Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete

Abstract

1. Introduction

2. Raw Materials and Test Methods

2.1. Raw Materials

2.2. Experimental Method

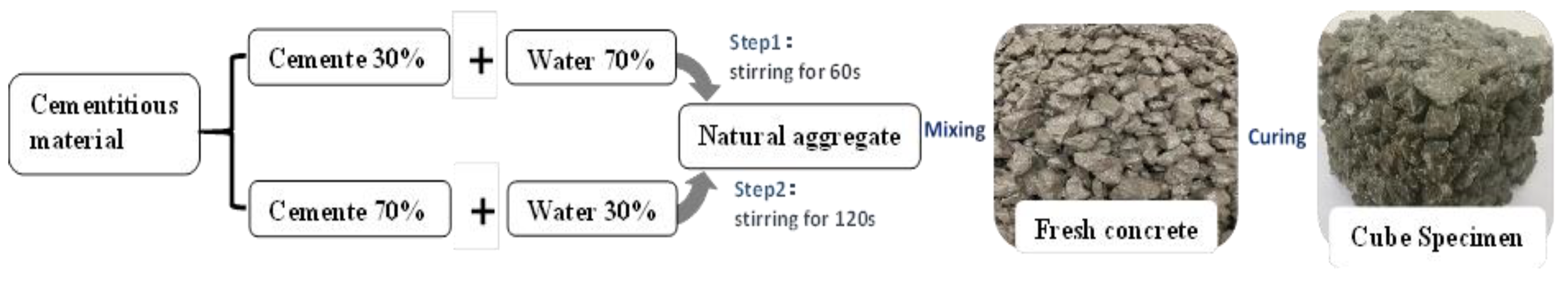

2.2.1. Mixing Proportions of Planting Concrete

2.2.2. Planting Concrete Preparation

2.2.3. Test Methods

- (1)

- Compressive strength: Compressive strength is an important indicator of the mechanical properties of planting concrete. To test the compressive strength of the planting concrete, cubic samples of planting concrete with dimensions of 150 mm × 150 mm × 150 mm were used [18]. There were three specimens in each group, and a total of 30 specimens were made. After forming and demolding the specimens, the compressive strength tests were carried out in standard holding rooms (temperature 20 ± 2 °C and 99% humidity) until the ages of 7 days and 28 days. The compressive strength is given in Equation (1).

- (2)

- Porosity: The porosity of planting concrete can be classified into connective porosity and gross porosity. The connective porosity is an important indicator for positive plant growth in planting concrete (porosity in the subsequent text refers collectively to connective porosity). The specific test is as follows [19]: After leaving the prepared planting concrete blocks to age for 28 days, the test block mass W1 was weighed. After the mass was soaked in water for 24 h and saturated with water, its mass in water W2 was weighed. The connective porosity is given in Equation (2).

- (3)

