Fracture Strain of Al–Si-Coated Press-Hardened Steels under Plane-Strain Bending

Abstract

1. Introduction

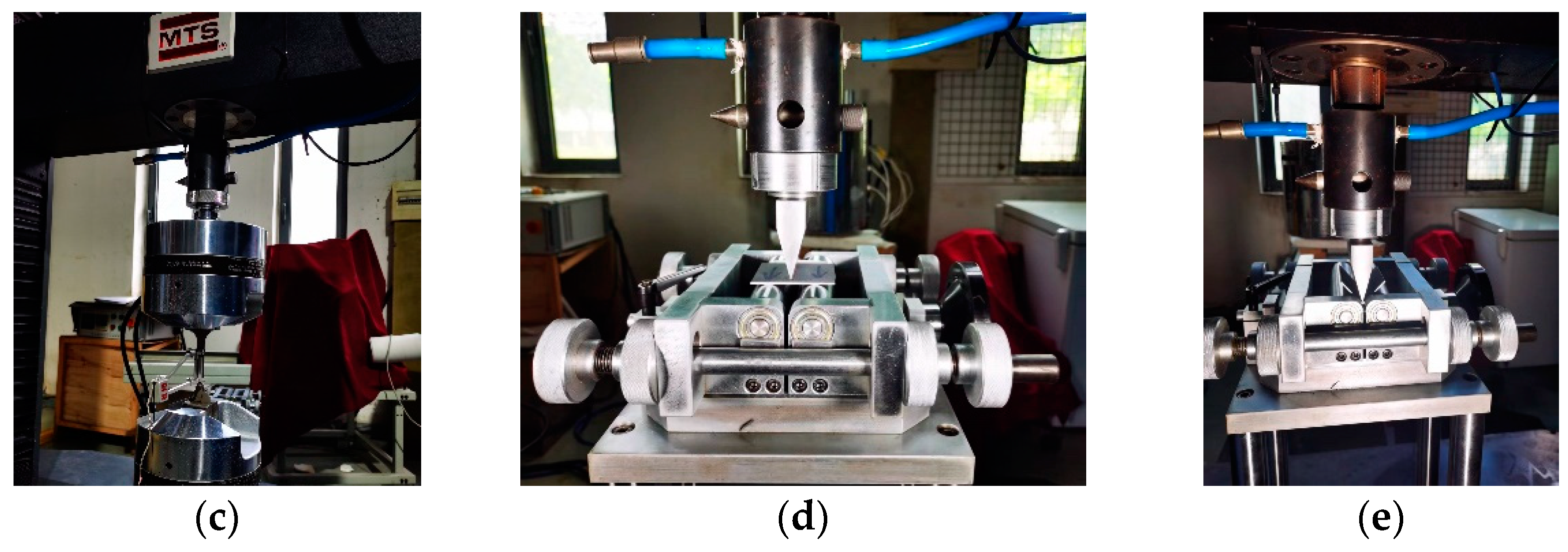

2. Experimental Procedure

2.1. Materials and Characterization

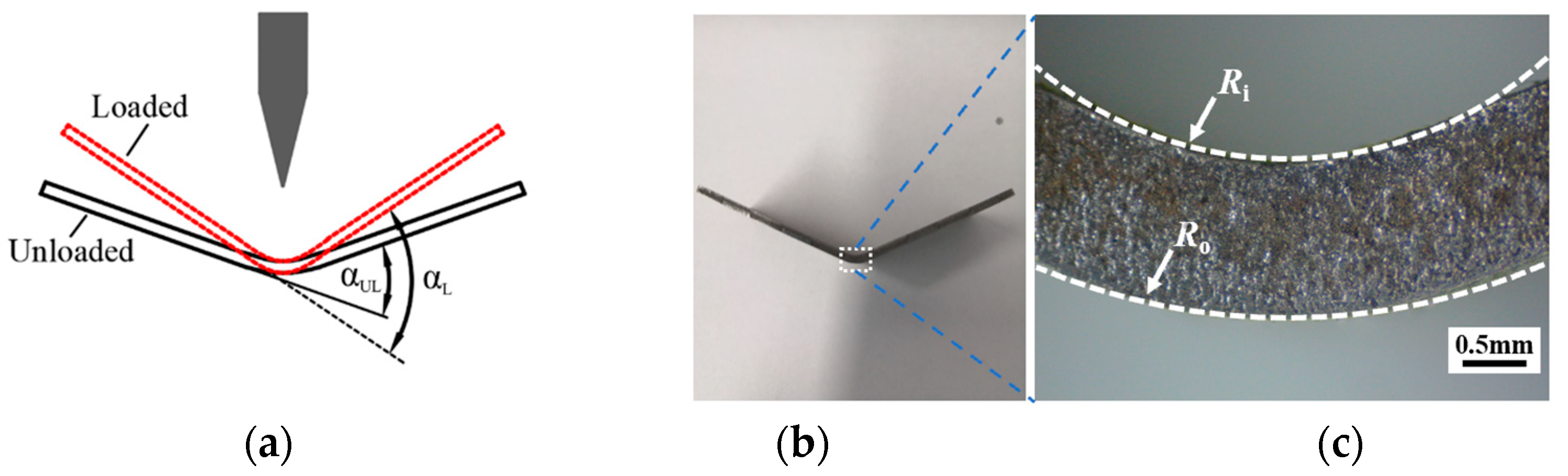

2.2. Methodology to Characterize Fracture Strain under Plane-Strain Bending

- (1)

- Step one is to calculate the maximum bending angle αmax using the punch displacement at the peak punch load, according to the formulation given in the VDA 238-100 bending test procedure.

- (2)

- Three interrupted bending tests are then carried out, each of which is stopped after reaching a prescribed punch displacement corresponding to a fraction (no less than 50%) of the αmax. In this work, these stopping displacements were chosen such that bending angles of 30°, 40°, and 50° were achieved for Thick(1.4/1.8), while 35°, 45°, and 55° were chosen for Thin(1.4/1.8).

