Prediction of Rapid Chloride Penetration Resistance to Assess the Influence of Affecting Variables on Metakaolin-Based Concrete Using Gene Expression Programming

Abstract

1. Introduction

2. Methodology

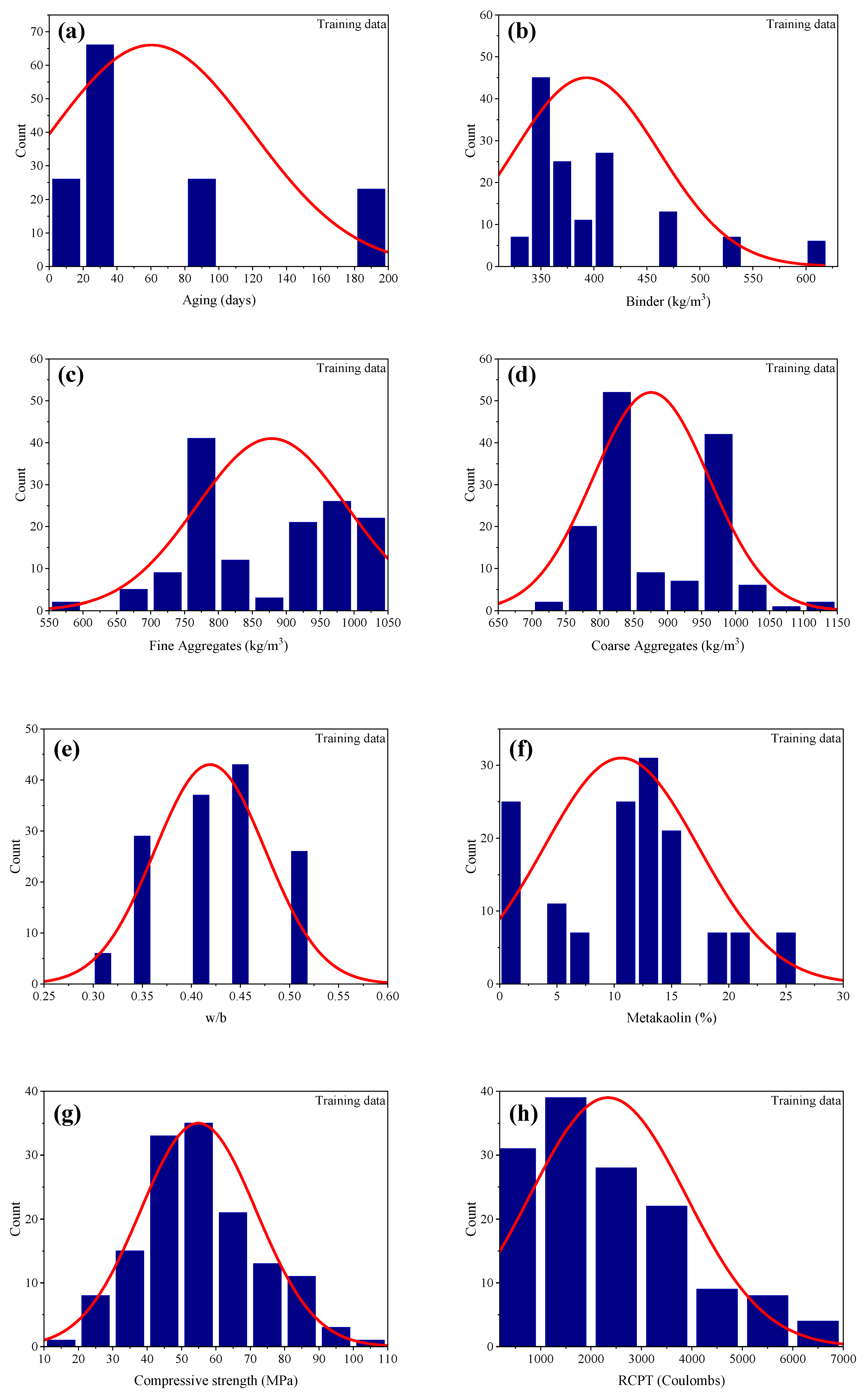

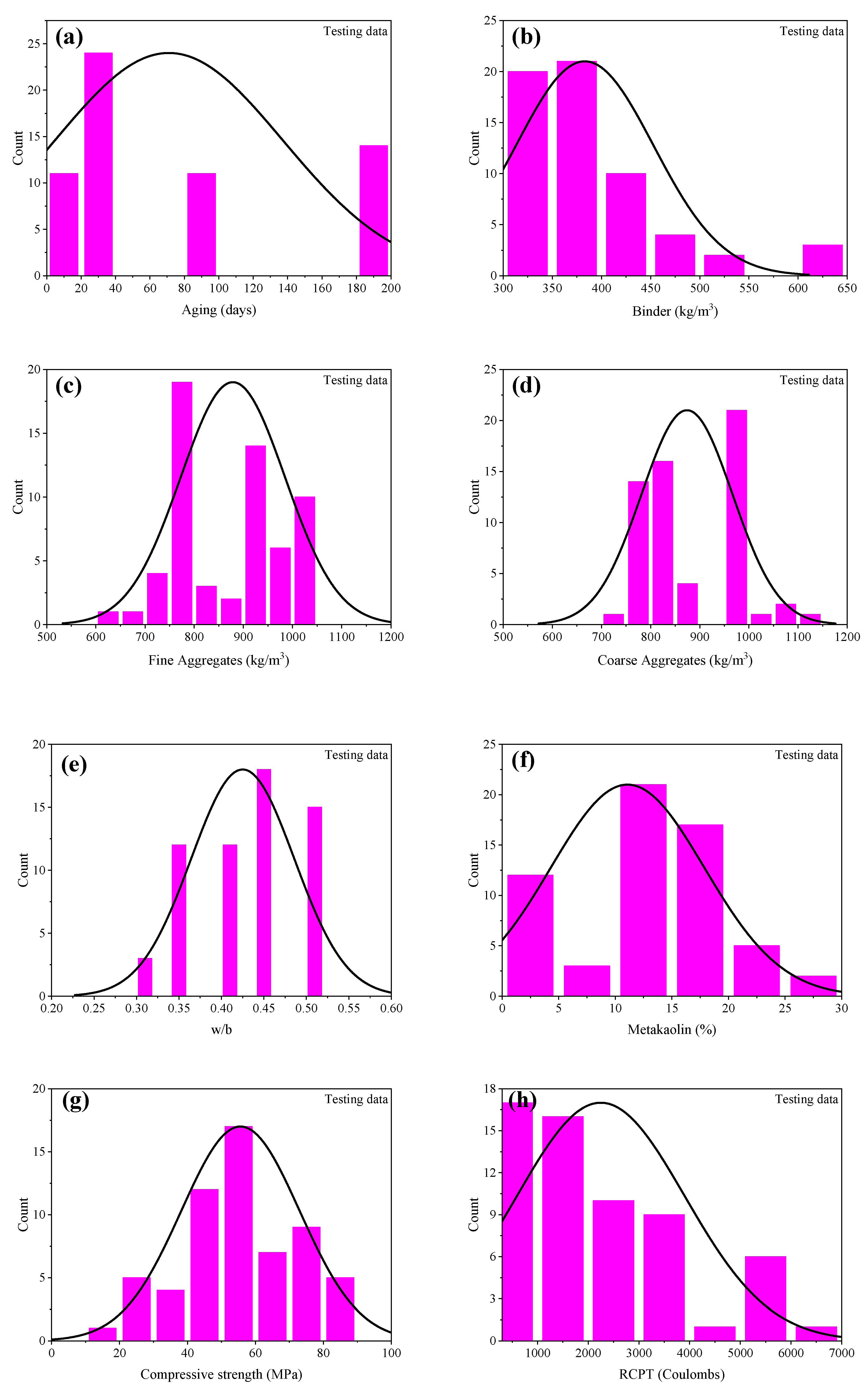

2.1. Database Compilation

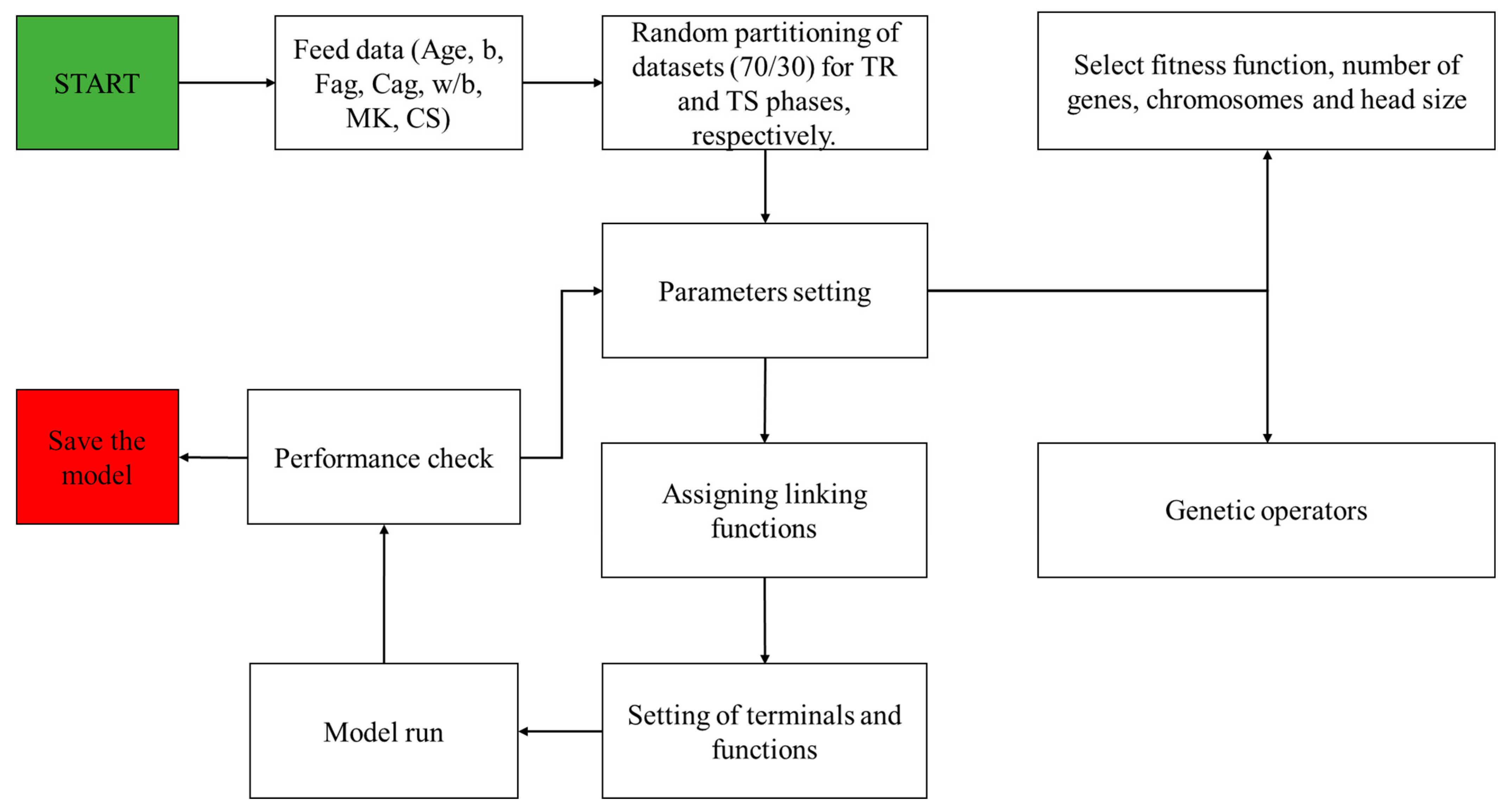

2.2. GEP Modelling

3. Results & Discussion

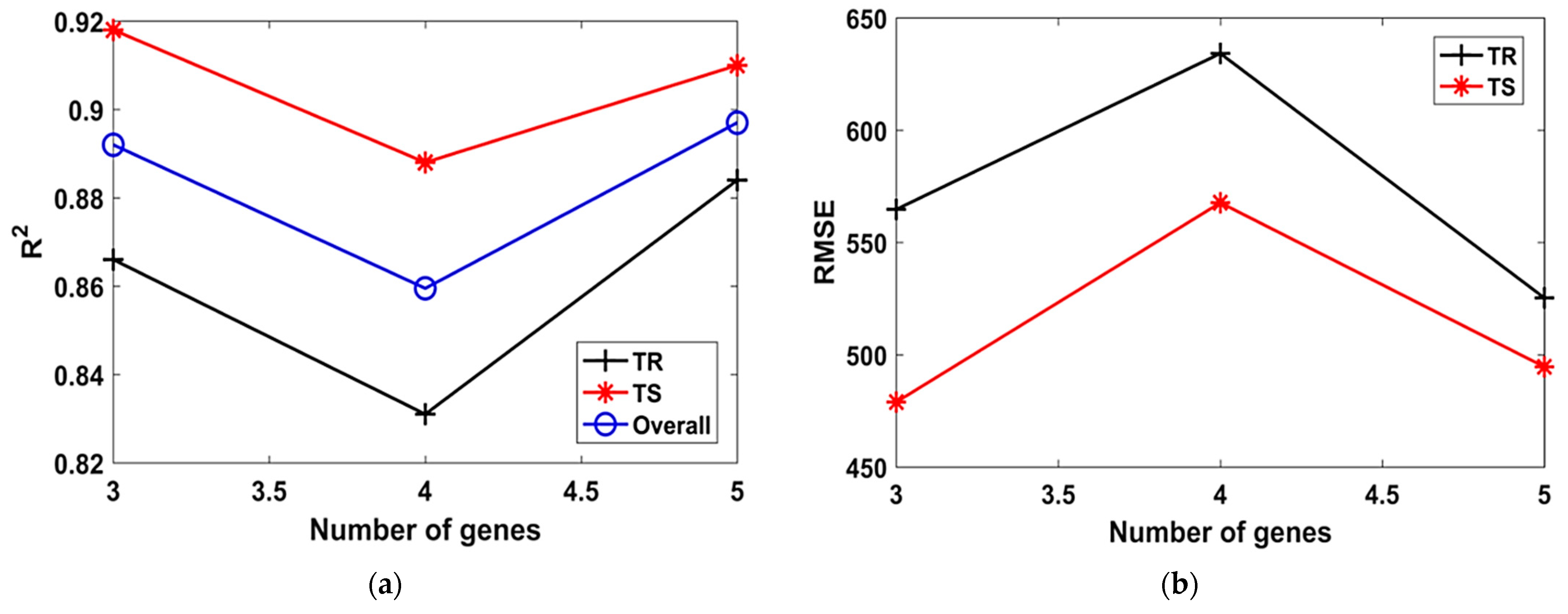

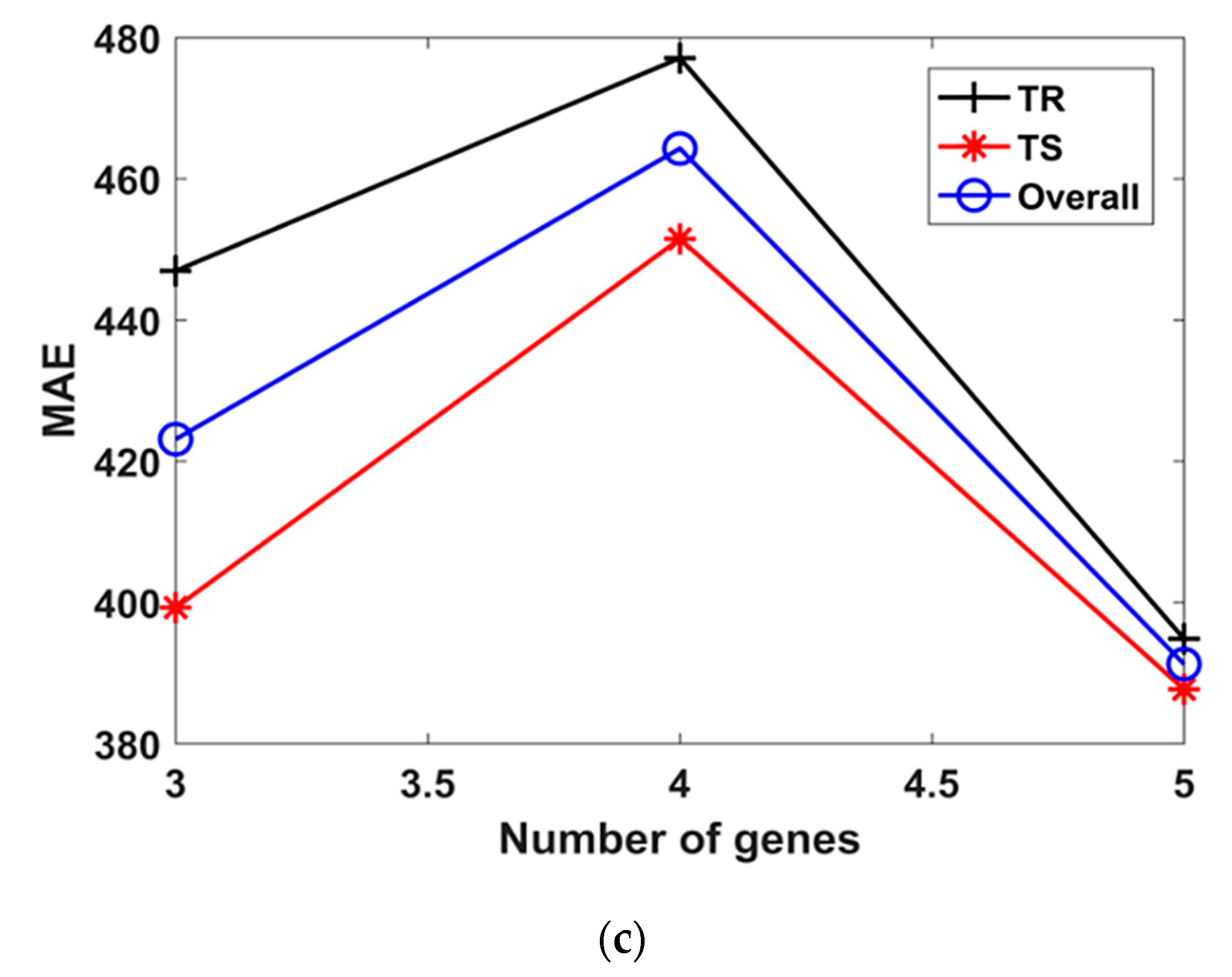

3.1. Effect of Variable Genetic Parameters

3.2. Performance of Models

3.2.1. Statistical Evaluation

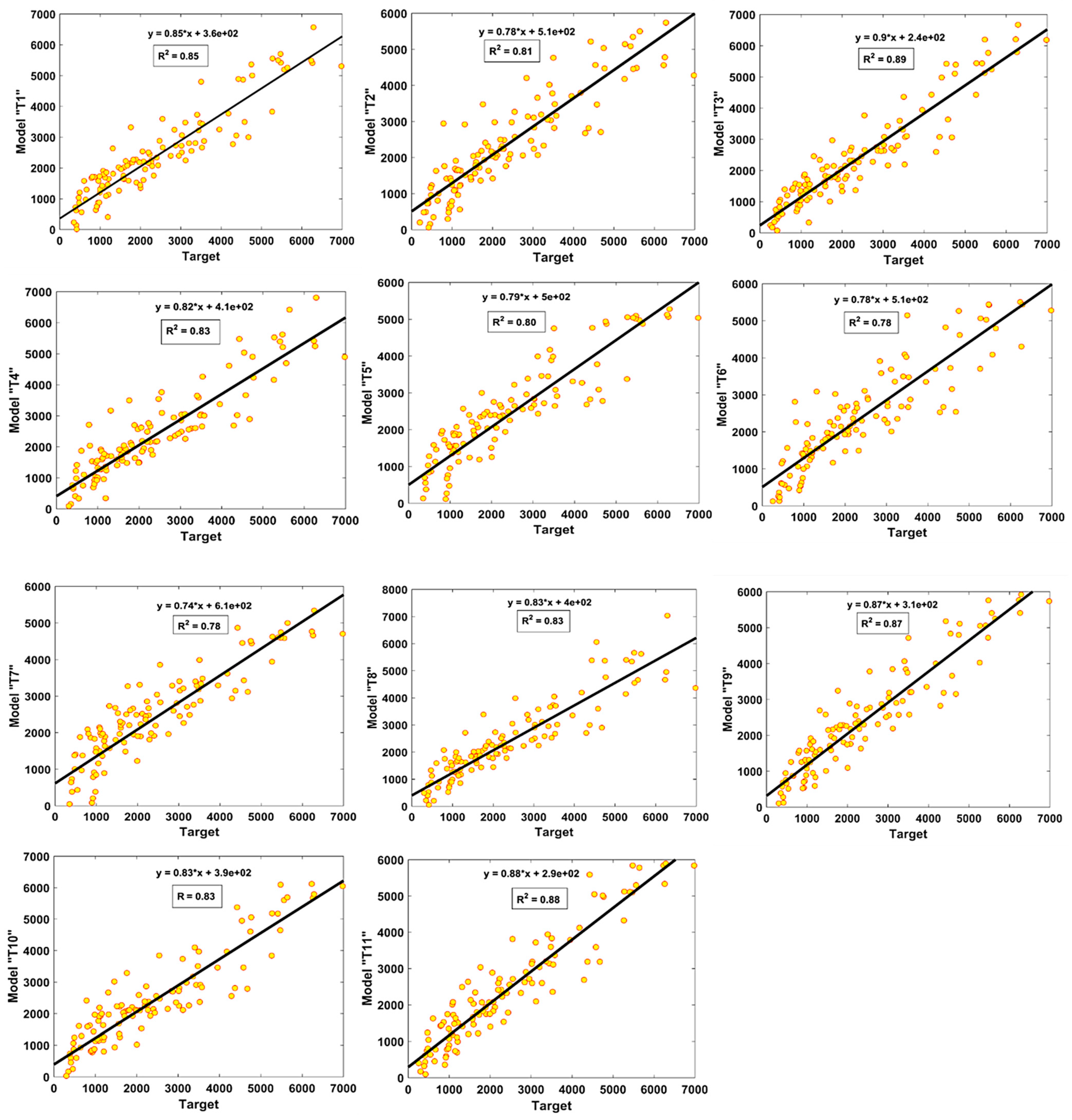

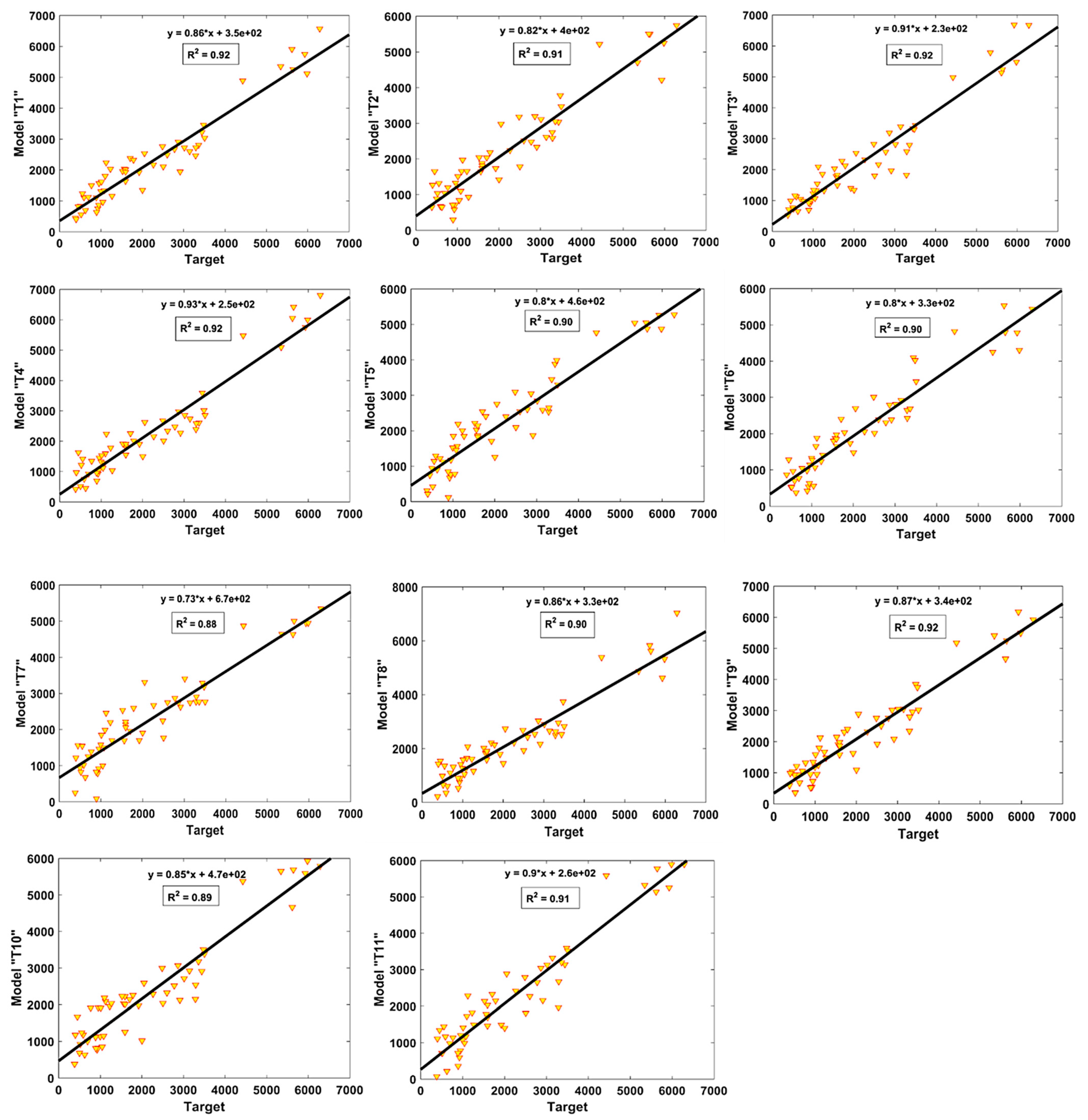

3.2.2. Comparison of Regression Slopes

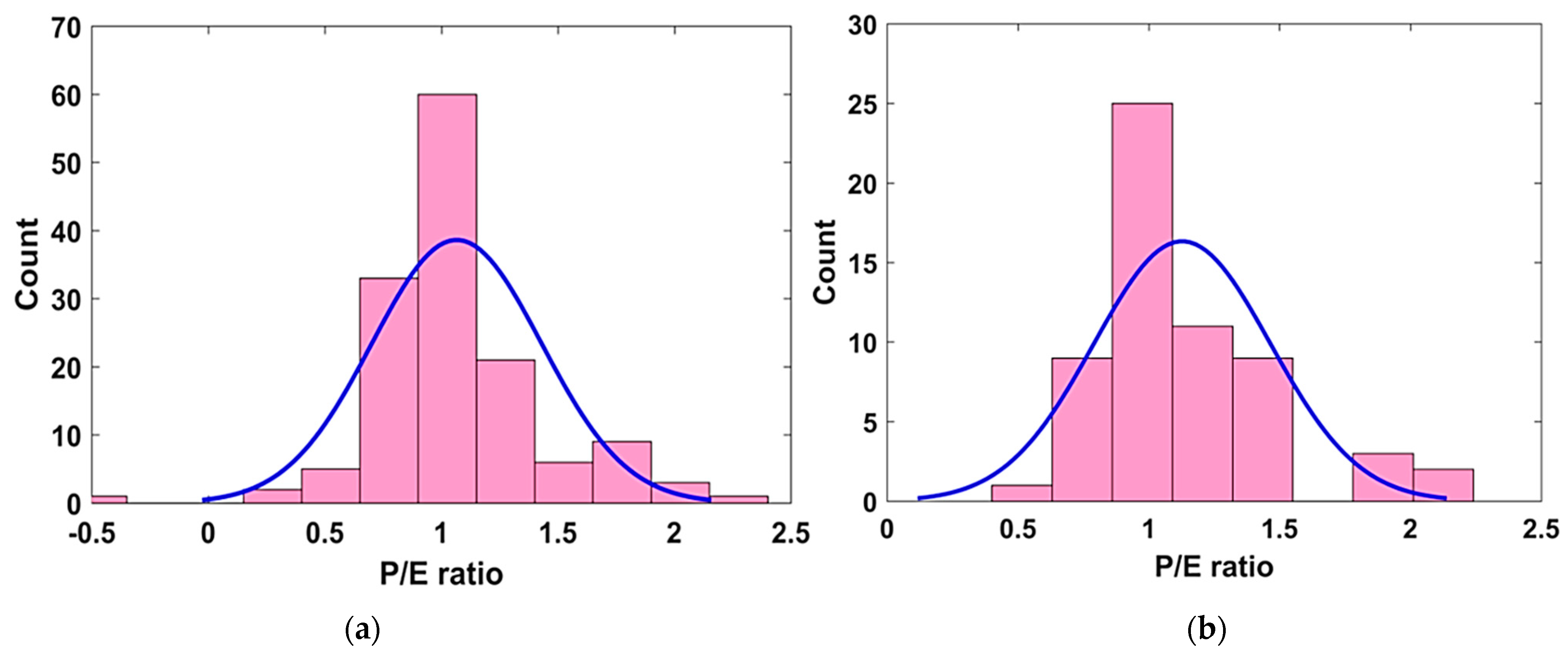

3.2.3. Model Predicted to Experimental (P/E) Ratio

3.2.4. Visual Interpretation of Results via Taylor Diagram

3.3. GEP Formulations

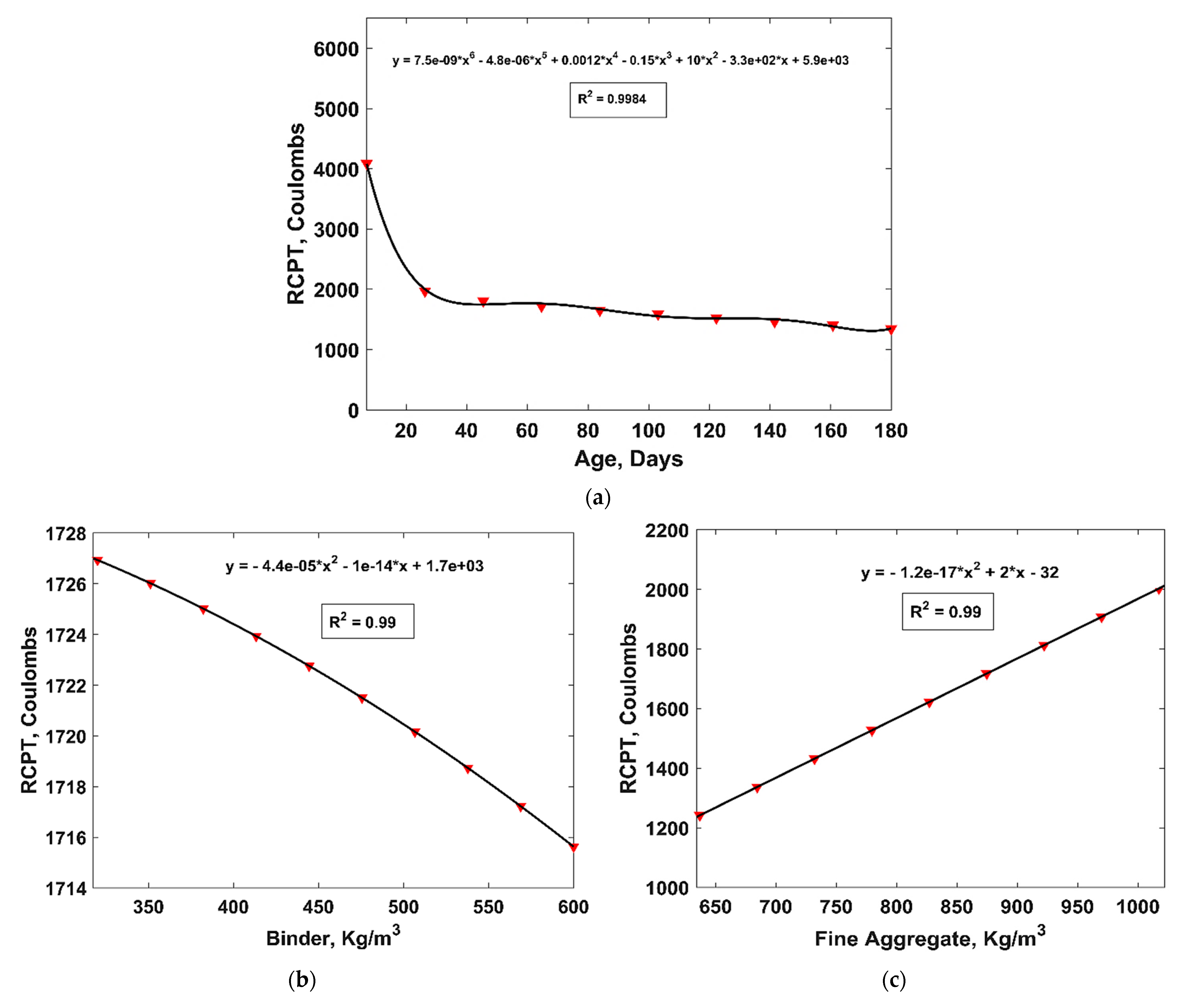

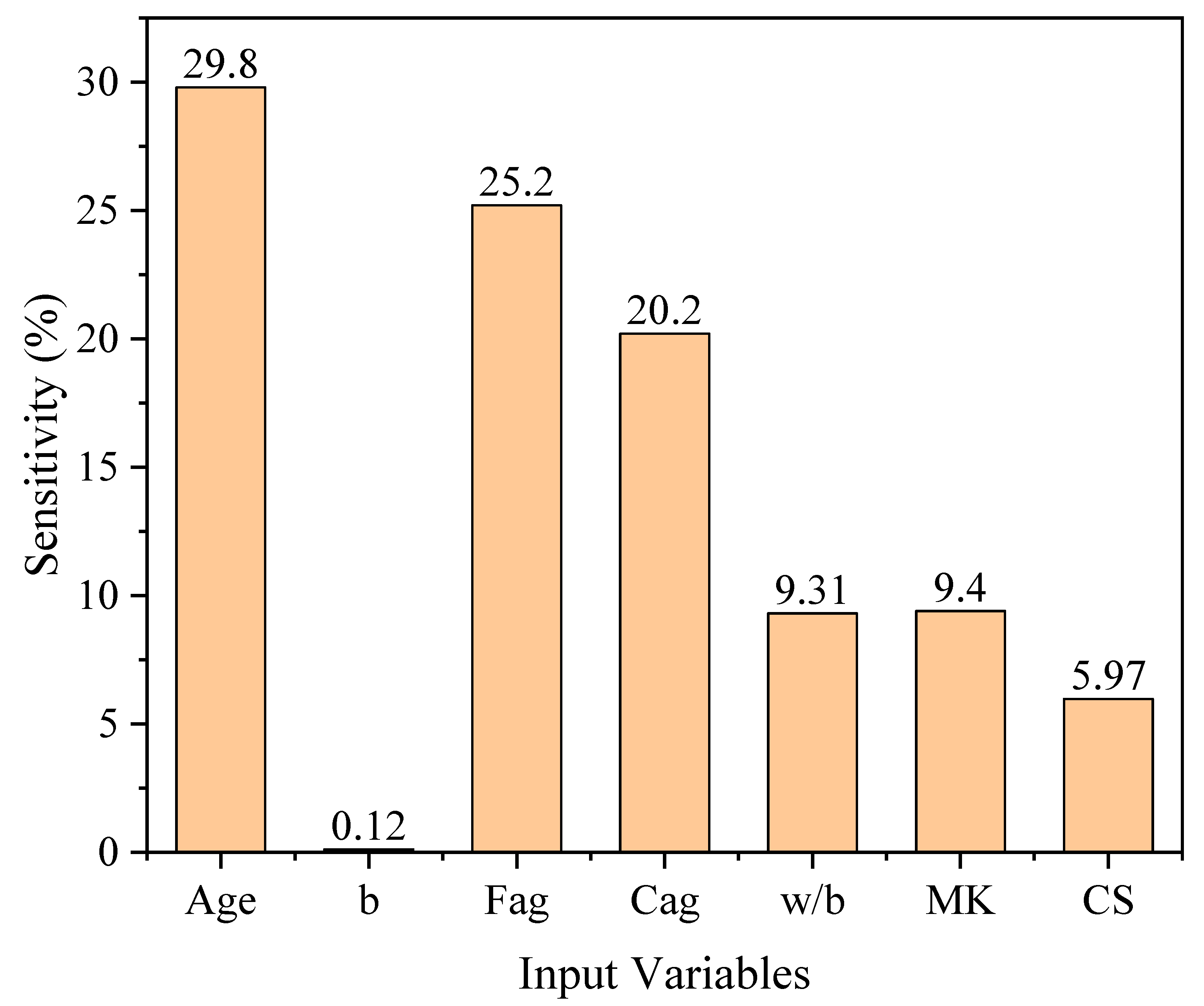

