Fusion Separation of Vanadium-Titanium Magnetite and Enrichment Test of Ti Element in Slag

Abstract

1. Introduction

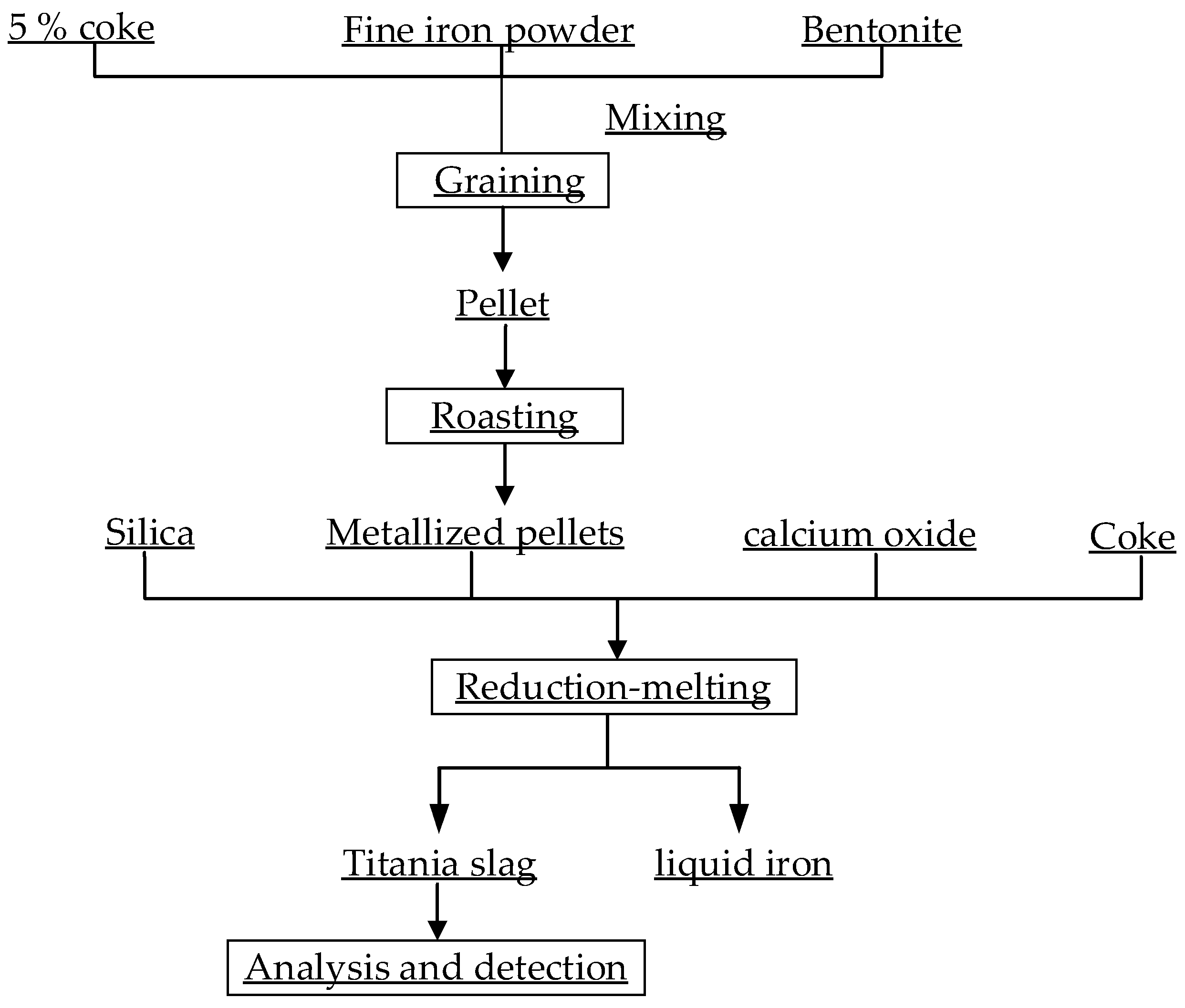

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

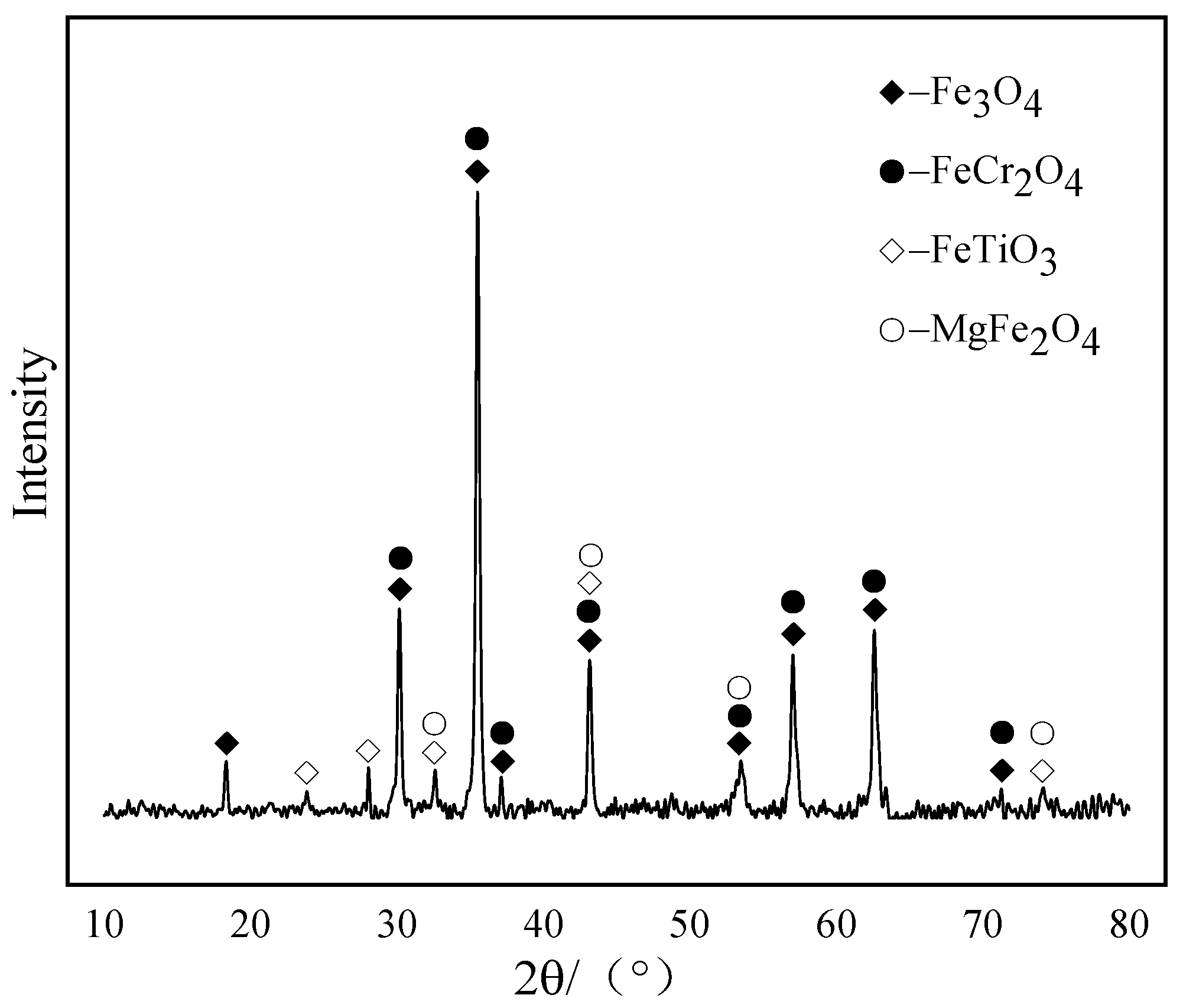

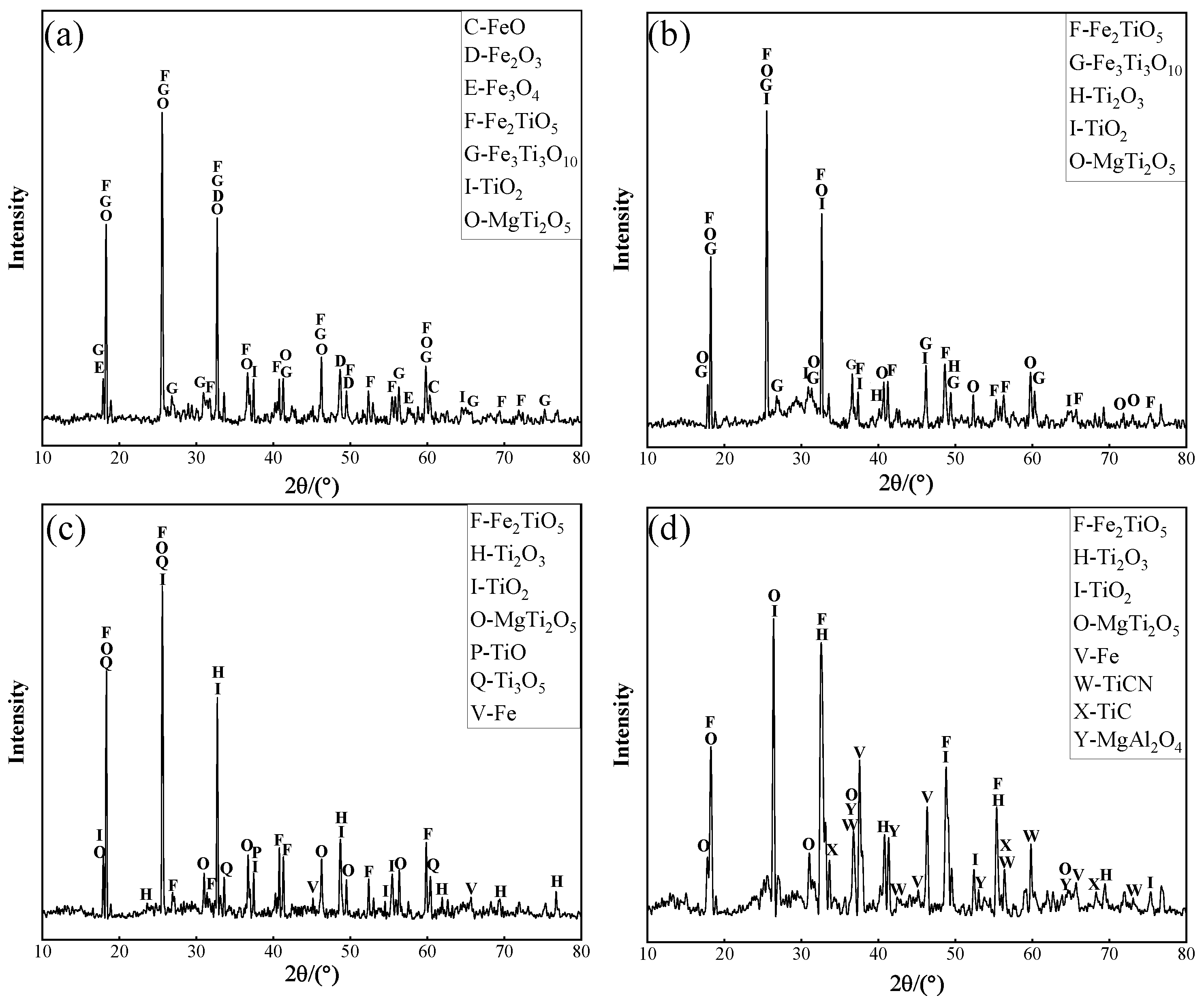

3.1. Results Analysis of Metalized Pellets

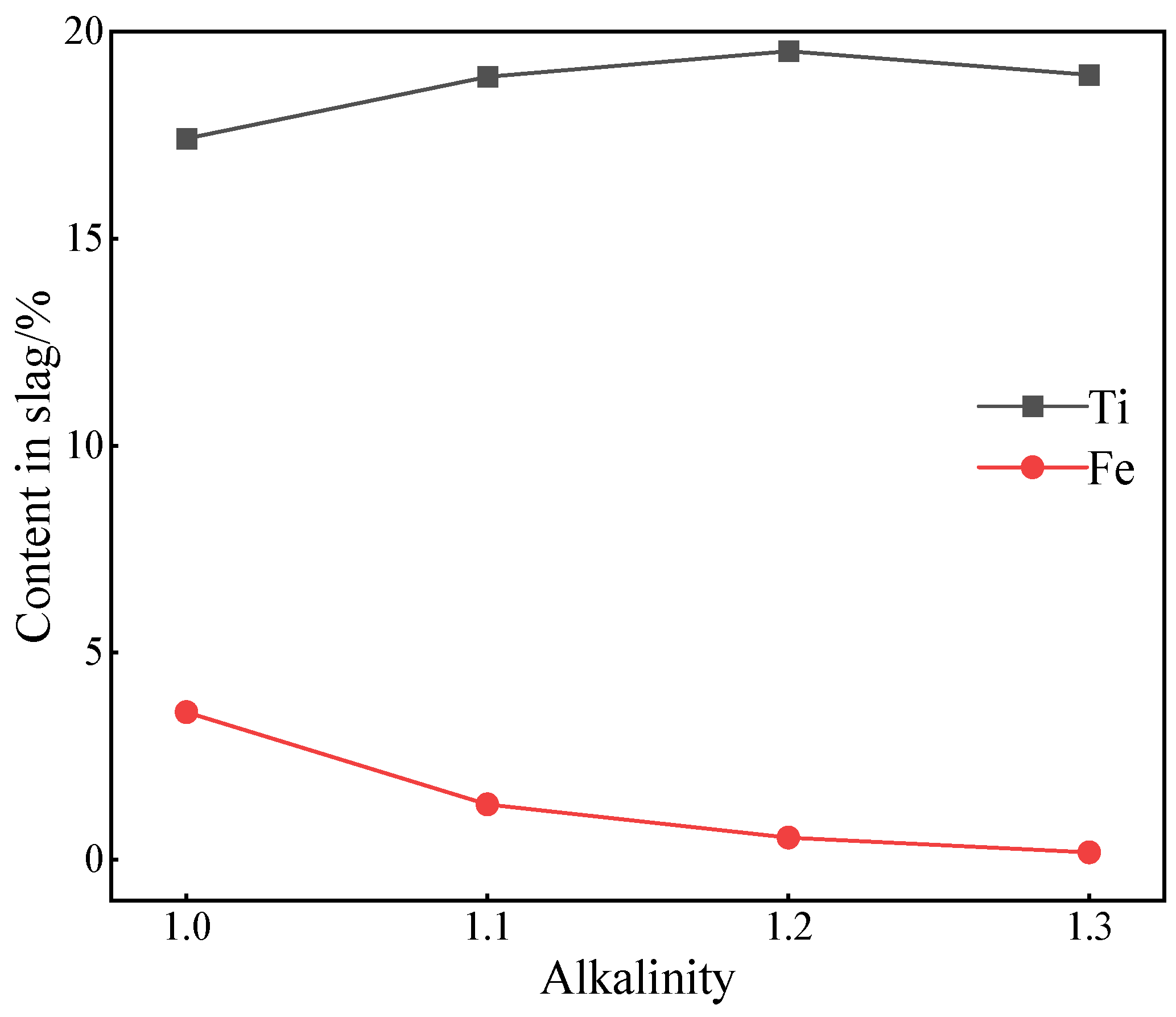

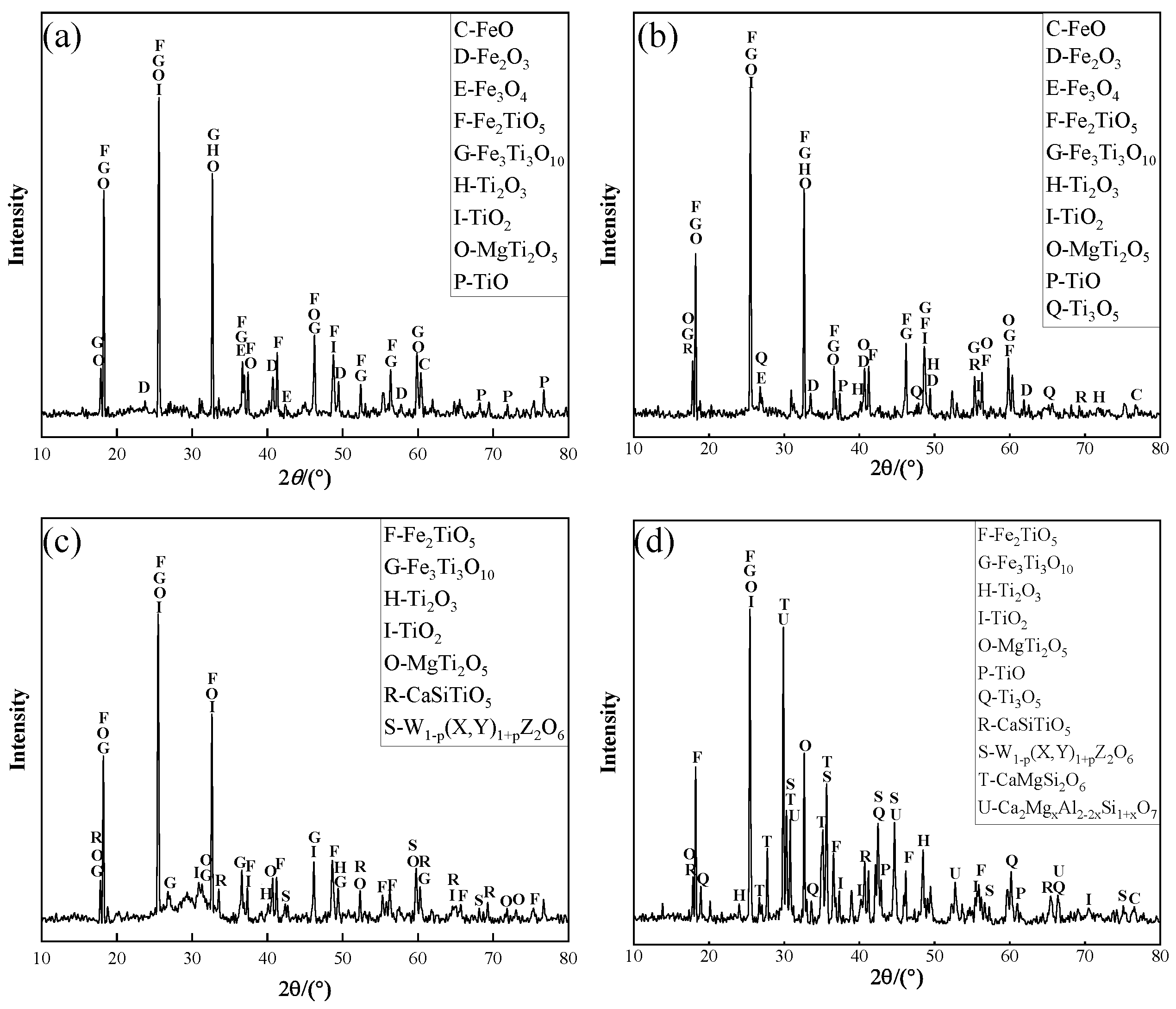

3.2. Effect of Alkalinity on Slag Phase

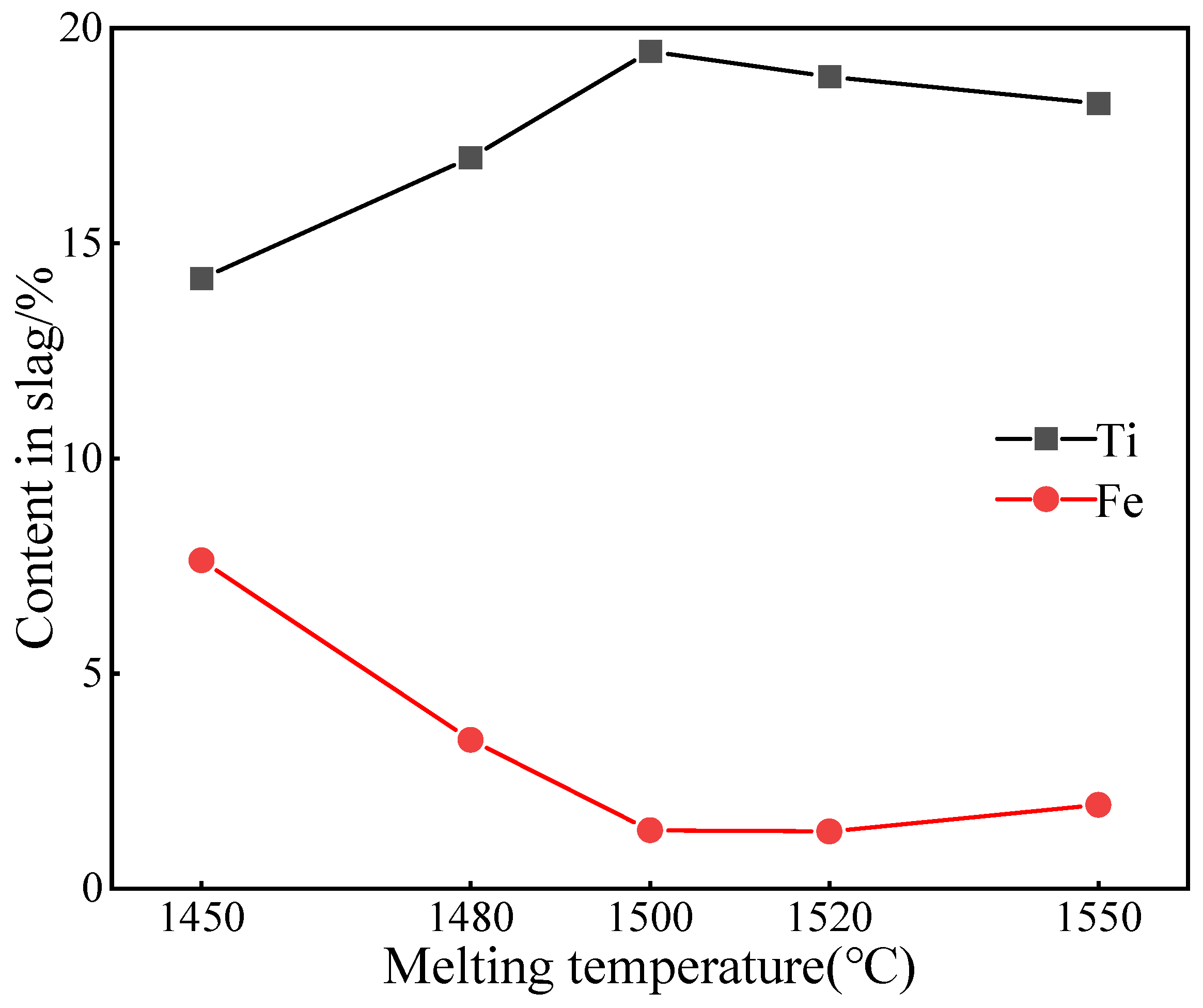

3.3. Effect of Melting Temperature on Slag Phase

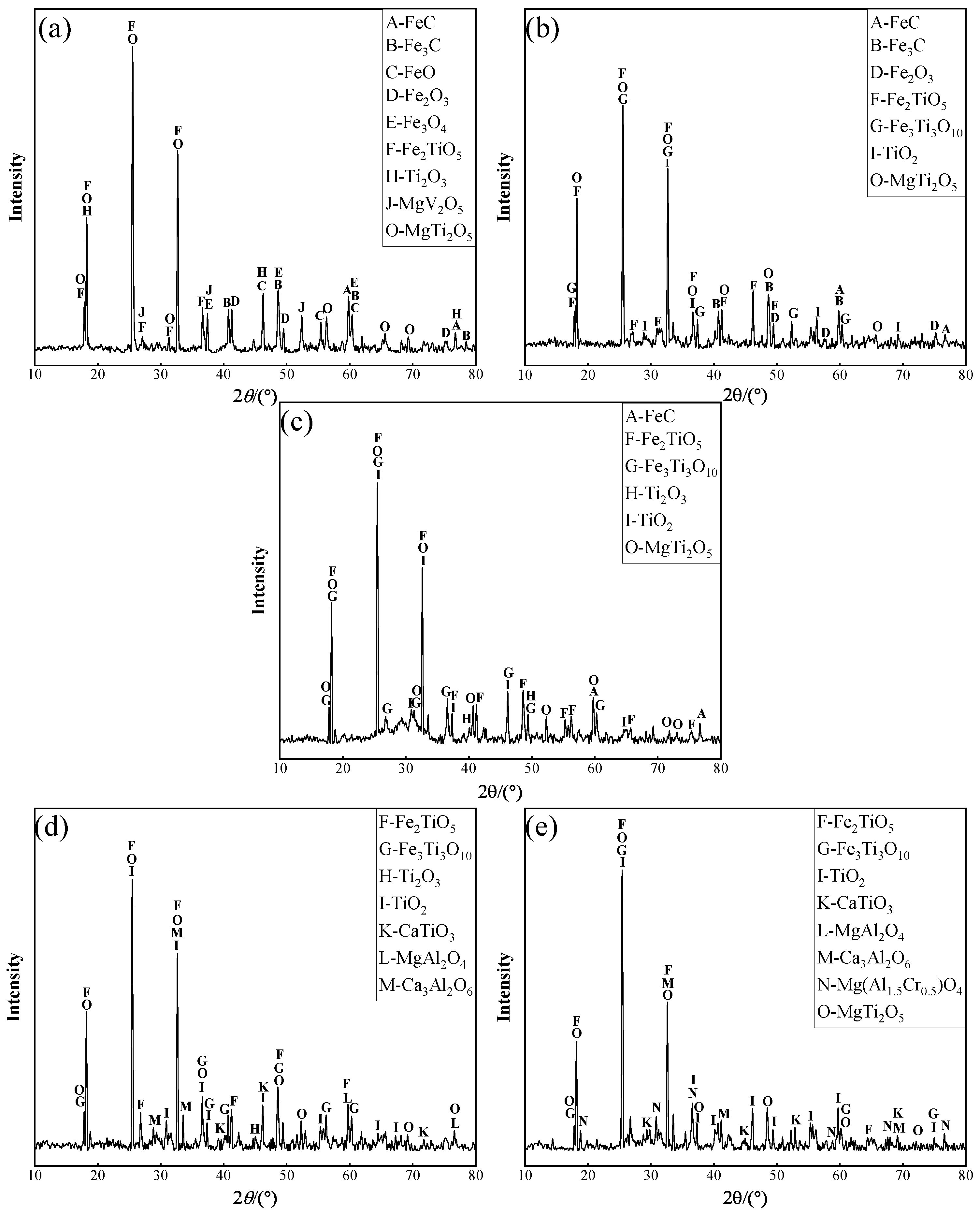

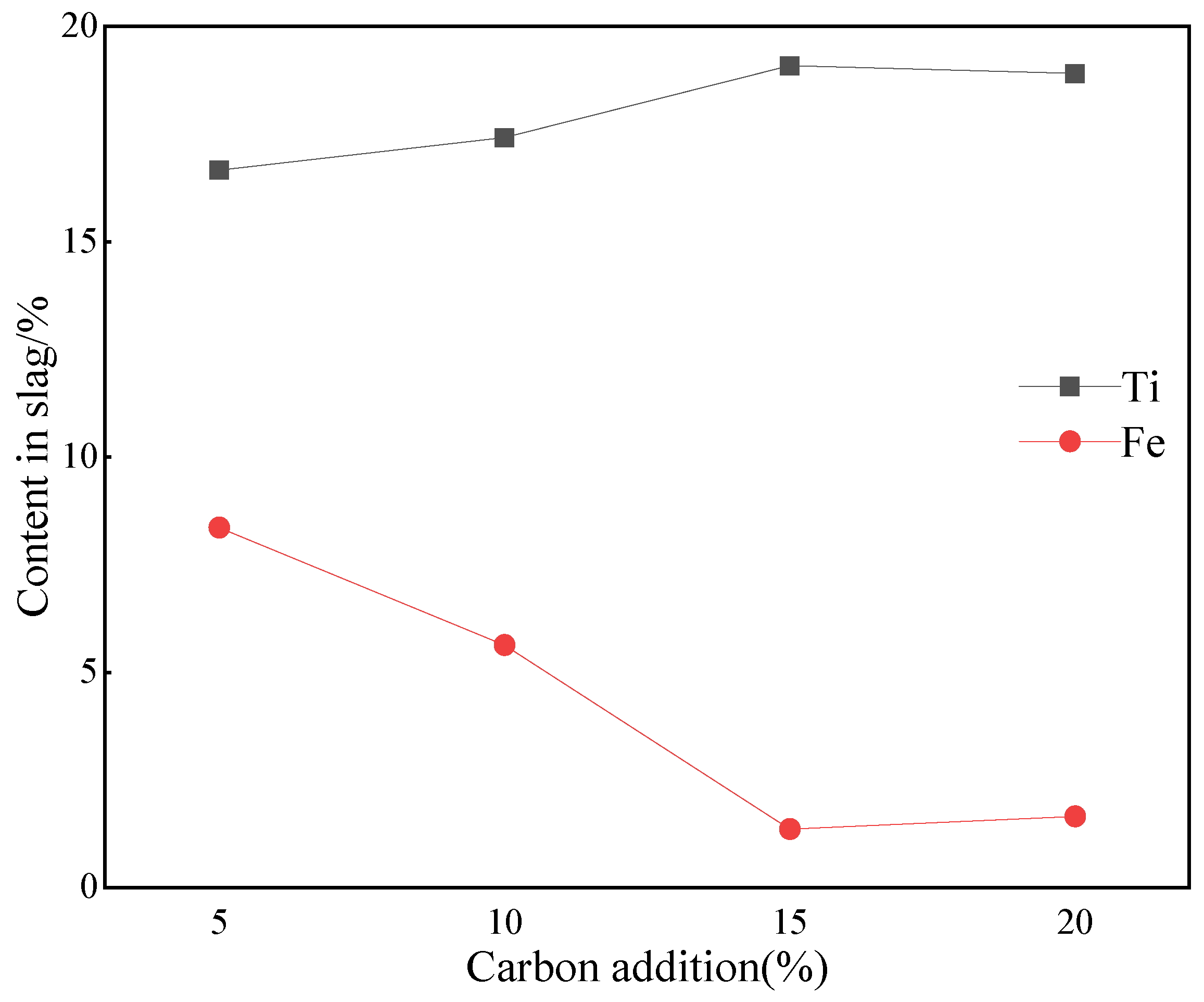

3.4. Effect of Carbon Content on Slag Phase

