Microstructure and Electrochemical Characterization of Ti-Sn Binary Alloys for Dental Applications

Abstract

1. Introduction

2. Materials and Methods

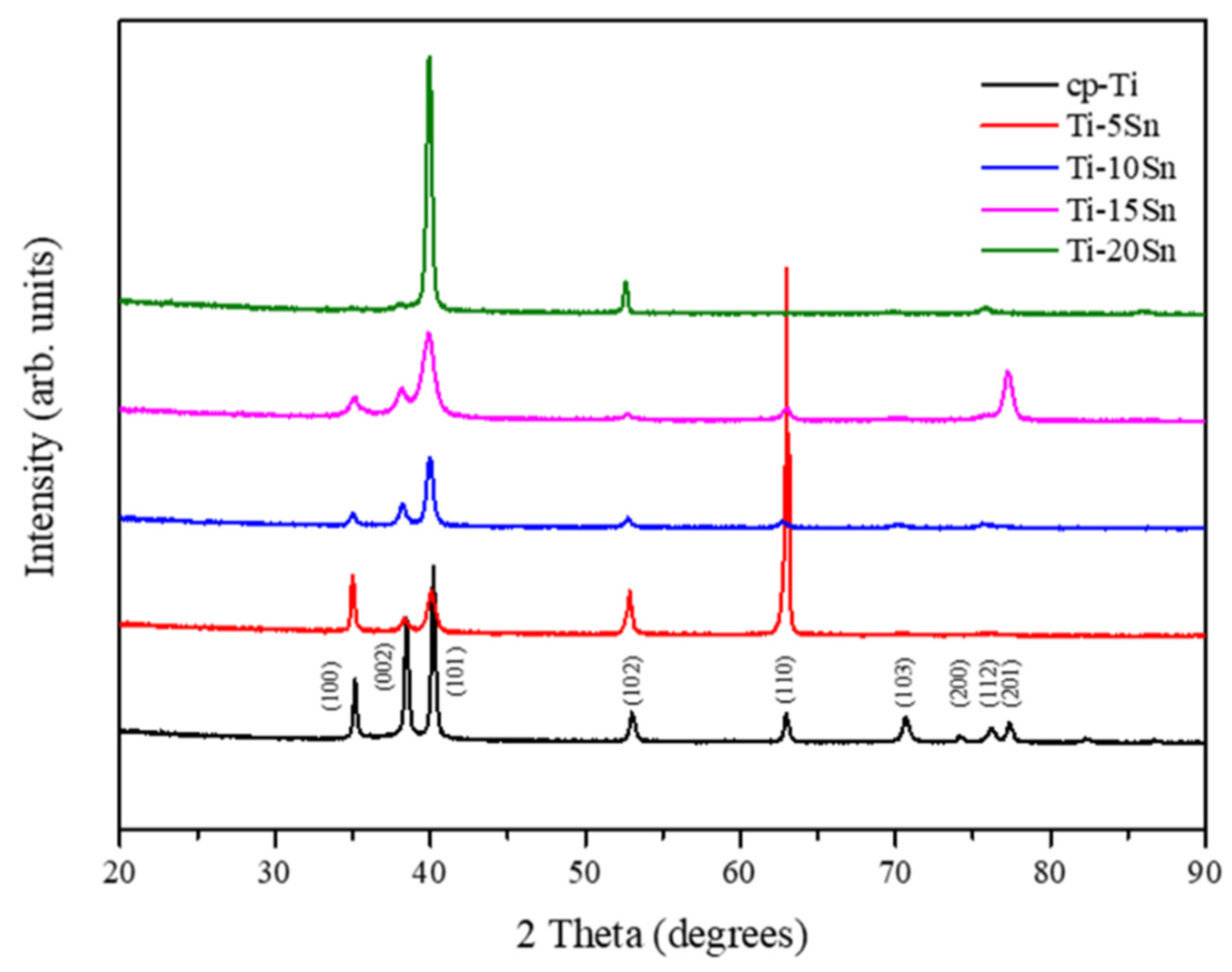

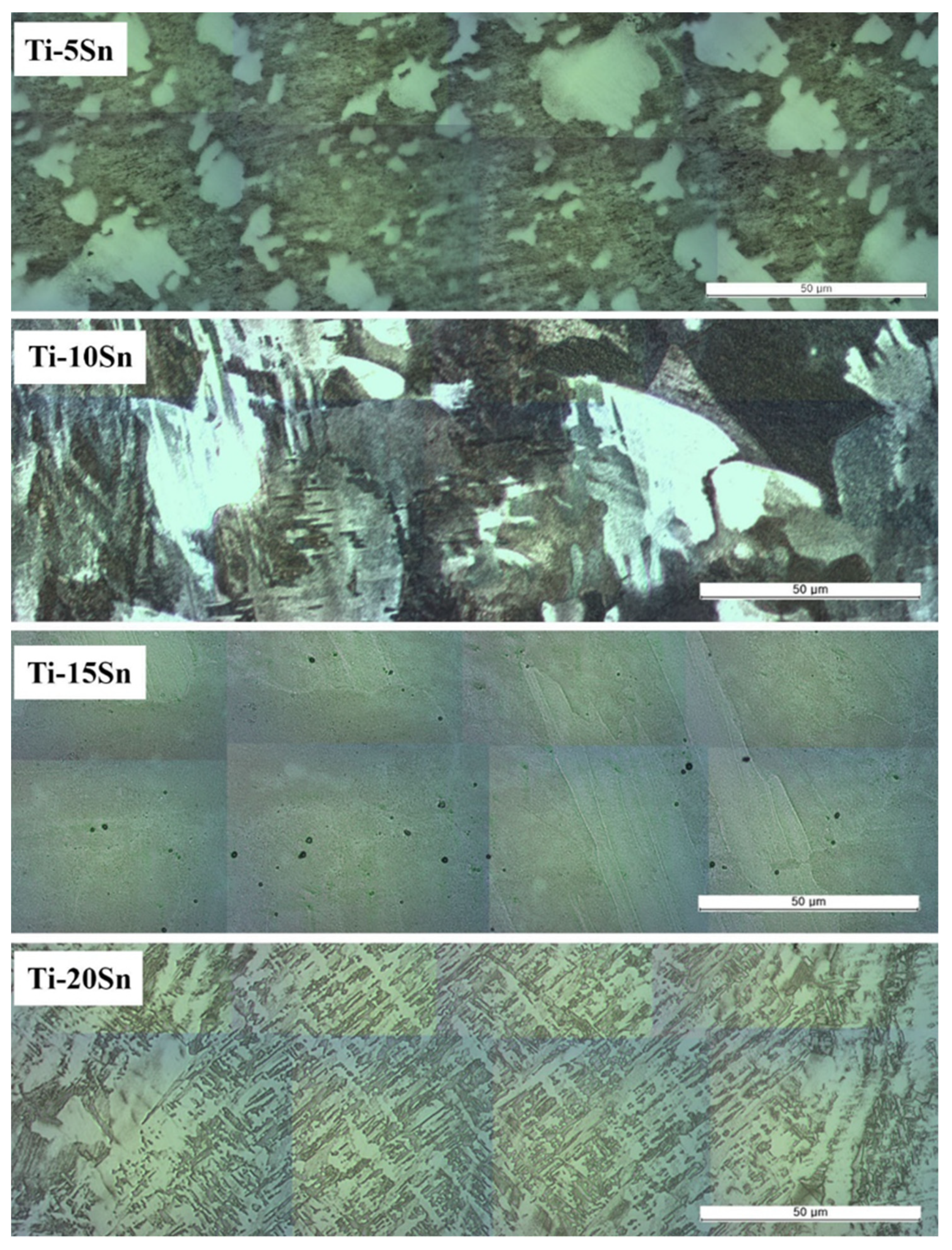

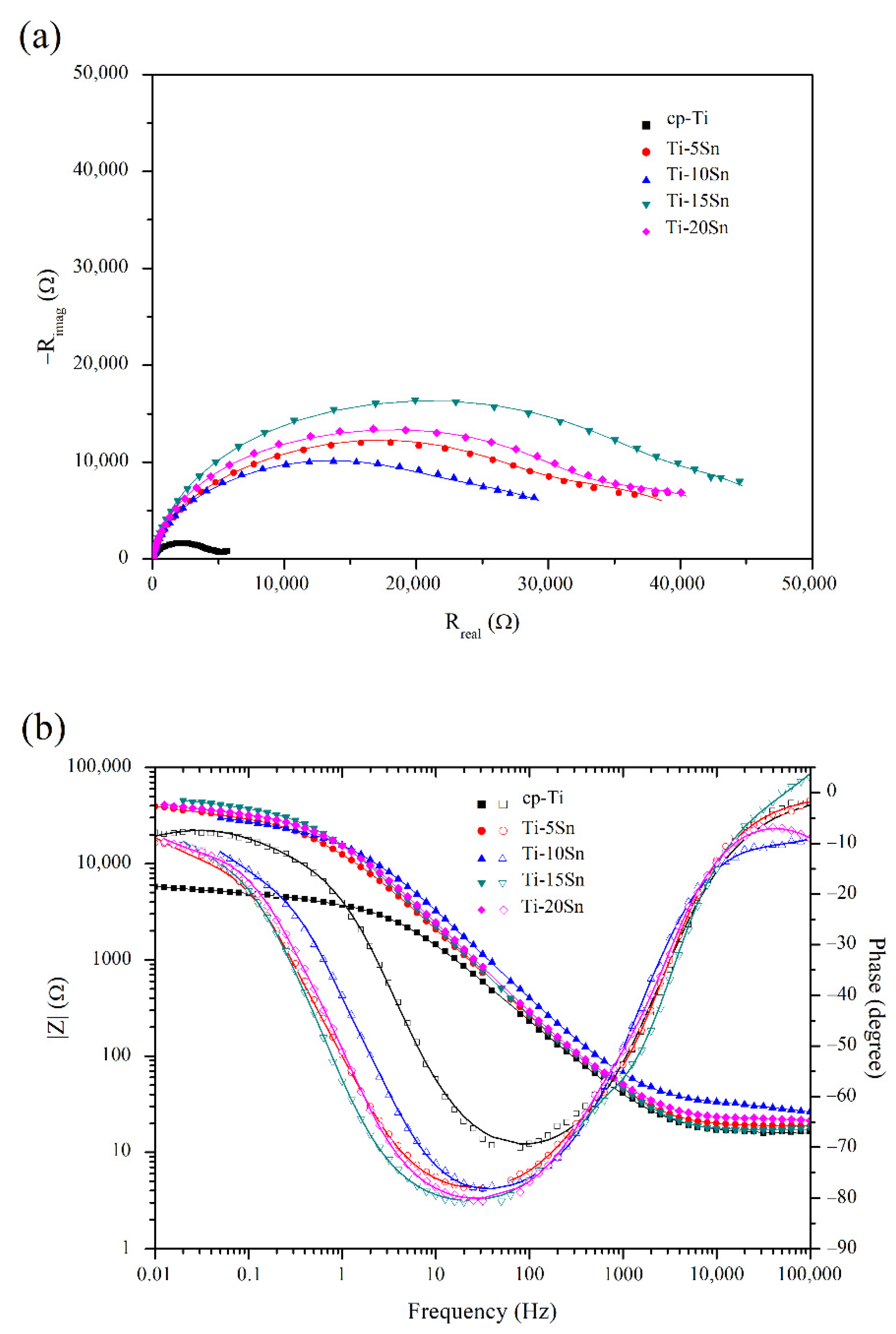

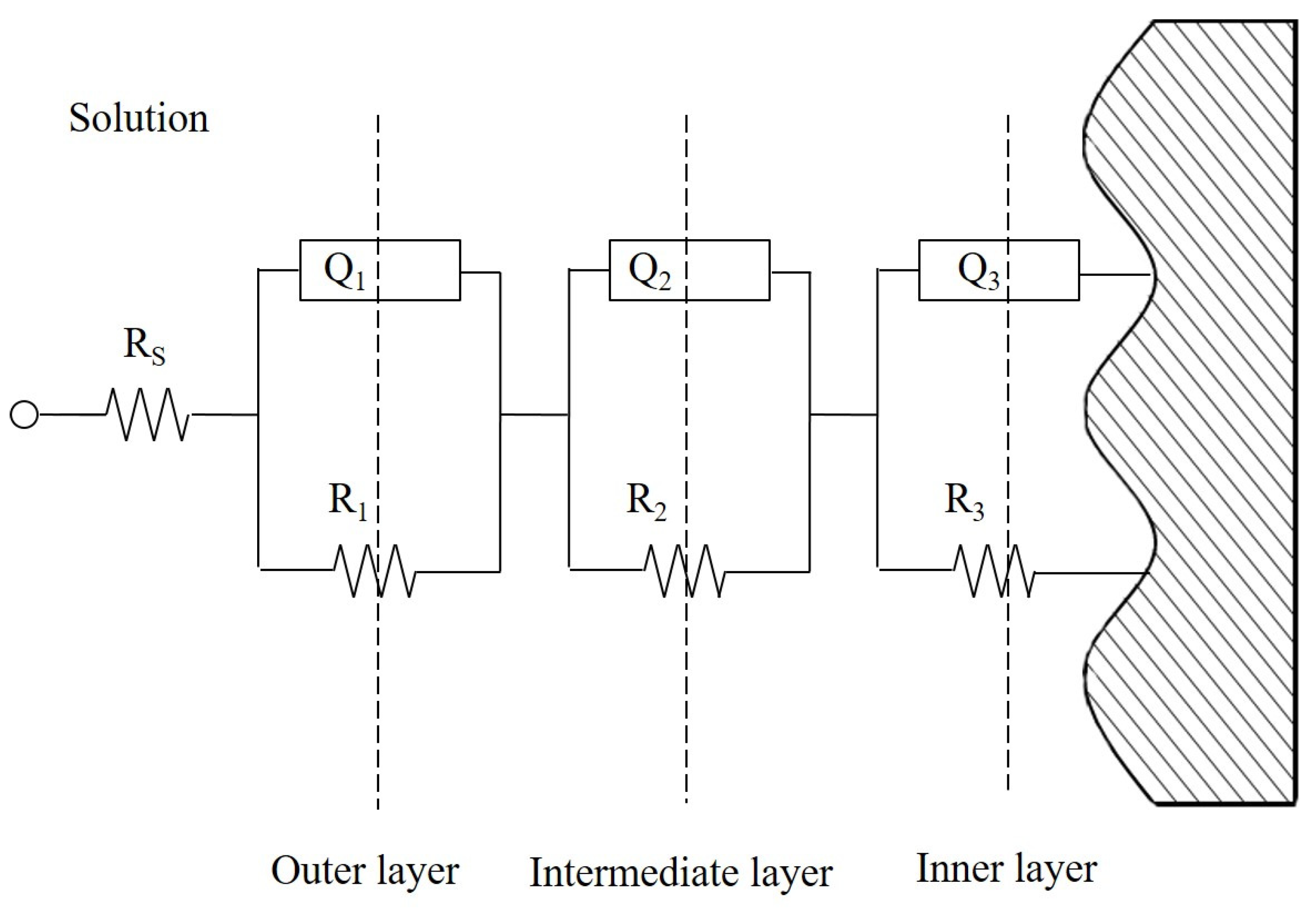

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davis, R.; Singh, A.; Jackson, M.J.; Coelho, R.T.; Prakash, D.; Charalambous, C.P.; da Silva, L.R.R.; Ahmed, W.; Lawrence, A.A. A comprehensive review on metallic implant biomaterials and their subtractive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 1473–1530. [Google Scholar] [CrossRef] [PubMed]

