Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life

Abstract

1. Introduction

2. Materials and Methods

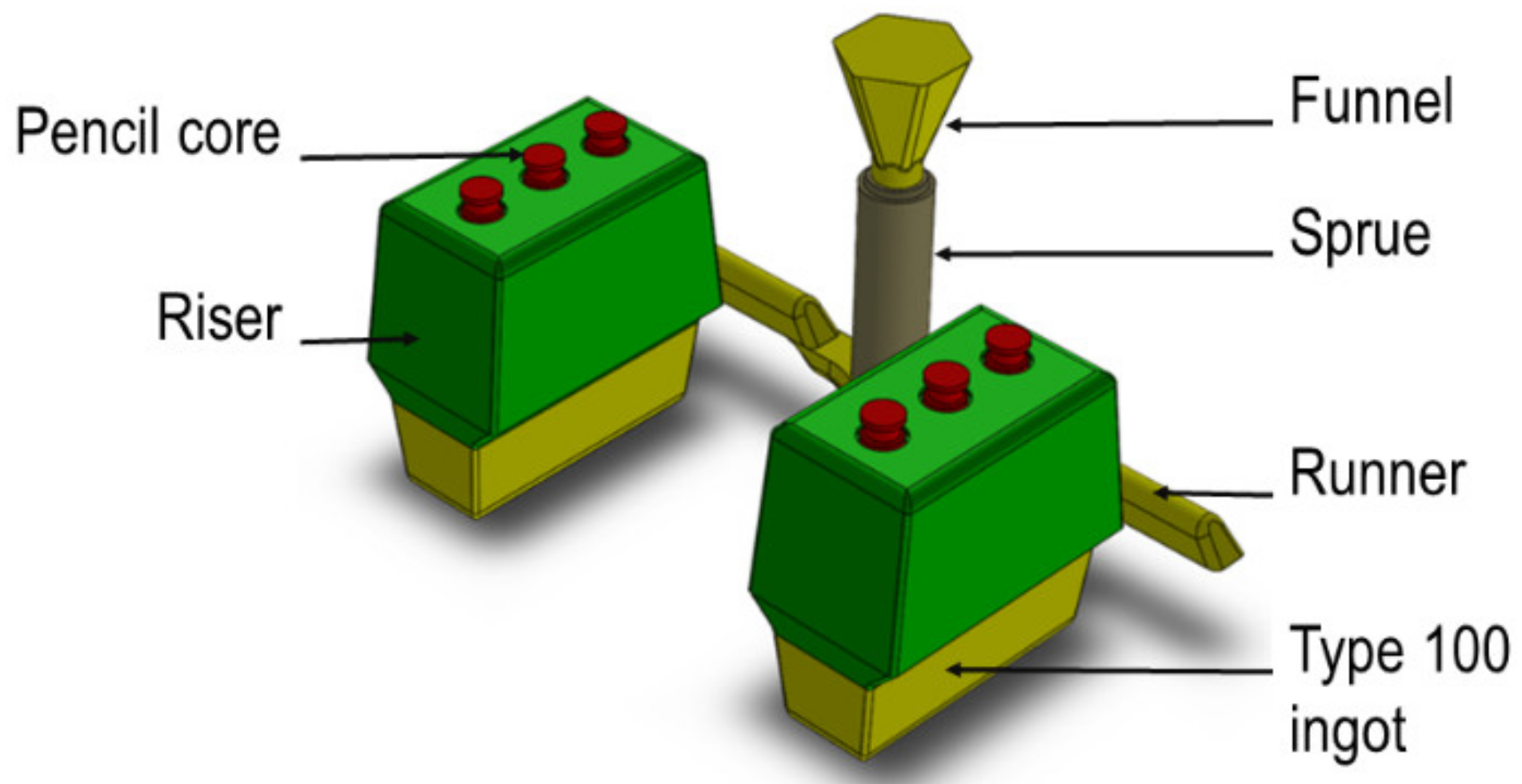

2.1. Ingots Casting

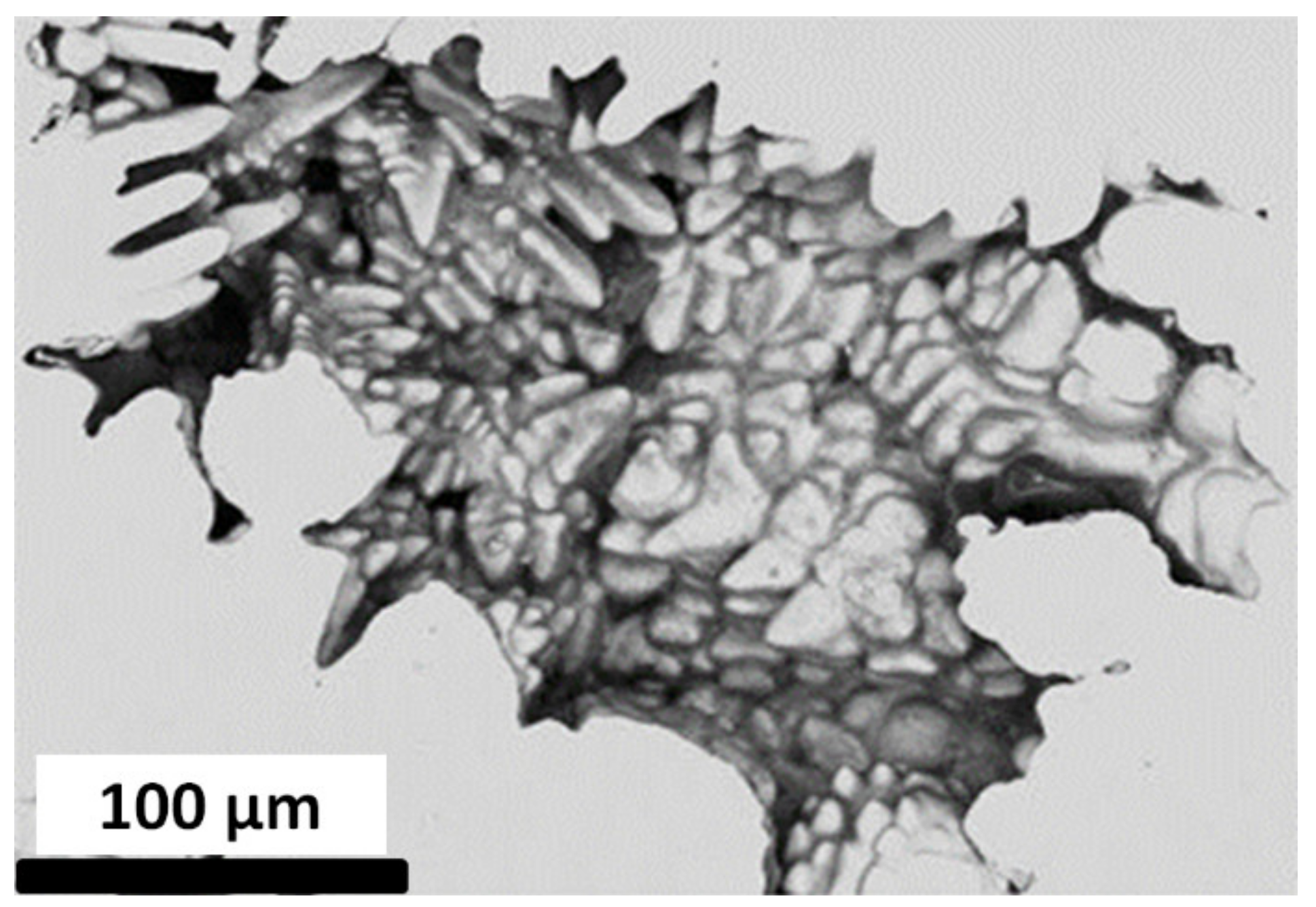

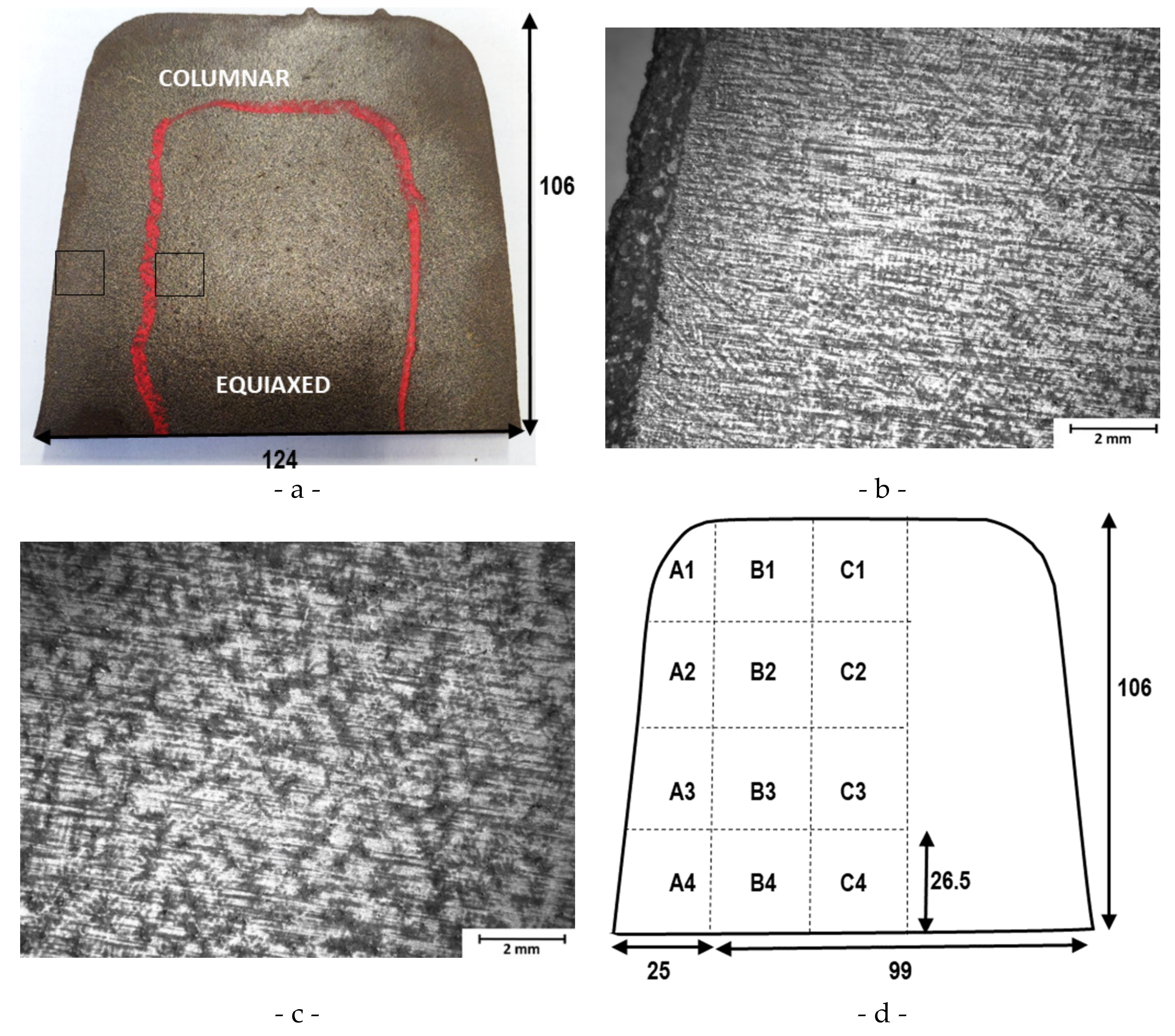

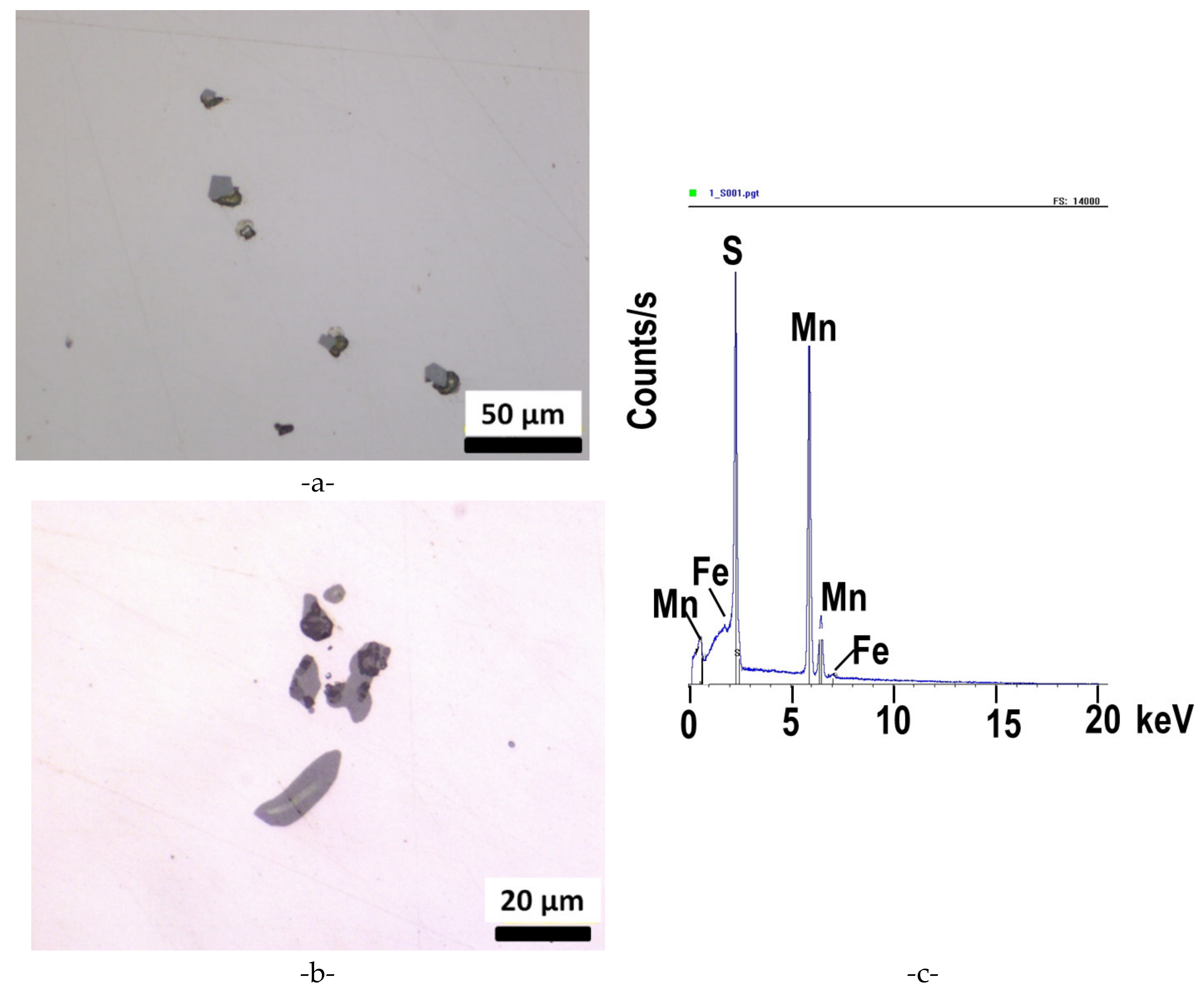

2.2. Microstructure

2.3. Mechanical Tests

2.3.1. Sample Preparation

2.3.2. Monotonic Mechanical Tests

2.3.3. Low Cycle Fatigue Tests

3. Microstructure and Mechanical Characterization

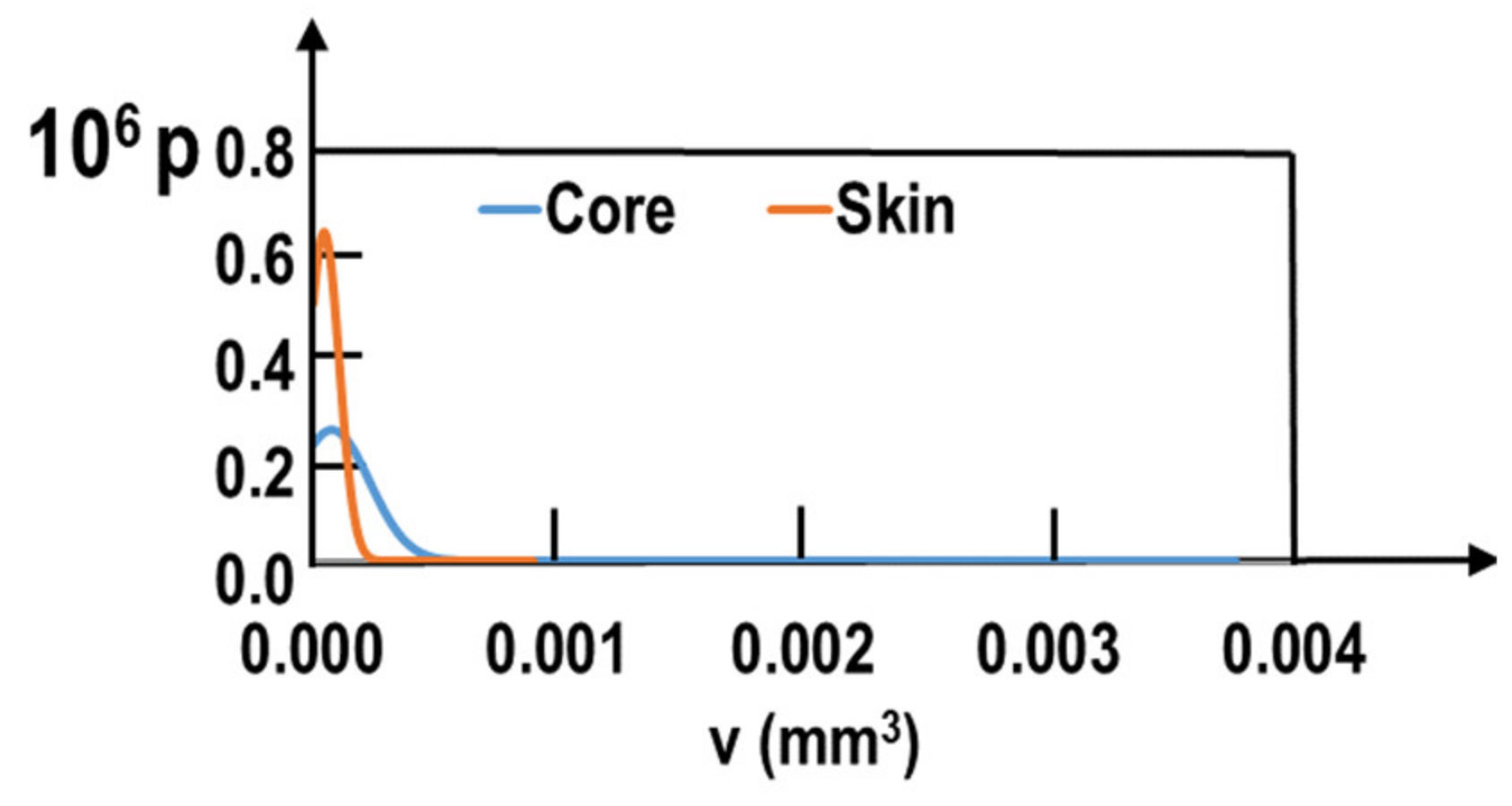

3.1. Microstructure

