Clustering Characterization of Acoustic Emission Signals Belonging to Twinning and Dislocation Slip during Plastic Deformation of Polycrystalline Sn

Abstract

1. Introduction

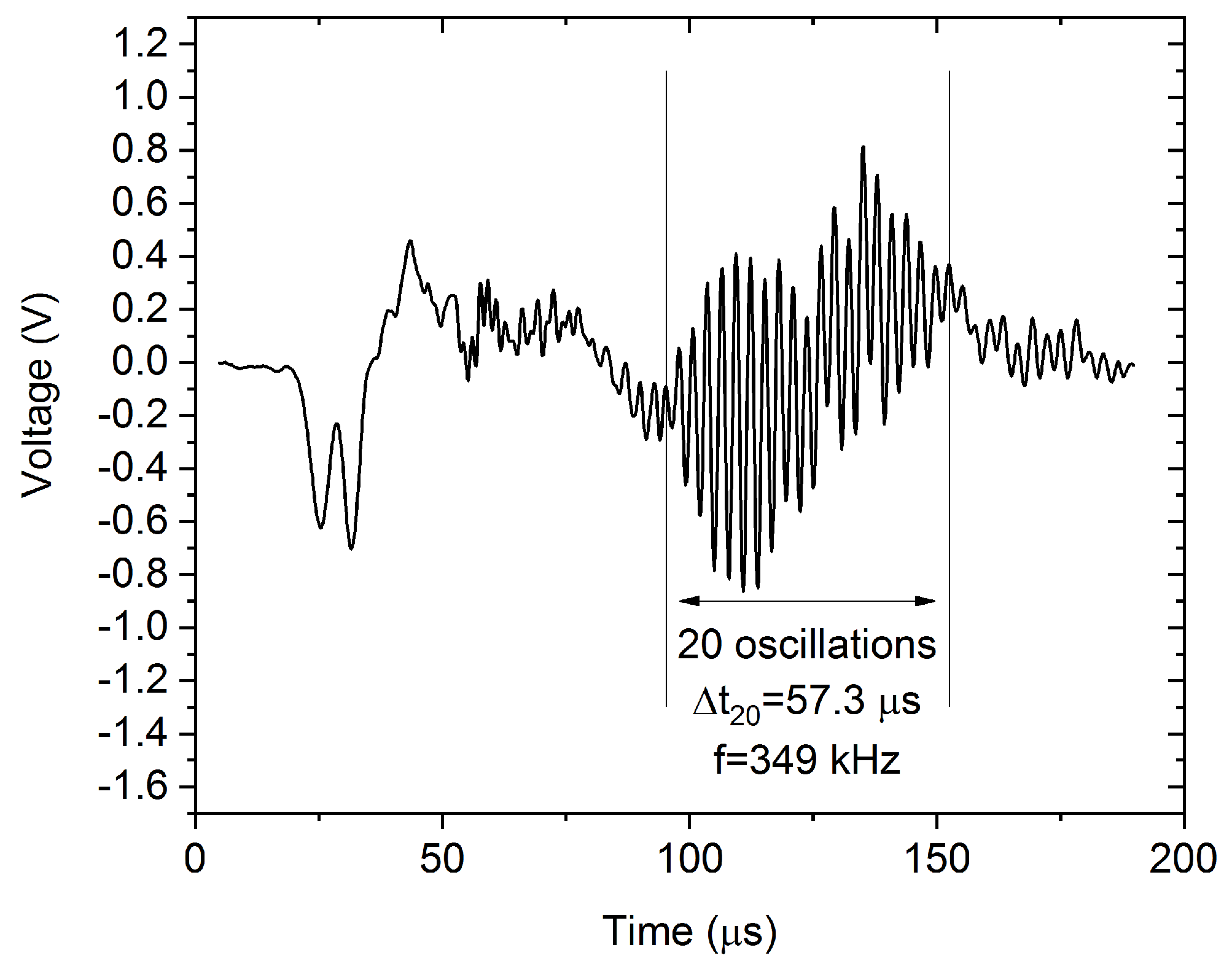

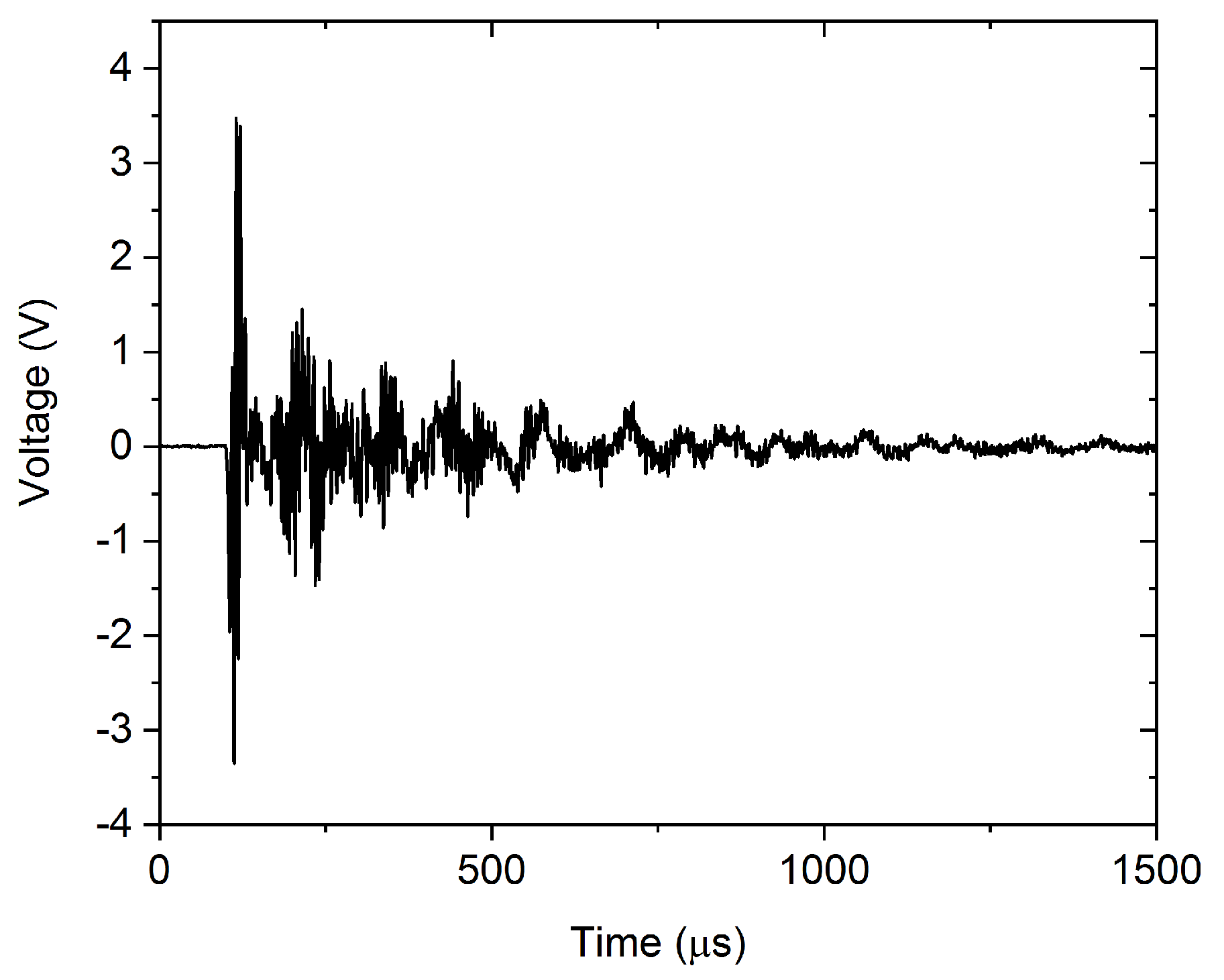

2. Materials and Methods

3. Results

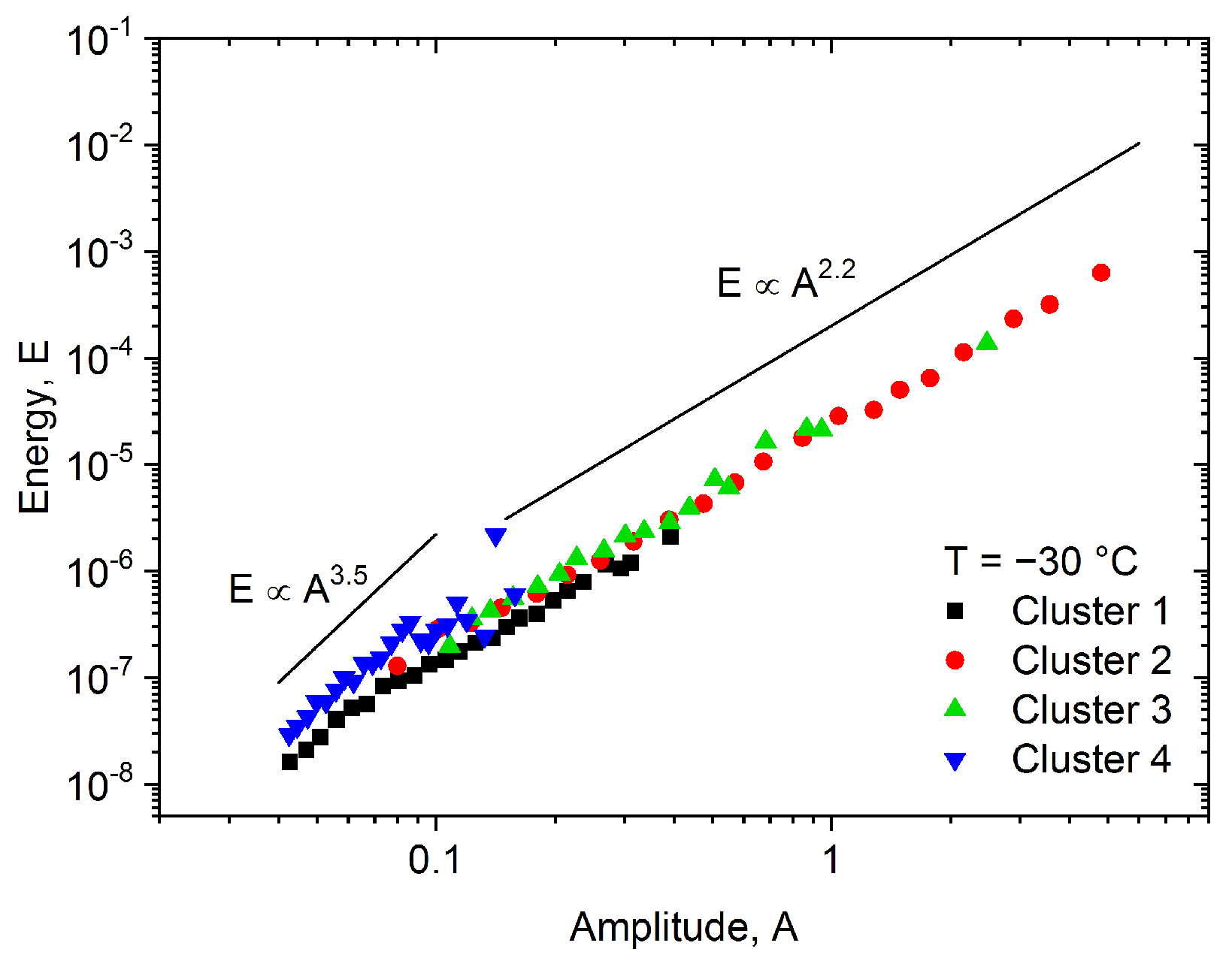

3.1. Low-Temperature Measurements

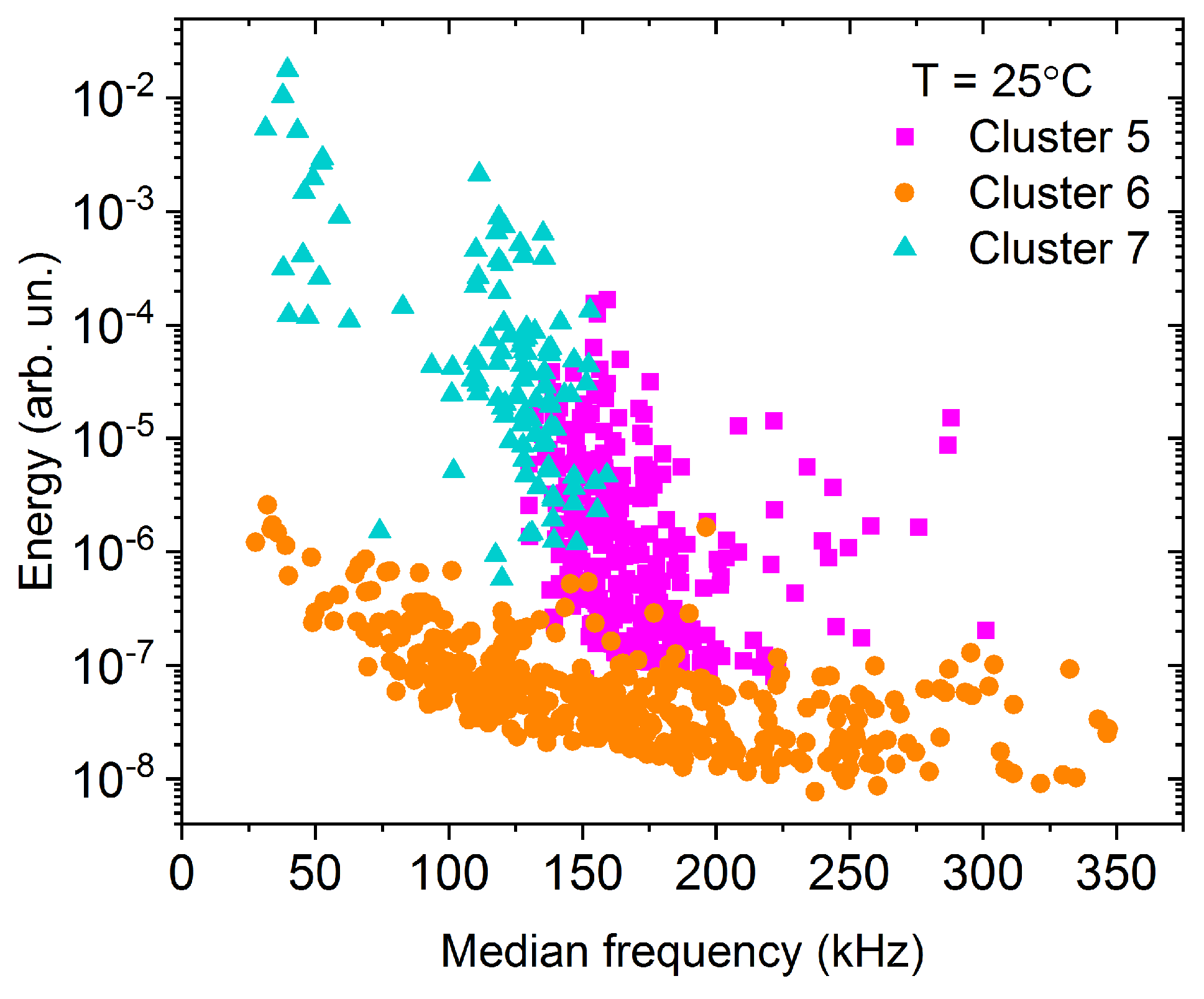

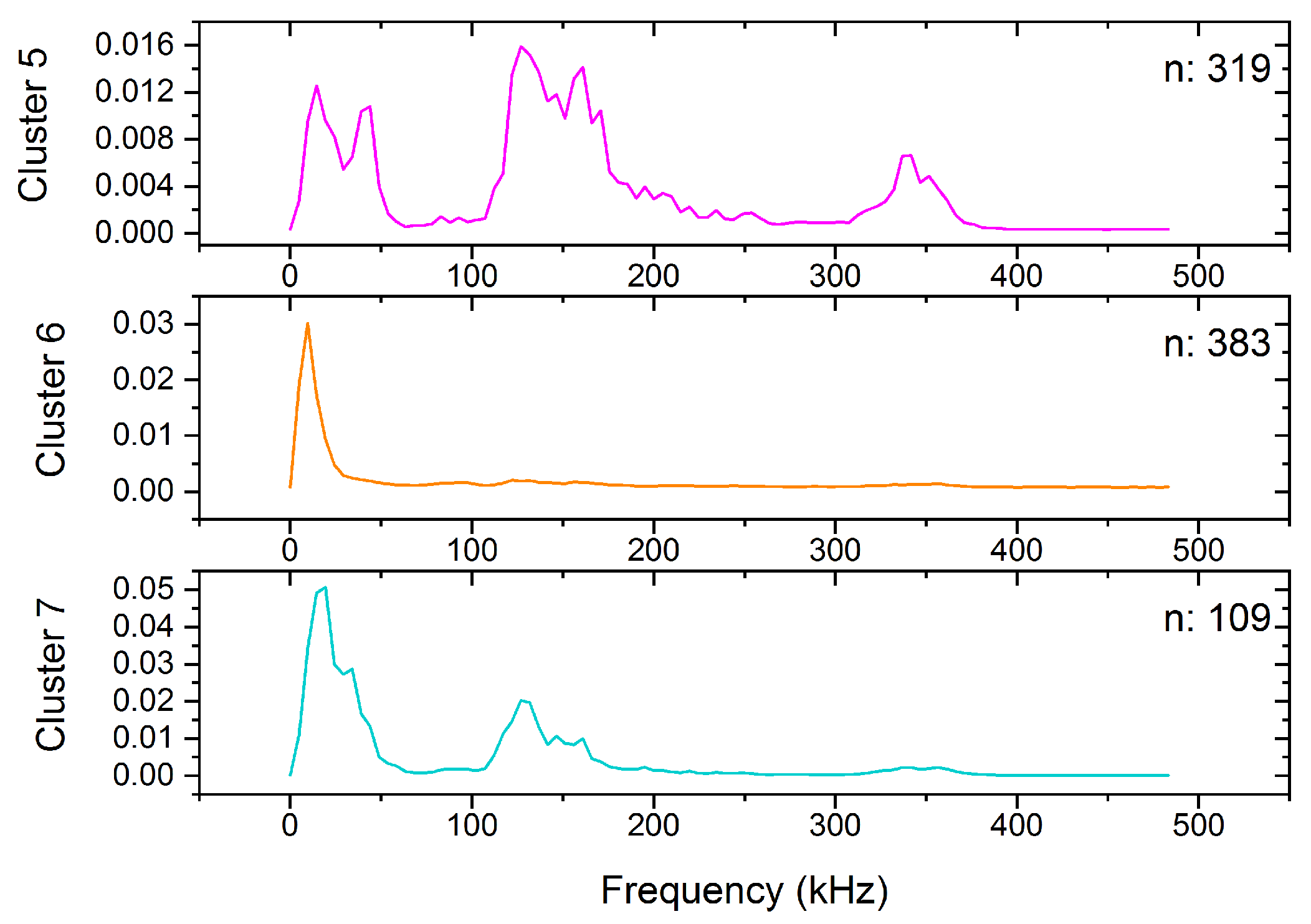

3.2. Room Temperature Measurements

4. Discussion

4.1. Low-Temperature Measurements

4.2. Room-Temperature Measurements

