Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading

Abstract

1. Introduction

2. Materials and Methods

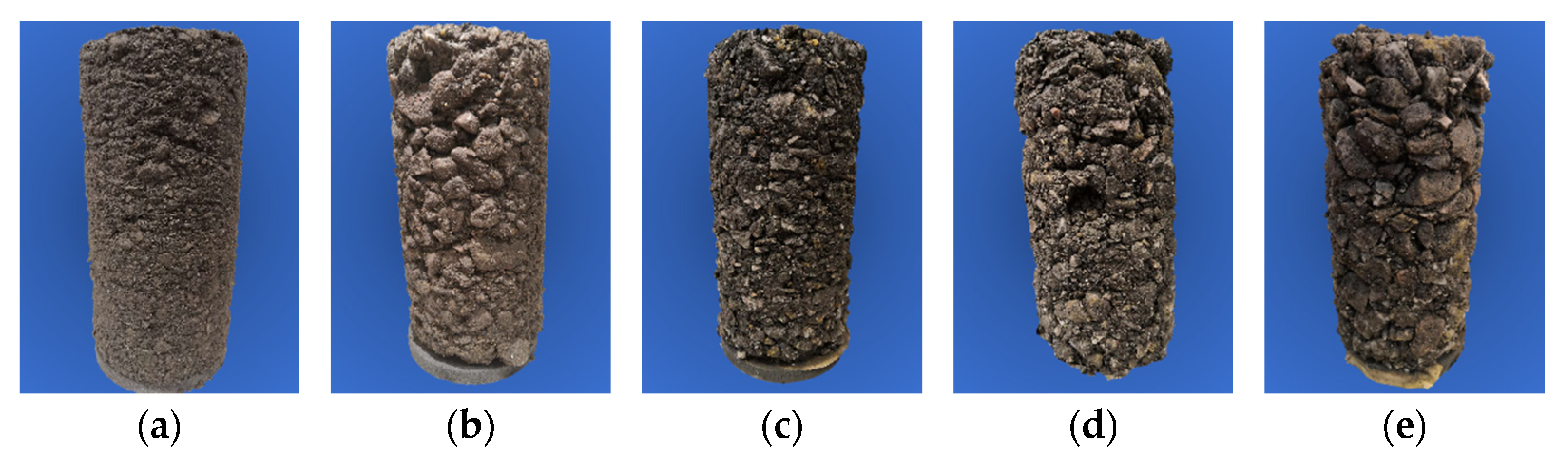

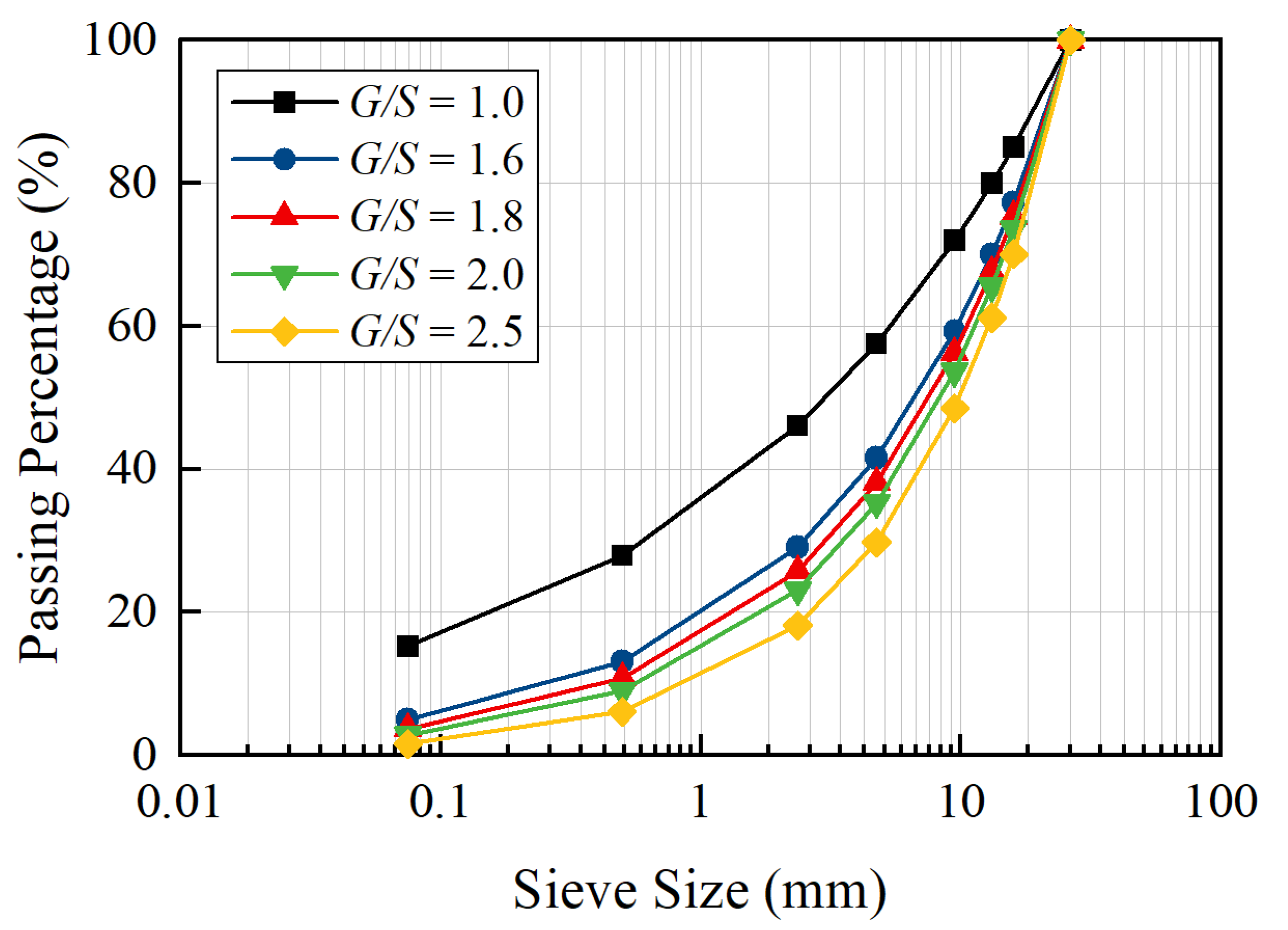

2.1. Materials Tested

2.2. Testing Apparatus

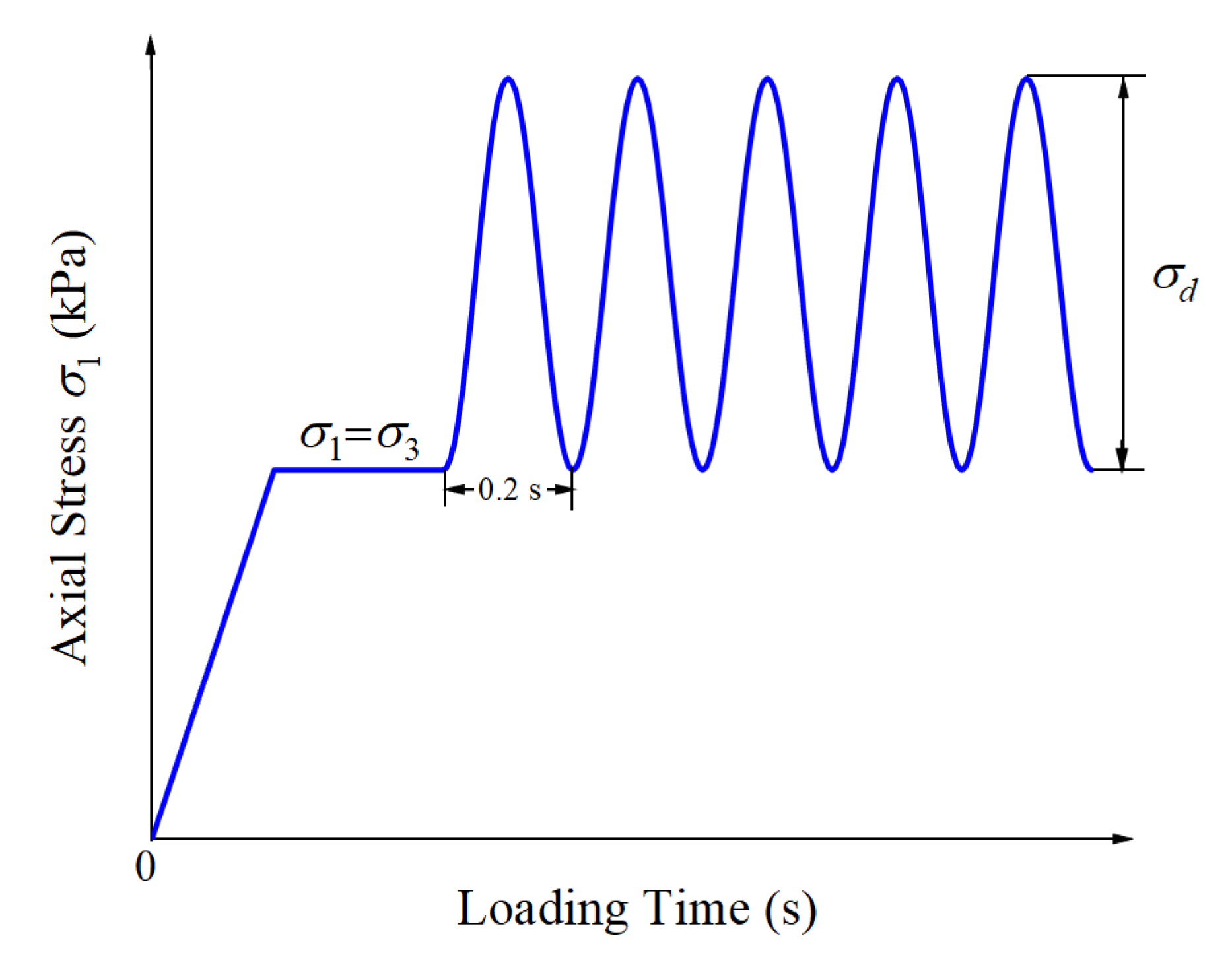

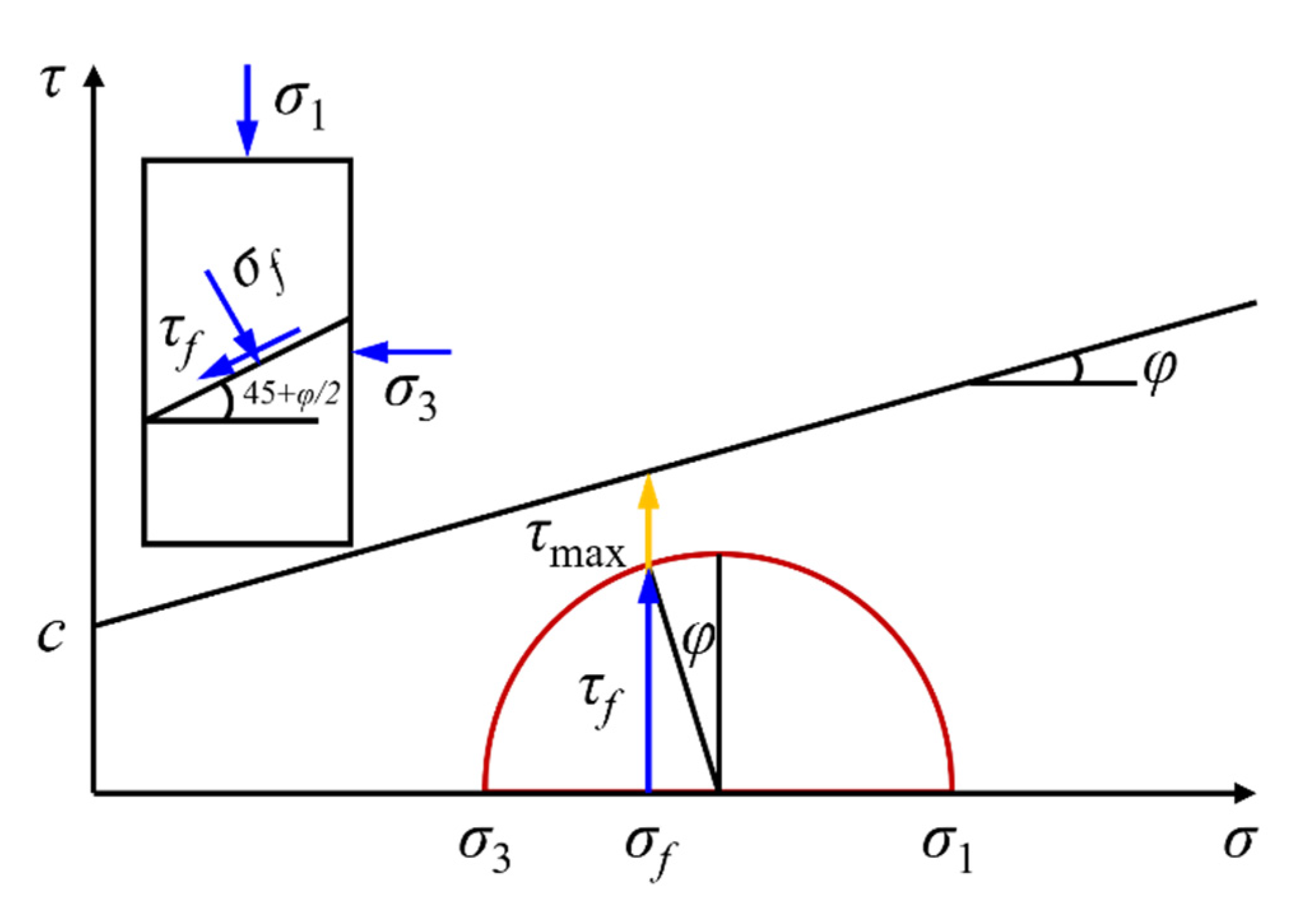

2.3. Cyclic Triaxial Tests

3. Testing Results and Analysis

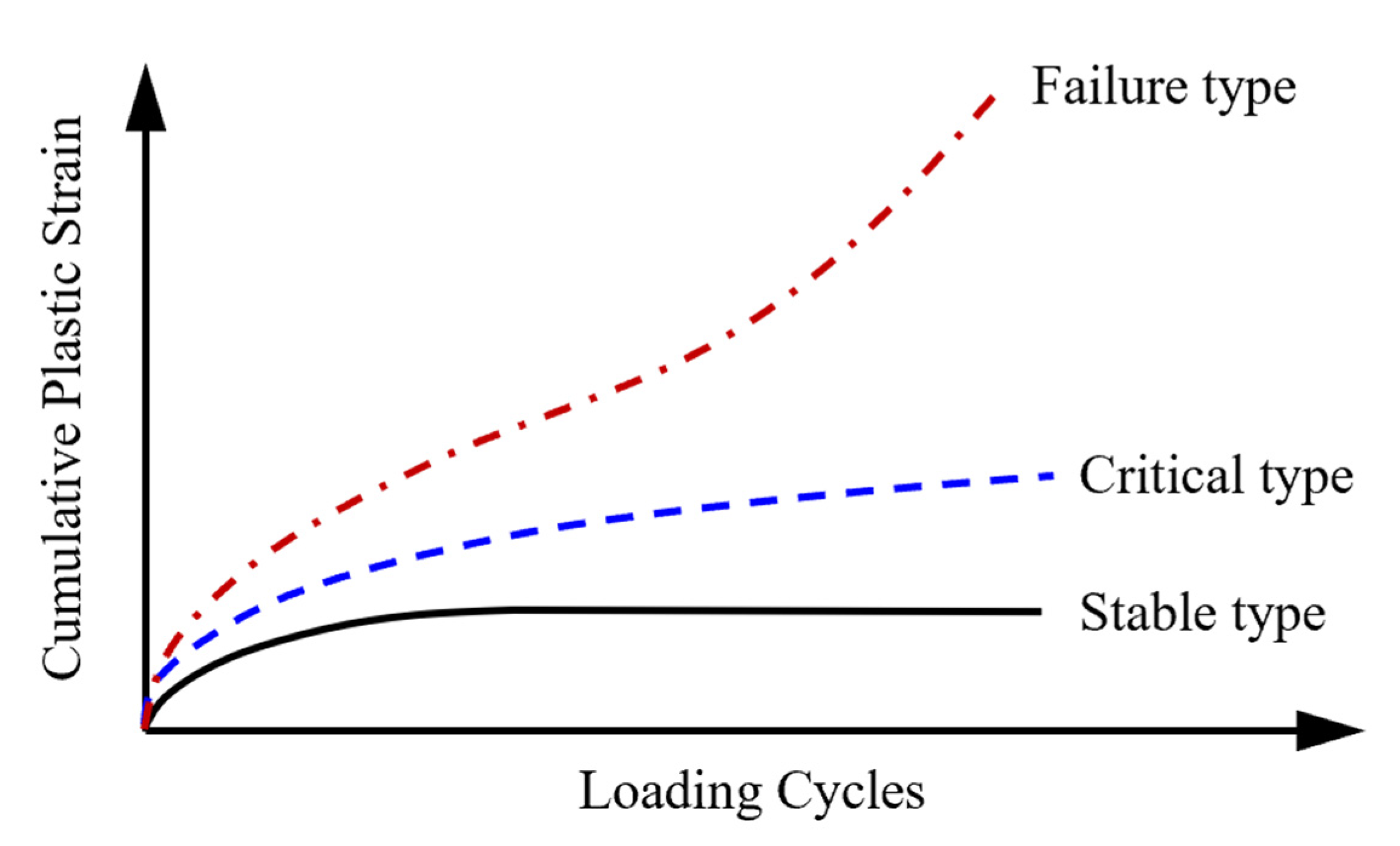

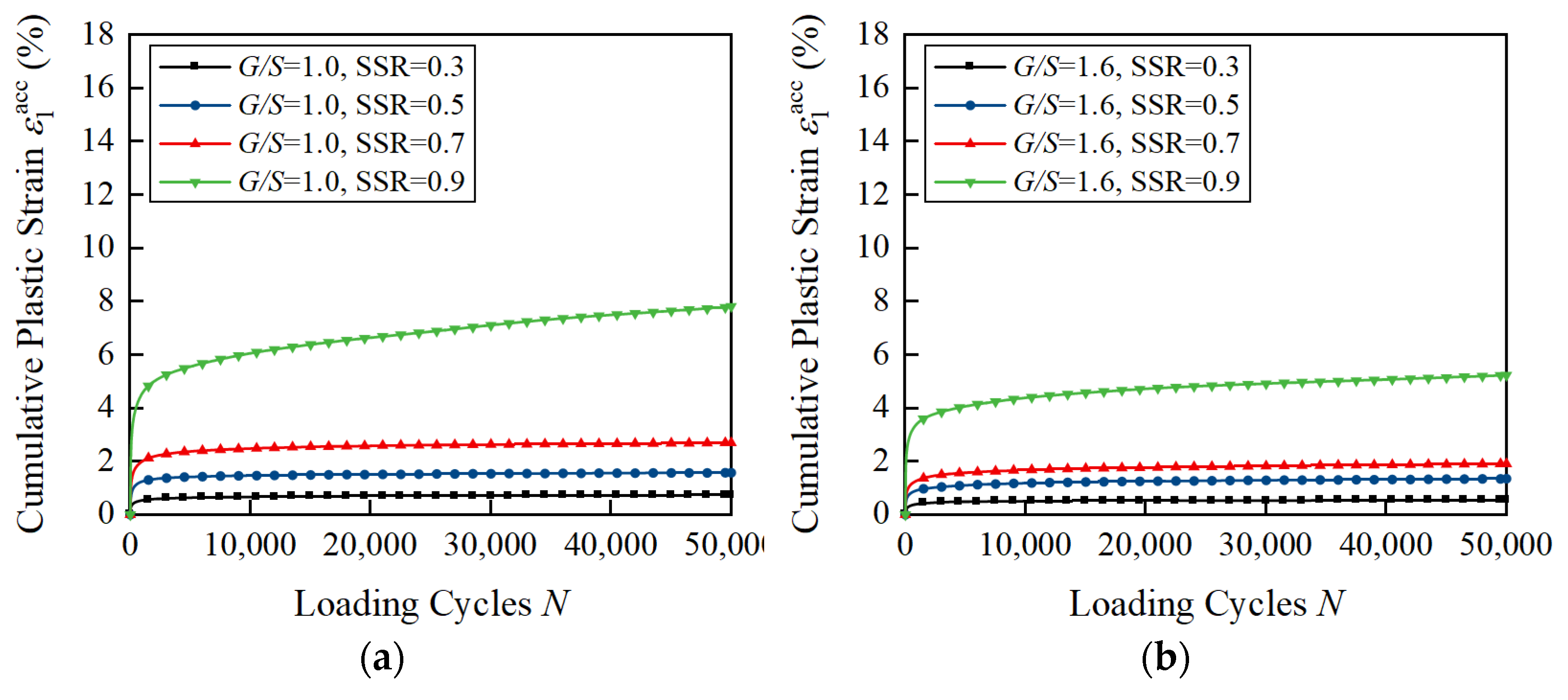

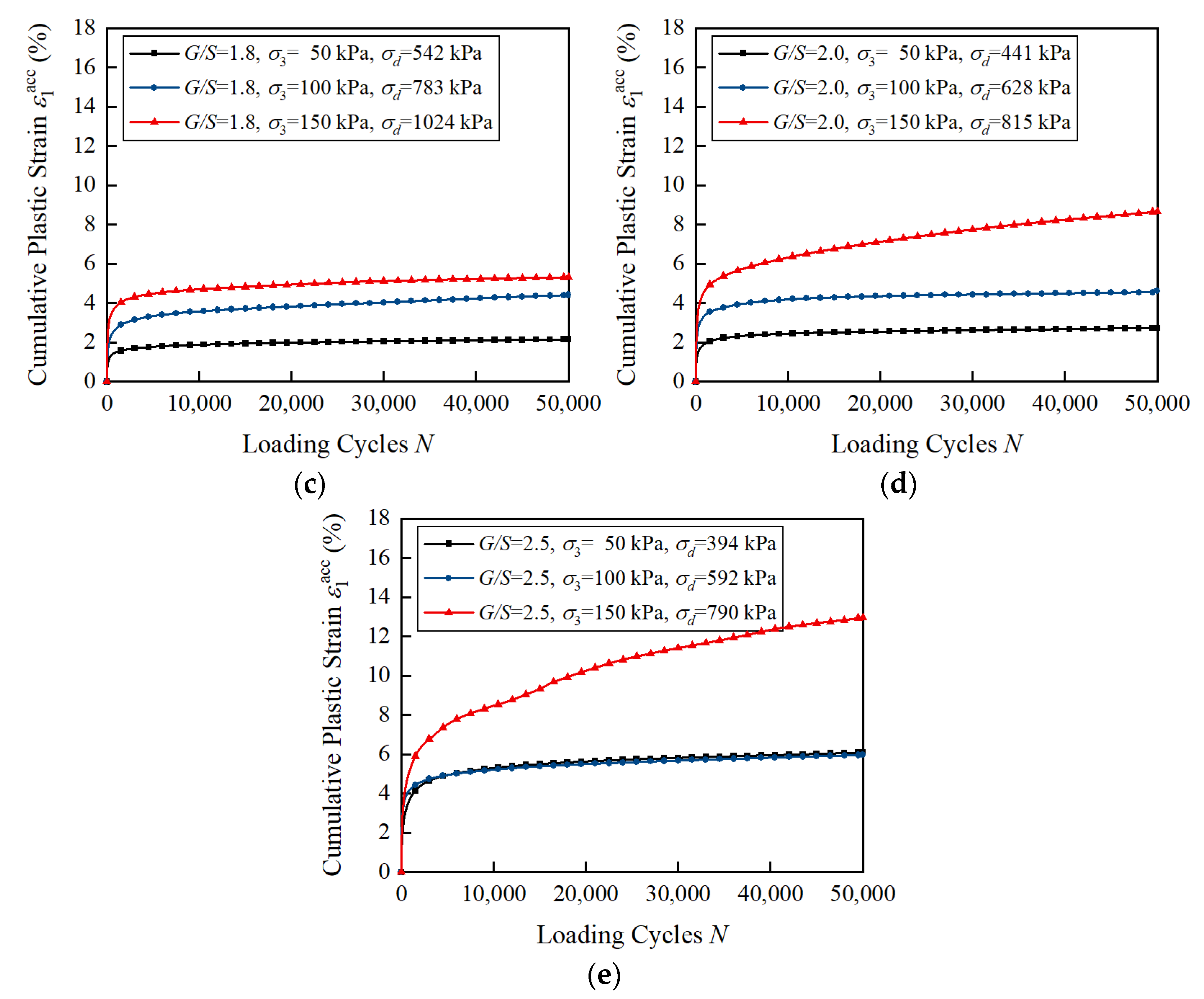

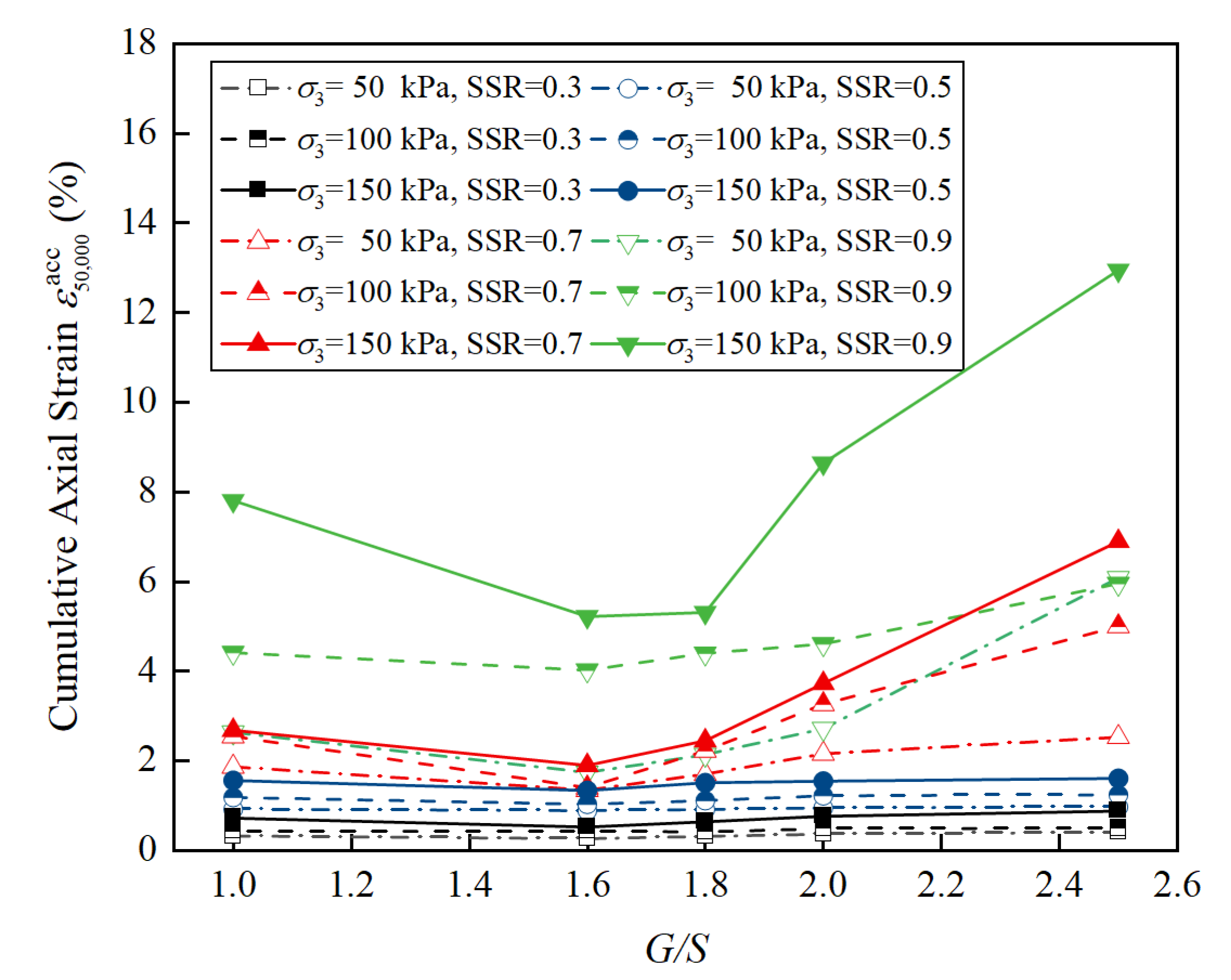

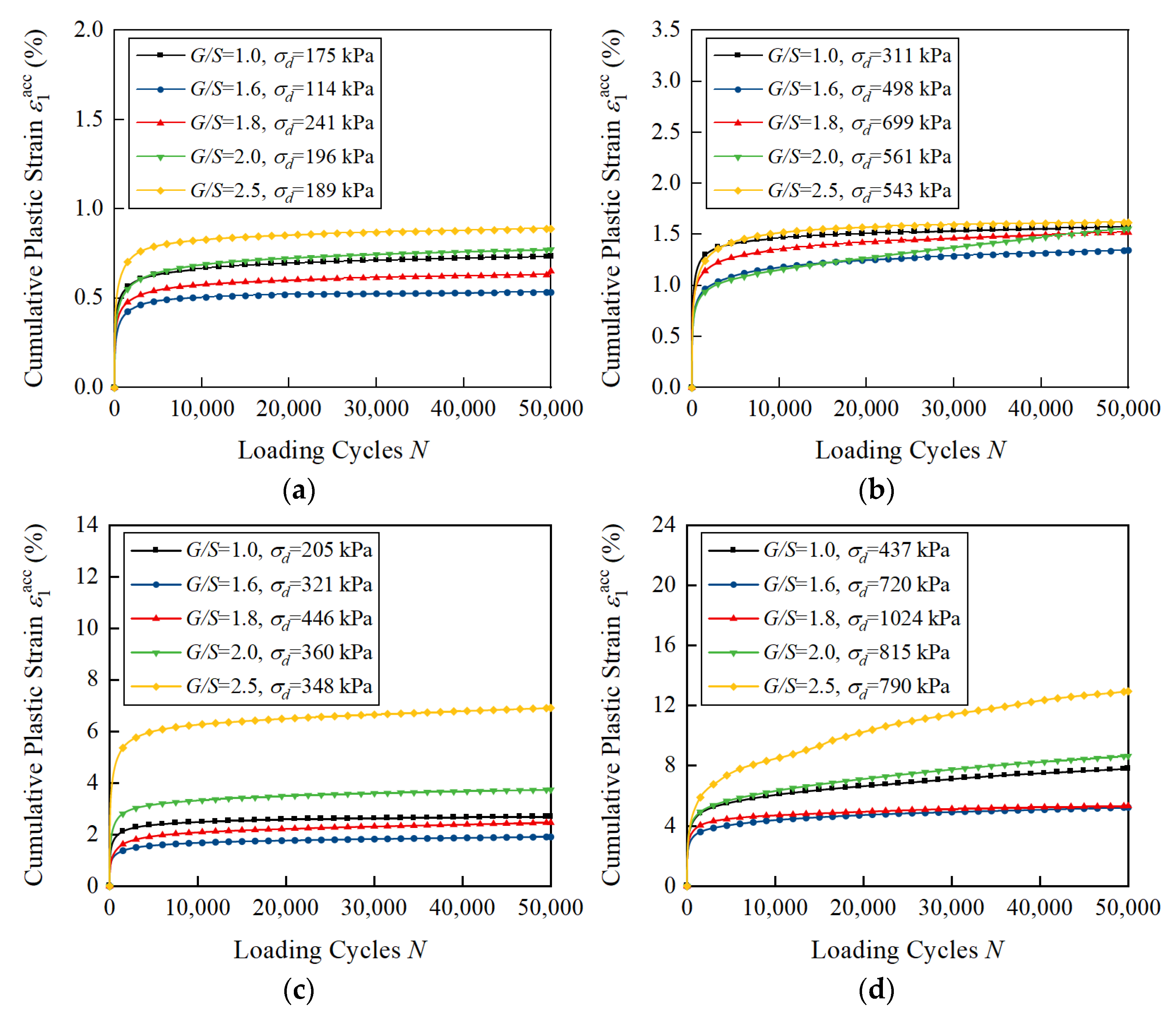

3.1. Effect of Shear Stress Ratio on the Cumulative Plastic Strain

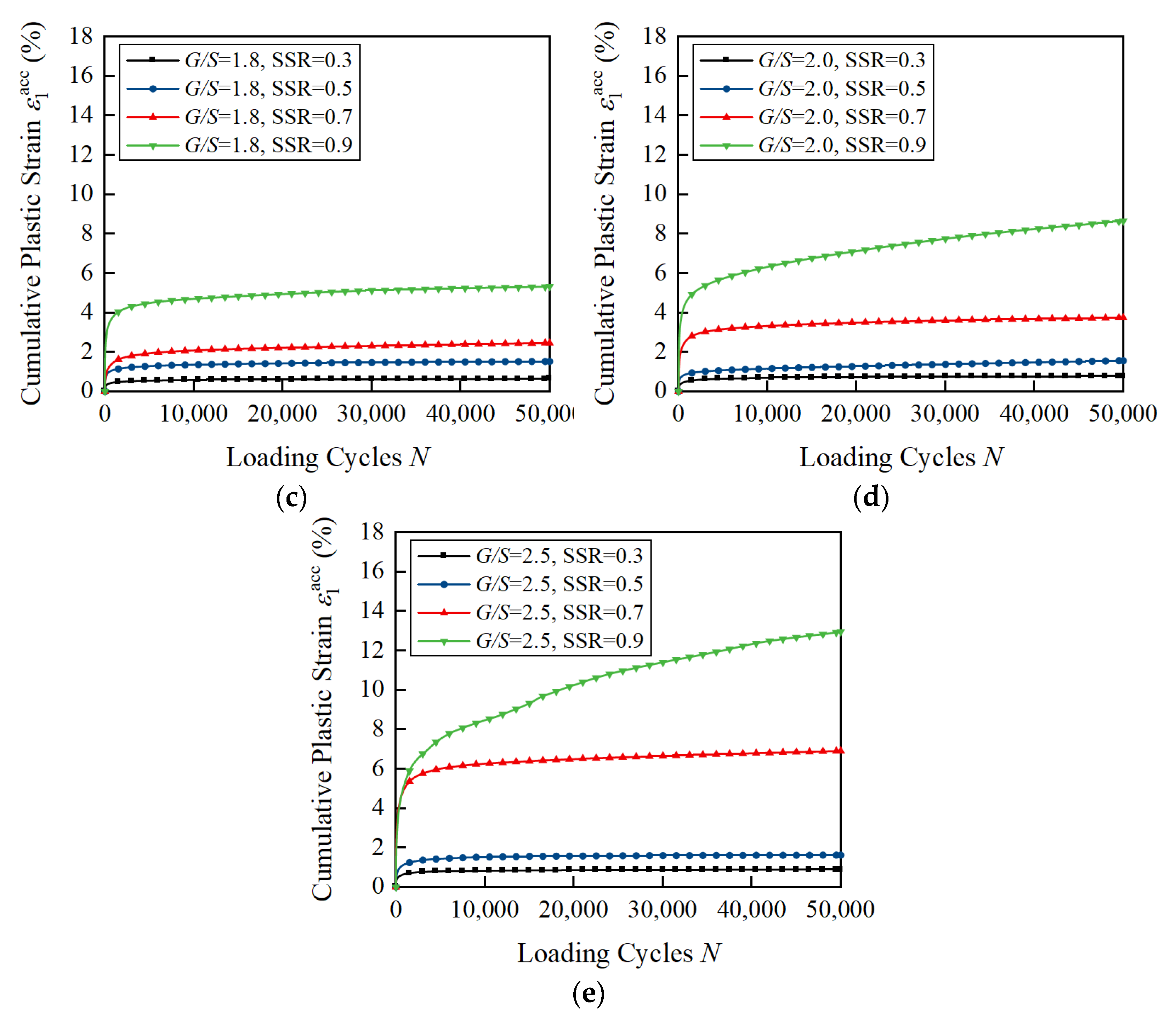

3.2. Effect of Confining Pressure on the Cumulative Plastic Strain

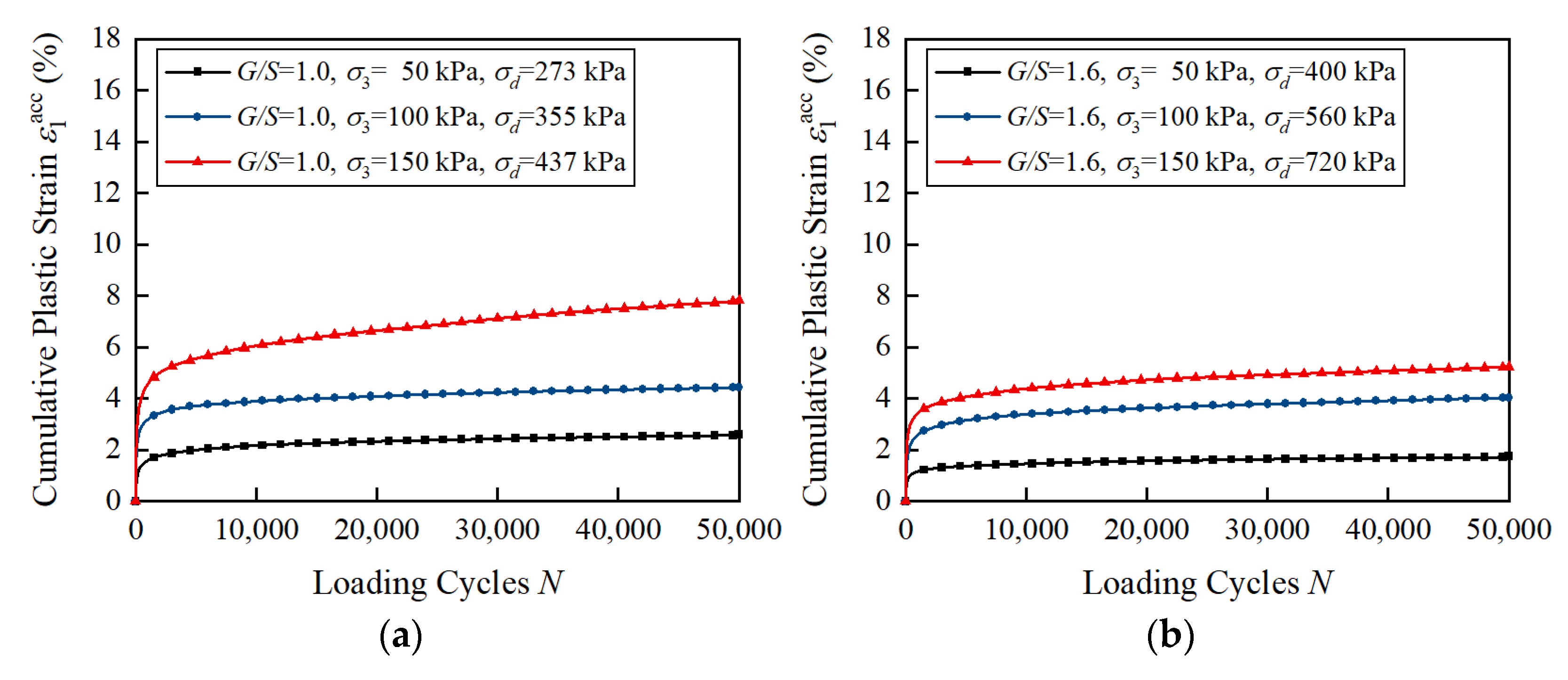

3.3. Effect of Gradation on the Cumulative Plastic Strain

4. Development of the Permanent Deformation Prediction Model

4.1. Development of Empirical Regression Model

4.2. Development of Neural-Network-Based Prediction Model

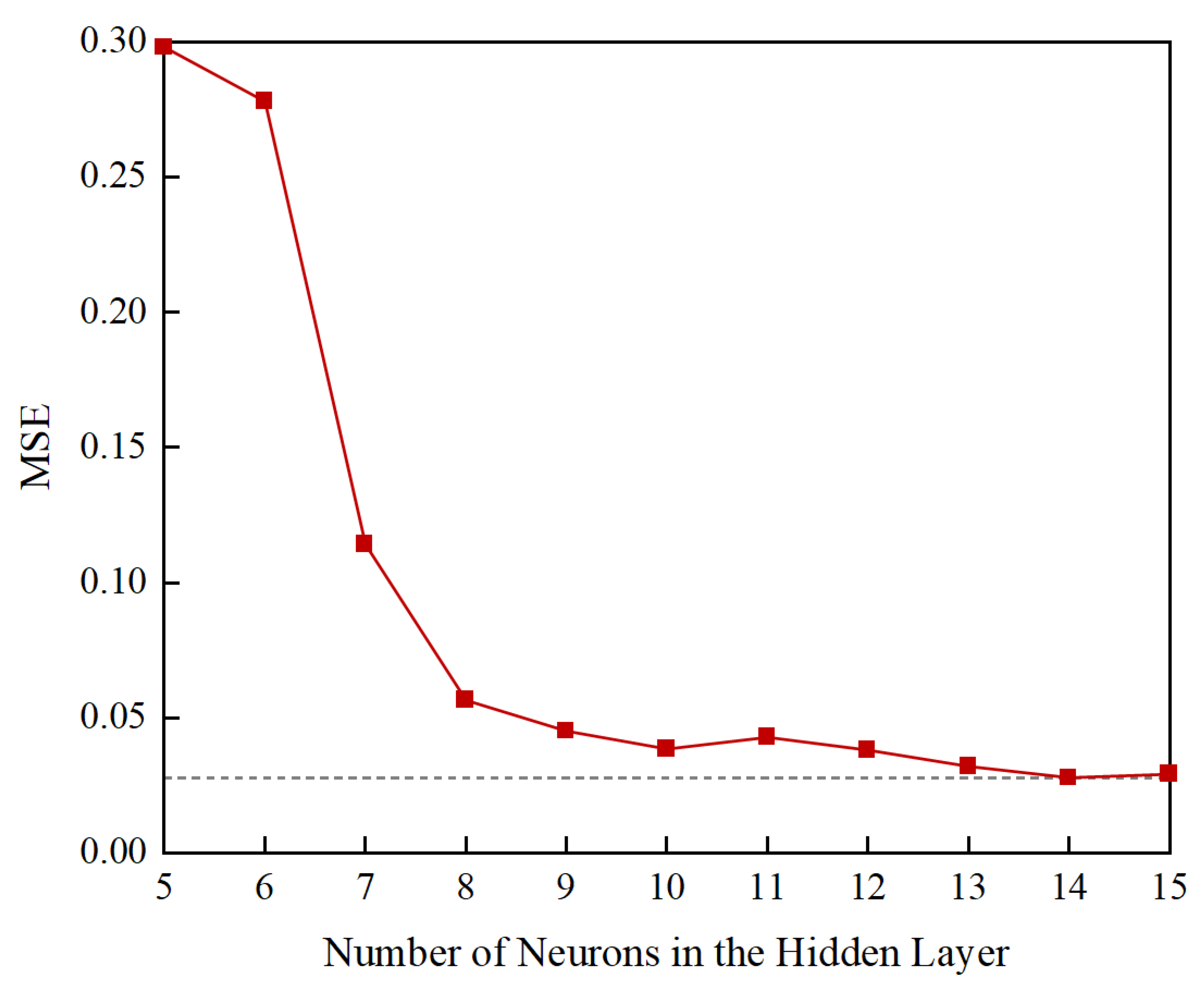

4.3. Optimization of Artificial Neural Network Structure

5. Discussion

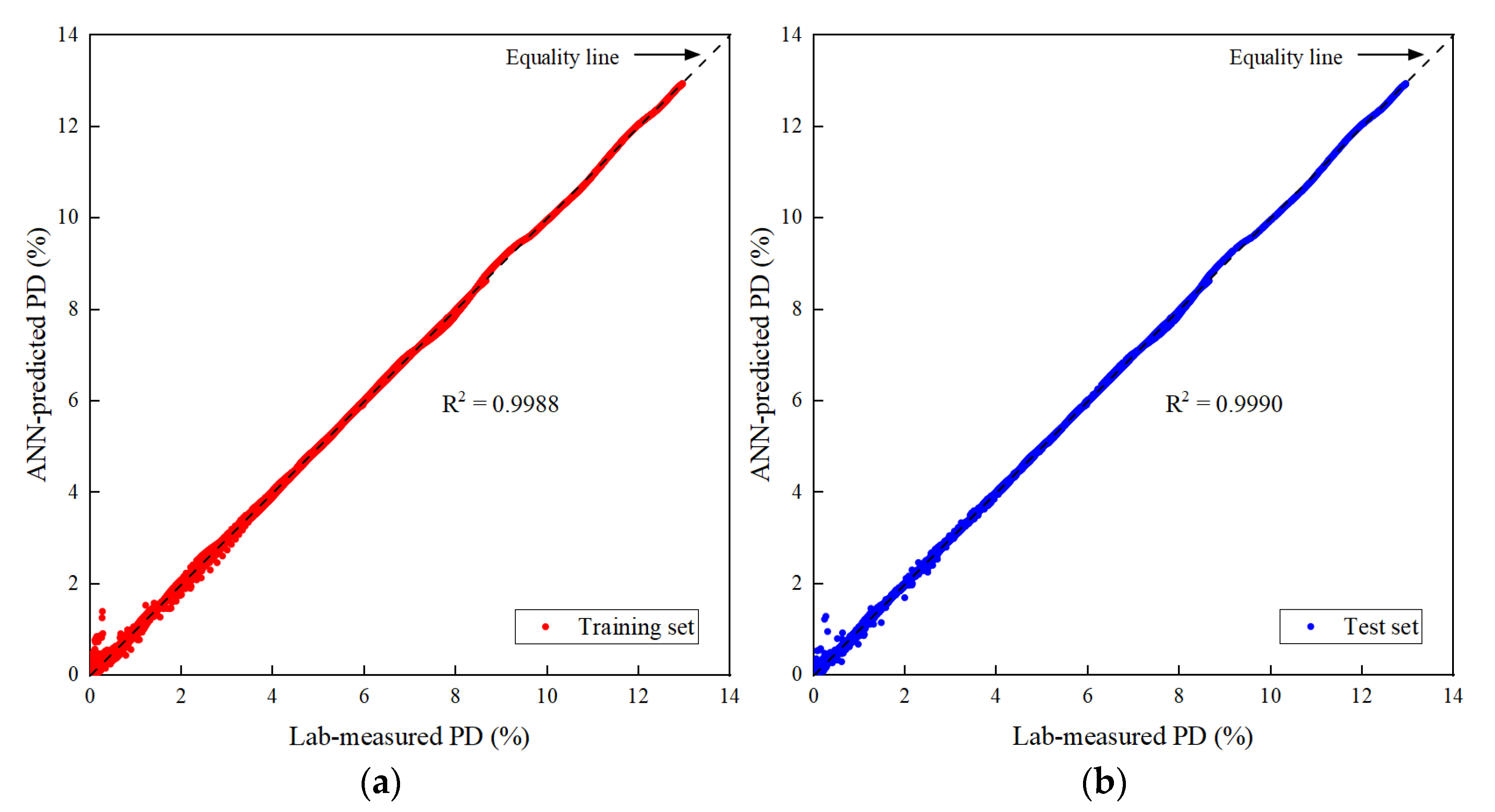

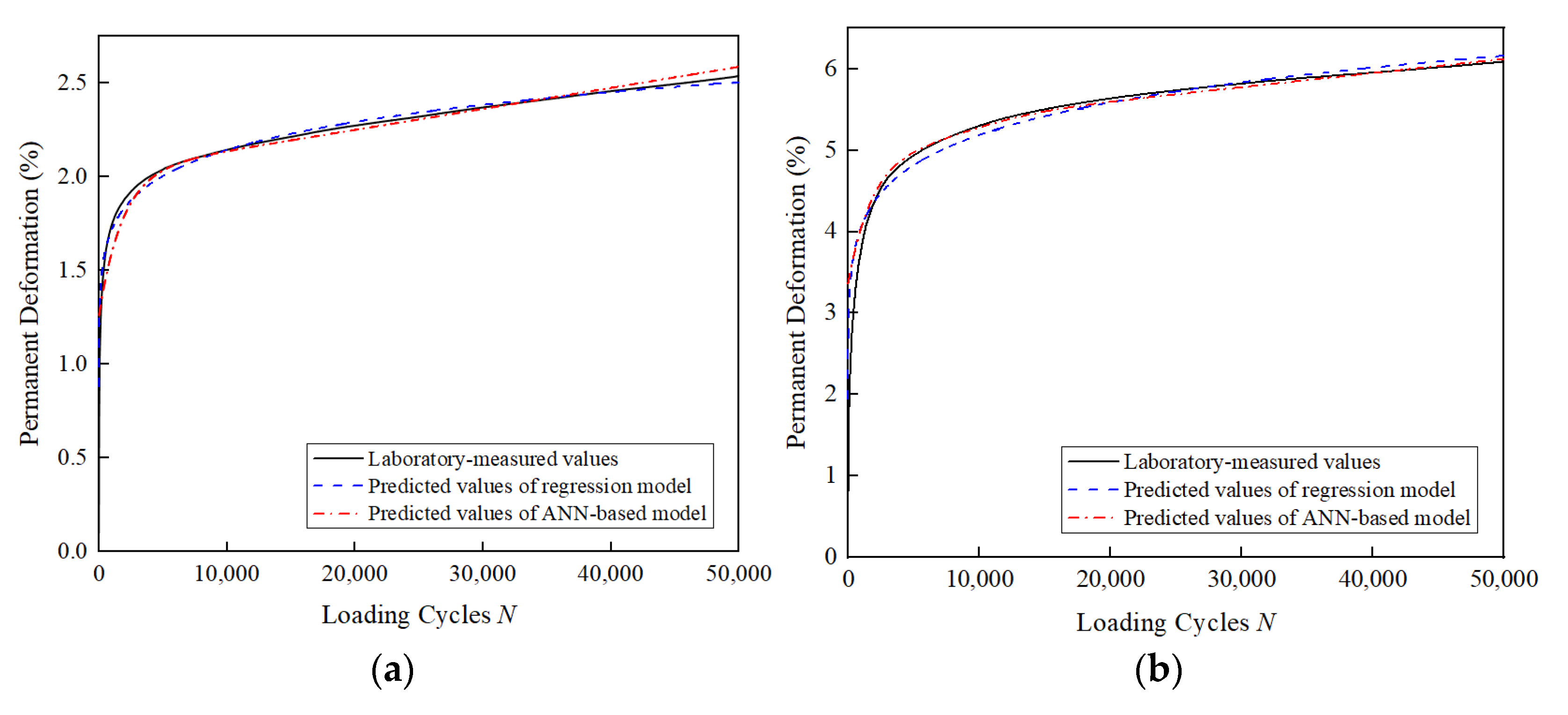

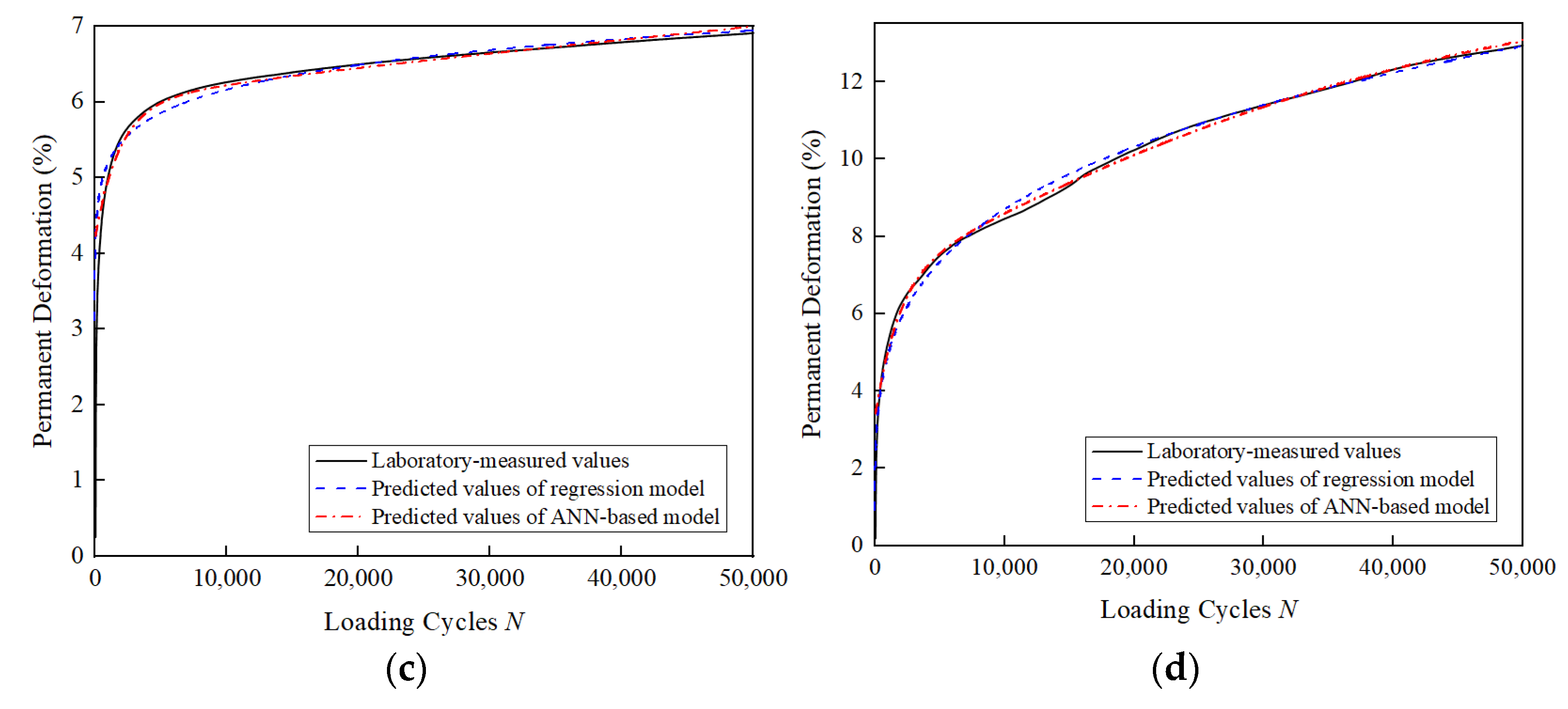

5.1. Comparison of the Predicted and Actual Values of Permanent Deformation

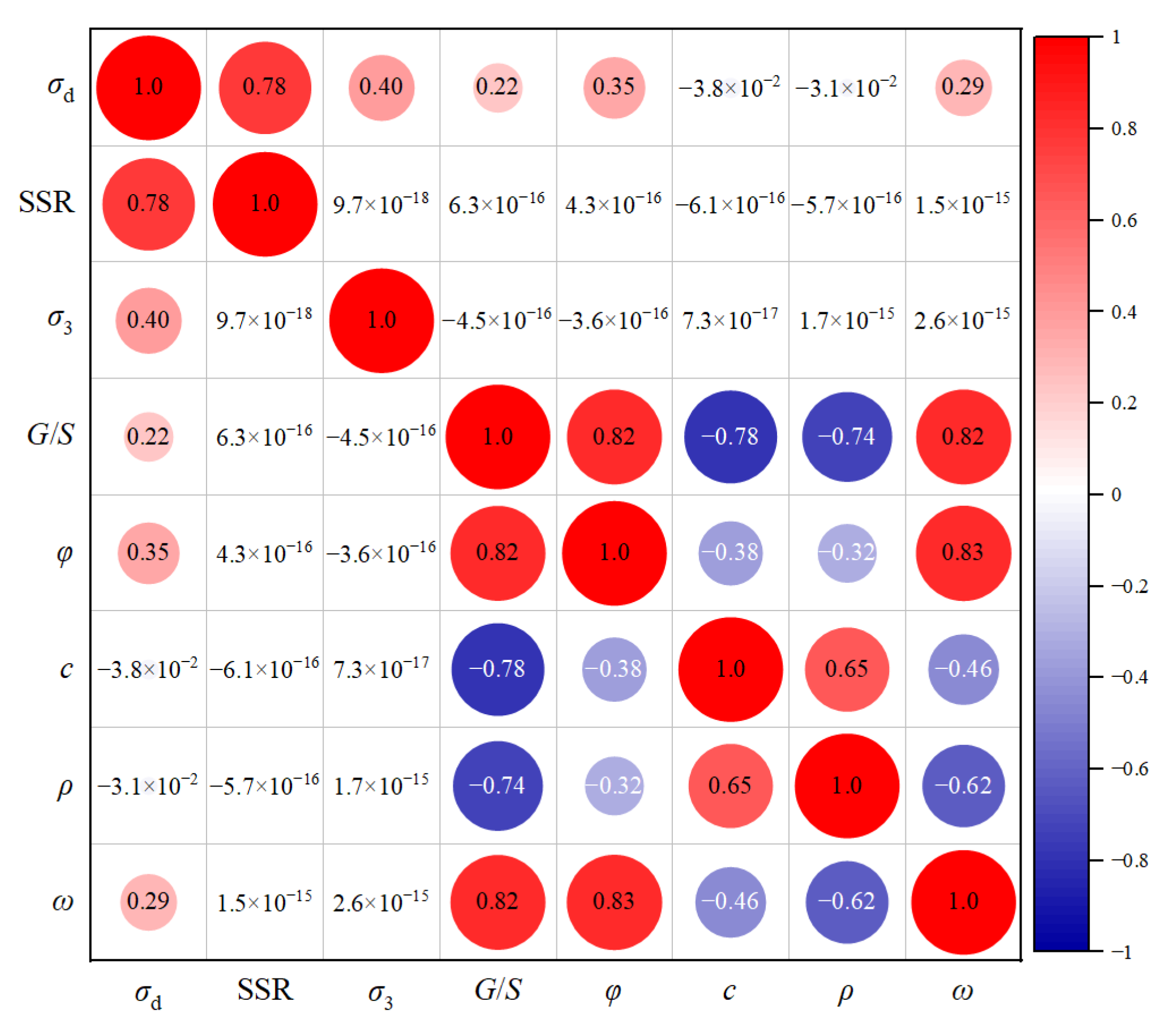

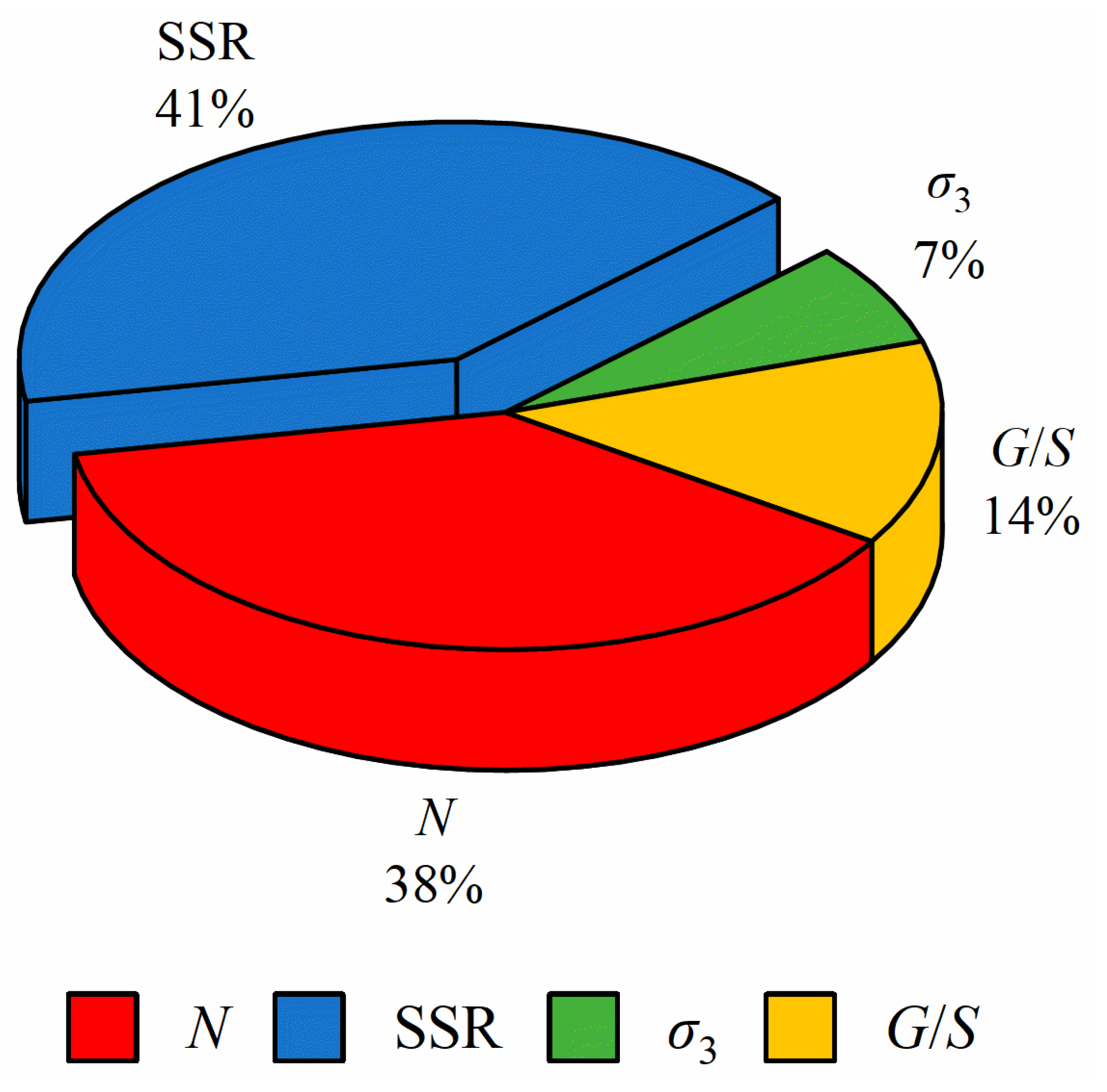

5.2. Sensitivity Analysis

6. Summary and Conclusions

- The consideration of both the shear stress ratio and deviatoric stress (or equivalently, confining pressure) is regarded indispensable for investigating the permanent deformation accumulation characteristics of UGMs. The applied stress level affects not only the magnitude but also the accumulation pattern of the permanent deformation induced. The effects of confining pressure and gradation on the accumulated plastic strain are more significant at a high shear stress ratio (e.g., SSR ≥ 0.7) than those at a relatively low shear stress ratio (e.g., SSR ≤ 0.5).

