Roadmap: Numerical-Experimental Investigation and Optimization of 3D-Printed Parts Using Response Surface Methodology

Abstract

1. Introduction

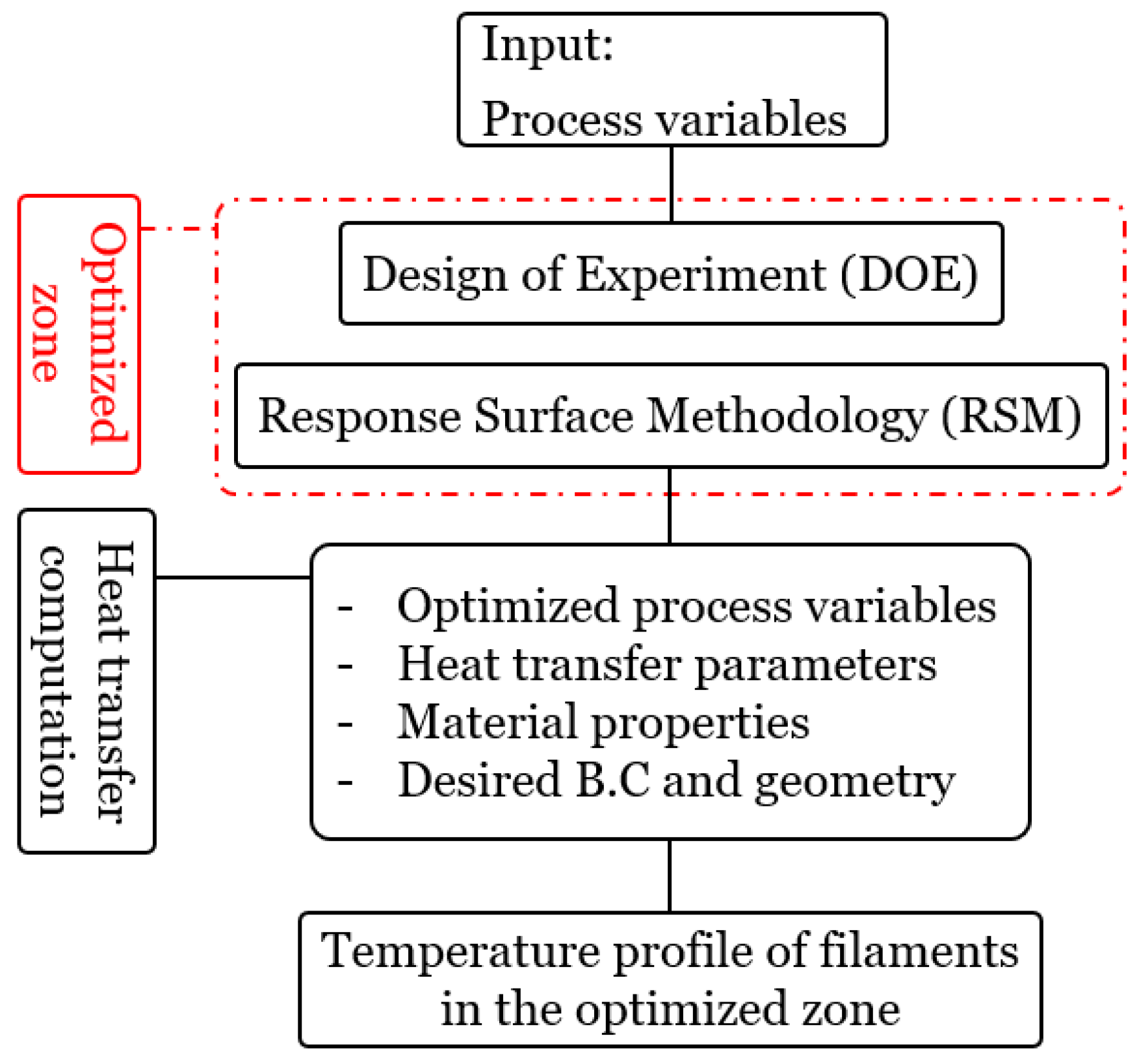

2. Materials and Methods

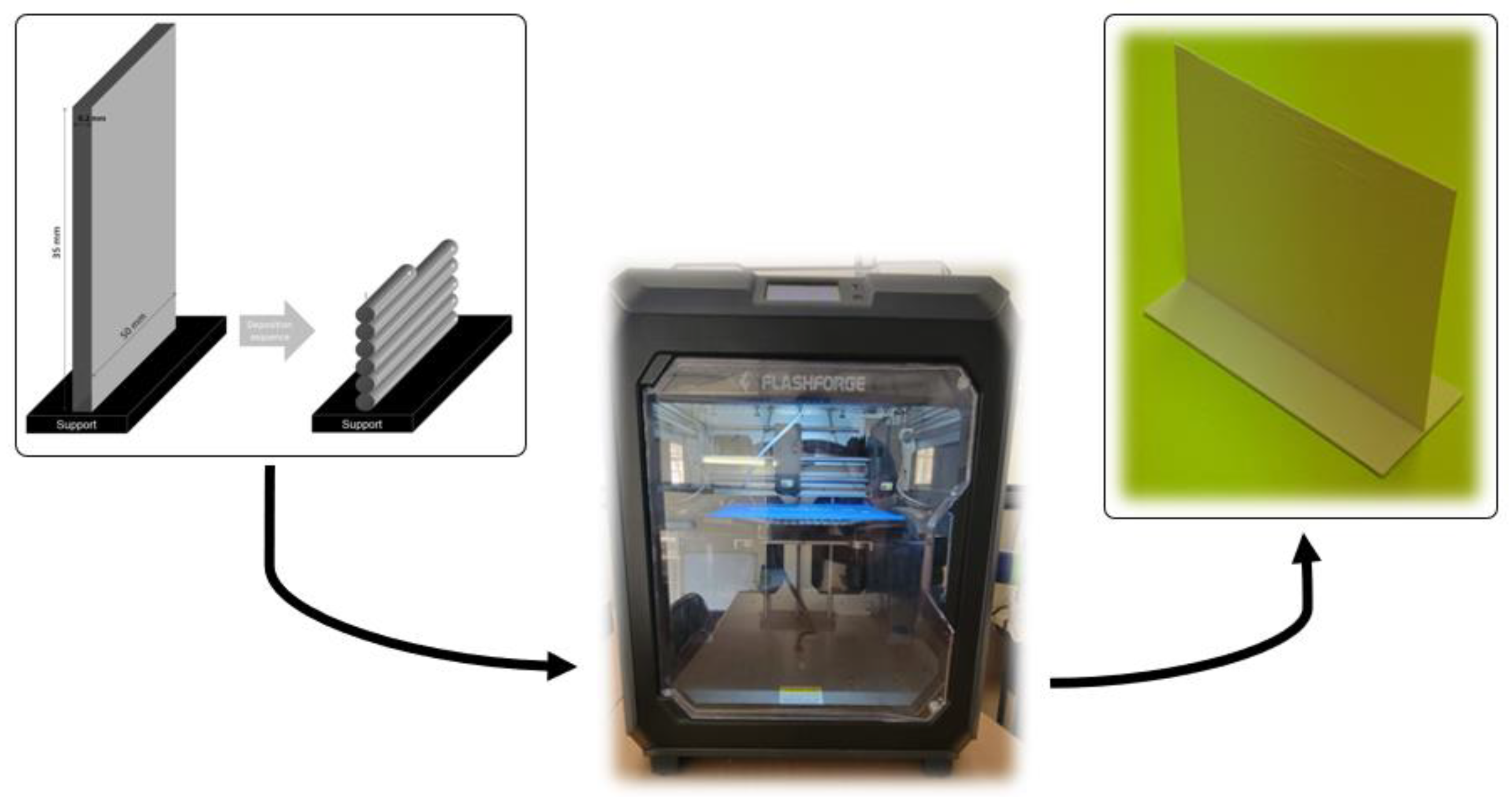

2.1. Material, 3D Printer, and Sample Preparation

2.2. Characterization Methods

2.2.1. Differential Scanning Calorimetry (DSC) Analysis

2.2.2. Mechanical Testing (Quasi-Static Tensile Test)