- Hwang, M.J.; Park, E.J.; Moon, W.J.; Song, H.J.; Park, Y.J. Characterization of passive layers formed on Ti-10 wt% (Ag, Au, Pd, or Pt) binary alloys and their effects on galvanic corrosion. Corros. Sci. 2015, 96, 152–159. [Google Scholar] [CrossRef]

- Nakagawa, M.; Matsuya, S.; Shiraishi, T.; Ohta, M. Effect of fluoride concentration and pH on corrosion behavior of titanium for dental use. J. Dent. Res. 1999, 78, 1568–1572. [Google Scholar] [CrossRef] [PubMed]

- Choubey, A.; Basu, B.; Balasubramaniam, R. Electrochemical behavior of Ti-based alloys in simulated human body fluid environment. Trends Biomater. Artif. Organs 2005, 18, 64–72. [Google Scholar]

- Geetha, M.; Kamachi Mudali, U.; Gogia, A.K.; Asokamani, R.; Raj, B. Influence of microstructure and alloying elements on corrosion behavior of Ti–13Nb–13Zr alloy. Corros. Sci. 2004, 46, 877–892. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Wang, Y.B.; Lin, J.P.; Zheng, Y.F. Development and properties of Ti-In binary alloys as dental biomaterials. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 1601–1606. [Google Scholar] [CrossRef]

- Kim, J.W.; Hwang, M.J.; Han, M.K.; Kim, Y.G.; Song, H.J.; Park, Y.J. Effect of manganese on the microstructure, mechanical properties and corrosion behavior of titanium alloys. Mater. Chem. Phys. 2016, 180, 341–348. [Google Scholar] [CrossRef]

- Nakagawa, M.; Matono, Y.; Matsuya, S.; Udoh, K.; Ishikawa, K. The effect of Pt and Pd alloying additions on the corrosion behavior of titanium in fluoride-containing environments. Biomaterials 2005, 26, 2239–2246. [Google Scholar] [CrossRef]

- Osório, W.R.; Cremasco, A.; Andrade, P.N.; Garcia, A.; Caram, R. Electrochemical behavior of centrifuged cast and heat treated Ti–Cu alloys for medical applications. Electrochim. Acta 2010, 55, 759–770. [Google Scholar] [CrossRef]