- Gradation has a remarkable effect on the long-term plastic strain accumulation of UGMs under repeated loading due to different inherent packing structures. The accumulated plastic axial strain was clearly the smallest for UGMs with gradation parameter G/S = 1.6 under all stress states of repeated loading, followed by UGMs with G/S = 1.0 and G/S = 2.5.

- The artificial-neural-network (ANN)-based model was proposed for predicting the permanent deformation accumulation of UGMs. It was found that the ANN-based model has better prediction accuracy and generalization ability than the classic empirical models.

- The ANN model with an input layer containing 4 neurons, a hidden layer containing 14 neurons and accumulated permanent deformation as the single output was constructed. The coefficients of determination for both the training and testing datasets were greater than 0.99, and the minimum mean square error value of the network was 0.0042. The sensitivity analysis results reveal that the number of load applications (N) and shear stress ratio (SSR) are the most critical factors influencing the permanent deformation accumulation of UGMs, while the gradation and confining pressure also play important roles.

- The ANN-based model developed in this study can be used to predict the accumulated plastic deformation of unbound aggregate base courses under long-term applications of repeated traffic loading, thus providing the theoretical basis for improving their structural design and deformation performance assessment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, F.; He, J.; Wang, G.; Zhao, Q. Numerical analysis of dynamic characteristics of coarse grained soils based on cyclic-mobility constitutive model. Rock Soil Mech. 2018, 39, 4627–4641. [Google Scholar]

- Ciampa, D.; Cioffi, R.; Colangelo, F.; Diomedi, M.; Farina, I.; Olita, S. Use of Unbound Materials for Sustainable Road Infrastructures. Appl. Sci. 2020, 10, 3465. [Google Scholar] [CrossRef]