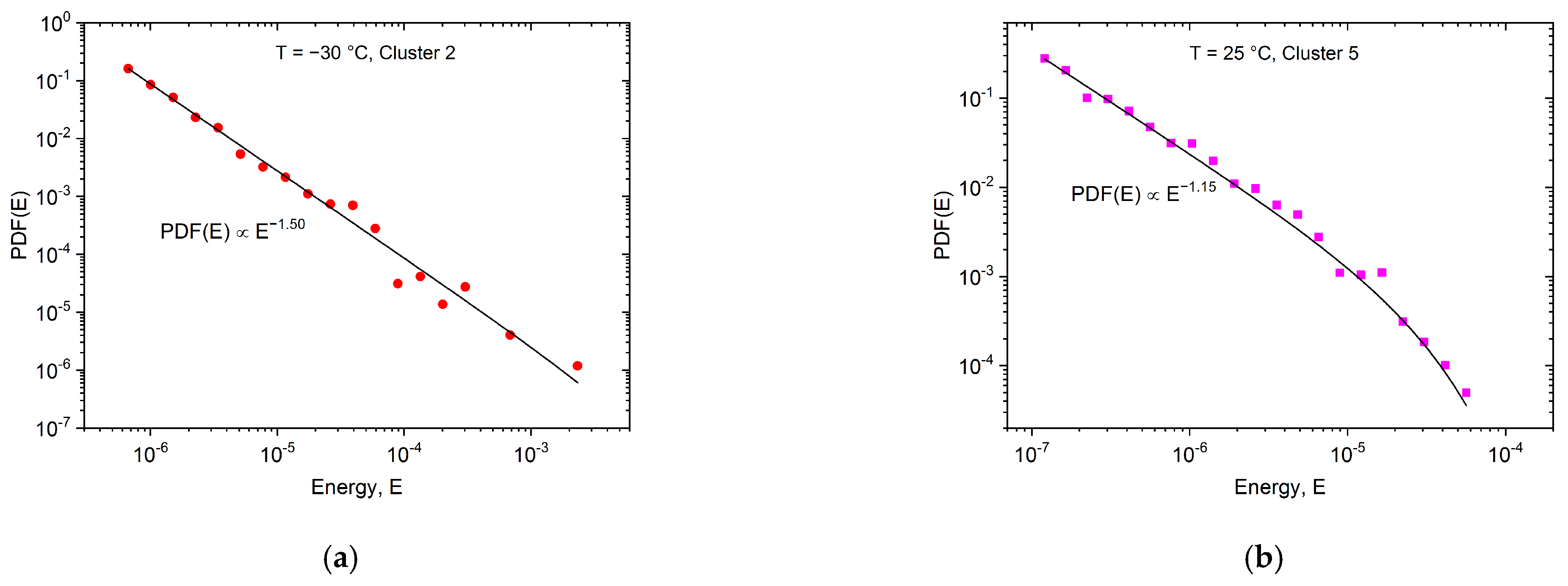

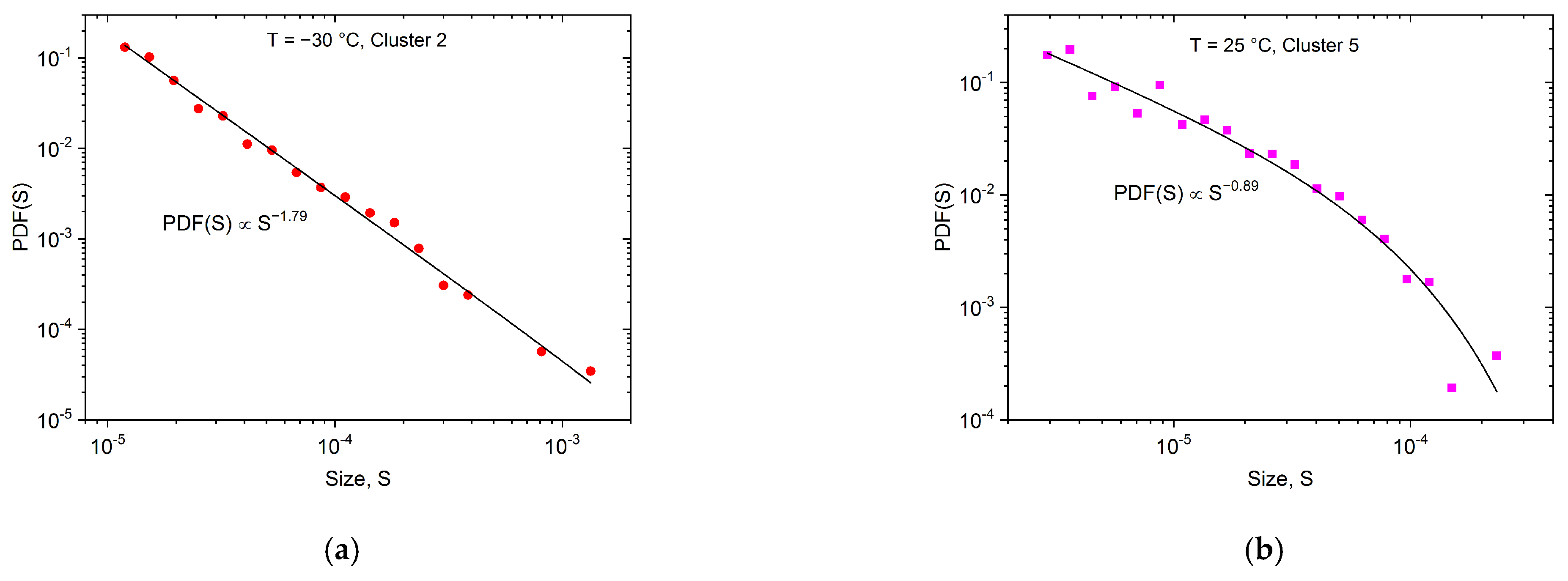

4.3. Statistical Analysis of the Clusters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scruby, C.B. Quantitative acoustic emission techniques. In Research Techniques in Non-Destructive Testing; Sharpe, R.S., Ed.; Academic Press: London, UK, 1985; Volume III, ISBN 0126390533. [Google Scholar]

- Heiple, C.R.; Carpenter, S.H. Acoustic emission produced by deformation of metals and alloys—A review. J. Acoust. Emiss. 1987, 6, 177–204. [Google Scholar]