3.4. Parametric and Sensitivity Analyses

4. Conclusions

- The tuning of the hyperparameter settings for the GEP model revealed that the model with Nc = 100, Hs = 8 and Ng = 3 (Model T3) resulted in an optimal GEP model, as evident from its high R2 values (i.e., 0.89 in the TR phase and 0.92 in the TS phase, respectively). Similarly, the values of RMSE = 513.9 and 464.1, and of MAE = 385.2 and 364.9, were also comparatively smaller than in all the other models in the TR and TS phases, respectively.

- The regression slope analysis showed that the predicted values were in good agreement with the experimental values, as indicated from the higher R2 values. It was also observed that the performance of the models improved in the TS phase, which was reflected in their higher R2 values, with the majority of developed models having R2 > 0.8. In addition, the P/E ratio analysis revealed that Model T3 was the best performing model, because a larger frequency was observed for the P/E ratio proximal to one.

- Similarly, the parametric analysis for the best performing Model T3 revealed that the amount of binder, compressive strength and age of the sample enhanced the RCP resistance of concrete specimens. However, among the different input variables, the RCP resistance sharply increased within the first 28 days of age of the concrete specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Rapid chloride ion penetration | RCP |

| Number of chromosomes | Nc |

| Number of genes | Ng |

| Head size | Hs |

| Gene expression programming | GEP |

| Amount of binder | b |

| Fine aggregate | Fag |

| Coarse aggregate | Cag |

| Water to binder ratio | w/b |

| Metakaolin | MK |

| Model predicted to experimental | P/E |

Appendix A

References

- Szostak, B.; Golewski, G.L. Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies 2020, 13, 6734. [Google Scholar] [CrossRef]