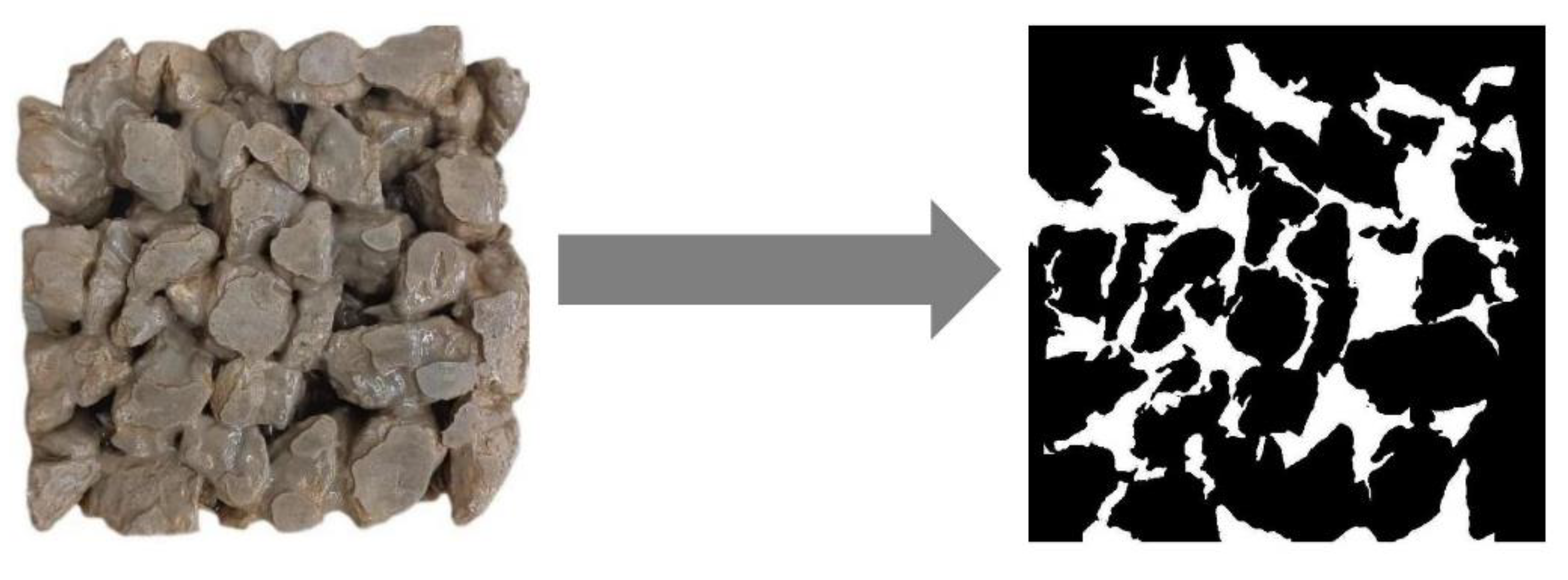

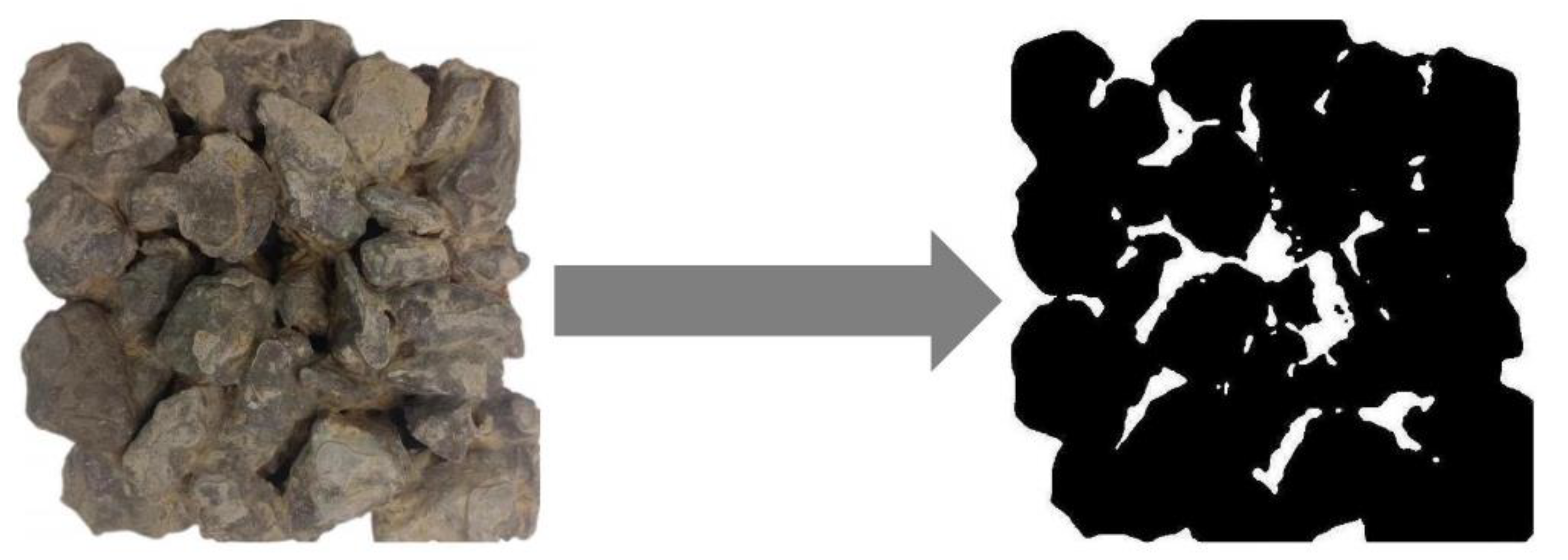

- Surface porosity analysis: A rock cutter was used to slice the cubic standard specimen into layers, and the specimen was evenly cut into 5 pieces with a slice thickness of 30 mm. The upper and lower surfaces of the cut section should be parallel and the surface should be smooth. The cut surfaces were polished with 150-grit sandpaper for more than 20 min to eliminate the scratches caused by the cut sections so that the surface of the section was smooth and flat and the structure of the hole was visible. A digital camera was used to photograph the concrete slices, and the images were equalized and grayscale-processed. Combined with the histogram image features, the pore grayscale values were judged to be in the range of 50–80, and the image binarization was achieved using the im2bw function in the mathematical software. The processing result is shown in Figure 2. The white part is the porosity part. After the processing of the slices, they were imported into the Image-Pro Plus 6.0 software (US MEDIA CYBERNETICS, Rockville, MD, USA) and the appropriate parameters were set. The pore structure parameters calculated were pore area, pore diameter (mean), and plane porosity. The plane porosity is calculated as a percentage of the slice area by the pore area and the plane porosity is calculated as in Equation (3):

- (4)

- SEM microscopic experiment: For SEM specimen preparation, concrete specimens of 20–40 mm grade with 0.29 water–cement ratio were cured to 7 days age and broken. A block with a section of about 1 cm × 1 cm × 1 cm was taken and the section was left untreated; the specimen sections were left untreated and then put into anhydrous ethanol for 48 h to end hydration. A small piece of the specimen was glued to the sample table and surface gold plating was performed to increase the electrical conductivity, and the thickness of the gold spray was about 20 nm. The sample was tested by SEM using a Gemini SEM300 scanning electron microscope (Carl Zeiss AG, Oberkochen, Germany) for SEM testing of the sample morphology, and the test was performed using a secondary electron SE2 detector.

- (5)

