Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces

Abstract

1. Introduction

2. Optical System and Structural Design Input

3. Structural Design and Finite Element Analysis

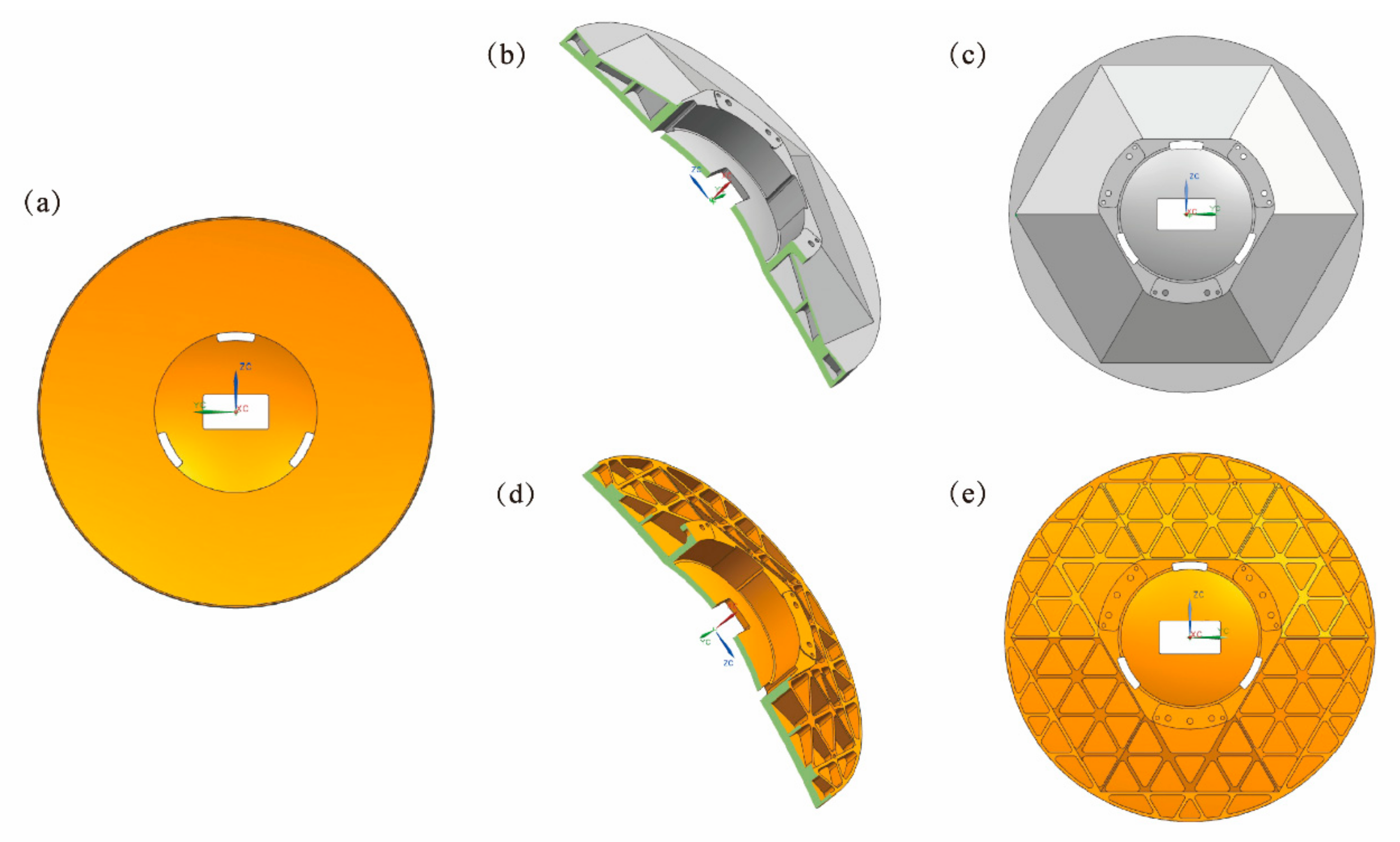

3.1. Structural Design for Mirrors with Compound Surfaces

3.2. Finite Element Analysis

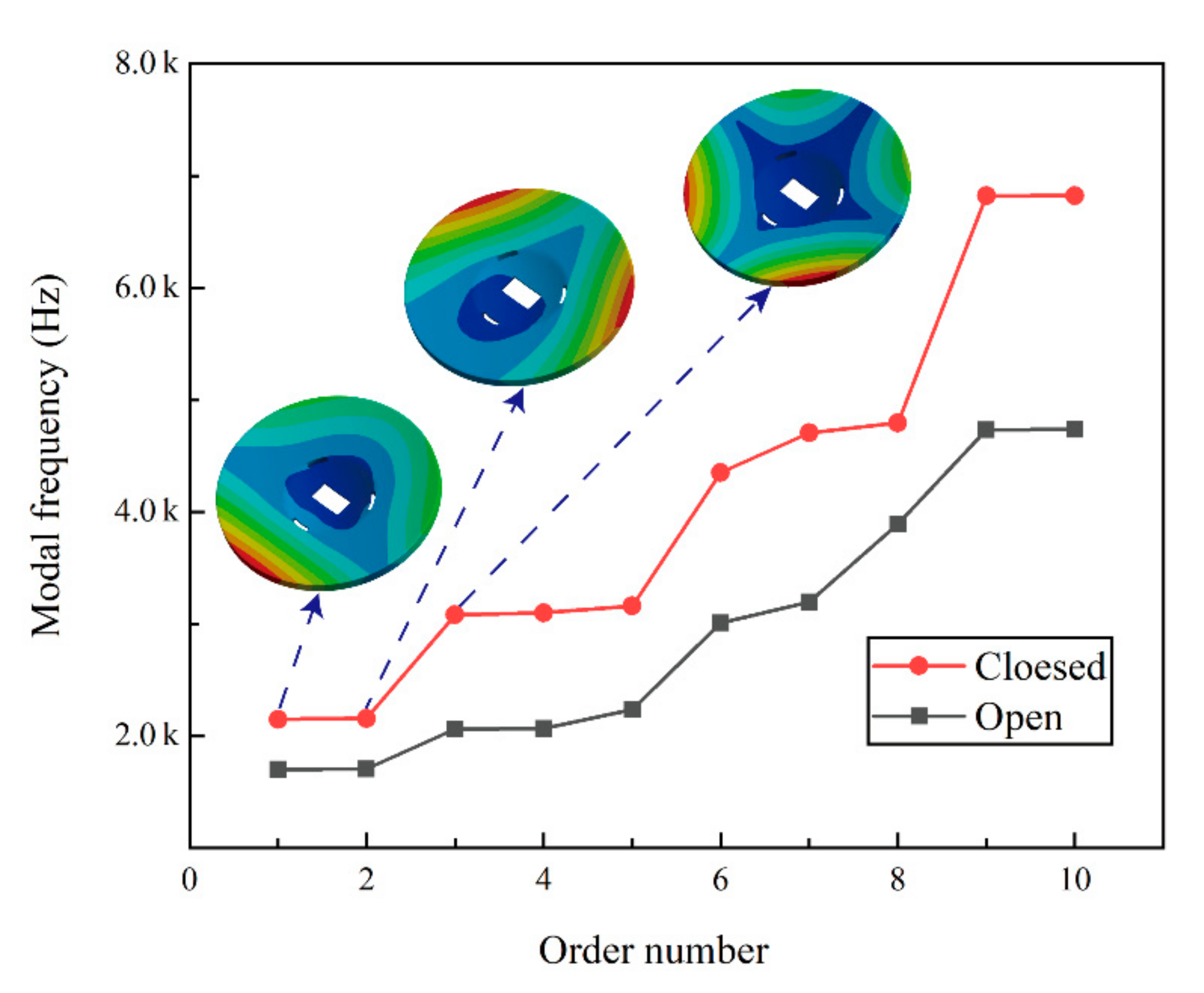

3.2.1. Modal Analysis

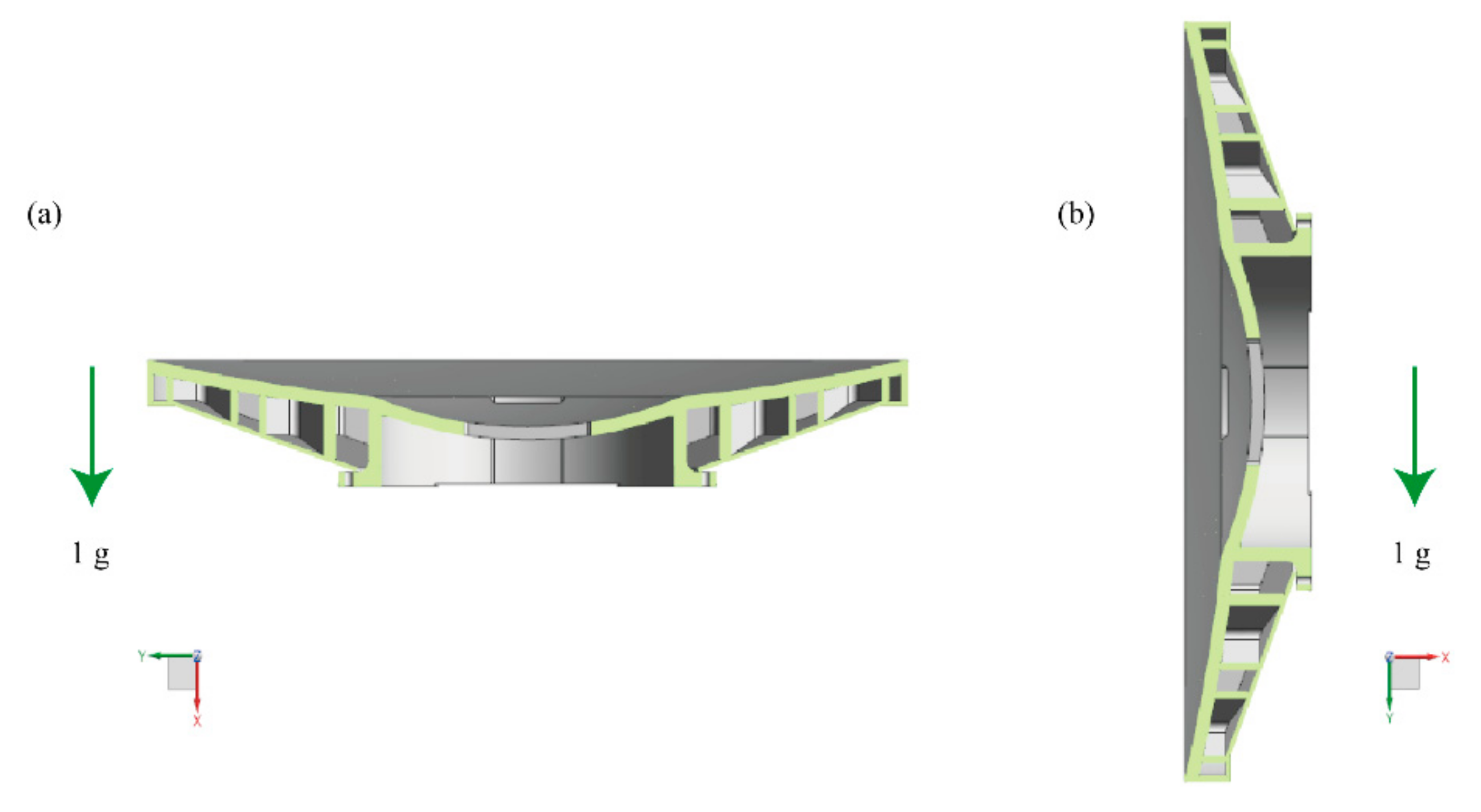

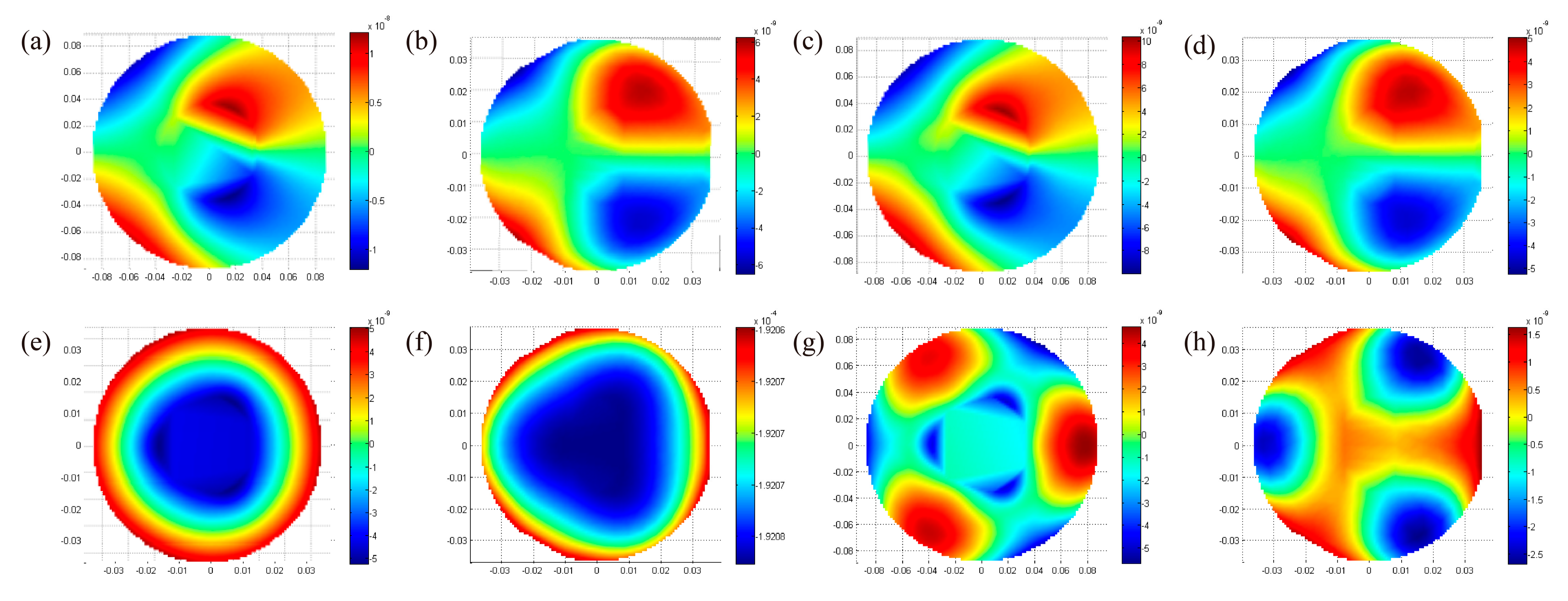

3.2.2. Gravity Deformation Analysis

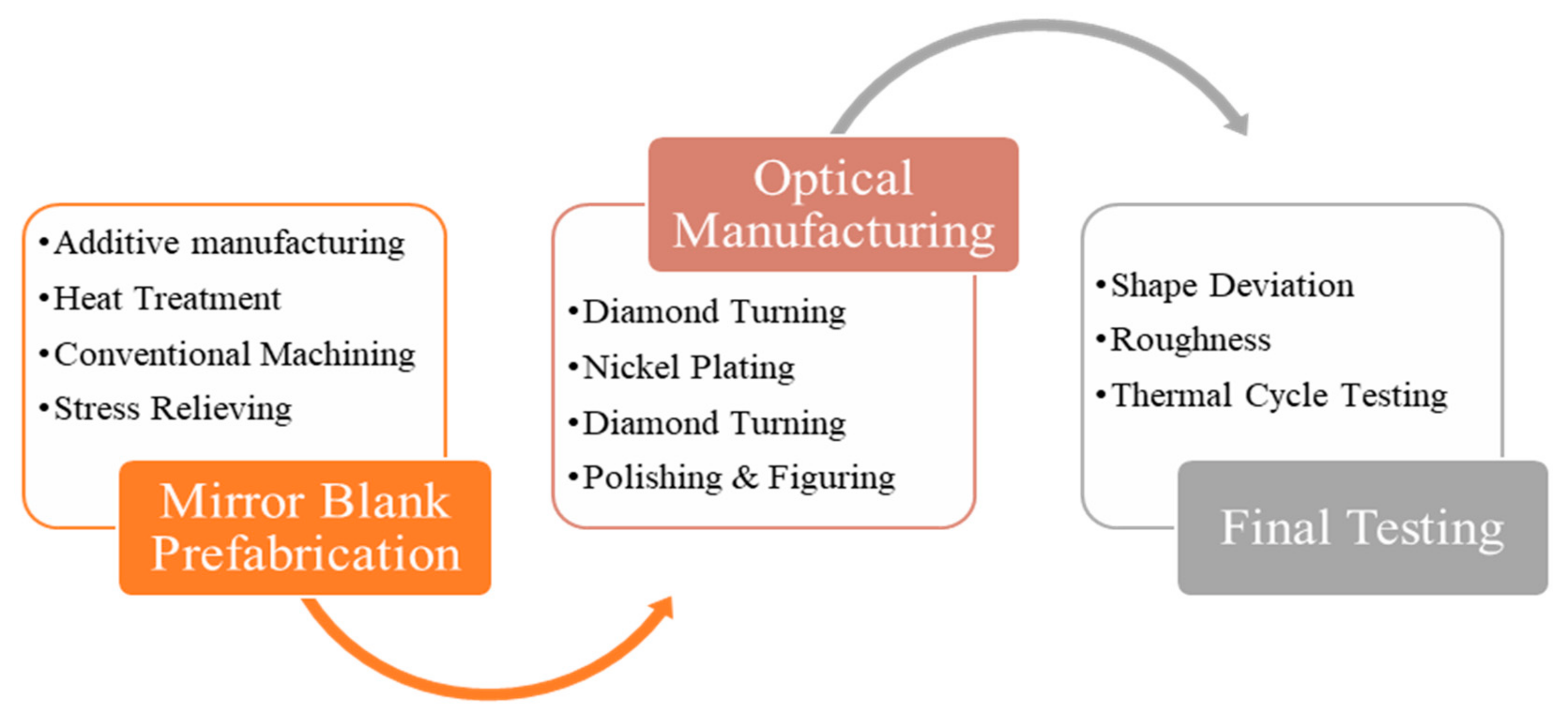

4. Mirror Fabrication

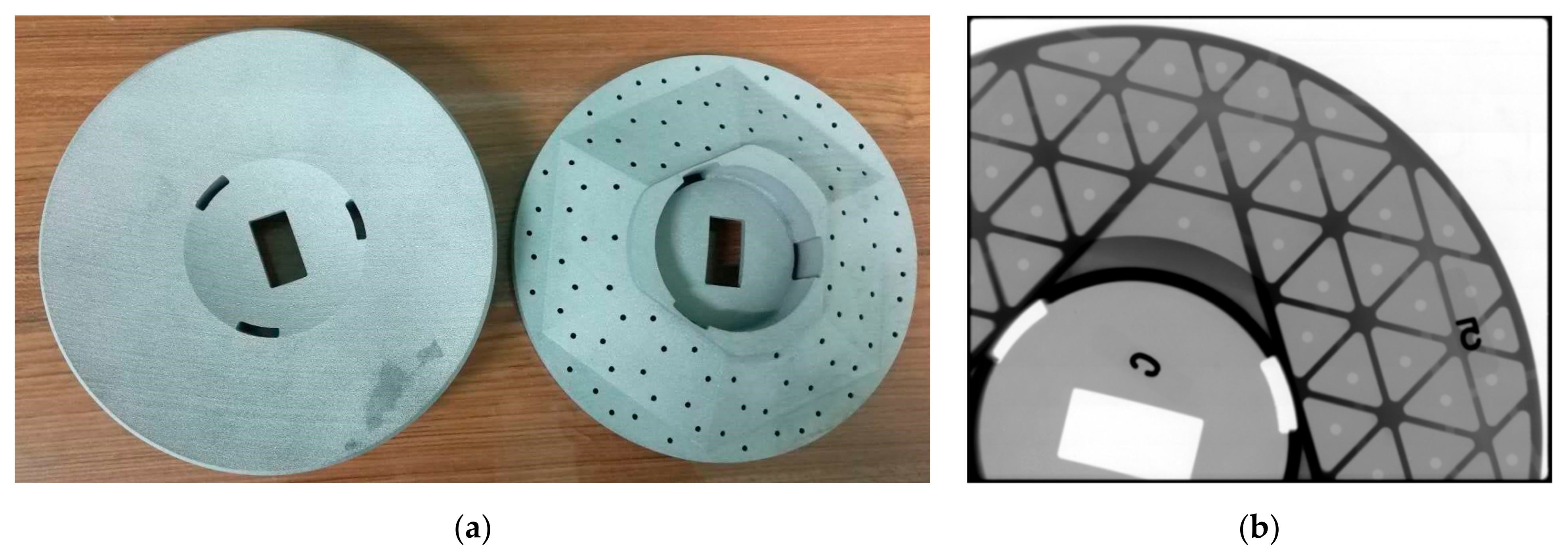

4.1. Mirror Blank Prefabrication

4.1.1. AM for the Mirror Blank

4.1.2. Heat Treatment and Densification

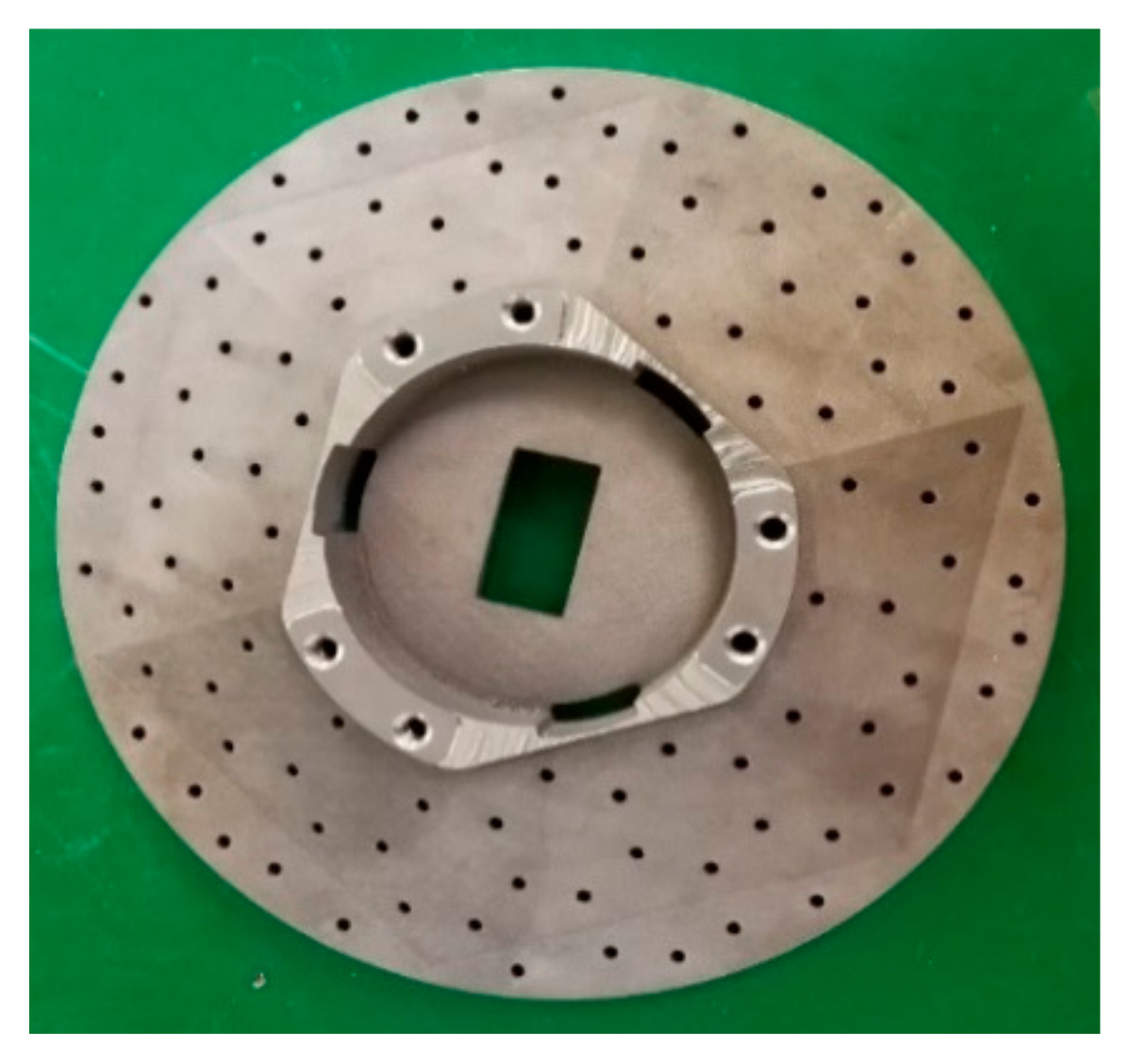