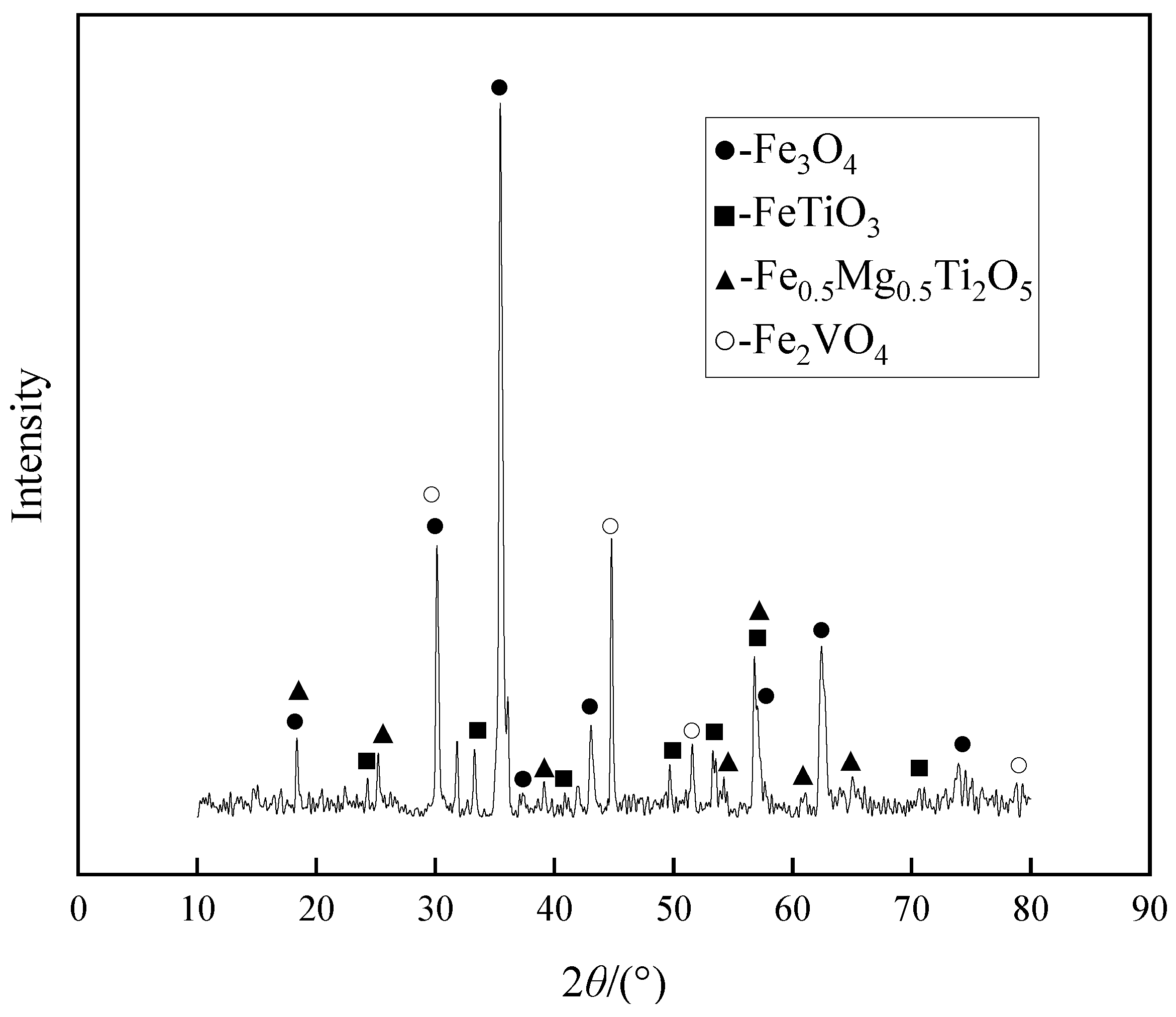

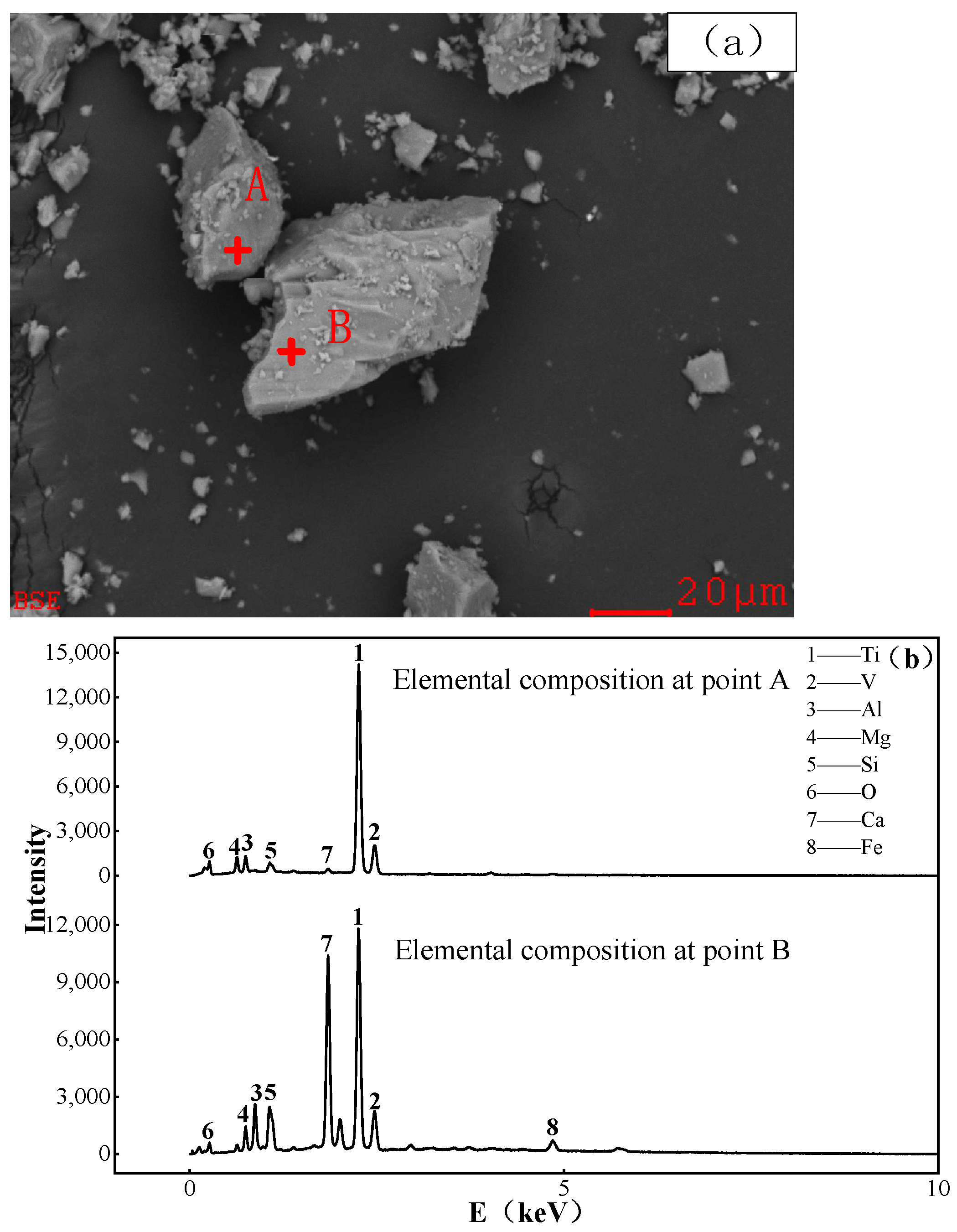

3.5. Phase Analysis of Slag

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wu, E.; Zhu, R.; Yang, S.; Ma, I.; Li, J.; Hou, J. Influences of technological parameters on smelting-separation process for metalized pellets of vanadium-bearing titanomagnetite concentrates. J. Iron Steel Res. Int. 2016, 23, 655–660. [Google Scholar] [CrossRef]

- Zhou, S.; Zheng, H.; Dong, Y.; Jiang, X.; Gao, Q.; Shen, F. Reduction dynamics of carbon-containing pellets of vanadium-bearing titanomagnetite. Iron Steel 2021, 56, 15–20+27. [Google Scholar]