- Miguel, M.-C.; Vespignani, A.; Zapperi, S.; Weiss, J.; Grasso, J.R. Intermittent dislocation flow in viscoplastic deformation. Nature 2001, 410, 667–671. [Google Scholar] [CrossRef] [PubMed]

- Rosinberg, M.L.; Vives, E. Metastability, Hysteresis, Avalanches, and Acoustic Emission: Martensitic Transitions in Functional Materials. In Disorder and Strain Induced Complexity in Functional Materials; Kakeshita, T., Fukuda, T., Saxena, A., Planes, A., Eds.; Springer Series in Materials Science; Springer: Berlin, Germany, 2012; Volume 148, pp. 249–272. ISBN 978-3-642-20943-7. [Google Scholar]

- Vives, E.; Soto-Parra, D.; Mañosa, L.; Romero, R.; Planes, A. Imaging the dynamics of martensitic transitions using acoustic emission. Phys. Rev. B 2011, 84, 060101. [Google Scholar] [CrossRef]

- Pomponi, E.; Vinogradov, A. A real-time approach to acoustic emission clustering. Mech. Syst. Signal Proc. 2013, 40, 791–804. [Google Scholar] [CrossRef]

- Vinogradov, A.; Lazarev, A.; Linderov, M.; Weidner, A.; Biermann, H. Kinetics of deformation processes in high-alloyed cast transformation-induced plasticity/twinning-induced plasticity steels determined by acoustic emission and scanning