- (3)

- For each interrupted bending test, αUL was directly measured on the unloaded specimen using AutoCAD software. The average springback angle Δα can be determined by comparing the loaded bending angle αL (prescribed in the previous step) and the unloaded bending angle αUL.

- (4)

- A deformed zone (marked with dashed lines in Figure 3b) in a cut specimen was selected as the area of interest. Then, an optical microscope (OM) with an appropriate magnification (25× in this study) was utilized to extract the profile.

- (5)

- The profile image of the deformed zone was then imported into the AutoCAD software, and the radii of the innermost and outermost fibers were determined by curve fitting (Ri and Ro in Figure 3c).

- (6)

- According to Equation (1), the equivalent strain at the outer surface for each interrupted bending test that was stopped at a prescribed αL can be calculated.

- (7)

- Finally, the fracture strain εf at the outer surface can be determined by extrapolating to the case when αmax is reached.

3. Results and Discussion

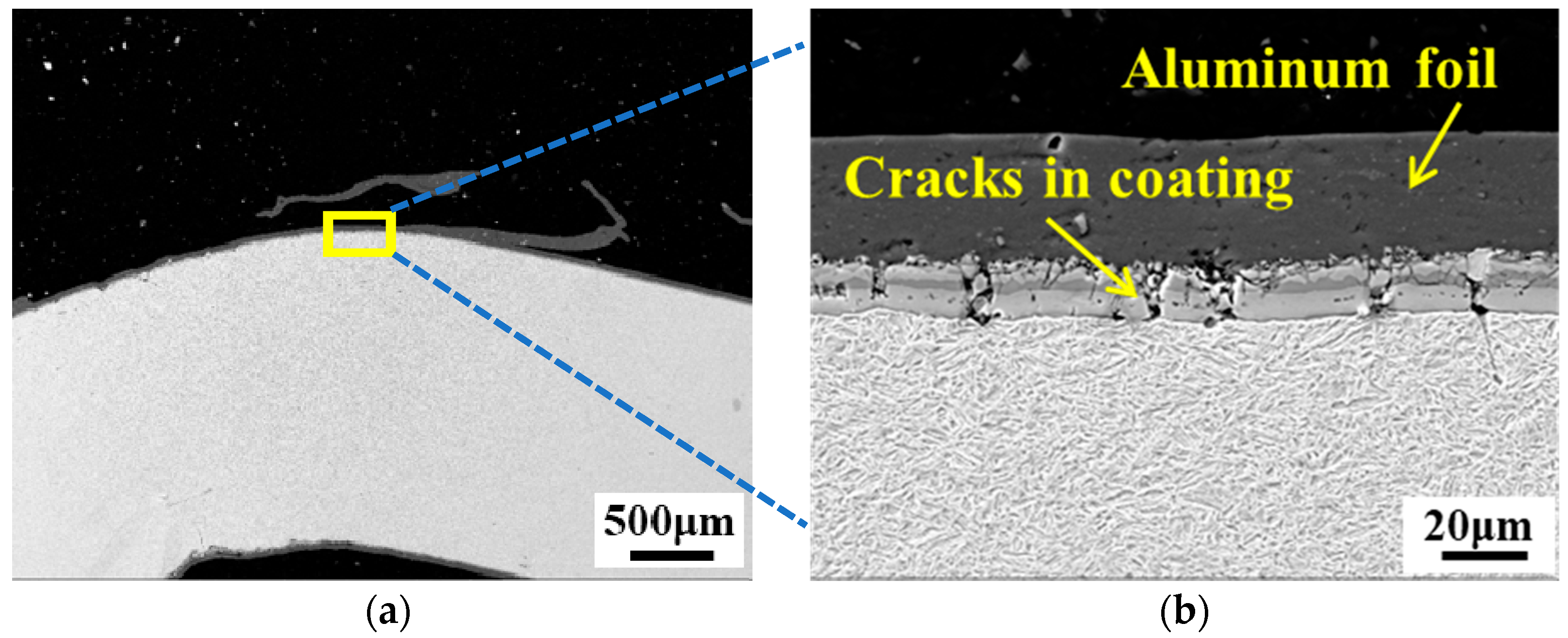

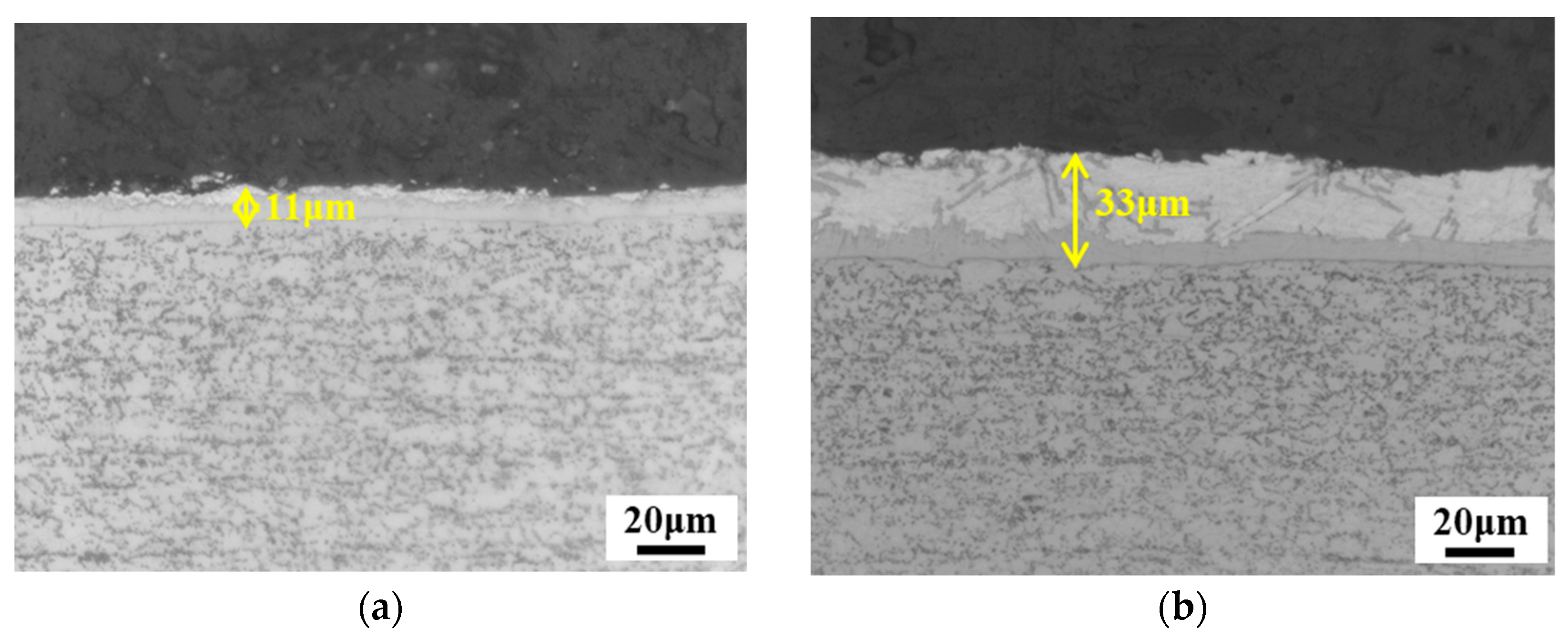