- Rombi, J.; Maltinti, F.; Coni, M. Sardinia Granite Scraps Application in Road Pavement Layers. In Computational Science and Its Applications—ICCSA 2022 Workshops; Gervasi, O., Murgante, B., Misra, S., Rocha, A.M.A.C., Garau, C., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2022; Volume 13382, pp. 613–623. ISBN 978-3-031-10591-3. [Google Scholar]

- Highway Research Board. The AASHO Road Test, Special Report 61E; Highway Research Board: Washington, DC, USA, 1962. [Google Scholar]

- Alnedawi, A.; Kafle, B.; Ullah, S.; Kerr, W. Investigation of Non-Standard Unbound Granular Materials under Cyclic Loads: Experimental and Regression Analyses. Int. J. Pavement Eng. 2022, 23, 2998–3010. [Google Scholar] [CrossRef]

- Qamhia, I.I.A.; Chow, L.C.; Mishra, D.; Tutumluer, E. Dense-Graded Aggregate Base Gradation Influencing Rutting Model Predictions. Transp. Geotech. 2017, 13, 43–51. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, A.; Li, J.; Li, F.; Peng, J. Gray Correlation Analysis and Prediction on Permanent Deformation of Subgrade Filled with Construction and Demolition Materials. Materials 2019, 12, 3035. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, W.; Zhao, Y. Permanent Deformation Characteristic of Asphalt Mixture under Coupling Effect of Moisture, Overload and Loading Frequency. Constr. Build. Mater. 2021, 272, 121985. [Google Scholar] [CrossRef]

- Qian, J.; Li, S.; Gu, X.; Zhang, J. A Unified Model for Estimating the Permanent Deformation of Sand under a Large Number of Cyclic Loads. Ocean Eng. 2019, 181, 293–302. [Google Scholar] [CrossRef]

- Alnedawi, A.; Nepal, K.P.; Al-Ameri, R. Effect of Loading Frequencies on Permanent Deformation of Unbound Granular Materials. Int. J. Pavement Eng. 2021, 22, 1008–1016. [Google Scholar] [CrossRef]

- Alnedawi, A.; Nepal, K.P.; Al-Ameri, R. The Effect of Cyclic Load Characteristics on Unbound Granular Materials. Transp. Infrastruct. Geotechnol. 2019, 6, 70–88. [Google Scholar] [CrossRef]