electron microscopy: Influence of austenite stability on deformation mechanisms. Acta Mater. 2013, 61, 2434–2449. [Google Scholar] [CrossRef]

- Vinogradov, A.; Danyuk, A.V.; Merson, D.L.; Yasnikov, L.S. Probing elementary dislocation mechanisms of local plastic deformation by the advanced acoustic emission technique. Scr. Mater. 2018, 151, 53–56. [Google Scholar] [CrossRef]

- Spark, G.; Maas, R. Shapes and velocity relaxation of dislocation avalanches in Au and Nb microcrystals. Acta Mater. 2018, 152, 86–95. [Google Scholar] [CrossRef]

- Chen, Y.; Gou, B.; Yuan, B.; Ding, X.; Sun, J.; Salje, E.K.H. Multiple Avalanche Processes in Acoustic Emission Spectroscopy: Multibranching of the Energy− Amplitude Scaling. Phys. Status Solidi B 2022, 259, 2100465. [Google Scholar] [CrossRef]

- Beke, D.L.; Daroczi, L.; Toth, L.Z.; Bolgar, M.K.; Shamy, N.M.; Hudak, A. Acoustic Emissions during Structural Changes in Shape Memory Alloys. Metals 2019, 9, 58. [Google Scholar] [CrossRef]

- Casals, B.; Dahmen, K.A.; Gou, B.; Rooke, S.; Salje, E.K.H. The duration-energy-size enigma for acoustic emission. Sci. Rep. 2021, 11, 5590. [Google Scholar] [CrossRef]

