Effect of Shale Powder on the Performance of Lightweight Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Testing Methods

2.3.1. Performance Tests

2.3.2. SEM, XRD and TG/DTG Tests

2.3.3. BET Test and Hydration Analysis

3. Result and Discussion

3.1. Effect of SP on the Performance of L-UHPC

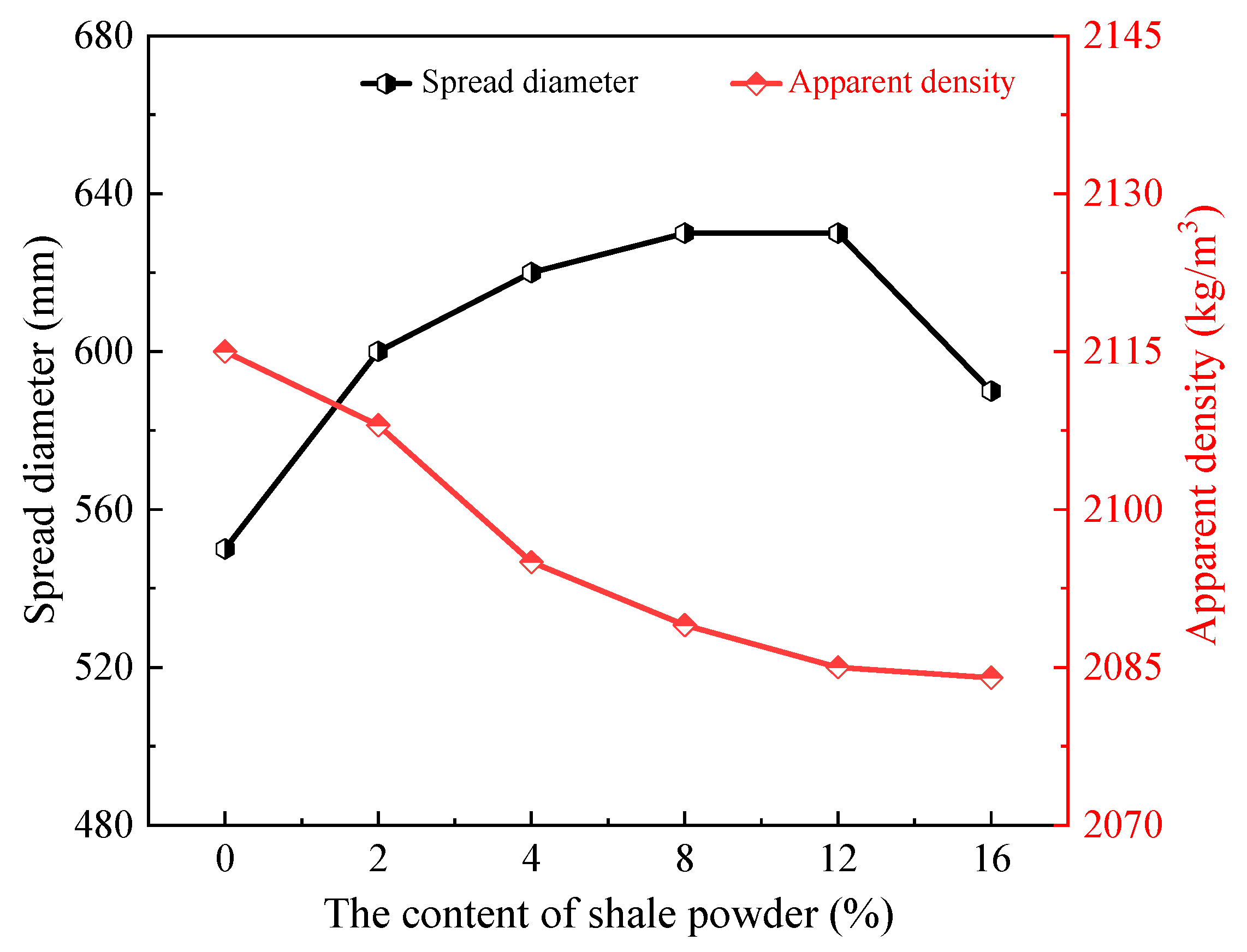

3.1.1. Spread Diameter and Apparent Density

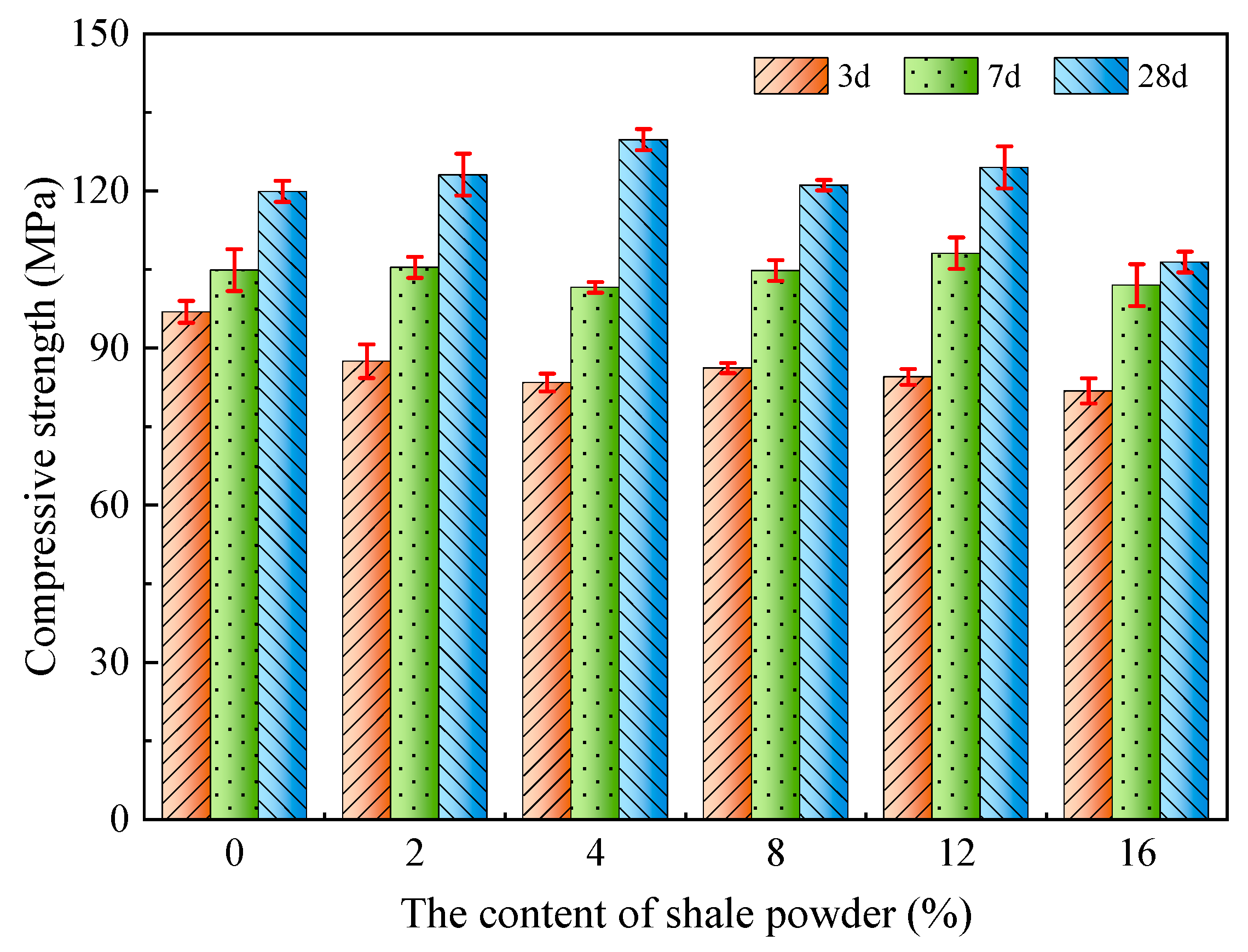

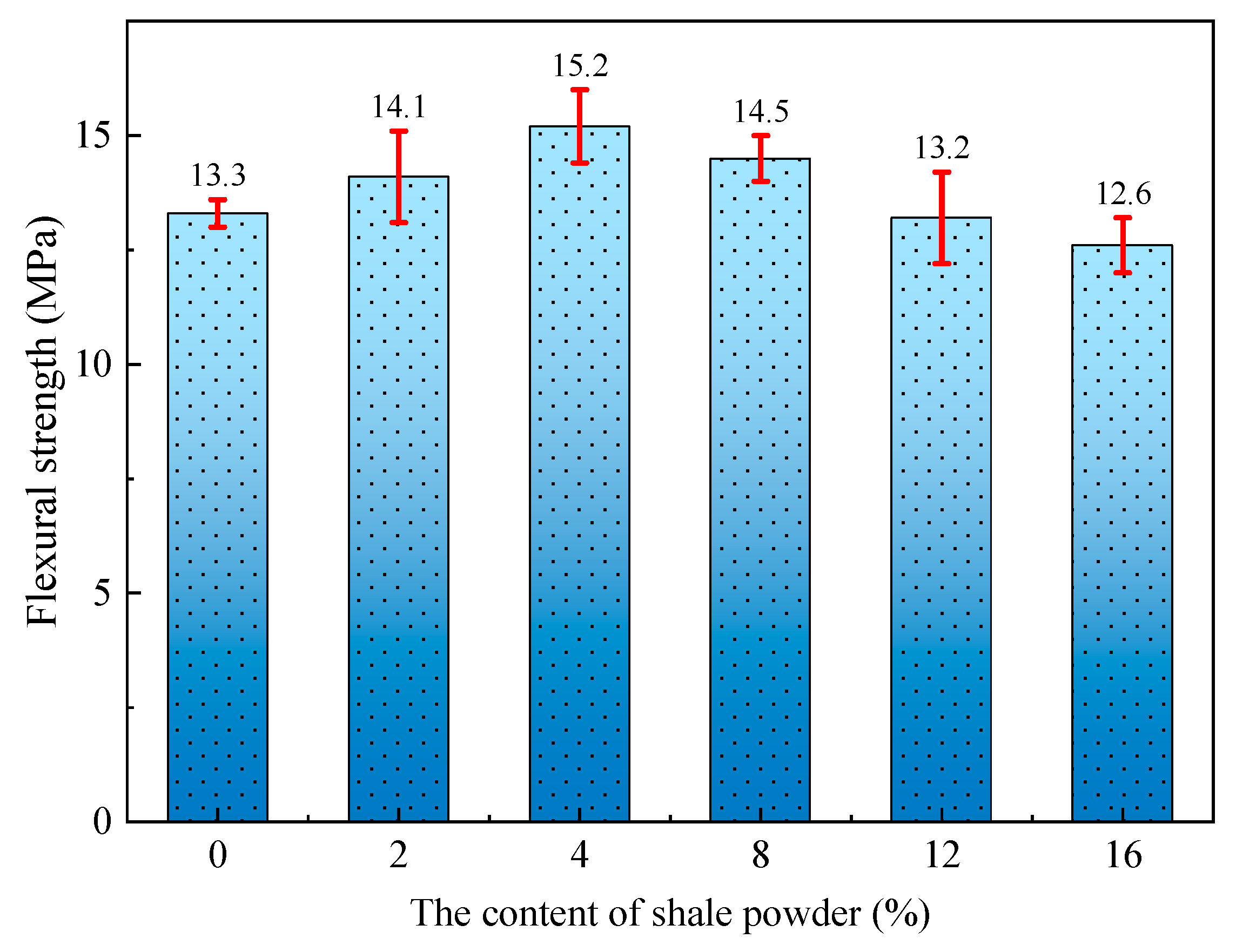

3.1.2. Mechanical Properties

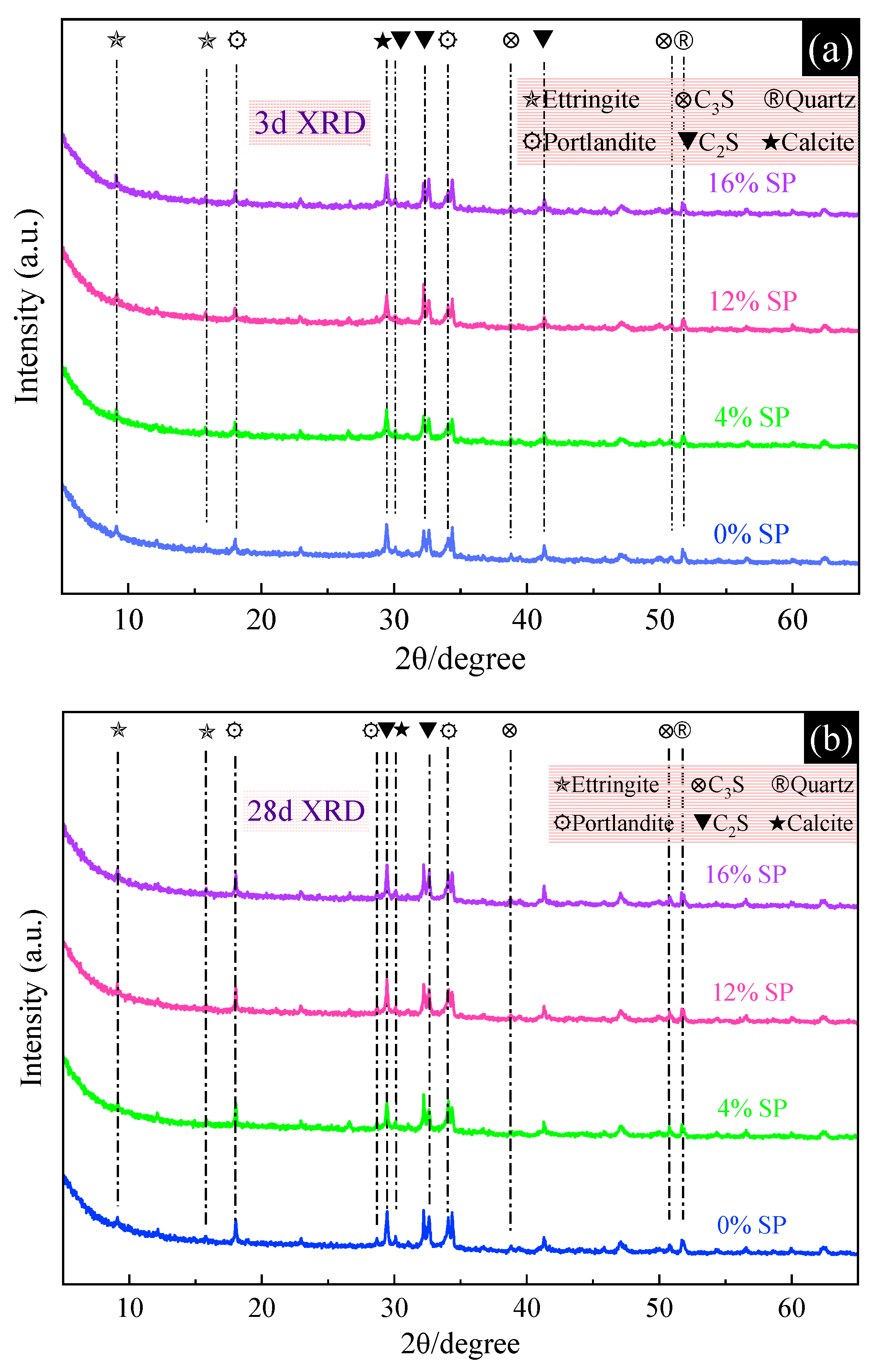

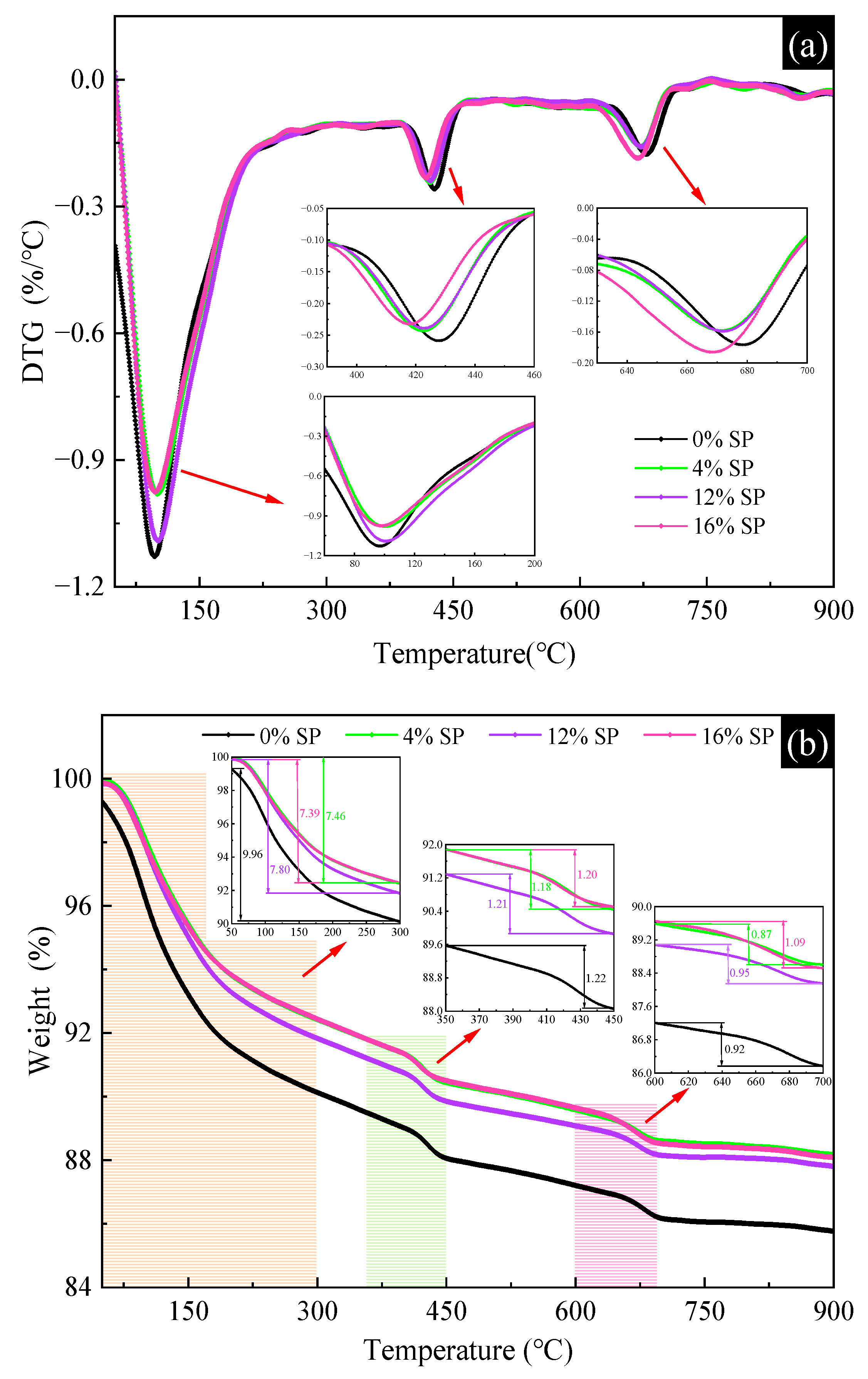

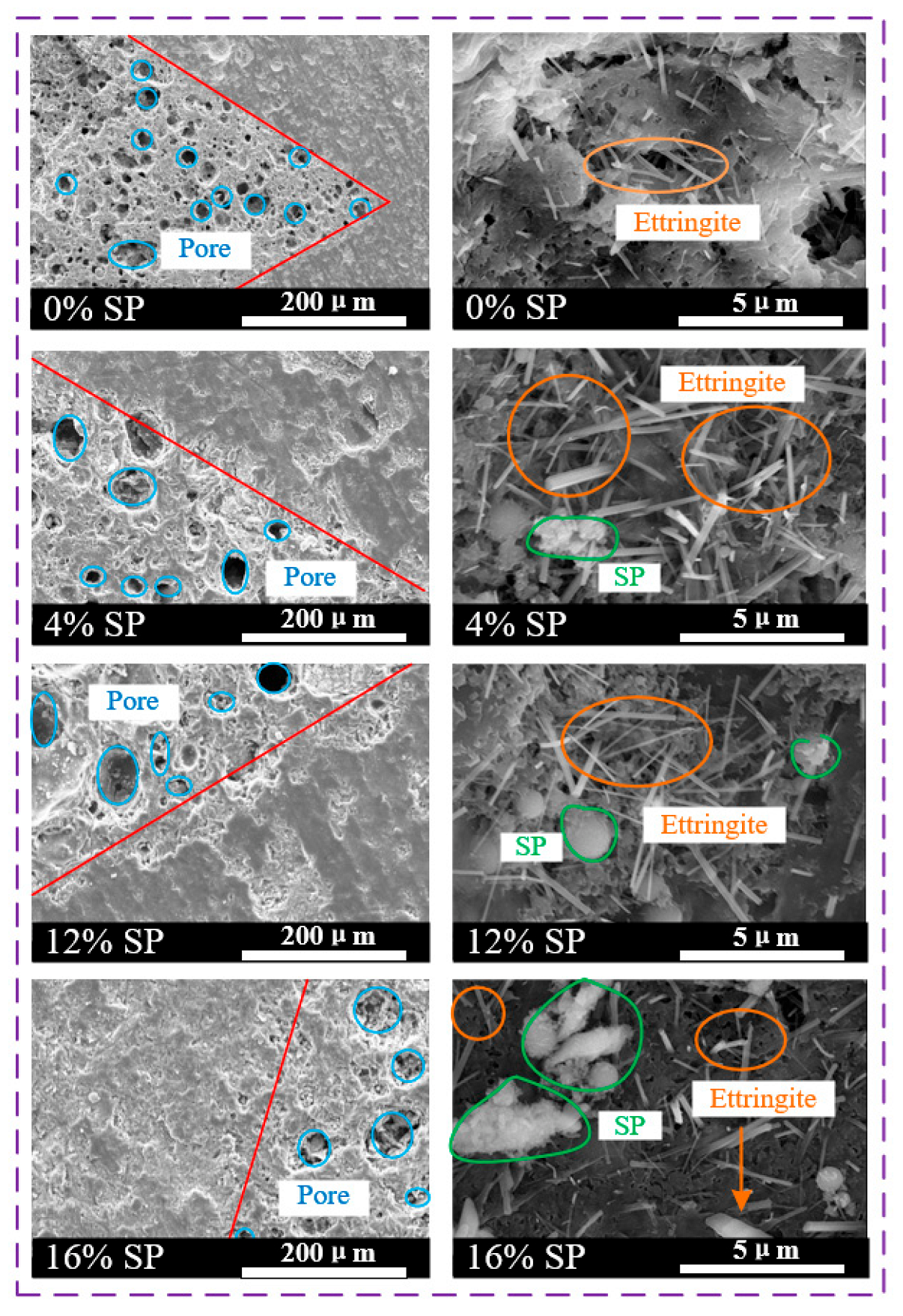

3.2. Effect of SP on the Hydration Product of L-UHPC