2.3. Design of Experiments (DOE)

3. Temperature Evolution and Heat Transfer

4. Results and Discussions

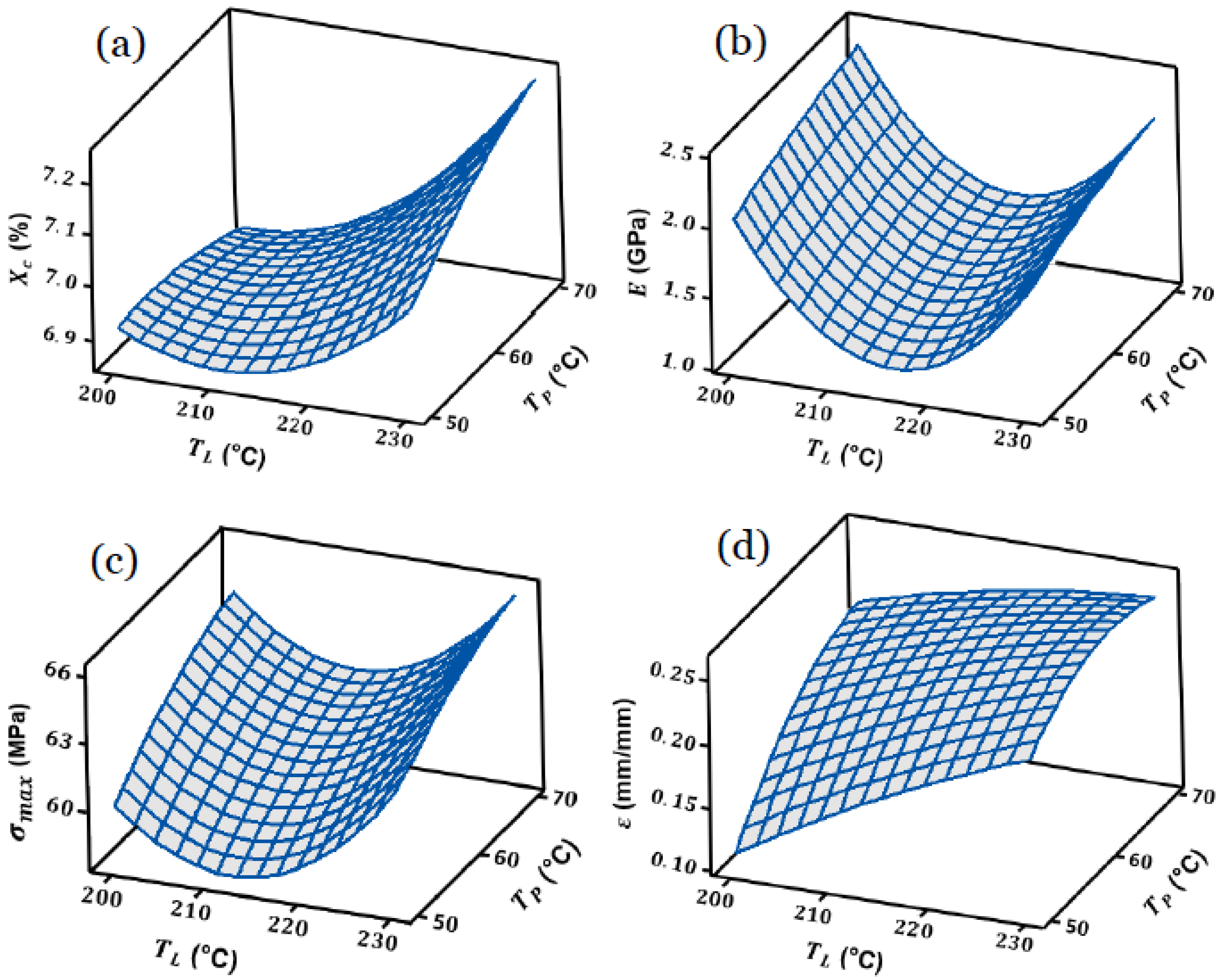

4.1. DSC and Tensile Analysis

4.2. RSM Fitting

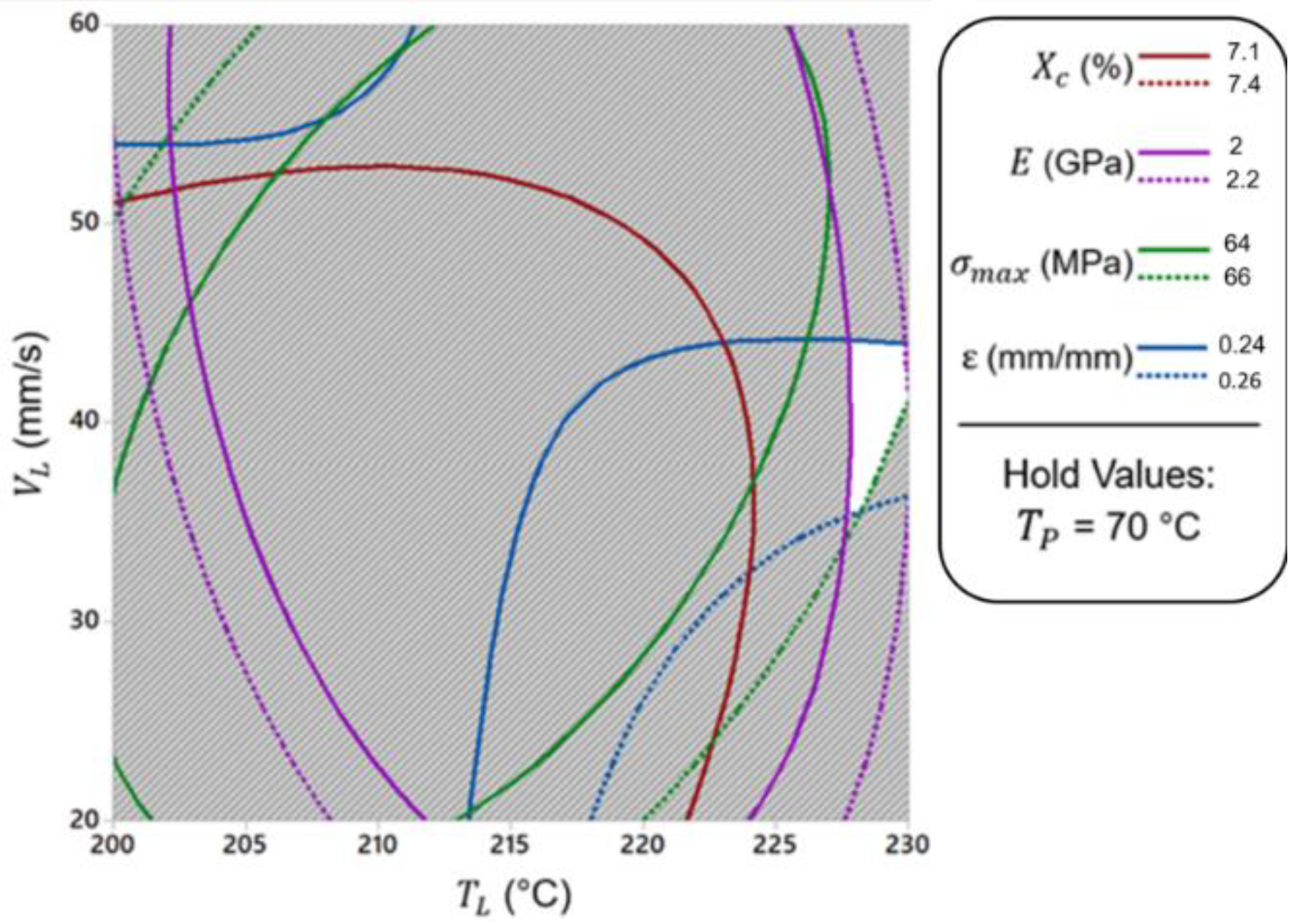

4.3. Response Optimization

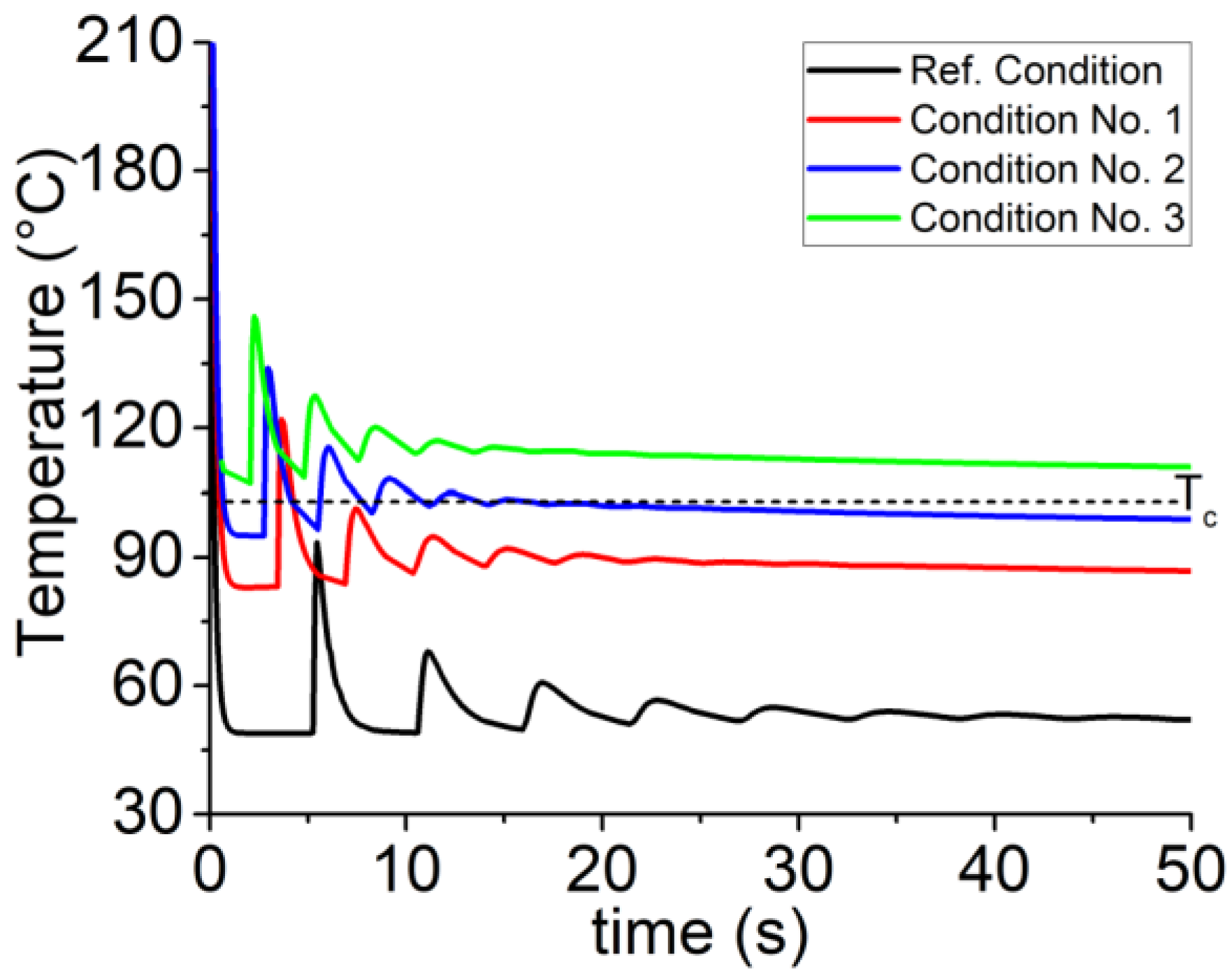

4.4. Optimized Temperature Profile of Filaments

- Reference Condition: TL = 210 °C, TP = 50 °C, VL = 20 mm.s−1