4.1.3. Conventional Machining and Thermal Cycling

4.2. Optical Manufacturing

4.2.1. SPDT before Plating

4.2.2. Surface Modification and Second Round SPDT

4.2.3. Polishing and Figuring

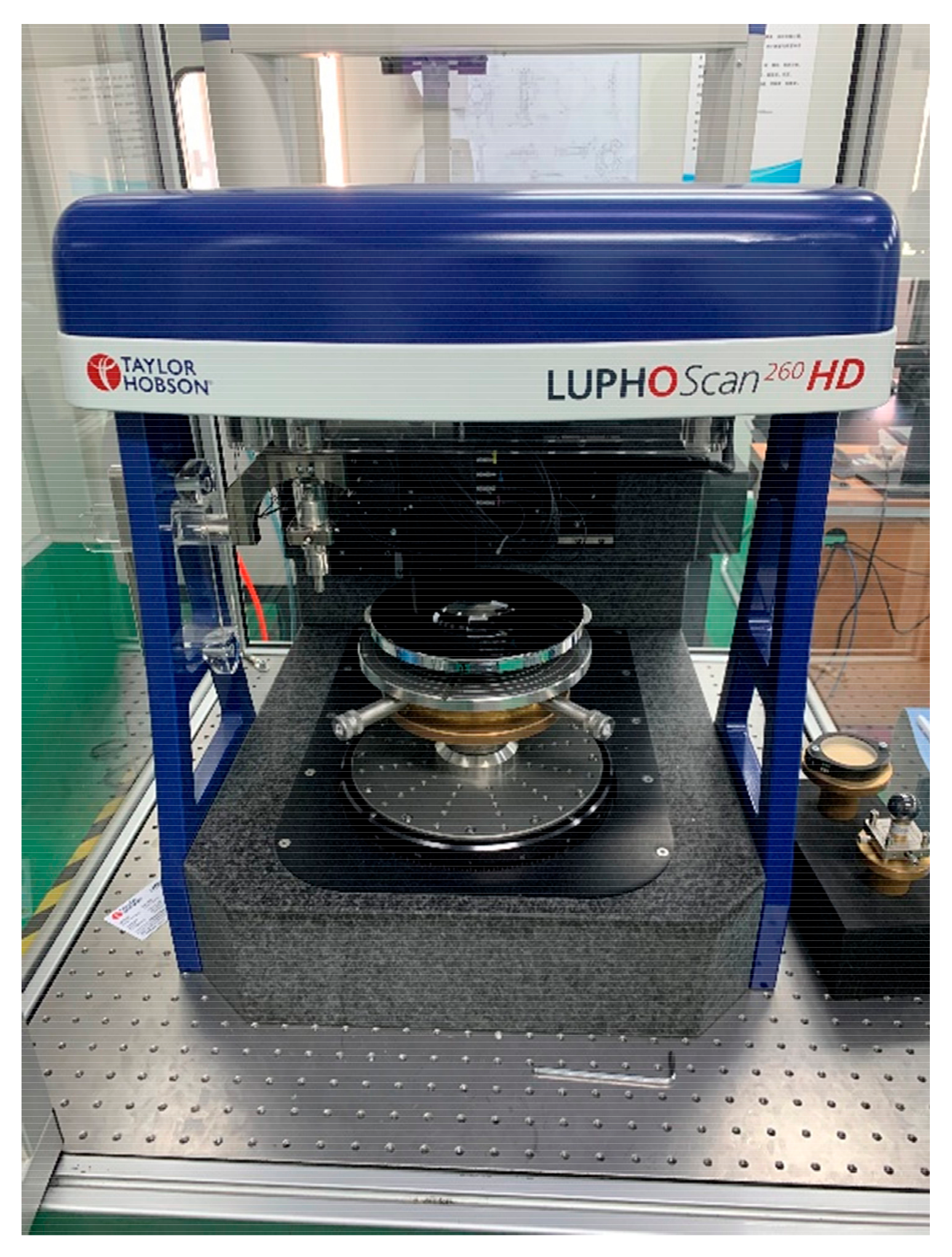

4.3. Final Testing

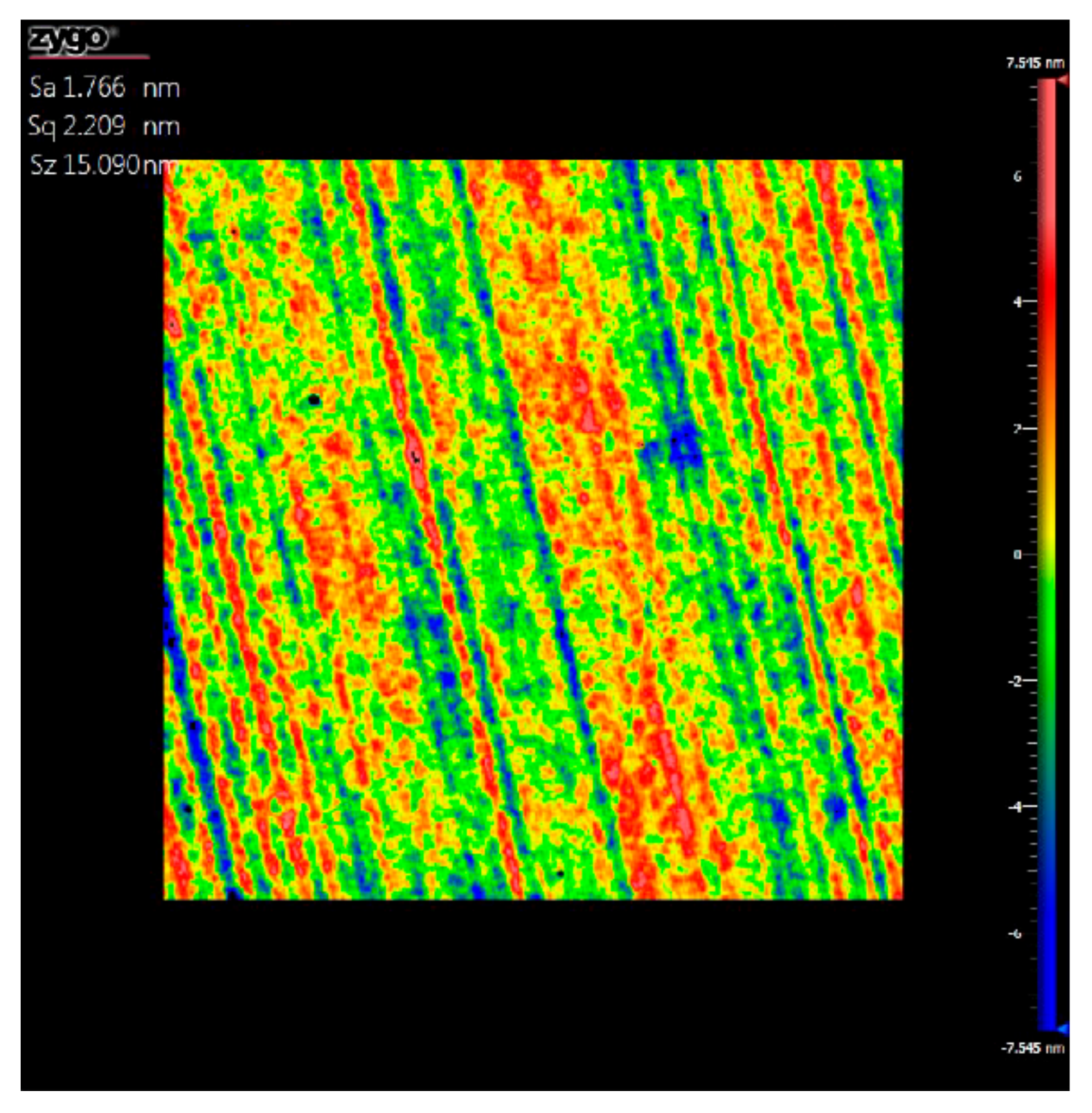

4.3.1. Surface-Shape Deviation and Roughness Testing

4.3.2. Thermal Cycle Testing

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sweeting, M.N. Modern small satellites-changing the economics of space. Proc. IEEE 2018, 106, 343–361. [Google Scholar] [CrossRef]

- Erdem, T.; Stefano, S.; Eberhard, G. Autonomous navigation for deep space small satellites: Scientific and technological advances. Acta Astronaut. 2022, 193, 56–74. