The Stress−Dilatancy Behaviour of Artificially Bonded Soils

Abstract

1. Introduction

2. General Stress−Plastic Dilatancy Equation

3. Stress–Strain Behaviour of Cemented Sand in Triaxial Compression

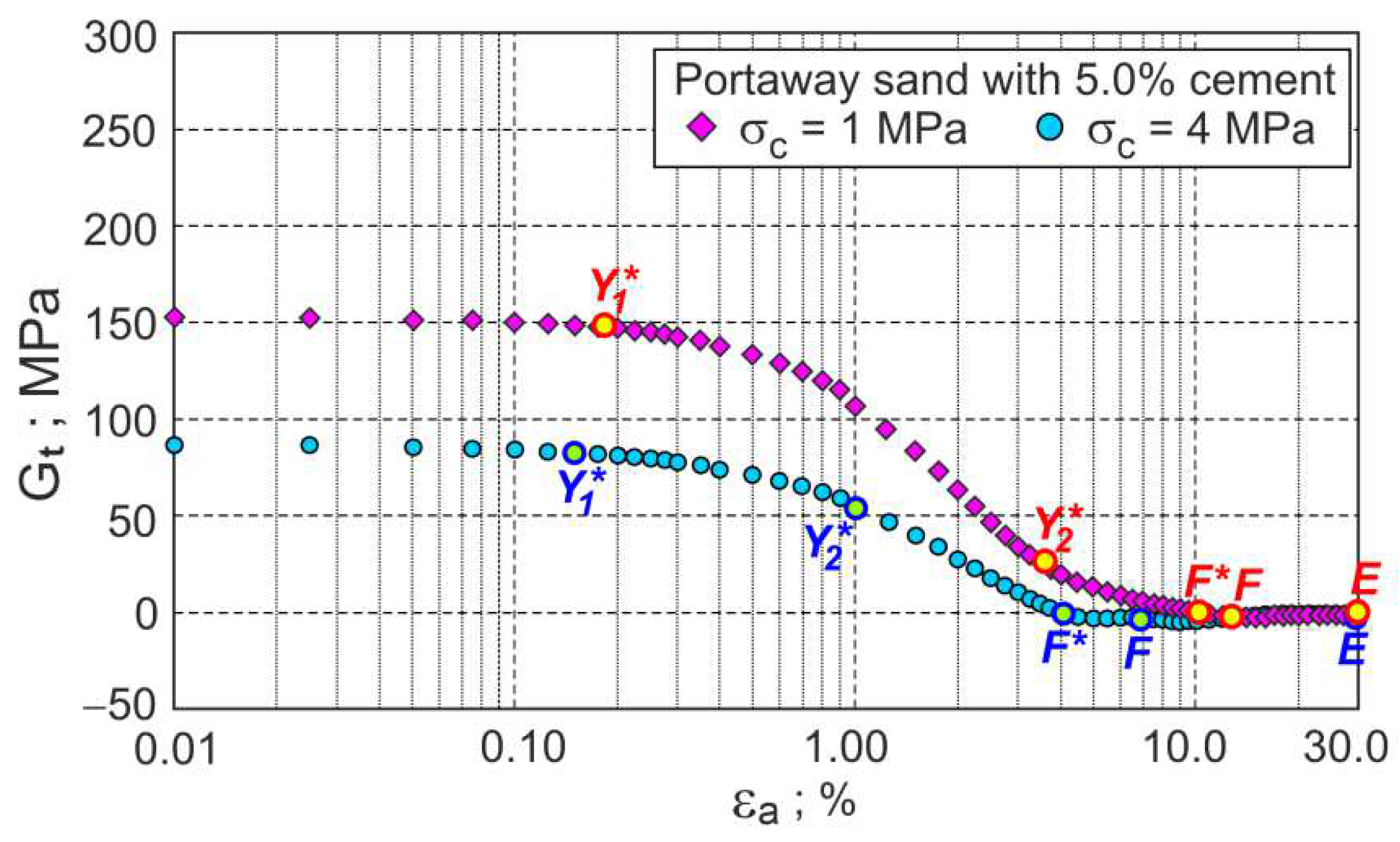

3.1. Characteristic Stages of Shearing

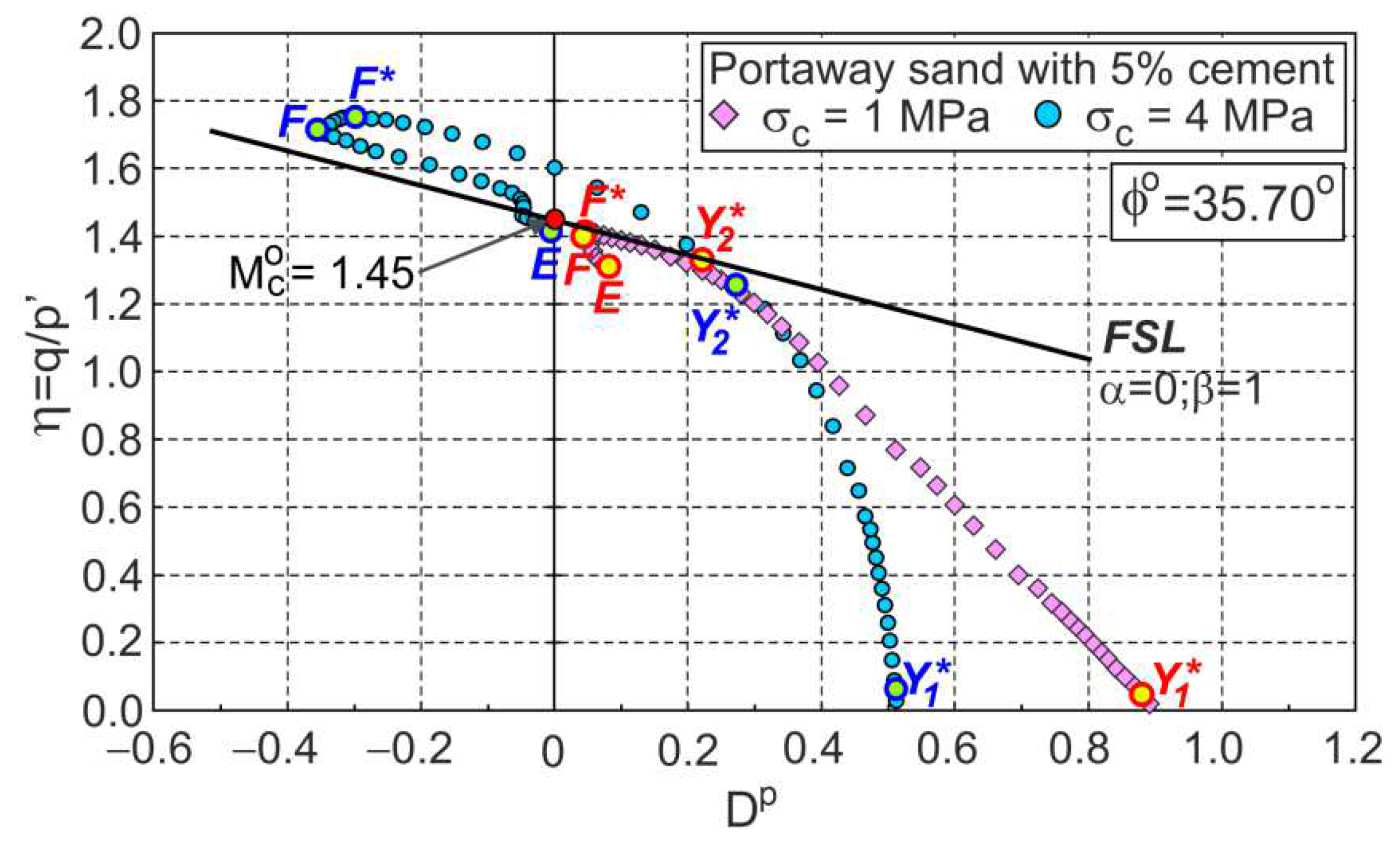

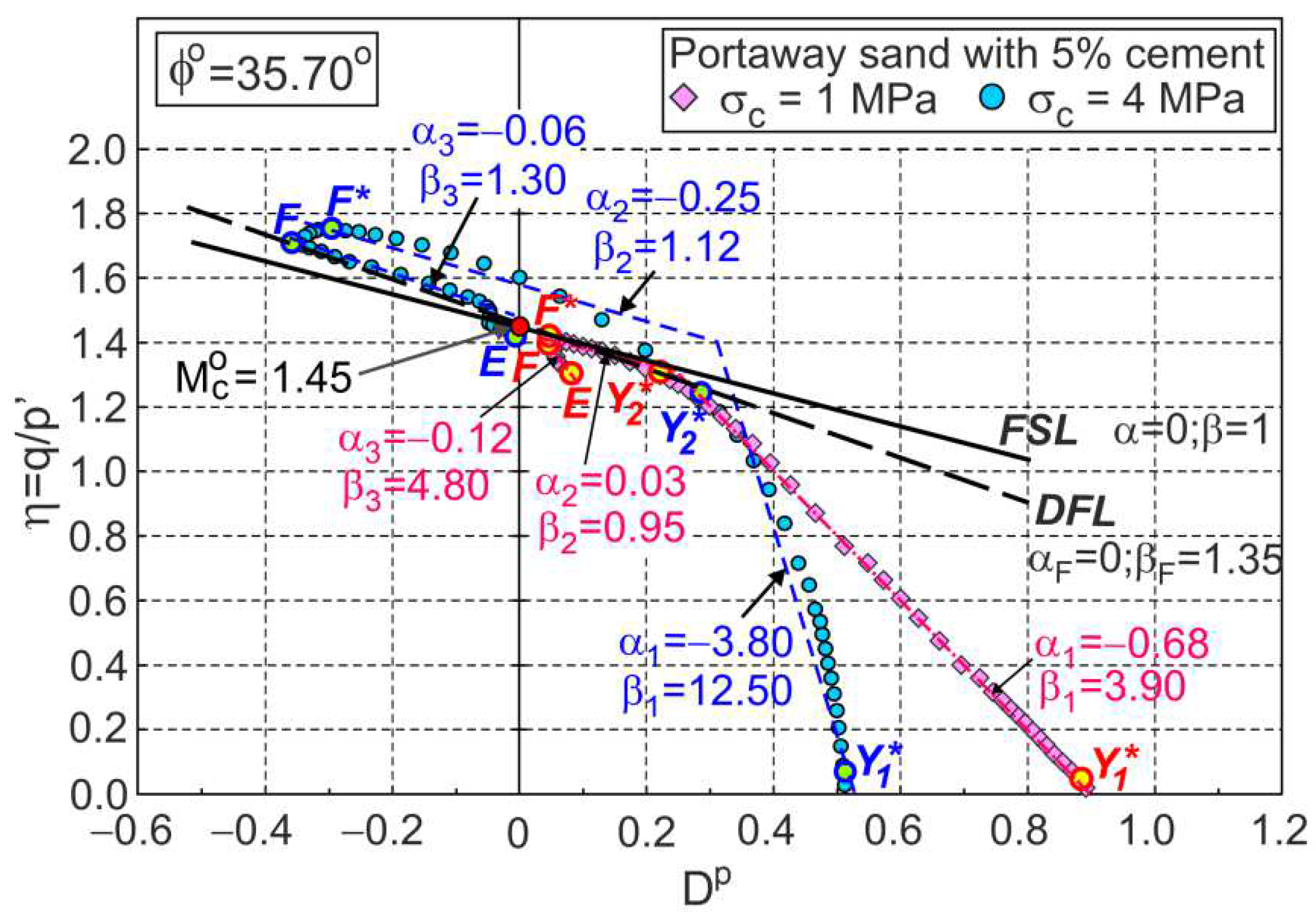

3.2. Stress–Dilatancy Relationship

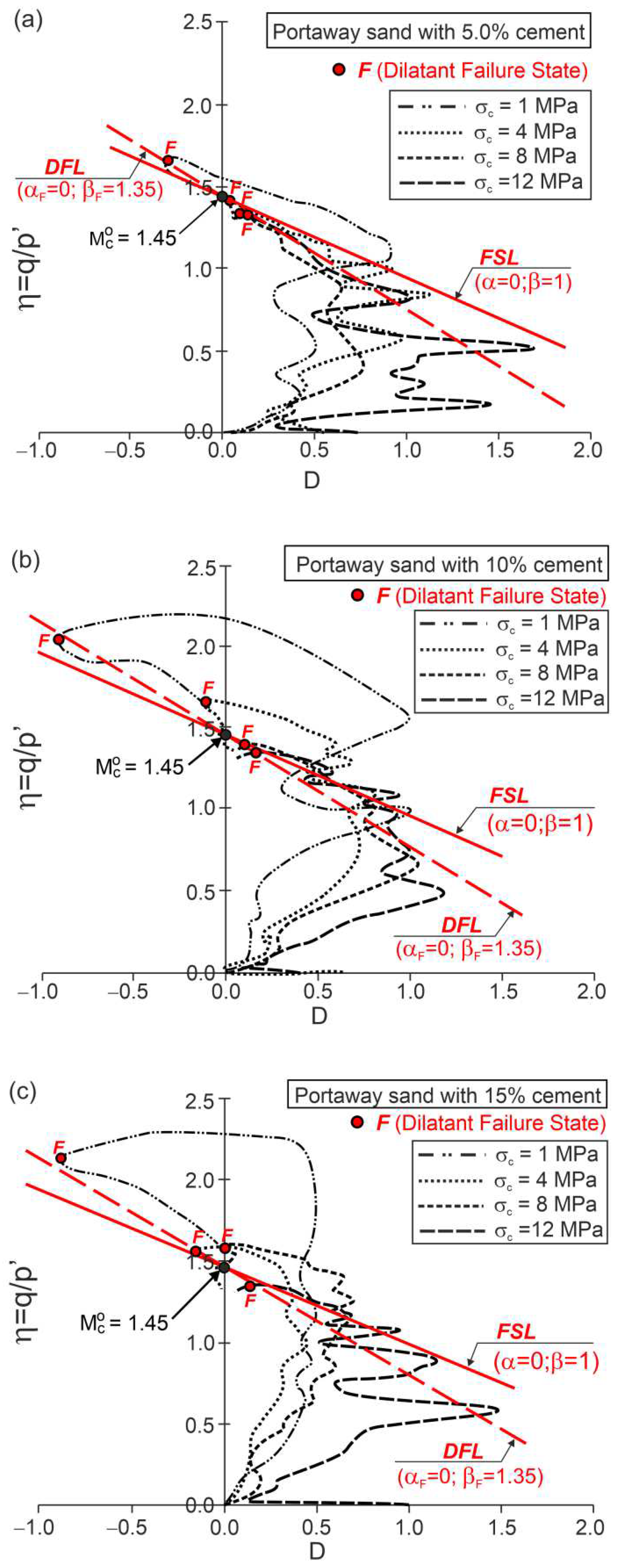

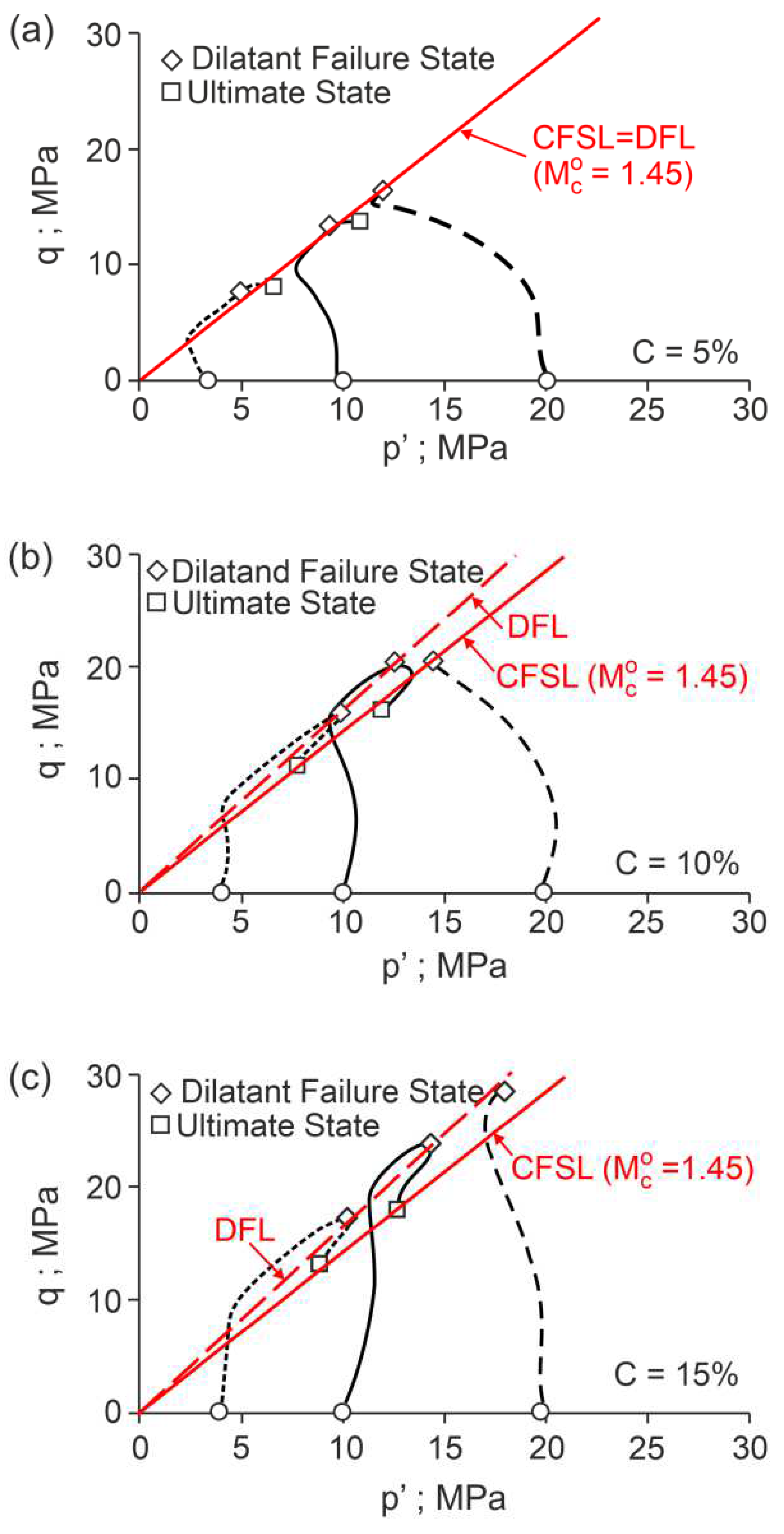

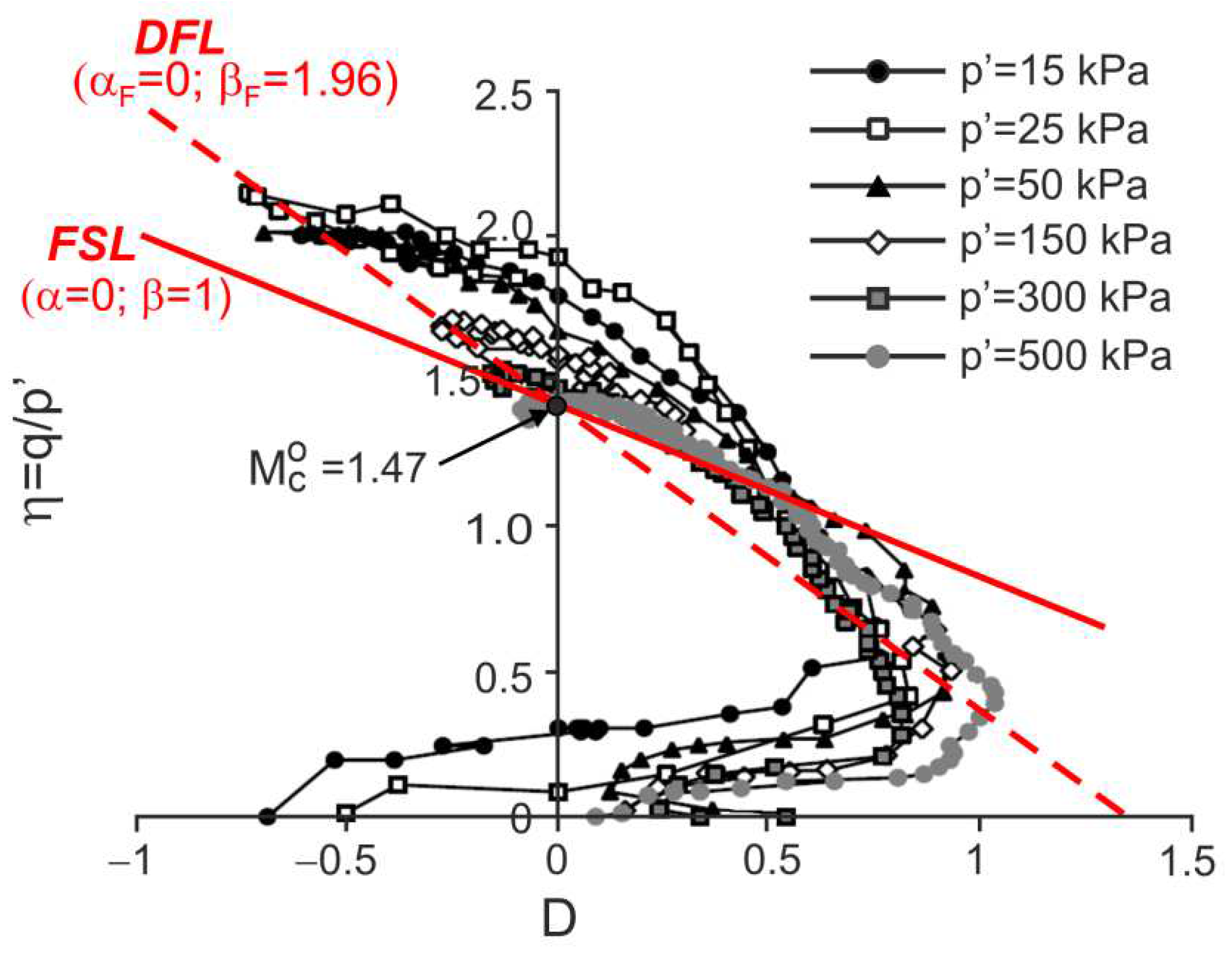

3.3. Dilatant Failure Line

4. Dilatant Failure of Some Artificially Bonded Soils

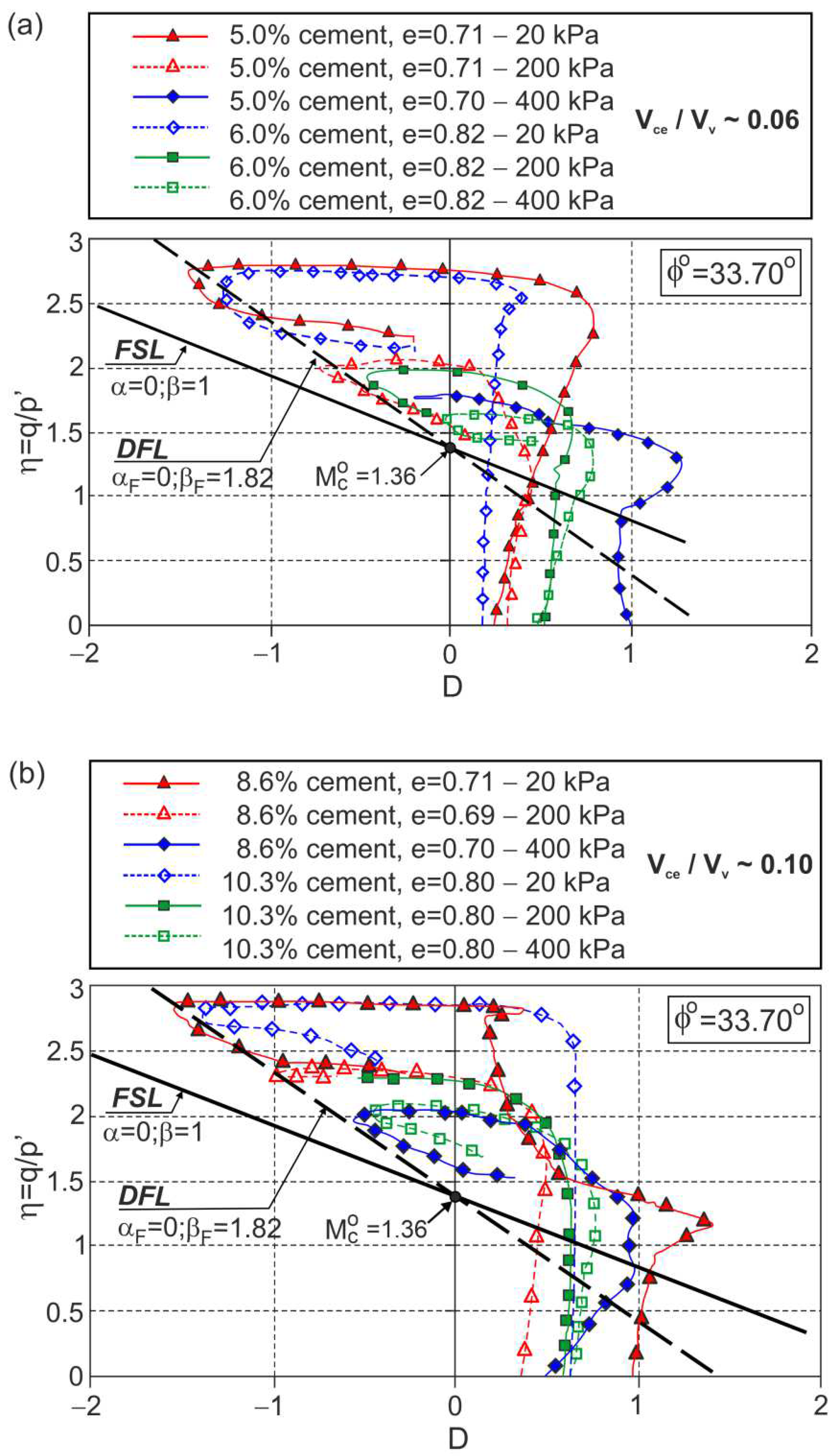