- He, Z.; Xue, X. Basic sintering characteristics of several typical vanadium titanium magnetite. Iron Steel 2020, 55, 20–25. [Google Scholar]

- Wu, E.; Hou, J.; Li, J. Experiment on solid state reduction of non-natural basicity carbon-containing pellet of vanadium-bearing titanomagnetite at high temperature. Iron Steel 2018, 53, 24–28. [Google Scholar]

- Fu, W.; Xie, H. Progress in Technology of Vanadium-Bearing Titanomagnetite Smelting at Pangang. Iron Steel 2008, 10, 21–24. [Google Scholar] [CrossRef]

- Zhang, Y.; Long, H.; Chun, T. Recovery of iron from vanadium-bearing titanomagnetite by deep direct reduction and melting process. J. Iron Steel Res. 2016, 28, 17–23. [Google Scholar]

- Han, Y.; Li, Y.; Gao, P. Innovative and efficient benefit technology of refractory iron ores based on suspended magnetization roasting. J. Iron Steel Res. 2019, 31, 89–94. [Google Scholar]

- Zeng, X.; Zhang, Y.; Xiong, W. Research on beneficiation test of a low-grade vanadium titanomagnetite. Multipurp. Util. Miner. Resour. 2017, 3, 67–70. [Google Scholar]

- Li, Z.; Zou, D. Experimental Research on the Recycle of Ilmenite from a Vanadium Titanium Magnetite Ore by the Combined Magnetic-flotation Process. Met. Mine 2017, 1, 67–72. [Google Scholar]

- Ma, L.; Zhang, J.; Wu, S. Treatment of vanadium-titanium magnetite based on fluxed green ball composition agglomeration process. J. Iron Steel Res. 2020, 32, 462–469. [Google Scholar]

