In-Depth Characterization of Laser-Welded Aluminum-and-Copper Dissimilar Joint for Electric Vehicle Battery Connections

Abstract

1. Introduction

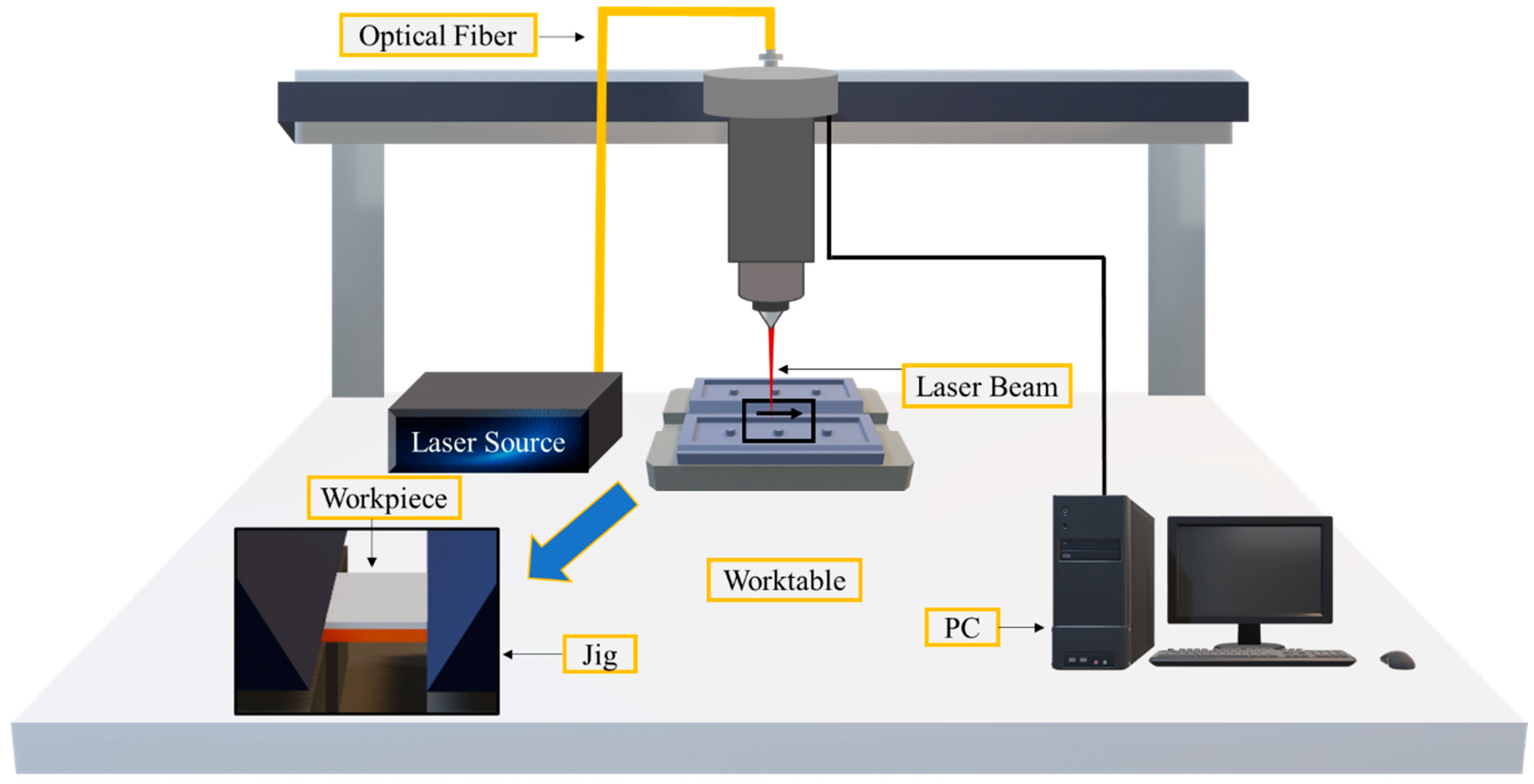

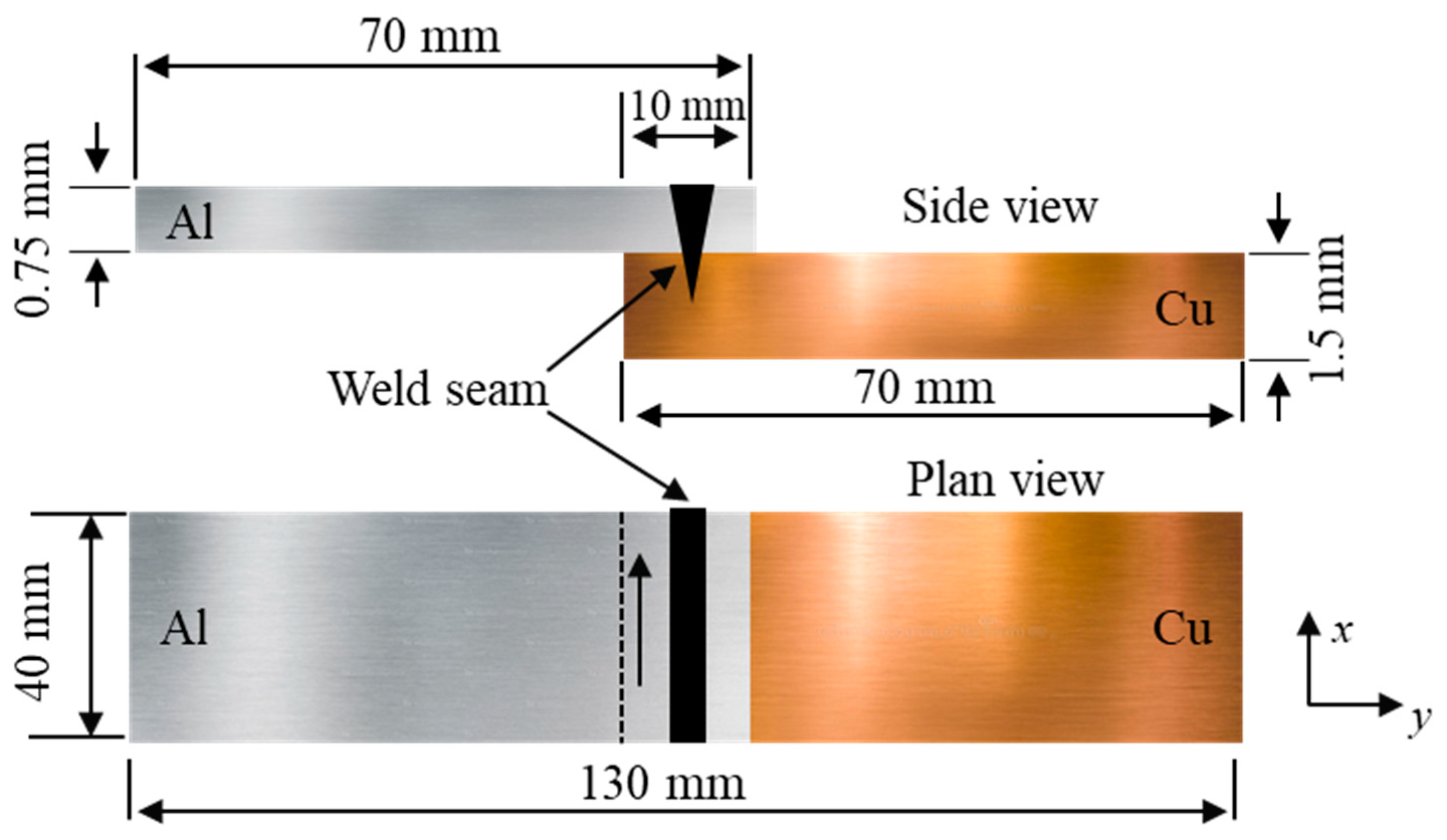

2. Materials and Methods

3. Results and Discussion

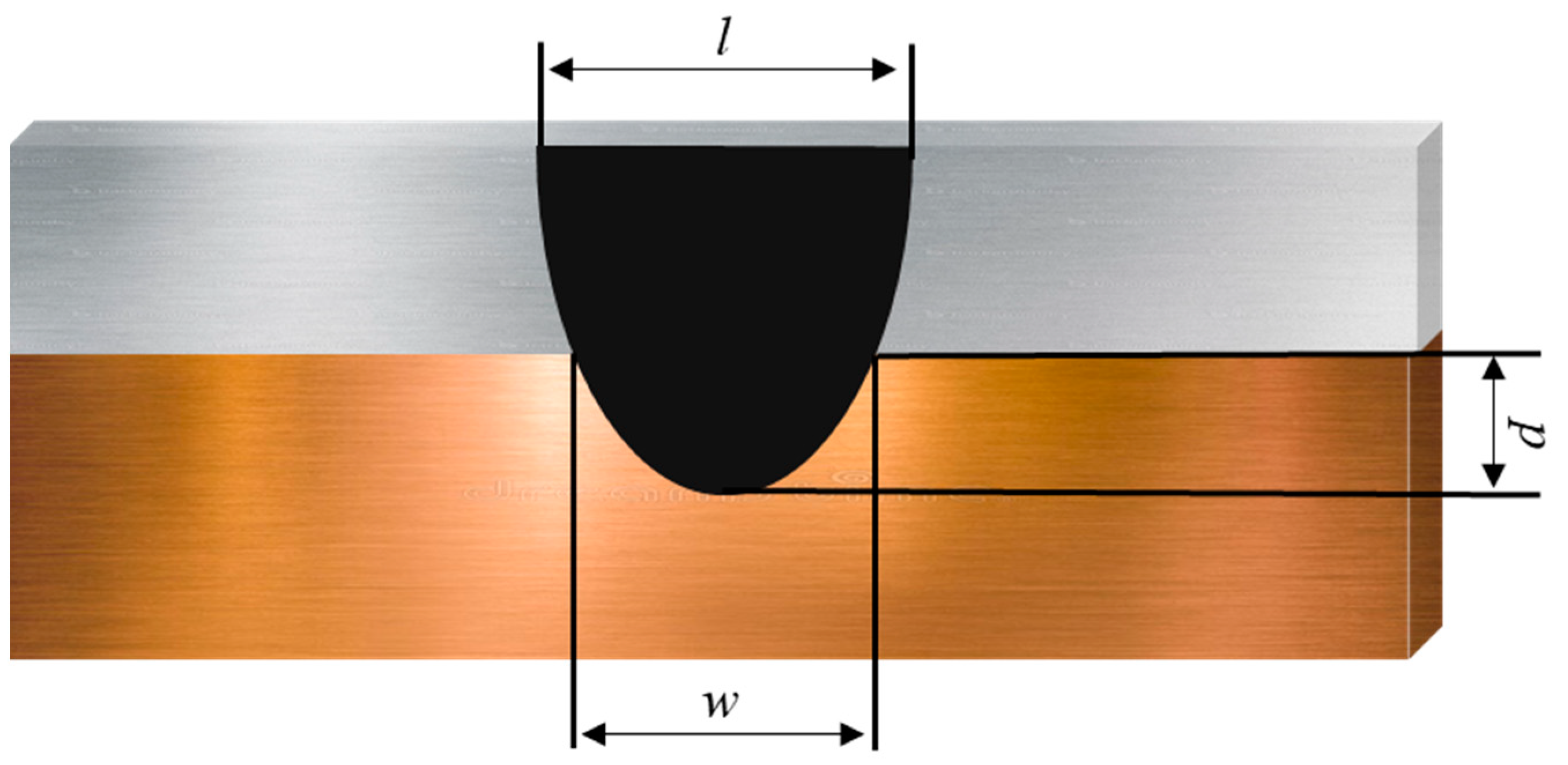

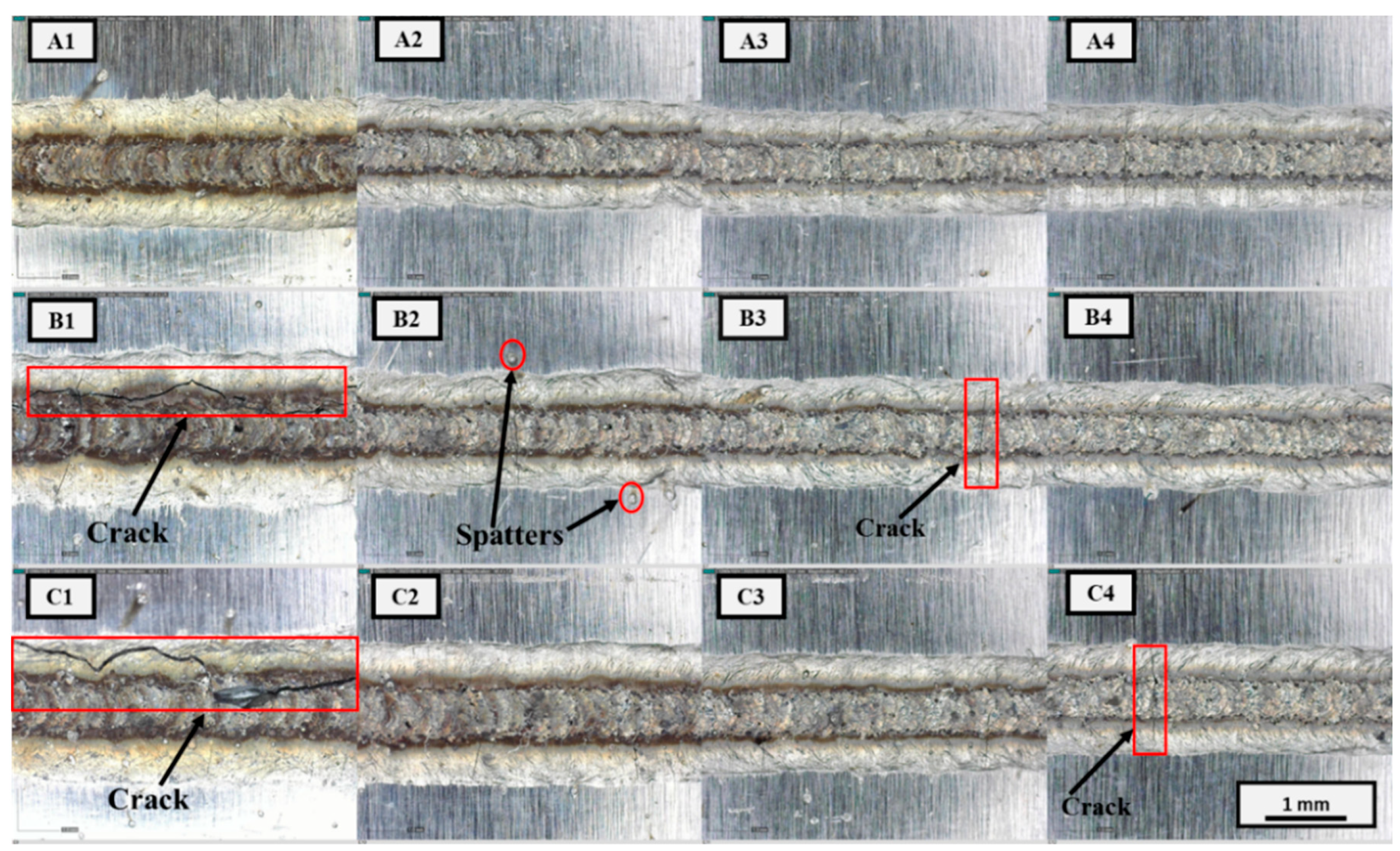

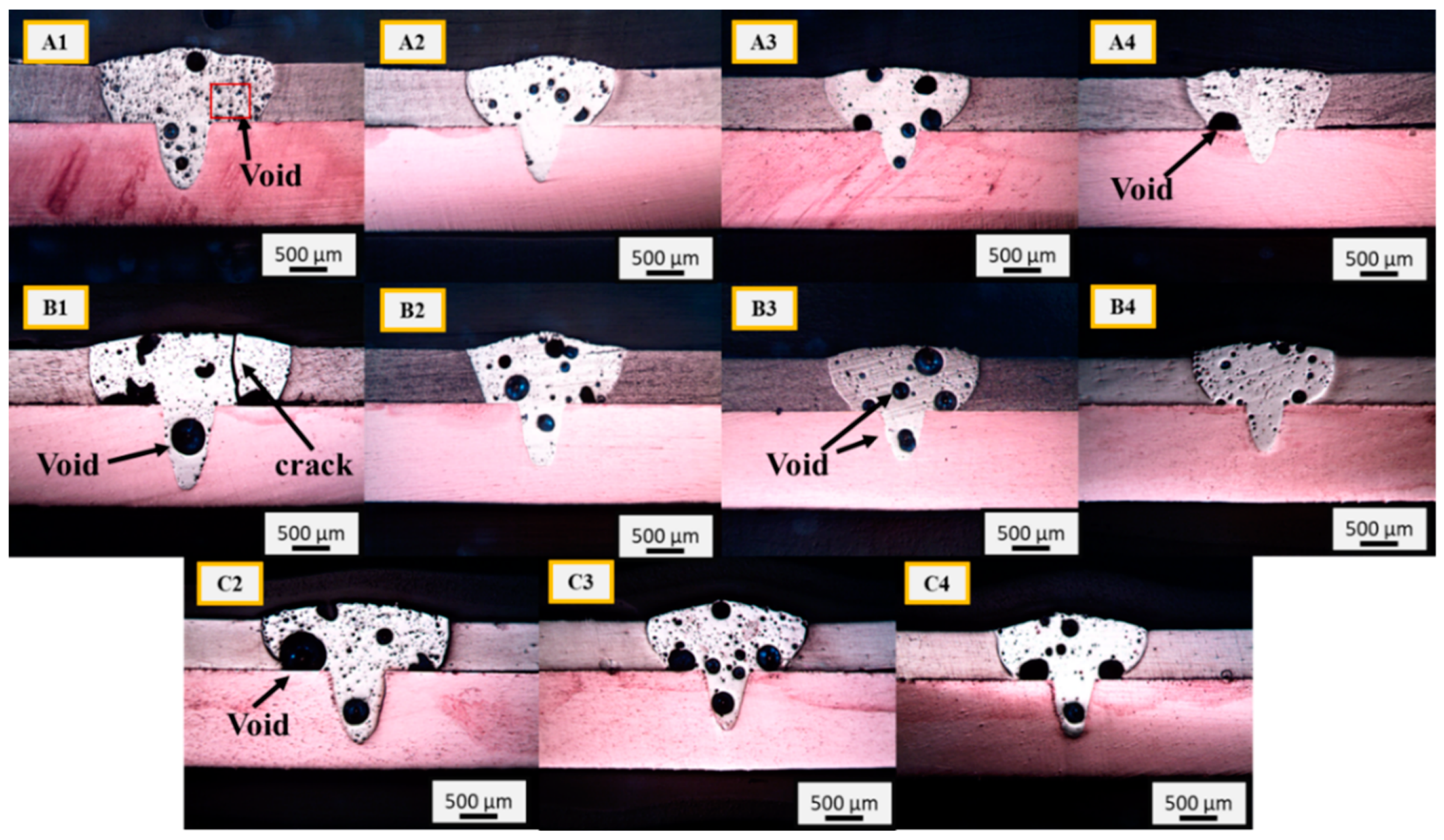

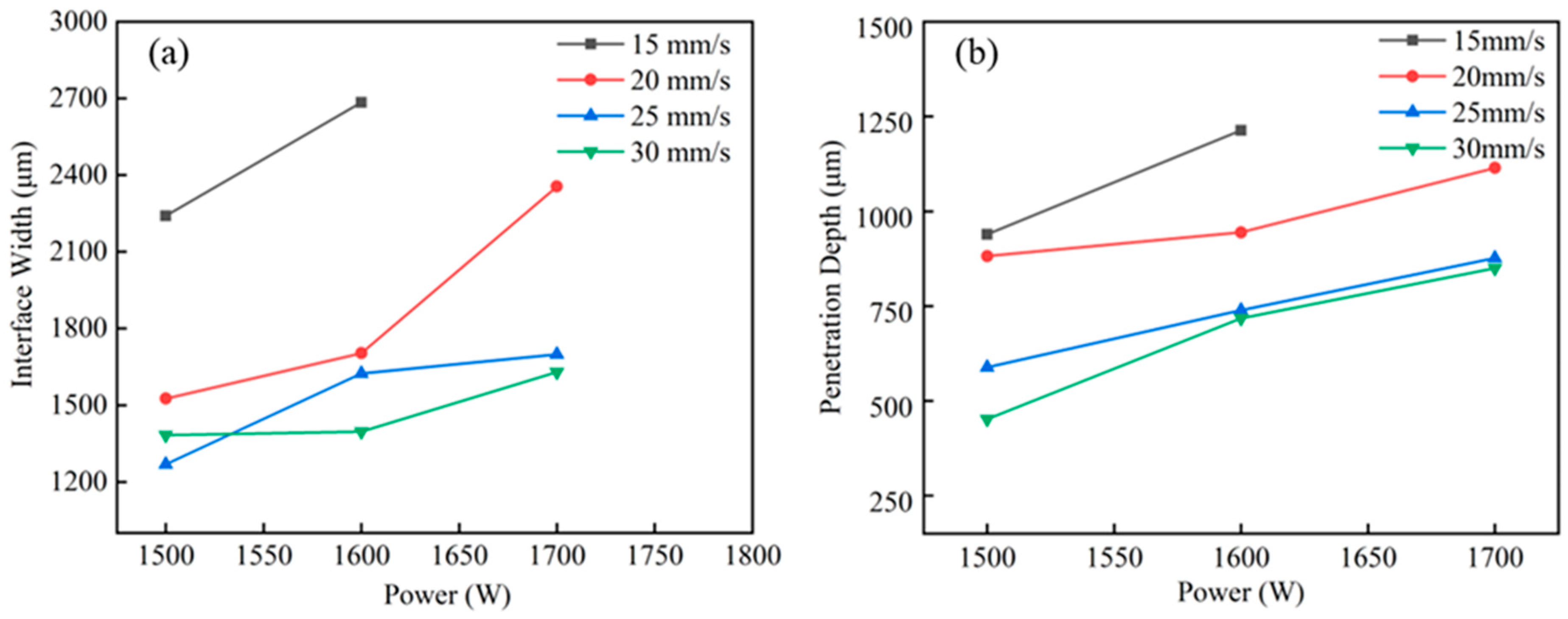

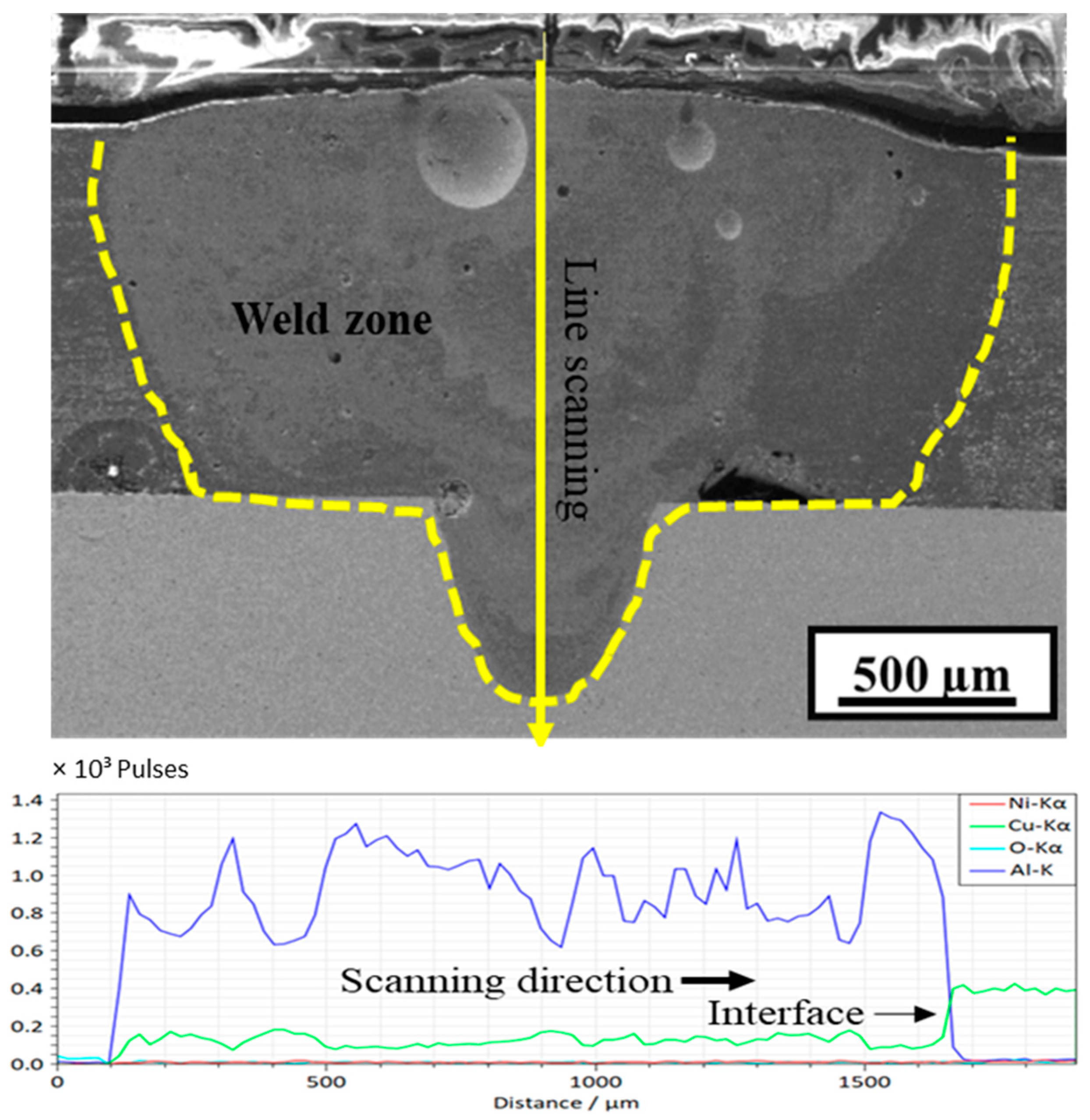

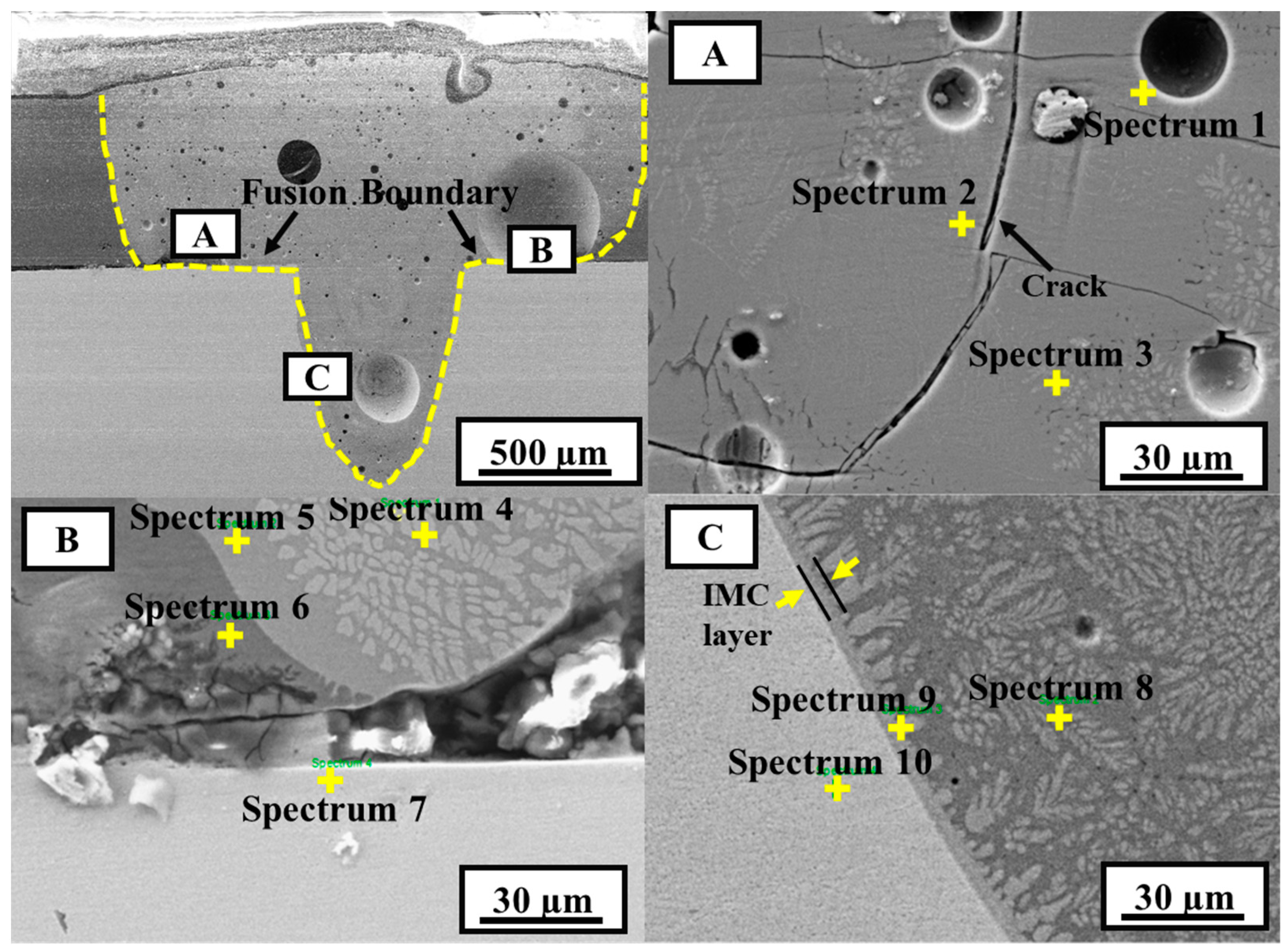

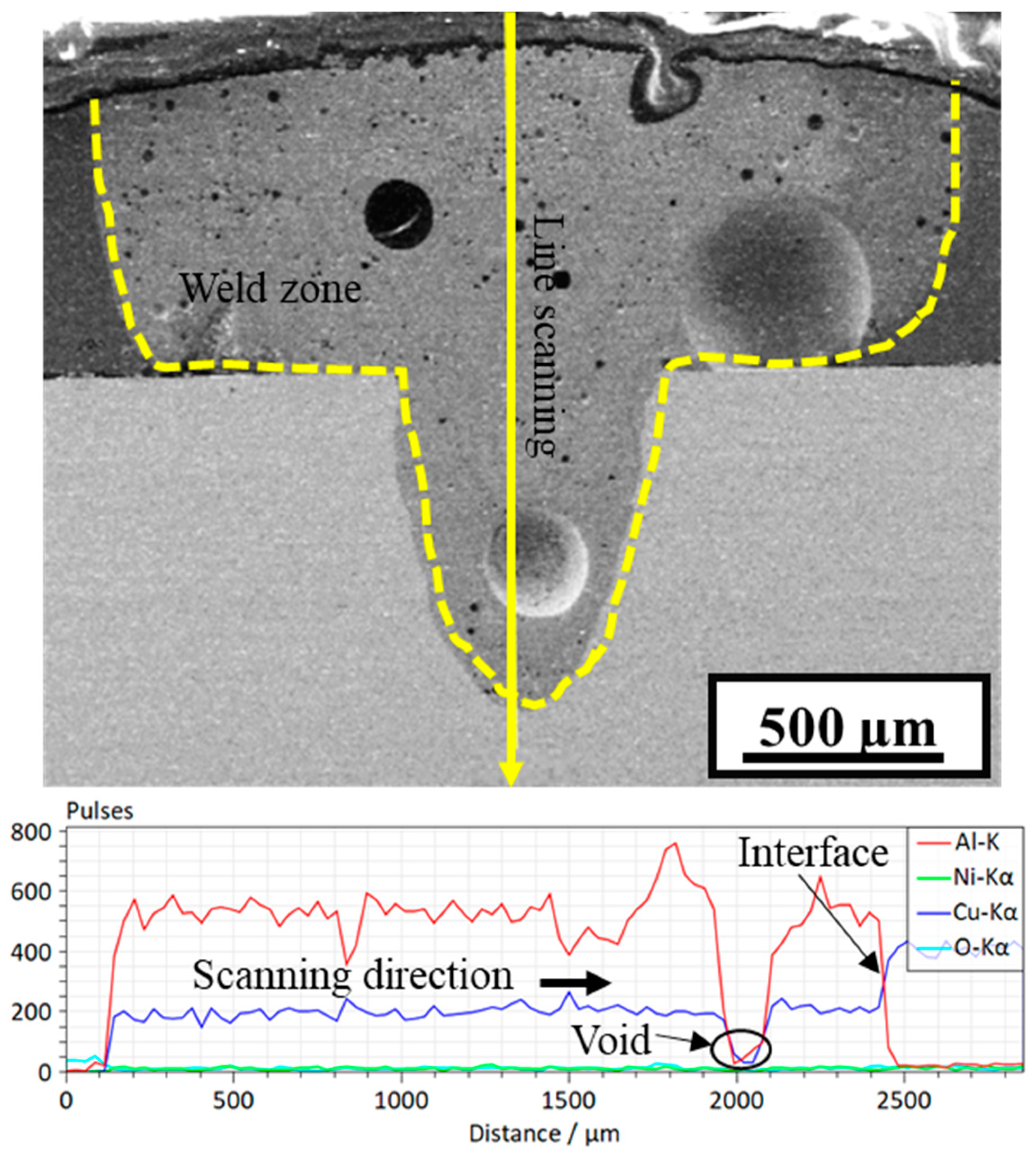

3.1. Analysis of the Weld Morphology and Defects

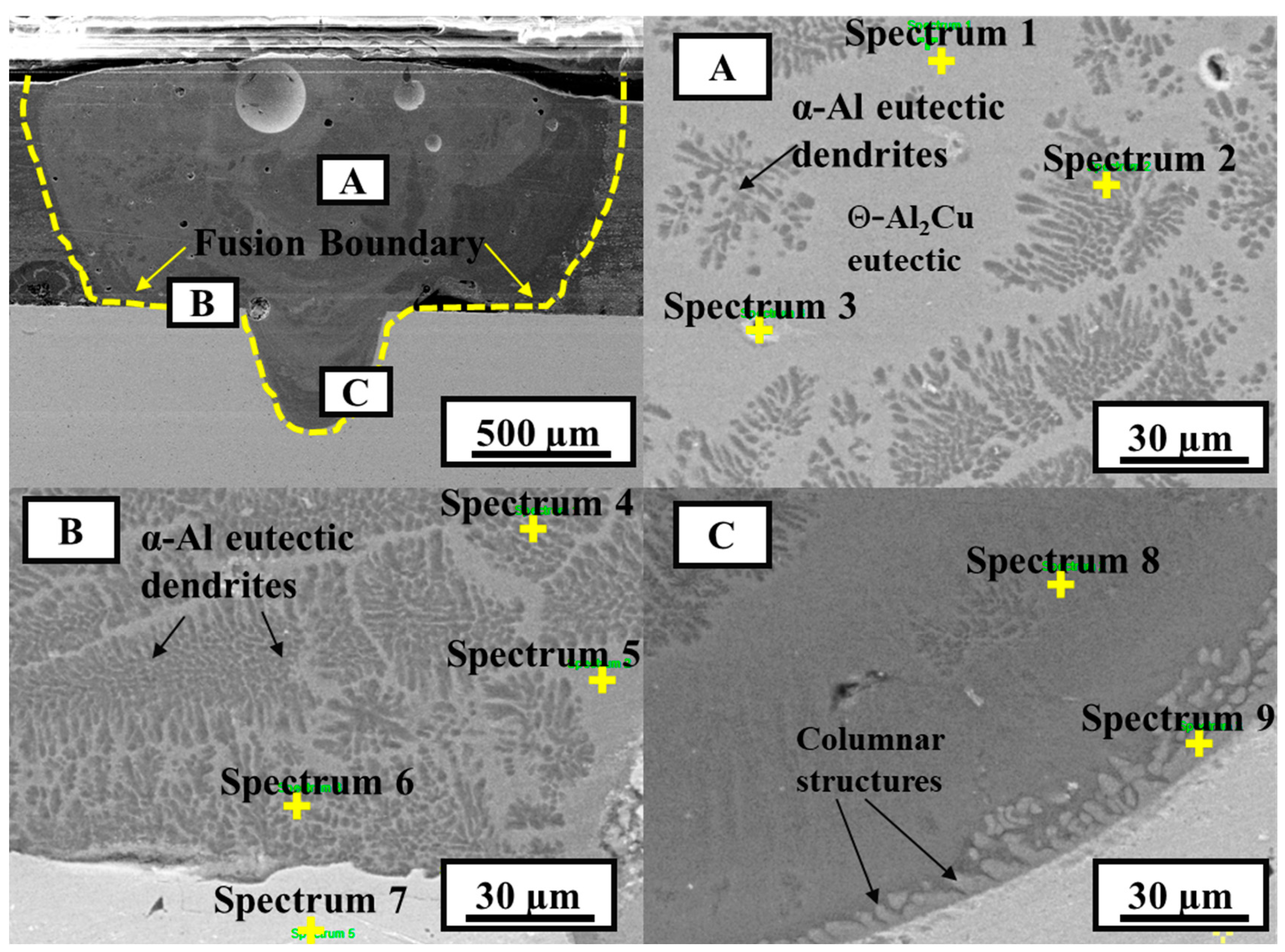

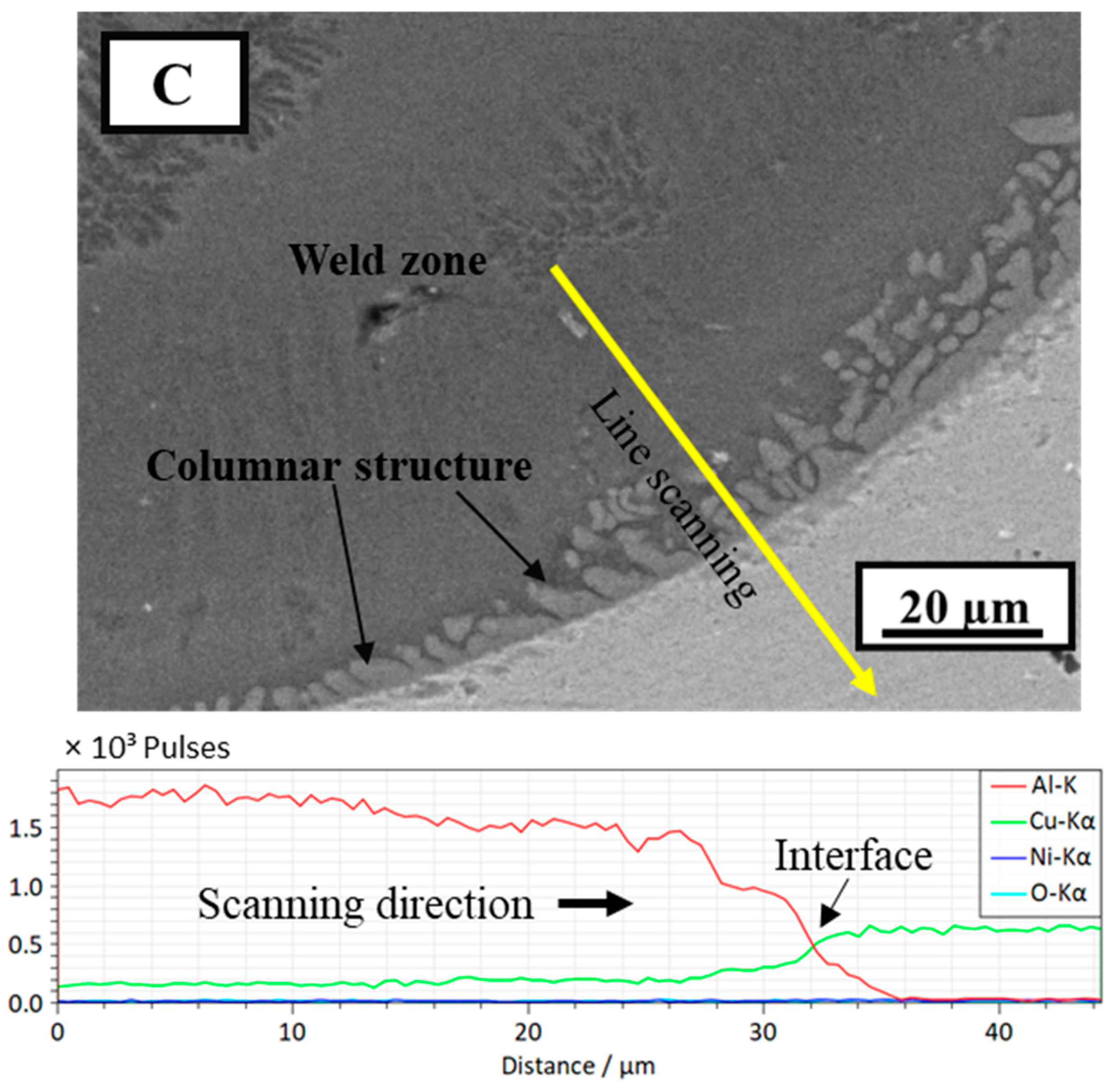

3.2. Analysis of the Weld Microstructure and Composition

