. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, P.; Wang, F. Effects of cryogenic thermal cycling on a La-based metallic glass: Relaxation or rejuvenation? J. Alloys Compd. 2022, 909, 164741. [Google Scholar] [CrossRef]

- Khanouki, M.T.A.; Tavakoli, R.; Aashuri, H. Temperature dependence of serrated flow, strain-rate sensitivity and activation volume in a Ti-based bulk metallic glass. J. Non-Cryst. Solids 2021, 553, 120497. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, H.; Gu, J.; Guo, N.; Shao, L.; Zhang, Y.; Yao, K.; Chen, N. High strain rate sensitivity of hardness in Ti-Zr-Hf-Be-(Cu/Ni) high entropy bulk metallic glasses. J. Alloys Compd. 2018, 742, 312–317. [Google Scholar] [CrossRef]

- Dong, F.; Chu, Y.; He, M.; Zhang, Y.; Li, W.; Liaw, P.K.; Wang, B.; Luo, L.; Su, Y.; Ritchie, R.O.; et al. Manipulating internal flow units toward favorable plasticity in Zr-based bulk-metallic glasses by hydrogenation. J. Mater. Sci. Technol. 2022, 102, 36–45. [Google Scholar] [CrossRef]

- Saini, P.; Narayan, R.L. On simultaneous enhancement in local yield strength and plasticity of short-term annealed bulk metallic glasses. J. Alloys Compd. 2022, 898, 162960. [Google Scholar] [CrossRef]

| Compositions | State | Poisson’s Ratio | Yield Strength (MPa) | Max. Compressive Strength (MPa) | Plasticity (%) |

|---|---|---|---|---|---|

| Zr56Co28Al16 | cast | ~0.367 | 2115 ± 10 | 2168 ± 20 | ~4.4 |

| Zr56Co28Al16 | PPD | - | 2122 ± 15 | 2420 ± 30 | ~21.8 |

| Zr46Cu46Al8 | cast | ~0.366 | 1990 ± 10 | 1995 ± 20 | ~0.2 |

| Zr46Cu46Al8 | PPD | - | 1992 ± 15 | 2120 ± 30 | ~3.5 |

| Fe48Cr15Mo14Y2C15B6 | cast | ~0.309 | - | 3239 ± 20 | 0 |

| Fe48Cr15Mo14Y2C15B6 | PPD | - | - | 2909 ± 30 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Zhang, H.; Yuan, X.; Song, K.; Liu, D. Applicability of Pre-Plastic Deformation Method for Improving Mechanical Properties of Bulk Metallic Glasses. Materials 2022, 15, 7574. https://doi.org/10.3390/ma15217574

Zhou C, Zhang H, Yuan X, Song K, Liu D. Applicability of Pre-Plastic Deformation Method for Improving Mechanical Properties of Bulk Metallic Glasses. Materials. 2022; 15(21):7574. https://doi.org/10.3390/ma15217574

Chicago/Turabian StyleZhou, Changshan, Hezhi Zhang, Xudong Yuan, Kaikai Song, and Dan Liu. 2022. "Applicability of Pre-Plastic Deformation Method for Improving Mechanical Properties of Bulk Metallic Glasses" Materials 15, no. 21: 7574. https://doi.org/10.3390/ma15217574

APA StyleZhou, C., Zhang, H., Yuan, X., Song, K., & Liu, D. (2022). Applicability of Pre-Plastic Deformation Method for Improving Mechanical Properties of Bulk Metallic Glasses. Materials, 15(21), 7574. https://doi.org/10.3390/ma15217574