Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview

Abstract

1. Introduction

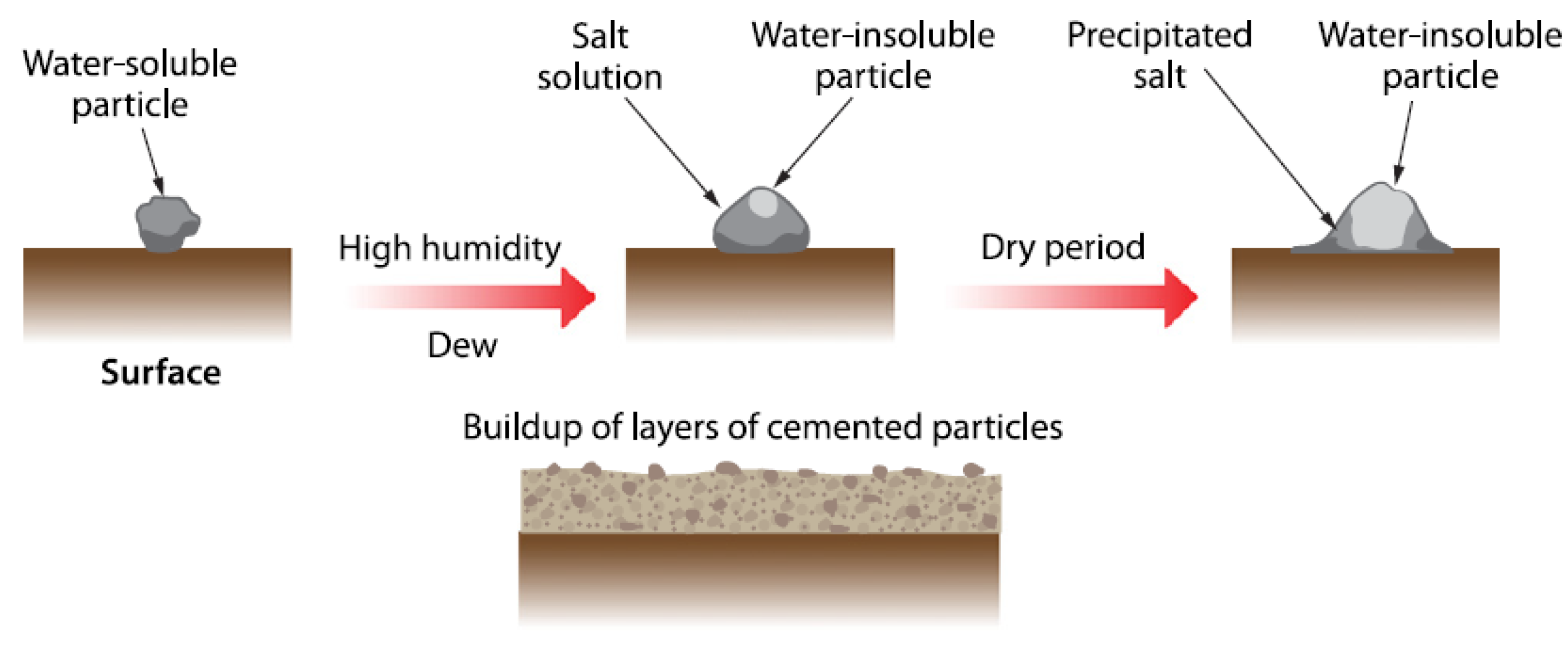

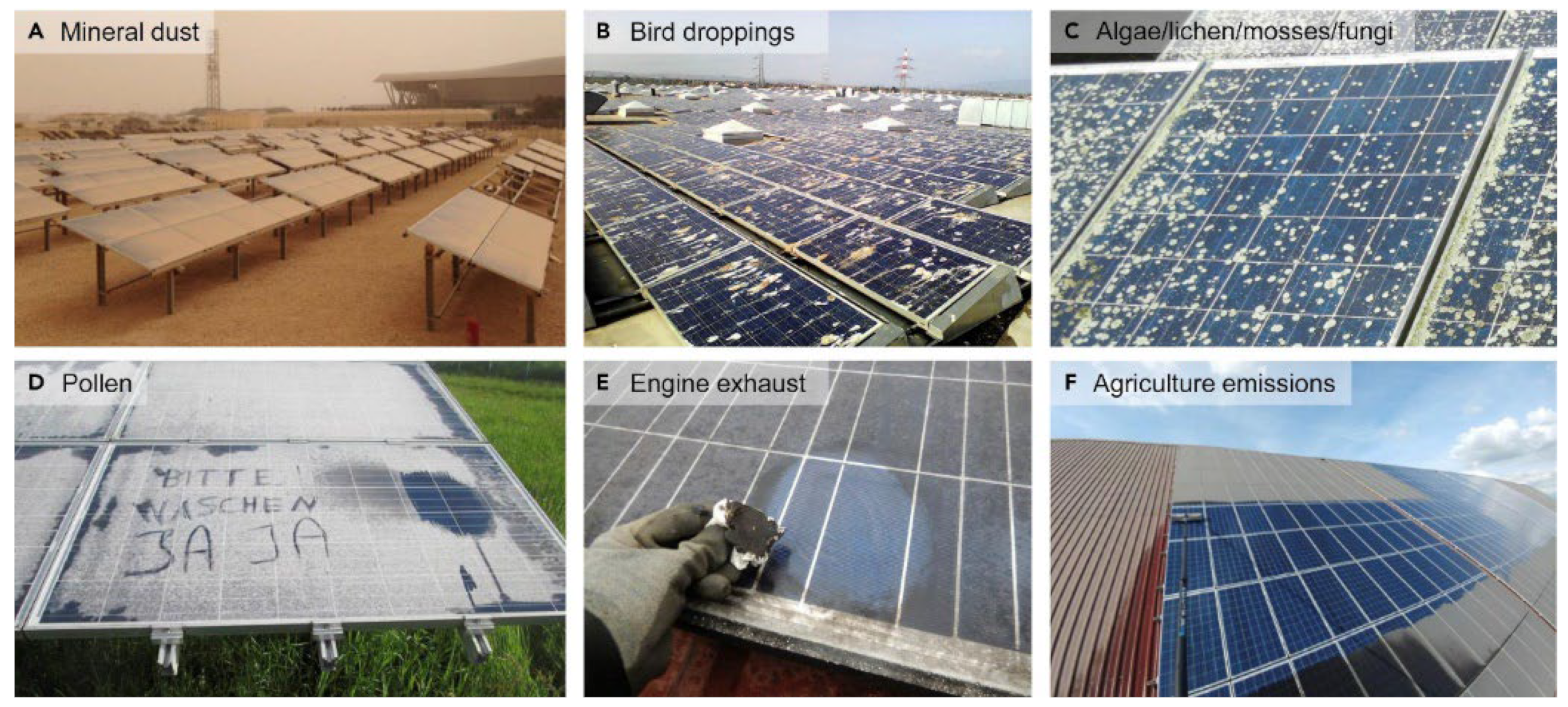

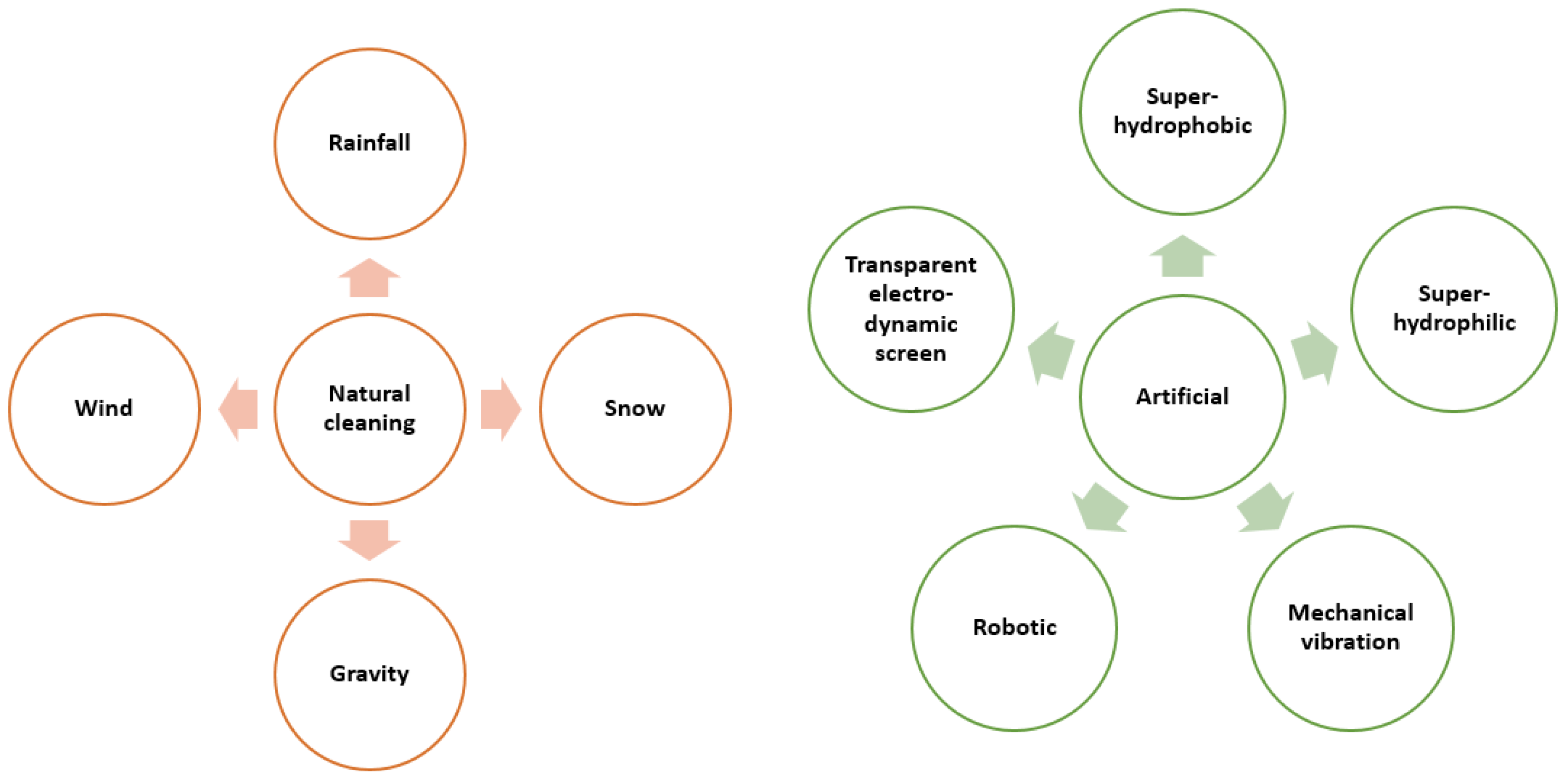

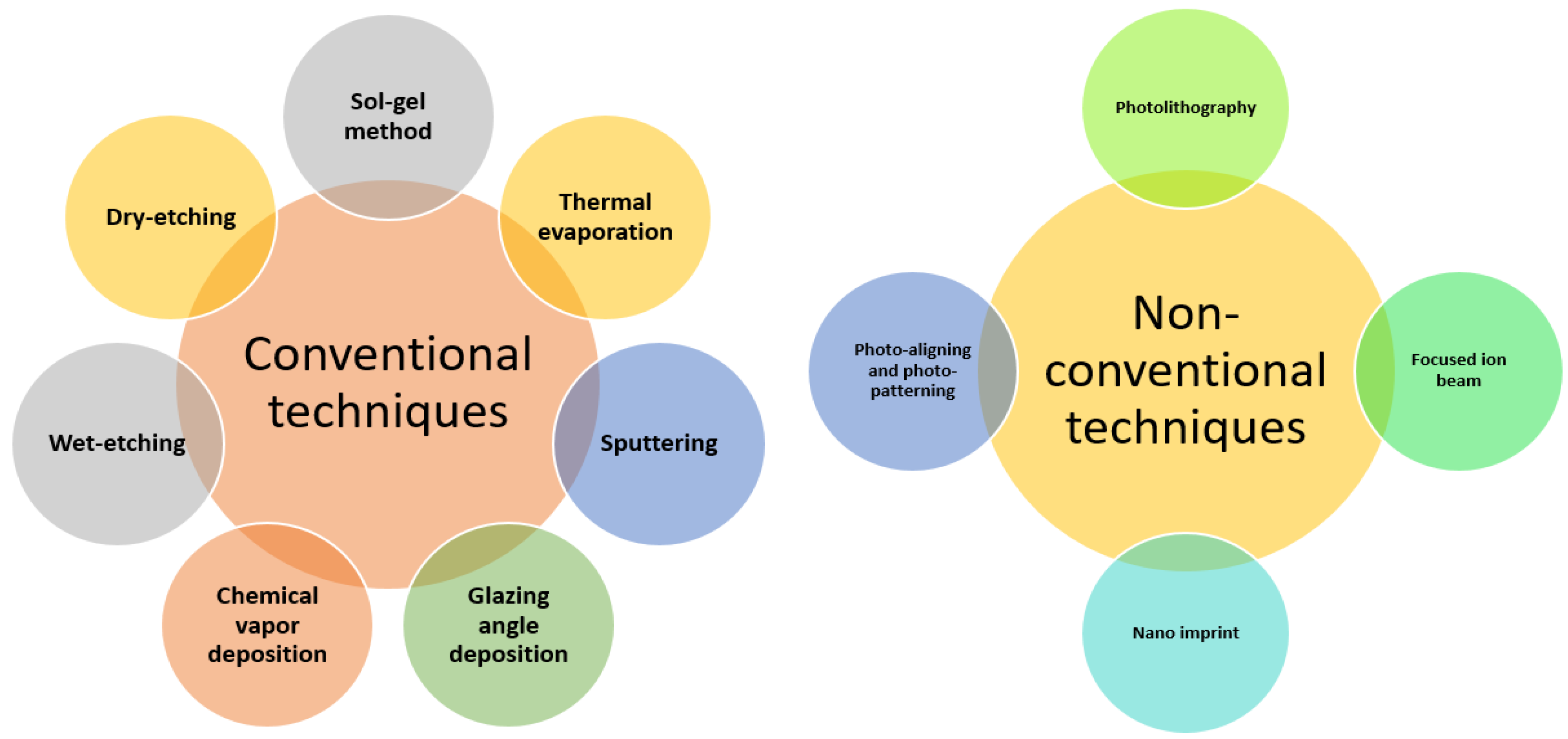

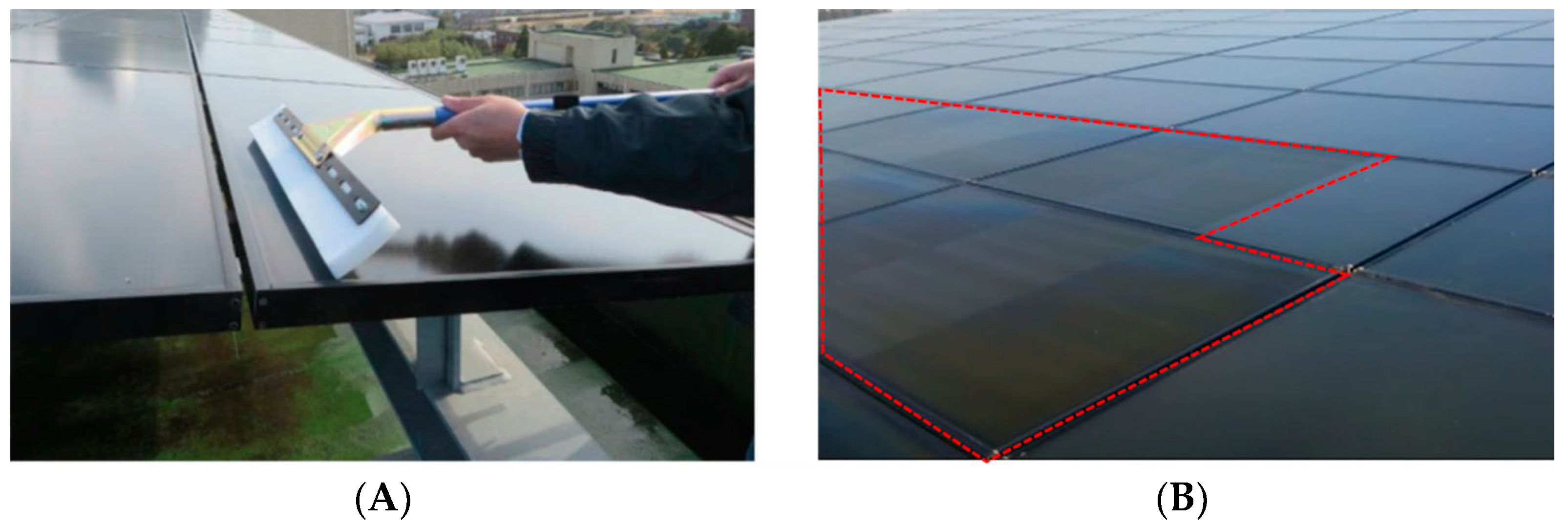

2. Anti-Dust Coating

3. Mechanisms for Preventing Soiling by Hydrophobic and Hydrophilic Coating

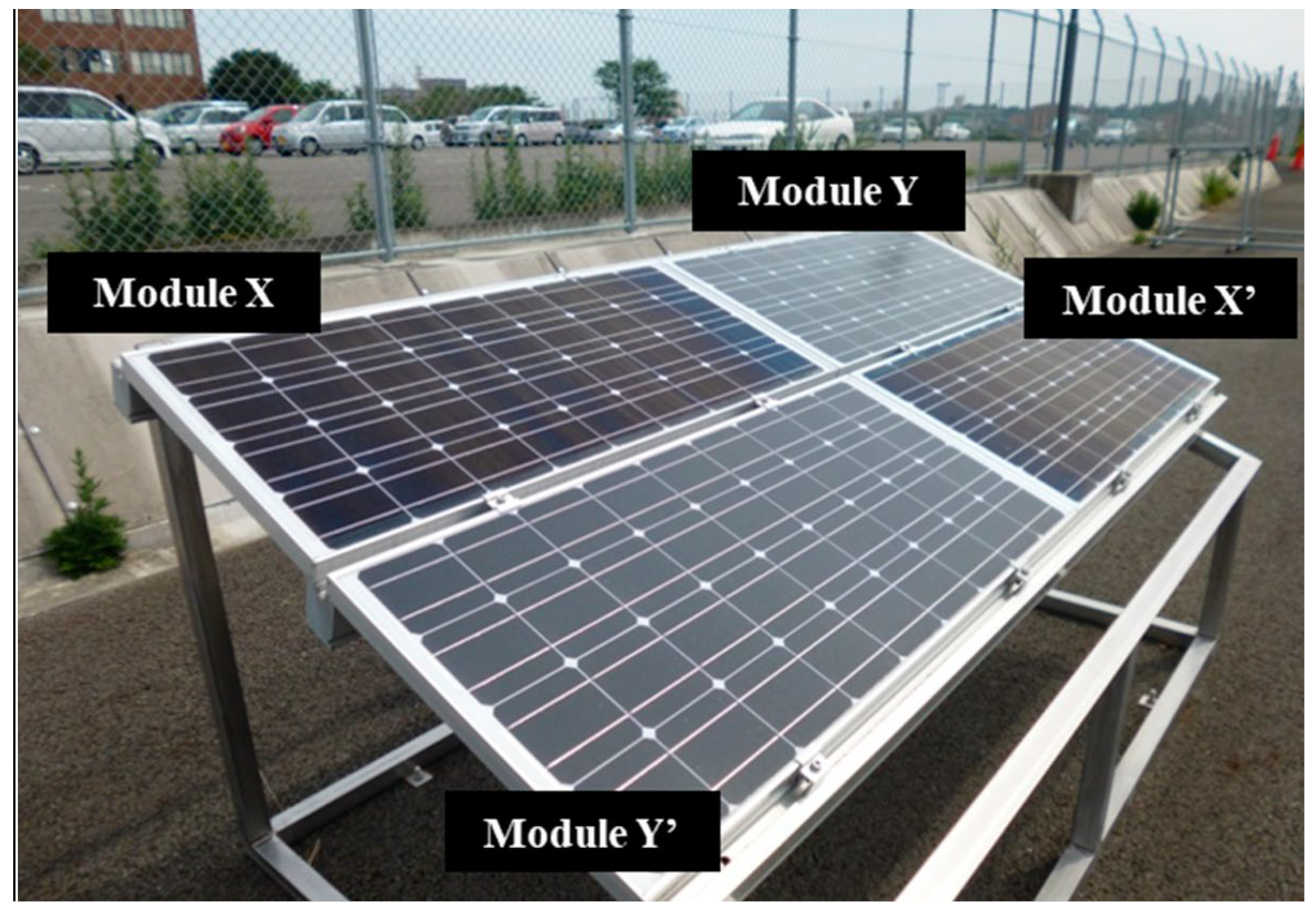

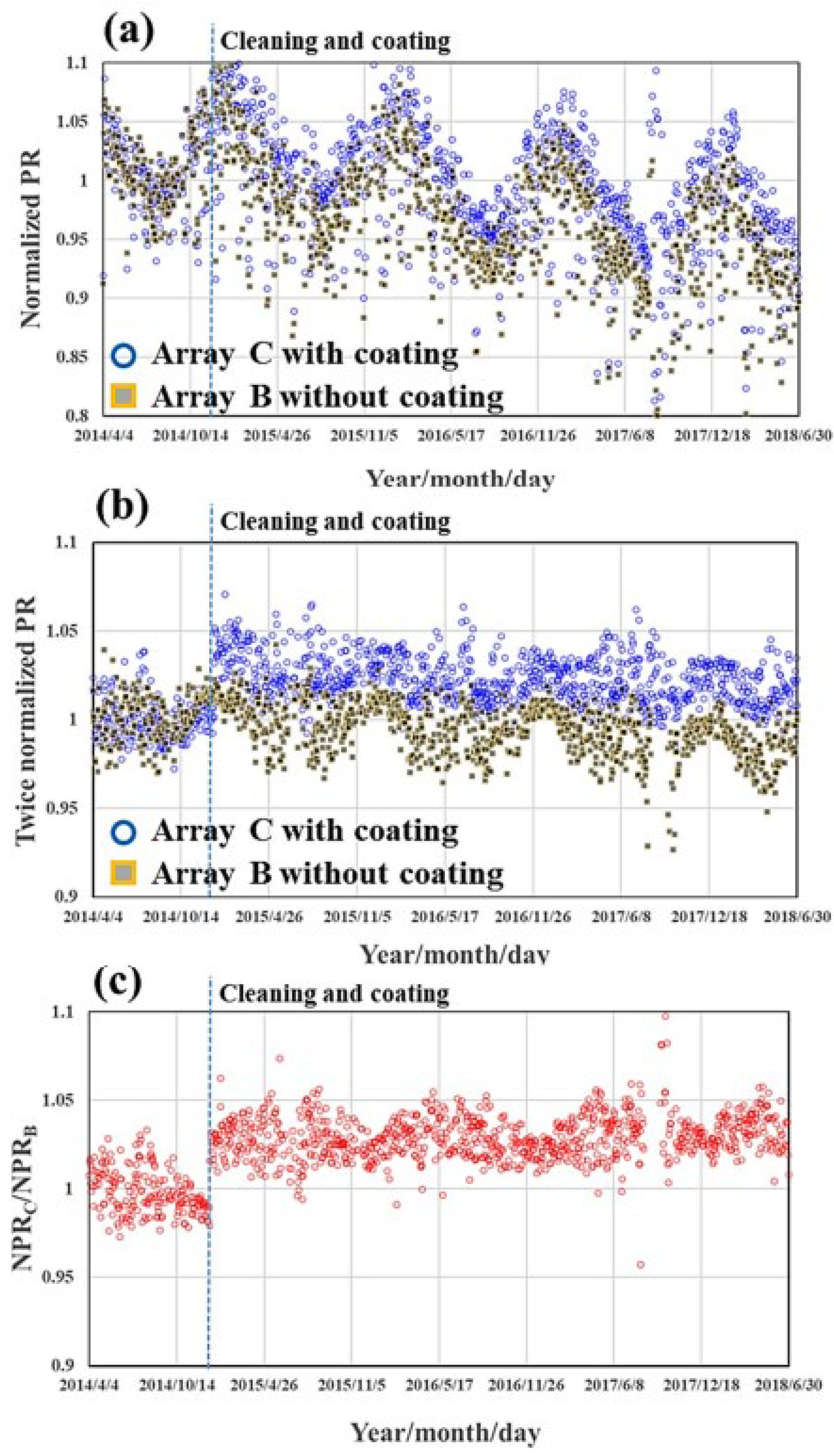

4. Silica Coating on Module by Dipping/Immersing

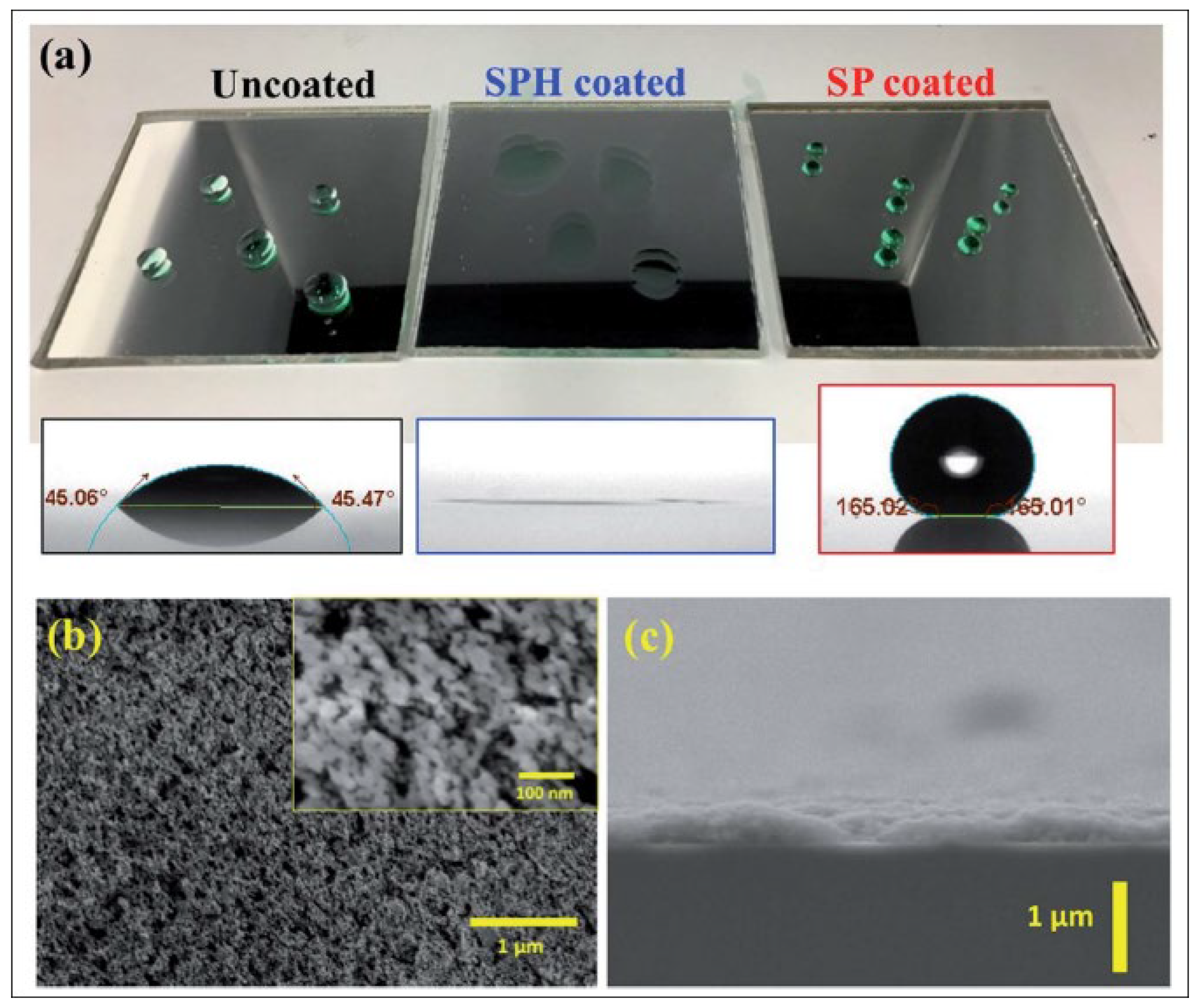

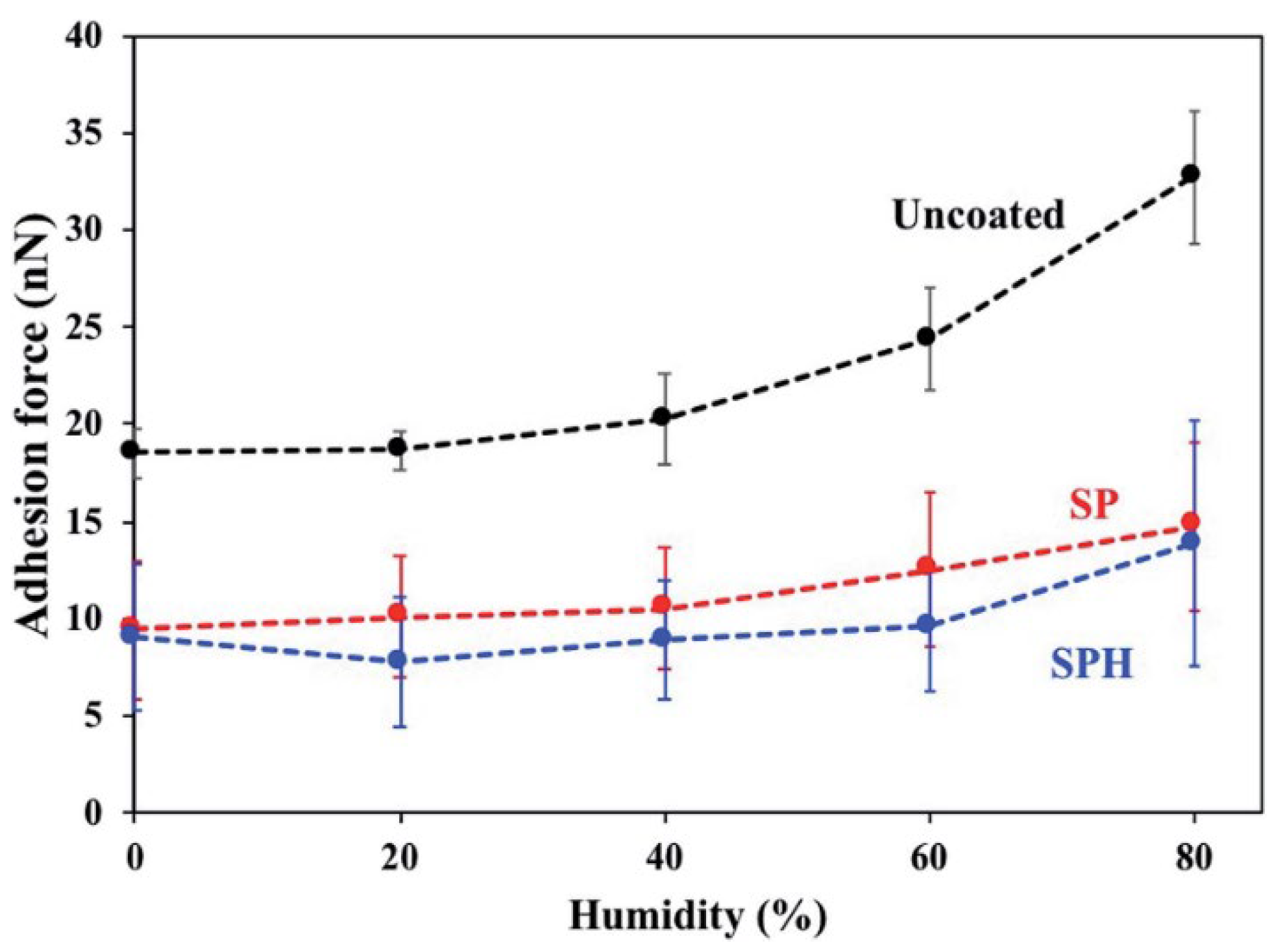

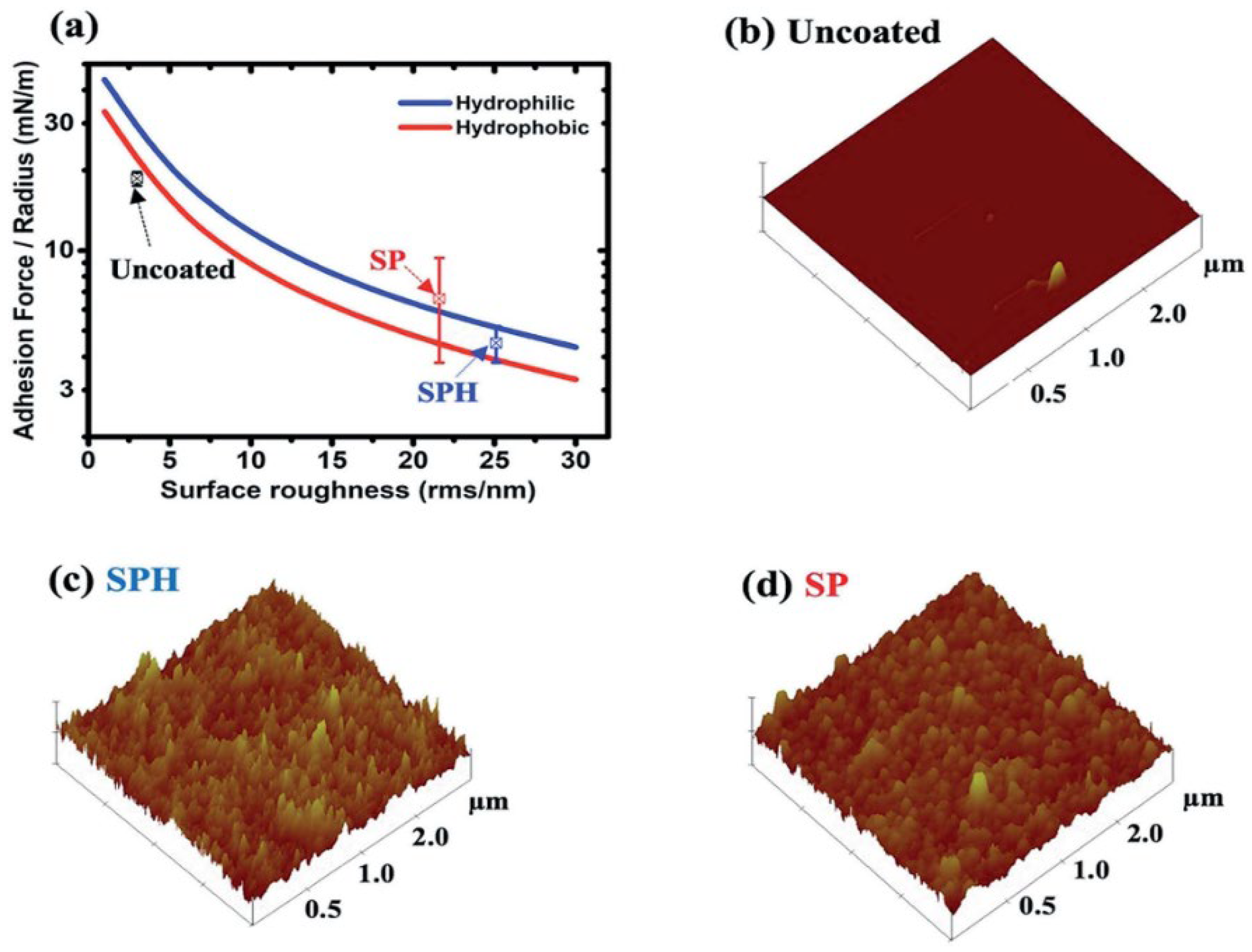

5. Adhesion Force Reduction in the SHP Coating