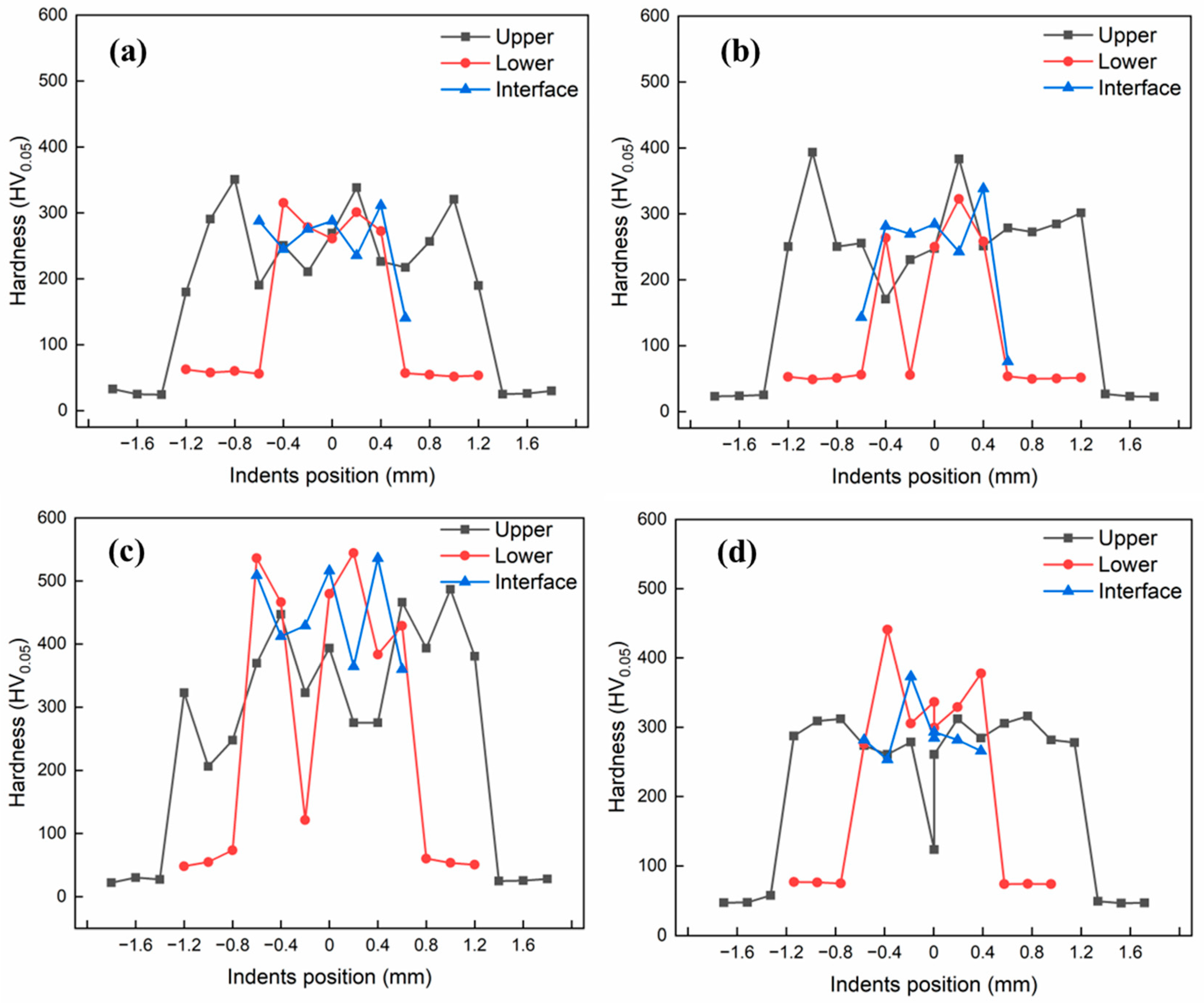

3.3. Vicker’s Microhardness Test

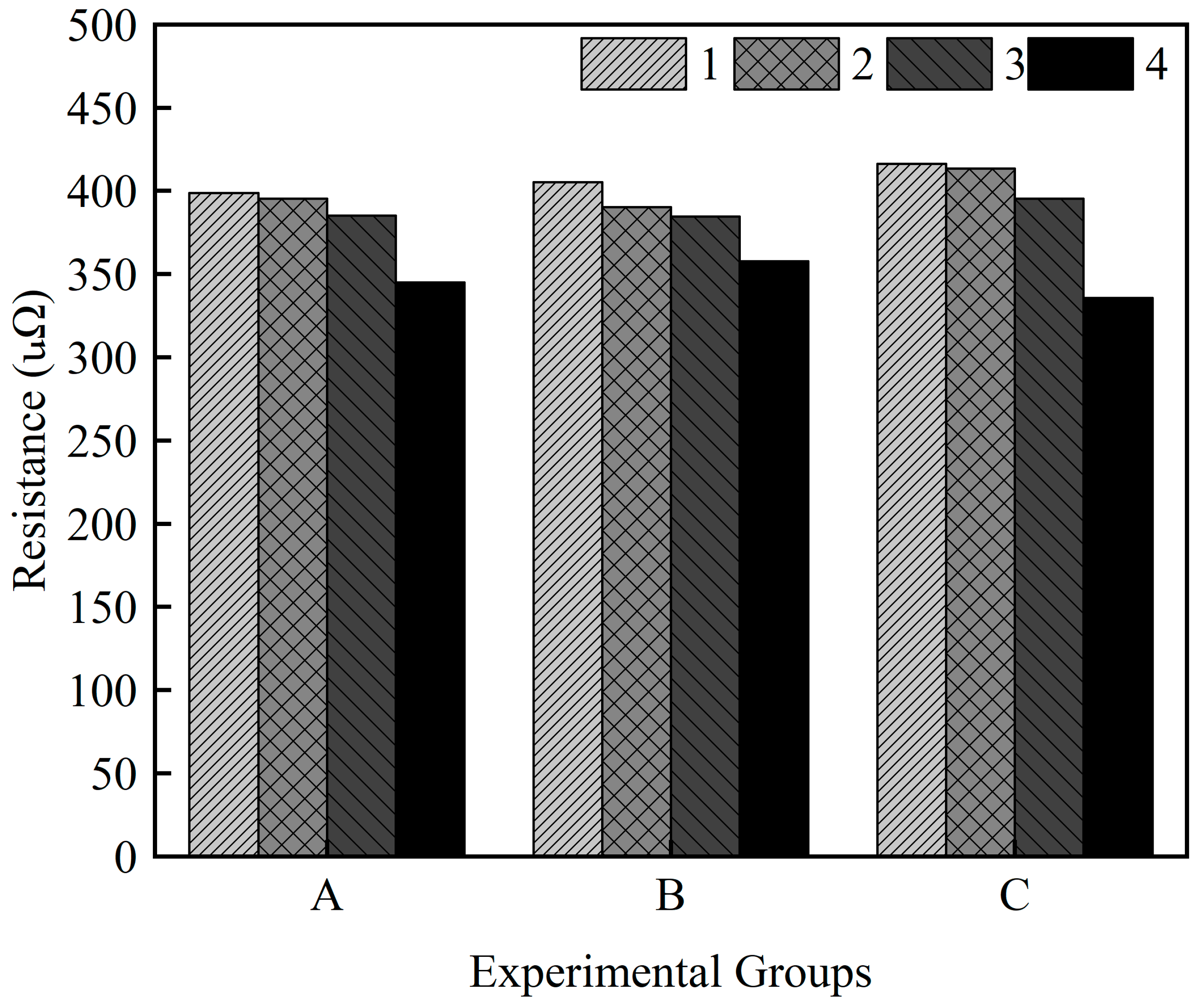

3.4. Electrical Contact Resistance

4. Conclusions

- The laser power and welding speed affected the weld characteristics. Weld defects, such as voids and cracks, appeared on the weld cross-sections.

- SEM/EDS of the weld microstructure revealed that the weld metal consisted of mixed-morphology dark (α-Al eutectic) and gray (Θ-Al2Cu eutectic) phases.

- At a high heat input, a more brittle Al4Cu9 IMC phase was formed, which likely caused the formation of cracks in the weld metal.

- The electrical contact resistance tended to decrease with increasing welding speed; however, the difference in resistance was negligible with varying laser power.