- Gruszczyński, M.; Lenart, M. Durability of mortars modified with the addition of amorphous aluminum silicate and silica fume. Theor. Appl. Fract. Mech. 2020, 107, 102526. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Rheology of Cement Pastes with Siliceous Fly Ash and the CSH Nano-Admixture. Materials 2021, 14, 3640. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson Education Canada: Toronto, ON, Canada, 2010; ISBN 978-0273732198. Available online: https://www.pearson.com/en-gb/subject-catalog/p/concrete-technology/P200000005115/9780273732198 (accessed on 30 August 2022).

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 1963. [Google Scholar]

- Zhou, Z.; Sofi, M.; Liu, J.; Li, S.; Zhong, A.; Mendis, P. Nano-CSH modified high volume fly ash concrete: Early-age properties and environmental impact analysis. J. Clean. Prod. 2021, 286, 124924. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N. An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced expansive soil subgrade. Eng. Sci. Technol. Int. J. 2020, 23, 1214–1222. [Google Scholar] [CrossRef]

- Aydin, S. Development of a high-temperature-resistant mortar by using slag and pumice. Fire Saf. J. 2008, 43, 610–617. [Google Scholar] [CrossRef]

- Kabay, N.; Miyan, N.; Özkan, H. Utilization of pumice powder and glass microspheres in cement mortar using paste replacement methodology. Constr. Build. Mater. 2021, 282, 122691. [Google Scholar] [CrossRef]

- Mehdipour, S.; Nikbin, I.M.; Dezhampanah, S.; Mohebbi, R.; Moghadam, H.H.; Charkhtab, S.; Moradi, A. Mechanical properties, durability and environmental evaluation of rubberized concrete incorporating steel fiber and metakaolin at elevated temperatures. J. Clean. Prod. 2020, 254, 120126. [Google Scholar] [CrossRef]

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards sustainable concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M.; Ketabdari, H. Effect of pozzolanic wastes on mechanical properties, durability and microstructure of the cementitious mortars. J. Build. Eng. 2020, 29, 101178. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B.; Jain, A.; Hanifehzadeh, M. Mitigating alkali-silica reaction induced concrete degradation through cement substitution by metakaolin and bentonite. Appl. Clay Sci. 2019, 182, 105257. [Google Scholar] [CrossRef]

- Sabir, B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Khatib, J.M.; Hibbert, J.J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 2005, 19, 460–472. [Google Scholar] [CrossRef]

- Seleem, H.E.D.H.; Rashad, A.M.; El-Sabbagh, B.A. Durability and strength evaluation of high-performance concrete in marine structures. Constr. Build. Mater. 2010, 24, 878–884. [Google Scholar] [CrossRef]

- Vejmelková, E.; Pavlíková, M.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Ondráček, M.; Sedlmajer, M.; Černý, R. High performance concrete with Czech metakaolin: Experimental analysis of strength, toughness and durability characteristics. Constr. Build. Mater. 2010, 24, 1404–1411. [Google Scholar] [CrossRef]