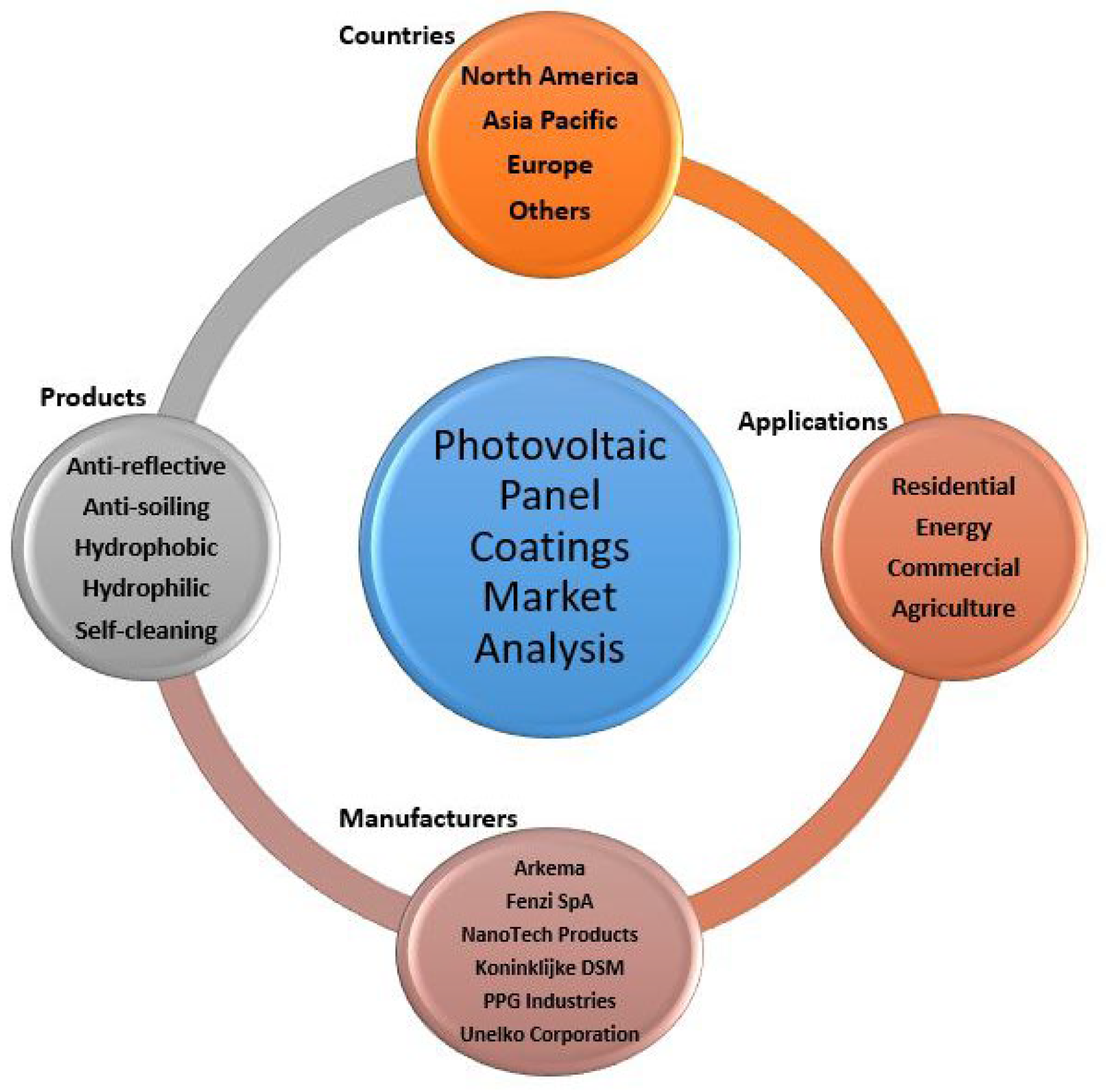

6. Anti-Soiling and Self-Cleaning Performance of SPH Coated Mirror

7. Solar Panel Coatings Market Overview

- − Arkema;

- − Fenzi SpA;

- − NanoTech Products;

- − Koninklijke DSM;

- − PPG Industries;

- − Unelko Corporation.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

Appendix A

| Name of the Company | Name of the Product | Date of Launching the Product | Price if Any | Specifications | Manufacturing Country |

|---|---|---|---|---|---|

| MoreSun | Talus Dirt Rejection Technology | 2014 | NA | USA | |

| DSM | Core–shell particle technology | Significantly better anti-soiling properties compared to our AR-coated or uncoated glass: <0.1% transmission loss after executing the DSM Taber soiling test | China | ||

