Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening

Abstract

1. Introduction

2. Experiments Setup

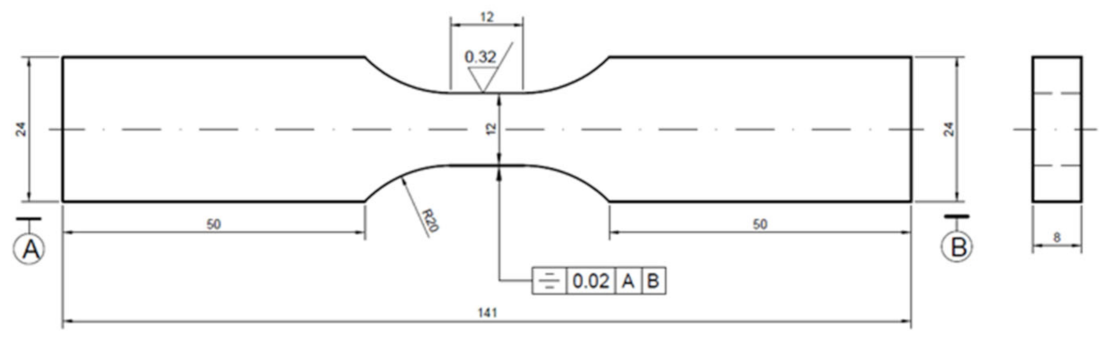

2.1. Specimen Preparation of Inconel 625

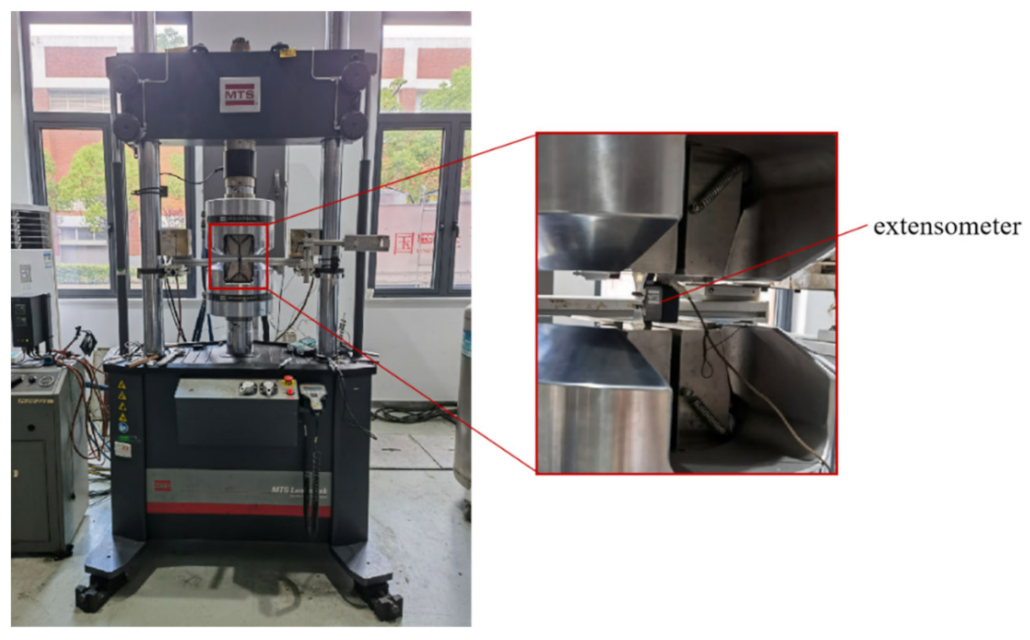

2.2. Fatigue Test Machine and Parameters