4.1. Osorio Sand with Cement Admixture

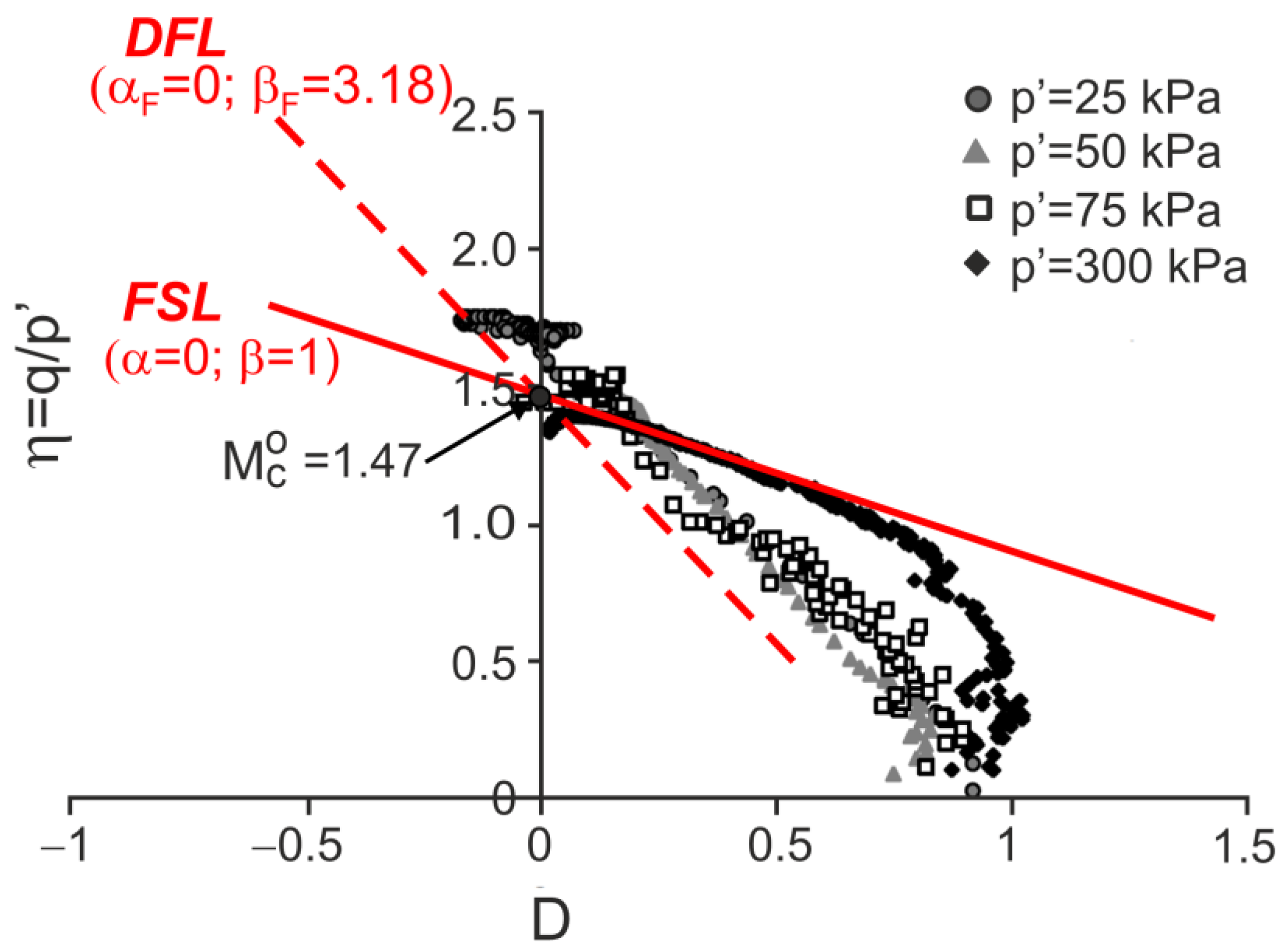

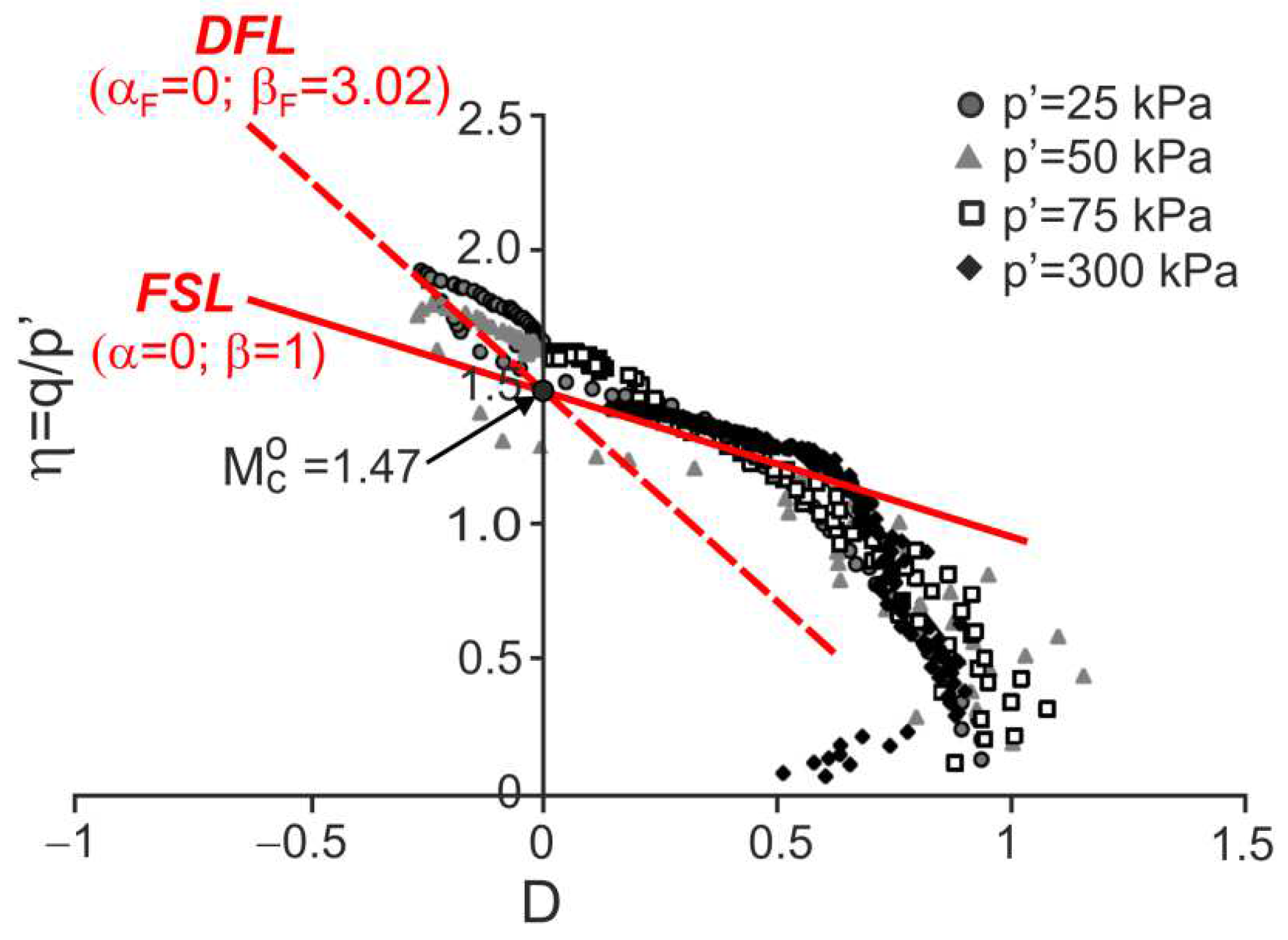

4.2. Residual Granitic Soil with Different Cement

5. Conclusions

- (1)

- For bonded soils, geomaterials with high stiffness, the elastic parts of the strains in global strains are small, and it can be assumed that the dilatancy and plastic dilatancy are equal.

- (2)

- The stress−dilatancy behaviour of naturally and artificially bonded soils in all stages of plastic flow can be approximated by the linear stress−dilatancy equation of the Frictional State Concept.

- (3)