- Cremasco, A.; Osório, W.R.; Freire, C.M.A.; Garcia, A.; Caram, R. Electrochemical corrosion behavior of a Ti–35Nb alloy for medical prostheses. Electrochim. Acta 2008, 53, 4867–4874. [Google Scholar] [CrossRef]

- Akimoto, T.; Ueno, T.; Tsutsumi, Y.; Doi, H.; Hanawa, T.; Wakabayashi, N. Evaluation of corrosion resistance of implant-use Ti-Zr binary alloys with a range of compositions. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 106, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Rosalbino, F.; Delsant, S.; Borzone, G.; Scavino, G. Influence of noble metals alloying additions on the corrosion behaviour of titanium in a fluoride-containing environment. J. Mater. Sci: Mater. Med. 2012, 23, 1129–1137. [Google Scholar] [CrossRef]

- Niinomi, M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci. Technol. Adv. Mater. 2016, 4, 445–454. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hong, Y.S.; Ho, W.F. Mechanical properties and deformation behavior of as-cast Ti–Sn alloys. J. Alloy. Compd. 2009, 479, 390–394. [Google Scholar] [CrossRef]

- Hsu, H.C.; Lin, H.C.; Wu, S.C.; Hong, Y.S.; Ho, W.F. Microstructure and grindability of as-cast Ti–Sn alloys. J. Mater. Sci. 2010, 45, 1830–1836. [Google Scholar] [CrossRef]

- Azmat, A.; Tufail, M.; Chandio, A.D. Synthesis and Characterization of Ti-Sn Alloy for Orthopedic Application. Materials 2021, 14, 7660. [Google Scholar] [CrossRef]

- ASTM G106-89 (Reapproved 2010); Standard Practice for Verification of Algorithm and Equipment for Electrochemical Impedance Measurements. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM G5-94 (Reapproved 2011); Standard Reference Test Method for Making Potentiostatic and Potentiodynamic Anodic Polarization Measurements. ASTM International: West Conshohocken, PA, USA, 2011.

- Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Li, C.T.; Ho, W.F. Effects of chromium addition on structure and mechanical properties of Ti-5Mo alloy. Mater Des. 2015, 65, 700–706. [Google Scholar] [CrossRef]

- Ho, W.F.; Wu, S.C.; Hsu, S.K.; Li, Y.C.; Hsu, H.C. Effects of molybdenum content on the structure and mechanical properties of as-cast Ti-10Zr-based alloys for biomedical applications. Mat. Sci. Eng. C-Mater. 2012, 32, 517–522. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Kao, W.H.; Ho, W.F. Structure and mechanical properties of as-cast Ti-5Nb-based alloy with Mo addition. Mat. Sci. Eng. A-Struct. 2013, 579, 86–91. [Google Scholar] [CrossRef]

- Ho, W.F.; Ju, C.P.; Lin, J.H.C. Structure and properties of cast binary Ti-Mo alloys. Biomaterials 1999, 20, 2115–2122. [Google Scholar] [CrossRef]

- Park, K.H.; Hwang, M.J.; Song, H.J.; Park, Y.J. Electrochemical and mechanical properties of cast Ti-V alloys for dental applications. Int. J. Electrochem. Sci. 2016, 11, 5552–5563. [Google Scholar] [CrossRef]

- Fekry, A.M.; Ameer, M.A. Electrochemistry and Impedance Studies on Titanium and Magnesium Alloys in Ringer’s Solution. Int. J. Electrochem. Sci. 2011, 6, 1342–1354. [Google Scholar]

- Tamilselvi, S.; Raman, V.; Rajendran, N. Corrosion behaviour of Ti-6Al-7Nb and Ti-6Al-4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim. Acta 2006, 52, 839–846. [Google Scholar] [CrossRef]

- Hwang, M.J.; Choi, H.R.; Kook, M.S.; Song, H.J.; Park, Y.J. Investigation of passivation and galvanic corrosion of Ti-Nb alloys and pure titanium. Mater. Corros. 2015, 66, 783–789. [Google Scholar] [CrossRef]

- Balaraju, J.N.; Selvi, V.E.; Grips, V.K.W.; Rajam, K.S. Electrochemical studies on electroless ternary and quaternary Ni–P based alloys. Electrochim. Acta 2006, 52, 1064–1074. [Google Scholar] [CrossRef]

- Zaveri, N.; McEwen, G.D.; Karpagavalli, R.; Zhou, A. Biocorrosion studies of TiO2 nanoparticle-coated Ti–6Al–4V implant in simulated biofluids. J. Nanoparticle Res. 2009, 12, 1609–1623. [Google Scholar] [CrossRef]