- Ramos, A.; Correia, A.G.; Indraratna, B.; Ngo, T.; Calçada, R.; Costa, P.A. Mechanistic-Empirical Permanent Deformation Models: Laboratory Testing, Modelling and Ranking. Transp. Geotech. 2020, 23, 100326. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Ahn, J. Experimental Evaluation of the Permanent Strains of Open-Graded Aggregate Materials. Road Mater. Pavement Des. 2021, 22, 1667–1678. [Google Scholar] [CrossRef]

- Ghabchi, R.; Zaman, M.; Khoury, N.; Kazmee, H.; Solanki, P. Effect of Gradation and Source Properties on Stability and Drainability of Aggregate Bases: A Laboratory and Field Study. Int. J. Pavement Eng. 2013, 14, 274–290. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, J.; Cao, Z.; Gu, C.; Wang, J. Influence of Grain Gradation on Permanent Strain of Unbound Granular Materials under Low Confining Pressure and High-Cycle Loading. Int. J. Geomech. 2018, 18, 04017156. [Google Scholar] [CrossRef]

- Monismith, C.L.; Ogawa, N.; Freeme, C.R. Permanent Deformation Characteristics of Subgrade Soils Due to Repeated Loading. Transp. Res. Rec. 1975, 1–17. Available online: https://onlinepubs.trb.org/Onlinepubs/trr/1975/537/537-001.pdf (accessed on 23 August 2022).

- Huang, M.; Yao, Z. Explicit Model for Cumulative Strain of Saturated Clay Subjected to Cyclic Loading. Chin. J. Geotech. Eng. 2011, 33, 325. [Google Scholar]

- Long, Y.; Zhang, J.; Ding, J.; Wang, W. The Cyclic Load Experiments and an Accumulated Deformation Model for Coarse-Grained Soil Filling. J. Vib. Shock 2017, 36, 128–133. [Google Scholar]

- Cai, Y.; Cao, X. Study of the Critical Dynamic Stress and Permanent Strain of the Subgrade-Soil under the Repeated Load. J. Southwest Jiaotong Univ. 1996, 31, 1–5. [Google Scholar]

- Li, D.; Selig, E.T. Cumulative Plastic Deformation for Fine-Grained Subgrade Soils. J. Geotech. Eng. 1996, 122, 1006–1013. [Google Scholar] [CrossRef]