- The failure and dilatant failure states are not equivalent for many triaxial compression tests of bonded soils. Dilatant failure states are more characteristic than failure states for these geomaterials.

- (4)

- The dilatant failure state line in the plane is defined by and , and intersects the vertical axis at the point , defining the critical frictional state angle (. The value of parameter for artificially bonded soils.

- (5)

- The parameters and for different stages of shear are functions of the quantity of the cement admixture and soil type. The frictional critical state angle ( does not depend on the amount of cement for the analysed artificially bonded soils.

- (6)

- The variety of the stress−strain behaviours of bonded soils can be described by the stress−dilatancy relationship, but the mechanics of this behaviour cannot be explained by the frictional state concept. The complex stress−strain behaviour of bonded soils should be further investigated experimentally and theoretically.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Liu, E.; Tang, Y. Investigation on mechanical properties of artificially structured soils under different stress paths. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 1–8. [Google Scholar] [CrossRef]

- Toll, D.G.; Malandraki, V.; Rahman, Z.A.; Gallipoli, D. Bonded Soils: Problematic or Predictable? In Proceedings of the 2nd International Conference on Problematic Soils, Kuala Lumpur, Malaysia, 3–5 December 2006; pp. 55–62. [Google Scholar]

- Wang, L.; Chu, J.; Wu, S.; Wang, H. Stress−dilatancy behavior of cemented sand: Comparison between bonding provided by cement and biocement. Acta Geotech. 2021, 16, 1441–1456. [Google Scholar] [CrossRef]

- Porcino, D.D.; Marciano, V. Bonding degradation and stress−dilatancy response of weakly cemented sands. Geomech. Geoengin. 2017, 12, 221–233. [Google Scholar] [CrossRef]

- Asghari, E.; Toll, D.G.; Haeri, S.M. Triaxial behavior of a cemented gravely sand, Tehran alluvium. Geotech. Geol. Eng. 2003, 21, 1–28. [Google Scholar] [CrossRef]