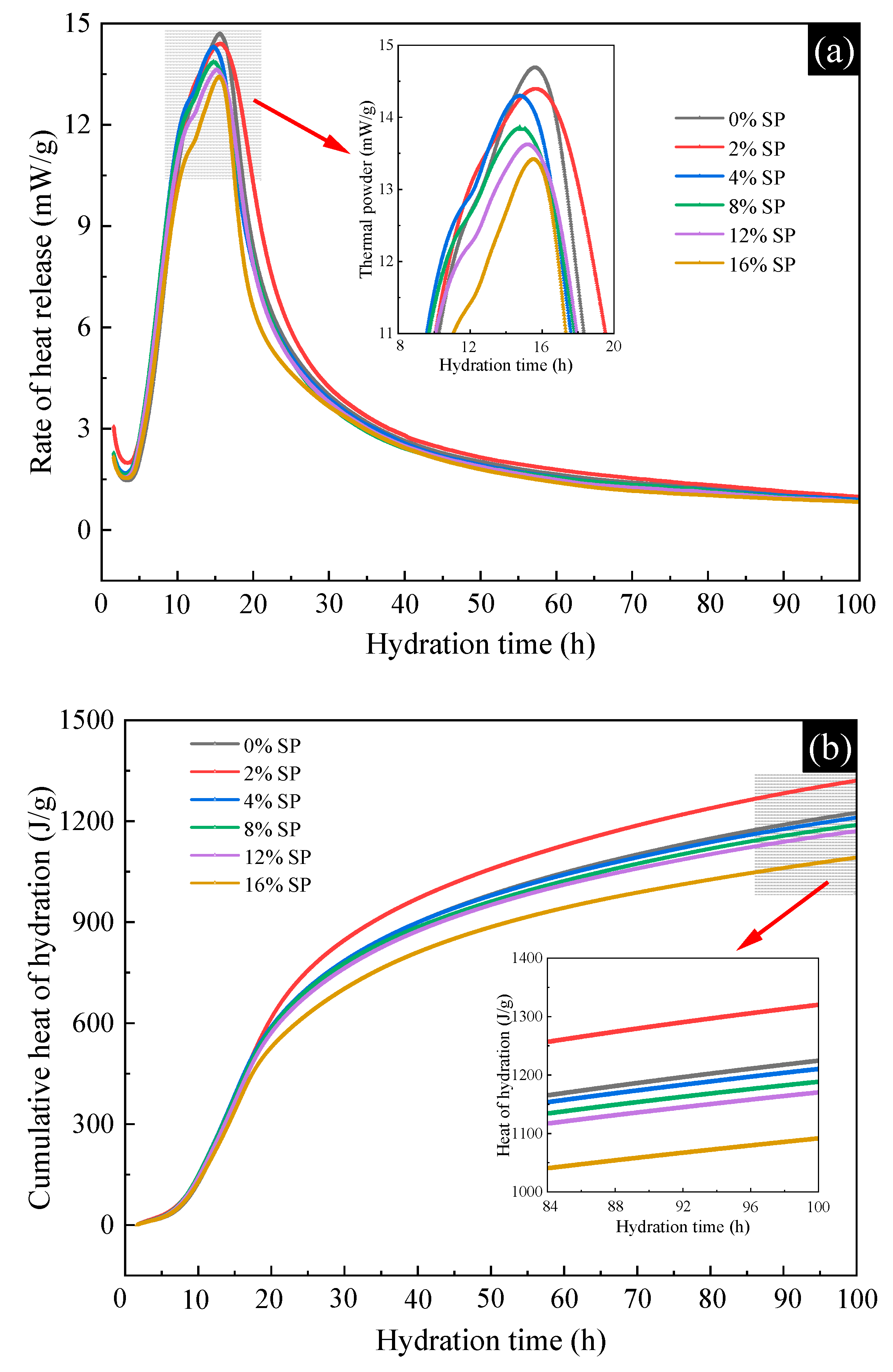

3.3. Effect of SP on the Exothermic Hydration of L-UHPC

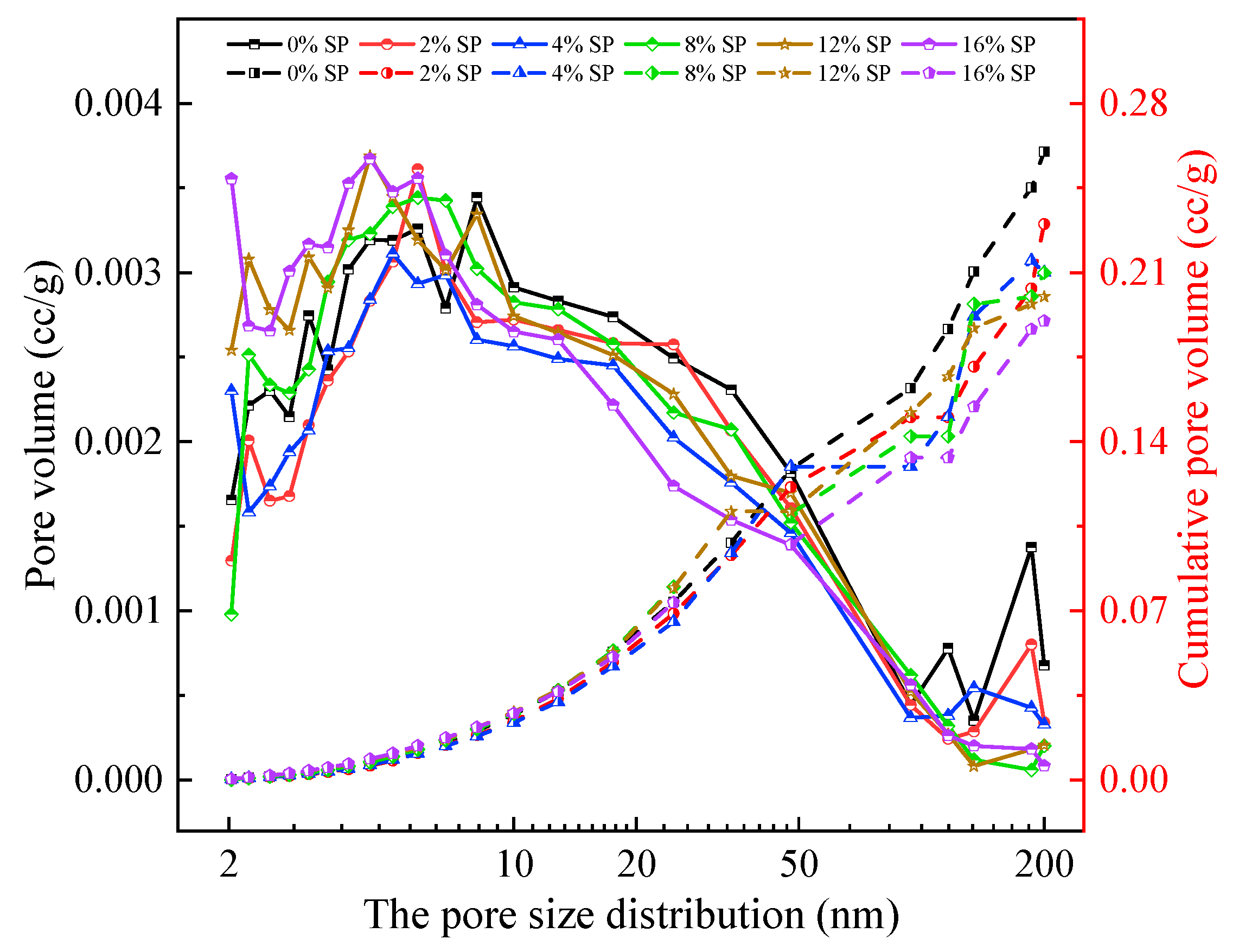

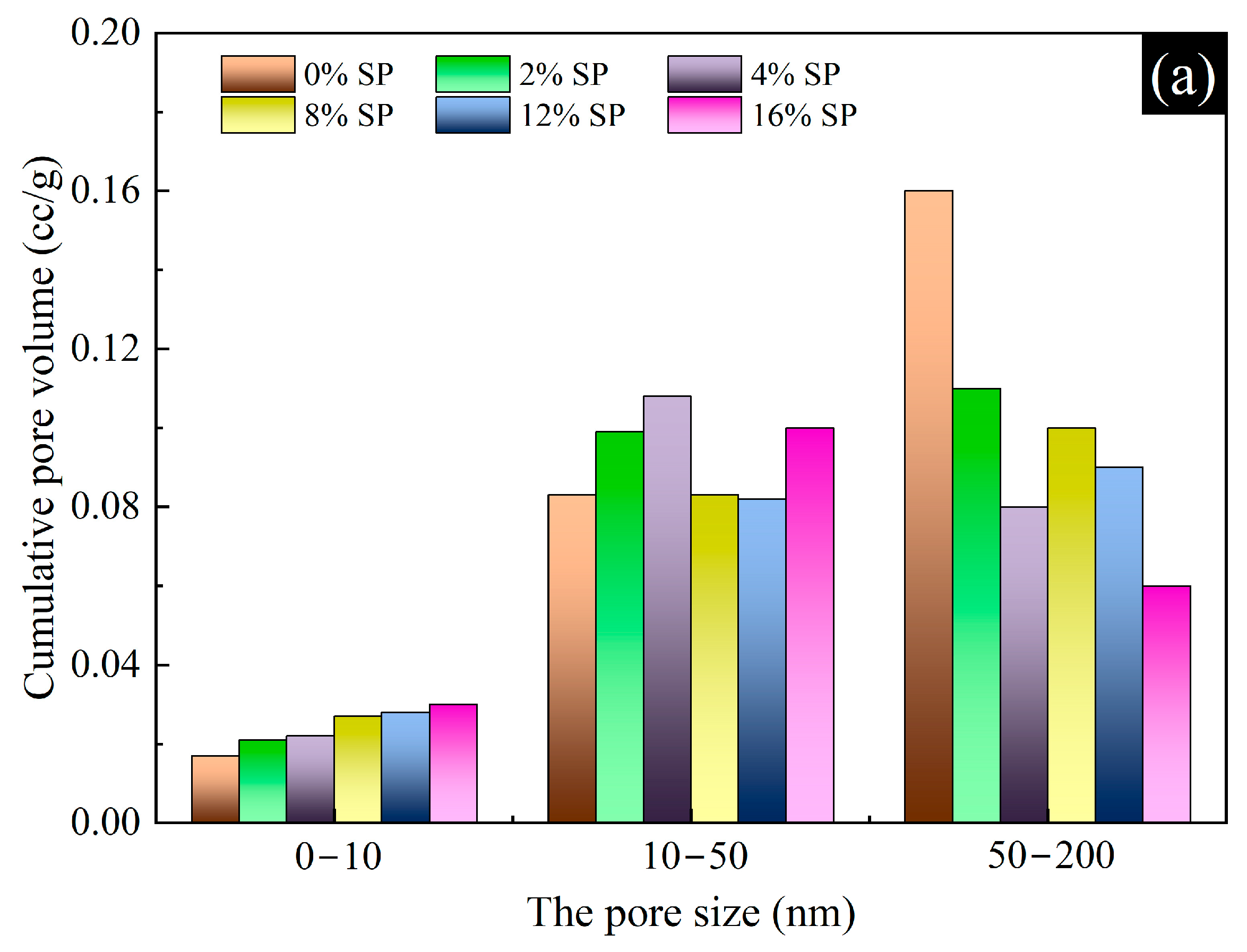

3.4. Effect of SP on the Pore Structure of L-UHPC

4. Discussion

5. Conclusions

- (a)

- With the increase in SP content, the spread diameter of L-UHPC first increased and then decreased, and the apparent density gradually decreased. The spread diameter and apparent density of L-UHPC were 630 mm and 2085 kg/m3, respectively, when the amount of SP was 12%.

- (b)

- Compared with L-UHPC without SP, the 3d compressive strength of L-UHPC mixed with SP became smaller. The 7d compressive strength did not change