- Kumar, J.; Sarmah, R.; Ananathakrishna, G. General framework for acoustic emission during plastic deformation. Phys. Rev. B 2015, 92, 1444109. [Google Scholar] [CrossRef]

- Chapek, J.; Knapek, M.; Minarik, P.; Dittrich, J.; Máthis, K. Characterization of Deformation Mechanisms in Mg Alloys by Advanced Acoustic Emission Methods. Metals 2018, 8, 644. [Google Scholar] [CrossRef]

- Salita, D.S.; Polyakov, V.V. Acoustic Emission during Plastic Deformation of Pb–Sn Alloys. Phys. Mesomech. 2020, 23, 593–600. [Google Scholar] [CrossRef]

- Chen, H.; Liu, M.; Chen, Y.; Li, S.; Miao, Y. Nonlinear Lamb Wave for Structural Incipient Defect Detection with Sequential Probabilistic Ratio Test. Secur. Commun. Netw. 2022, 2022, 9851533. [Google Scholar] [CrossRef]

- Salje, E.K.H.; Dahmen, K. Crackling noise in disordered materials. Annu. Rev. Condens. Matter Phys. 2014, 5, 233–254. [Google Scholar] [CrossRef]

- Richeton, T.; Dobron, P.; Chmelik, F.; Weiss, J.; Louchet, F. On the critical character of plasticity in metallic single crystals. Mat. Sci. Eng. A 2006, 424, 190–195. [Google Scholar] [CrossRef]

- Chi-Cong, V.; Weiss, J. Asymmetric Damage Avalanche Shape in Quasibrittle Materials and Subavalanche (Aftershock) Clusters. Phys. Rev. Lett. 2020, 125, 105502. [Google Scholar] [CrossRef]

- Antonaglia, J.; Wright, W.J.; Gu, X.; Byer, R.R.; Hufnagel, T.C.; LeBlanc, M.; Uhl, J.T.; Dahmen, K.A. Bulk metallic glasses deform via slip avalanches. Phys. Rev. Lett. 2014, 112, 1555501. [Google Scholar] [CrossRef]

- Anastassopoulos, A.A.; Philippidis, T.P. Clustering methodology for the evaluation of acoustic emission from composites. J. Acoust. Emiss. 1995, 13, 11–22. [Google Scholar]

- Dubes, R.; Jain, A.K. Clustering techniques: The user’s dilemma. Pattern Recognition 1976, 8, 247–260. [Google Scholar] [CrossRef]

- Knezevic, M.; Zecevic, M.; Beyerlein, I.J.; Bingert, J.F.; McCabe, R.J. Strain rate and temperature effects on the selection of primary and secondary slip and twinning systems in HCP Zr. Acta Mater. 2015, 88, 55–73. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Zecevic, M.; Knezevic, M.; Beyerlein, I.J.; Tomé, C.N. An elasto-plastic self-consistent model with hardening based on dislocation density, twinning and de-twinning: Application to strain path changes in HCP metals. Mater. Sci. Eng. A 2015, 638, 262–274. [Google Scholar] [CrossRef]

- Daróczi, L.; Elrasasi, T.Y.; Arjmandabasi, T.; Tóth, L.Z.; Veres, B.; Beke, D.L. Change of Acoustic Emission Characteristics during Temperature Induced Transition from Twinning to Dislocation Slip under Compression in Polycrystalline Sn. Materials 2021, 15, 224. [Google Scholar] [CrossRef] [PubMed]

- Drozdenko, D.; Bohlen, J.; Chmelík, F.; Lukáč, P.; Dobroň, P. Acoustic emission study on the activity of slip and twin mechanisms during compression testing of magnesium single crystals. Mater. Sci. Eng. A 2016, 650, 20–27. [Google Scholar] [CrossRef]

- Weidner, A.; Vinogradov, A.; Vollmer, M.; Krooβ, P.; Kriegel, M.J.; Klemm, V.; Chumljakov, Y.; Niendorf, T.; Biermann, H. In situ characterization of the functional degredation of [001] oriented Fe-Mn-Al-Ni single crystal under compression using acoustic emission measurements. Acta Mater. 2021, 220, 117333. [Google Scholar] [CrossRef]

- Mathis, K.; Csiszar, G.; Capek, J.; Gubicza, J.; Clausen, B.; Lukas, P.; Vinogradov, A.; Agnew, S.R. Effect of the loading mode on the evolution of the deformation mechanism on randomly textured magnesium polycrystals-comparison of experiment and modeling results. Int. J. Plast. 2015, 72, 127–150. [Google Scholar] [CrossRef]

- Tóth, L.Z.; Szabó, S.; Daróczi, L.; Beke, L. Calorimetric and acoustic emission study of martensitic transformation in singlecrystalline Ni2MnGa alloys. Phys. Rev. B 2014, 90, 224103. [Google Scholar] [CrossRef]