- Yuan, Z.; Pan, J.; Zhu, D. Study on the properties of magnesia flux pellets prepared from vanadium—Titanium magnetite. Sinter. Pelletizing 2021, 46, 47–52+85. [Google Scholar]

- Zhang, J.; Dai, X.; Yan, D.; Qi, Y. Carbothermal sodium reduction process of vanadium-bearing titanomagnetite. Iron Steel 2016, 51, 6–9. [Google Scholar]

- Huang, Z.; Jiang, X.; Yi, L. Effects of biomass on reduction of vanadium-bearing titanomagnetite and process enhancement. Iron Steel 2021, 56, 12–20. [Google Scholar]

- Zhang, Y.; Wang, L.; Chen, D.; Wang, W.; Liu, Y.; Zhao, H.; Qi, T. A method for recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite. Int. J. Miner. Metall. Mater. 2018, 25, 131–144. [Google Scholar] [CrossRef]

- Li, N.; Zhang, J.; Liu, X.; Liu, Z.; Liu, Y. Effects of MgO and TiO2 on comprehensive metallurgical properties of magnesia vanadium titanium pellets. Iron Steel 2017, 52, 14–21. [Google Scholar]

- Wang, X.; Hong, L.; Sun, C. Effect of NaOH on Direct Reduction of Vanadium Titano-magnetite. Iron Steel Vanadium Titan. 2020, 41, 89–93. [Google Scholar]

- Hou, Y.; Hong, L.; Sun, C. Study on Alkali Fusion Process of V-Ti Magnetite Concentrate at Lower Temperature. Iron Steel Vanadium Titan. 2020, 41, 6–13. [Google Scholar]

- Chu, M.; Tang, Y.; Liu, Z. Presentation situation and process of comprehensive utility for high-chromium vanadium-bearing titanomagnetie. J. Iron Steel Res. 2017, 29, 335–344. [Google Scholar]

- Chen, D.; Song, B.; Wang, L. Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal. Miner. Eng. 2011, 24, 864–869. [Google Scholar] [CrossRef]

- Xiao, J.; Peng, Y.; Chen, T. Extraction of scandium from Sc-bearing V-Ti magnetite tailings using roasting and leaching. Chin. J. Nonferrous Met. 2021, 31, 1611–1620. [Google Scholar]

- Zhang, J.; Ren, Y.; Liu, C.; Li, J.; Zhang, J. Dephosphorization of Vanadate Leaching Solution by Chloride-Free Dephosphorizing Agent. Int. J. Chem. Eng. Appl. 2013, 4, 406–409. [Google Scholar] [CrossRef]