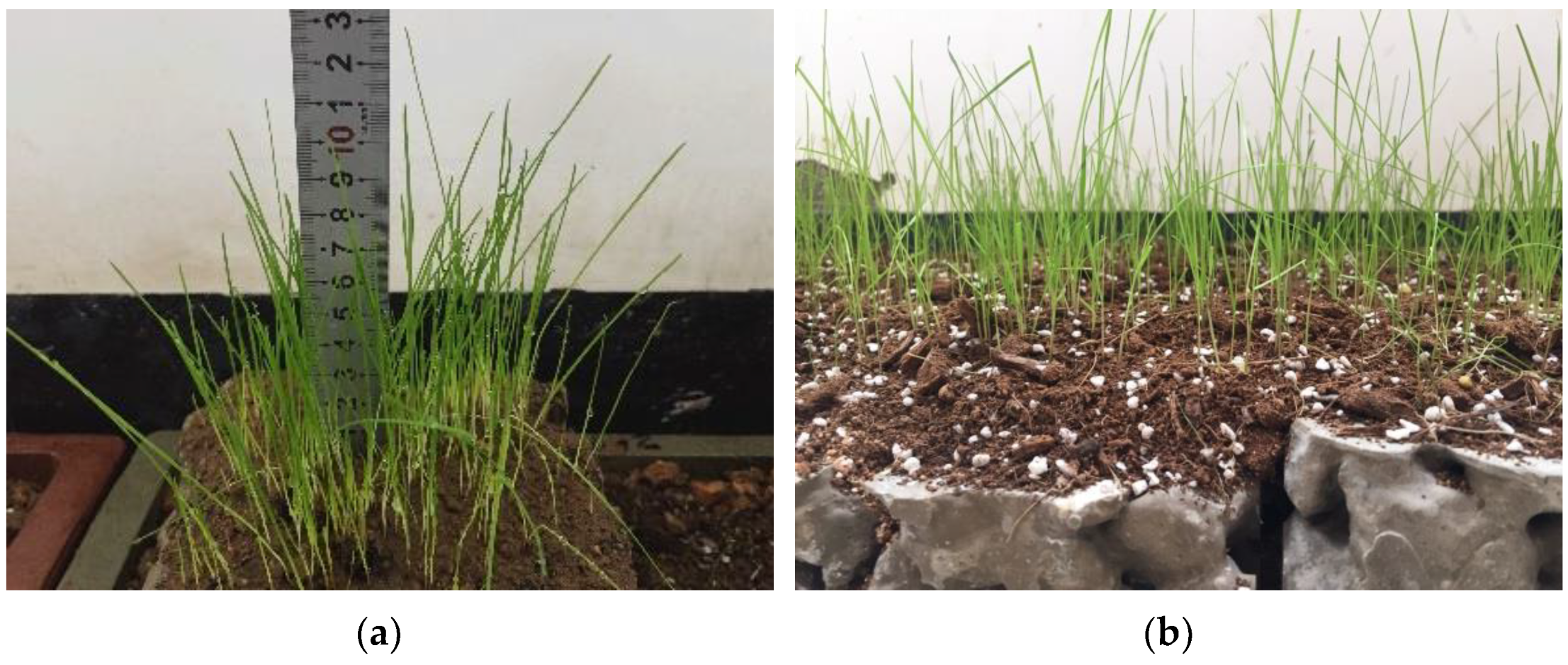

- Planting experiment: Tall fescue was selected for planting in the experiment, and the seeds are shown in Figure 3a. Tall fescue is a perennial ground cover plant of the grass family and is one of the plants that grow well in a resilient manner; it can adapt to a degree of acidity and salinity, with the most suitable environment for tall fescue growth having the pH of 4.7–8.6. Seeds should be kept refrigerated at 0–10 °C prior to sowing and soaked in water for germination 24 h prior to sowing. The top-set planting configuration used for the experiment is shown in Figure 3b. The root length was measured using a straightedge to determine plant height and root length during the experiment, and the germination and growth of tall fescue in soil and planting concrete were noted. The method of measuring root length is shown in Figure 3c.

- (6)

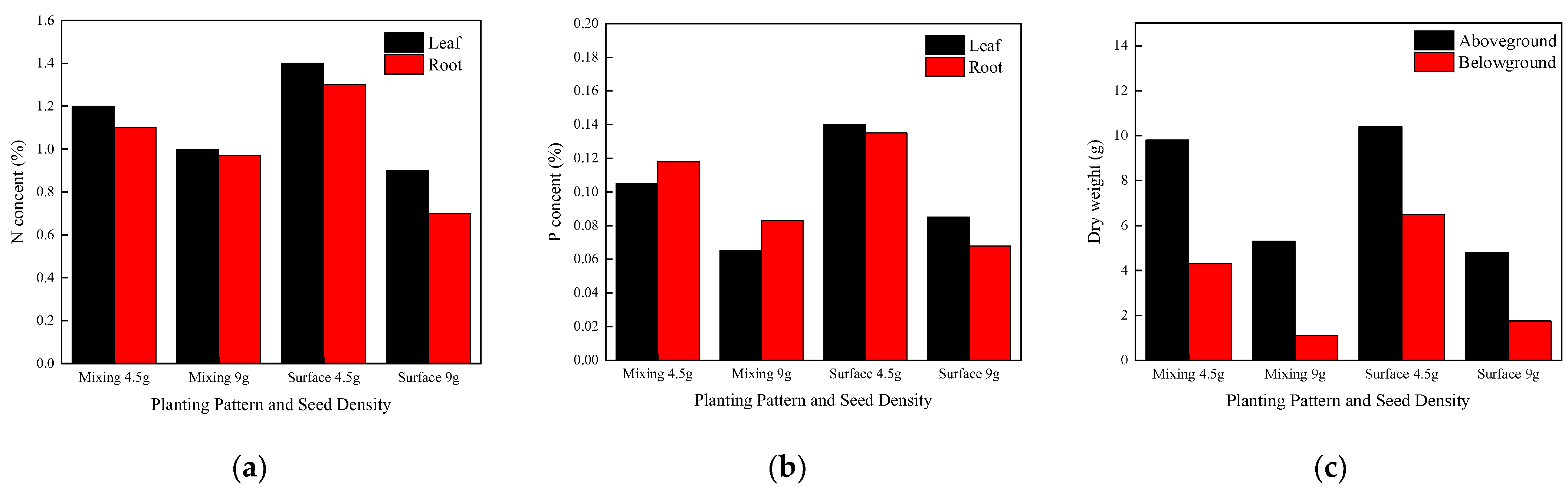

- Determination of biomass and elemental levels in plant leaves and roots: After 50 days of growth, tall fescue plants grown with different planting methods and planting densities were taken as samples. The tall fescue plants were removed from the planting concrete completely; the stems and leaves were separated from the root system with scissors, and the root system was rinsed with distilled water. Each pot of stem and root samples was separately placed in a 115 °C oven for 15 min to inactivate the enzymes and then dried at 75 °C. Three tall fescue plants were taken for measuring the biomass of stems, leaves, and roots, and another three plants were taken for measuring the total nitrogen and phosphorus content in tall fescue. The total nitrogen content was determined by the H2SO4–H2O2 decoction method, and the total phosphorus content was determined by the alkali fusion molybdenum antimony anti-colorimetric method.