- Corte, M.B. Response of Lightly Cemented Sand under Multiaxial Loading. PhD Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, Brazil, 2020. Available online: https://lume.ufrgs.br (accessed on 20 August 2022).

- Cruz, N.; Viana da Fonseca, A.; Rodrigues, C. The influence of microfabrics in bonded soils behaviour, based in laboratorial comparison of artificially and naturally cemented specimens. In Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering, Athens, Greece, 11–15 September 2011; Amagnostopulos, A., Pachakis, M., Tsatsanifos, C., Eds.; pp. 173–178. [Google Scholar] [CrossRef]

- Marri, A.; Wanatowski, D.; Yu, H.S. Drained behavior of cemented sand in high pressure triaxial compression tests. Geomech. Geoengin. 2012, 7, 159–174. [Google Scholar] [CrossRef]

- Vranna, A.D.; Tika, T. Monotonic and cyclic behaviour of weakly cemented sands. In Deformation Characteristics of Geomaterials; Rinaldi, V.A., Zeballos, M.E., Clariá, J.J., Eds.; IOS Press BV: Amsterdam, The Netherlands, 2015; Volume 6, pp. 1010–1017. [Google Scholar] [CrossRef]

- Marri, A. The Mechanical Behavior of Cemented Granular Materials et High Pressures. PhD Thesis, The University of Nottingham, Nottingham, UK, September 2010. Available online: http://eprints.nottingham.ac.uk/id/eprint/11670 (accessed on 20 August 2022).