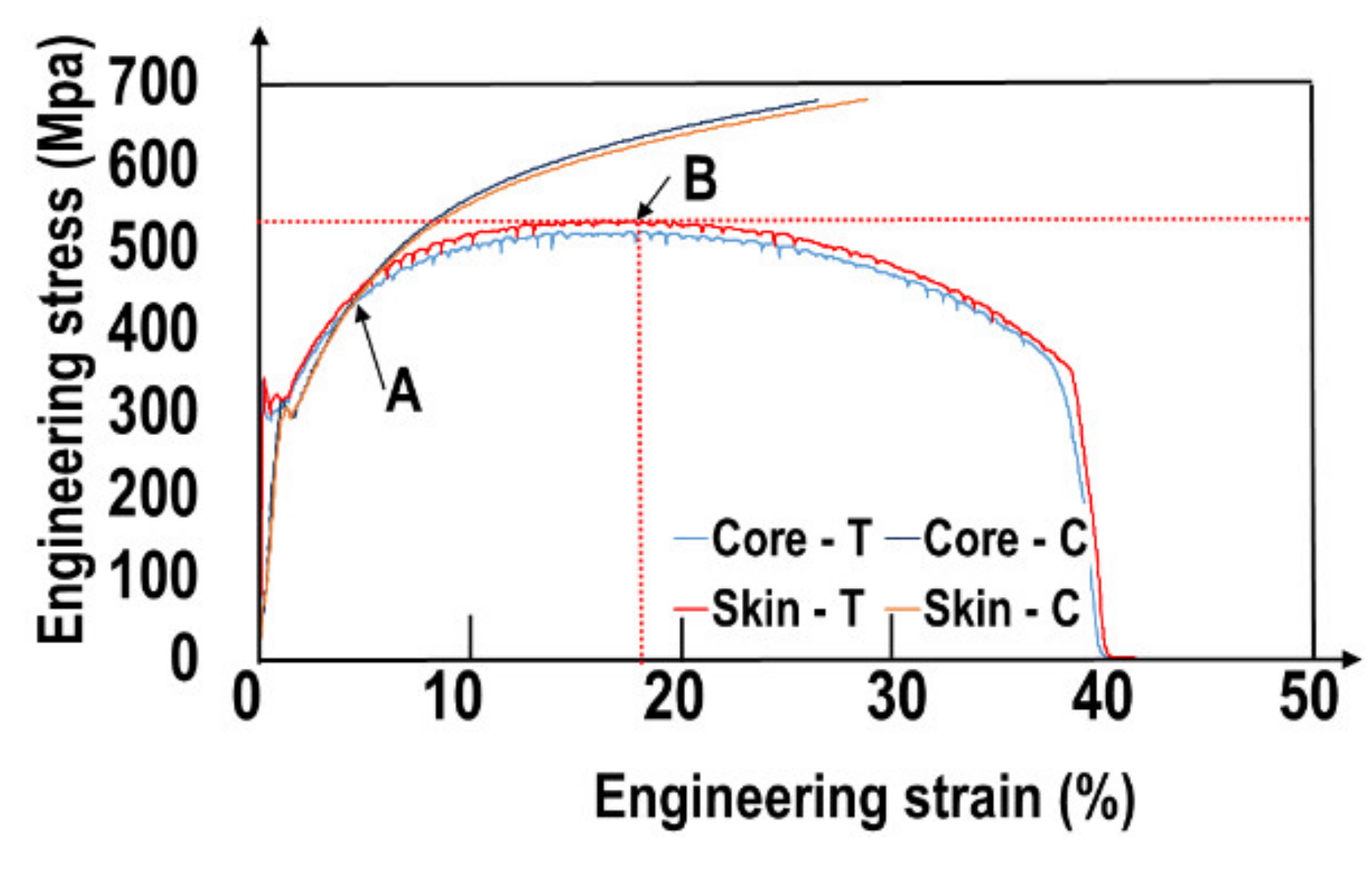

3.2. Monotonic Mechanical Properties

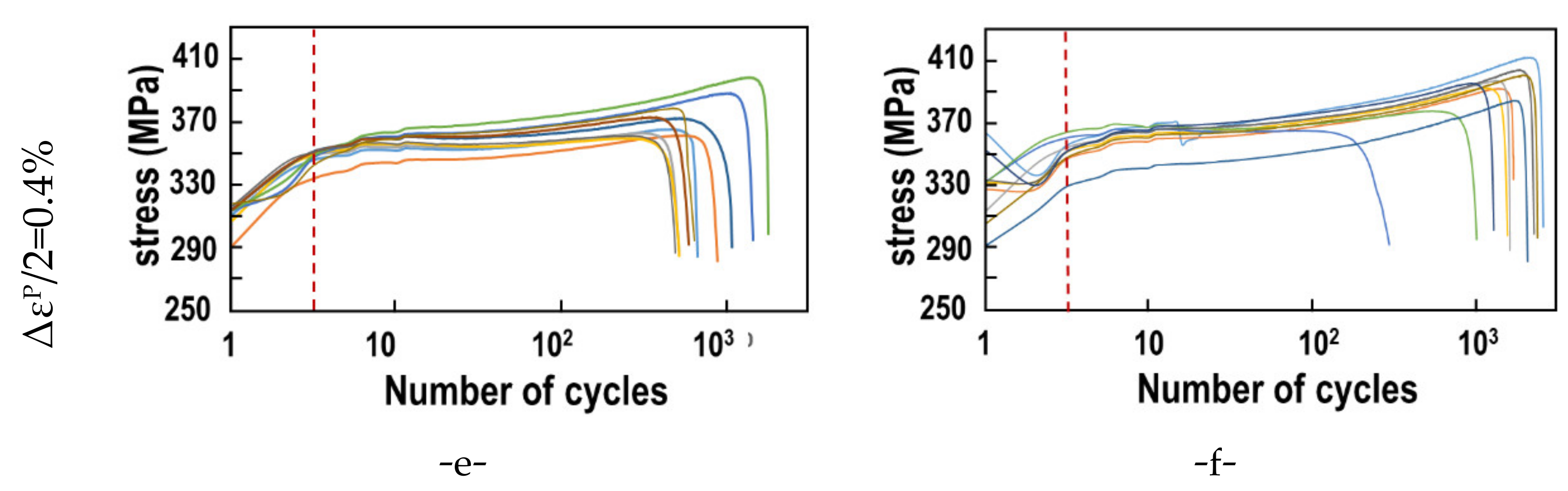

4. Low Cycle Fatigue Tests

4.1. Low Cycle Fatigue S-N-Curves

4.2. Number of Cycles at Failure

4.2.1. Manson–Coffin Parameters

4.2.2. Difference between Ingot Core and Skin

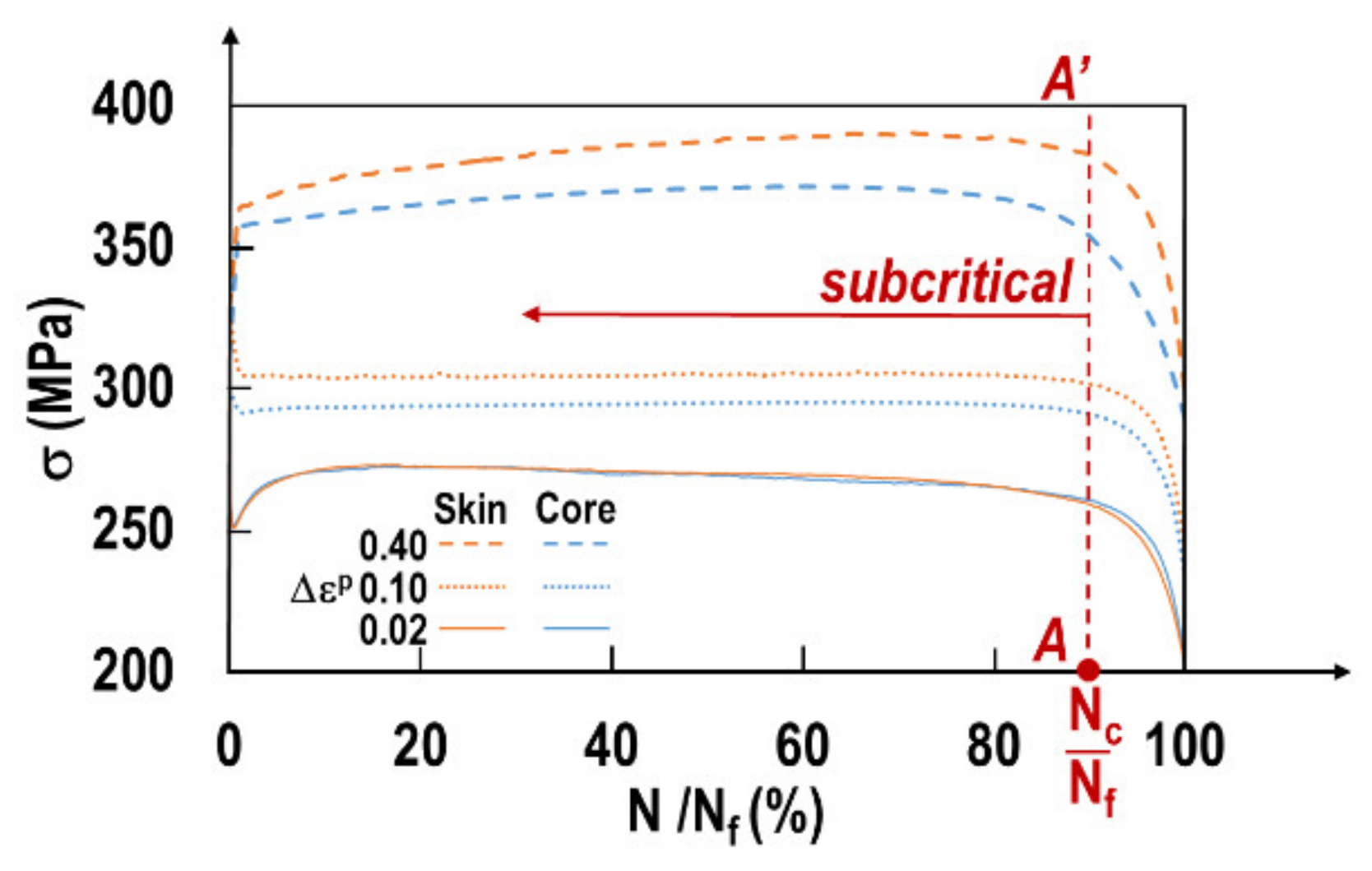

4.3. Remaining Load Carrying Capacity during Cycling

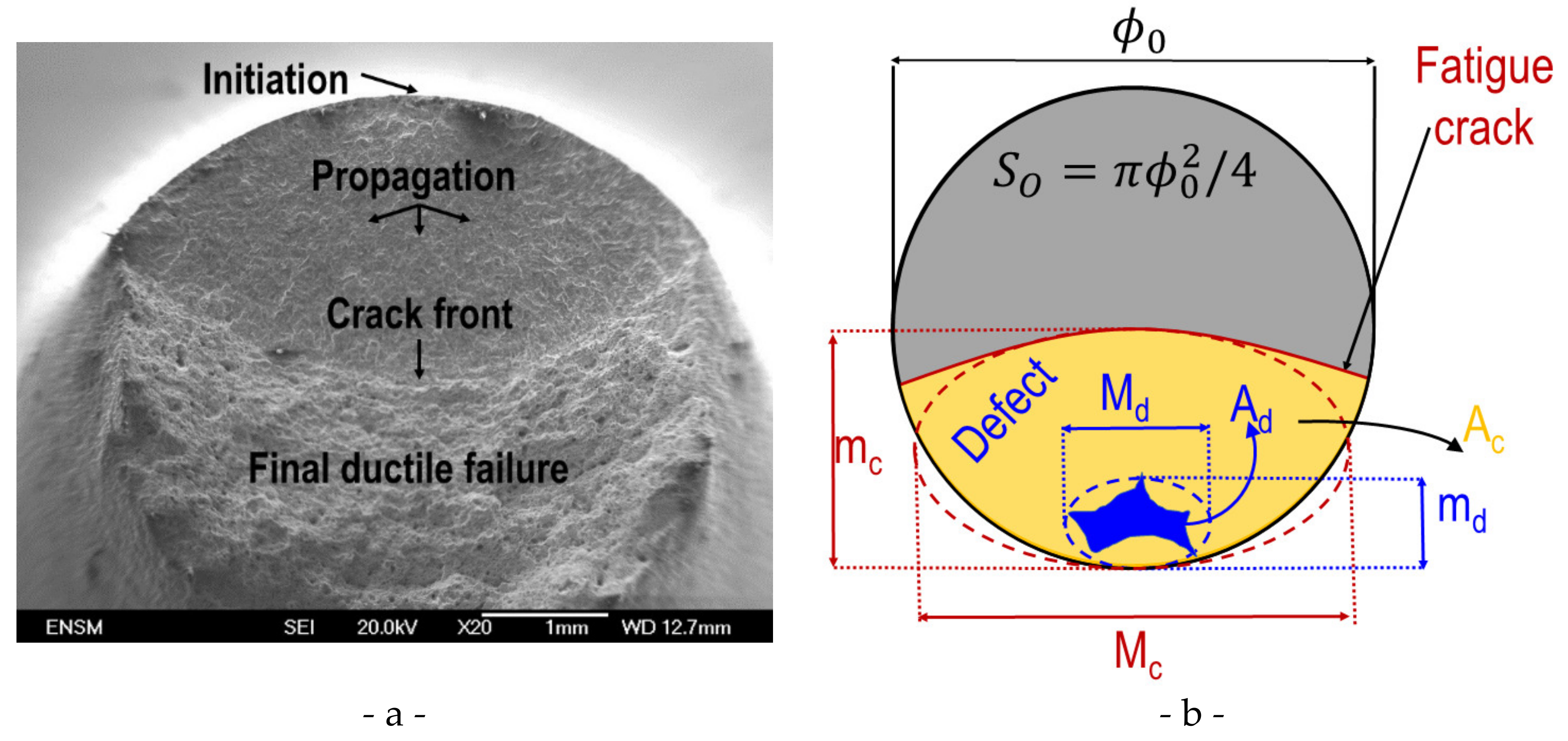

4.4. Microscopic Analysis of Damage and Murakami Type Law

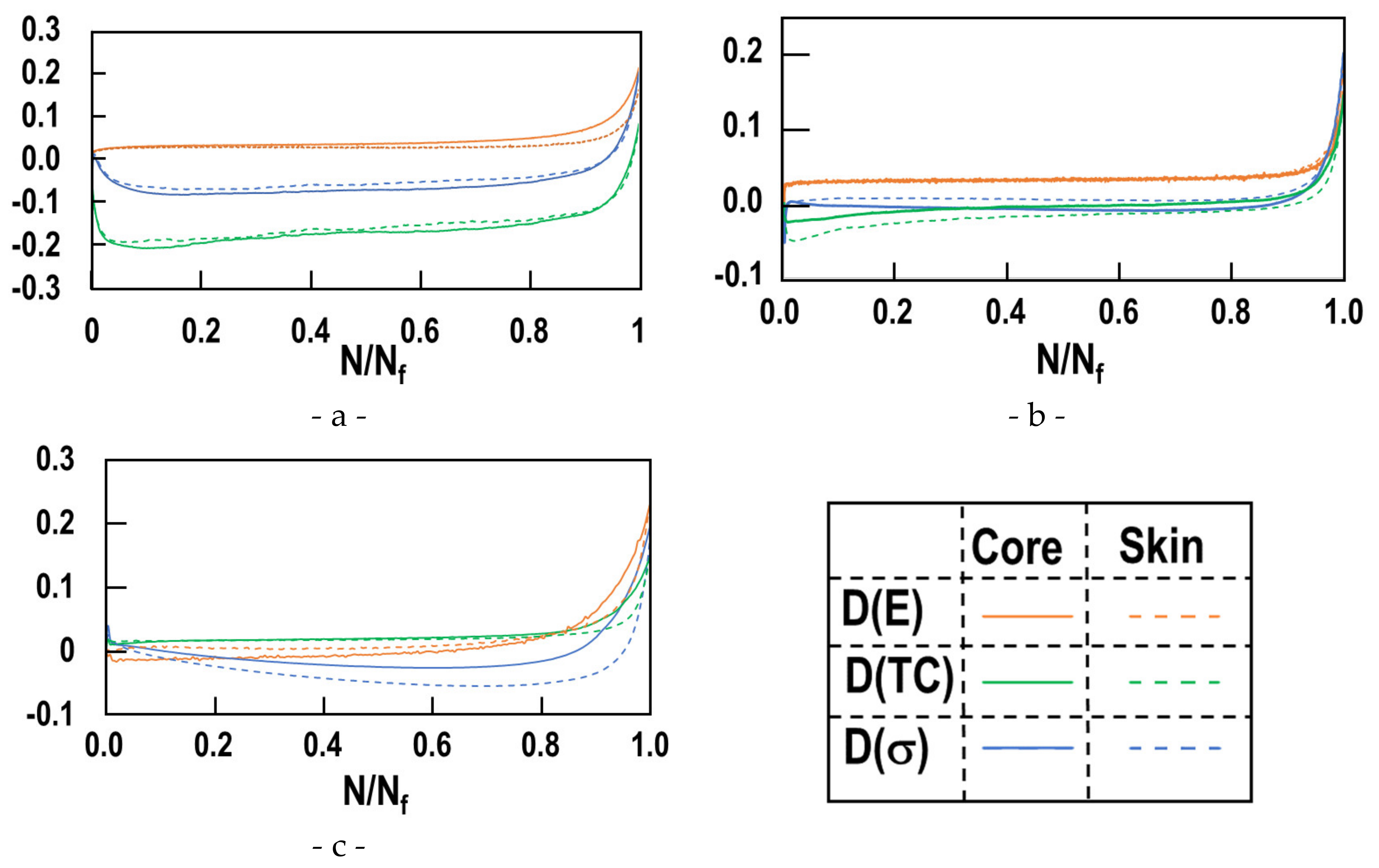

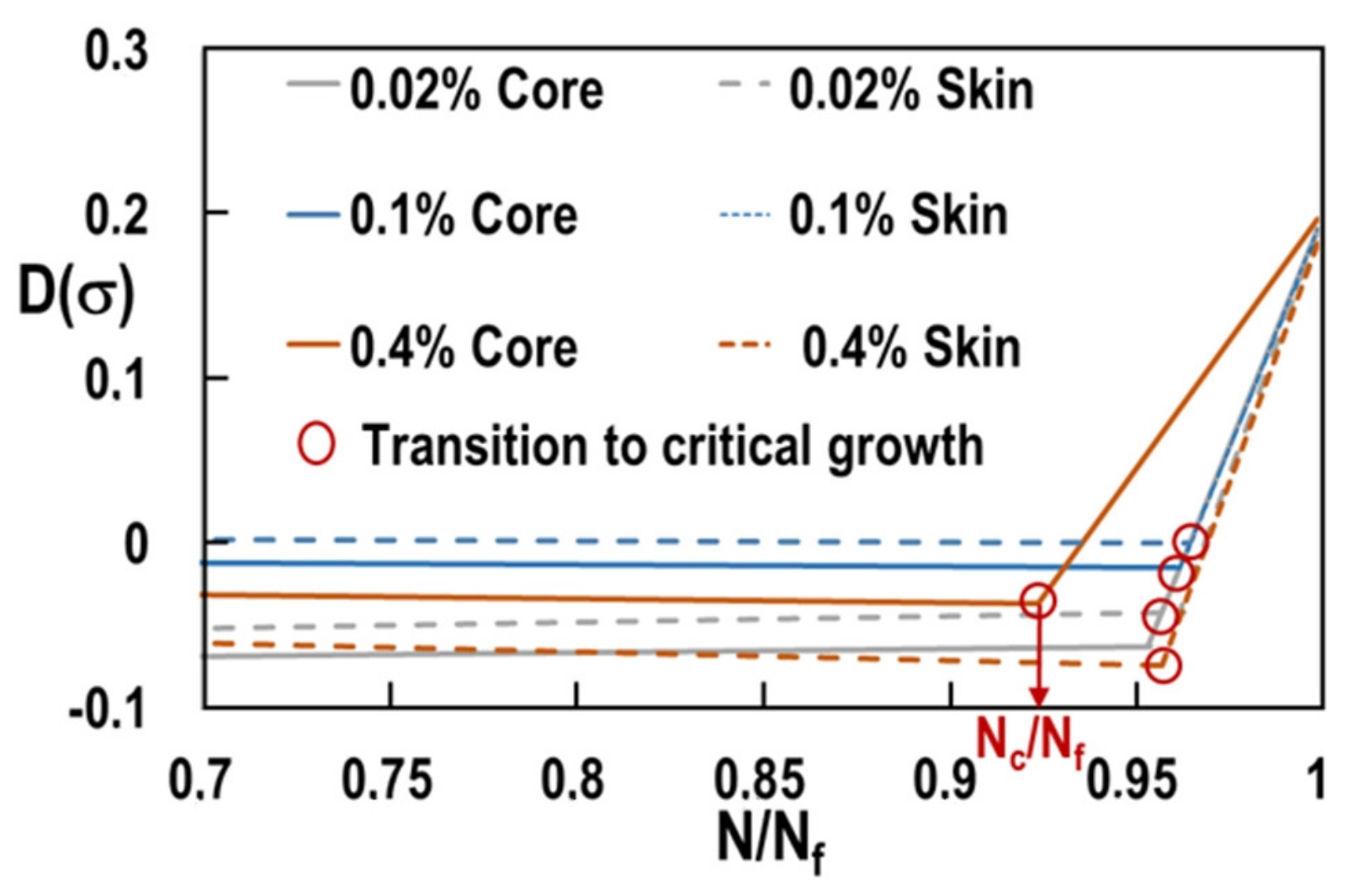