- The Vickers microhardness test validated the IMC phase identification in the weld metal. Moreover, the hardness of the weld metal was higher than that of the base metals, indicating the possibility of IMC formation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadeghian, A.; Iqbal, N. A Review on Dissimilar Laser Welding of Steel-Copper, Steel-Aluminum, Aluminum-Copper, and Steel-Nickel for Electric Vehicle Battery Manufacturing. Opt. Laser Technol. 2022, 146, 107595. [Google Scholar] [CrossRef]

- IEA. Global Supply Chains of EV Batteries—Analysis. Available online: https://www.iea.org/reports/global-supply-chains-of-ev-batteries (accessed on 14 July 2022).

- Faria, R.; Moura, P.; Delgado, J.; de Almeida, A.T. A Sustainability Assessment of Electric Vehicles as a Personal Mobility System. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Colsa, A. Comparative Study on the Differences between the EU and US Legislation on Emissions in the Automotive Sector. Eur. Parliam. Res. Serv. 2016. [Google Scholar]

- Varga, B.O.; Sagoian, A.; Mariasiu, F. Prediction of Electric Vehicle Range: A Comprehensive Review of Current Issues and Challenges. Energies 2019, 12, 946. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric Vehicles Batteries: Requirements and Challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, C.; Wu, Y. Analysis of Research and Development Trend of the Battery Technology in Electric Vehicle with the Perspective of Patent. Energy Procedia 2017, 105, 4274–4280. [Google Scholar] [CrossRef]