significantly, and the overall fluctuation range was between 2.8% and 3.1%. Both 28d flexural strength and 28d compressive strength showed a trend of increasing and then decreasing with the increase in SP amount. When the SP content was 4%, the 28d flexural and compressive strengths of L-UHPC reached the maximum value, which was 15.2 and 129.8 MPa, respectively.

- (c)

- With the increase in SP content, the peak strength of portlandite in the hydration products of L-UHPC gradually decreased. At the same time, the pores near the interface transition zone were significantly fewer and the pore structure was denser.

- (d)

- The addition of SP decreased the exothermic heat of hydration, delayed the hydration process, and reduced the exothermic rate of cement in the initial hydration. However, the moderate amount of SP had less effect on the exothermic hydration of L-UHPC.

- (e)

- The incorporation of SP optimized the pore size distribution and reduced the total pore volume in L-UHPC. The filling effect of a moderate amount of SP could effectively reduce the volume of harmful pores (50~200 nm) in L-UHPC. However, excessive dosing of SP made the cement content decrease, causing the volume of harmless pores (0~10 nm) in L-UHPC to decrease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, J.X.; Shen, P.L.; Ali, H.A.; Poon, C.S. Mix design and performance of lightweight ultra high-performance concrete. Mater. Des. 2022, 216, 110553. [Google Scholar] [CrossRef]

- Bajaber, M.A.; Hakeem, I.Y. Uhpc evolution, development, and utilization in construction: A review. J. Mater. Res. Technol. 2021, 10, 1058–1074. [Google Scholar] [CrossRef]

- Qiu, L.S.; Dong, S.F.; Yu, X.; Han, B.G. Self-sensing ultra-high performance concrete for in-situ monitoring. Sens. Actuat. A-Phys. 2021, 331, 113049. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Huang, J.; Fu, C.Q.; Huang, L.; Ye, H.L. Characterization of steel reinforcement corrosion in concrete using 3D laser scanning techniques. Constr. Build. Mater. 2021, 270, 121402. [Google Scholar] [CrossRef]