4.4.1. Different Damage Parameters

4.4.2. Murakami Type Analysis

5. Discussion and Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Stefanescu, D.M. ASM Handbook; ASM International the Materials Information Company: Materials Park, OH, USA, 2008; Volume 15, Chapter 1; ISBN 978-0-87170-711-6. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 2004; ISBN 978-0-521-57847-9. [Google Scholar]

- Pineau, A.; Bathias, C. Fatigue of Materials and Structures, Fundamentals; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Francois, D.; Pineau, A.; Zaoui, A. Mechanical Behaviour of Materials, Volume II: Fracture Mechanics and Damage, Solid Mechanics and its Applications; Gladwell, G.M.I., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 191, pp. 305–362. [Google Scholar]

- Mughrabi, H. Dislocations clustering and long range internal stresses in monotonically and cyclically deformed metal crystals. Rev. Phys Appl. 1988, 23, 367–379. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 0-08-044064-9. [Google Scholar]

- Zerbst, U.; Klinger, C. Material defects as cause for the fatigue failure of metallic components. Int. J. Fatigue 2019, 127, 312–323. [Google Scholar] [CrossRef]

- Dantzig, J.; Rappaz, M. Solidification, 2nd ed.; EPFL Press: Lausanne, Switzerland, 2016. [Google Scholar]

- Masson, J.-M. Fonderie et Moulage de l’acier-Évolution des Procédés D’élaboration, Techniques de L’ingénieur. 2005. Available online: https://www.techniques-ingenieur.fr/ (accessed on 4 October 2022).

- Bhadeshia, H.; Honeycombe, R. Honeycombe, Steels: Microstructure and Properties, 4th ed.