- Condition No. 1: TL = 230 °C, TP = 70 °C, VL = 35 mm.s−1

- Condition No. 2: TL = 230 °C, TP = 70 °C, VL = 40 mm.s−1

- Condition No. 3: TL = 230 °C, TP = 70 °C, VL = 45 mm.s−1.

- Liquefier temperature: Negligible effect on the cooling rate and onset of the re-heating peaks.

- Platform temperature: Considerable effect on the entire temperature profile and onset of the re-heating peaks.

- Print speed: Considerable effect on the occurrence and onset of the re-heating peaks.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Noorani, R. Rapid Prototyping: Principles and Applications; John Wiley & Sons Incorporated: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. Int. Sch. Res. Not. 2012, 12, 208760. [Google Scholar] [CrossRef]

- Ashley, S. Rapid prototyping systems. Mech. Eng. 1991, 113, 34. [Google Scholar]

- Demir, H. The Effects on Thermal Efficiency of Yttria-Stabilized Zirconia and Lanthanum Zirconate-Based Thermal Barrier Coatings on Aluminum Heating Block for 3D Printer. Coatings 2021, 11, 792. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Kulkarni, P.; Marsan, A.; Dutta, D. A review of process planning techniques in layered manufacturing. Rapid Prototyp. J. 2000, 6, 18–35. [Google Scholar] [CrossRef]