2.3. Microscopic Characterization

3. Results and Discussion

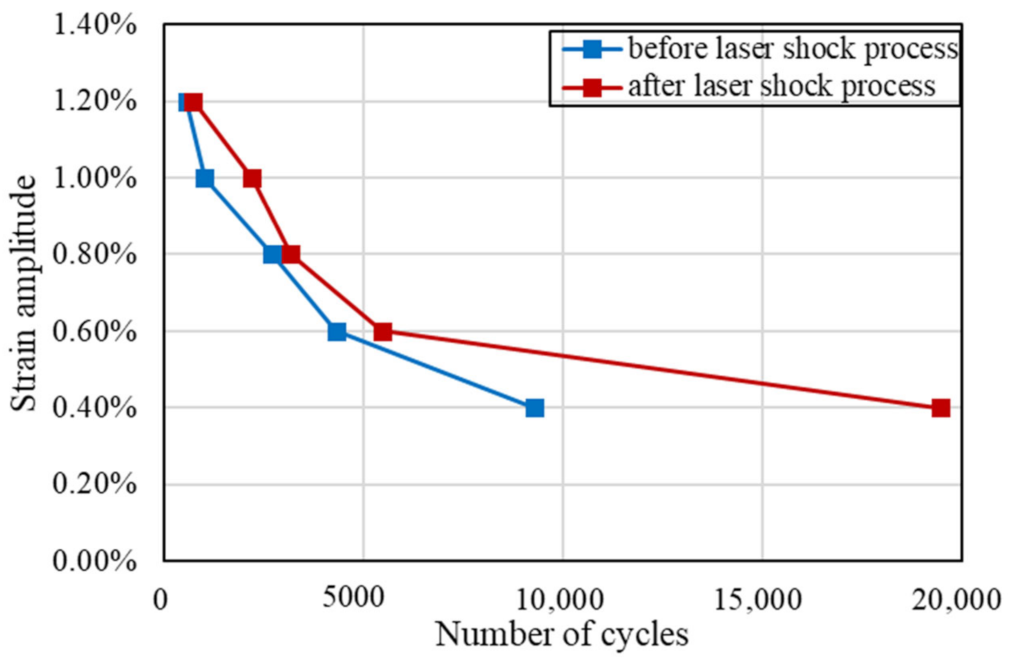

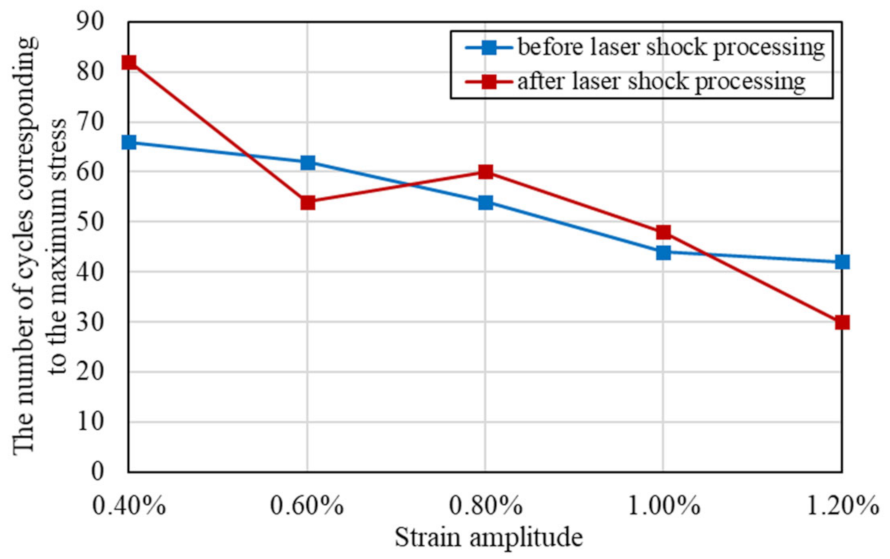

3.1. Strain Fatigue Life

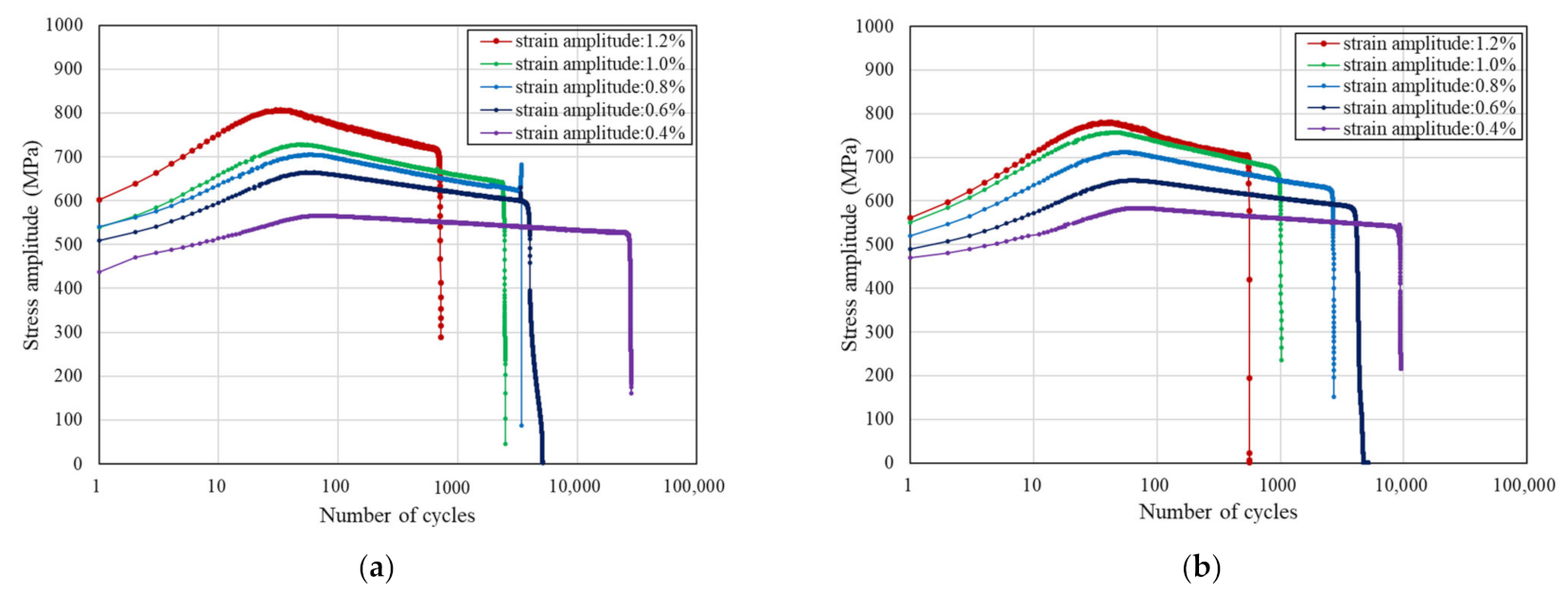

3.2. Cyclic Strain Hardening and Softening Behavior

