Influence of a Flat Polyimide Inlay on the Propagation of Guided Ultrasonic Waves in a Narrow GFRP-Specimen

Abstract

1. Introduction

2. Materials and Methods

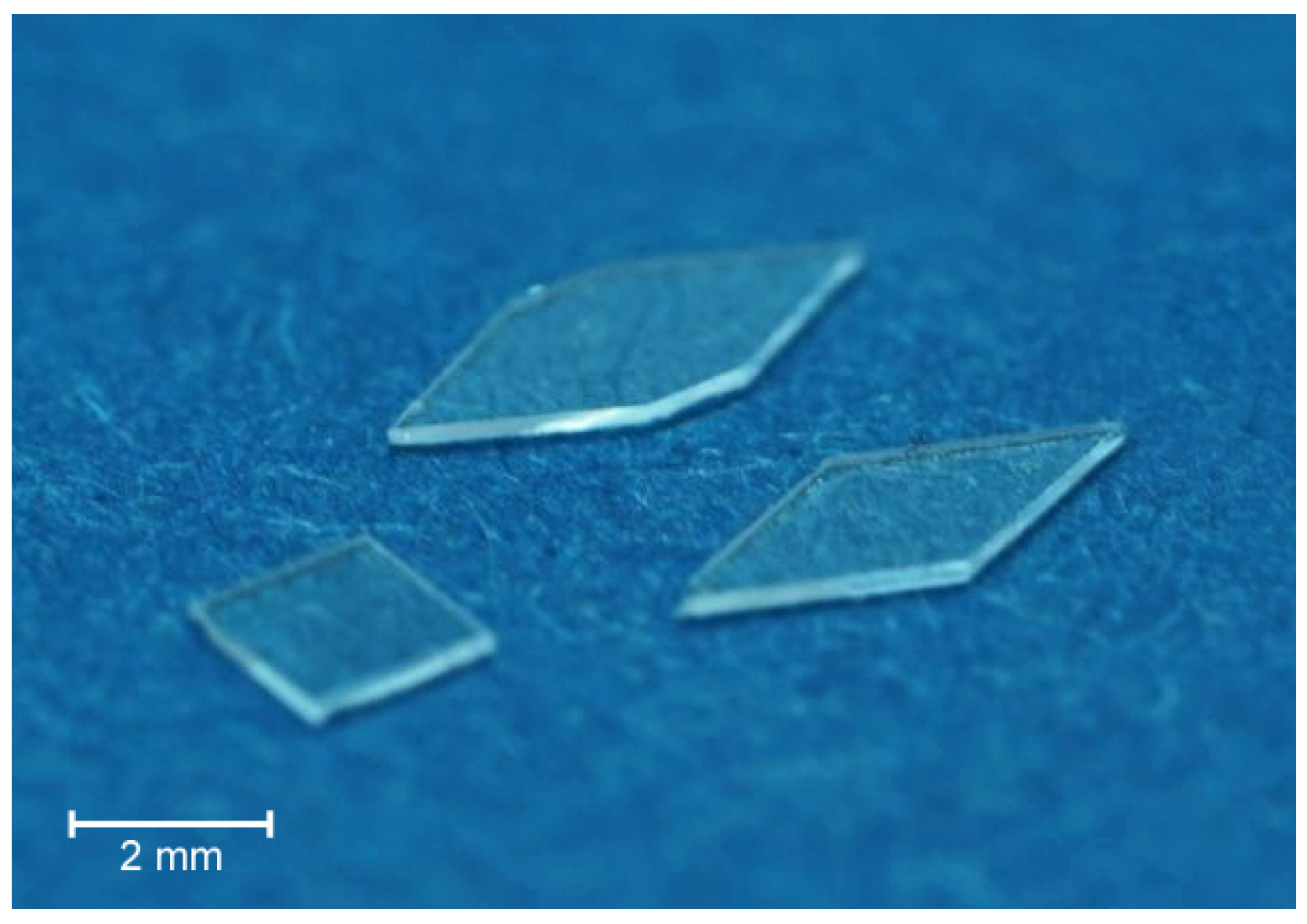

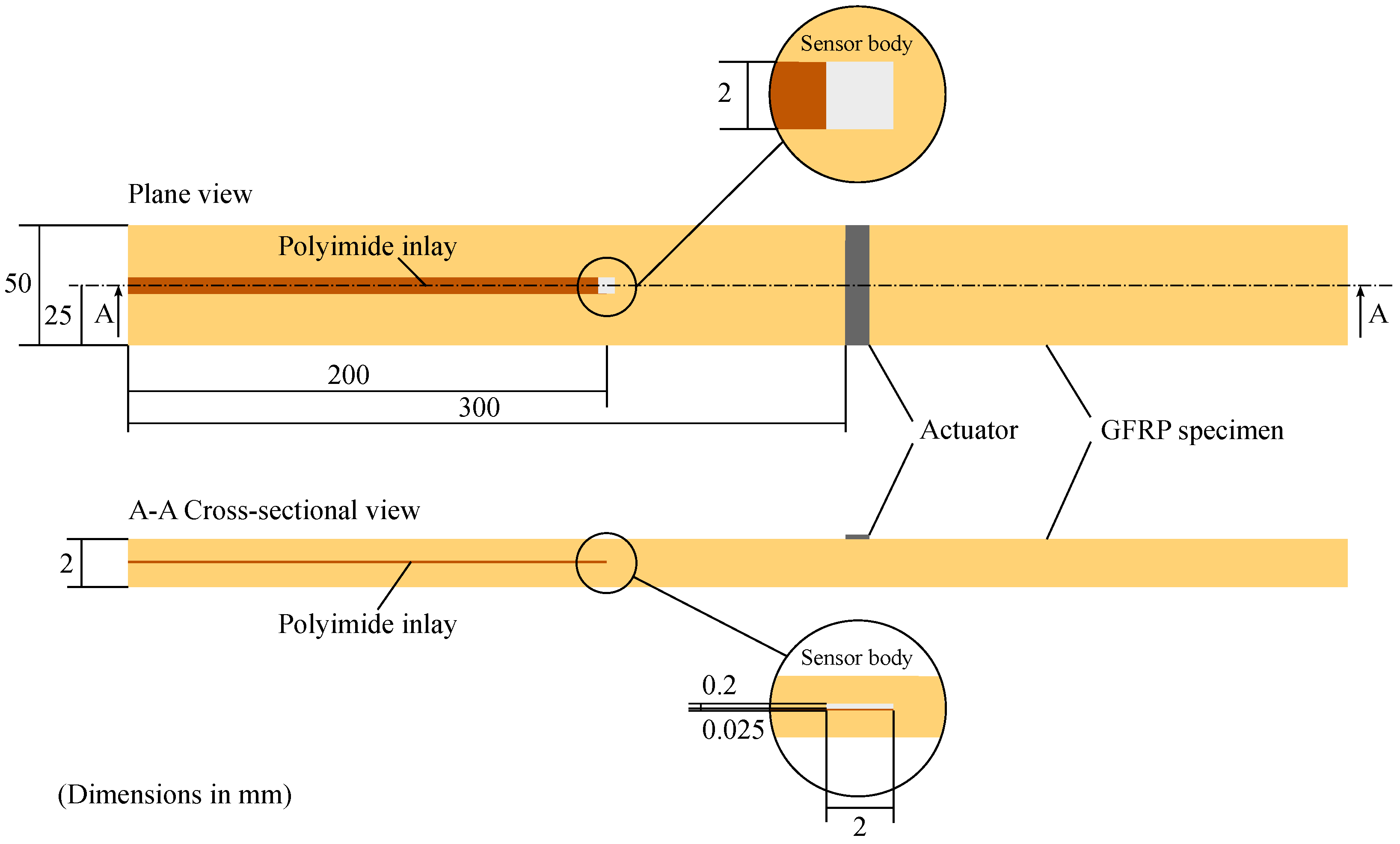

2.1. Design of the Specimens

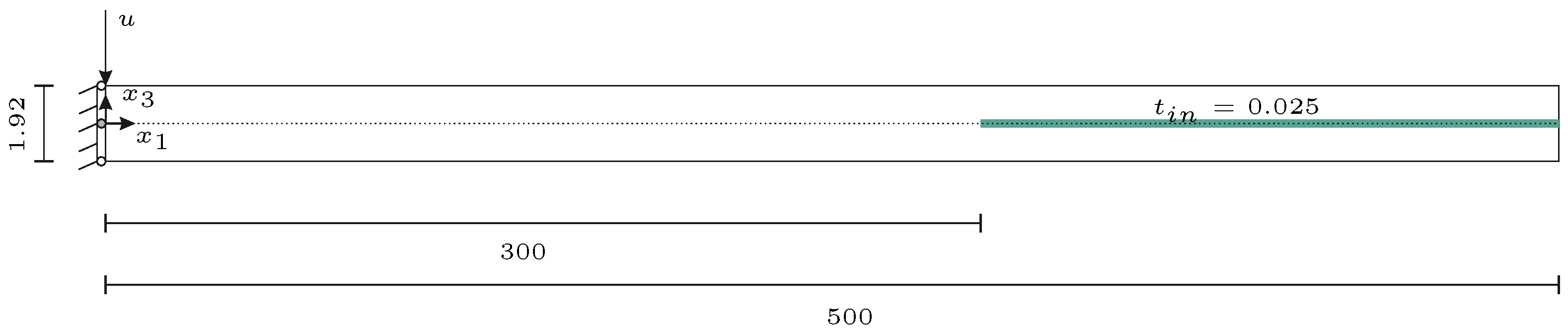

2.2. 2D Numerical Model to Simulate GUW Interactions with Integrated Polyimide Inlays