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Wang, K.; Wang, Y.; Ji, Z.; Wang, D. Off-axis three-mirror freeform telescope with a large linear field of view based on an integration mirror. Appl. Opt. 2016, 55, 8962–8970. [Google Scholar] [CrossRef] [PubMed]

- Robert, A.W.; William, C.D.; Sara, R.; Heap, T.H.; Stephen, E.K.; Lloyd, R.P.; Michael, S.R.; Eric, M.; Brian, F.; Marty, V.; et al. Optical design for CETUS: A wide-field 1.5-m aperture U.V. payload being studied for a NASA probe class mission study. J. Astron. Telesc. Instrum. Syst. 2019, 5, 024006. [Google Scholar] [CrossRef]

- Atkins, C.; Feldman, C.H.; Brooks, D.; Willingale, R.; Doel, P.; Roulet, M.; Watson, S.; Cochrane, W.; Hugot, E. Additive manufactured X-ray optics for astronomy. In Optics for EUV, X-ray, and Gamma-ray Astronomy VIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10399. [Google Scholar] [CrossRef]

- Steinkopf, R.; Gebhardt, A.; Scheiding, S.; Rohde, M.; Stenzel, O.; Gliech, S.; Giggel, V.; Loscher, H.; Ullrich, G.; Rucks, P.; et al. Metal mirrors with excellent figure and roughness. Int. Soc. Opt. Photonics 2008, 7102, 71020. [Google Scholar] [CrossRef]

- Zhao, T.; Hu, H.; Peng, X.; Du, C.; Guan, C.; Yong, J. Study on the surface crystallization mechanism and inhibition method in the CMP process of aluminum alloy mirrors. Appl. Opt. 2019, 58, 6091–6097. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, X.; Tan, S.; Xie, X. Design and Manufacture of an Off-axis Aluminum Mirror for Visible-light Imaging. Curr. Opt. Photonics 2017, 1, 364–371. [Google Scholar]

- Xie, Y.; Mao, X.; Li, J.; Wang, F.; Wang, P.; Gao, R.; Li, X.; Ren, S.; Xu, Z.; Dong, R. Optical design and fabrication of an all-aluminum unobscured two-mirror freeform imaging telescope. Appl. Opt. 2020, 3, 833–840. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Jia, P.; Shen, H.; Xu, Y. Optical performance of aluminum mirror for cryogenic applications. Optik 2021, 231, 166282. [Google Scholar] [CrossRef]

- Vukobratovich, D.; Schaefer, J.P. Large stable aluminum optics for aerospace applications. Proc. SPIE 8125. Optomechanics 2011: Innovations and Solutions, 81250T (24 September 2011). Available online: https://ur.art1lib.com/book/40487207/32b77f (accessed on 30 August 2022).