3.1. Microstructural Characterization

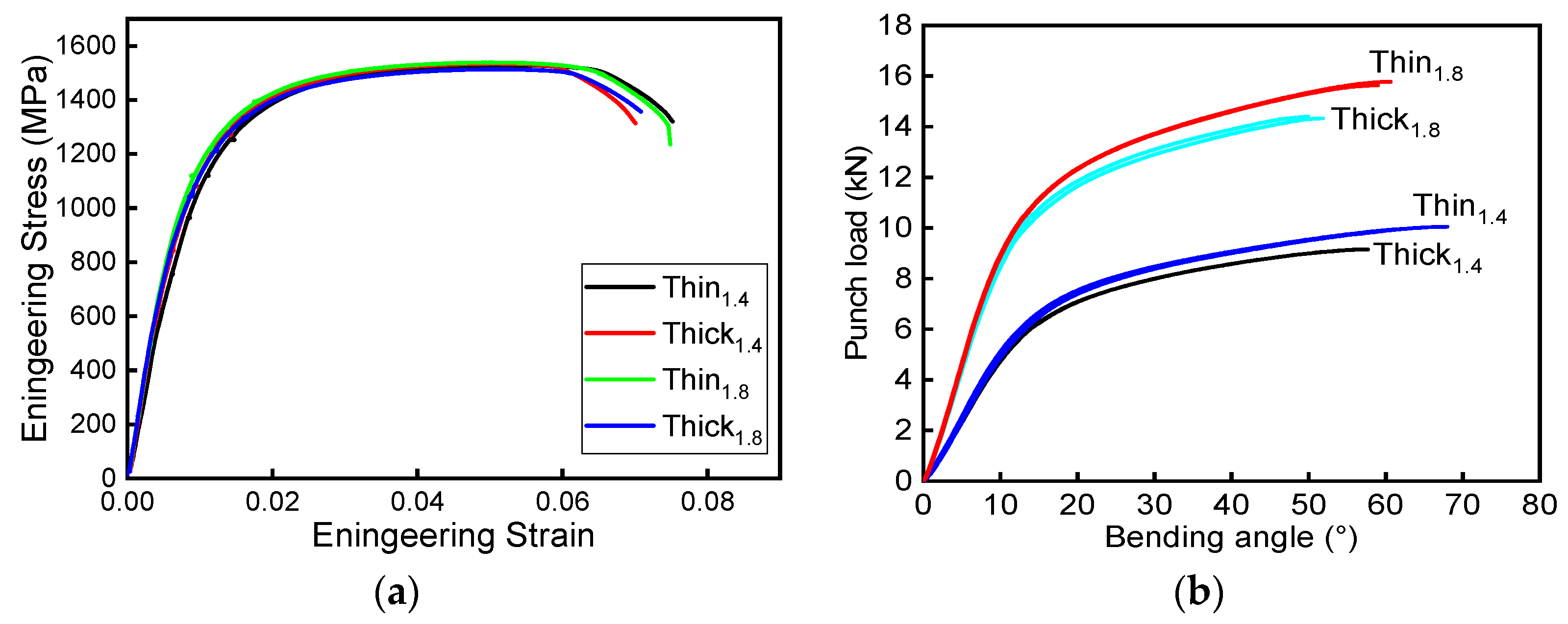

3.2. Mechanical Properties

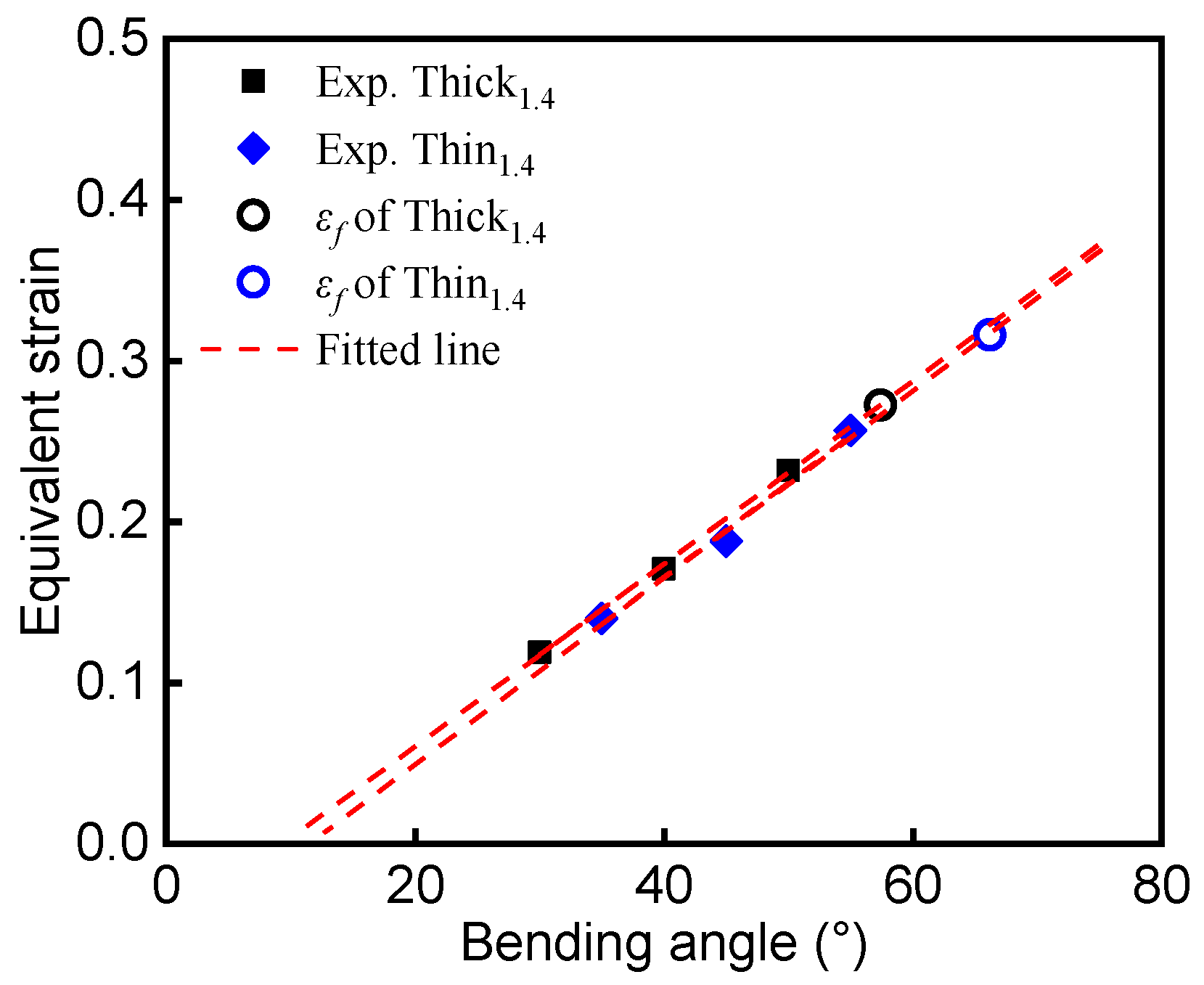

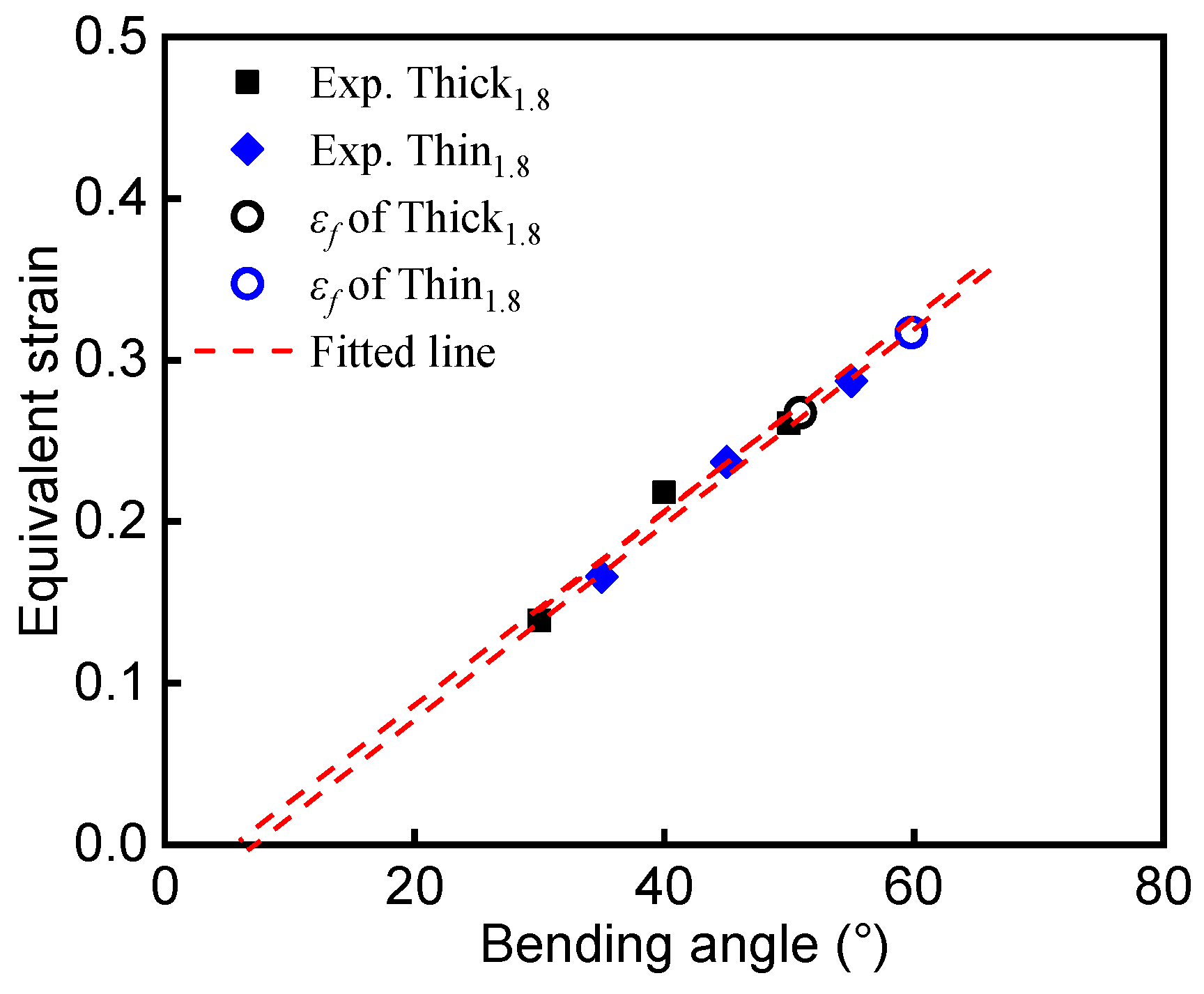

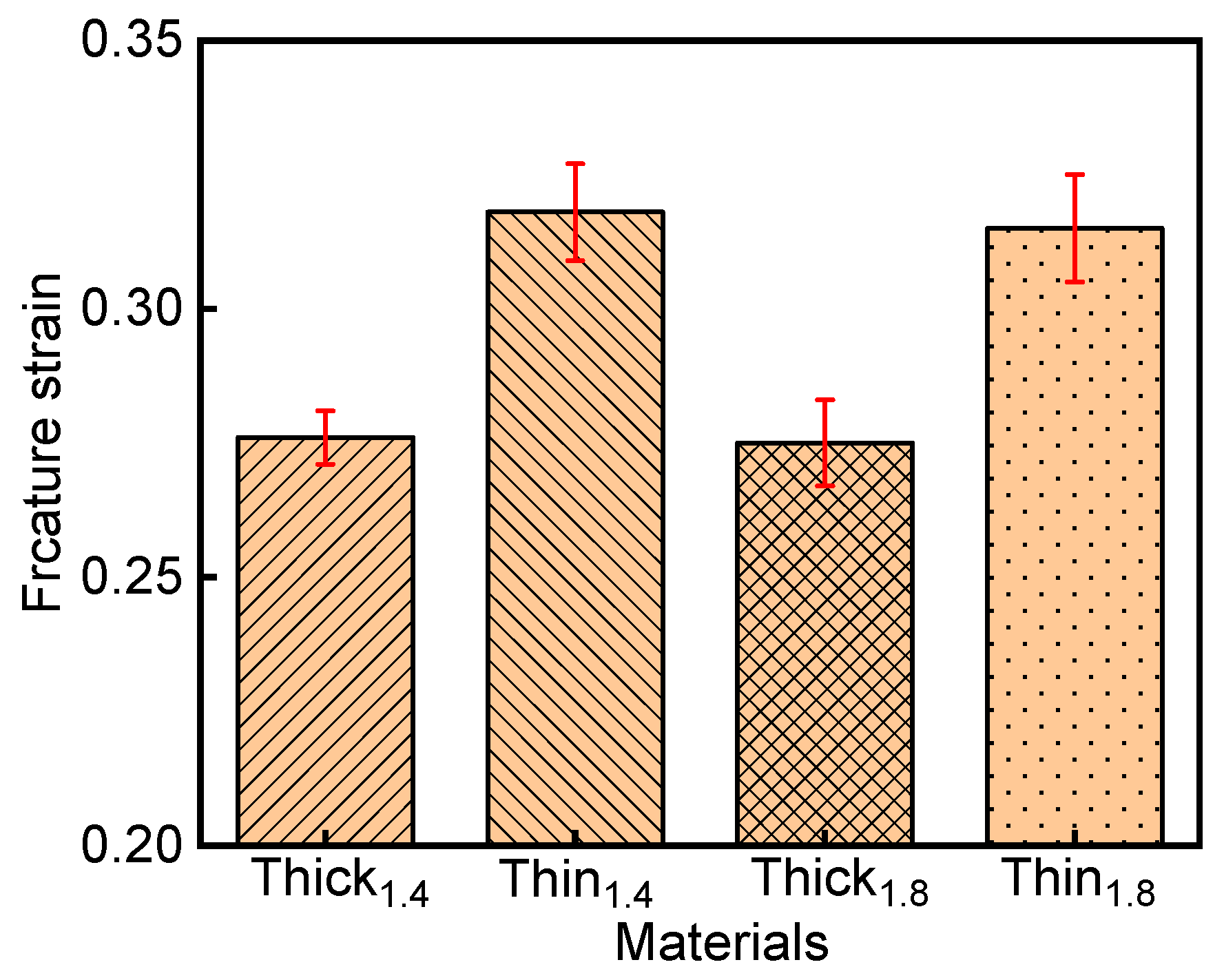

3.3. Determination of Fracture Strain

3.4. The Critical Role of High Fracture Strain under Plane-Strain Bending

4. Conclusions

- (1)