- Perner, A.; Vetter, J. 8-Lithium-Ion Batteries for Hybrid Electric Vehicles and Battery Electric Vehicles. In Advances in Battery Technologies for Electric Vehicles; Woodhead Publishing Series in Energy; Scrosati, B., Garche, J., Tillmetz, W., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 173–190. ISBN 978-1-78242-377-5. [Google Scholar]

- Cai, W. Lithium-Ion Battery Manufacturing for Electric Vehicles: A Contemporary Overview. In Advances in Battery Manufacturing, Service, and Management Systems; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 1–28. [Google Scholar]

- Zwicker, M.F.R.; Moghadam, M.; Zhang, W.; Nielsen, C. V Automotive Battery Pack Manufacturing—A Review of Battery to Tab Joining. J. Adv. Join. Process. 2020, 1, 100017. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.L.; Zhang, H. Microstructure and Mechanical Properties of Pulsed Laser Welded Al/Steel Dissimilar Joint. Trans. Nonferrous Met. Soc. China 2016, 26, 994–1002. [Google Scholar] [CrossRef]

- Shin, J.; Kang, S.; Hyun, K.; Ji, H. In-Depth Characterization of an Aluminum Alloy Welded by a Dual-Mode Fiber Laser. J. Mater. Res. Technol. 2022, 18, 2910–2921. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, H.; Li, M. Dissimilar Copper-Aluminum Joint Processed by Low-Temperature Nickel Electroplating. J. Mater. Process. Technol. 2017, 242, 68–76. [Google Scholar] [CrossRef]

- Das, A.; Li, D.; Williams, D.; Greenwood, D. Joining Technologies for Automotive Battery Systems Manufacturing. World Electr. Veh. J. 2018, 9, 22. [Google Scholar] [CrossRef]

- Chelladurai Asirvatham, M.; Collins, S.; Masters, I. Laser Wobble Welding of Steel to Aluminium Busbar Joints for Li-Ion Battery Packs. Opt. Laser Technol. 2022, 151, 108000. [Google Scholar] [CrossRef]

- Schmalen, P.; Plapper, P.; Cai, W. Process Robustness of Laser Braze-Welded Al/Cu Connectors. SAE Int. J. Altern. Powertrains 2016, 5, 195–204. [Google Scholar] [CrossRef]

- Kumar, N.; Masters, I.; Das, A. In-Depth Evaluation of Laser-Welded Similar and Dissimilar Material Tab-to-Busbar Electrical Interconnects for Electric Vehicle Battery Pack. J. Manuf. Process. 2021, 70, 78–96. [Google Scholar] [CrossRef]