- Kong, X.; Jiang, G. Cumulative Deformation Properties of Red Mudstone Soils under Cyclic Loading. J. Yangtze Riv. Sci. Res. Inst. 2012, 29, 68. [Google Scholar]

- Liu, W.; Leng, W.; Cai, D.; Zhou, W.; Chen, F.; Fang, L. Cyclic Vibration Tests on Coarse Grained Soil of Heavy Haul Railway Subgrade and Study on Accumulative Dynamic Strain. J. China Railw. Soc. 2015, 37, 91–97. [Google Scholar]

- Leng, W.; Zhou, W.; Nie, R.; Zhao, C.; Liu, W.; Yang, Q. Analysis of Dynamic Characteristics and Accumulative Deformation of Coarse-Grained Soil Filling of Heavy-Haul Railway. Rock Soil Mech. 2016, 37, 728–736. [Google Scholar]

- Ghanizadeh, A.R.; Heidarabadizadeh, N.; Jalali, F. Artificial Neural Network Back-Calculation of Flexible Pavements with Sensitivity Analysis Using Garson’s and Connection Weights Algorithms. Innov. Infrastruct. Solut. 2020, 5, 63. [Google Scholar] [CrossRef]

- Yang, X.; Guan, J.; Ding, L.; You, Z.; Lee, V.C.S.; Mohd Hasan, M.R.; Cheng, X. Research and Applications of Artificial Neural Network in Pavement Engineering: A State-of-the-Art Review. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 1000–1021. [Google Scholar] [CrossRef]

- Deng, Y.; Shi, X. An Accurate, Reproducible and Robust Model to Predict the Rutting of Asphalt Pavement: Neural Networks Coupled with Particle Swarm Optimization. IEEE Trans. Intell. Transp. Syst. 2022, 1–10. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer Feedforward Networks Are Universal Approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Mollahasani, A.; Alavi, A.H.; Gandomi, A.H.; Rashed, A. Nonlinear Neural-Based Modeling of Soil Cohesion Intercept. KSCE J. Civ. Eng. 2011, 15, 831–840. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Tatari, O. Evaluating the Use of Neural Networks and Genetic Algorithms for Prediction of Subgrade Resilient Modulus. Int. J. Pavement Eng. 2013, 14, 364–373. [Google Scholar] [CrossRef]

- Kim, S.-H.; Yang, J.; Jeong, J.-H. Prediction of Subgrade Resilient Modulus Using Artificial Neural Network. KSCE J. Civ. Eng. 2014, 18, 1372–1379. [Google Scholar] [CrossRef]