- Grosgogeat, B.; Reclaru, L.; Lissac, M.; Dalard, F. Measurement and evaluation of galvanic corrosion between titanium/Ti6Al4V implants and dental alloys by electrochemical techniques and auger spectrometry. Biomaterials 1999, 20, 933–941. [Google Scholar] [CrossRef]

| Sample | Vickers Hardness (kgf/mm2) |

|---|---|

| cp-Ti | 154.44 ± 5.93 |

| Ti-5Sn | 342.20 ± 61.28 |

| Ti-10Sn | 334.80 ± 29.08 |

| Ti-15Sn | 449.60 ± 73.59 |

| Ti-20Sn | 442.00 ± 22.45 |

| Sample | Solution | Outer Layer | Intermediate Layer | Inner Layer | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rs (Ω) | R1 (kΩ) | CPE1 (µ S⋅sn1) | n1 | R2 (kΩ) | CPE2 (µ S⋅sn2) | n2 | R3 (kΩ) | CPE3 (µ S⋅sn3) | n3 | |

| cp-Ti | 15.3 (1.5) | 2.53 (1.48) | 2367 (3611) | 0.76 (0.06) | 7.62 (6.14) | 4216 (3973) | 0.78 (0.07) | 2.55 (1.19) | 183 (271) | 0.80 (0.05) |

| Ti-5Sn | 14.6 (4.8) | 11.05 (8.96) | 509 (756) | 0.88 (0.42) | 5.75 (2.39) | 977 (1476) | 0.87 (0.09) | 8.89 (6.43) | 117 (177) | 0.85 (0.07) |

| Ti-10Sn | 21.1 (2.4) | 7.13 (9.07) | 269 (295) | 0.70 (0.03) | 9.92 (5.00) | 1580 (1360) | 0.76 (0.18) | 2.87 (1.87) | 15 (4) | 0.93 (0.06) |

| Ti-15Sn | 14.8 (1.9) | 16.30 (12.60) | 570 (860) | 0.84 (0.10) | 9.41 (8.70) | 21 (12) | 0.91 (0.03) | 10.98 (5.92) | 1030 (1070) | 0.80 (0.12) |

| Ti-20Sn | 19.9 (4.2) | 9.71 (7.39) | 81 (62) | 0.79 (0.13) | 6.28 (6.30) | 14 (2) | 0.95 (0.04) | 15.50 (3.77) | 710 (271) | 0.72 (0.08) |