- Fu, C.Q.; Fang, D.M.; Ye, H.L.; Huang, L.; Wang, J.D. Bond degradation of non-uniformly corroded steel rebars in concrete. Eng. Struct. 2021, 226, 111392. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.H.; Gao, X.; Xiao, X.G.; Zhang, X.B.; Wang, Y.Y.; He, Y.J. Low carbon design of an ultra-high performance concrete (Uhpc) incorporating phosphorous slag. J. Clean. Prod. 2019, 240, 118157. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-uhpfrc. Mater Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Wang, X.P.; Yu, R.; Shui, Z.H.; Zhao, Z.; Song, Q.L.; Yang, B.; Fan, D.Q. Development of a novel cleaner construction product: Ultra-high performance concrete incorporating lead-zinc tailings. J. Clean. Prod. 2018, 196, 172–182. [Google Scholar] [CrossRef]

- Rangaraju, P.R.; Li, Z.Q. Development of UHPC using ternary blends of ultra-fine class F fly ash, meta-kaolin and portland cement. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: New York, NY, USA, 2016; Volume 1. [Google Scholar]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: Mew sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Liu, S.H.; Kong, Y.N.; Wang, L. A comparison of hydration properties of cement–low quality fly ash binder and cement–limestone powder binder. J. Therm. Anal. Calorim. 2014, 116, 937–943. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (scms) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Jing, R.; Liu, Y.; Yan, P.Y. Uncovering the effect of fly ash cenospheres on the macroscopic properties and microstructure of ultra high-performance concrete (Uhpc). Constr. Build. Mater. 2021, 286, 122977. [Google Scholar] [CrossRef]

- Chen, T.F.; Gao, X.J.; Ren, M. Effects of autoclave curing and fly ash on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2018, 158, 864–872. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Gu, C.P.; Ji, Y.J.; Yao, J.K.; Yang, Y.; Liu, J.T.; Ni, T.Y.; Zhou, H.J.; Tong, Y.Y.; Zhang, X.F. Feasibility of recycling sewage sludge ash in ultra-high performance concrete: Volume deformation, microstructure and ecological evaluation. Constr. Build. Mater. 2022, 318, 125823. [Google Scholar] [CrossRef]

- Lu, J.X.; Ali, H.A.; Jiang, Y.; Guan, X.W.; Shen, P.L.; Chen, P.Y.; Poon, C.S. A novel high-performance lightweight concrete prepared with glass-uhpc and lightweight microspheres: Towards energy conservation in buildings. Compos. Part B Eng. 2022, 247, 110295. [Google Scholar] [CrossRef]

- Abbasi, S.; Jannaty, M.H.; Faraj, R.H.; Shahbazpanahi, S.; Mosavi, A. The effect of incorporating silica stone waste on the mechanical properties of sustainable concretes. Materials 2020, 13, 3832. [Google Scholar] [CrossRef]

- Alajarmeh, O.; Zeng, X.S.; Aravinthan, T.; Shelley, T.; Alhawamdeh, M.; Mohammed, A.; Nicol, L.; Vedernikov, A.; Safonov, A.; Schubel, P. Compressive behaviour of hollow box pultruded frp columns with continuous-wound fibres. Thin-Walled Struct. 2021, 168, 108300. [Google Scholar] [CrossRef]

- Vedernikov, A.N.; Safonov, A.A.; Gusev, S.A.; Carlone, P.; Tucci, F.; Akhatov, I.S. Spring-in experimental evaluation of L-Shaped pultruded profiles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 747, 12013. [Google Scholar] [CrossRef]

- Qian, D.; Yu, R.; Shui, Z.H.; Sun, Y.; Jiang, C.Y.; Zhou, F.J.; Ding, M.X.; Tong, X.S.; He, Y.J. A novel development of green ultra-high performance concrete (Uhpc) based on appropriate application of recycled cementitious material. J. Clean. Prod. 2020, 261, 121231. [Google Scholar] [CrossRef]

- Shen, P.L.; Zheng, H.B.; Xuan, D.X.; Lu, J.X.; Poon, C.S. Feasible use of municipal solid waste incineration bottom ash in ultra-high performance concrete. Cem. Concr. Compos. 2020, 114, 103814. [Google Scholar] [CrossRef]

- Chang, Z.Y.; Long, G.C.; Xie, Y.J.; Zhou, J.L. Recycling sewage sludge ash and limestone for sustainable cementitious material production. J. Build. Eng. 2022, 49, 104035. [Google Scholar] [CrossRef]

- Chen, J.J.; Li, B.H.; Ng, P.L.; Kwan, A.K.H. Adding granite polishing waste to reduce sand and cement contents and improve performance of mortar. J. Clean. Prod. 2021, 279, 123653. [Google Scholar] [CrossRef]

- Snellings, R.; Mertens, G.; Adriaens, R.; Elsen, J. In situ synchrotron X-ray powder diffraction study of the early age hydration of cements blended with zeolitite and quartzite fines and water-reducing agent. Appl. Clay Sci. 2013, 72, 124–131. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Afshinnia, K.; Rangaraju, P.R. Efficiency of ground glass fiber as a cementitious material, in mitigation of alkali-silica reaction of glass aggregates in mortars and concrete. J. Build. Eng. 2018, 15, 171–180. [Google Scholar] [CrossRef]

- Park, S.; Wu, S.Y.; Liu, Z.C.; Pyo, S. The role of supplementary cementitious materials (SCMs) in ultra high performance concrete (UHPC): A review. Materials 2021, 14, 1472. [Google Scholar] [CrossRef]

- Ling, G.; Shui, Z.; Gao, X.; Sun, T.; Yu, R.; Li, X.S. Utilizing iron ore tailing as cementitious material for eco-friendly design of ultra-high performance concrete (Uhpc). Materials 2021, 14, 1829. [Google Scholar] [CrossRef]

- Sufian, M.; Ullah, S.; Ostrowski, K.A.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A.A. An experimental and empirical study on the use of waste marble powder in construction material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef]

- Zheng, S.Y.; Liang, J.L.; Hu, Y.J.; Wei, D.Y.; Lan, Y.F.; Du, H.L.; Rong, H.L. An experimental study on compressive properties of concrete with manufactured sand using different stone powder content. Ferroelectrics 2021, 579, 189–198. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A.; Poon, C.S. Heat of hydration of portland high-calcium fly ash cement incorporating limestone powder: Effect of limestone particle size. Constr. Build. Mater. 2014, 66, 410–417. [Google Scholar] [CrossRef]

- Knop, Y.; Peled, A.; Cohen, R. Influences of limestone particle size distributions and contents on blended cement properties. Constr. Build. Mater. 2014, 71, 26–34. [Google Scholar] [CrossRef]

- Mashaly, A.O.; Shalaby, B.N.; Rashwan, M.A. Performance of mortar and concrete incorporating granite sludge as cement replacement. Constr. Build. Mater. 2018, 169, 800–818. [Google Scholar] [CrossRef]

- Xiong, Z.Q.; Wang, P.; Wang, Y.L. Hydration behaviors of portland cement with different lithologic stone powders. Int. J. Concr. Struct. Mater. 2015, 9, 55–60. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Standard Press: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Standard Press: Beijing, China, 2016.