- Zhang, K.; Xie, X.; Wang, C.; Wang, H.; Xu, F.; Wang, H.; Zhang, X.; Guan, H.; Qu, H.; Zhang, J. Optomechanical Performances of Advanced Lightweight Mirrors Based on Additive Manufacturing. Micromachines 2022, 13, 1334. [Google Scholar] [CrossRef]

- Qiao, G.; Hu, H.; Zhang, X.; Luo, X.; Xue, D.; Zhang, G.; Hu, H.; Yi, L.; Yang, Y.; Deng, W. Stress-induced deformation of the coating on large lightweight freeform optics. Opt. Express 2021, 29, 4755–4769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Qu, H.; Guan, H.; Zhang, J.; Zhang, X.; Xie, X.; Yan, L.; Wang, C. Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review. Appl. Sci. 2021, 11, 10630. [Google Scholar] [CrossRef]

- Linares, J.-M.; Chaves-Jacob, J.; Lopez, Q.; Sprauel, J.-M. Fatigue life optimization for 17-4Ph steel produced by selective laser melting. Rapid Prototyp. J. 2022, 28, 1182–1192. [Google Scholar] [CrossRef]

- Zhou, Y.; Abbara, E.M.; Jiang, D.; Azizi, A.; Poliks, M.D.; Ning, F. High-cycle fatigue properties of curved-surface AlSi10Mg parts fabricated by powder bed fusion additive manufacturing. Rapid Prototyp. J. 2022, 28, 1346–1360. [Google Scholar] [CrossRef]

- Sweeney, M.; Acreman, M.; Vettese, T.; Myatt, R.; Thompson, M. Application and testing of additive manufacturing for mirrors and precision structures. In Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems II; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9574, p. 957406. [Google Scholar] [CrossRef]

- Hartung, J.; Beier, M.; Risse, S. Novel applications based on freeform technologies. Proc. SPIE 10692. 2018, Optical Fabrication, Testing, and Metrology VI, 106920K (5 June 2018). Available online: https://neurophotonics.spiedigitallibrary.org/conference-proceedings-of-spie/10692/106920K/Novel-applications-based-on-freeform-technologies/10.1117/12.2313100.short (accessed on 30 August 2022).

- Snell, R.; Atkins, C.; Schnetler, H.; Todd, I.; Hernández-Nava, E.; Lyle, A.R.; Maddison, G.; Morris, K.; Miller, C.; Roulet, M.; et al. An additive manufactured CubeSat mirror incorporating a novel circular lattice. Proc. SPIE 11451. Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation IV, 114510C (13 December 2020). Available online: https://eprints.whiterose.ac.uk/172542/ (accessed on 30 August 2022).

- Giganto, S.; Martínez-Pellitero, S.; Cuesta, E.; Zapico, P.; Barreiro, J. Proposal of design rules for improving the accuracy of selective laser melting (SLM) manufacturing using benchmarks parts. Rapid Prototyp. J. 2022, 28, 1129–1143. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, X.; Fu, Q.; Wang, L.; Shi, G.; Tan, S.; Zhang, K.; Liu, M. Assembly-level topology optimization and additive manufacturing of aluminum alloy primary mirrors. Opt. Express 2022, 30, 6258–6273. [Google Scholar] [CrossRef]

- Ahmad, A. Handbook of Optomechanical Engineering; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Valente, T.M.; Vukobratovich, D. A Comparison of the merits of open-back, symmetric sandwich, and contoured back mirrors as light-weighted optics. In Proceedings of the Precision Engineering and Optomechanics, San Diego, CA, USA, 10–11 August 1989; pp. 20–36. [Google Scholar]

- Zhang, L.; Wang, T.; Zhang, F.; Zhao, H.; Zhao, Y.; Zheng, X. Design and optimization of integrated flexure mounts for unloading lateral gravity of a lightweight mirror for space application. Appl. Opt. 2021, 60, 417–426. [Google Scholar] [CrossRef]

- Shao, M.; Zhang, L.; Jia, X. Optomechanical integrated optimization of a lightweight mirror for space cameras. Appl. Opt. 2021, 60, 539–546. [Google Scholar] [CrossRef]

- Mathieu, O.; Jean-Paul, G.; Guilhem, R.; Camille, F.; Mathieu, S. A solution to the hot cracking problem for aluminium alloys manufactured by laser beam melting. Acta Mater. 2020, 197, 40–53. [Google Scholar] [CrossRef]

- Mahyar, K.; AmirHossein, G.; Martin, L.; Elmira, S.; Laura, C.; Ian, G.; David, D.; Stuart, B.; Milan, B.; Bernard, R. The effect of absorption ratio on meltpool features in laser-based powder bed fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Martin, L.; Peter, C.; Qian, M.; Milan, B.; Xie, Y. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Xu, K.; Zhang, Y.; Hu, H.; Tao, X.; Zhang, Z.; Deng, W.; Zhang, X. Design and Fabrication of Extremely Lightweight Truss-Structured Metal Mirrors. Materials 2022, 15, 4562. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Shi, Z.; Lee, Y.; Wang, H. Optical surface generation on additively manufactured AlSiMg0.75 alloys wit ultrasonic vibration-assisted machining. J. Mater. Process. Technol. 2020, 280, 116597. [Google Scholar] [CrossRef]

- Bahaa, S.; Żaneta, G.; Agnieszka, C.; Bartłomiej, W.; Marcin, H.; Maarten, G.; Bart, V.; Koen, B.; Chris, V.; Emilia, C.; et al. Novel design for an additively manufactured nozzle to produce tubular scaffolds via fused filament fabrication. Addit. Manuf. 2022, 49, 102467. [Google Scholar] [CrossRef]

- Tocci, M.; Pola, A.; Gelfi, M. Effect of a New High-Pressure Heat Treatment on Additively Manufactured AlSi10Mg Alloy. Metall. Mater. Trans. A 2020, 51, 4799–4811. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Springer, S.; Grün, F.; Taschauer, M. Effect of HIP Treatment on Microstructure and Fatigue Strength of Selectively Laser Melted AlSi10Mg. J. Manuf. Mater. Process. 2019, 3, 16. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, Z.; Xue, D.; Zhang, X. Ultra-precision fabrication of a nickel-phosphorus layer on aluminum substrate by SPDT and MRF. Appl. Opt. 2018, 57, F62–F67. [Google Scholar] [CrossRef] [PubMed]

- Kinast, J.; Hilpert, E.; Rohloff, R.-R.; Gebhardt, A.; Tünnermann, A. Thermal expansion coefficient analyses of electroless nickel with varying phosphorous concentrations. Surf. Coat. Technol. 2014, 259, 500–503. [Google Scholar] [CrossRef]

- Xu, C.; Peng, X.; Liu, J.; Hu, H.; Lai, T.; Yang, Q.; Xiong, Y. A High Efficiency and Precision Smoothing Polishing Method for NiP Coating of Metal Mirror. Micromachines 2022, 13, 1171. [Google Scholar] [CrossRef] [PubMed]