- Parande, A.K.; Ramesh Babu, B.; Aswin Karthik, M.; Deepak Kumaar, K.K.; Palaniswamy, N. Study on strength and corrosion performance for steel embedded in metakaolin blended concrete/mortar. Constr. Build. Mater. 2008, 22, 127–134. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sulfate resistance of self compacting concrete incorporating copper slag as fine aggregates with mineral admixtures. Constr. Build. Mater. 2021, 287, 122985. [Google Scholar] [CrossRef]

- ASTM C1202-19; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Badogiannis, E.; Aggeli, E.; Papadakis, V.G.; Tsivilis, S. Evaluation of chloride-penetration resistance of metakaolin concrete by means of a diffusion—Binding model and of the k-value concept. Cem. Concr. Compos. 2015, 63, 1–7. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Asteris, P.G. A Comparative Study of ANN and ANFIS Models for the Prediction of Cement-Based Mortar Materials Compressive Strength; Springer: London, UK, 2021; Volume 33, ISBN 0123456789. [Google Scholar]

- Bardhan, A.; Biswas, R.; Kardani, N.; Iqbal, M.; Samui, P.; Singh, M.P.; Asteris, P.G. A novel integrated approach of augmented grey wolf optimizer and ANN for estimating axial load carrying-capacity of concrete-filled steel tube columns. Constr. Build. Mater. 2022, 337, 127454. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Fallah, A.; Armaghani, D.J.; Azizi, A.; Mohamad, E.T. Three hybrid intelligent models in estimating flyrock distance resulting from blasting. Eng. Comput. 2019, 35, 243–256. [Google Scholar] [CrossRef]

- Baykasoǧlu, A.; Öztaş, A.; Özbay, E. Prediction and multi-objective optimization of high-strength concrete parameters via soft computing approaches. Expert Syst. Appl. 2009, 36, 6145–6155. [Google Scholar] [CrossRef]

- Topçu, I.B.; Saridemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Saridemir, M. Predicting the compressive strength of mortars containing metakaolin by artificial neural networks and fuzzy logic. Adv. Eng. Softw. 2009, 40, 920–927. [Google Scholar] [CrossRef]

- Mohammadi Golafshani, E.; Arashpour, M.; Behnood, A. Predicting the compressive strength of green concretes using Harris hawks optimization-based data-driven methods. Constr. Build. Mater. 2022, 318, 125944. [Google Scholar] [CrossRef]

- Tien Bui, D.; Nhu, V.H.; Hoang, N.D. Prediction of soil compression coefficient for urban housing project using novel integration machine learning approach of swarm intelligence and Multi-layer Perceptron Neural Network. Adv. Eng. Inform. 2018, 38, 593–604. [Google Scholar] [CrossRef]

- Shariati, M.; Mafipour, M.S.; Ghahremani, B.; Azarhomayun, F.; Ahmadi, M.; Trung, N.T.; Shariati, A. A novel hybrid extreme learning machine–grey wolf optimizer (ELM-GWO) model to predict compressive strength of concrete with partial replacements for cement. Eng. Comput. 2022, 38, 757–779. [Google Scholar] [CrossRef]

- Khan, K.; Salami, B.A.; Iqbal, M.; Amin, M.N.; Ahmed, F.; Jalal, F.E. Compressive Strength Estimation of Fly Ash/Slag Based Green Concrete by Deploying Artificial Intelligence Models. Materials 2022, 15, 3722. [Google Scholar] [CrossRef]

- Kumar, S.; Rai, B.; Biswas, R.; Samui, P.; Kim, D. Prediction of rapid chloride permeability of self-compacting concrete using Multivariate Adaptive Regression Spline and Minimax Probability Machine Regression. J. Build. Eng. 2020, 32, 101490. [Google Scholar] [CrossRef]

- Ge, D.-M.; Zhao, L.-C.; Esmaeili-Falak, M. Estimation of rapid chloride permeability of SCC using hyperparameters optimized random forest models. J. Sustain. Cem.-Based Mater. 2022, 1–19. [Google Scholar] [CrossRef]

- Abu Yaman, M.; Abd Elaty, M.; Taman, M. Predicting the ingredients of self compacting concrete using artificial neural network. Alex. Eng. J. 2017, 56, 523–532. [Google Scholar] [CrossRef]

- Mohammadzadeh, S.D.; Bolouri Bazaz, J.; Alavi, A.H. An evolutionary computational approach for formulation of compression index of fine-grained soils. Eng. Appl. Artif. Intell. 2014, 33, 58–68. [Google Scholar] [CrossRef]

- Alavi, A.H.; Gandomi, A.H.; Sahab, M.G.; Gandomi, M. Multi expression programming: A new approach to formulation of soil classification. Eng. Comput. 2010, 26, 111–118. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of artificial neural network and genetic programming as predictive tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Liu, Q.F.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef]

- Hanandeh, S.; Ardah, A.; Abu-Farsakh, M. Using artificial neural network and genetics algorithm to estimate the resilient modulus for stabilized subgrade and propose new empirical formula. Transp. Geotech. 2020, 24, 100358. [Google Scholar] [CrossRef]

- Al-Alaily, H.S.; Hassan, A.A.A. Refined statistical modeling for chloride permeability and strength of concrete containing metakaolin. Constr. Build. Mater. 2016, 114, 564–579. [Google Scholar] [CrossRef]

- Safarzadegan Gilan, S.; Bahrami Jovein, H.; Ramezanianpour, A.A. Hybrid support vector regression—Particle swarm optimization for prediction of compressive strength and RCPT of concretes containing metakaolin. Constr. Build. Mater. 2012, 34, 321–329. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Bahrami Jovein, H. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Asteris, P.G.; Skentou, A.D.; Bardhan, A.; Samui, P.; Pilakoutas, K. Predicting concrete compressive strength using hybrid ensembling of surrogate machine learning models. Cem. Concr. Res. 2021, 145, 106449. [Google Scholar] [CrossRef]

- Feng, D.-C.; Wang, W.-J.; Mangalathu, S.; Taciroglu, E. Interpretable XGBoost-SHAP Machine-Learning Model for Shear Strength Prediction of Squat RC Walls. J. Struct. Eng. 2021, 147, 04021173. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Iqbal, M.; Jalal, F.E.; Onyia, M.E.; Onuoha, I.C. Application of 3-algorithm ANN programming to predict the strength performance of hydrated-lime activated rice husk ash treated soil. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 259–274. [Google Scholar] [CrossRef]

- Iqbal, M.; Onyelowe, K.C.; Jalal, F.E. Smart computing models of California bearing ratio, unconfined compressive strength, and resistance value of activated ash-modified soft clay soil with adaptive neuro-fuzzy inference system and ensemble random forest regression techniques. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 207–225. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Kafodya, I.; Xian, G.; Li, H. Durability study of pultruded CFRP plates immersed in water and seawater under sustained bending: Water uptake and effects on the mechanical properties. Compos. Part B Eng. 2015, 70, 138–148. [Google Scholar] [CrossRef]