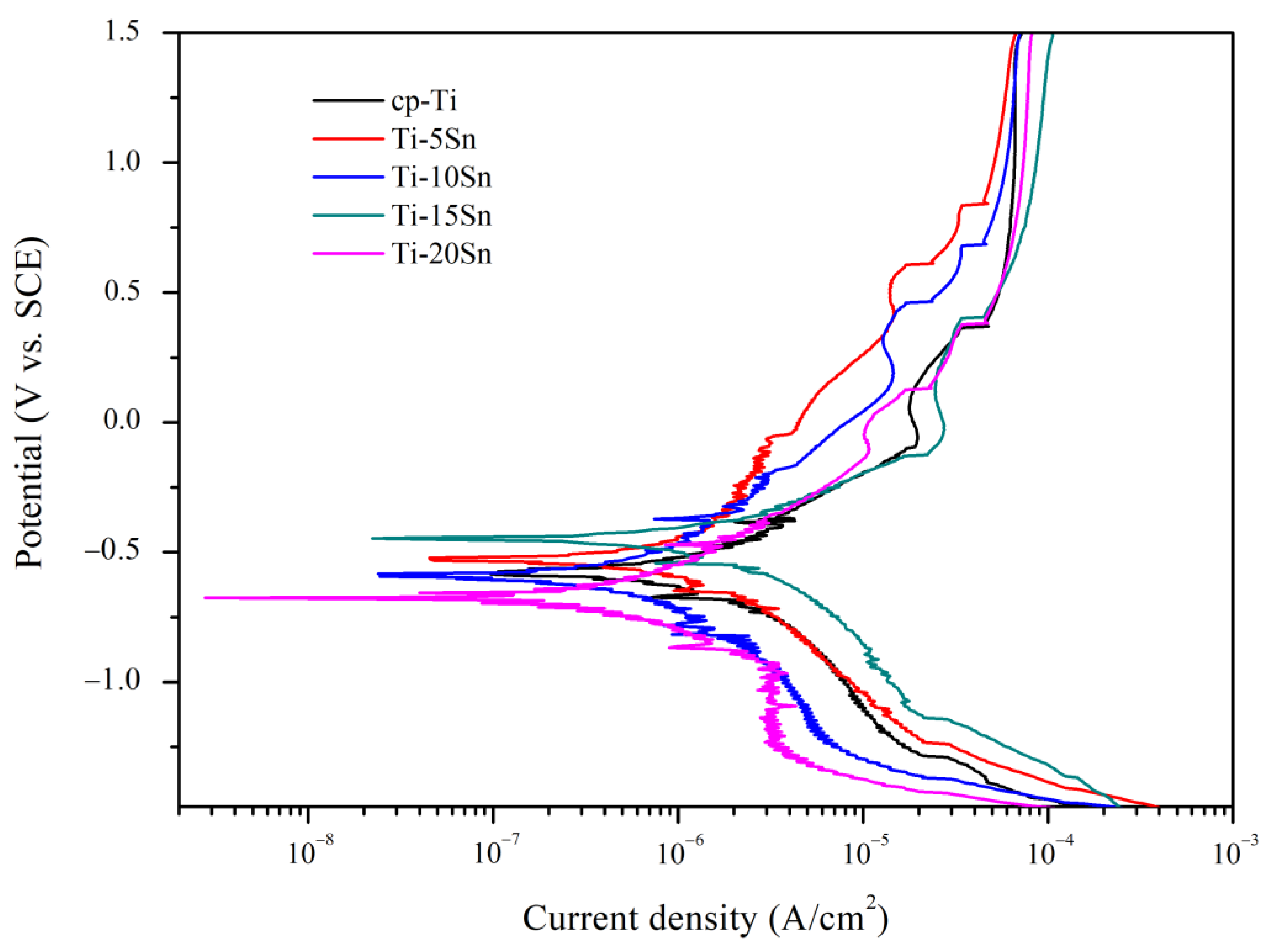

| Sample | Ecorr (mV) | Icorr (×10−6 A/cm2) | βa | βb | Rp (×kΩ) | Corrosion Rate (×10−2 mm/year) |

|---|---|---|---|---|---|---|

| cp-Ti | −574 ± 41 | 0.611 ± 0.171 | 0.267 ± 0.091 | 0.188 ± 0.179 | 78.7 ± 10.5 | 1.88 ± 0.53 |

| Ti-5Sn | −530 ± 43 | 0.407 ± 0.066 | 0.199 ± 0.013 | 0.163 ± 0.021 | 97.8 ± 21.6 | 1.25 ± 0.20 |

| Ti-10Sn | −577 ± 110 | 0.254 ± 0.171 | 0.187 ± 0.035 | 0.146 ± 0.027 | 193.9 ± 124 | 0.78 ± 0.53 |

| Ti-15Sn | −519 ± 55 | 0.325 ± 0.149 | 0.186 ± 0.013 | 0.143 ± 0.021 | 123.8 ± 54 | 1.00 ± 0.46 |

| Ti-20Sn | −723 ± 102 | 0.196 ± 0.103 | 0.173 ± 0.06 | 0.159 ± 0.021 | 223.0 ± 119 | 0.61 ± 0.32 |