2.3. Experimental Setups for Determination of GUW Interactions at Integrated Inlays

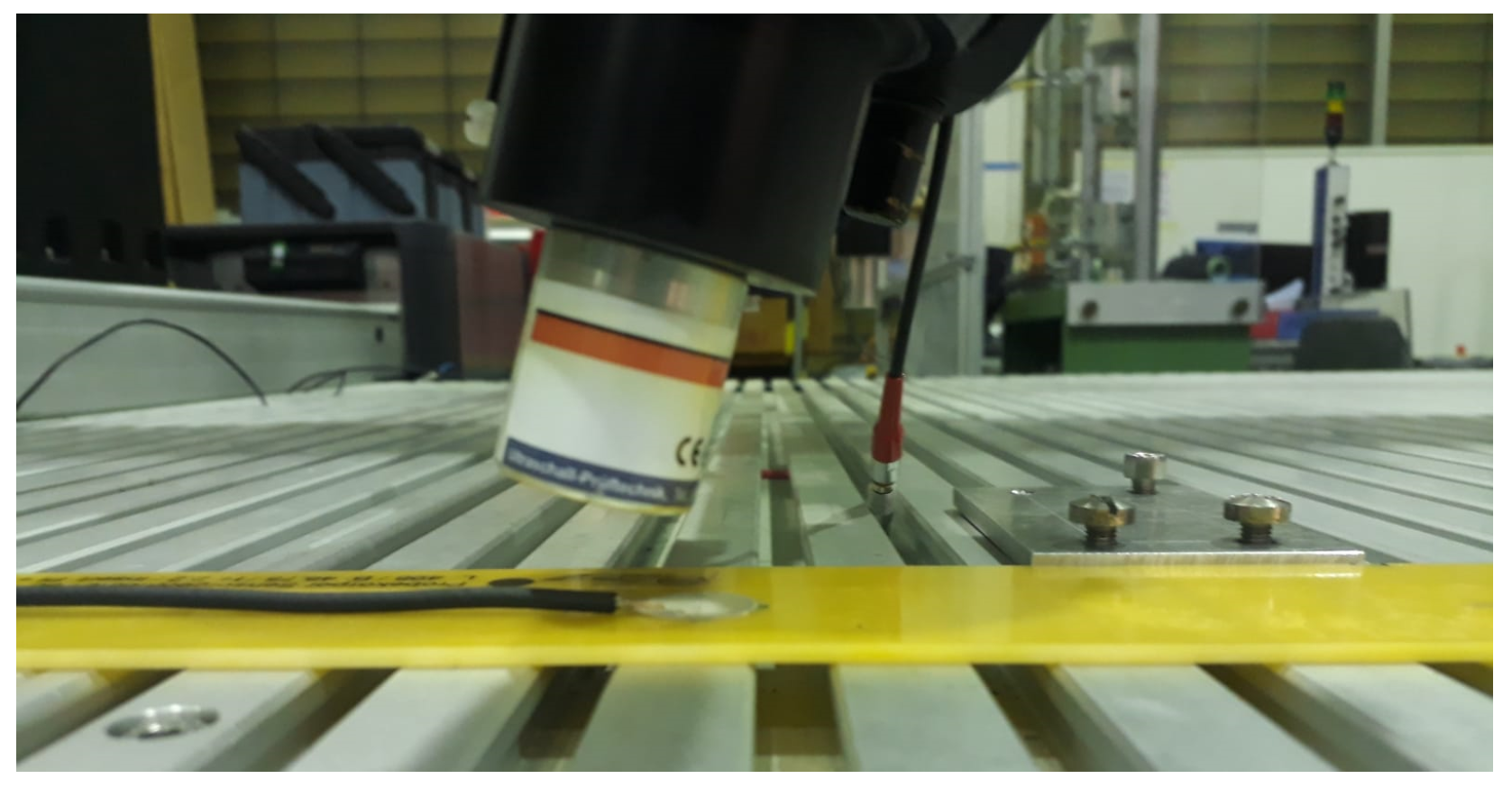

2.3.1. Detection of GUW Interactions Using Air-Coupled Ultrasonic Technique

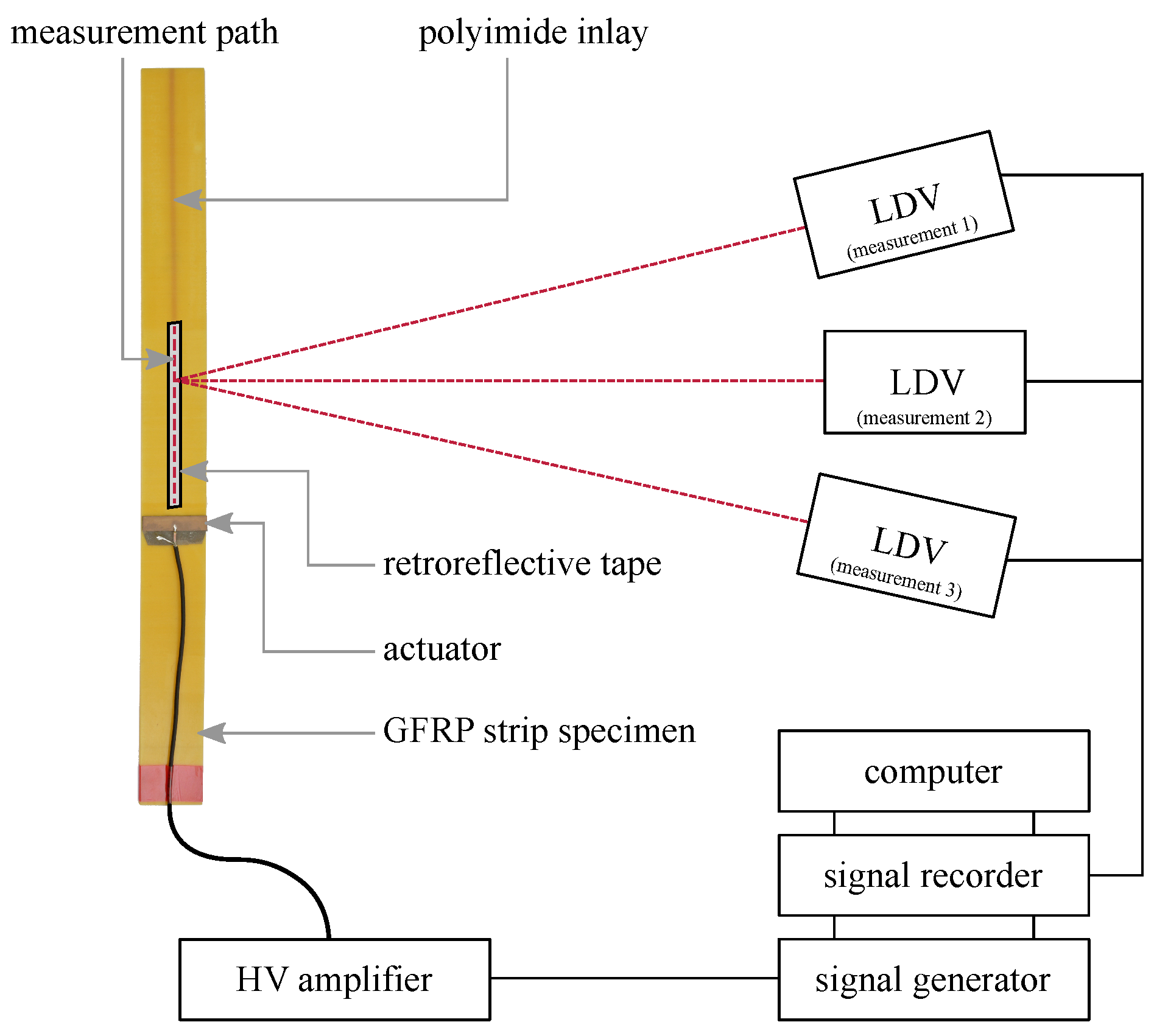

2.3.2. Detection of GUW Interactions Using 3D Laser Doppler Vibrometry

2.4. Identification of Occurring Reflections by Means of Continuous Wavelet Transformation

3. Results