- Hague, R.; Mansour, S.; Saleh, N. Material and design considerations for rapid manufacturing. Int. J. Prod. Res. 2004, 42, 4691–4708. [Google Scholar] [CrossRef]

- Iftikhar, A.; Khan, M.; Alam, K.; Jaffery, S.H.I.; Ali, L.; Ayaz, Y.; Khan, A. Turbine blade manufacturing through rapid tooling (RT) process and its quality inspection. Mater. Manuf. Process. 2013, 28, 534–538. [Google Scholar] [CrossRef]

- Anderson, J.R.; Chiu, D.T.; Jackman, R.J.; Cherniavskaya, O.; McDonald, J.C.; Wu, H.; Whitesides, S.H.; Whitesides, G.M. Fabrication of topologically complex three-dimensional microfluidic systems in PDMS by rapid prototyping. Anal. Chem. 2000, 72, 3158–3164. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Yagnik, D. Fused deposition modeling–a rapid prototyping technique for product cycle time reduction cost effectively in aerospace applications. IOSR J. Mech. Civ. Eng. 2014, 5, 62–68. [Google Scholar]

- Chennakesava, P.; Narayan, Y.S. Fused deposition modeling-insights. In Proceedings of the International Conference on Advances in Design and Manufacturing (ICAD & M’14), Tamil Nadu, India, 5–7 December 2014. [Google Scholar]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Experimental investigation. Rapid Prototyp. J. 2001, 7, 148–158. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.; Bellehumeur, C.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Bellehumeur, C.; Li, L.; Sun, Q.; Gu, P. Modeling of bond formation between polymer filaments in the fused deposition modeling process. J. Manuf. Process. 2004, 6, 170–178. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp. J. 2003, 9, 219–230. [Google Scholar] [CrossRef]

- Vanaei, S.; Parizi, M.S.; Vanaei, S.; Salemizadehparizi, F.; Vanaei, H.R. An overview on materials and techniques in 3d bioprinting toward biomedical application. Eng. Regen. 2021, 2, 1–18. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- El Magri, A.; Vaudreuil, S.; El Mabrouk, K.; Touhami, M.E. Printing temperature effects on the structural and mechanical performances of 3D printed Poly-(phenylene sulfide) material. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ulaanbaatar, Mongolia, 10–13 September 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical property optimization of FDM PLA in shear with multiple objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Górski, F.; Kuczko, W.; Wichniarek, R. Impact strength of ABS parts manufactured using Fused Deposition Modeling technology. Arch. Mech. Technol. Autom. 2014, 34, 3–12. [Google Scholar]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Andrzejewski, J. Experimental determination of critical orientation of ABS parts manufactured using fused deposition modelling technology. J. Mach. Eng. 2015, 15, 121–132. [Google Scholar]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The effect of process parameters in fused deposition modelling on bonding degree and mechanical properties. Rapid Prototyp. J. 2018, 24, 80–92. [Google Scholar] [CrossRef]

- Letcher, T.; Rankouhi, B.; Javadpour, S. Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; American Society of Mechanical Engineers Digital Collection: New York, NY, USA. [Google Scholar]

- Sun, X.; Cao, L.; Ma, H.; Gao, P.; Bai, Z.; Li, C. Experimental analysis of high temperature PEEK materials on 3D printing test. In Proceedings of the 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Hunan, China, 14–15 January 2017. [Google Scholar]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, M.; Li, S.; Si, L.; Peng, J.; Hu, Y. Mechanical property parametric appraisal of fused deposition modeling parts based on the gray Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 89, 2387–2397. [Google Scholar] [CrossRef]

- Motaparti, K.P. Effect of Build Parameters on Mechanical Properties of Ultem 9085 Parts by Fused Deposition Modeling; Missouri University of Science and Technology: Rolla, MO, USA, 2016. [Google Scholar]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Mahmood, S.; Qureshi, A.; Goh, K.L.; Talamona, D. Tensile strength of partially filled FFF printed parts: Experimental results. Rapid Prototyp. J. 2017, 23, 122–128. [Google Scholar] [CrossRef]