| 3M | Anti-soiling liquid 600 | 2012 | NA | Water-based liquid | USA |

| The consortium comprises leading commercial and academic partners, including: Opus Materials Technologies, TWI, Only Solar, The French Alternative Energies and Atomic Energy Commission (CEA) London South Bank University (LSBU), Arctic (Advanced Resins & Coatings Technologies Innovation Centre), and a supply chain capability in Millidyne. | Solar Sharc | 2020 | NA | Functionalized silica nanoparticles (30–500) | France/UK |

| BASF SE | RELESTe Powder PUR Anti-Sticker c | 2014 | NA | Powder coating | Germany |

| PPG Industries, Inc. | PPG High Performance Coatings | 2012 | NA | Coating with organic material with silicon-containing compounds | USA |

| Rads Global Business | NA | 2021 | NA | To reduce cleaning cost by around 60%. The anti-reflective and anti-corrosive coating is also said to mitigate potential-induced degradation | Netherlands |

| Sherwin-Williams | Acrylic latex paint | 2020 | NA | Self-cleaning | USA |

| Taypro Private Limited | Anti-dust solar shield | 2020 | NA | Anti-dust thin film coating | India |

| HYDRASOL | HYDRASOL NANO COATING | 2019 | NA | Appearance: colorless, liquid Coating thickness: less 1 micron | India |

| P3C Technology and Solution Self-cleaning glasses | NA | 2019 | NA | NA | India |

| NanoSonic | HybridShield Solar | 2019 | NA | Thin films | USA |

| UNELKO CORPORATION | Solar Shield and the Repel | 2019 | NA | Solar panels | USA |

| P2i | NA | NA | NA | Nanocoating | UK |

| Nanopool GMBH | NPe coatings | 2019 | NA | Silicon dioxide | Germany |

| Nanoman | Nanoman solar | NA | USD 199 | Nanotechnology enabled coating, engineered for use on solar panels | Australia |

References

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Miller, D.C.; Kurtz, S.R. Durability of Fresnel lenses: A review specific to the concentrating photovoltaic appli-cation. Sol. Energy Mater. Sol. Cells 2011, 95, 2037–2068. [Google Scholar] [CrossRef]