- Clark, B.A.; Brown, P.W. The formation of calcium sulfoaluminate hydrate compounds: Part II. Cem. Concr. Res. 2000, 30, 233–240. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A. Cement Replacement Materials; Springer: Berlin/Heidelberg, Germany, 2014; pp. 299–323. [Google Scholar]

- Kakali, G.; Tsivilis, S.; Aggeli, E.; Bati, M. Hydration products of C3A, C3S and portland cement in the presence of CaCO3. Cem. Concr. Res. 2000, 30, 1073–1077. [Google Scholar] [CrossRef]

- Bai, M.; Long, G.C.; Wang, F. Properties and microstructural characteristics of manganese tailing sand concrete. Materials 2022, 15, 5583. [Google Scholar] [CrossRef]

- Qian, J.S.; Yu, J.C.; Sun, H.Q.; Ma, Y. Formation and function of ettringite in cement hydrates. J. Chin. Ceram. Soc. 2017, 45, 1569–1581. [Google Scholar] [CrossRef]

- Knapen, E.; Van Gemert, D. Cement hydration and microstructure formation in the presence of water-soluble polymers. Cem. Concr. Res. 2009, 39, 6–13. [Google Scholar] [CrossRef]

- Esteves, L.P. On the hydration of water-entrained cement-silica systems: Combined SEM, XRD and thermal analysis in cement pastes. Thermochim. Acta 2011, 518, 27–35. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F.; Arteaga, A. Determination of kinetic equations of alkaline activation of blast furnace slag by means of calorimetric data. J. Therm. Anal. Calorim. 1998, 52, 945–955. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | TiO2 | |