- Li, J.; Tang, E.; Qin, C. Experimental Research on Deep Reduction and Grinding Separation of Low Ti-bearing Vanadium-titanium Magnetite. Iron Steel Vanadium Titan. 2016, 37, 25–29. [Google Scholar]

- Zhang, Y.; Yi, L.; Wang, L.; Chen, D.; Wang, W.; Liu, Y.; Zhao, H.; Qi, T. A novel process for the recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite:sodium modification–direct reduction coupled process. Int. J. Miner. Metall. Mater. 2017, 24, 504–511. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, L.; Chen, D. Behaviors of vanadium and chromium in coal-based direct reduction of high-chromium vanadium-bearingtitanomagnetite concentrates followed by magnetic separation. Trans. Nonferrous Met. Soc. China 2015, 25, 1325–1333. [Google Scholar] [CrossRef]

- Sun, H.; Adetoro, A.A.; Wang, Z.; Pan, F.; Li, L. Direct Reduction Behaviors of Titanomagnetite Ore by Carbon Monoxide in Fluidized Bed. ISIJ Int. 2016, 56, 936–943. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, Q.; Li, H. The technical state and development trend of the direct reduction of titanomagnetite by fluidized bed. Chin. J. Process Eng. 2018, 18, 1146–1159. [Google Scholar]

- Ma, Z. Research on Reasonable Burden Structure and Ti Influencing Factors of Low Grade Iron ore Blast Furnace; Kunming University of Science and Technology: Kunming, China, 2017. [Google Scholar]

- Yang, S. Metallurgical Charge Processing Technology; Metallurgical Industry Press: Beijing, China, 2008; pp. 3–4. [Google Scholar]

- Sun, Y.; Zheng, H.; Dong, Y.; Jiang, X.; Shen, Y.; Shen, F. Melting and separation behavior of slag and metal phases in metallized pellets obtained from the direct-reduction process of vanadium-bearing titanomagnetite. Int. J. Miner. Process. 2015, 119–124. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, S.; Guo, Y.; Chen, F.; Zheng, F. Effects of Basicity and MgO in Slag on the Behaviors of Smelting Vanadium Titanomagnetite in the Direct Reduction-Electric Furnace Process. Metals 2016, 6, 107. [Google Scholar] [CrossRef]

- Xing, X.; Liu, Y.; Ju, J. Synthesis and Non-isothermal Carbothermic Reduction of FeTiO3-Fe2O3 Solid Solution Systems. Rare Met. Mater. Eng. 2018, 47, 2775–2781. [Google Scholar]

- Lv, Q.; Huang, H.; Wan, X. Liquid generation capabilities of Chengde vanadium-titanium magnetite during sintering. Iron Steel 2015, 50, 19–24. [Google Scholar]

- Kong, W.; Liu, J.; He, Z. Thermodynamic reseach on liquid phase format behavior and crystallization process of blast furniture slag. J. Iron Steel Res. 2021, 33, 375–384. [Google Scholar]

- Gan, M.; Sun, Y.F.; Fan, X.H.; Ji, Z.Y.; Lv, W.; Chen, X.L.; Jiang, T. Preparing high-quality vanadium titano-magnetite pellets for large-scale blast furnaces as ironmaking burden. Ironmak. Steelmak. 2020, 47, 130–137. [Google Scholar] [CrossRef]

- Mi, Z.; Yang, S.; Jiang, T.; Zhang, L.; Xiao, J.; Xue, X.; Zhang, W. Effects of carbon content on the sintering behavior of low-titanium vanadium-titanium magnetite. Metall. Res. Technol. 2016, 113, 612. [Google Scholar]

- Li, Y.; Chen, S.; Duan, H. A New Process of Extracting Titanium from Vanadium–Titanium Magnetite. Crystals 2021, 11, 327. [Google Scholar] [CrossRef]

| TFe | FeO | SiO2 | CaO | MgO | Al2O3 | P | S | TiO2 | V2O5 | Cr | Burning Loss |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 56.20 | 18.19 | 3.50 | 0.60 | 2.30 | 5.32 | 0.01 | 0.03 | 10.89 | 0.74 | 1.08 | 1.14 |

| Industrial Analysis (%) | Elementary Analysis (%) | Heat (MJ/kg) | Ash Fusion Temperature (℃) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aad | FCad | Mad | Vad | St,d | Pd | Had | Qnet,ar | DT | FT | HT | ST |

| 13.18 | 84.97 | 0.24 | 1.61 | 0.32 | 0.01 | 0.18 | 28.03 | 1120 | 1210 | 1170 | 1150 |

| Ti | Ca | O | Si | V | Fe | Al | Mg | γFe | γV | γTi |

|---|---|---|---|---|---|---|---|---|---|---|

| 18.84 | 17.82 | 35.2 | 17.44 | 0.13 | 0.23 | 7.18 | 3.16 | 99.86 | 95.64 | 93.54 |

| Element Composition (%) | Ti | V | Al | Mg | Si | O | Ca | Fe |

|---|---|---|---|---|---|---|---|---|

| A | 54.36 | 0.51 | 3.85 | 4.6932 | 0.68 | 34.94 | 0.70 | — |

| B | 41.38 | 1.17 | 3.24 | 1.36 | 5.60 | 22.23 | 21. | 3.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Liu, S.; Guo, S.; Zhang, T.; Li, J. Fusion Separation of Vanadium-Titanium Magnetite and Enrichment Test of Ti Element in Slag. Materials 2022, 15, 6795. https://doi.org/10.3390/ma15196795

Yang S, Liu S, Guo S, Zhang T, Li J. Fusion Separation of Vanadium-Titanium Magnetite and Enrichment Test of Ti Element in Slag. Materials. 2022; 15(19):6795. https://doi.org/10.3390/ma15196795

Chicago/Turabian StyleYang, Shuangping, Shouman Liu, Shijie Guo, Tiantian Zhang, and Jianghan Li. 2022. "Fusion Separation of Vanadium-Titanium Magnetite and Enrichment Test of Ti Element in Slag" Materials 15, no. 19: 6795. https://doi.org/10.3390/ma15196795

APA StyleYang, S., Liu, S., Guo, S., Zhang, T., & Li, J. (2022). Fusion Separation of Vanadium-Titanium Magnetite and Enrichment Test of Ti Element in Slag. Materials, 15(19), 6795. https://doi.org/10.3390/ma15196795