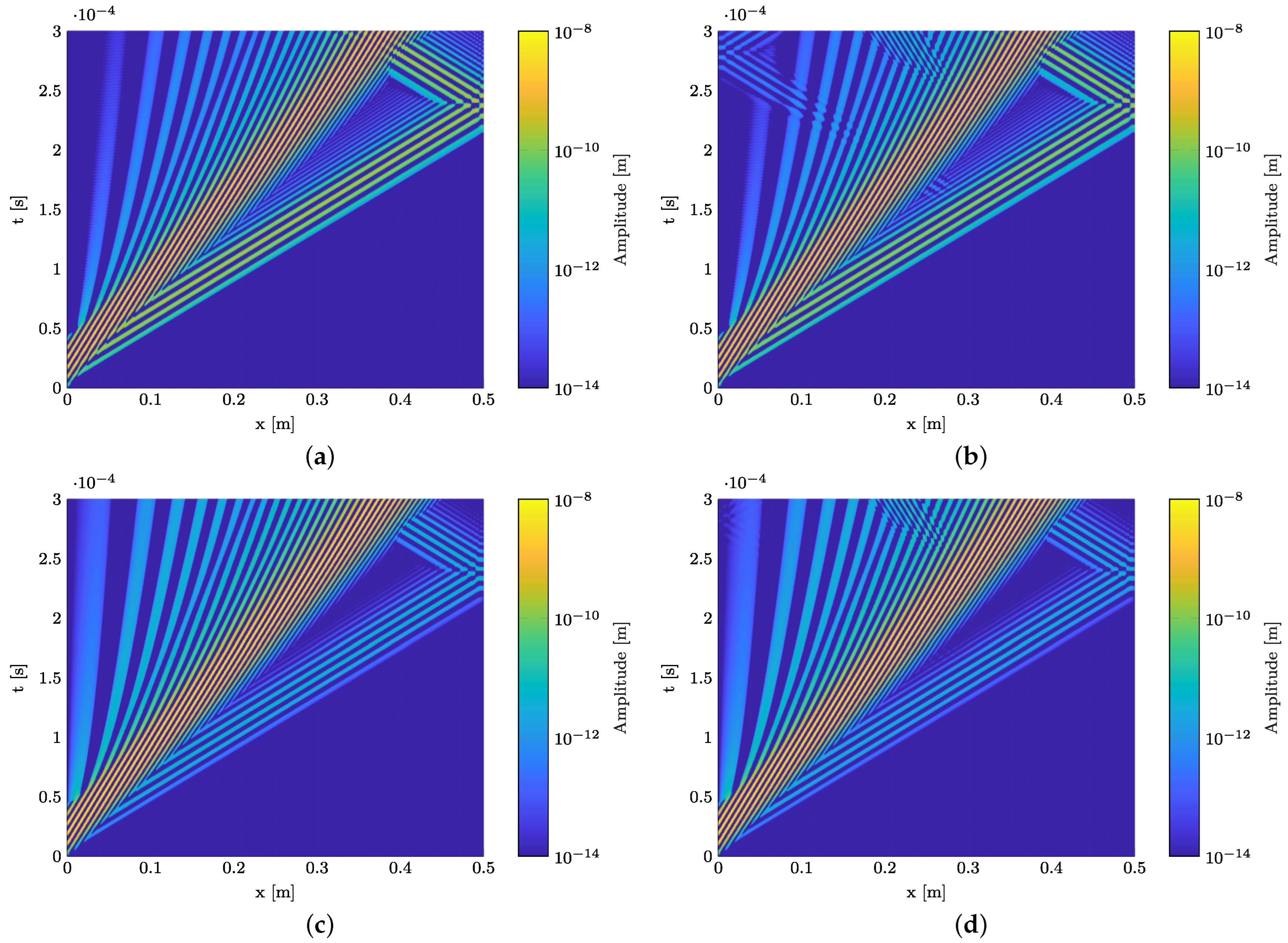

3.1. GUW Interactions at Integrated Polyimide Inlays Estimated by the 2D Numerical Model

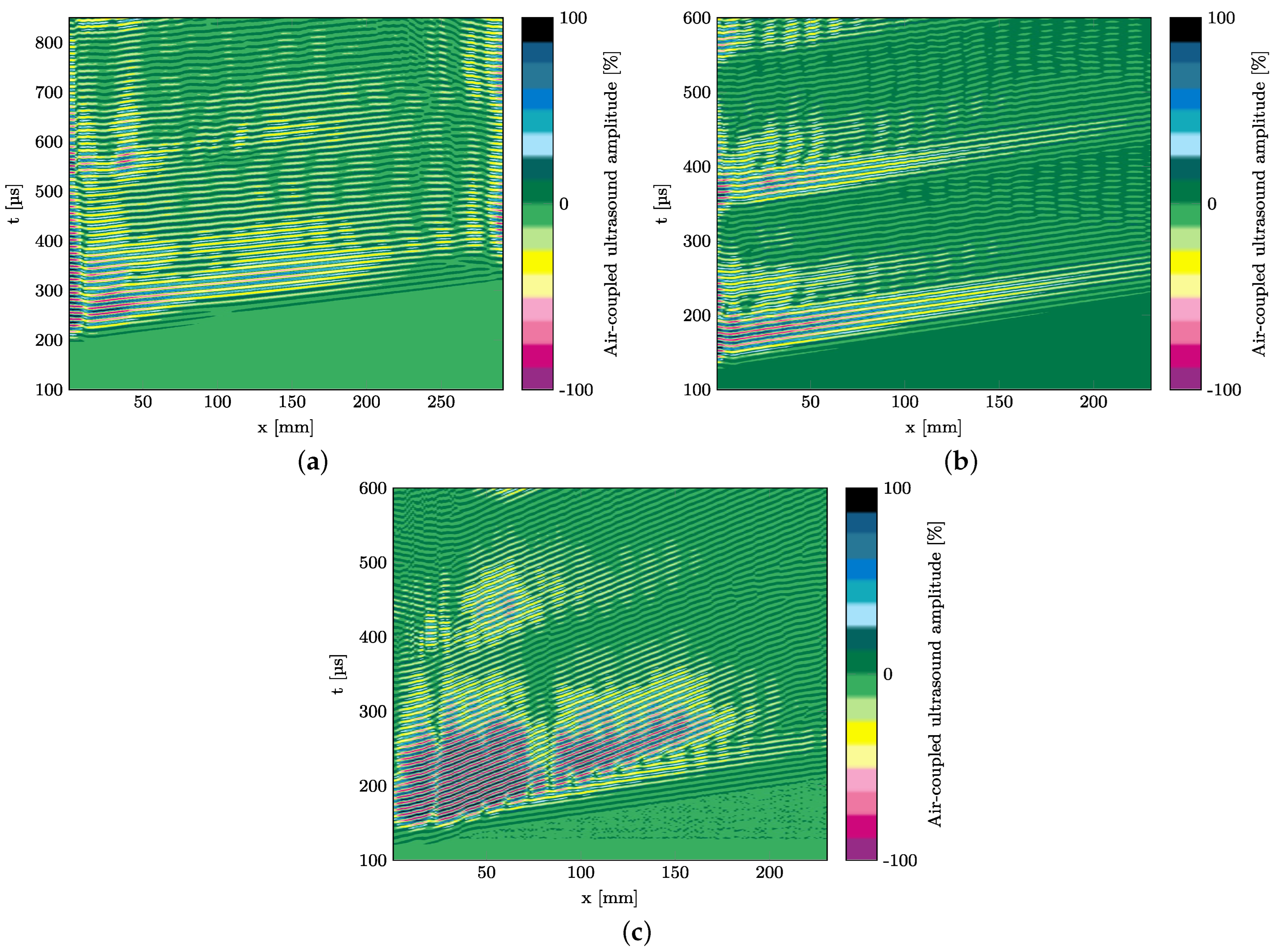

3.2. Detectability of GUW Interactions Using Air-Coupled Ultrasonic Technique

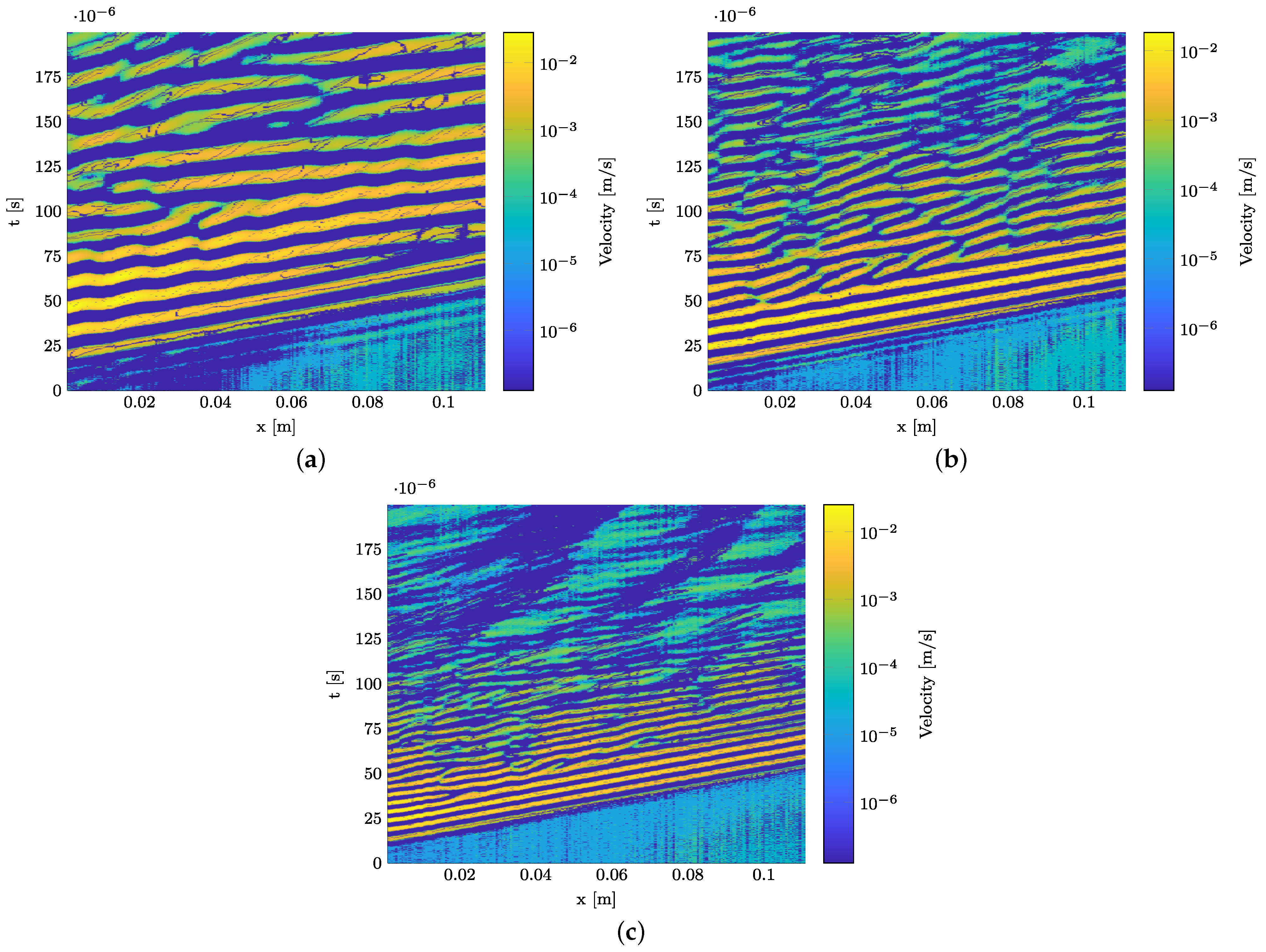

3.3. Detectability of GUW Interactions Using 3D Laser Doppler Vibrometry

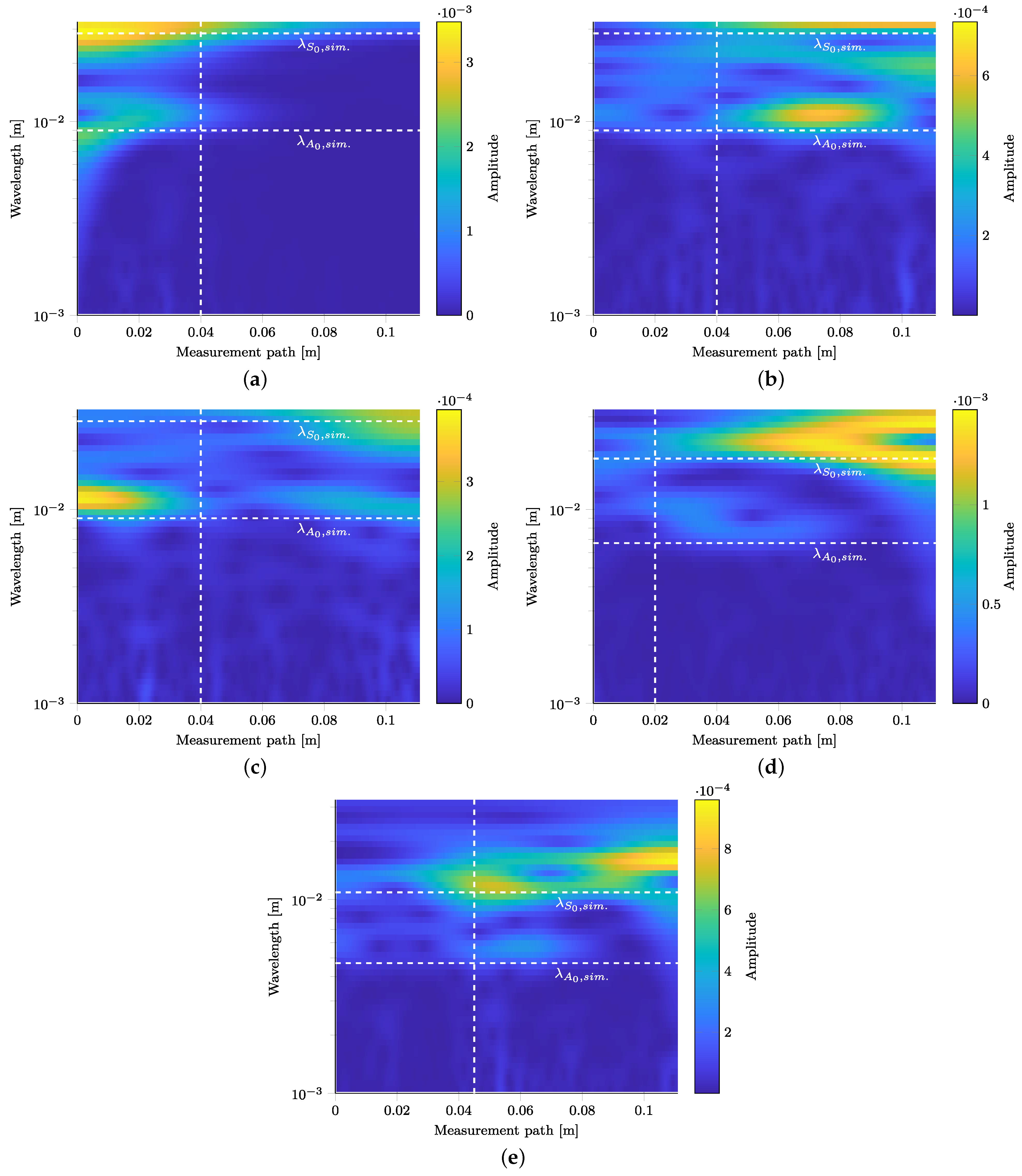