3. Results and Discussion

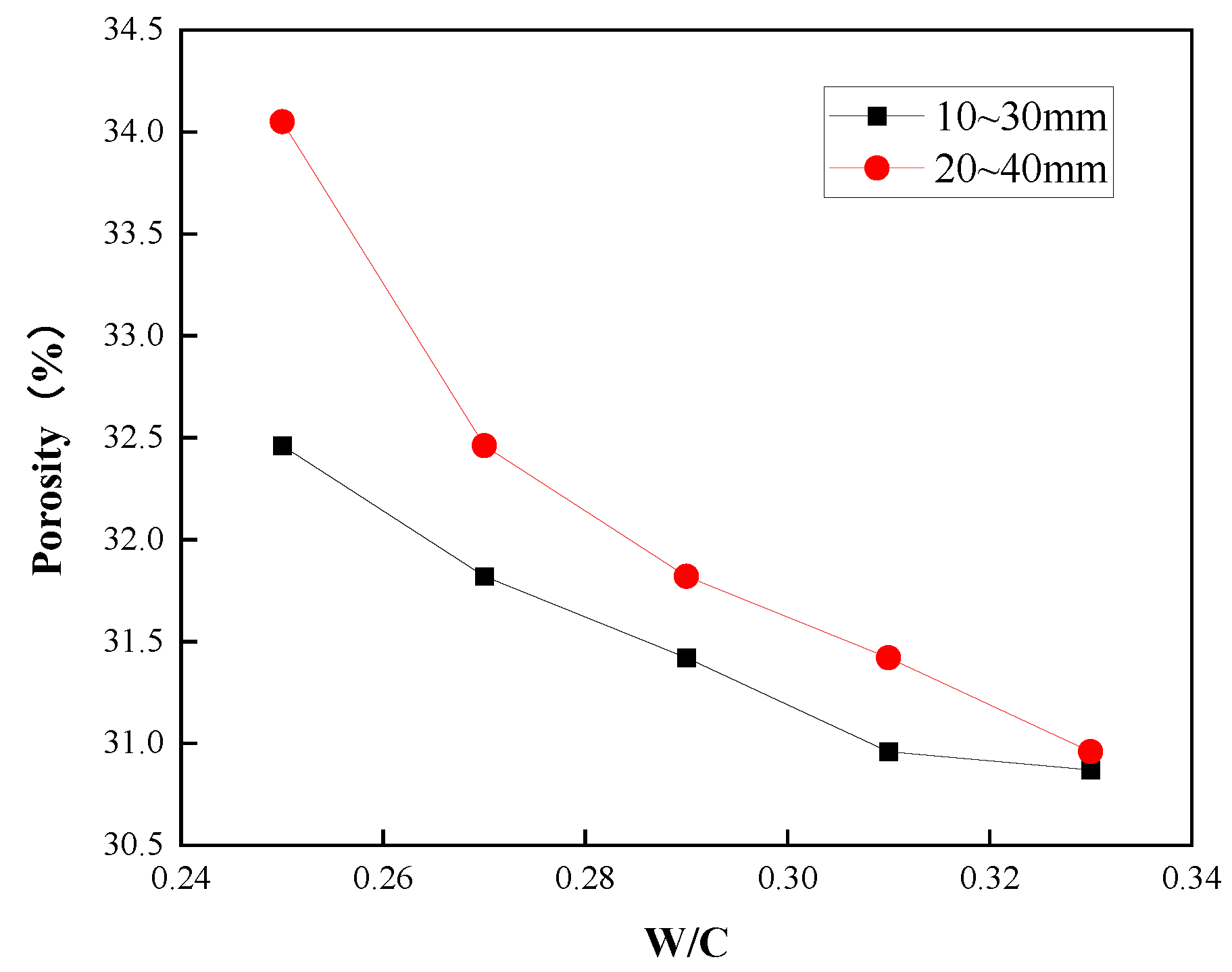

3.1. Effect of Water–Cement Ratio and Aggregate Particle Size on Porosity

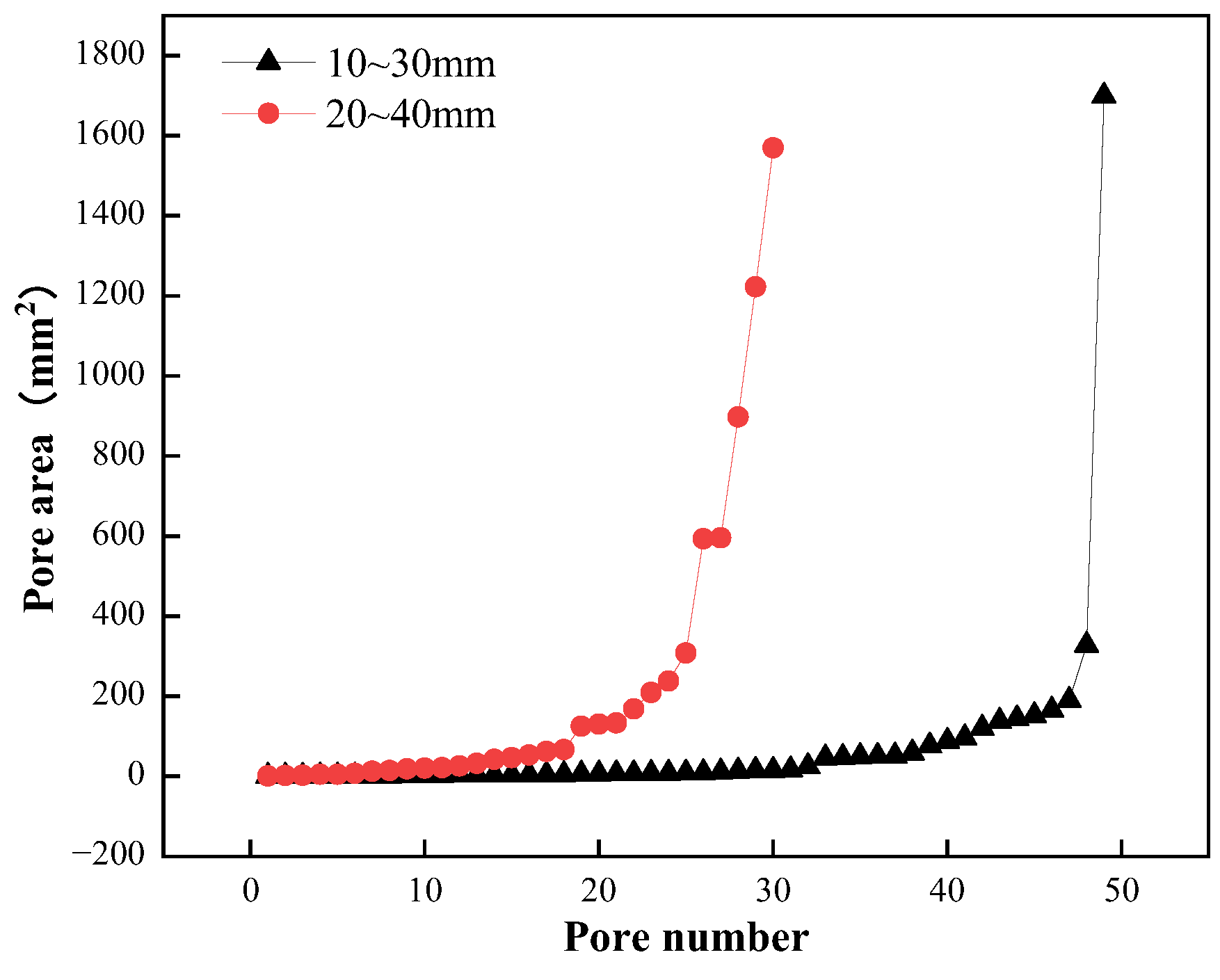

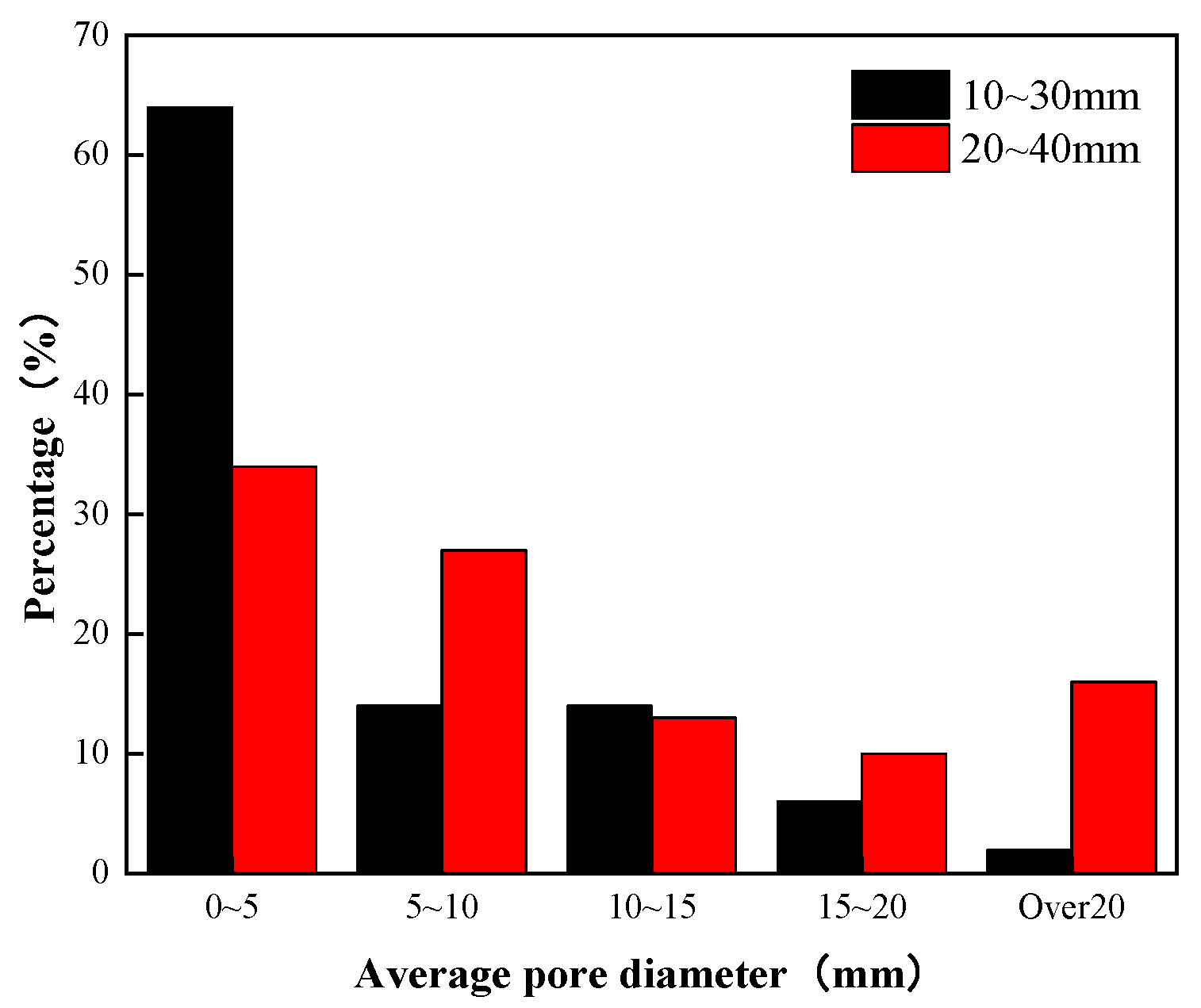

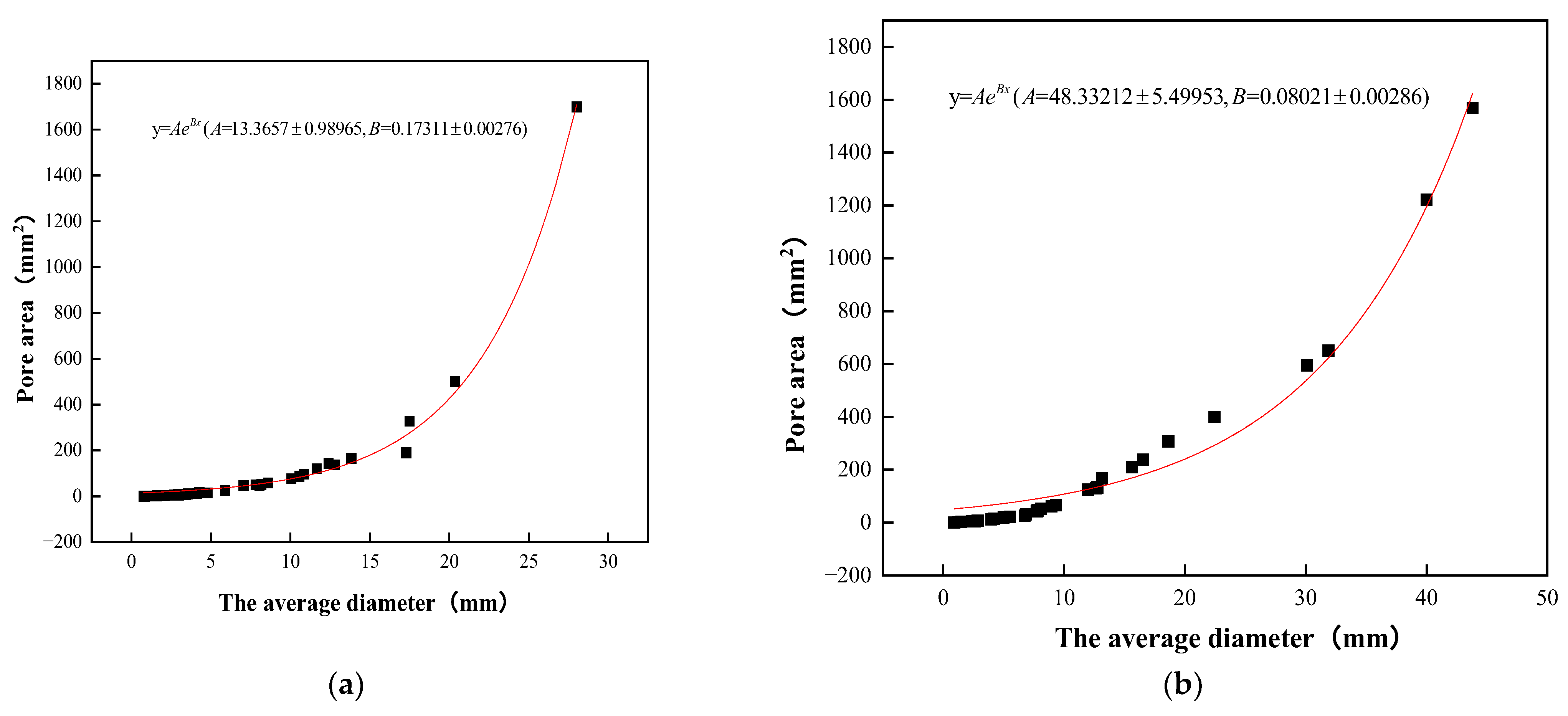

3.2. Characterization of the Pore Structure of Planting Concrete Surfaces

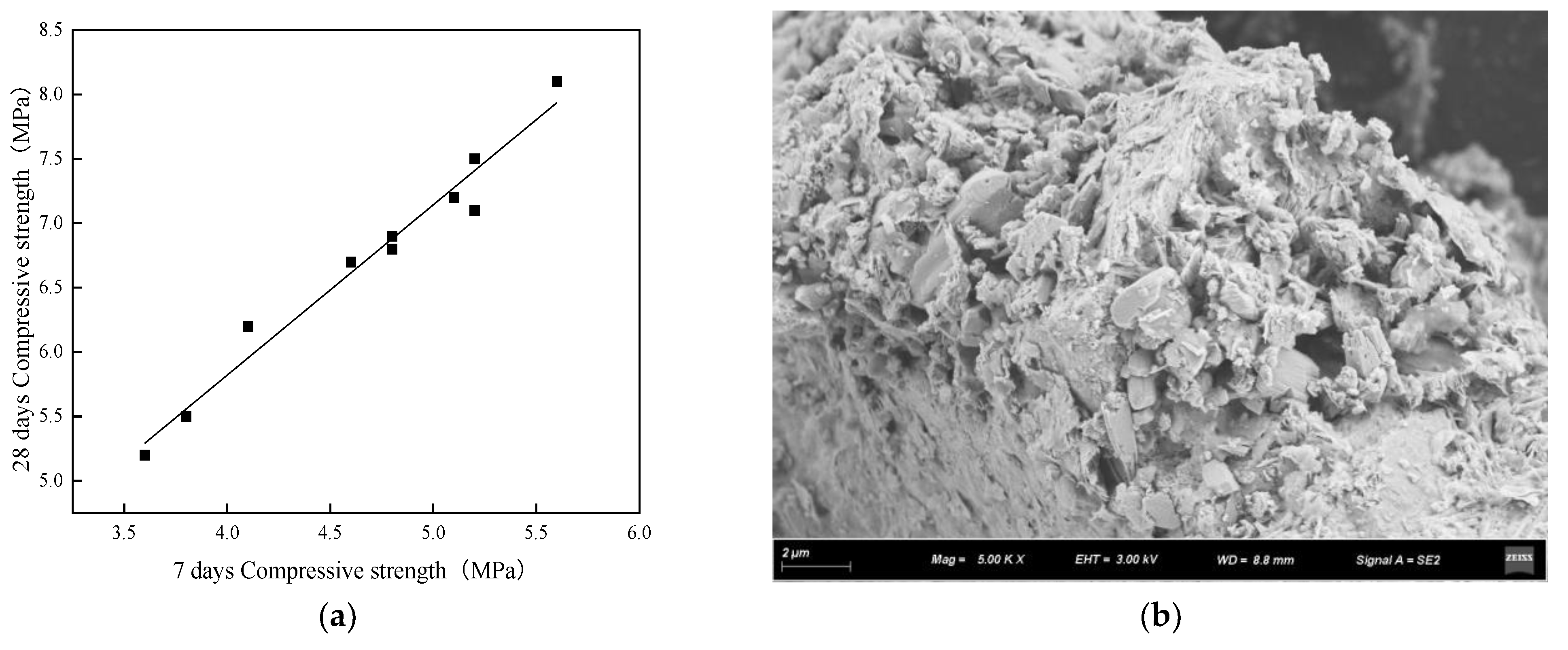

3.3. Effect of Water–Cement Ratio and Porosity on Compressive Strength

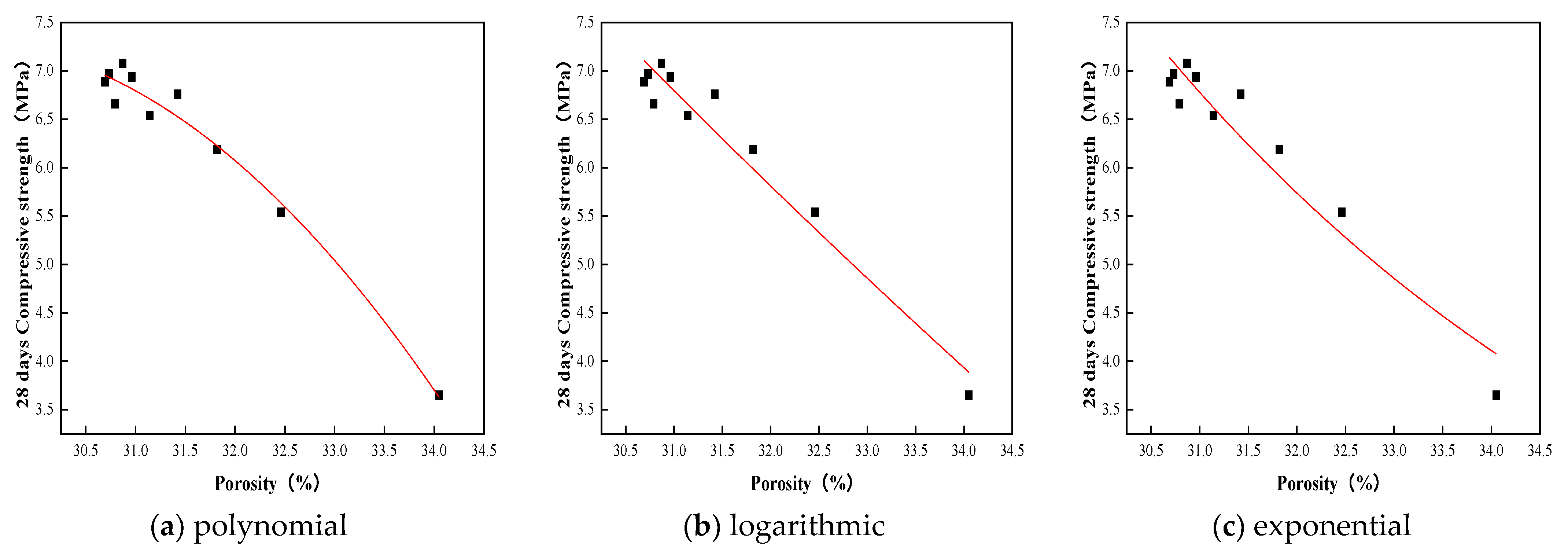

3.4. Relationship between Compressive Strength and Porosity

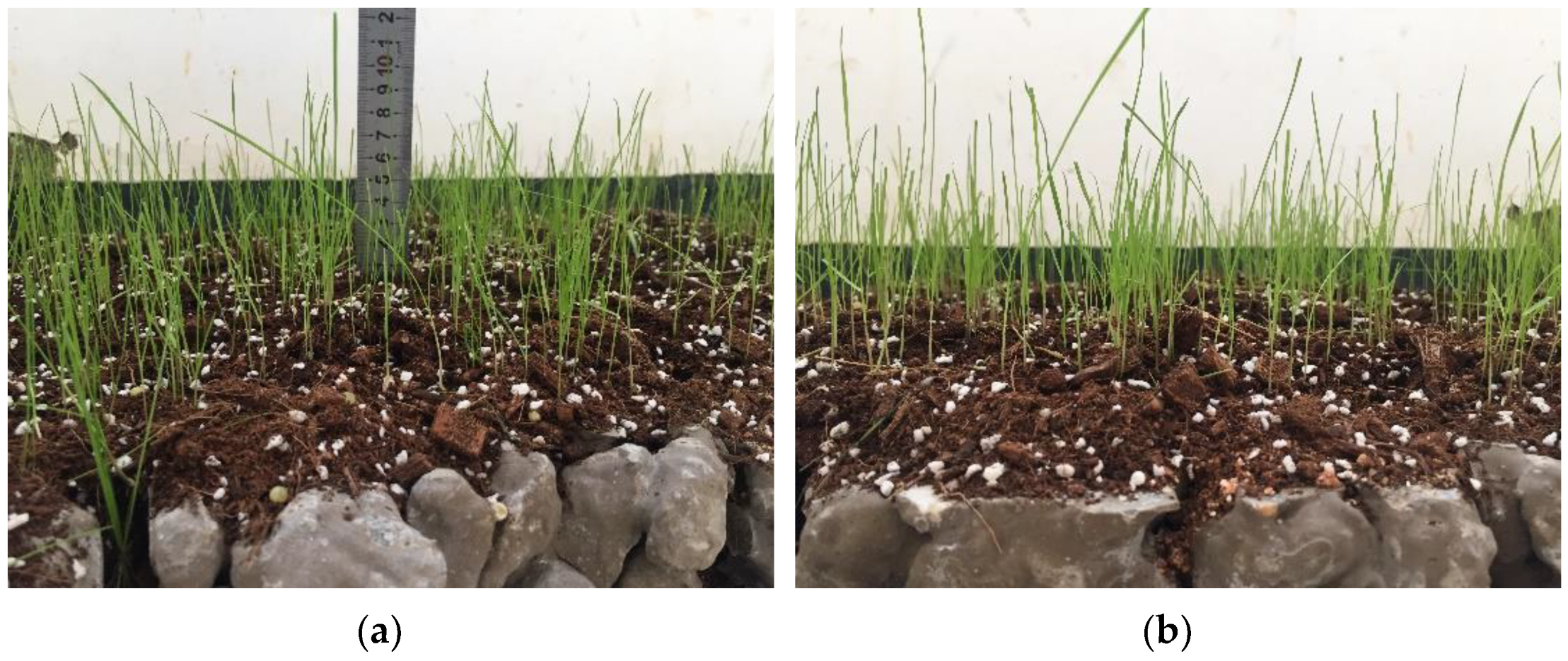

3.5. Planting Experiment

3.6. Biomass and Elemental Content of Plant Leaves and Roots

4. Conclusions

- (1)

- The porosity of planting concrete decreases with increasing water–cement ratio, and the larger the aggregate particle size, the greater the porosity at the same water–cement ratio.

- (2)

- With the same water–cement ratio, the porosity of the planting concrete prepared with 10–30 mm aggregates is lower than that of the planting concrete prepared with 20–40 mm aggregates. The average diameter of the planting concrete shows an exponential relationship with the porosity of the planes; the exponential relationship equation is .