- Shin, J.-H.; Han, K.-S.; Lee, H. Anti-reflection and hydrophobic characteristics of M-PDMS based moth-eye nano-patterns on protection glass of photovoltaic systems. Prog. Photovolt. Res. Appl. 2010, 19, 339–344. [Google Scholar] [CrossRef]

- Muszanska, A.K.; Busscher, H.J.; Herrmann, A.; van der Mei, H.C.; Norde, W. Pluronic–lysozyme conjugates as anti-adhesive and antibacterial bifunctional polymers for surface coating. Biomaterials 2011, 32, 6333–6341. [Google Scholar] [CrossRef]

- Cañete, C.; Moreno, J.R.; Carretero, M.; Piliougine, M.; Sidrach-de-Cardona, M.; Hirose, J.; Ogawa, S. Effect of the self-cleaning coating surface in the temperature and soiling losses of photovoltaic modules. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt, Germany, 24–28 September 2012. [Google Scholar]

- Appels, R.; Muthirayan, B.; Beerten, A.; Paesen, R.; Driesen, J.; Poortmans, J. The effect of dust deposition on photovoltaic modules. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1886–1889. [Google Scholar]

- Yu, M.; Long, Y.-Z.; Sun, B.; Fan, Z. Recent advances in solar cells based on one-dimensional nanostructure arrays. Nanoscale 2012, 4, 2783–2796. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Xia, H.; Kim, E.; Sun, H.-B. Recent developments in superhydrophobic surfaces with unique structural and functional properties. Soft Matter 2012, 8, 11217–11231. [Google Scholar] [CrossRef]

- Roth, R.; Ballif, C.; Chapuis, V. Effect of Soiling on Performances of Crystalline Silicon PV Modules Deployed in an Arid Climate in Relation to Front Glass Texture and Treatment; Ecole Polytechnique Federale de Lausanne: Lausanne, Switzerland, 2012. [Google Scholar]

- Burton, P.D.; King, B.H. Artificial soiling of photovoltaic module surfaces using traceable soil components. In Proceedings of the 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), IEEE, Tampa, FL, USA, 16–21 June 2013; pp. 1542–1545. [Google Scholar]

- Orel, B.; Jerman, I.; Koželj, M.; Perše, L.S.; Kunič, R. Materials Aspects of Solar Paint Coatings for Building Applications. In Advances in the Development of Cool Materials for the Built Environment; Bentham Science Publishers: Sharjah, United Arab Emirates, 2013; p. 120. [Google Scholar]

- Cañete, C.; Zorrilla-Casanova, J.; Carretero, J.; Piliougine, M.; de Cardona, M.S.; Hirose, J.; Ogawa, S. Performance of photovoltaic modules with self-cleaning coating surface after two years of outdoor exposure in southern spain. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013. [Google Scholar]

- Hunter, S.R.; Smith, D.B.; Polizos, G.; Schaeffer, D.A.; Lee, D.F.; Datskos, P.G. Low cost anti-soiling coatings for CSP collector mirrors and heliostats. In High and Low Concentrator Systems for Solar Energy Applications IX; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9175, p. 91750J. [Google Scholar]

- Polizos, G.; Schaeffer, D.A.; Smith, D.B.; Lee, D.F.; Datskos, P.G.; Hunter, S.R. Enhanced Durability Transparent Superhydrophobic Anti-Soiling Coatings for CSP Applications. In Energy Sustainability; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 45868, p. V001T02A030. [Google Scholar] [CrossRef]

- Bagnold, R.A. The Physics of Blown Sand and Desert Dust; Methuen and Co. Ltd.: London, UK, 1965. [Google Scholar]

- Herrmann, J.; Lorenz, T.; Slamova, K.; Klimm, E.; Koehl, M.; Weiss, K.-A. Desert applications of PV modules. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC) 2014, Denver, CO, USA, 8–13 June 2014; pp. 2043–2046. [Google Scholar] [CrossRef]

- Berghold, J.; Grunow, P. From the Impact of Harsh Climates and Environmental Conditions on pv-Modules-Development of a Soiling and Abrasion test. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 23–25 September 2014. [Google Scholar]

- Pop, S.C.; Abbaraju, V.; Brophy, B.; Yang, Y.S.; Maghsoodi, S.; Gonsalves, P. A highly abra-sive-resistant, long-lasting anti-reflective coating for PV module glass. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 2715–2719. [Google Scholar]

- Schaeffer, D.A.; Polizos, G.; Smith, D.B.; Lee, D.F.; Rajic, S.; Datskos, P.G.; Hunter, S.R. Spray-On Anti-Soiling Coatings That Exhibit High Transparency and Mechanical Durability. In Sensors, and Command, Control, Communications, and Intelligence (C3I) Technologies for Homeland Security and Home-land Defense XIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9074, p. 90740C. [Google Scholar]

- Haschke, J.; Lemerle, R.; Aïssa, B.; Abdallah, A.A.; Kivambe, M.M.; Boccard, M.; Ballif, C. Annealing of Silicon Heterojunction Solar Cells: Interplay of Solar Cell and Indium Tin Oxide Properties. IEEE J. Photovolt. 2019, 9, 1202–1207. [Google Scholar] [CrossRef]

- Park, Y.-B.; Im, H.; Im, M.; Choi, Y.-K. Self-cleaning effect of highly water-repellent microshell structures for solar cell applications. J. Mater. Chem. 2010, 21, 633–636. [Google Scholar] [CrossRef]

- Bentouaf, A.; Mebsout, R.; Rached, H.; Amari, S.; Reshak, A.H.; Aïssa, B. Theoretical investigation of the structural, electronic, magnetic and elastic properties of binary cubic C15-Laves phases TbX2 (X = Co and Fe). J. Alloys and compounds 2016, 689, 885–893. [Google Scholar] [CrossRef]

- Rossi, G.; Altavilla, C.; Scarfato, P.; Ciambelli, P.; Incarnato, L. Deposition of transparent and flexible nanolayer barrier on standard coating materials for photovoltaic devices. Surf. Coatings Technol. 2014, 239, 200–205. [Google Scholar] [CrossRef]

- Aïssa, B.; Khayyat, M.M. Self-Healing Materials Systems as a Way for Damage Mitigation in Composites Structures Caused by Orbital Space Debris. In Handbook of Research on Nanoscience, Nanotechnology, and Advanced Materials; Boudina, M., Davim, J.P., Eds.; IGI Global Disseminator of Knowledge Publisher: Hershey, PA, USA, 2014; Chapter 1; pp. 1–25. ISBN 9781466658240. [Google Scholar]

- Hu, J.; Bodard, N.; Sari, O.; Riffat, S. CFD simulation and validation of self-cleaning on solar panel surfaces with superhydrophilic coating. Future Cities Environ. 2015, 1, 8. [Google Scholar] [CrossRef]

- Schaeffer, D.A.; Polizos, G.; Smith, D.B.; Lee, D.F.; Hunter, S.R.; Datskos, P.G. Optically transparent and environmentally durable superhydrophobic coating based on functionalized SiO2 nanoparti-cles. Nanotechnology 2015, 26, 55602. [Google Scholar] [CrossRef]

- Weber, T.; Ferretti, N.; Schneider, F.; Janker, A.; Trawny, M.; Berghold, J. Impact & Con-sequences of Soiling and Cleaning of PV Modules. In Proceedings of the NREL Photovoltaic Reliability Workshop (PVMRW), Denver, CO, USA, 24–27 February 2015. [Google Scholar]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Oh, W.; Chan, S.-I. The Performance Loss by the Soiling of Photovoltaic Modules. J. Korean Sol. Energy Soc. 2015, 35, 63–71. [Google Scholar] [CrossRef][Green Version]

- Mazumder, M.K.; Horenstein, M.N.; Heiling, C.; Stark, J.W.; Sayyah, A.; Yellowhair, J.; Raychowdhury, A. Environmental degradation of the optical surface of PV modules and solar mirrors by soiling and high RH and mitigation methods for minimizing energy yield losses. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–6. [Google Scholar]

- Mazumder, M.K.; Horenstein, M.N.; Joglekar, N.R. Prototype Development and Evaluation of Self-Cleaning Concentrated Solar Power Collectors; No. DOE-EE0005794_Boston_Mazumder_EDS; Boston University: Boston, MA, USA, 2015. [Google Scholar]

- Afzal, A.; Habib, A.; Ulhasan, I.; Shahid, M.; Rehman, A. Antireflective Self-Cleaning TiO2 Coatings for Solar Energy Harvesting Applications. Front. Mater. 2021, 8, 687059. [Google Scholar] [CrossRef]

- Fares, E.; Aissa, B.; Isaifan, R.J. Inkjet printing of metal oxide coatings for enhanced photovoltaic soiling environmental applications. Glob. J. Environ. Sci. Manag. 2022, 8, 1–18. [Google Scholar] [CrossRef]