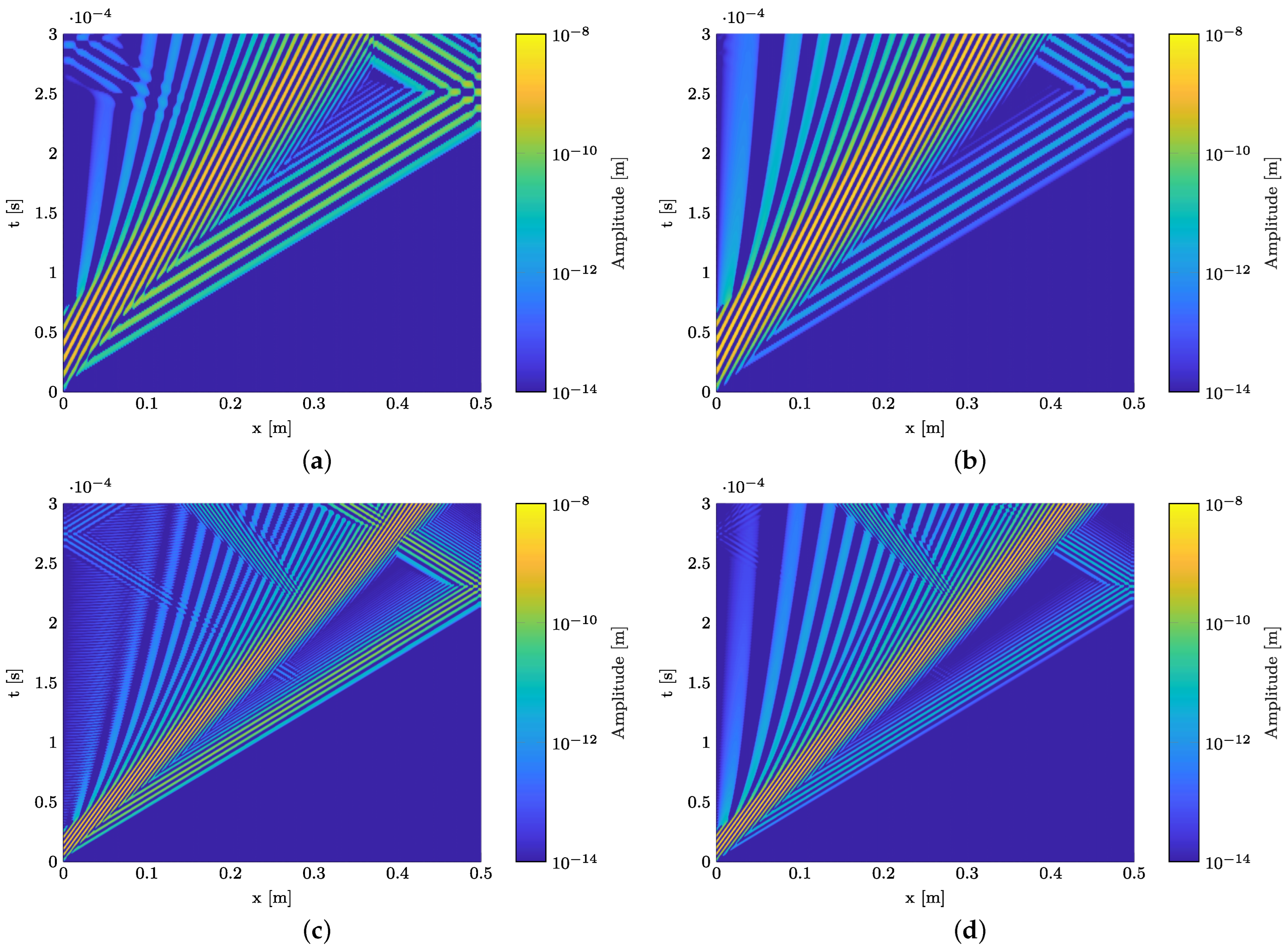

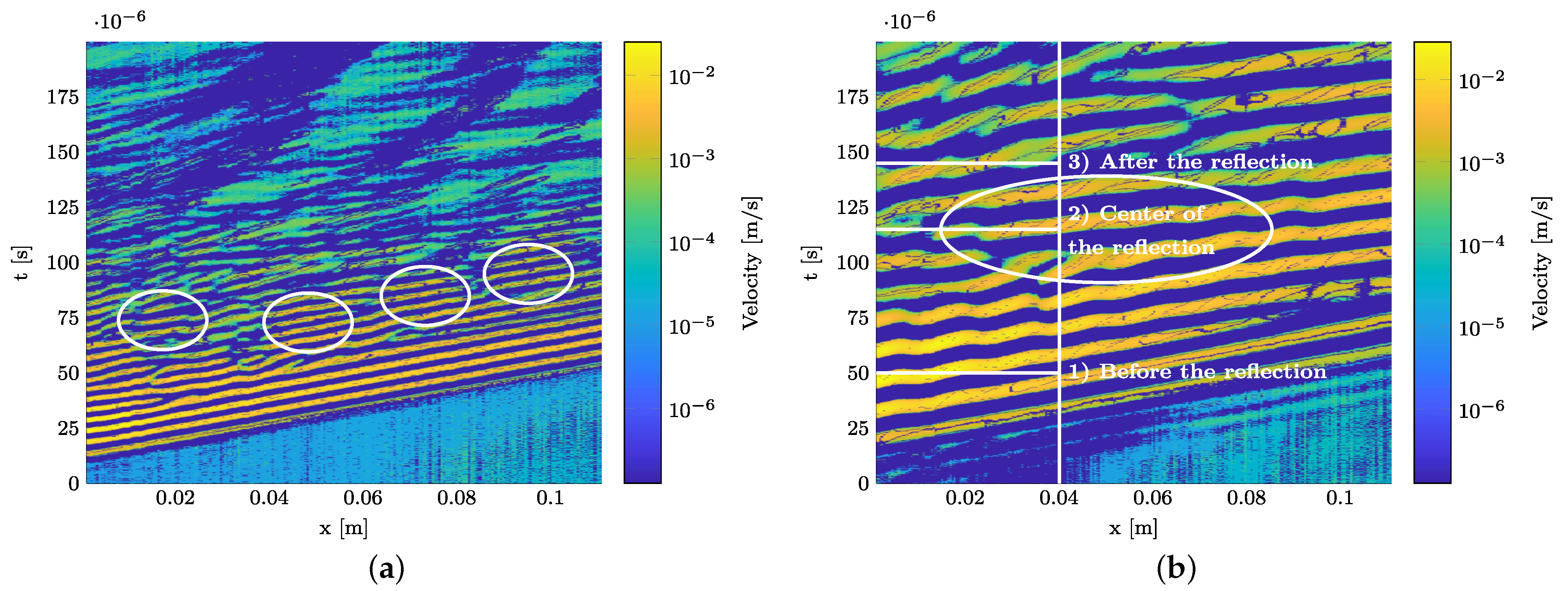

3.4. Identification of GUW Interactions by Means of Spatial Continuous Wavelet Transformation

3.4.1. Reflection Identification at 75 kHz

3.4.2. Reflection Identification at 120 kHz

3.4.3. Reflection Identification at 200 kHz

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giurgiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors; Academic Press/Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Su, Z.; Ye, L. (Eds.) Identification of Damage Using LAMB Waves: From Fundamentals to Applications; Lecture Notes in Applied and Computational Mechanics; Springer: London, UK, 2009; Volume 48. [Google Scholar]

- Balageas, D.; Fritzen, C.P.; Güemes, A. Structural Health Monitoring; ISTE Ltd and ISTE: London, UK; Newport Beach, CA, USA, 2006. [Google Scholar] [CrossRef]

- Lammering, R.; Gabbert, U.; Sinapius, M.; Schuster, T.; Wierach, P. (Eds.) Lamb-Wave Based Structural Health Monitoring in Polymer Composites; Research Topics in Aerospace; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Guo, N.; Cawley, P. The interaction of Lamb waves with delaminations in composite laminates. J. Acoust. Soc. Am. 1993, 94, 2240–2246. [Google Scholar] [CrossRef]