- (3)

- With an aggregate gradation of 10–30 mm, the optimum water–cement ratio should be controlled at 0.31–0.33, when the compressive strength ranges from 6.90 to 7.10 MPa and porosity is 30.8–31.0%. With the aggregate gradation of 20–40 mm, the optimum water–cement ratio should be controlled at 0.28–0.30, at which point the compressive strength ranges from 7.75 to 8.10 MPa and the porosity ranges from 29.8 to 30.5%.

- (4)

- The growth of the compressive strength of the planting concrete is rapid in the early stages, with a linear relationship between the 28-day compressive strength and the 7-day compressive strength: . A fitting analysis of the relationship between compressive strength and porosity of the planting concrete was carried out; the correlation coefficient R2 was calculated, and it was found that the exponential model could better reflect the relationship between compressive strength and porosity of the planting concrete.

- (5)

- Tall fescue can adapt to a degree of acidity and salinity and is a resilient growing plant, suitable for planting on planting concrete. The height of all 10-day plants was around 10 cm, the root system reached 7 cm in length, and the roots were entering the internal pores of the concrete. The roots of the 25-day plants reached a length of 12 cm and were able to puncture a 10 cm thick planting concrete test block.

- (6)

- The effectiveness of planting concrete is influenced not only by its own properties, but also by the way in which the plants are planted and the density at which they are planted. The selection of surface planting methods with a reasonable seed density can achieve excellent planting results. In addition, plant height, cover, number of individuals and root condition around and at the base of the concrete block, leaf rootstock element content, and aboveground and belowground biomass can be used to assess the vegetation performance of the planting concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tamai, M.; Mizuguchi, H.; Hatanaka, S.; Katahira, H.; Nakazawa, T.; Yanagibashi, K.; Kunieda, M. Design, construction and recent applications of porous concrete in Japan. In Proceedings of the JCI Symposium on Design, Construction, and Recent Applications of Porous Concrete, Tokyo, Japan, 10 June 2004; Japan Concrete Institute: Tokyo, Japan, 2004; pp. 1–10. [Google Scholar]