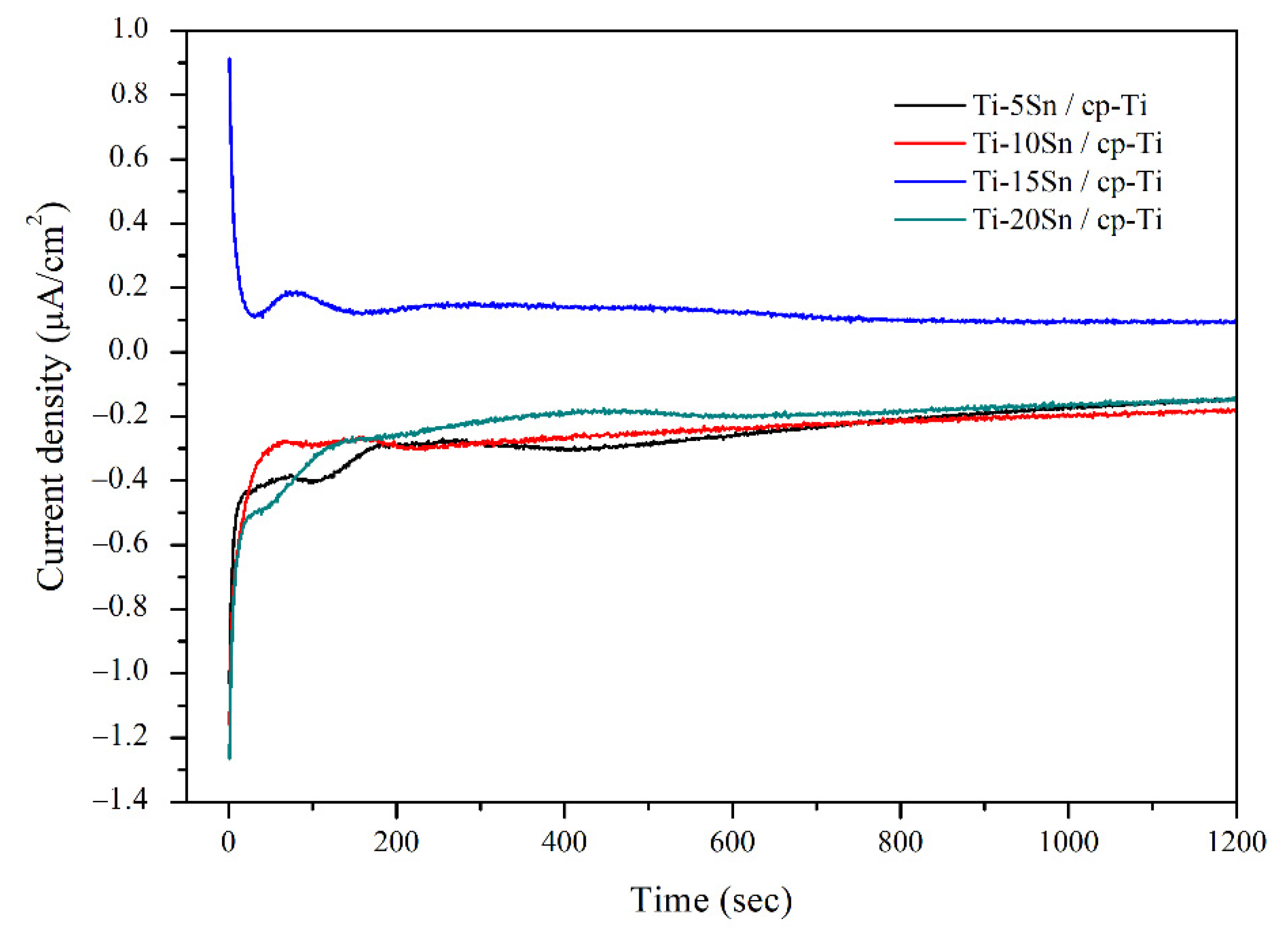

| Sample | Current Density (μA/cm2) | ||||||

|---|---|---|---|---|---|---|---|

| 1 s | 5 s | 10 s | 60 s | 600 s | 1200 s | Integrate | |

| Ti-5Sn | −1.65 ± 0.65 | −1.04 ± 0.36 | −0.78 ± 0.24 | −0.41 ± 0.08 | −0.23 ± 0.06 | −0.14 ± 0.03 | 297.72 ± 57.35 |

| Ti-10Sn | −1.34 ± 0.29 | −0.86 ± 0.21 | −0.69 ± 0.18 | −0.40 ± 0.10 | −0.22 ± 0.09 | −0.17 ± 0.10 | 298.33 ± 106.82 |

| Ti-15Sn | 1.10 ± 0.21 | 0.611 ± 0.17 | 0.40 ± 0.15 | 0.13 ± 0.07 | 0.08 ± 0.04 | 0.07 ± 0.03 | 121.33 ± 64.36 |

| Ti-20Sn | −1.67 ± 0.46 | −1.09 ± 0.27 | −0.85 ± 0.18 | −0.46 ± 0.08 | −0.20 ± 0.08 | −0.14 ± 0.06 | 282.38 ± 91.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, M.-J.; Song, H.-J.; Park, Y.-J. Microstructure and Electrochemical Characterization of Ti-Sn Binary Alloys for Dental Applications. Materials 2022, 15, 6897. https://doi.org/10.3390/ma15196897

Hwang M-J, Song H-J, Park Y-J. Microstructure and Electrochemical Characterization of Ti-Sn Binary Alloys for Dental Applications. Materials. 2022; 15(19):6897. https://doi.org/10.3390/ma15196897

Chicago/Turabian StyleHwang, Moon-Jin, Ho-Jun Song, and Yeong-Joon Park. 2022. "Microstructure and Electrochemical Characterization of Ti-Sn Binary Alloys for Dental Applications" Materials 15, no. 19: 6897. https://doi.org/10.3390/ma15196897

APA StyleHwang, M.-J., Song, H.-J., & Park, Y.-J. (2022). Microstructure and Electrochemical Characterization of Ti-Sn Binary Alloys for Dental Applications. Materials, 15(19), 6897. https://doi.org/10.3390/ma15196897