- Pudipeddi, G.T.; Ng, C.T.; Kotousov, A. Mode Conversion and Scattering of Lamb Waves at Delaminations in Composite Laminates. J. Aerosp. Eng. 2019, 32, 04019067. [Google Scholar] [CrossRef]

- Mallet, L.; Lee, B.C.; Staszewski, W.J.; Scarpa, F. Structural health monitoring using scanning laser vibrometry: II. Lamb waves for damage detection. Smart Mater. Struct. 2004, 13, 261–269. [Google Scholar] [CrossRef]

- Schmidt, D. Modenselektive Übertragung von Lambwellen in Faserverbundstrukturen: Dissertation; DLR-Forschungsbericht 2014; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Braunschweig, Germany, 2014; Volume 24. [Google Scholar]

- Haus, J.N.; Lang, W.; Roloff, T.; Rittmeier, L.; Bornemann, S.; Sinapius, M.; Dietzel, A. MEMS Vibrometer for Structural Health Monitoring Using Guided Ultrasonic Waves. Sensors 2022, 22, 5368. [Google Scholar] [CrossRef] [PubMed]

- Lissenden, C.J.; Liu, Y.; Choi, G.W.; Yao, X. Effect of Localized Microstructure Evolution on Higher Harmonic Generation of Guided Waves. J. Nondestruct. Eval. 2014, 33, 178–186. [Google Scholar] [CrossRef]

- de Lima, W.; Hamilton, M.F. Finite-amplitude waves in isotropic elastic plates. J. Sound Vib. 2003, 265, 819–839. [Google Scholar] [CrossRef]

- Deng, M.; Pei, J. Assessment of accumulated fatigue damage in solid plates using nonlinear Lamb wave approach. Appl. Phys. Lett. 2007, 90, 121902. [Google Scholar] [CrossRef]

- Pruell, C.; Kim, J.Y.; Qu, J.; Jacobs, L.J. Evaluation of plasticity driven material damage using Lamb waves. Appl. Phys. Lett. 2007, 91, 231911. [Google Scholar] [CrossRef]

- Rauter, N.; Lammering, R.; Kühnrich, T. On the detection of fatigue damage in composites by use of second harmonic guided waves. Compos. Struct. 2016, 152, 247–258. [Google Scholar] [CrossRef]

- Kessler, S.S.; Spearing, S.M.; Soutis, C. Damage detection in composite materials using Lamb wave methods. Smart Mater. Struct. 2002, 11, 269–278. [Google Scholar] [CrossRef]

- Chai, G.B.; Manikandan, P. Low velocity impact response of fibre-metal laminates—A review. Compos. Struct. 2014, 107, 363–381. [Google Scholar] [CrossRef]

- Morinière, F.; Alderliesten, R.; Tooski, M.; Benedictus, R. Damage evolution in GLARE fibre-metal laminate under repeated low-velocity impact tests. Cent. Eur. J. Eng. 2012, 2, 603–611. [Google Scholar] [CrossRef]

- Zheng, K.; Li, Z.; Ma, Z.; Chen, J.; Zhou, J.; Su, X. Damage detection method based on Lamb waves for stiffened composite panels. Compos. Struct. 2019, 225, 111137. [Google Scholar] [CrossRef]

- Burkov, M.V.; Eremin, A.V.; Byakov, A.V.; Lyubutin, P.S.; Panin, S.V. Impact Damage Detection in Laminate and Honeycomb CFRPs using Lamb Wave Ultrasonic Sensing. Russ. J. Nondestruct. Test. 2021, 57, 114–124. [Google Scholar] [CrossRef]

- Sharif-Khodaei, Z.; Aliabadi, M.H. Lamb-Wave Based Damage Detection in Anisotropic Composite Plates. Key Eng. Mater. 2014, 627, 1–4. [Google Scholar] [CrossRef]

- Fakih, M.A.; Mustapha, S.; Harb, M.; Ng, C.T. Understanding the interaction of the fundamental Lamb-wave modes with material discontinuity: Finite element analysis and experimental validation. Struct. Health Monit. 2021, 21, 640–665. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, A.; Kumar, S.; Kalra, S. Delamination Detection and Evaluation in Composite Laminates Using Guided Ultrasonic Waves. In Recent Trends in Industrial and Production Engineering; Dubey, A.K., Sachdeva, A., Mehta, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022; pp. 47–56. [Google Scholar] [CrossRef]

- Hameed, M.S.; Li, Z.; Chen, J.; Qi, J. Lamb-Wave-Based Multistage Damage Detection Method Using an Active PZT Sensor Network for Large Structures. Sensors 2019, 19, 2010. [Google Scholar] [CrossRef]

- Zimmermann, E.; Eremin, A.; Lammering, R. Analysis of the continuous mode conversion of Lamb waves in fiber composites by a stochastic material model and laser vibrometer experiments. GAMM-Mitteilungen 2018, 41, 201800001. [Google Scholar] [CrossRef]

- Hennings, B.; Lammering, R. Material modeling for the simulation of quasi-continuous mode conversion during Lamb wave propagation in CFRP-layers. Compos. Struct. 2016, 151, 142–148. [Google Scholar] [CrossRef]

- Wang, S.; Lasn, K. Integration of optical fibre sensors by material extrusion 3-D printing—The effect of bottom interlayer thickness. Mater. Des. 2022, 221, 110914. [Google Scholar] [CrossRef]

- Leng, J.; Asundi, A. Structural health monitoring of smart composite materials by using EFPI and FBG sensors. Sens. Actuator A Phys. 2003, 103, 330–340. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.; Chakraborty, A.; Dasgupta, K.; Bhattacharya, D. Fibre Bragg gratings in structural health monitoring-Present status and applications. Sens. Actuator A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Masmoudi, S.; El Mahi, A.; Turki, S. Fatigue behaviour and structural health monitoring by acoustic emission of E-glass/epoxy laminates with piezoelectric implant. Appl. Acoust. 2016, 108, 50–58. [Google Scholar] [CrossRef]

- Paget, C.A.; Levin, K.; Delebarre, C. Actuation performance of embedded piezoceramic transducer in mechanically loaded composites. Smart Mater. Struct. 2002, 11, 886–891. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Kumar, A.; Ooi, T.K.; Chang, F.K. Built-in Sensor Network for Structural Health Monitoring of Composite Structure. J. Intell. Mater. Syst. Struct. 2007, 18, 39–49. [Google Scholar] [CrossRef]

- Lin, M.; Chang, F.K. The manufacture of composite structures with a built-in network of piezoceramics. Compos. Sci. Technol. 2002, 62, 919–939. [Google Scholar] [CrossRef]

- Andreades, C.; Meo, M.; Ciampa, F. Fatigue testing and damage evaluation using smart CFRP composites with embedded PZT transducers. Mater. Today Proc. 2021, 34, 260–265. [Google Scholar] [CrossRef]

- Feng, T.; Aliabadi, M.F. Structural Integrity Assessment of Composites Plates with Embedded PZT Transducers for Structural Health Monitoring. Materials 2021, 14, 6148. [Google Scholar] [CrossRef]