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Niyama, E. A Method of Shrinkage Prediction and Its Application to Steel Casting Practice. AFS Int. Cast Met. J. 1982, 3, 507–517. [Google Scholar]

- Rotella, A. Fatigue d’un Alliage D’aluminium Moulé A357-T6: Rôle de la Morphologie, de la Position des Défauts et Application à Une Structure Pour le Calcul de la Durée de vie en Fatigue. Ph.D. Thesis, ISAE-ENSMA, Chasseneuil-du-Poitou, France, 2017. [Google Scholar]

- Standard E446; Reference Radiographs for Steel Castings up to 2 inches (51 mm) in Thickness. 2002 Annual Book of ASTM Standards; American Society of Testing and Materials: West Conshohocken, PA, USA, 2002; Volume 3, pp. 189–191.

- Standard E186; Standard Reference Radiographs for Heavy-Walled 4 ½ to 12-in. (114 to 305-mm) Steel Castings. 2002 Annual Book of ASTM Standards; American Society of Testing and Materials: West Conshohocken, PA, USA, 2002; Volume 3, pp. 81–83.

- Standard E280; Standard Reference Radiographs for Heavy-Walled 2 to 4 ½-in. (51 to 114-mm) Steel Castings. 2002 Annual Book of ASTM Standards; American Society of Testing and Materials: West Conshohocken, PA, USA, 2002; Volume 3, pp. 125–127.