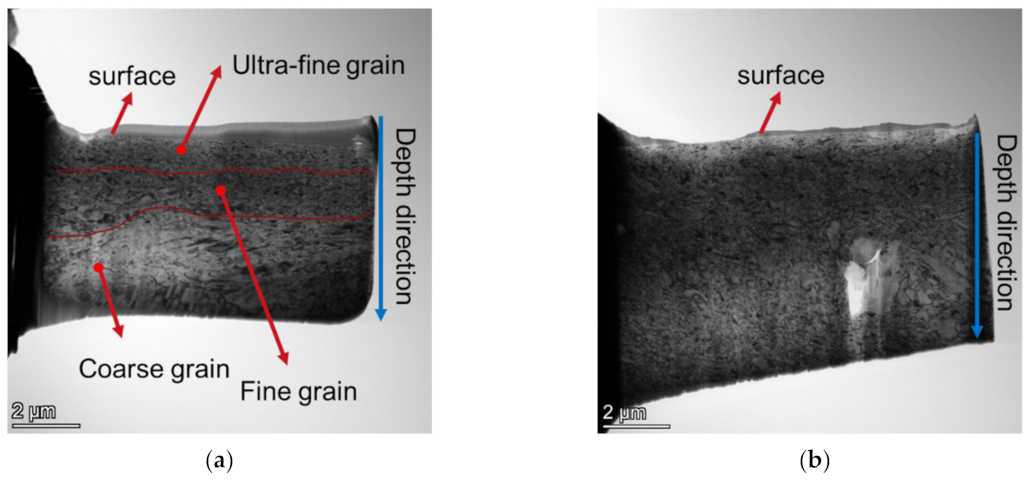

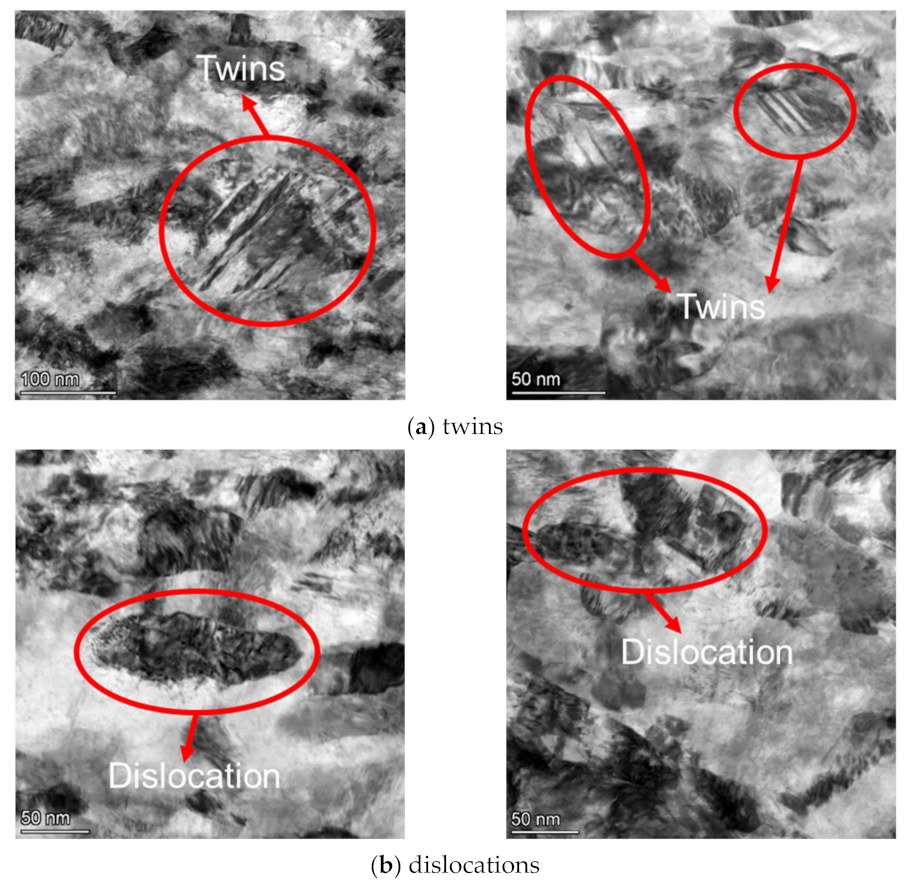

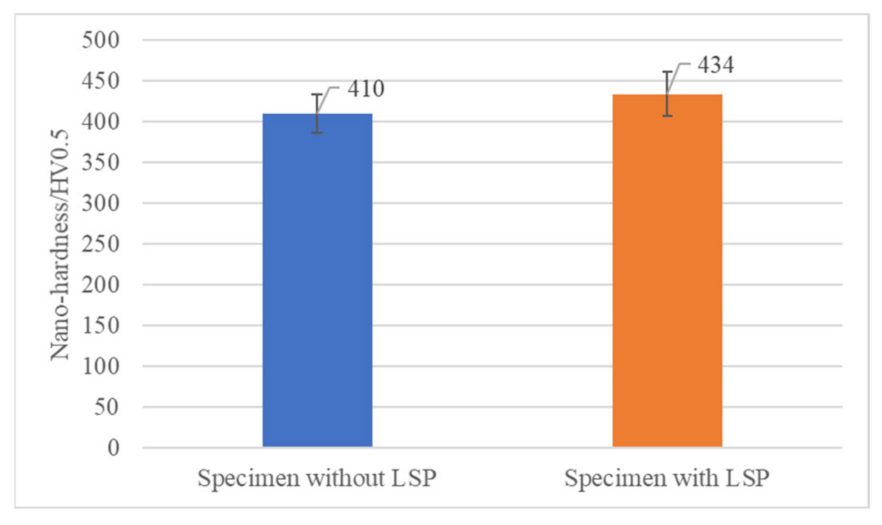

3.3. Microstructures and Hardness

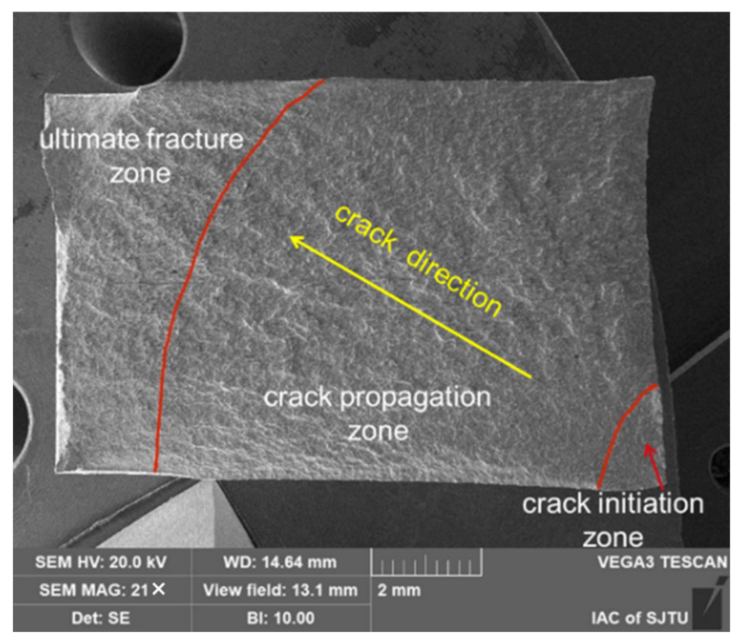

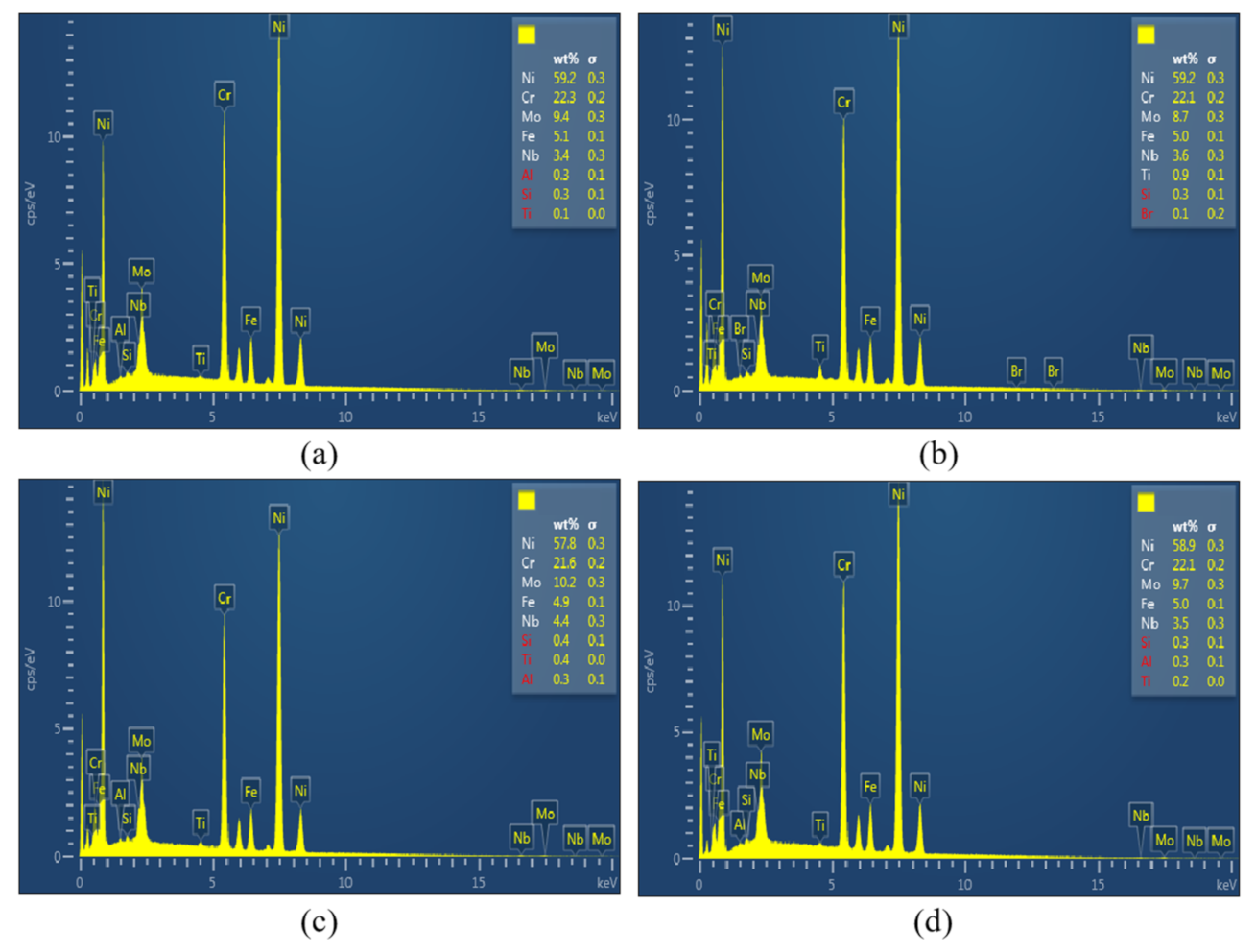

3.4. Microstructure Characterization of the Fracture