- Andreades, C.; Mahmoodi, P.; Ciampa, F. Characterisation of smart CFRP composites with embedded PZT transducers for nonlinear ultrasonic applications. Compos. Struct. 2018, 206, 456–466. [Google Scholar] [CrossRef]

- Mall, S. Integrity of graphite/epoxy laminate embedded with piezoelectric sensor/actuator under monotonic and fatigue loads*. Smart Mater. Struct. 2002, 11, 527–533. [Google Scholar] [CrossRef]

- Yang, B.; Xuan, F.Z.; Jin, P.; Hu, C.; Xiao, B.; Li, D.; Xiang, Y.; Lei, H. Damage Localization in Composite Laminates by Building in PZT Wafer Transducers: A Comparative Study with Surface–Bonded PZT Strategy. Adv. Eng. Mater. 2018, 21, 1801040. [Google Scholar] [CrossRef]

- Feng, T.; Bekas, D.; Aliabadi, M.H.F. Active Health Monitoring of Thick Composite Structures by Embedded and Surface-Mounted Piezo Diagnostic Layer. Sensors 2020, 20, 3410. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Wang, X.; Chen, Z.; Ye, L.; Wang, D. A built-in active sensor network for health monitoring of Composite Structures. Smart Mater. Struct. 2006, 15, 1939–1949. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A.; Bao, J.J. Piezoelectric Wafer Embedded Active Sensors for Aging Aircraft Structural Health Monitoring. Struct. Health Monit. 2002, 1, 41–61. [Google Scholar] [CrossRef]

- Kostson, E.; Fromme, P. Fatigue crack growth monitoring in multi-layered structures using guided ultrasonic waves. J. Phys. Conf. Ser. 2009, 195, 012003. [Google Scholar] [CrossRef]

- Chan, H.; Masserey, B.; Fromme, P. High frequency guided ultrasonic waves for hidden fatigue crack growth monitoring in multi-layer model aerospace structures. Smart Mater. Struct. 2015, 24, 025037. [Google Scholar] [CrossRef]

- Moser, F.; Jacobs, L.J.; Qu, J. Modeling elastic wave propagation in waveguides with the finite element method. NDT E Int. 1999, 32, 225–234. [Google Scholar] [CrossRef]

- Marwitz, S.; Zabel, V. Operational Modal Analysis with a 3D Laser Vibrometer Without External Reference. In Rotating Machinery, Hybrid Test Methods, Vibro-Acoustics & Laser Vibrometry; de Clerck, J., Epp, D.S., Eds.; Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Cham, Switzerland, 2016; Volume 8, pp. 75–85. [Google Scholar] [CrossRef]

- Roloff, T.; Mitkus, R.; Lion, J.N.; Sinapius, M. 3D-Printable Piezoelectric Composite Sensors for Acoustically Adapted Guided Ultrasonic Wave Detection. Sensors 2022, 22, 6964. [Google Scholar] [CrossRef]

- Debnath, L.; Shah, F.A. Wavelet Transforms and Their Applications; Birkhäuser Boston: Boston, MA, USA, 2015. [Google Scholar] [CrossRef]

- The MathWorks, Inc. MATLAB Documentation: Continuous 1-D Wavelet Transform. Available online: https://de.mathworks.com/help/wavelet/ref/cwt.html (accessed on 31 January 2022).

- Rauter, N.; Hennings, B.; Neumann, M.N.; Asmus, A.; Lammering, R. Wave Propagation in Elastic Solids: An Analytical Approach. In Lamb-Wave Based Structural Health Monitoring in Polymer Composites; Lammering, R., Gabbert, U., Sinapius, M., Schuster, T., Wierach, P., Eds.; Research Topics in Aerospace; Springer International Publishing: Cham, Switzerland, 2018; pp. 17–62. [Google Scholar] [CrossRef]

| Inlay Type | Position |

|---|---|

| no insert | - |

| polyimide/no sensor | 8th/9th layer (midplane) |

| polyimide/square | 8th/9th layer (midplane) |

| polyimide/rhombic | 8th/9th layer (midplane) |

| polyimide/flattened rhombic | 8th/9th layer (midplane) |

| polyimide/rhombic | 12th/13th layer |

| Material | ||||||

|---|---|---|---|---|---|---|

| [GPa] | [GPa] | [GPa] | [GPa] | [-] | [g/m] | |

| GFRP DLS1611 (Hexcel Corp.) | 54 | 9.4 | 5.55 | 3.75 | 0.33 | 1980 |

| Polyimide | 2.5 | 2.5 | 1.52 | 1.52 | 0.34 | 1420 |

| Burst Center Frequency | ||

|---|---|---|

| [kHz] | [m/s] | [m/s] |

| 75 | 2682 | 2197 |

| 120 | 2500 | 2193 |

| 200 | 2444 | 2179 |

| Wave Package | Spatial Starting Point | Temporal Starting Point |

|---|---|---|

| [mm] | [ms] | |

| 1 | 15 | 0.075 |

| 2 | 40 | 0.07 |

| 3 | 65 | 0.08 |

| 4 | 90 | 0.09 |

| Burst Center Frequency | Spatial Location | Temporal Point | ||

|---|---|---|---|---|

| Before Reflection | Center of Reflection | After Reflection | ||

| [kHz] | [mm] | [s] | [s] | [s] |

| 75 | 40 | 50 | 115 | 145 |

| 120 | 20 | 50 | 75 | 95 |

| 200 | 45 | 60 | 70 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rittmeier, L.; Roloff, T.; Rauter, N.; Mikhaylenko, A.; Haus, J.N.; Lammering, R.; Dietzel, A.; Sinapius, M. Influence of a Flat Polyimide Inlay on the Propagation of Guided Ultrasonic Waves in a Narrow GFRP-Specimen. Materials 2022, 15, 6752. https://doi.org/10.3390/ma15196752

Rittmeier L, Roloff T, Rauter N, Mikhaylenko A, Haus JN, Lammering R, Dietzel A, Sinapius M. Influence of a Flat Polyimide Inlay on the Propagation of Guided Ultrasonic Waves in a Narrow GFRP-Specimen. Materials. 2022; 15(19):6752. https://doi.org/10.3390/ma15196752

Chicago/Turabian StyleRittmeier, Liv, Thomas Roloff, Natalie Rauter, Andrey Mikhaylenko, Jan Niklas Haus, Rolf Lammering, Andreas Dietzel, and Michael Sinapius. 2022. "Influence of a Flat Polyimide Inlay on the Propagation of Guided Ultrasonic Waves in a Narrow GFRP-Specimen" Materials 15, no. 19: 6752. https://doi.org/10.3390/ma15196752

APA StyleRittmeier, L., Roloff, T., Rauter, N., Mikhaylenko, A., Haus, J. N., Lammering, R., Dietzel, A., & Sinapius, M. (2022). Influence of a Flat Polyimide Inlay on the Propagation of Guided Ultrasonic Waves in a Narrow GFRP-Specimen. Materials, 15(19), 6752. https://doi.org/10.3390/ma15196752