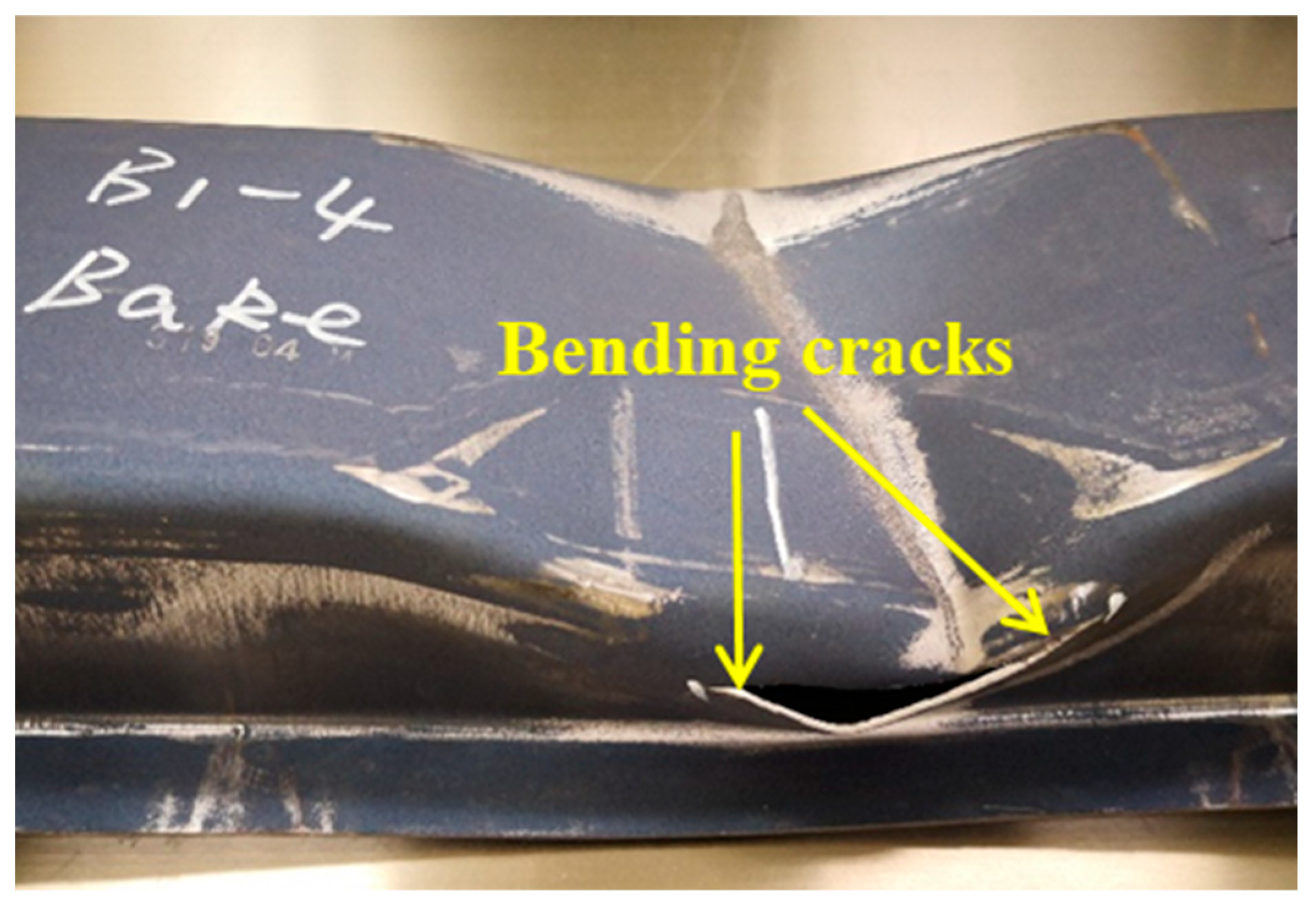

- A recently developed methodology was employed to determine the fracture strain εf of Al–Si-coated 22MnB5 steels under plane-strain bending, which is difficult to measure by DIC methods due to the Al–Si coating cracking at low strains. Unlike the bending angle, the fracture strain is an intrinsic characteristic of the material and can be used directly as an input material parameter for computer-aided engineering (CAE) simulations.

- (2)