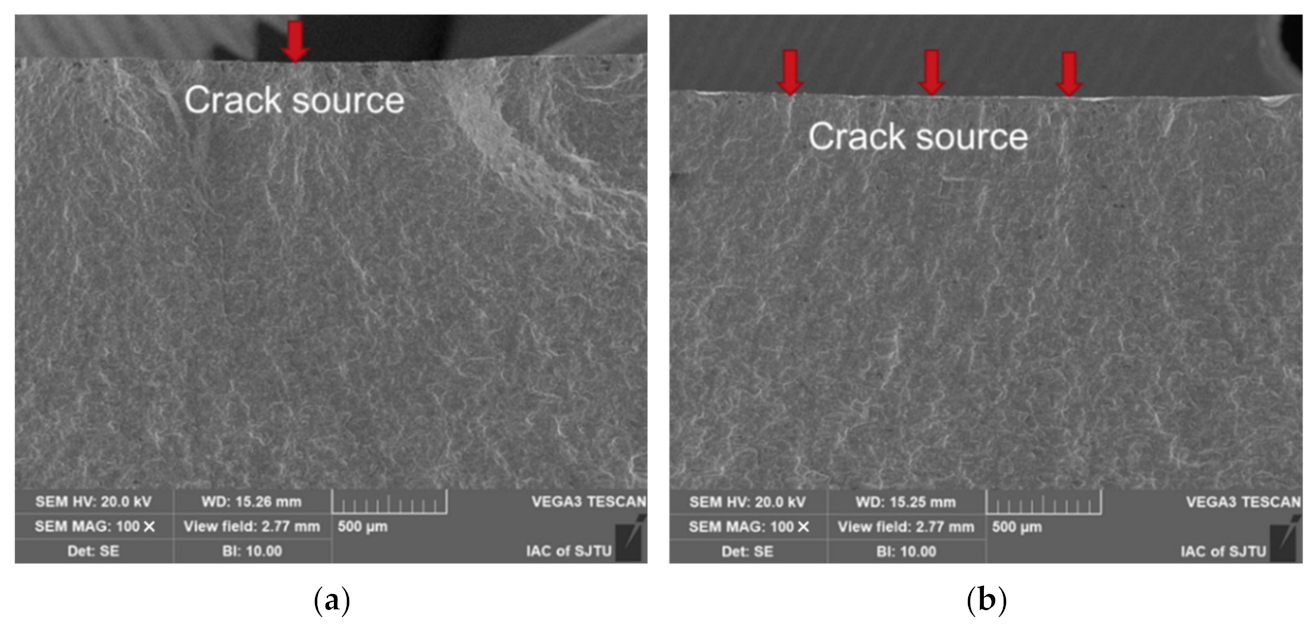

3.4.1. Crack Initiation Zone

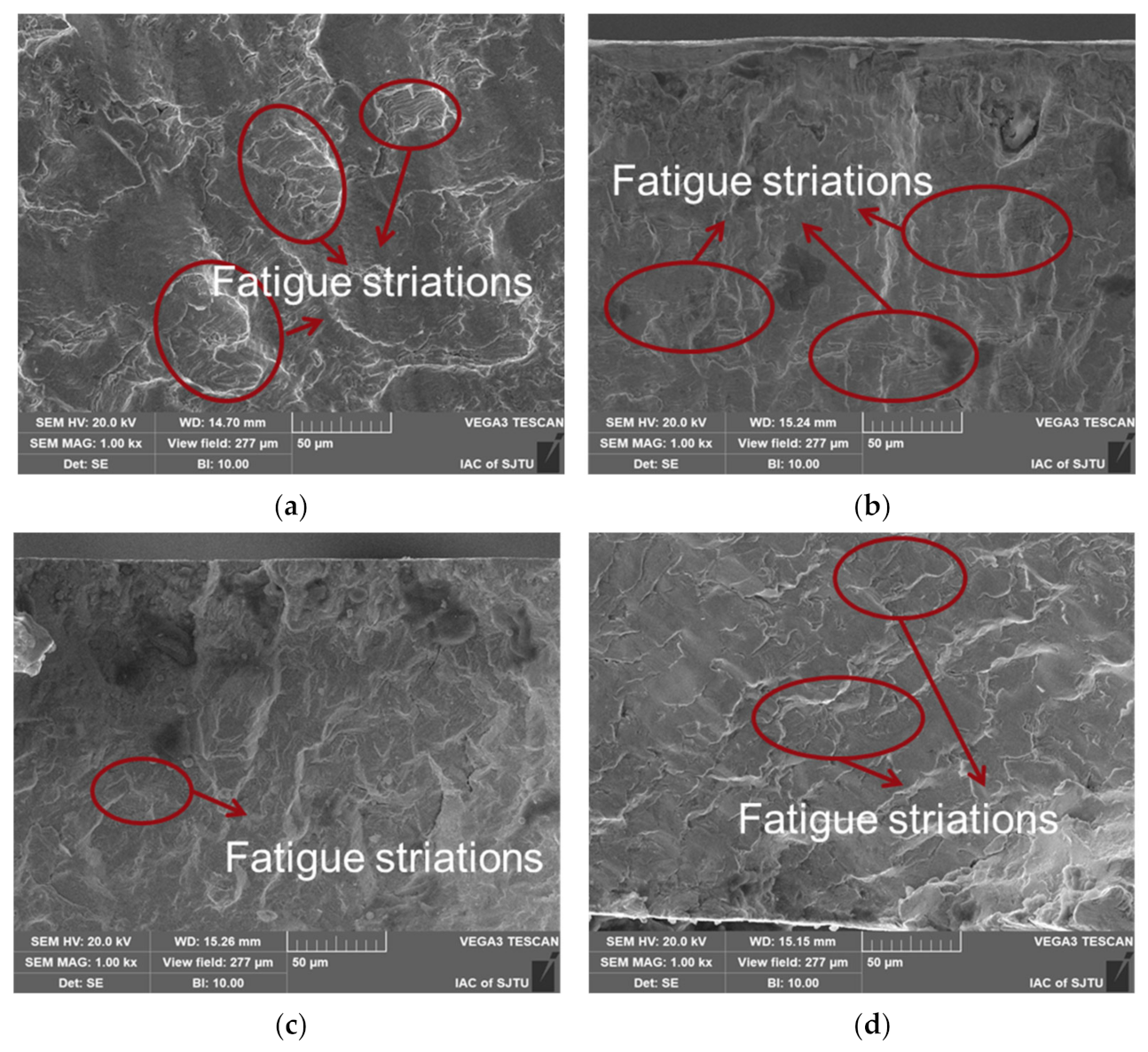

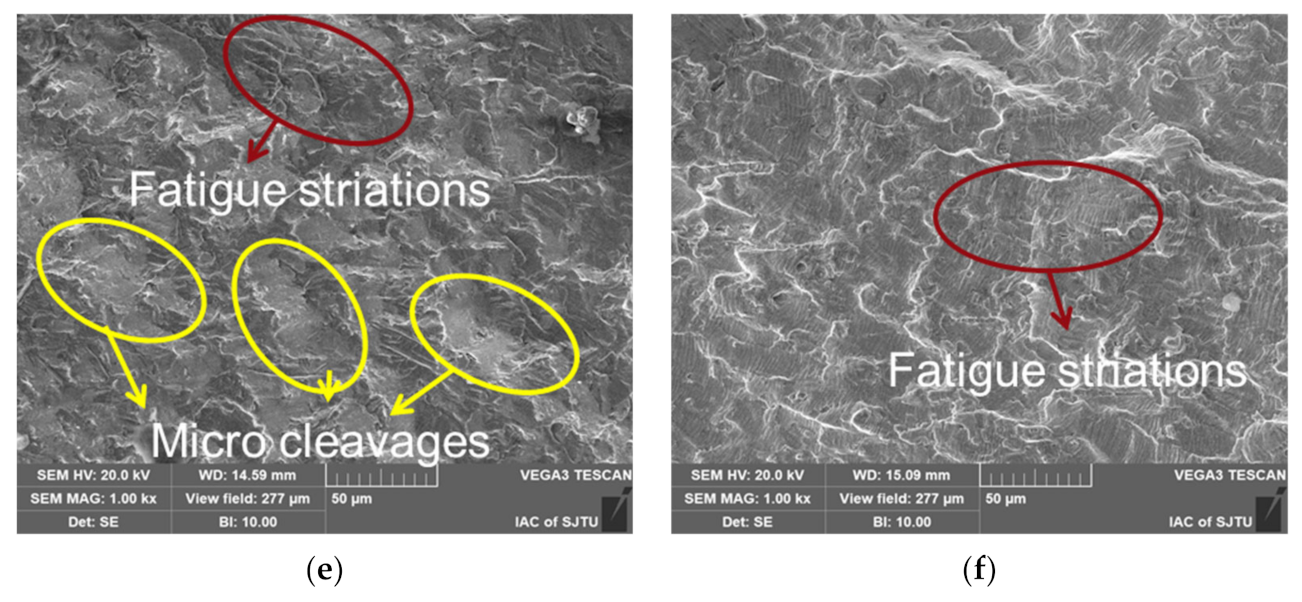

3.4.2. Crack Propagation Zone

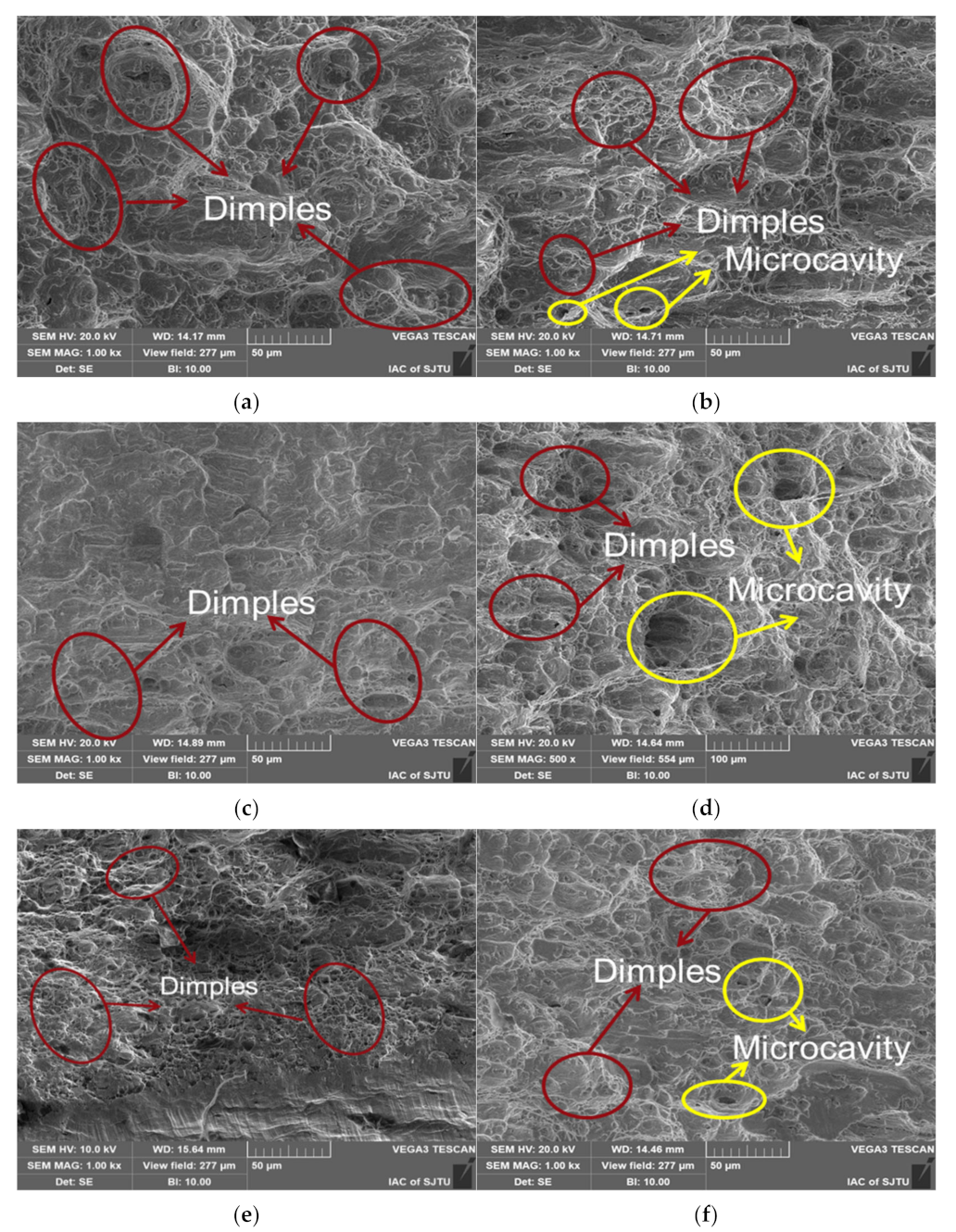

3.4.3. Ultimate Fracture Zone

4. Conclusions

- (1)

- LSP could effectively improve the low-cycle fatigue life of Inconel 625.

- (2)

- Specimens before and after LSP exhibited similar cyclic strain–stress response behavior as the primary cyclic hardening followed by long-term cyclic softening and approximate maximum cycle stress and cycle number corresponding to the maximum stress.

- (3)

- Less values of the number of crack initiations, space of fatigue striations and size of dimples or micropores contributed to the higher fatigue of the specimen after LSP.