- Liu, Q.F.; Iqbal, M.F.; Yang, J.; Lu, X.Y.; Zhang, P.; Rauf, M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constr. Build. Mater. 2021, 268, 121082. [Google Scholar] [CrossRef]

| Descriptive Statistics | Age | b | Fag | Cag | w/b | MK | Compressive Strength | RCPT |

|---|---|---|---|---|---|---|---|---|

| Average | 63.53 | 389.92 | 0.42 | 10.76 | 878.46 | 874.97 | 55.11 | 2309.98 |

| Standard Error | 4.35 | 4.88 | 0.004 | 0.48 | 7.70 | 6.18 | 1.19 | 111.36 |

| Median | 28 | 360 | 0.45 | 12.5 | 881.30 | 832.5 | 52.7 | 1973 |

| Standard Deviation | 61.63 | 69.21 | 0.058 | 6.74 | 109.21 | 87.69 | 17.01 | 1578.79 |

| Sample Variance | 3798.46 | 4790.43 | 0.003 | 45.41 | 11,925.88 | 7689.79 | 289.30 | 2492.57 × 103 |

| Kurtosis | −0.42 | 2.19 | −0.90 | −0.49 | −0.99 | −0.82 | −0.31 | 0.11 |

| Skewness | 1.04 | 1.69 | −0.24 | −0.10 | −0.25 | 0.34 | 0.25 | 0.93 |

| Minimum | 7 | 320 | 0.3 | 0 | 589.2 | 707 | 19 | 203 |

| Maximum | 180 | 600 | 0.5 | 25 | 1017.5 | 1111.7 | 108 | 6982 |

| Trial/Model | No. of Variables | No. of Chromosomes | Head Size | No. of Genes | TR Phase | TS Phase | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSE | MAE | R2 | RMSE | MAE | |||||

| T1 | 7 | 30 | 8 | 3 | 0.84 | 602.1 | 475.3 | 0.92 | 478.2 | 386.6 |

| T2 | 6 | 50 | 8 | 3 | 0.81 | 681.3 | 483.3 | 0.90 | 526.6 | 424 |

| T3 | 7 | 100 | 8 | 3 | 0.89 | 513.9 | 385.2 | 0.92 | 464.1 | 364.9 |

| T4 | 7 | 150 | 8 | 3 | 0.83 | 641.3 | 483.3 | 0.92 | 482.7 | 383.1 |

| T5 | 6 | 200 | 8 | 3 | 0.79 | 641.3 | 568.3 | 0.89 | 562.2 | 477.3 |

| T6 | 7 | 100 | 9 | 3 | 0.78 | 723.3 | 538.0 | 0.89 | 561.9 | 433.1 |

| T7 | 7 | 100 | 10 | 3 | 0.78 | 728.7 | 593.5 | 0.88 | 625.6 | 521.3 |

| T8 | 7 | 100 | 11 | 3 | 0.83 | 641.2 | 469.6 | 0.89 | 527.2 | 423.5 |

| T9 | 7 | 100 | 12 | 3 | 0.87 | 564.8 | 447 | 0.92 | 478.9 | 399.3 |

| T10 | 6 | 100 | 8 | 4 | 0.83 | 634.2 | 477.1 | 0.89 | 567.7 | 451.5 |

| T11 | 7 | 100 | 8 | 5 | 0.88 | 525.3 | 394.8 | 0.91 | 494.6 | 387.7 |

| Index | Range/Ideal Value |

|---|---|

| R2 | (0–1)/1 |

| RMSE | )/0 |

| MAE | )/0 |

| Statistic | R2 | RMSE | MAE | |||

|---|---|---|---|---|---|---|

| Rank | 1st | 2nd | 1st | 2nd | 1st | 2nd |

| TR Phase | T3 | T11 | T3 | T11 | T3 | T11 |

| TS Phase | T3, T1 | - | T3 | T1 | T3 | T4 |

| Input Variables | Constant Input Parameters | No. of Datapoints | |

|---|---|---|---|

| Parameter | Range | ||

| Age | 7–180 | B = 389.93, w/b = 0.42, MK = 10.76, Fag = 878.46, Cag = 874.97, compressive strength = 55.12 | 9 |

| b | 320–600 | Age = 63.53, w/b = 0.42, MK = 10.76, Fag = 878.46, Cag = 874.97, compressive strength = 55.12 | |

| Fag | 589.2–1017.5 | Age = 63.53, B = 389.93, w/b = 0.42, MK = 10.76, Cag = 874.97, compressive strength = 55.12 | |

| Cag | 707–1111.7 | Age = 63.53, B = 389.93, w/b = 0.42, MK = 10.76, Fag = 878.46, compressive strength = 55.12 | |

| w/b | 0.3–0.5 | Age = 63.53, B = 389.93, MK = 10.76, Fag = 878.46, Cag = 874.97, compressive strength = 55.12 | |

| MK | 0–25 | Age = 63.53, B = 389.93, w/b = 0.42, Fag = 878.46, Cag = 874.97, compressive strength = 55.12 | |

| compressive strength | 19–108 | Age = 63.53, B = 389.93, w/b = 0.42, MK = 10.76, Fag = 878.46, Cag = 874.97 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amin, M.N.; Raheel, M.; Iqbal, M.; Khan, K.; Qadir, M.G.; Jalal, F.E.; Alabdullah, A.A.; Ajwad, A.; Al-Faiad, M.A.; Abu-Arab, A.M. Prediction of Rapid Chloride Penetration Resistance to Assess the Influence of Affecting Variables on Metakaolin-Based Concrete Using Gene Expression Programming. Materials 2022, 15, 6959. https://doi.org/10.3390/ma15196959

Amin MN, Raheel M, Iqbal M, Khan K, Qadir MG, Jalal FE, Alabdullah AA, Ajwad A, Al-Faiad MA, Abu-Arab AM. Prediction of Rapid Chloride Penetration Resistance to Assess the Influence of Affecting Variables on Metakaolin-Based Concrete Using Gene Expression Programming. Materials. 2022; 15(19):6959. https://doi.org/10.3390/ma15196959

Chicago/Turabian StyleAmin, Muhammad Nasir, Muhammad Raheel, Mudassir Iqbal, Kaffayatullah Khan, Muhammad Ghulam Qadir, Fazal E. Jalal, Anas Abdulalim Alabdullah, Ali Ajwad, Majdi Adel Al-Faiad, and Abdullah Mohammad Abu-Arab. 2022. "Prediction of Rapid Chloride Penetration Resistance to Assess the Influence of Affecting Variables on Metakaolin-Based Concrete Using Gene Expression Programming" Materials 15, no. 19: 6959. https://doi.org/10.3390/ma15196959

APA StyleAmin, M. N., Raheel, M., Iqbal, M., Khan, K., Qadir, M. G., Jalal, F. E., Alabdullah, A. A., Ajwad, A., Al-Faiad, M. A., & Abu-Arab, A. M. (2022). Prediction of Rapid Chloride Penetration Resistance to Assess the Influence of Affecting Variables on Metakaolin-Based Concrete Using Gene Expression Programming. Materials, 15(19), 6959. https://doi.org/10.3390/ma15196959