- Grabmann, S.; Kriegler, J.; Harst, F.; Günter, F.J.; Zaeh, M.F. Laser Welding of Current Collector Foil Stacks in Battery Production–Mechanical Properties of Joints Welded with a Green High-Power Disk Laser. Int. J. Adv. Manuf. Technol. 2022, 118, 2571–2586. [Google Scholar] [CrossRef]

- Lerra, F.; Ascari, A.; Fortunato, A. The Influence of Laser Pulse Shape and Separation Distance on Dissimilar Welding of Al and Cu Films. J. Manuf. Process. 2019, 45, 331–339. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Liverani, E.; Fortunato, A. Experimental Investigation on the Effect of Spot Diameter on Continuous-Wave Laser Welding of Copper and Aluminum Thin Sheets for Battery Manufacturing. Opt. Laser Technol. 2022, 145, 107495. [Google Scholar] [CrossRef]

- Trinh, L.N.; Lee, D. The Characteristics of Laser Welding of a Thin Aluminum Tab and Steel Battery Case for Lithium-Ion Battery. Metals 2020, 10, 842. [Google Scholar] [CrossRef]

- Schmalen, P.; Plapper, P. Evaluation of Laser Braze-Welded Dissimilar Al-Cu Joints. Phys. Procedia 2016, 83, 506–514. [Google Scholar] [CrossRef]

- Solchenbach, T.; Plapper, P. Mechanical Characteristics of Laser Braze-Welded Aluminium-Copper Connections. Opt. Laser Technol. 2013, 54, 249–256. [Google Scholar] [CrossRef]

- Zuo, D.; Hu, S.; Shen, J.; Xue, Z. Intermediate Layer Characterization and Fracture Behavior of Laser-Welded Copper/Aluminum Metal Joints. Mater. Des. 2014, 58, 357–362. [Google Scholar] [CrossRef]

- Yan, S.; Hong, Z.; Watanabe, T.; Jingguo, T. CW/PW Dual-Beam YAG Laser Welding of Steel/Aluminum Alloy Sheets. Opt. Lasers Eng. 2010, 48, 732–736. [Google Scholar] [CrossRef]

- Weigl, M.; Albert, F.; Schmidt, M. Enhancing the Ductility of Laser-Welde Copper-Aluminum Connections by Using Adapted Filler Materia. Phys. Procedia 2011, 12, 335–341. [Google Scholar] [CrossRef]

- Chen, N.; Wang, H.; Veeresh, P.; Li, J.; Oswald, J.; Xi, L.; Wagner, S.; Sekol, R.; Liu, V.; Wang, K.; et al. Achieving Brittle-Intermetallic-Free and High-Conductivity Aluminum/Copper Joints Using Nickel-Phosphorus Coatings. Mater. Des. 2021, 199, 109435. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H.; Rinker, T.; Tan, W. Investigation of Metal Mixing in Laser Keyhole Welding of Dissimilar Metals. Mater. Des. 2020, 195, 109056. [Google Scholar] [CrossRef]

- Ardika, R.D.; Triyono, T.; Muhayat, N. Triyono A Review Porosity in Aluminum Welding. Procedia Struct. Integr. 2021, 33, 171–180. [Google Scholar] [CrossRef]

- Jarwitz, M.; Fetzer, F.; Weber, R.; Graf, T. Weld Seam Geometry and Electrical Resistance of Laser-Welded, Aluminum-Copper Dissimilar Joints Produced with Spatial Beam Oscillation. Metals 2018, 8, 510. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Zn | Ti | V | Other | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.070 | 0.300 | 0.010 | 0.020 | 0.010 | 0.010 | 0.020 | 0.020 | 0.019 | Bal. |

| Group | Sample No. | Laser Power (W) | Scan Speed (mm/s) | Heat Input (J/mm) | Power Density (106 W/cm2) |

|---|---|---|---|---|---|

| A | A1 | 1500 | 15 | 100.0 | 19.11 |

| A2 | 20 | 75.0 | 19.11 | ||

| A3 | 25 | 60.0 | 19.11 | ||

| A4 | 30 | 50.0 | 19.11 | ||

| B | B1 | 1600 | 15 | 106.7 | 20.38 |

| B2 | 20 | 80.0 | 20.38 | ||

| B3 | 25 | 64.0 | 20.38 | ||

| B4 | 30 | 53.3 | 20.38 | ||

| C | C1 | 1700 | 15 | 113.3 | 21.66 |

| C2 | 20 | 85.0 | 21.66 | ||

| C3 | 25 | 68.0 | 21.66 | ||

| C4 | 30 | 56.7 | 21.66 |

| Spectrum | Al (at.%) | Cu (at.%) | Ni (at.%) | Possible Phase |

|---|---|---|---|---|

| 1 | 91.84 | 8.16 | 0 | Al–Cu eutectic |

| 2 | 79.82 | 20.18 | 0 | Θ-Al2Cu |

| 3 | 93.44 | 6.56 | 0 | Al–Cu eutectic |

| 4 | 92.45 | 6.71 | 0.84 | Al–Cu eutectic |

| 5 | 93 | 7 | 0 | Al–Cu eutectic |

| 6 | 91.20 | 8.80 | 0 | Al–Cu eutectic |

| 7 | 7.75 | 89.85 | 2.4 | Cu (Solid solution) |

| 8 | 92.16 | 6.82 | 0.74 | Al–Cu eutectic |

| 9 | 92.11 | 6.38 | 1.51 | Al–Cu eutectic |

| Spectrum | Al (at.%) | Cu (at.%) | Ni (at.%) | Possible Phase |

|---|---|---|---|---|

| 1 | 83.86 | 16.14 | 0 | Al–Cu eutectic |

| 2 | 23.16 | 76.84 | 0 | Al4Cu9 |

| 3 | 85.63 | 14.37 | 0 | Al–Cu eutectic |

| 4 | 86.78 | 13.22 | 0 | Al–Cu eutectic |

| 5 | 88.68 | 11.32 | 0 | Al–Cu eutectic |

| 6 | 95.26 | 4.74 | 0 | Al–Cu eutectic |

| 7 | 25.83 | 0 | 74.17 | Ni3Al |

| 8 | 84.74 | 15.26 | 0 | Al–Cu eutectic |

| 9 | 77.16 | 22.84 | 0 | Θ-Al2Cu |

| 10 | 0 | 100 | 0 | Cu (Solid Solution) |

| Phase | Nominal Composition | Chemical Composition [%at. Cu] | Electrical Resistivity [µΩ cm] | Hardness [HV] |

|---|---|---|---|---|

| (Al) | 0–2.2 | 2.4 | 36 | |

| Θ | Al2Cu | 31.9–33 | 8.0 | 630 |

| ƞ | AlCu | 51.9–54.8 | 11.4 | 905 |

| ζ | Al3Cu4 | 56–57.5 | 12.2 | 930 |

| ƴ | Al4Cu9 | 64–69 | 14.2 | 770 |

| (Cu) | 80.3–100 | 2.0 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.; Shin, J. In-Depth Characterization of Laser-Welded Aluminum-and-Copper Dissimilar Joint for Electric Vehicle Battery Connections. Materials 2022, 15, 7463. https://doi.org/10.3390/ma15217463

Ali S, Shin J. In-Depth Characterization of Laser-Welded Aluminum-and-Copper Dissimilar Joint for Electric Vehicle Battery Connections. Materials. 2022; 15(21):7463. https://doi.org/10.3390/ma15217463

Chicago/Turabian StyleAli, Sajid, and Joonghan Shin. 2022. "In-Depth Characterization of Laser-Welded Aluminum-and-Copper Dissimilar Joint for Electric Vehicle Battery Connections" Materials 15, no. 21: 7463. https://doi.org/10.3390/ma15217463

APA StyleAli, S., & Shin, J. (2022). In-Depth Characterization of Laser-Welded Aluminum-and-Copper Dissimilar Joint for Electric Vehicle Battery Connections. Materials, 15(21), 7463. https://doi.org/10.3390/ma15217463