- Zheng, M.; Chen, S.; Wang, B. Mix Design Method for Permeable Base of Porous Concrete. Int. J. Pavement Res. Technol. 2012, 5, 102–107. [Google Scholar]

- Olek, J.; Weiss, W.J.; Neithalath, N.; Marolf, A.; Sell, E.; Thornton, W. Development of Quiet and Durable Porous Portland Cement Concrete Paving Materials; Purdue University: West Lafayette, IN, USA, 2003. [Google Scholar]

- Fujiwara, T.; Meiarashi, S.; Namikawa, Y.; Hasebe, M. Reduction of equivalent continuous A-weighted sound pressure levels by porous elastic road surfaces. Appl. Acoust. 2005, 66, 766–778. [Google Scholar] [CrossRef]

- Mun, S. Sound absorption characteristics of porous asphalt concrete pavements. Can. J. Civ. Eng. 2010, 37, 273–278. [Google Scholar] [CrossRef]

- Faiz, H.; Ng, S.; Rahman, M. A state-of-the-art review on the advancement of sustainable vegetation concrete in slope stability. Constr. Build. Mater. 2022, 326, 126502. [Google Scholar] [CrossRef]

- Wang, F.; Sun, C.; Ding, X.; Kang, T.; Nie, X. Experimental study on the vegetation growing recycled concrete and synergistic effect with plant roots. Materials 2019, 12, 1855. [Google Scholar] [CrossRef] [PubMed]