- (4)

- After LSP, the ultra-fine grains, twins and dislocations appeared at the 1μm depth, which prevented crack initiation, crack propagation and ultimate fracture, increasing the surface’s microhardness and prolonging the fatigue life of Inconel 625.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rao, C.V.; Srinivas, N.S.; Sastry, G.V.S.; Singh, V. Low cycle fatigue, deformation and fracture behaviour of Inconel 617 alloy. Mater. Sci. Eng. A 2019, 765, 138286. [Google Scholar] [CrossRef]

- Bergs, T.; Grünebaum, T.; Fricke, K.; Barth, S.; Ganser, P. Life cycle assessment for milling of Ti- and Ni-based alloy aero engine components. Procedia CIRP 2021, 98, 625–630. [Google Scholar] [CrossRef]

- Ozaner, O.C.; Karabulut, Ş.; İzciler, M. Study of the surface integrity and mechanical properties of turbine blade fir trees manufactured in Inconel 939 using laser powder bed fusion. J. Manuf. Process. 2022, 79, 47–59. [Google Scholar] [CrossRef]

- Kliuev, M.; Wegener, K. Method of Machining Diffusors in Inconel 718 Turbine Blades for Film Cooling using EDM Drilling and Shaping. Procedia CIRP 2020, 95, 511–515. [Google Scholar] [CrossRef]

- Saberi, E.; Nakhodchi, S.; Dargahi, A.; Nikbin, K. Predicting stress and creep life in Inconel 718 blade-disk attachments. Eng. Fail. Anal. 2020, 108, 104226. [Google Scholar] [CrossRef]

- Jeong, D.H.; Choi, M.J.; Goto, M.; Lee, H.C.; Kim, S. Effect of service exposure on fatigue crack propagation of Inconel 718 turbine disc material at elevated temperatures. Mater. Charact. 2014, 95, 232–244. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, J.H.; Sa, J.W.; Lee, Y.S.; Park, C.K.; Moon, S.I. Stress rupture characteristics of Inconel 718 alloy for ramjet combustor. Mater. Sci. Eng. A 2008, 483, 262–265. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Simpson, J.A.; Wright, R.N. Low Cycle Fatigue of Alloy 617 at 850 °C and 950 °C. J. Eng. Mater. Technol. 2013, 135, 031005. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Z.; Kanouté, P.; Retraint, D. Experimental analysis and constitutive modelling of cyclic behaviour of 316L steels including hardening/softening and strain range memory effect in LCF regime. Int. J. Plast. 2018, 107, 54–78. [Google Scholar] [CrossRef]

- Li, H.; Jing, H.; Xu, L.; Zhao, L.; Han, Y.; Tang, Z.; Wang, X.; Zhang, Y. Cyclic deformation behavior of an Fe-Ni-Cr alloy at 700 °C: Microstructural evolution and cyclic hardening model. Mater. Sci. Eng. A 2019, 744, 94–111. [Google Scholar] [CrossRef]

- Li, S.; Jiang, W.; Xie, X.; Dong, Z. A Comparison of Amplitude-and Time-Dependent Cyclic Deformation Behavior for Fully-Austenite Stainless Steel 316L and Duplex Stainless Steel 2205. Materials 2021, 14, 5594. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Chen, J.; Tian, W.; Li, Y.; Jin, W. Low Cycle Fatigue Behavior of Steam Generator Tubes under Axial Loading. Materials 2018, 11, 1944. [Google Scholar] [CrossRef] [PubMed]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Trdan, U.; Porro, J.A.; Ocaña, J.L.; Grum, J. Laser shock peening without absorbent coating (LSPwC) effect on 3D surface topography and mechanical properties of 6082-T651 Al alloy. Surf. Coat. Technol. 2012, 208, 109–116. [Google Scholar] [CrossRef]

- Tan, Y.; Wu, G.; Yang, J.M.; Pan, T. Laser shock peening on fatigue crack growth behaviour of aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 649–656. [Google Scholar] [CrossRef]

- Halilovič, M.; Issa, S.; Wallin, M.; Hallberg, H.; Ristinmaa, M. Prediction of the residual state in 304 austenitic steel after laser shock peening—Effects of plastic deformation and martensitic phase transformation. Int. J. Mech. Sci. 2016, 111, 24–34. [Google Scholar] [CrossRef]

- González, J.; Bagherifard, S.; Guagliano, M. Influence of different shot peening treatments on surface state and fatigue behaviour of Al 6063 alloy. Eng. Fract. Mech. 2017, 185, 72–81. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Cui, C.Y.; Sun, G.F.; Zhou, J.Z.; Zhang, L.; You, J.; Chen, K.M.; Zhong, J.W. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts. Acta Mater. 2010, 58, 3984–3994. [Google Scholar] [CrossRef]

- Kumagai, M.; Akita, K.; Imafuku, M.; Ohya, S.I. Workhardening and the microstructural characteristics of shot- and laser-peened austenitic stainless steel. Mater. Sci. Eng. A 2014, 608, 21–24. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Milman, Y.V.; Iefimov, M.O.; Prokopenko, G.I.; Silberschmidt, V.V.; Danylenko, M.I.; Kotko, A.V. Characterization of ultrasonically peened and lasershock peened surface layers of AISI 321 stainless steel. Surf. Coat. Technol. 2008, 202, 4875–4883. [Google Scholar] [CrossRef]

- Altenberger, I.; Scholtes, B.; Martin, U.; Oettel, H. Cyclic deformation and near surface microstructures of shot peened or deep rolled austenitic stainless steel AISI 304. Mater. Sci. Eng. A 1999, 264, 1–16. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Sun, G.F.; Gu, Y.Y.; Zhou, J.Z.; Ren, X.D.; Zhang, X.C.; Zhang, L.F.; Chen, K.M.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Rozmus-Górnikowska, M.; Kusiński, J.; Cieniek, Ł. Effect of Laser Shock Peening on the Microstructure and Properties of the Inconel 625 Surface Layer. J. Mater. Eng. Perform. 2020, 29, 1544–1549. [Google Scholar] [CrossRef]