- Rezaeian, M.; Ferreira, P.M.V.; Ekinci, A. Mechanical behavior of a compacted well-graded granular material with and without cement. Soils Found. 2019, 59, 687–698. [Google Scholar] [CrossRef]

- Kichon, Z. A Study on the Effects of Lime on the Mechanical of London Clay. PhD Thesis, London South Bank University, London, UK, December 2015. [Google Scholar] [CrossRef]

- Belokas, G.; Kavvadas, M. An anisotropic model for structured soils. Part I: Theory. Comput. Geotech. 2010, 37, 737–747. [Google Scholar] [CrossRef]

- Rahimi, M.; Chan, D.; Nouri, A. Bounding Surface Constitutive Model for Cemented Sand under Monotonic Loading. Int. J. Geomech. 2016, 16, 04015049. [Google Scholar] [CrossRef]

- Liu, E.-L.; Yu, H.-S.; Zhou, C.; Nie, Q.; Luo, K.-T. A Binary-Medium Constitutive Model for Artificially Structured Soils Based on the Disturbed State Concept and Homogenization Theory. Int. J. Geomech. 2017, 17, 04016154. [Google Scholar] [CrossRef]

- Rahimi, M. Review of Proposed Stress-Dilatancy Relationships and Plastic Potential Functions for Uncemented and Cemented Sands. J. Geol. Res. 2019, 1, 19–34. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress-dilatancy for soils. Part I: The frictional state theory. Studia Geotech. Mech. 2016, 38, 51–58. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress-dilatancy for soils. Part II: Experimental validation for triaxial tests. Studia Geotech. Mech. 2016, 38, 59–65. [Google Scholar] [CrossRef]

- Wang, J.H.; Leung, S.C. Characterization of Cemented Sand by Experimental and Numerical Investigations. J. Geotech. Geoenviron. Eng. 2008, 134, 992–1004. [Google Scholar] [CrossRef]

- Bhandari, A.R. The Mechanical of an Unbonded Locked Sand at Low Effective Stress. PhD Thesis, University of Southampton, Southampton, UK, June 2009. [Google Scholar]

- Jardine, R.J. Some observations on the kinematic nature of stiffness. Soils Found. 1992, 32, 111–124. [Google Scholar] [CrossRef]

- Coop, M.R. On the mechanics of reconstituted and natural sands. In Deformation Characteristics of Geomaterials. Recent Investigations and Prospects; Di Benedetto, H., Doanh, T., Geoffroy, H., Sauzéat, C., Eds.; Taylor & Francis Group: London, UK, 2005; pp. 29–58. [Google Scholar]

- Coop, M.R.; Willson, S.M. Behaviour of Hydrocarbon Reservoir Sands and Sandstones. J. Geotech. Geoenviron. Eng. 2003, 129, 1010–1019. [Google Scholar] [CrossRef]

- Baudet, B.A. Modelling Effects of Structure in Soft Natural Clays. PhD Thesis, City University London, London, UK, 2001. [Google Scholar]

- Dołżyk-Szypcio, K. Stress−Dilatancy Relationship for Crushed Latite Basalt. Studia Geotech. Mech. 2018, 40, 6–10. [Google Scholar] [CrossRef]

- Dołżyk-Szypcio, K. Stress−Dilatancy Relationship of Erksak Sand under Drained Triaxial Compression. Geosciences 2020, 10, 353. [Google Scholar] [CrossRef]

- Consoli, N.C.; Cruz, R.C.; Viana da Fonseca, A.; Coop, M.R. Influence of Cement–Voids Ratio on Stress−Dilatancy Behaviour of Artificially Cemented Sand. J. Geotech. Geoenviron. Eng. 2012, 138, 100–109. [Google Scholar] [CrossRef]

- Cruz, N. Modelling Geomechanics of Residual Soils by DMT Tests. PhD Thesis, University of Porto, Porto, Portugal, 2010. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szypcio, Z.; Dołżyk-Szypcio, K. The Stress−Dilatancy Behaviour of Artificially Bonded Soils. Materials 2022, 15, 7068. https://doi.org/10.3390/ma15207068

Szypcio Z, Dołżyk-Szypcio K. The Stress−Dilatancy Behaviour of Artificially Bonded Soils. Materials. 2022; 15(20):7068. https://doi.org/10.3390/ma15207068

Chicago/Turabian StyleSzypcio, Zenon, and Katarzyna Dołżyk-Szypcio. 2022. "The Stress−Dilatancy Behaviour of Artificially Bonded Soils" Materials 15, no. 20: 7068. https://doi.org/10.3390/ma15207068

APA StyleSzypcio, Z., & Dołżyk-Szypcio, K. (2022). The Stress−Dilatancy Behaviour of Artificially Bonded Soils. Materials, 15(20), 7068. https://doi.org/10.3390/ma15207068