- Tóth, L.Z.; Daróczi, L.; Szabó, S.; Beke, D.L. Simultaneous investigation of thermal, acoustic, and magnetic emission during martensitic transformation in single-crystalline Ni2MnGa. Phys. Rev. B 2016, 93, 144108. [Google Scholar] [CrossRef]

- Lebyodkin, M.; Shashkov, I.; Lebedkina, T.; Mathis, K.; Dobron, P.; Chmelik, F. Role of superposition of dislocation avalanches in the statistics of acoustic emission during plastic deformation. Phys. Rev. E 2013, 88, 042402. [Google Scholar] [CrossRef]

- Chen, Y.; Gou, B.; Fu, W.; Chen, C.; Ding, X.; Sun, J.; Salje, E.K.H. Fine structures of acoustic emission spectra: How to separate dislocation movements and entanglements in 316L stainless steel. Appl. Phys. Lett. 2020, 117, 262901. [Google Scholar] [CrossRef]

- Kamel, S.M.; Samy, N.M.; Tóth, L.Z.; Daróczi, L.; Beke, D.L. Denouement of the Energy-Amplitude and Size-Amplitude Enigma for Acoustic-Emission Investigations of Materials. Materials 2022, 15, 4556. [Google Scholar] [CrossRef]

- Fisher, D.S. Collective transport in random media: From supercondutors to earth quakes. Phys. Rep. 1998, 301, 113–150. [Google Scholar] [CrossRef]

- McFaul, L.W.; Wright, W.J.; Sickle, J.; Dahmen, K.A. Force oscillations distort avalanche shapes. Mater. Res. Lett. 2019, 7, 496–502. [Google Scholar] [CrossRef]

- LeBlanc, M.; Angheluta, L.; Dahmen, K.; Goldenfeld, N. Universal fluctuations and extreme statistics of avalanches near the depinning transition. Phys. Rev. E 2013, 87, 022126. [Google Scholar] [CrossRef] [PubMed]

- Friedman, N.; Jennings, A.T.; Tsekenis, G.; Kim, J.Y.; Tao, M.; Uhl, J.T.; Dahmen, K.A. Statistics of dislocation slip avalanches in nanosized single crystals show tuned critical behavior predicted by a simple mean field model. Phys. Rev. Lett. 2012, 109, 095507. [Google Scholar] [CrossRef]

- Clauset, A.; Shalizi, C.R.; Newman, M.E. Power-law distributions in empirical data. SIAM Rev. 2009, 51, 661–703. [Google Scholar] [CrossRef]

- Salje, E.K.H.; Planes, A.; Vives, E. Analysis of crackling noise using the maximum-likelihood method: Power-law mixing and exponential damping. Phys. Rev. E 2017, 96, 042122. [Google Scholar] [CrossRef] [PubMed]

| Temperature | Cluster (Number of Avalanches) | Energy Exponent, ε | Size Exponent, τ |

|---|---|---|---|

| −30 °C | 1 (904) | 1.3 ± 0.1 * | 1.5 ± 0.1 * |

| 2 (272) | 1.57 ± 0.05 | 1.92 ± 0.05 | |

| 3 (101) | 1.4 ± 0.2 * | 1.55 ± 0.2 * | |

| 4 (199) | 1.6 ± 0.1 | 1.65 ± 0.1 | |

| 25 °C | 5 (319) | 1.35 ± 0.1 | 1.55 ± 0.1 |

| 6 (383) | 1.5 ± 0.1 | 1.6 ± 0.1 | |

| 7 (109) | 1.35 ± 0.2 * | 1.6 ± 0.2 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, L.Z.; Daróczi, L.; Elrasasi, T.Y.; Beke, D.L. Clustering Characterization of Acoustic Emission Signals Belonging to Twinning and Dislocation Slip during Plastic Deformation of Polycrystalline Sn. Materials 2022, 15, 6696. https://doi.org/10.3390/ma15196696

Tóth LZ, Daróczi L, Elrasasi TY, Beke DL. Clustering Characterization of Acoustic Emission Signals Belonging to Twinning and Dislocation Slip during Plastic Deformation of Polycrystalline Sn. Materials. 2022; 15(19):6696. https://doi.org/10.3390/ma15196696

Chicago/Turabian StyleTóth, László Z., Lajos Daróczi, Tarek Y. Elrasasi, and Dezső L. Beke. 2022. "Clustering Characterization of Acoustic Emission Signals Belonging to Twinning and Dislocation Slip during Plastic Deformation of Polycrystalline Sn" Materials 15, no. 19: 6696. https://doi.org/10.3390/ma15196696

APA StyleTóth, L. Z., Daróczi, L., Elrasasi, T. Y., & Beke, D. L. (2022). Clustering Characterization of Acoustic Emission Signals Belonging to Twinning and Dislocation Slip during Plastic Deformation of Polycrystalline Sn. Materials, 15(19), 6696. https://doi.org/10.3390/ma15196696