- Melanie, U.; Bauer, J.; Frank, F.; Thomas, A. Ion beam planarization of optical aluminum surfaces. J. Astron. Telesc. Instrum. Syst. 2020, 6, 014001. [Google Scholar] [CrossRef]

| Authors | Aperture (mm) | Material | Highlight |

|---|---|---|---|

| Sweeney et al. [17] | 75–150 | AlSi10Mg etc. | Process exploration and validation |

| Hartung et al. [18] | 76 | AlSi40 | Novel lightweight structure design |

| Robert et al. [4] | 72 | AlSi10Mg | Lattice mirror design for CubeSat |

| Yan et al. [21] | 58 | AlSi10Mg | Assembly-level topology optimization and integration design |

| This study | 175 | AlSi10Mg | Large aperture and integration design with compound surfaces |

| Parameter | Specification (PM) | Specification (TM) |

|---|---|---|

| Optical prescription | Aspheric surface | Aspheric surface |

| Radius of curvature | 396 mm | 98 mm |

| Effective Aperture | 175 mm | 70 mm |

| Form error | Better than RMS 1/10λ (λ = 632.8 nm) | |

| Roughness | Better than 2 nm | |

| First-order modal frequency | 2000 Hz | |

| Lightweight rate | 70% | |

| Order Number | Open-Frequency (Hz) | Closed-Frequency (Hz) |

|---|---|---|

| 1 | 1703.4 | 2149.6 |

| 2 | 1705.3 | 2157.2 |

| 3 | 2064.1 | 3082.5 |

| 4 | 2068.1 | 3099.7 |

| 5 | 2236.1 | 3160.1 |

| 6 | 3011.3 | 4351.0 |

| 7 | 3195.2 | 4705.6 |

| 8 | 3891.6 | 4795.5 |

| 9 | 4733.5 | 6821.2 |

| 10 | 4736.1 | 6823.9 |

| Open-PM | Open-TM | Closed-PM | Closed-TM | |

|---|---|---|---|---|