- Seifeddine, K.; Amziane, S.; Toussaint, E. State of the art on the mechanical properties of pervious concrete. Eur. J. Environ. Civ. Eng. 2021, 1–29. [Google Scholar] [CrossRef]

- Kim, H.-H.; Kim, C.-S.; Jeon, J.-H.; Park, C.-G. Effects on the physical and mechanical properties of porous concrete for plant growth of blast furnace slag, natural jute fiber, and styrene butadiene latex using a dry mixing manufacturing process. Materials 2016, 9, 84. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Bhutta, M.A.R.; Hasanah, N.; Farhayu, N.; Hussin, M.W.; bin Md Tahir, M.; Mirza, J. Properties of porous concrete from waste crushed concrete (recycled aggregate). Constr. Build. Mater. 2013, 47, 1243–1248. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Kizinievic, O.; Sarkauskas, A. The impact of coarse aggregate content on infiltration rate, structure and other physical & mechanical properties of pervious concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 569–582. [Google Scholar]

- Liu, Q.; Su, L.; Xiao, H.; Xu, W.; Yan, W.; Xia, Z. Preparation of shale ceramsite vegetative porous concrete and its performance as a planting medium. Eur. J. Environ. Civ. Eng. 2021, 25, 2111–2126. [Google Scholar] [CrossRef]

- da Costa, F.B.P.; Haselbach, L.M.; da Silva Filho, L.C.P. Pervious concrete for desired porosity: Influence of w/c ratio and a rheology-modifying admixture. Constr. Build. Mater. 2021, 268, 121084. [Google Scholar] [CrossRef]

- Kim, H.-H.; Park, C.-G. Plant growth and water purification of porous vegetation concrete formed of blast furnace slag, natural jute fiber and styrene butadiene latex. Sustainability 2016, 8, 386. [Google Scholar] [CrossRef]

- Bao, X.; Liao, W.; Dong, Z.; Wang, S.; Tang, W. Development of vegetation-pervious concrete in grid beam system for soil slope protection. Materials 2017, 10, 96. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, B.; Yang, Y.; Xu, W.; Ding, Y.; Xia, Z. Effect of organic material type and proportion on the physical and mechanical properties of vegetation-concrete. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Ma, H.; Wu, Z.; Zhang, J.; Yu, H.; Liang, L. Uniaxial compressive properties of ecological concrete: Experimental and three-dimensional (3D) mesoscopic investigation. Constr. Build. Mater. 2021, 278, 121034. [Google Scholar] [CrossRef]

- Wen, F.; Fan, H.; Zhai, S.; Zhang, K.; Liu, F. Pore characteristics analysis and numerical seepage simulation of antifreeze permeable concrete. Constr. Build. Mater. 2020, 255, 119310. [Google Scholar] [CrossRef]

- Hasselman, D.; Fulrath, R. The effect of a small fraction of spherical porosity on the elastic moduli of glass. J. Am. Ceram.Soc. 1964, 47, 52–53. [Google Scholar] [CrossRef]

- Schiller, K. Strength of porous materials. Cem. Concr. Res. 1971, 1, 419–422. [Google Scholar] [CrossRef]

- Ryshkewitch, E. Compression strength of porous sintered alumina and zirconia: 9th communication to ceramography. J. Am. Ceram. Soc. 1953, 36, 65–68. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Hatanaka, S.; Chareerat, T.; Mishima, N.; Yuasa, Y. Cement paste characteristics and porous concrete properties. Constr. Build. Mater. 2008, 22, 894–901. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Hatanaka, S.; Mishima, N.; Yuasa, Y.; Chareerat, T. Effects of binder strength and aggregate size on the compressive strength and void ratio of porous concrete. Int. J. Miner. Metall. Mater. 2009, 16, 714–719. [Google Scholar]

- Fairey, N.; Lefkovitch, L. Crop density and seed production of tall fescue (Festuca arundinacea Schreber). 1. Yield and plant development. Can. J. Plant Sci. 1999, 79, 535–541. [Google Scholar] [CrossRef]

- Khan, S.; Anwar, S.; Kuai, J.; Ullah, S.; Fahad, S.; Zhou, G. Optimization of nitrogen rate and planting density for improving yield, nitrogen use efficiency, and lodging resistance in oilseed rape. Front. Plant Sci. 2017, 8, 532. [Google Scholar] [CrossRef]

- Jia, Q.; Xu, Y.; Ali, S.; Sun, L.; Ding, R.; Ren, X.; Zhang, P.; Jia, Z. Strategies of supplemental irrigation and modified planting densities to improve the root growth and lodging resistance of maize (Zea mays L.) under the ridge-furrow rainfall harvesting system. Field Crops Res. 2018, 224, 48–59. [Google Scholar] [CrossRef]

| Cement Type | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | L.O.I |

|---|---|---|---|---|---|---|---|

| P O 42.5 | 65.52 | 22.45 | 4.49 | 4.13 | 1.47 | 0.94 | 1.09 |

| Cement Type | Specific Surface Area (m2 kg−1) | Density (g cm−3) | Water Consumption at Standard Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | 1 Day | 7 Days | 1 Day | 7 Days | ||||

| P O 42.5 | 368 | 3.1 | 25 | 185 | 240 | 9.6 | 34.5 | 1.9 | 6.1 |

| Particle Size (mm) | Surface Density (kg m−3) | Tight Packing Density (kg m−3) | Tight Packing Porosity (%) | Water Content (%) | Water Absorption (%) | Crushing Indicators(%) |

|---|---|---|---|---|---|---|

| 10–30 | 2710 | 1520 | 44.3 | 1.5 | 0.35 | 11.0 |

| 20–40 | 2690 | 1565 | 41.8 | 3.1 | 0.92 | 13.7 |

| Type | Equation | R2 |

|---|---|---|

| Polynomial | y = A+ B1x + B2x2 | 0.92 |

| Logarithmic function | y = Aln(x) + B | 0.94 |

| Exponential function | y = AeBx | 0.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Du, W.; Zhao, G.; Shi, M.; Xue, B. Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete. Materials 2022, 15, 6685. https://doi.org/10.3390/ma15196685

Chen J, Du W, Zhao G, Shi M, Xue B. Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete. Materials. 2022; 15(19):6685. https://doi.org/10.3390/ma15196685

Chicago/Turabian StyleChen, Jianguo, Weilian Du, Guanqi Zhao, Mingsheng Shi, and Binghan Xue. 2022. "Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete" Materials 15, no. 19: 6685. https://doi.org/10.3390/ma15196685

APA StyleChen, J., Du, W., Zhao, G., Shi, M., & Xue, B. (2022). Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete. Materials, 15(19), 6685. https://doi.org/10.3390/ma15196685