- Beckermann, C.; Hardin, R.A. Effect of Porosity on Mechanical Properties of 8630 Cast Steel. In Proceedings of the 58th SFSA Technical and Operating Conference, no Paper No 4.4, Chicago, IL, USA, 4–6 November 2004. [Google Scholar]

- Serrano-Munoz, I.; Jean-Yves Buffiere, J.-Y.; Mokso, R.; Verdu, C.; Nadot, Y. Location, location & size: Defects close to surfaces dominate fatigue crack initiation, Nature. Sci. Rep. 2017, 7, 45239. [Google Scholar] [CrossRef]

- Carlson, K.D.; Beckermann, C. Prediction of Shrinkage Pore Volume Fraction Using a Dimensionless Niyama Criterion. Metall. Mater. Trans. A 2009, 40, 163–175. [Google Scholar] [CrossRef]

- Shouzhu, O.; Carlson, K.D.; Hardin, R.A.; Beckermann, C. Development of New Feeding-Distance Rules Using Casting Simulation: Part II. The New Rules. Metall. Mater. Trans. B 2002, 33, 741–755. [Google Scholar]

- Han, Q.; Guo, Q.; Yin, Y.; Xing, Y. Fatigue Behaviour of G20Mn5QT Cast Steel and Butt Welds with Q345B Steel. Int. J. Steel Struct. 2016, 16, 139–149. [Google Scholar] [CrossRef]

- Wu, S.C.; Qin, Q.B.; Hu, Y.N.; Branco, R.; Li, C.H.; Williams, C.J.; Zhang, W.H. The microstructure, mechanical, and fatigue behaviors of MAG welded G20Mn5 cast steel. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1051–1063. [Google Scholar] [CrossRef]

- Nagel, S.; Rauber, C.; Veile, I.; Knödel, P.; Ummenhofer, T. Influence of internal imperfections on the fatigue resistance of cast steel–testing methodology. MATEC Web Conf. 2019, 300, 09001. [Google Scholar] [CrossRef]

- CTIF. Méthode Micrographique de Détermination des Inclusions non Métalliques des Aciers Moulés (BNIF 500). Available online: https://ctif-editions.com/ (accessed on 4 October 2022).

- Manson, S.S. Behavior of Materials under Conditions of Thermal Stress; REPORT 1170; National Advisory Committee for Aeronautics: Moffett Field, CA, USA, 1954.

- Manson, S.S.; Halford, G.R. Fatigue and Durability of Structural Materials; ASM International: Materials Park, OH, USA, 2006; ISBN 0-87170-825-6. [Google Scholar]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge University Press: New York, NY, USA, 1990; Chapter 7. [Google Scholar]

- Murakami, Y.; Endo, M. Quantitative evaluation of fatigue strength of metals containing various small defects or cracks. Eng. Fract. Mech. 1983, 17, 1–15. [Google Scholar]

- Xua, Y.; Lia, Z.; Xua, J.; Han, Q. Fatigue crack growth of G20Mn5QT cast steel based on a two parameter driving force model. Eng. Fract. Mech. 2019, 208, 13–26. [Google Scholar] [CrossRef]

- Łagoda, T.; Vantadori, S.; Głowacka, K.; Kurek, M.; Kluger, K. Using the Smith-Watson-Topper Parameter and Its Modifications to Calculate the Fatigue Life of Metals: The State-of-the-Art. Materials 2022, 15, 3481. [Google Scholar] [CrossRef]

| C | Mn | Si | S | P | Ni | Cr | Mo | V | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.18 | 1.12 | 0.36 | 0.009 | 0.011 | 0.07 | 0.26 | 0.05 | 0.005 | 0.05 | 97.8 |

| Strain Level | Signal (Strain) | Censoring (Cycles) | Shutoff | |

|---|---|---|---|---|

| 1 | 0.02 | Triangular | 106 | |

| 2 | 0.1 | 105 | ||

| 3 | 0.4 | 104 |

| Location | G Index | |

|---|---|---|

| Skin | 16.4 | 8.8 |

| Core | 16.9 | 8.9 |

| Location | MnS Type III (Fine) | MnS Type III (Thick) |

|---|---|---|

| Skin | 1.13 | 0.60 |

| Core | 1.08 | 0.68 |

| Location | ||||

|---|---|---|---|---|

| skin | 0.0104 | 403 | 5.3 104 | 46.6 |

| core | 0.00947 | 234 | 8.8 104 | 55.2 |

| Core | Skin | |

|---|---|---|

| UTS (Mpa) | 518 | 528 |

| Rp0.2 (Mpa) | 293 | 309 |

| A% (%) | 37% | 37% |

| Ferrite micro-hardness (HV) | 113 | 121 |

| Pearlite micro-hardness (HV) | 303 | 291 |

| Macro-hardness (HV) | 140 | 142 |

| ΔεP/2 | |||||

|---|---|---|---|---|---|

| 0.02% | 0.1% | 0.4% | |||

| Core | Skin | Core | Skin | Core | Skin |

| 92339 | 108684 | 13796 | 17940 | 835 | 1697 |

| c | ||

|---|---|---|

| Skin | 0.2996 | 0.714 |

| Core | 0.8822 | 0.626 |

| Global | 0.5536 | 0.677 |

| ΔεP/2 | |||||||

|---|---|---|---|---|---|---|---|

| 0.02% | 0.1% | 0.4% | |||||

| Core | Skin | Core | Skin | Core | Skin | ||

| Number of cycles at failure Nf | mean | 92339 | 108684 | 13796 | 17940 | 835 | 1 697 |

| stand. dev. | 29511 | 20524 | 4703 | 3776 | 433 | 704 | |

| stand. dev./mean | 34% | 20% | 34% | 21% | 52% | 41% | |

| max. | 139875 | 148455 | 22677 | 24428 | 1741 | 2617 | |

| Min. | 48754 | 83775 | 8937 | 13195 | 473 | 298 | |

| 15% | 30% | 51% | |||||

| σstab. (MPa) | 251.5 | 251.7 | 292.2 | 308.6 | 362.2 | 369.4 | |

| Damage Variable | Δεp/2 | |||||

|---|---|---|---|---|---|---|

| 0.02% | 0.1% | 0.4% | ||||

| Core | Skin | Core | Skin | Core | Skin | |

| D1 | 28% | 24% | 30% | 29% | 30% | 35% |

| D2 | 28% | 24% | 28% | 29% | 30% | 35% |

| D3 | 34% | 33% | 36% | 38% | 39% | 44% |

| D4 | 35% | 34% | 36% | 38% | 38% | 43% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bermond, A.; Roume, C.; Stolarz, J.; Lenci, M.; Carton, J.-F.; Klocker, H. Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life. Materials 2022, 15, 7072. https://doi.org/10.3390/ma15207072

Bermond A, Roume C, Stolarz J, Lenci M, Carton J-F, Klocker H. Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life. Materials. 2022; 15(20):7072. https://doi.org/10.3390/ma15207072

Chicago/Turabian StyleBermond, Antonin, Claire Roume, Jacques Stolarz, Matthieu Lenci, Jean-François Carton, and Helmut Klocker. 2022. "Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life" Materials 15, no. 20: 7072. https://doi.org/10.3390/ma15207072

APA StyleBermond, A., Roume, C., Stolarz, J., Lenci, M., Carton, J.-F., & Klocker, H. (2022). Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life. Materials, 15(20), 7072. https://doi.org/10.3390/ma15207072