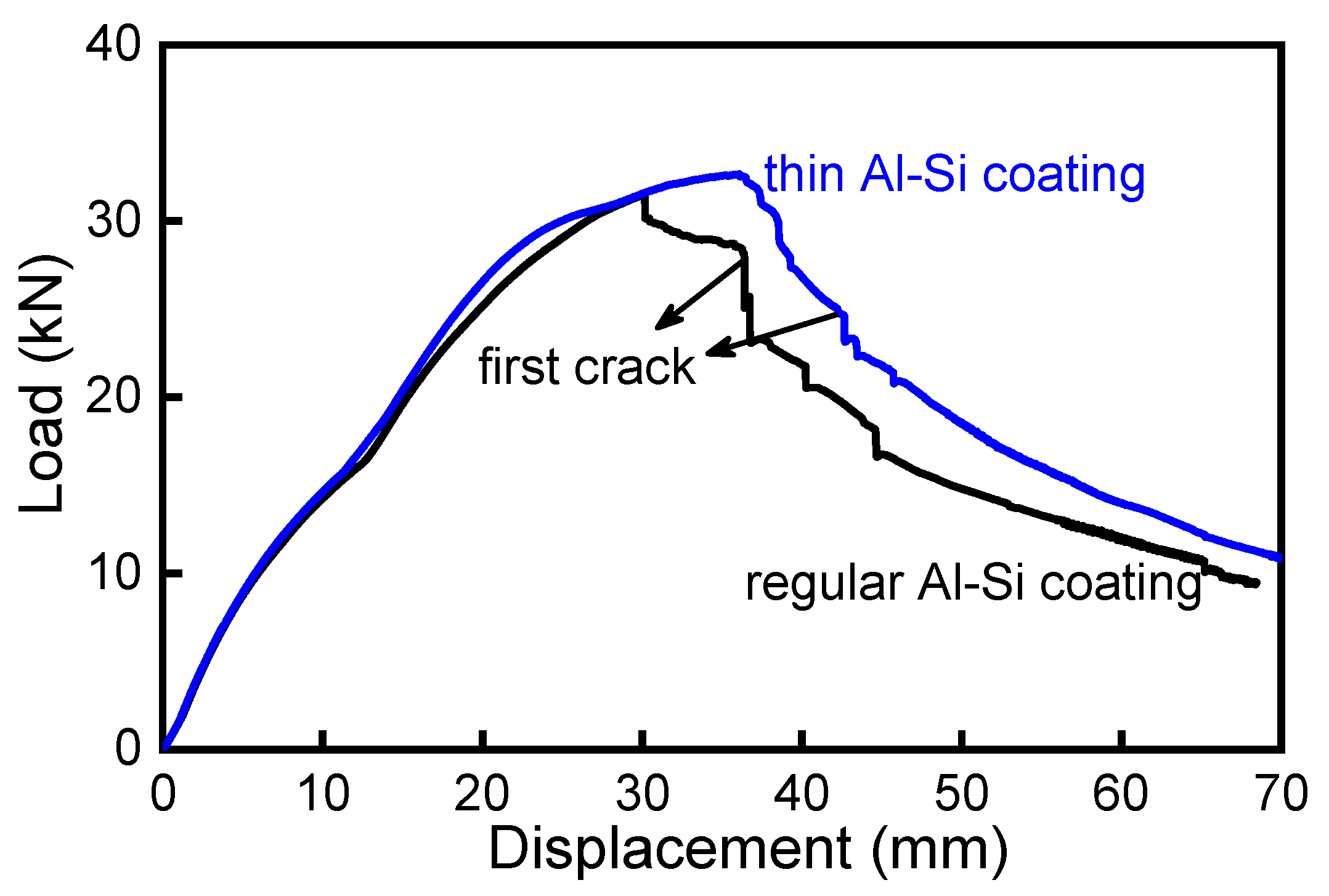

- A thicker coating results in reduced substrate thickness. During tensile testing, a higher thickness ratio of thin-coated sheets was engaged in deformation, improving the total strength and elongation of the material simultaneously. At the same thickness, a larger bending angle represents higher fracture strain. The thickness of the substrate involved in deformation is also responsible for the peak load. In addition, greater toughness of the surface martensite leads to a higher bending angle.

- (3)

- Materials with higher fracture strain have better collision energy absorption. For components and parts, thinner material design can be realized without sacrificing energy absorption ability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, L.; Yu, Q.; Wang, Z.; Ell, J.; Huang, M.X.; Ritchie, R.O. Making ultrastrong steel tough by grain-boundary delamination. Science 2020, 368, 1347–1352. [Google Scholar] [CrossRef]

- Abio, A.; Bonada, F.; Pujante, J.; Grané, M.; Nievas, N.; Lange, D.; Pujol, O. Machine Learning-Based Surrogate Model for Press Hardening Process of 22MnB5 Sheet Steel Simulation in Industry 4.0. Materials 2022, 15, 3647. [Google Scholar] [CrossRef]

- Tong, C.; Rong, Q.; Yardley, V.; Li, X.; Luo, J.; Zhu, G.; Shi, Z. New Developments and Future Trends in Low-Temperature Hot Stamping Technologies: A Review. Metals 2020, 10, 1652. [Google Scholar] [CrossRef]

- Löbbe, C.; Hering, O.; Hiegemann, L.; Tekkaya, A.E. Setting Mechanical Properties of High Strength Steels for Rapid Hot Forming Processes. Materials 2016, 9, 229. [Google Scholar] [CrossRef] [PubMed]

- Wróbel, I.; Skowronek, A.; Grajcar, A. A Review on Hot Stamping of Advanced High-Strength Steels: Technological-Metallurgical Aspects and Numerical Simulation. Symmetry 2022, 14, 969. [Google Scholar] [CrossRef]

- Jin, X.; Gong, Y.; Han, X.; Du, H.; Ding, W.; Zhu, B.; Zhang, Y.; Feng, Y.; Ma, M.; Liang, B.; et al. A Review of Current State and Prospect of the Manufacturing and Application of Advanced Hot Stamping Automobile Steels. Acta Metall. Sin. 2020, 56, 411–428. [Google Scholar]

- Yi, H.; Chang, Z.; Cai, H.; Du, P.; Yang, D. Strength, ductility and fracture strain of press-hardening steels. Acta Metall. Sin. 2020, 56, 429–443. [Google Scholar]

- Hou, Z.; Min, J.; Wang, J.; Lu, Q.; He, Z.; Chai, Z.; Xu, W. Effect of Rapid Heating on Microstructure and Tensile Properties of a Novel Coating-Free Oxidation-Resistant Press-Hardening Steel. JOM 2021, 73, 3195–3203. [Google Scholar] [CrossRef]

- Yoo, J.; Kim, S.; Jo, M.; Kim, S.; Oh, J.; Kim, S.; Lee, S.; Sohn, S. Effects of Al-Si coating structures on bendability and resistance to hydrogen embrittlement in 1.5-GPa-grade hot-press-forming steel. Acta Mater. 2022, 225, 117561. [Google Scholar] [CrossRef]

- Thom, V.; Duc, H.; Nguyen, C.; Nguyen, D. Thermal Buckling Analysis of Cracked Functionally Graded Plates. Int. J. Struct. Stab. Dyn. 2022, 22, 2250089. [Google Scholar]

- Cong, P.; Van, T.; Duc, H. Phase field model for fracture based on modified couple stress. Eng. Fract. Mech. 2022, 269, 108534. [Google Scholar] [CrossRef]

- Nam, V.; Duc, H.; Nguyen, C.; Thom, V.; Hong, T. Phase-field buckling analysis of cracked stiffened functionally graded plates. Compos. Struct. 2019, 217, 50–59. [Google Scholar]

- Cheong, K.; Butcher, C.; Dykeman, J. The Influence of the Through-Thickness Strain Gradients on the Fracture Characterization of Advanced High-Strength Steels. SAE Int. J. Mater. Manuf. 2018, 11, 541–552. [Google Scholar] [CrossRef]

- Rosenthal, S.; Maaß, F.; Kamaliev, M.; Hahn, M.; Gies, S.; Tekkaya, A.E. Lightweight in Automotive Components by Forming Technology. Automot. Innov. 2020, 3, 195–209. [Google Scholar] [CrossRef]

- Wagner, L.; Larour, P.; Dolzer, D.; Leomann, F.; Suppan, C. Experimental issues in the instrumented 3 point bending VDA238-100 test. IOP Conf. Ser. Mater. Sci. Eng. 2020, 967, 012079. [Google Scholar] [CrossRef]

- Tang, B.; Wu, F.; Guo, N.; Liu, J.; Ge, H.; Bruschi, S.; Li, X. Numerical modeling of ductile fracture of hot stamped 22MnB5 boron steel parts in three-point bending. Int. J. Mech. Sci. 2020, 188, 105951. [Google Scholar] [CrossRef]