- Raney, K.; Lani, E.; Kalla, D.K. Experimental characterization of the tensile strength of ABS parts manufactured by fused deposition modeling process. Mater. Today Proc. 2017, 4, 7956–7961. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; Mclouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical properties optimization of poly-ether-ether-ketone via fused deposition modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed]

- Nancharaiah, T.; Raju, D.R.; Raju, V.R. An experimental investigation on surface quality and dimensional accuracy of FDM components. Int. J. Emerg. Technol. 2010, 1, 106–111. [Google Scholar]

- EL Magri, A.; El Mabrouk, K.; Vaudreuil, S.; Chibane, H.; Touhami, M.E. Optimization of printing parameters for improvement of mechanical and thermal performances of 3D printed poly(ether ether ketone) parts. J. Appl. Polym. Sci. 2020, 137, 49087. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Durão, L.F.C.S.; Barkoczy, R.; Zancul, E.; Ho, L.L.; Bonnard, R. Optimizing additive manufacturing parameters for the fused deposition modeling technology using a design of experiments. Prog. Addit. Manuf. 2019, 4, 291–313. [Google Scholar] [CrossRef]

- Goupy, J.; Creighton, L. Introduction to Design of Experiments with JMP Examples; SAS Publishing: Cary, NC, USA, 2007. [Google Scholar]

- Vanaei, H.R.; Raissi, K.; Deligant, M.; Shirinbayan, M.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Toward the understanding of temperature effect on bonding strength, dimensions and geometry of 3D-printed parts. J. Mater. Sci. 2020, 55, 14677–14689. [Google Scholar] [CrossRef]

- Vanaei, H. Etude et Modélisation de la Rhéologie des Polymères au Cours du Procédé FDM (Fabrication Additive). Ph.D. Thesis, HESAM, Paris, France, 2021. [Google Scholar]

- Vadori, R.; Mohanty, A.K.; Misra, M. The Effect of Mold Temperature on the Performance of Injection Molded Poly(Lactic Acid)-Based Bioplastic. Macromol. Mater. Eng. 2013, 298, 981–990. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S.; Touhami, M.E. Experimental investigation and optimization of printing parameters of 3D printed polyphenylene sulfide through response surface methodology. J. Appl. Polym. Sci. 2021, 138, 49625. [Google Scholar] [CrossRef]

- D’Amico, A.; Peterson, A.M. An adaptable FEA simulation of material extrusion additive manufacturing heat transfer in 3D. Addit. Manuf. 2018, 21, 422–430. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Deligant, M.; Shirinbayan, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. A comparative in-process monitoring of temperature profile in fused filament fabrication. Polym. Eng. Sci. 2021, 61, 68–76. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Shirinbayan, M.; Costa, S.F.; Duarte, F.M.; Covas, J.A.; Deligant, M.; Khelladi, S.; Tcharkhtchi, A. Experimental study of PLA thermal behavior during fused filament fabrication. J. Appl. Polym. Sci. 2021, 138, 49747. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Khelladi, S.; Deligant, M.; Shirinbayan, M.; Tcharkhtchi, A. Numerical Prediction for Temperature Profile of Parts Manufactured using Fused Filament Fabrication. J. Manuf. Process. 2022, 76, 548–558. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Dou, H.; Cheng, Y.; Ye, W.; Zhang, D.; Li, J.; Miao, Z.; Rudykh, S. Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Murugan, R.; Mitilesh, R.; Singamneni, S. Influence of process parameters on the mechanical behaviour and processing time of 3D printing. Int. J. Mod. Manuf. Technol. 2019, 1, 21–27. [Google Scholar]

- Chang, B.P.; Akil, H.M.; Nasir, R.B.; Khan, A. Optimization on wear performance of UHMWPE composites using response surface methodology. Tribol. Int. 2015, 88, 252–262. [Google Scholar] [CrossRef]

- Rosenzweig, N.; Narkis, M. Sintering rheology of amorphous polymers. Polym. Eng. Sci. 1981, 21, 1167–1170. [Google Scholar] [CrossRef]