- Hossain, M.I.; Al Kubaisi, G.; Aïssa, B.; Mansour, S. Probing the hydrophilic behaviour of e-beam evaporated silica thin films for PV-soiling application. Mater. Sci. Technol. 2022, 38, 753–759. [Google Scholar] [CrossRef]

- Aïssa, B.; Scabbia, G.; Figgis, B.W.; Lopez, J.G.; Benito, V.B. PV-soiling field-assessment of Mars™ optical sensor operating in the harsh desert environment of the state of Qatar. Sol. Energy 2022, 239, 139–146. [Google Scholar] [CrossRef]

- Figgis, B.; Scabbia, G.; Aissa, B. Condensation as a predictor of PV soiling. Sol. Energy 2022, 238, 30–38. [Google Scholar] [CrossRef]

- Kam-Lum, E.; Meyers, B.E.; Cosme, D.; Aissa, B.; Scabbia, G. Scabbia Soiling Rate Determination from Referenced Systems in Desert Climate using PVInsight Soiling Algorithm. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 2552–2554. [Google Scholar]

- Hossain, M.I.; Aïssa, B.; Samara, A.; Mansour, S.A.; Broussillou, C.A.; Benito, V.B. Hydrophilic Antireflection and Antidust Silica Coatings. ACS Omega 2021, 6, 5276–5286. [Google Scholar] [CrossRef]

- Fares, E.; Buffiere, M.; Figgis, B.; Haik, Y.; Isaifan, R.J. Soiling of photovoltaic panels in the Gulf Cooperation Council countries and mitigation strategies. Sol. Energy Mater. Sol. Cells 2021, 231, 111303. [Google Scholar] [CrossRef]

- Khan, M.Z.; Ghaffar, A.; Bahattab, M.A.; Mirza, M.; Lange, K.; Abaalkheel, I.M.S.; Alqahtani, M.H.M.; Aldhuwaile, A.A.A.; Alqahtani, S.H.; Qasem, H.; et al. Outdoor performance of anti-soiling coatings in various climates of Saudi Arabia. Sol. Energy Mater. Sol. Cells 2021, 235, 111470. [Google Scholar] [CrossRef]

- Kadari, A.S.; Ech-Chergui, A.N.; Aïssa, B.; Mukherjee, S.K.; Benaioun, N.; Zakaria, Y.; Zekri, A.; Reda, C.M.; Mehdi, A.; Rabea, R.; et al. Growth and characterization of transparent vanadium doped zinc oxide thin films by means of a spray pyrolysis process for TCO application. J. Sol-Gel Sci. Technol. 2022, 103, 691–703. [Google Scholar] [CrossRef]

- Salvaggio, M.G.; Passalacqua, R.; Abate, S.; Perathoner, S.; Centi, G.; Lanza, M.; Stassi, A. Functional nano-textured titania-coatings with self-cleaning and antireflective properties for photovoltaic surfaces. Sol. Energy 2016, 125, 227–242. [Google Scholar] [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R.; et al. Techno-Economic Assessment of Soiling Losses and Mitigation Strategies for Solar Power Generation. Joule 2019, 3, 2303–2321. [Google Scholar] [CrossRef]

- Okubo, M.; Kuwahara, T. Emission regulations. In New Technologies for Emission Control in Marine Diesel Engines; Elsevier: Amsterdam, The Netherlands, 2019; pp. 25–51. [Google Scholar] [CrossRef]

- Micheli, L.; Muller, M. An investigation of the key parameters for predicting PV soiling losses. Prog. Photovolt. Res. Appl. 2017, 25, 291–307. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Alghoul, M.; Alawadhi, H. Experimental investigation of dust pollutants and the impact of environmental parameters on PV performance: An experimental study. Environ. Dev. Sustain. 2016, 20, 155–174. [Google Scholar] [CrossRef]

- Styszko, K.; Jaszczur, M.; Teneta, J.; Hassan, Q.; Burzyńska, P.; Marcinek, E.; Łopian, N.; Samek, L. An analysis of the dust deposition on solar photovoltaic modules. Environ. Sci. Pollut. Res. 2019, 26, 8393–8401. [Google Scholar] [CrossRef]

- Ilse, K.K.; Gurumoorthy, H.N.; Bahattab, M.A.; Alqahtani, S.H.; Mirza, M.; Glaubitt, W.; Naumann, V.; Hagendorf, C.; Bagdahn, J. Particle size-dependent adhesion forces and wind removal efficiency of anti-soiling coatings on textured solar glasses. MRS Commun. 2019, 9, 964–970. [Google Scholar] [CrossRef]

- Costa, S.C.; Diniz, A.S.A.; Kazmerski, L.L. Solar energy dust and soiling R&D progress: Literature review update for 2016. Renew. Sustain. Energy Rev. 2018, 82, 2504–2536. [Google Scholar] [CrossRef]

- Gostein, M.; Caron, J.R.; Littmann, B. Measuring soiling losses at utility-scale PV power plants. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC) 2014, Denver, CO, USA, 8–13 June 2014; pp. 885–890. [Google Scholar] [CrossRef]

- Jones, R.K.; Baras, A.; Al Saeeri, A.; Al Qahtani, A.; Al Amoudi, A.O.; Al Shaya, Y.; Alodan, M.; Al-Hsaien, S.A. Optimized Cleaning Cost and Schedule Based on Observed Soiling Conditions for Photovoltaic Plants in Central Saudi Arabia. IEEE J. Photovolt. 2016, 6, 730–738. [Google Scholar] [CrossRef]

- Gholami, A.; Saboonchi, A.; Alemrajabi, A.A. Experimental study of factors affecting dust accumulation and their effects on the transmission coefficient of glass for solar applications. Renew. Energy 2017, 112, 466–473. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Ayaz, A.; Ahmad, H.; Ahmad, F.; Khan, A.; Tarmazi, S.M.H.; Gul, R.M.; Saher, S. Self-cleaning of glass surface to maximize the PV cell efficiency. IOP Conf. Series: Mater. Sci. Eng. 2020, 899, 12006. [Google Scholar] [CrossRef]

- Miller, D.C.; Muller, M.T.; Simpson, L.J. Review of Artificial Abrasion Test Methods for PV Module Technology; National Renewable Energy Lab: Golden, CO, USA, 2016. [Google Scholar] [CrossRef]

- Nishioka, K.; Moe, S.P.; Ota, Y. Long-Term Reliability Evaluation of Silica-Based Coating with Antireflection Effect for Photovoltaic Modules. Coatings 2019, 9, 49. [Google Scholar] [CrossRef]

- Pandiyan, P.; Saravanan, S.; Chinnadurai, T.; Ramji, T.; Prabaharan, N.; Umashankar, S. Mitigation Techniques for Removal of Dust on Solar Photovoltaic System. In Electrical and Electronic Devices, Circuits, and Materials: Technological Challenges and Solutions; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 373–392. [Google Scholar] [CrossRef]

- Toth, S.; Muller, M.; Miller, D.C.; Moutinho, H.; To, B.; Micheli, L.; Linger, J.; Engtrakul, C.; Einhorn, A.; Simpson, L. Soiling and cleaning: Initial observations from 5-year photovoltaic glass coating durability study. Sol. Energy Mater. Sol. Cells 2018, 185, 375–384. [Google Scholar] [CrossRef]

- Kawasaki, H.; Ohshima, T.; Yagyu, Y.; Ihara, T.; Shinohara, M.; Suda, Y. Preparation of Sn doped SiO2 thin films by magnetron sputtering deposition using metal and metal-oxide powder targets. Jpn. J. Appl. Phys. 2018, 58, SAAD04. [Google Scholar] [CrossRef]

- Ali, K.; Khan, S.A.; Jafri, M.Z.M. Structural and optical properties of ITO/TiO2 anti-reflective films for solar cell applications. Nanoscale Res. Lett. 2014, 9, 175. [Google Scholar] [CrossRef]

- Jang, G.G.; Smith, D.B.; Polizos, G.; Collins, L.; Keum, J.K.; Lee, D.F. Transparent superhydrophilic and superhydrophobic nanoparticle textured coatings: Comparative study of anti-soiling performance. Nanoscale Adv. 2018, 1, 1249–1260. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, Y.; Jiang, C.; Liu, H.; Ji, Y.; Zhang, F.; Fan, R.; Chen, D. Effect of oxygen flow rate on microstructure properties of SiO2 thin films prepared by ion beam sputtering. J. Non-Cryst. Solids 2018, 482, 203–207. [Google Scholar] [CrossRef]