- Cheong, K.; Omer, K.; Butcher, C.; George, R.; Dykeman, J. Evaluation of the VDA 238-100 tight radius bending test using digital image correlation strain measurement. IOP Publ. J. Phys. Conf. Ser. 2017, 896, 012075. [Google Scholar] [CrossRef]

- Verband der Automobilindustrie (VDA). VDA 238-100 Plate Bending Test for Metallic Materials; VDA: Berlin, Germany, 2010. [Google Scholar]

- Min, J.; Stoughton, T.B.; Carsley, J.E.; Lin, J. Compensation for process-dependent effects in the determination of localized necking limits. Int. J. Mech. Sci. 2016, 117, 115–134. [Google Scholar] [CrossRef]

- Noder, J.; Abedini, A.; Butcher, C. Evaluation of the VDA 238–100 Tight Radius Bend Test for Plane Strain Fracture Characterization of Automotive Sheet Metals. Exp. Mech. 2020, 60, 787–800. [Google Scholar] [CrossRef]

- Cai, H.L.; Wang, J.F.; Wu, D.; Yi, H.L. A Simple Methodology to Determine Fracture Strain of Press-Hardened Steels Under Plane Strain Bending. Metall. Mater. Trans. A 2021, 52, 644–654. [Google Scholar] [CrossRef]

- Noder, J.; Abedini, A.; Butcher, C. New Methodologies for Fracture Detection of Automotive Steels in Tight Radius Bending: Application to the VDA 238–100 V-Bend Test. Exp. Mech. 2021, 61, 667–679. [Google Scholar] [CrossRef]

- Drillet, P.; Spehner, D.; Kefferstein, R. Coated Steel Strips, Methods of Making the Same, Methods of Using the Same, Stamping Blanks Pre-Pared from the Same, Stamped Products Prepared from the Same, and Articles of Manufacture Which Contain Such a Stamped Product. China Patent 8,307,680, 29 November 2017. [Google Scholar]

- Cho, L.; Golem, L.; Seo, E.; Bhattacharya, D.; Speer, J.; Findley, K. Microstructural characteristics and mechanical properties of the Al–Si coating on press hardened 22MnB5 steel. J. Alloys Compd. 2020, 846, 156349. [Google Scholar] [CrossRef]

- Yi, H.; Liu, H.; Chang, Z.; Xiong, X. Hot Stamped Component, Pre-Coated Steel Sheet Used for Hot Stamping and Hot Stamping Process. China Patent 11,248,276, 10 December 2020. [Google Scholar]

- Niu, G.; Zurob, H.; Misra, R.D.K.; Tang, Q.; Zhang, Z.; Nguyen, M.; Wang, L.; Wu, H.; Zou, Y. Superior fracture toughness in a high-strength austenitic steel with heterogeneous lamellar microstructure. Acta Mater. 2022, 226, 117642. [Google Scholar] [CrossRef]

| Materials | C | Mn | Si | Al | Ti | B |

|---|---|---|---|---|---|---|

| Thin1.4 | 0.22 | 1.21 | 0.23 | 0.034 | 0.029 | 0.004 |

| Thick1.4 | 0.22 | 1.14 | 0.24 | 0.027 | 0.037 | 0.003 |

| Thin1.8 | 0.22 | 1.20 | 0.24 | 0.058 | 0.029 | 0.003 |

| Thick1.8 | 0.22 | 1.21 | 0.22 | 0.042 | 0.028 | 0.003 |

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Thin1.4 | 1227 ± 17 | 1518 ± 23 | 7.5 ± 0.4 |

| Thick1.4 | 1189 ± 14 | 1489 ± 12 | 7.0 ± 0.5 |

| Thin1.8 | 1219 ± 19 | 1525 ± 29 | 7.6 ± 0.3 |

| Thick1.8 | 1205 ± 15 | 1502 ± 8 | 7.1 ± 0.2 |

| Thin1.4 | Thick1.4 | ||||

|---|---|---|---|---|---|

| αL(°) | αUL(°) | Δα(°) | αL(°) | αUL(°) | Δα(°) |

| 35.0 | 25.5 | 9.6 | 30.1 | 21 | 9.1 |

| 45.0 | 35.7 | 9.3 | 40.6 | 31 | 9.6 |

| 55.0 | 47.3 | 7.7 | 50.0 | 41.5 | 8.5 |

| Average Δα(°) 8.9 ± 1.0 | Average Δα(°) 9.1 ± 0.6 | ||||

| Thin1.8 | Thick1.8 | ||||

|---|---|---|---|---|---|

| αL(°) | αUL(°) | Δα(°) | αL(°) | αUL(°) | Δα(°) |

| 35.0 | 26.3 | 9.6 | 30.1 | 21 | 9.1 |

| 45.0 | 36.8 | 9.3 | 40.6 | 31 | 9.6 |

| 55.0 | 46.9 | 7.7 | 50.0 | 41.5 | 8.5 |

| Average Δα(°) 8.3 ± 0.3 | Average Δα(°) 8.3 ± 0.5 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Song, W.; Yi, H.; Wang, J.; Min, J. Fracture Strain of Al–Si-Coated Press-Hardened Steels under Plane-Strain Bending. Materials 2022, 15, 7345. https://doi.org/10.3390/ma15207345

Hou Z, Song W, Yi H, Wang J, Min J. Fracture Strain of Al–Si-Coated Press-Hardened Steels under Plane-Strain Bending. Materials. 2022; 15(20):7345. https://doi.org/10.3390/ma15207345

Chicago/Turabian StyleHou, Zeran, Wei Song, Hongliang Yi, Jianfeng Wang, and Junying Min. 2022. "Fracture Strain of Al–Si-Coated Press-Hardened Steels under Plane-Strain Bending" Materials 15, no. 20: 7345. https://doi.org/10.3390/ma15207345

APA StyleHou, Z., Song, W., Yi, H., Wang, J., & Min, J. (2022). Fracture Strain of Al–Si-Coated Press-Hardened Steels under Plane-Strain Bending. Materials, 15(20), 7345. https://doi.org/10.3390/ma15207345