|---|---|---|---|---|---|---|---|---|---|

| C | 19.83 | 4.38 | 3.27 | 64.08 | 1.25 | 2.21 | 0.84 | 0.16 | 0.25 |

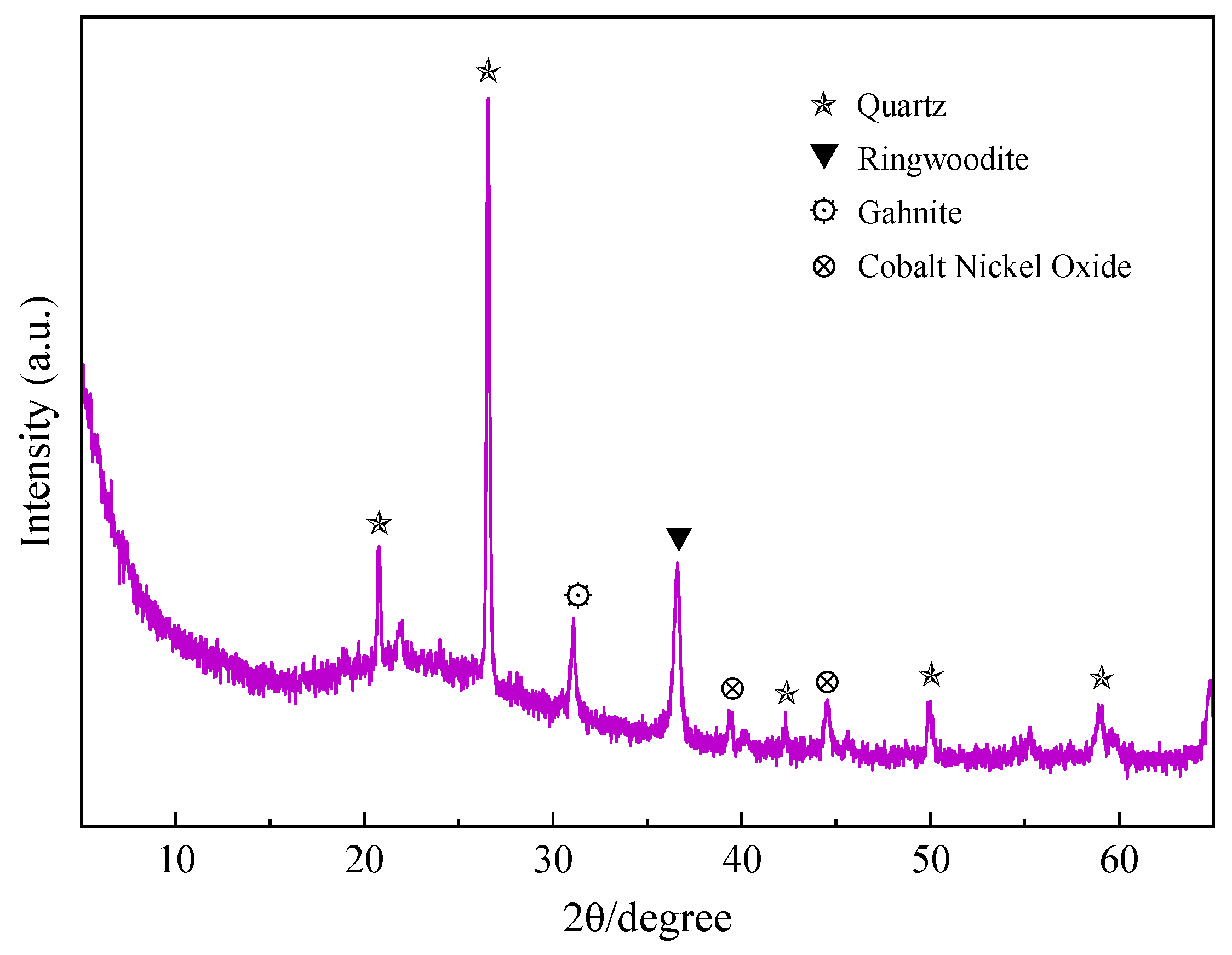

| SP | 61.9 | 19.7 | 7.04 | 0.87 | 0 | 0.18 | 5.14 | 1.32 | 0 |

| FA | 62.6 | 19.71 | 3.72 | 6.28 | 0.97 | 0.13 | 1.36 | 1.22 | 0.67 |

| SF | 93.05 | 0.48 | 0.13 | 0.79 | 0.33 | 0.75 | 0.14 | 0.07 | 0 |

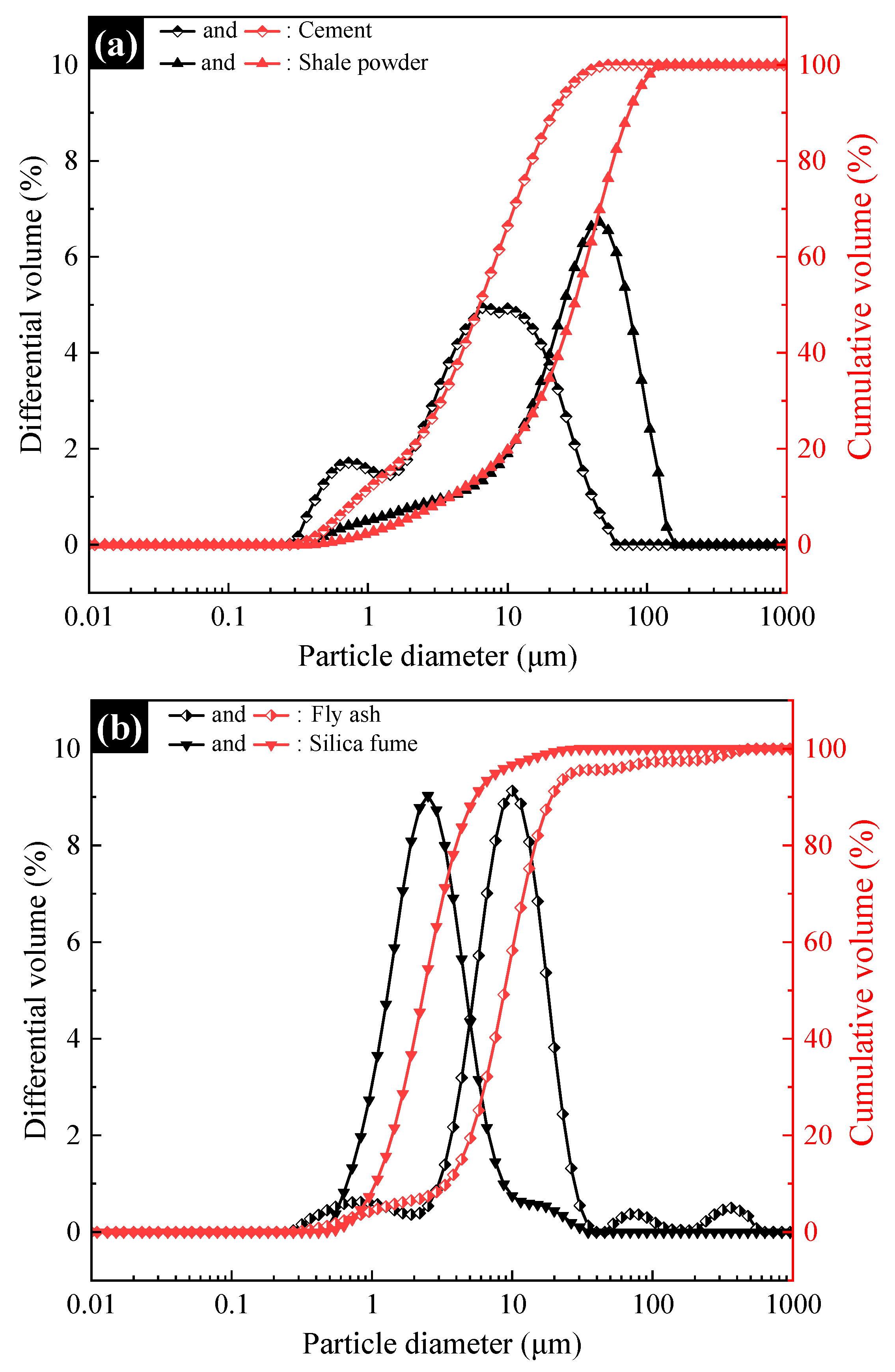

| Specific Surface Area | D50 | |

|---|---|---|

| C | 0.36 | 6.304 |

| SP | 0.21 | 28.02 |

| FA | 0.56 | 8.83 |

| SF | 24.52 | 2.35 |

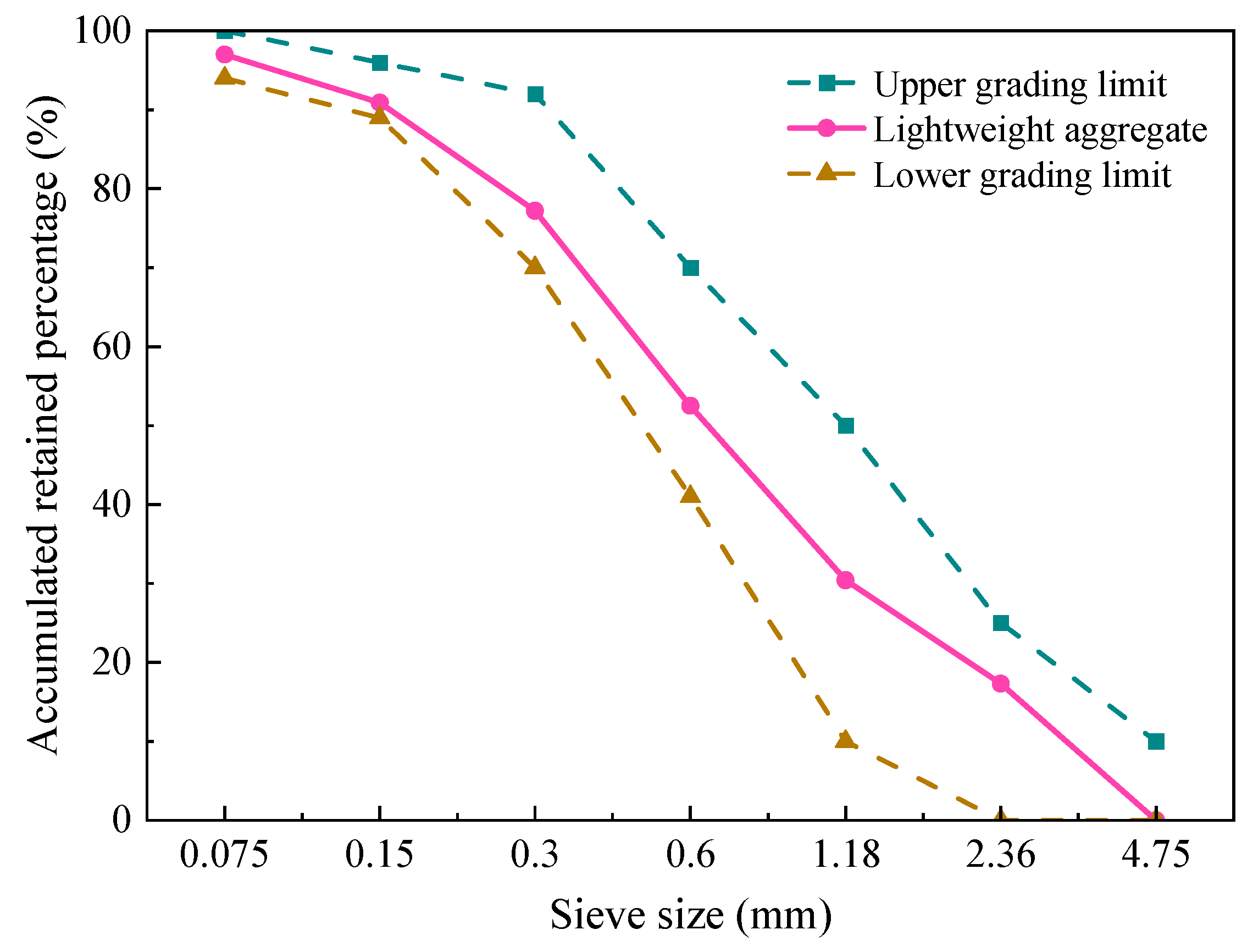

| Stone Powder/% | Water Absorption/% | Cylinder Compressive Strength/MPa | Bulk Density/kg·m−3 | Apparent Density/kg·m−3 | |

|---|---|---|---|---|---|

| LWA | 2.6 | 10.2 | 6.4 | 740 | 1320 |

| Sample No. | C (kg/m3) | SP (kg/m3) | FA (kg/m3) | SF (kg/m3) | LWA (kg/m3) | W (kg/m3) | Steel Fiber (%) | SP Content (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 852 | 0 | 180 | 168 | 660 | 204 | 2.0 | 0 |

| 2 | 835 | 17 | 180 | 168 | 660 | 204 | 2.0 | 2 |

| 3 | 818 | 34 | 180 | 168 | 660 | 204 | 2.0 | 4 |

| 4 | 784 | 68 | 180 | 168 | 660 | 204 | 2.0 | 8 |

| 5 | 750 | 102 | 180 | 168 | 660 | 204 | 2.0 | 12 |

| 6 | 716 | 136 | 180 | 168 | 660 | 204 | 2.0 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, K.; Ding, Q. Effect of Shale Powder on the Performance of Lightweight Ultra-High-Performance Concrete. Materials 2022, 15, 7225. https://doi.org/10.3390/ma15207225

Guo K, Ding Q. Effect of Shale Powder on the Performance of Lightweight Ultra-High-Performance Concrete. Materials. 2022; 15(20):7225. https://doi.org/10.3390/ma15207225

Chicago/Turabian StyleGuo, Kaizheng, and Qingjun Ding. 2022. "Effect of Shale Powder on the Performance of Lightweight Ultra-High-Performance Concrete" Materials 15, no. 20: 7225. https://doi.org/10.3390/ma15207225

APA StyleGuo, K., & Ding, Q. (2022). Effect of Shale Powder on the Performance of Lightweight Ultra-High-Performance Concrete. Materials, 15(20), 7225. https://doi.org/10.3390/ma15207225