- Aïssa, B.B.; El Khakani, M.A. The channel length effect on the electrical performance of suspended-single-wall-carbon-nanotubes-based field effect transistors. Nanotechnology 2009, 20, 175203. [Google Scholar] [CrossRef]

- Abdullah, M.; Rusop, M. Novel ITO/arc-TiO2 antireflective conductive substrate for transmittance enhanced properties in dye-sensitized solar cells. Microelectron. Eng. 2013, 108, 99–105. [Google Scholar] [CrossRef]

- Hocine, D.; Belkaid, M.; Pasquinelli, M.; Escoubas, L.; Simon, J.; Rivière, G.; Moussi, A. Improved efficiency of multicrystalline silicon solar cells by TiO2 antireflection coatings derived by APCVD process. Mater. Sci. Semicond. Process. 2013, 16, 113–117. [Google Scholar] [CrossRef]

- Leem, J.W.; Yu, J.S.; Jun, D.-H.; Heo, J.; Park, W.-K. Efficiency improvement of III–V GaAs solar cells using biomimetic TiO2 subwavelength structures with wide-angle and broadband antireflection properties. Sol. Energy Mater. Sol. Cells 2014, 127, 43–49. [Google Scholar] [CrossRef]

- Lien, S.; Wuu, D.; Yeh, W.; Liu, J. Tri-layer antireflection coatings (SiO2/SiO2–TiO2/TiO2) for silicon solar cells using a sol–gel technique. Sol. Energy Mater. Sol. Cells 2006, 90, 2710–2719. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, J.C.; Zhao, B.X.; Sun, J.J. Sputtered TiO2 Films for Photovoltaic Cell’s Antireflection Coating. Int. J. Nanosci. 2012, 11, 1250008. [Google Scholar] [CrossRef]

- Li, D.; Wan, D.; Zhu, X.; Wang, Y.; Han, Z.; Han, S.; Shan, Y.; Huang, F. Broadband antireflection TiO2–SiO2 stack coatings with refractive-index-grade structure and their applications to Cu(In,Ga)Se2 solar cells. Sol. Energy Mater. Sol. Cells 2014, 130, 505–512. [Google Scholar] [CrossRef]

- Taheri, M.L.; McGowan, S.; Nikolova, L.; Evans, J.E.; Teslich, N.; Lu, J.P.; LaGrange, T.; Rosei, F.; Siwick, B.J.; Browning, N.D. In situ laser crystallization of amorphous silicon: Controlled nanosecond studies in the dynamic transmission electron microscope. Appl. Phys. Lett. 2010, 97, 32102. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, W.; Han, M.; Guan, L.; Han, L.; Hemraj, A.; Tam, K.C. A durable and sustainable superhydrophobic surface with inter-twined cellulose/SiO2 blends for anti-icing and self-cleaning applications. Mater. Des. 2022, 217, 110628. [Google Scholar] [CrossRef]

- Yu, X.; Liu, X.; Shi, X.; Zhang, Z.; Wang, H.; Feng, L. SiO2 nanoparticle-based superhydrophobic spray and multi-functional surfaces by a facile and scalable method. Ceram. Int. 2019, 45, 15741–15744. [Google Scholar] [CrossRef]

- Zhang, L.; Xue, X.; Zhang, H.; Huang, Z.; Zhang, Z. Superhydrophobic surface with excellent me-chanical robustness, water impact resistance and hydrostatic pressure resistance by two-step spray-coating tech-nique. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106405. [Google Scholar] [CrossRef]

- Available online: https://www.verifiedmarketresearch.com/wp-content/uploads/2021/04/Solar-Panel-Coatings-Market-Size-And-Forecast.jpg (accessed on 11 July 2022).

- Available online: https://www.verifiedmarketresearch.com/wp-content/uploads/2021/04/Solar-Panel-Coatings-Market-Segmentation-Analysis.jpg (accessed on 12 July 2022).

| O–Si | O | Si–O | Si | C | C-Fx | F | O–Si/Si–O | C-Fx/F | |

|---|---|---|---|---|---|---|---|---|---|

| Uncoated | 53.7 | 6 | 27.1 | 0 | 7.2 | 0 | 0 | 2.0 | — |

| SPH | 53.1 | 10.0 | 27.1 | 3.0 | 6.3 | 0 | 0 | 2.0 | — |

| SP | 45.8 | 0.4 | 22.5 | 0.0 | 7.7 | 7.0 | 15.5 | 2.0 | 0.45 |

| Cell Type | Coating Method | ARC Materials | ARC Thickness (nm) | Reflectivity Measurement | Cell Characteristics | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Range, λ (nm) | Reflectance (%) | Jsc | Voc | FF | ɳ (%) | |||||

| Dye-sensitized solar cell (ITO/p-TiO2) | Without ARC RF magnetron | TiO2 sputtering | - | - | 6.17 | 0.662 | 6.17 | 2.30 | [65] | |

| 60 | - | 8.93 | 0.669 | 0.58 | 3.44 | |||||

| Multicrystalline silicon solar cells GaAs solar cell | Without ARC APCVD | TiO2 without ARC electron beam TiO2 evaporation and dry TiO2 (SWS) etching | 300–1150 | 35.0 | 28.63 | 0.561 | 70 | 11.24 | [66] | |

| 60 | 8.6 | 33.86 | 0.585 | 72 | 14.26 | |||||

| 350–900 | >40 | 18.38 | 1.011 | 79.22 | 14.74 | [67] | ||||

| ∼63 | 9.5 | 23.65 | 1.012 | 79.46 | 18.98 | |||||

| 50 | 6.2 | 24.82 | 1.012 | 78.42 | 19.66 | |||||

| Monocrystalline silicon solar cell | Without ARC sol–gel process and TiO2 dip coating SiO2/TiO2 (DLAR) SiO2/SiO2- TiO2/TiO2 (TLAR) | 400–1000 | 37.0 | 16.2 | 0.61 | 76.4 | 11.36 | [68] | ||

| 56.8 | 9.3 | 24.8 | 0.61 | 76.2 | 14.49 | |||||

| 41.3/64.6 | 6.2 | 25.8 | 0.61 | 76.6 | 14.99 | |||||

| 56.8/ | 3.2 | 27.1 | 0.61 | 76.7 | 15.85 | |||||

| 69.4/86.8 | ||||||||||

| Silicon solar cell | Without ARC DC reactive | TiO2 magnetron SiO2/TiO2 sputtering (DLAR) | 400–900 | 36.0 | 24.8 | 0.62 | 79.1 | 12.2 | [69] | |

| ∼100 | 10.3 | 34.2 | 0.63 | 77.9 | 16.8 | |||||

| ∼90/∼110 | 3.7 | 37.2 | 0.63 | 78.2 | 18.4 | |||||

| Monocrystalline silicon solar cell | Without ARC RF magnetron | SiO2 sputtering TiO2/SiO2 (DLAR) | 400–1000 | 35 | 9.24 | 0.442 | 69 | 2.8 | [61] | |

| 81.1 | 15 | 12.35 | 0.504 | 72 | 4.5 | |||||

| 18.0/40.7 | 7 | 16.13 | 0.520 | 75 | 6.2 | |||||

| CIGS: Cu(In,Ga)Se2 solar cell | Without ARC Sol–gel process and TiO2–SiO2 dip coating | Stacks | 250–2500 | - | 33.36 | 0.510 | 65.85 | 11.20 | [70] | |

| Six stacks | - | 35.12 | 0.521 | 66.40 | 12.15 | |||||

| 36–115 | ||||||||||

| Crystalline silicon solar cell | Without ARC electron beam evaporation | TiO2 In/TiO2 Al2O3/In/TiO2 | 400–1050 | - | 26.10 | 0.54 | - | 10.96 | [71] | |

| 20 | - | 30.38 | 0.55 | - | 12.84 | |||||

| 3.8/20 | - | 32.16 | 0.55 | - | 13.69 | |||||

| 65/3.8/20 | - | 39.89 | 0.55 | - | 16.93 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.I.; Ali, A.; Bermudez Benito, V.; Figgis, B.; Aïssa, B. Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview. Materials 2022, 15, 7139. https://doi.org/10.3390/ma15207139

Hossain MI, Ali A, Bermudez Benito V, Figgis B, Aïssa B. Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview. Materials. 2022; 15(20):7139. https://doi.org/10.3390/ma15207139

Chicago/Turabian StyleHossain, Mohammad Istiaque, Adnan Ali, Veronica Bermudez Benito, Benjamin Figgis, and Brahim Aïssa. 2022. "Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview" Materials 15, no. 20: 7139. https://doi.org/10.3390/ma15207139

APA StyleHossain, M. I., Ali, A., Bermudez Benito, V., Figgis, B., & Aïssa, B. (2022). Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview. Materials, 15(20), 7139. https://doi.org/10.3390/ma15207139