- Saha, S.; Gu, F.; Luo, X.; Lytton, R.L. Use of an Artificial Neural Network Approach for the Prediction of Resilient Modulus for Unbound Granular Material. Transp. Res. Rec. 2018, 2672, 23–33. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S. Experimental and ANN Analysis of Temperature Effects on the Permanent Deformation Properties of Demolition Wastes. Transp. Geotech. 2020, 24, 100365. [Google Scholar] [CrossRef]

- Ullah, S.; Tanyu, B.F.; Zainab, B. Development of an Artificial Neural Network (ANN)-Based Model to Predict Permanent Deformation of Base Course Containing Reclaimed Asphalt Pavement (RAP). Road Mater. Pavement Des. 2021, 22, 2552–2570. [Google Scholar] [CrossRef]

- JTG/T F20-2015; Technical guidelines for construction of highway roadbases. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Xiao, Y.; Kong, K.; Aminu, U.F.; Li, Z.; Li, Q.; Zhu, H.; Cai, D. Characterizing and Predicting the Resilient Modulus of Recycled Aggregates from Building Demolition Waste with Breakage-Induced Gradation Variation. Materials 2022, 15, 2670. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Wang, X.; Yu, Q.; Ren, J.; Hua, W.; Mustafina, R.; Zhang, F.; Feng, H.; Zhang, T. Discrete Element Modeling of Instability Mechanisms of Unbound Permeable Aggregate Base Materials in Triaxial Compression. Materials 2022, 15, 2716. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y. Performance-Based Evaluation of Unbound Aggregates Affecting Mechanistic Response and Performance of Flexible Pavements. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2014. [Google Scholar]

- Yu, Q.; Wang, M.; Xiao, Y.; Hua, W.; Wang, X.; Wang, W.; Chen, X. Experimental Investigation of Strength and Deformation Characteristics of Unbound Permeable Base Materials. Chin. J. Rock Mech. Eng. 2022, 41, 614–630. [Google Scholar]

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- AASHTO Designation T307-99; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2003.