- Su, C.; Zhou, J.; Meng, X.; Huang, S. Improvement in Fatigue Performance of Aluminium Alloy Welded Joints by Laser Shock Peening in a Dynamic Strain Aging Temperature Regime. Materials 2016, 9, 799. [Google Scholar] [CrossRef] [PubMed]

- Spadaro, L.; Hereñú, S.; Strubbia, R.; Rosas, G.G.; Bolmaro, R.; González, C.R. Effects of laser shock processing and shot peening on 253 MA austenitic stainless steel and their consequences on fatigue properties. Opt. Laser Technol. 2020, 122, 105892. [Google Scholar] [CrossRef]

- Sun, R.; Huang, W.; Cao, Z.; Che, Z.; Zou, S.; Wu, J. Fatigue life extension of 42CrMo high-strength steel and its micro strengthening mechanism under laser shock peening. IOP Conf. Ser. Mater. Sci. Eng. 2020, 892, 012005. [Google Scholar] [CrossRef]

- Colin, J.; Fatemi, A.; Taheri, S. Cyclic Hardening and Fatigue Behavior of Stainless Steel 304L. J. Mater. Sci. 2010, 46, 145–154. [Google Scholar] [CrossRef]

- León-Cázares, F.D.; Monni, F.; Jackson, T.; Galindo-Nava, E.I.; Rae, C.M.F. Stress Response and Microstructural Evolution of Nickel-based Superalloys during Low Cycle Fatigue: Physics-based Modelling of Cyclic Hardening and Softening. Int. J. Plast. 2020, 128, 102682. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Kushibe, A.; Inoue, Y.; Otsuka, H.; Tsuzaki, K. Effect of Strain Amplitude on the Low-cycle Fatigue Behavior of a New Fe–15Mn–10Cr–8Ni–4Si Seismic Damping Alloy. Int. J. Fatigue 2016, 88, 132–141. [Google Scholar] [CrossRef]

- Chen, L.; Sun, Y.; Li, L.; Ren, X. Microstructural Evolution and Mechanical Properties of Selective Laser Melted a Nickel-based Superalloy after Post Treatment. Mater. Sci. Engineering. A Struct. Mater. Prop. Microstruct. Process. 2020, 792, 139649. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Effect of Temperature on Microstructure and Residual Stresses Induced by Surface Treatments in Inconel 718 SPF. Surf. Coat. Technol. 2018, 344, 93–101. [Google Scholar] [CrossRef]

- Lv, W.; Liu, Z.; Hua, Y.; Hou, X. Effects of Overlap Rate and Energy Density on Mechanical Properties of Inconel 718 by Multiple Small-spot-LSP Impacts. Mater. Res. Express 2019, 6, 66576. [Google Scholar] [CrossRef]

- Sullivan, A.M.; Crooker, T.W. A Crack-opening-displacement Technique for Crack Length Measurement in Fatigue Crack Growth Rate Testing—Development and Evaluation. Eng. Fract. Mech. 1977, 9, 159–166. [Google Scholar] [CrossRef]

- Wang, X.D.; Song, S.L.; Liu, P.; Zhu, Z.W.; Zhang, H.F.; Ren, X.C. Shear Band Deformation and Fatigue Striations during Three-point Bending Fatigue Crack Growth in Brittle Metallic Glass. J. Non-Cryst. Solids 2020, 536, 119988. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, L.J.; Sun, G.F.; Luo, K.Y.; Zhang, Y.K.; Cai, J.; Cui, C.Y.; Luo, X.M. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts. Acta Mater. 2017, 127, 252–266. [Google Scholar] [CrossRef]

- Sheng, J.; Liu, H.; Lin, Y.; Liu, K.; Zhou, G.; Wang, Y.; Agyenim-Boateng, E.; Huang, S. Micromechanism of High-temperature Fatigue Properties of Inconel 718 Nickel-based Alloy Treated by Laser Peening. J. Laser Micro Nanoeng. 2022, 17, 58–68. [Google Scholar]

- Zhang, H.; Cai, Z.; Wan, Z.; Peng, P.; Zhang, H.; Sun, R.; Che, Z.; Guo, C.; Li, B.; Guo, W. Microstructure and mechanical properties of laser shock peened 38CrSi steel. Mater. Sci. Eng. A 2020, 788, 139486. [Google Scholar] [CrossRef]

- Nie, X.; He, W.; Zang, S.; Wang, X.; Zhao, J. Effect study and application to improve high cycle fatigue resistance of TC11 titanium alloy by laser shock peening with multiple impacts. Surf. Coat. Technol. 2014, 253, 68–75. [Google Scholar] [CrossRef]

- Pandey, C.; Saini, N.; Mahapatra, M.M.; Kumar, P. Study of the Fracture Surface Morphology of Impact and Tensile Tested Cast and Forged (C&F) Grade 91 Steel at Room Temperature for Different Heat Treatment Regimes. Eng. Fail. Anal. 2017, 71, 131–147. [Google Scholar]

| Element | C | Cr | Co | Si | Mo | Mn | Ti | Al | Nb | Fe | Ni |

| Content % | 0.10 | 23 | 1.0 | 0.5 | 10.0 | 0.5 | 0.4 | 0.4 | 4.15 | 5 | balance |

| Wavelength | Pulse Width | Repetition Rate | Energy | Laser Spot Size |

|---|---|---|---|---|

| 1064 nm | 15 ns | 5 Hz | 15 J | 4 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wu, H.; Du, H.; Yao, Z. Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening. Materials 2022, 15, 7269. https://doi.org/10.3390/ma15207269

Sun Y, Wu H, Du H, Yao Z. Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening. Materials. 2022; 15(20):7269. https://doi.org/10.3390/ma15207269

Chicago/Turabian StyleSun, Yaofei, Han Wu, Haifeng Du, and Zhenqiang Yao. 2022. "Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening" Materials 15, no. 20: 7269. https://doi.org/10.3390/ma15207269

APA StyleSun, Y., Wu, H., Du, H., & Yao, Z. (2022). Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening. Materials, 15(20), 7269. https://doi.org/10.3390/ma15207269