- Hopper, R.W. Coalescence of two equal cylinders: Exact results for creeping viscous plane flow driven by capillarity. J. Am. Ceram. Soc. 1984, 67, C-262–C-264. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Liquefier temperature TL (°C) | 200–230 |

| Platform temperature TP (°C) | 50–100 |

| Print speed VL (mm.s−1) | 20–60 |

| Layer height (mm) | 0.2 |

| Infill (%) | 100 |

| Filament cross-section | Circular |

| Run Order | Factors | Responses | |||||

|---|---|---|---|---|---|---|---|

| TL (°C) | TP (°C) | VL (mm.s−1) | E (GPa) | σmax (MPa) | ɛ (mm.mm−1) | ||

| 1 | 200 | 50 | 40 | 6.95 | 2 | 60 | 0.2 |

| 2 | 210 | 70 | 40 | 6.9 | 1.2 | 58 | 0.21 |

| 3 | 210 | 50 | 60 | 7.25 | 1 | 56.5 | 0.23 |

| 4 | 210 | 50 | 40 | 6.83 | 1.1 | 56.5 | 0.18 |

| 5 | 220 | 50 | 60 | 7.1 | 1.8 | 64 | 0.25 |

| 6 | 230 | 70 | 60 | 7.1 | 2.1 | 66.5 | 0.23 |

| 7 | 220 | 50 | 20 | 7.25 | 1.4 | 62 | 0.12 |

| 8 | 200 | 70 | 20 | 6.8 | 1.9 | 59 | 0.194 |

| 9 | 220 | 50 | 40 | 7.1 | 1.5 | 62 | 0.21 |

| 10 | 230 | 50 | 20 | 6.83 | 1.1 | 57 | 0.105 |

| 11 | 230 | 70 | 20 | 6.8 | 1.4 | 59.5 | 0.27 |

| 12 | 220 | 70 | 40 | 7 | 1.5 | 62.5 | 0.25 |

| 13 | 200 | 70 | 40 | 6.8 | 2.1 | 62 | 0.19 |

| 14 | 200 | 50 | 20 | 6.72 | 1.8 | 59 | 0.1 |

| 15 | 230 | 50 | 40 | 7 | 2 | 65 | 0.26 |

| 16 | 210 | 50 | 20 | 5.12 | 1.2 | 60 | 0.097 |

| 17 | 220 | 70 | 60 | 7.1 | 1.9 | 65 | 0.26 |

| 18 | 210 | 70 | 20 | 6.83 | 1.3 | 61.5 | 0.25 |

| 19 | 230 | 70 | 40 | 6.9 | 2.2 | 66 | 0.27 |

| 20 | 200 | 50 | 60 | 6.87 | 2.1 | 62.5 | 0.18 |

| 21 | 220 | 70 | 20 | 7.5 | 1.5 | 63 | 0.23 |

| 22 | 200 | 70 | 60 | 6.9 | 2.1 | 63 | 0.2 |

| 23 | 230 | 50 | 60 | 6.95 | 2 | 64.5 | 0.27 |

| 24 | 210 | 70 | 60 | 7.1 | 1.2 | 57 | 0.25 |

| Condition No. | TL (°C) | TP (°C) | VL (mm.s−1) |

|---|---|---|---|

| 1 | 230 | 70 | 35 |

| 2 | 230 | 70 | 40 |

| 3 | 230 | 70 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanaei, H.R.; Khelladi, S.; Tcharkhtchi, A. Roadmap: Numerical-Experimental Investigation and Optimization of 3D-Printed Parts Using Response Surface Methodology. Materials 2022, 15, 7193. https://doi.org/10.3390/ma15207193

Vanaei HR, Khelladi S, Tcharkhtchi A. Roadmap: Numerical-Experimental Investigation and Optimization of 3D-Printed Parts Using Response Surface Methodology. Materials. 2022; 15(20):7193. https://doi.org/10.3390/ma15207193

Chicago/Turabian StyleVanaei, Hamid Reza, Sofiane Khelladi, and Abbas Tcharkhtchi. 2022. "Roadmap: Numerical-Experimental Investigation and Optimization of 3D-Printed Parts Using Response Surface Methodology" Materials 15, no. 20: 7193. https://doi.org/10.3390/ma15207193

APA StyleVanaei, H. R., Khelladi, S., & Tcharkhtchi, A. (2022). Roadmap: Numerical-Experimental Investigation and Optimization of 3D-Printed Parts Using Response Surface Methodology. Materials, 15(20), 7193. https://doi.org/10.3390/ma15207193