- Cao, Z.; Cai, Y.; Xu, C. Dynamic Response of Pavement Subjected to Moving Traffic Load. J. Zhejiang Univ. (Eng. Sci.) 2009, 23, 777–781. [Google Scholar]

- Kim, I.T. Permanent Deformation Behavior of Airport Flexible Pavement Base and Subbase. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2005. [Google Scholar]

- Chen, W.-B.; Feng, W.-Q.; Yin, J.-H.; Borana, L.; Chen, R.-P. Characterization of Permanent Axial Strain of Granular Materials Subjected to Cyclic Loading Based on Shakedown Theory. Constr. Build. Mater. 2019, 198, 751–761. [Google Scholar] [CrossRef]

- Barksdale, R.D. Laboratory Evaluation of Rutting in Base Course Materials. In Proceedings of the Presented at the Third International Conference on the Structural Design of Asphalt Pavements, Grosvenor House, Park Lane, London, UK, 11–15 September 1972; Volume 1. [Google Scholar]

- Hornych, P. Comportement Mécanique Des Graves Non Traitées. Bull. Liaison Lab. Ponts Chaussees 1994, 27–38. Available online: https://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&lang=en&idt=6383970 (accessed on 23 August 2022).

- Wolff, H.; Visser, A.T. Incorporating Elasto-Plasticity in Granular Layer Pavement Design. Proc. Inst. Civ. Eng.—Transp. 1994, 105, 259–272. [Google Scholar] [CrossRef]

- Huurman, M. Permanent Deformation in Concrete Block Pavements. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1997. [Google Scholar]

- Korkiala-Tanttu, L. Verification of Rutting Calculation for Unbound Road Materials. Proc. Inst. Civ. Eng.—Transp. 2009, 162, 107–114. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Zhu, Z.; Wang, X.; Yu, Z. Study of Accumulated Deformation of Gravel Filler of Subgrade under Cyclic Loading. Adv. Eng. Sci. 2018, 50, 130–137. [Google Scholar]

- Ren, X.-W.; Xu, Q.; Teng, J.; Zhao, N.; Lv, L. A Novel Model for the Cumulative Plastic Strain of Soft Marine Clay under Long-Term Low Cyclic Loads. Ocean Eng. 2018, 149, 194–204. [Google Scholar] [CrossRef]

- Chow, L.C. Permanent Deformation Behavior of Unbound Granular Materials and Rutting Model Development. Master’s Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2014. [Google Scholar]

- Qamhia, I.I.A.; Moaveni, M.; Byun, Y.-H.; Feng, B.; Tutumluer, E. Implementation Framework of the UIUC Aggregate Base Rutting Model. Int. J. Pavement Eng. 2021, 22, 1305–1317. [Google Scholar] [CrossRef]

- Alnedawi, A.; Al-Ameri, R.; Nepal, K.P. Neural Network-Based Model for Prediction of Permanent Deformation of Unbound Granular Materials. J. Rock Mech. Geotech. Eng. 2019, 11, 1231–1242. [Google Scholar] [CrossRef]

- Ghorbani, B.; Sadrossadat, E.; Bolouri Bazaz, J.; Rahimzadeh Oskooei, P. Numerical ANFIS-Based Formulation for Prediction of the Ultimate Axial Load Bearing Capacity of Piles through CPT Data. Geotech. Geol. Eng. 2018, 36, 2057–2076. [Google Scholar] [CrossRef]

- Rostami, M.F.; Sadrossadat, E.; Ghorbani, B.; Kazemi, S.M. New Empirical Formulations for Indirect Estimation of Peak-Confined Compressive Strength and Strain of Circular RC Columns Using LGP Method. Eng. Comput. 2018, 34, 865–880. [Google Scholar] [CrossRef]

- Basheer, I.A. Empirical Modeling of the Compaction Curve of Cohesive Soils. Can. Geotech. J. 2001, 38, 29–45. [Google Scholar] [CrossRef]

- Das, S.K.; Basudhar, P.K. Undrained Lateral Load Capacity of Piles in Clay Using Artificial Neural Network. Comput. Geotech. 2006, 33, 454–459. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Bo, M.W. Development of Genetic-Based Models for Predicting the Resilient Modulus of Cohesive Pavement Subgrade Soils. Soils Found. 2020, 60, 398–412. [Google Scholar] [CrossRef]

- Sadrossadat, E.; Ghorbani, B.; Oskooei, R.; Kaboutari, M. Use of Adaptive Neuro-Fuzzy Inference System and Gene Expression Programming Methods for Estimation of the Bearing Capacity of Rock Foundations. Eng. Comput. 2018, 35, 2078–2106. [Google Scholar] [CrossRef]

- Sadrossadat, E.; Ghorbani, B.; Zohourian, B.; Kaboutari, M.; Rahimzadeh Oskooei, P. Predictive Modelling of the M R of Subgrade Cohesive Soils Incorporating CPT-Related Parameters through a Soft-Computing Approach. Road Mater. Pavement Des. 2020, 21, 701–719. [Google Scholar] [CrossRef]

- Amari, S.; Murata, N.; Muller, K.-R.; Finke, M.; Yang, H.H. Asymptotic Statistical Theory of Overtraining and Cross-Validation. IEEE Trans. Neural Netw. 1997, 8, 985–996. [Google Scholar] [CrossRef]

- Getahun, M.A.; Shitote, S.M.; Gariy, Z.C.A. Artificial Neural Network Based Modelling Approach for Strength Prediction of Concrete Incorporating Agricultural and Construction Wastes. Constr. Build. Mater. 2018, 190, 517–525. [Google Scholar] [CrossRef]

- Garson, G.D. Interpreting Neural-Network Connection Weights. AI Expert 1991, 6, 46–51. [Google Scholar]