| Radial (P.V. nm) | 22.8 | 12.9 | 20.6 | 10.5 |

| Radial (RMS nm) | 5.4 | 3.3 | 4.6 | 2.6 |

| Axial (P.V. nm) | 58.3 | 18.6 | 10.5 | 4.4 |

| Axial (RMS nm) | 16.7 | 4.0 | 2.5 | 1.0 |

| Process Steps | PM-RMS (nm) | TM-RMS (nm) |

|---|---|---|

| First Round SPDT | / | / |

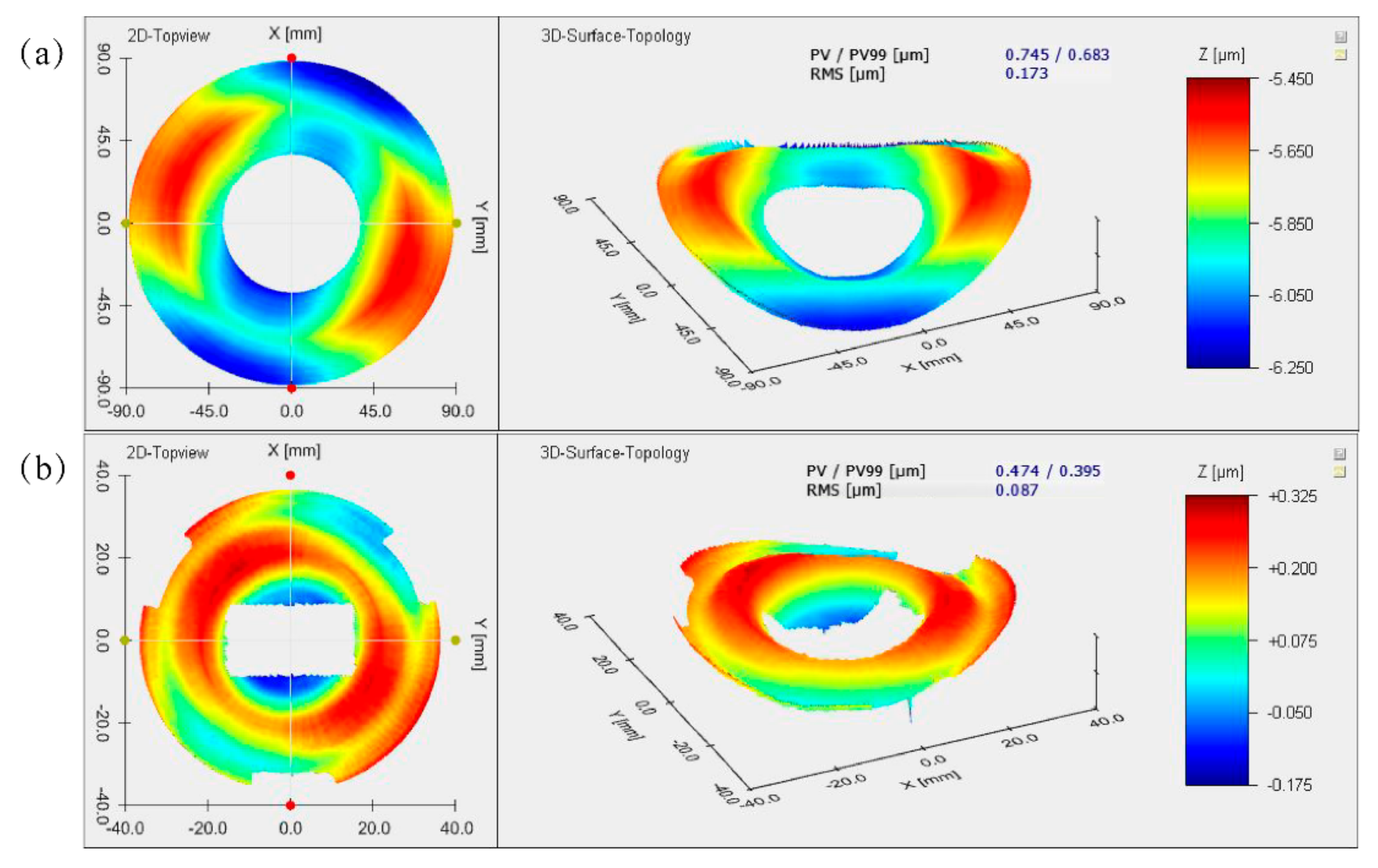

| NiP + Second Round SPDT | 173 | 93 |

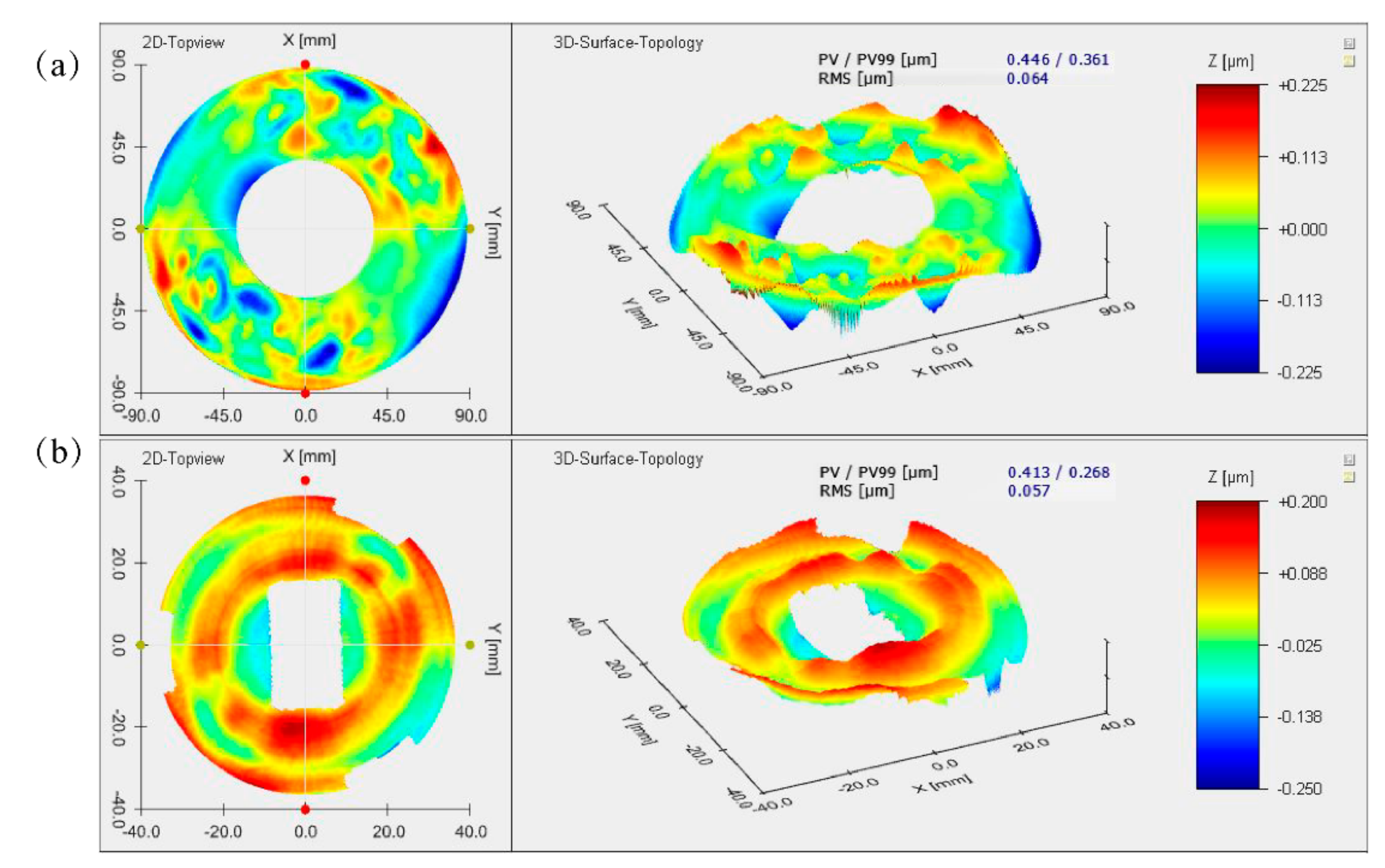

| Polishing | 64 | 57 |

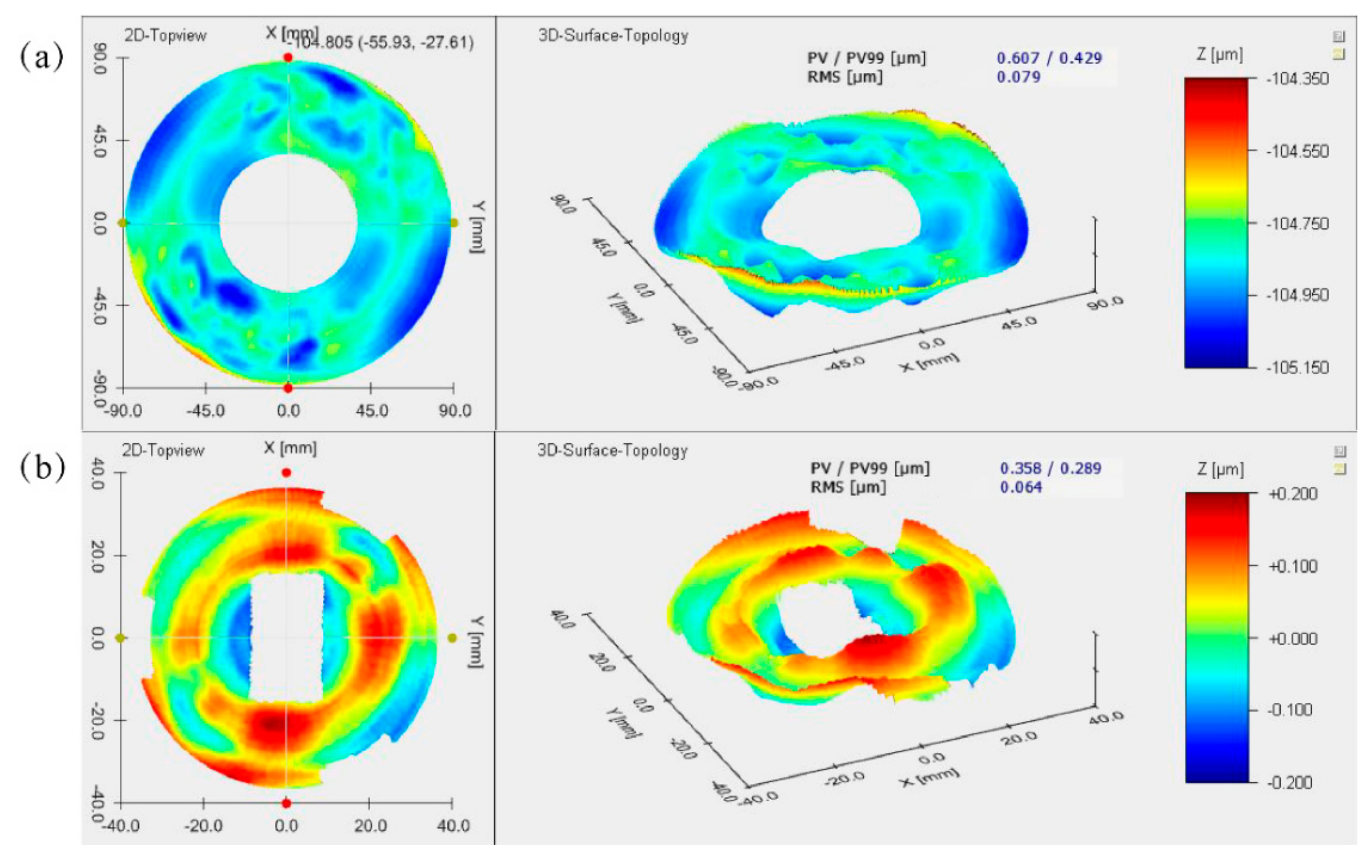

| After the thermal cycle test | 79 | 64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, C.; Qu, H.; Guan, H.; Wang, H.; Zhang, X.; Xie, X.; Wang, H.; Zhang, K.; Li, L. Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces. Materials 2022, 15, 7050. https://doi.org/10.3390/ma15207050

Zhang J, Wang C, Qu H, Guan H, Wang H, Zhang X, Xie X, Wang H, Zhang K, Li L. Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces. Materials. 2022; 15(20):7050. https://doi.org/10.3390/ma15207050

Chicago/Turabian StyleZhang, Jizhen, Chao Wang, Hemeng Qu, Haijun Guan, Ha Wang, Xin Zhang, Xiaolin Xie, He Wang, Kai Zhang, and Lijun Li. 2022. "Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces" Materials 15, no. 20: 7050. https://doi.org/10.3390/ma15207050

APA StyleZhang, J., Wang, C., Qu, H., Guan, H., Wang, H., Zhang, X., Xie, X., Wang, H., Zhang, K., & Li, L. (2022). Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces. Materials, 15(20), 7050. https://doi.org/10.3390/ma15207050