| G/S | Dmax (mm) | n | Cu | Cc |

|---|---|---|---|---|

| 1.0 | 26.5 | 0.32 | 270.22 | 3.55 |

| 1.6 | 26.5 | 0.51 | 29.09 | 1.97 |

| 1.8 | 26.5 | 0.56 | 23.64 | 2.08 |

| 2.0 | 26.5 | 0.61 | 18.09 | 1.90 |

| 2.5 | 26.5 | 0.71 | 11.63 | 1.63 |

| Specimen No. | G/S | (°) | |||||

|---|---|---|---|---|---|---|---|

| A050 | 1.0 | 50 | 71/128/195/273 | 29.2 | 65.5 | 2.341 | 4.311 |

| A100 | 100 | 93/166/253/355 | |||||

| A150 | 150 | 114/205/311/437 | |||||

| B050 | 1.6 | 50 | 97/178/277/400 | 40.9 | 64.8 | 2.344 | 4.329 |

| B100 | 100 | 136/250/288/560 | |||||

| B150 | 150 | 175/321/498/720 | |||||

| C050 | 1.8 | 50 | 128/236/370/542 | 47.9 | 64.3 | 2.351 | 4.470 |

| C100 | 100 | 184/341/535/783 | |||||

| C150 | 150 | 241/446/699/1024 | |||||

| D050 | 2.0 | 50 | 106/195/304/441 | 43.6 | 64.0 | 2.271 | 4.481 |

| D100 | 100 | 152/277/432/628 | |||||

| D150 | 150 | 196/360/561/815 | |||||

| E050 | 2.5 | 50 | 94/173/271/394 | 45.5 | 48.7 | 2.270 | 4.472 |

| E100 | 100 | 142/261/407/592 | |||||

| E150 | 150 | 189/348/543/790 |

| Model No. | Model Equations | Authors |

|---|---|---|

| 1 | Barksdale [44] | |

| 2 | Monismith et al. [16] | |

| 3 | Hornych et al. [45] | |

| 4 | Wolff and Visser [46] | |

| 5 | + | Huurman [47] |

| 6 | Korkiala [48] | |

| 7 | Li et al. [49] | |

| 8 | Ren et al. [50] |

| G/S | SSR | A | B | C | D | RMSE | R2 | |

|---|---|---|---|---|---|---|---|---|

| 1.0 | 50 | 0.3 | 0.4832 | 0.0684 | 0.9220 | 4.1788 | 0.0051 | 0.9411 |

| 0.5 | 0.2505 | 0.0849 | 0.8005 | 5.0295 | 0.0133 | 0.9635 | ||

| 0.7 | 0.1888 | 0.0534 | 0.7651 | 6.4989 | 0.0342 | 0.8785 | ||

| 0.9 | 0.0982 | 0.1169 | 0.6790 | 17.1183 | 0.0305 | 0.9849 | ||

| 100 | 0.3 | 0.4649 | 0.0819 | 0.9136 | 4.2107 | 0.0072 | 0.9515 | |

| 0.5 | 0.2729 | 0.0653 | 0.8210 | 4.9240 | 0.0207 | 0.9218 | ||

| 0.7 | 0.1764 | 0.0757 | 0.7623 | 6.6560 | 0.0483 | 0.9247 | ||

| 0.9 | 0.1265 | 0.0832 | 0.7246 | 15.1815 | 0.0459 | 0.9795 | ||

| 150 | 0.3 | 0.5285 | 0.0751 | 0.9420 | 4.1003 | 0.0126 | 0.9382 | |

| 0.5 | 0.2882 | 0.0587 | 0.8338 | 4.8561 | 0.0293 | 0.8934 | ||

| 0.7 | 0.1731 | 0.0698 | 0.7653 | 6.7009 | 0.0522 | 0.9141 | ||

| 0.9 | 0.1119 | 0.1449 | 0.7162 | 16.0544 | 0.0821 | 0.9908 | ||

| 1.6 | 50 | 0.3 | 0.3816 | 0.0839 | 0.8731 | 4.3648 | 0.0041 | 0.9585 |

| 0.5 | 0.2456 | 0.0601 | 0.8050 | 5.0533 | 0.0186 | 0.8794 | ||

| 0.7 | 0.1248 | 0.0956 | 0.7142 | 7.4552 | 0.0179 | 0.9745 | ||

| 0.9 | 0.0784 | 0.1024 | 0.6632 | 18.8969 | 0.0167 | 0.9873 | ||

| 100 | 0.3 | 0.4277 | 0.0719 | 0.8980 | 4.2769 | 0.0078 | 0.9299 | |

| 0.5 | 0.2117 | 0.0807 | 0.7896 | 5.2340 | 0.0171 | 0.9494 | ||

| 0.7 | 0.1301 | 0.0617 | 0.7313 | 7.3654 | 0.0264 | 0.9022 | ||

| 0.9 | 0.0922 | 0.1121 | 0.6983 | 17.6156 | 0.0418 | 0.9874 | ||

| 150 | 0.3 | 0.4356 | 0.0644 | 0.9026 | 4.2622 | 0.0151 | 0.8175 | |

| 0.5 | 0.2020 | 0.0942 | 0.7886 | 5.2898 | 0.0179 | 0.9734 | ||

| 0.7 | 0.1169 | 0.0931 | 0.7251 | 7.6077 | 0.0263 | 0.9709 | ||

| 0.9 | 0.0944 | 0.1091 | 0.7096 | 17.4442 | 0.0341 | 0.9947 | ||

| 1.8 | 50 | 0.3 | 0.3911 | 0.0718 | 0.8806 | 4.3455 | 0.0040 | 0.9634 |

| 0.5 | 0.1988 | 0.0902 | 0.7787 | 5.3089 | 0.0125 | 0.9709 | ||

| 0.7 | 0.1376 | 0.0689 | 0.7377 | 7.2348 | 0.0229 | 0.9549 | ||

| 0.9 | 0.0810 | 0.0893 | 0.6797 | 18.6554 | 0.0258 | 0.9760 | ||

| 100 | 0.3 | 0.3638 | 0.0857 | 0.8709 | 4.4003 | 0.0068 | 0.9564 | |

| 0.5 | 0.2009 | 0.0752 | 0.7891 | 5.2971 | 0.0222 | 0.9225 | ||

| 0.7 | 0.1123 | 0.1107 | 0.7224 | 7.6945 | 0.0216 | 0.9888 | ||

| 0.9 | 0.0808 | 0.1225 | 0.6934 | 18.6340 | 0.0526 | 0.9849 | ||

| 150 | 0.3 | 0.3954 | 0.0778 | 0.8872 | 4.3376 | 0.0121 | 0.9298 | |

| 0.5 | 0.1982 | 0.0823 | 0.7931 | 5.3137 | 0.0178 | 0.9740 | ||

| 0.7 | 0.1038 | 0.1158 | 0.7208 | 7.8728 | 0.0417 | 0.9692 | ||

| 0.9 | 0.3426 | 0.0829 | 0.8214 | 7.2148 | 0.0627 | 0.9738 | ||

| 2.0 | 50 | 0.3 | 0.4141 | 0.0869 | 0.8901 | 4.3025 | 0.0060 | 0.9572 |

| 0.5 | 0.2259 | 0.0777 | 0.7936 | 5.1556 | 0.0164 | 0.9412 | ||

| 0.7 | 0.1528 | 0.0813 | 0.7466 | 6.9900 | 0.0297 | 0.9639 | ||

| 0.9 | 0.0989 | 0.0805 | 0.6983 | 17.1070 | 0.0442 | 0.9498 | ||

| 100 | 0.3 | 0.4260 | 0.0753 | 0.8977 | 4.2802 | 0.0088 | 0.9358 | |

| 0.5 | 0.4697 | 0.0817 | 0.9135 | 4.2193 | 0.0186 | 0.9573 | ||

| 0.7 | 0.1592 | 0.0799 | 0.7624 | 6.8952 | 0.0605 | 0.9357 | ||

| 0.9 | 0.1102 | 0.0722 | 0.7243 | 16.2673 | 0.0797 | 0.9321 | ||

| 150 | 0.3 | 0.4271 | 0.0938 | 0.8992 | 4.2787 | 0.0146 | 0.9487 | |

| 0.5 | 0.1568 | 0.1550 | 0.7568 | 5.5818 | 0.0298 | 0.9716 | ||

| 0.7 | 0.1496 | 0.0851 | 0.7608 | 7.0390 | 0.0607 | 0.9543 | ||

| 0.9 | 0.0823 | 0.1744 | 0.6990 | 18.3691 | 0.1142 | 0.9889 | ||

| 2.5 | 50 | 0.3 | 0.4597 | 0.0782 | 0.9112 | 4.2198 | 0.0059 | 0.9593 |

| 0.5 | 0.2305 | 0.0865 | 0.7940 | 5.1305 | 0.0180 | 0.9457 | ||

| 0.7 | 0.1574 | 0.0967 | 0.7476 | 6.9182 | 0.0285 | 0.9807 | ||

| 0.9 | 0.1252 | 0.1066 | 0.7272 | 15.2272 | 0.1315 | 0.9460 | ||

| 100 | 0.3 | 0.4363 | 0.0747 | 0.9019 | 4.2615 | 0.0077 | 0.9489 | |

| 0.5 | 0.1993 | 0.1086 | 0.7819 | 5.3036 | 0.0226 | 0.9627 | ||

| 0.7 | 0.1920 | 0.0773 | 0.7867 | 6.4585 | 0.0599 | 0.9694 | ||

| 0.9 | 0.1171 | 0.0859 | 0.7305 | 15.7838 | 0.0591 | 0.9822 | ||

| 150 | 0.3 | 0.4994 | 0.0669 | 0.9284 | 4.1512 | 0.0203 | 0.8775 | |

| 0.5 | 0.2303 | 0.0737 | 0.8092 | 5.1317 | 0.0441 | 0.8601 | ||

| 0.7 | 0.1991 | 0.0740 | 0.7977 | 6.3732 | 0.1266 | 0.9279 | ||

| 0.9 | 0.0709 | 0.2455 | 0.6851 | 19.1834 | 0.1593 | 0.9941 |

| Statistical Parameters | Input Variables | Output Variable | |||

|---|---|---|---|---|---|

| N | SSR | G/S | PD | ||

| Maximum | 50,000 | 0.9 | 150 | 2.5 | 12.9555 |

| Minimum | 10 | 0.3 | 50 | 1.0 | 0.0060 |

| Median | 25,005 | 0.6 | 100 | 1.8 | 1.4535 |

| Mean | 25,005 | 0.6 | 100 | 1.7800 | 2.2008 |

| Standard deviation | 14,435.2 | 0.2582 | 50 | 0.5495 | 2.0921 |

| Coefficient of variance | 1.7322 | 2.3238 | 2 | 3.2390 | 1.0520 |

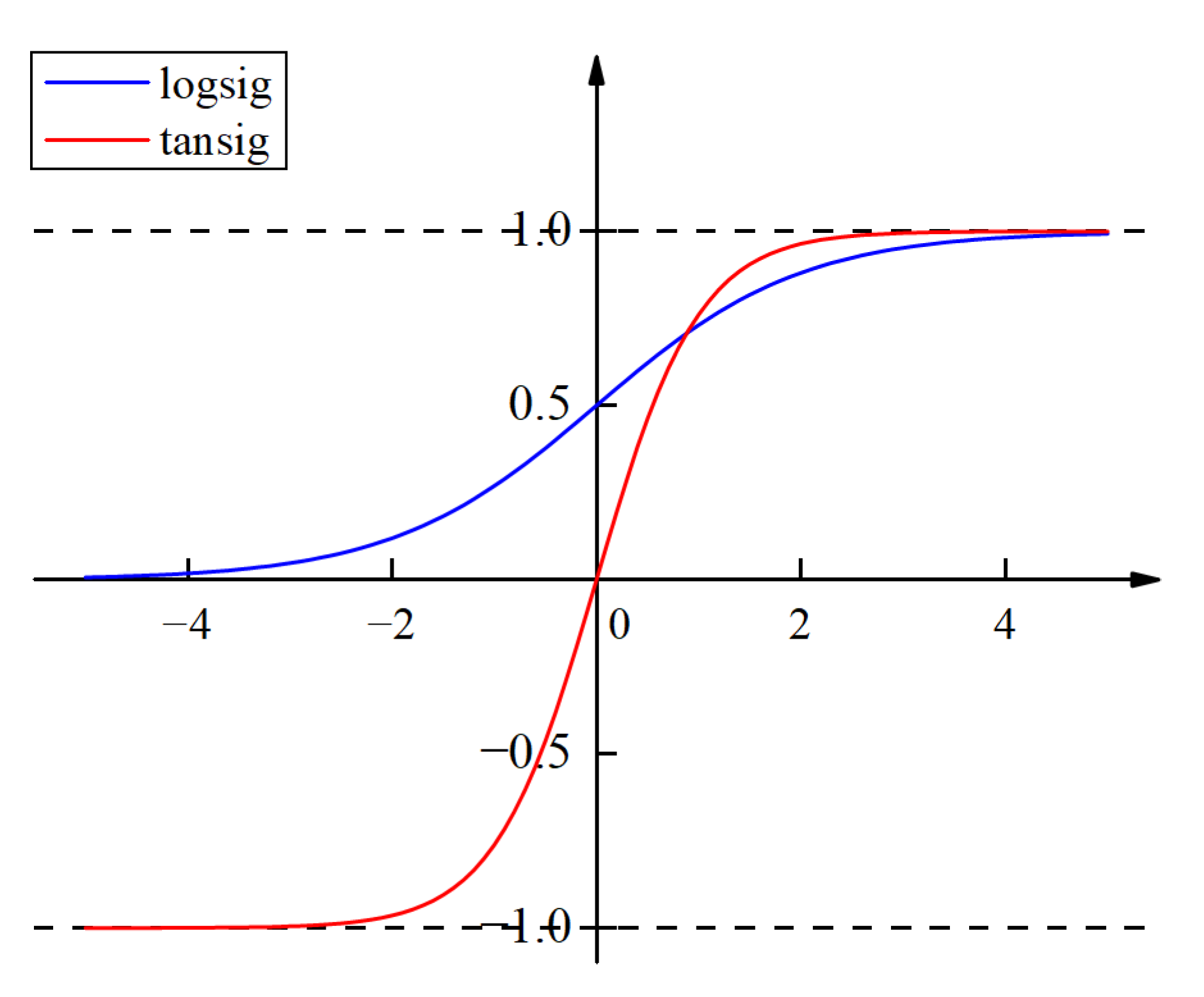

| Performance Parameters | Activation Function | |

|---|---|---|

| logsig | tansig | |

| MSE (mm2) | 0.0051 | 0.0043 |

| RMSE (mm) | 0.0717 | 0.0657 |

| MAE (mm) | 0.0448 | 0.0427 |

| R2 | 0.9988 | 0.9990 |

| Performance Parameters | Data Normalization | |

|---|---|---|

| Without | With | |

| MSE (mm2) | 0.0072 | 0.0043 |

| RMSE (mm) | 0.0846 | 0.0657 |

| MAE (mm) | 0.0490 | 0.0427 |

| R2 | 0.9984 | 0.9990 |

| Performance Parameters | Dataset | ||

|---|---|---|---|

| Training Set | Testing Set | Overall | |

| MSE (mm2) | 0.0053 | 0.0049 | 0.0052 |

| RMSE (mm) | 0.0728 | 0.0703 | 0.0723 |

| MAE (mm) | 0.0406 | 0.0406 | 0.0406 |

| R2 | 0.9988 | 0.9989 | 0.9988 |

| Number of Hidden Neurons (j) | ||||||

|---|---|---|---|---|---|---|

| 1 | −0.113 | −4.191 | −0.399 | 0.784 | −58.986 | 7.901 |

| 2 | −2.597 | 87.644 | −8.837 | −28.461 | −0.110 | −70.350 |

| 3 | 0.000 | 0.658 | 0.908 | 0.469 | 0.239 | −0.183 |

| 4 | 0.190 | −7.038 | −22.867 | −9.040 | 0.074 | 6.952 |

| 5 | −0.023 | 0.572 | 0.075 | 1.297 | −4.016 | −2.775 |

| 6 | −0.962 | −12.145 | −3.371 | −4.020 | −0.625 | 18.961 |

| 7 | −0.038 | −1.147 | 1.285 | −1.047 | −0.108 | 0.922 |

| 8 | −0.177 | 3.441 | 0.648 | −5.559 | −0.070 | −0.770 |

| 9 | 0.064 | 2.339 | 0.537 | 3.224 | −5.314 | −3.012 |

| 10 | −0.516 | 5.357 | 6.681 | −3.762 | 3.493 | −4.368 |

| 11 | 7.763 | −0.486 | −0.217 | −0.153 | 56.515 | 11.303 |

| 12 | −0.032 | −0.660 | −0.033 | 1.477 | −0.205 | 0.948 |

| 13 | 0.519 | −5.267 | −6.590 | 3.717 | 3.482 | 4.310 |

| 14 | −0.057 | −2.180 | −0.505 | −2.951 | −6.094 | 2.835 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, W.; Yu, Q.; Xiao, Y.; Li, W.; Wang, M.; Chen, Y.; Li, Z. Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading. Materials 2022, 15, 7303. https://doi.org/10.3390/ma15207303

Hua W, Yu Q, Xiao Y, Li W, Wang M, Chen Y, Li Z. Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading. Materials. 2022; 15(20):7303. https://doi.org/10.3390/ma15207303

Chicago/Turabian StyleHua, Wenjun, Qunding Yu, Yuanjie Xiao, Wenqi Li, Meng Wang, Yuliang Chen, and Zhiyong Li. 2022. "Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading" Materials 15, no. 20: 7303. https://doi.org/10.3390/ma15207303

APA StyleHua, W., Yu, Q., Xiao, Y., Li, W., Wang, M., Chen, Y., & Li, Z. (2022). Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading. Materials, 15(20), 7303. https://doi.org/10.3390/ma15207303