Study on the Surface Layer Properties and Fatigue Life of a Workpiece Machined by Centrifugal Shot Peening and Burnishing

Abstract

1. Introduction

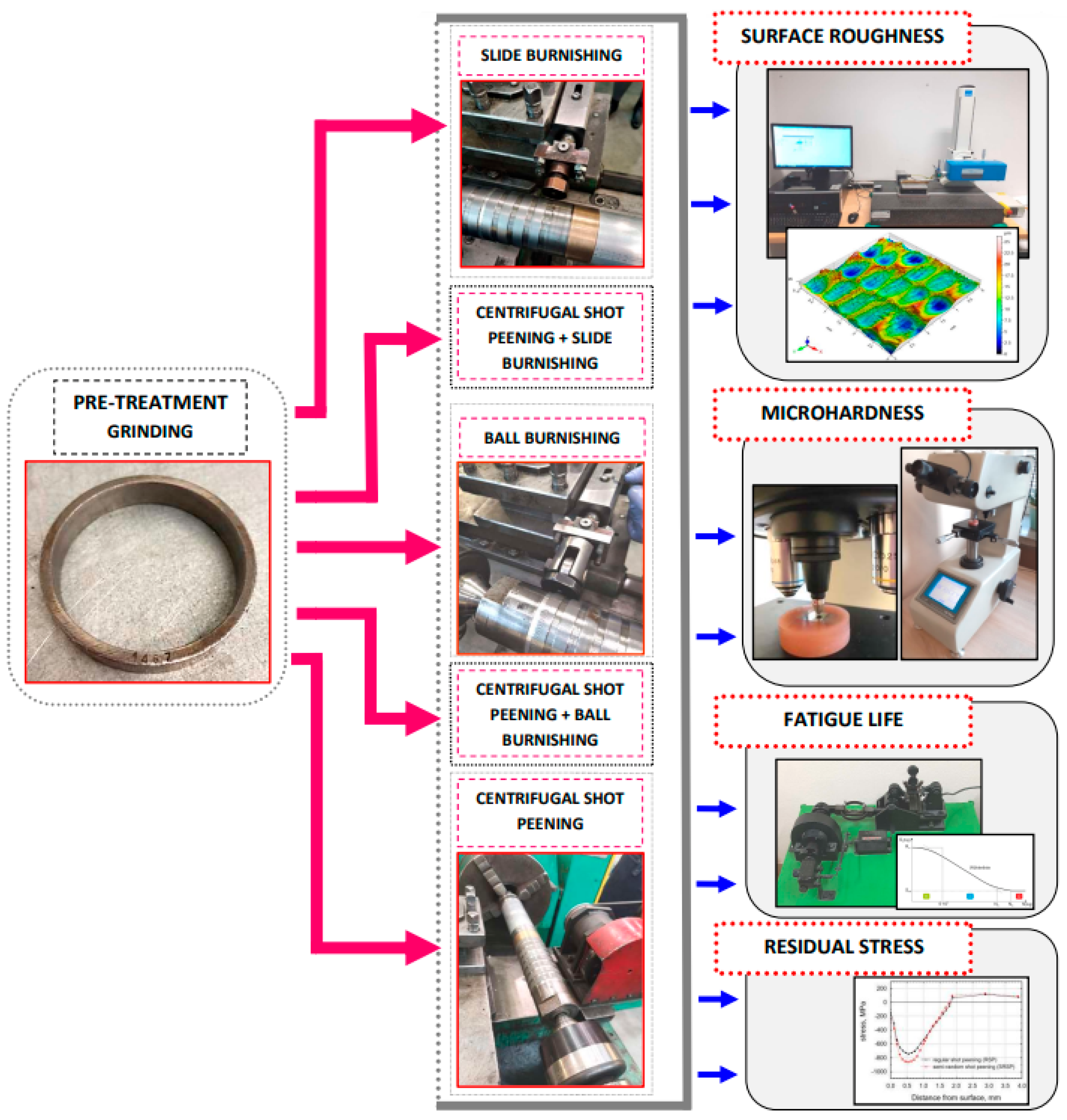

2. Materials and Methods

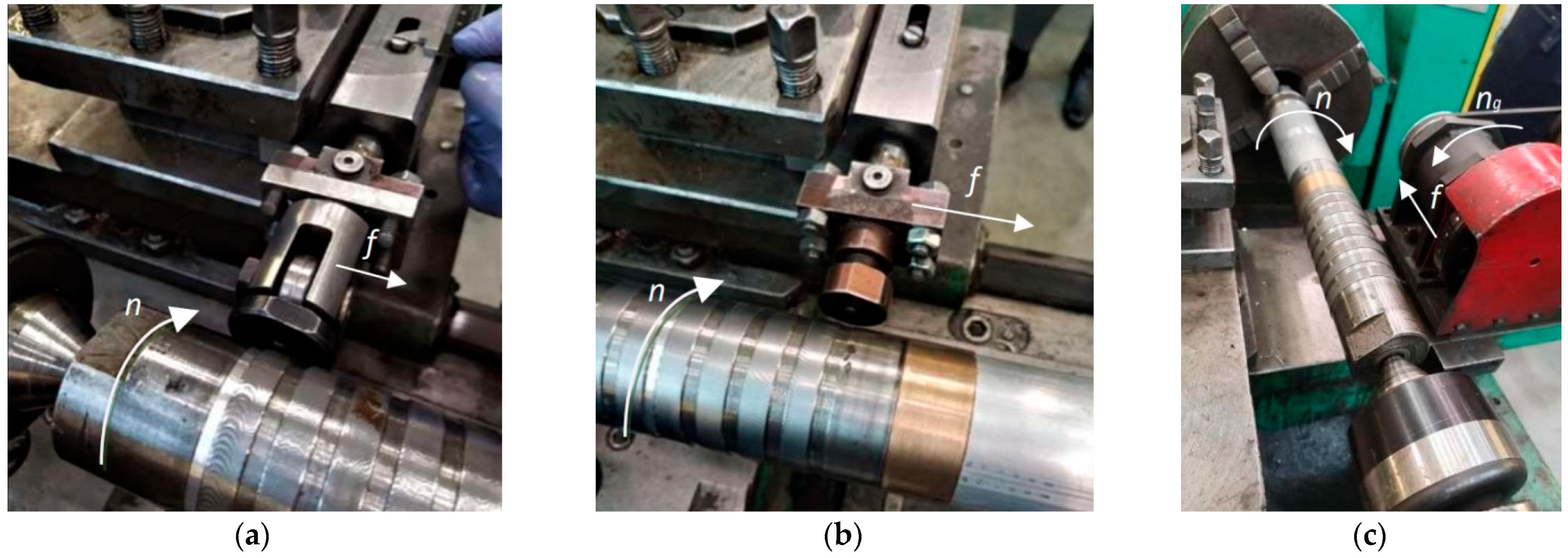

- (a)

- slide burnishing (SB),

- (b)

- ball burnishing (BB),

- (c)

- centrifugal shot peening (CSP),

- (d)

- centrifugal shot peening + slide burnishing (CSP + SB),

- (e)

- centrifugal shot peening + ball burnishing (CSP + BB).

- -

- burnishing force F = 300 N,

- -

- ball burnishing feed f = 0.1 mm/rev.,

- -

- burnishing speed vn = 0.53 m/s.

- -

- slide burnishing force F = 125 N,

- -

- slide burnishing feed f = 0.05 mm/rev.,

- -

- slide burnishing speed vn = 0.53 m/s.

- -

- tangential speed of centrifugal shot peening head vg = 25.4 m/s

- -

- tangential speed workpiece v = 0.18 m/s

- -

- centrifugal shot peening feed f = 0.15 mm/rev.

- -

- infeed g = 0.30 mm.

3. Results and Discussion

3.1. Surface Topography

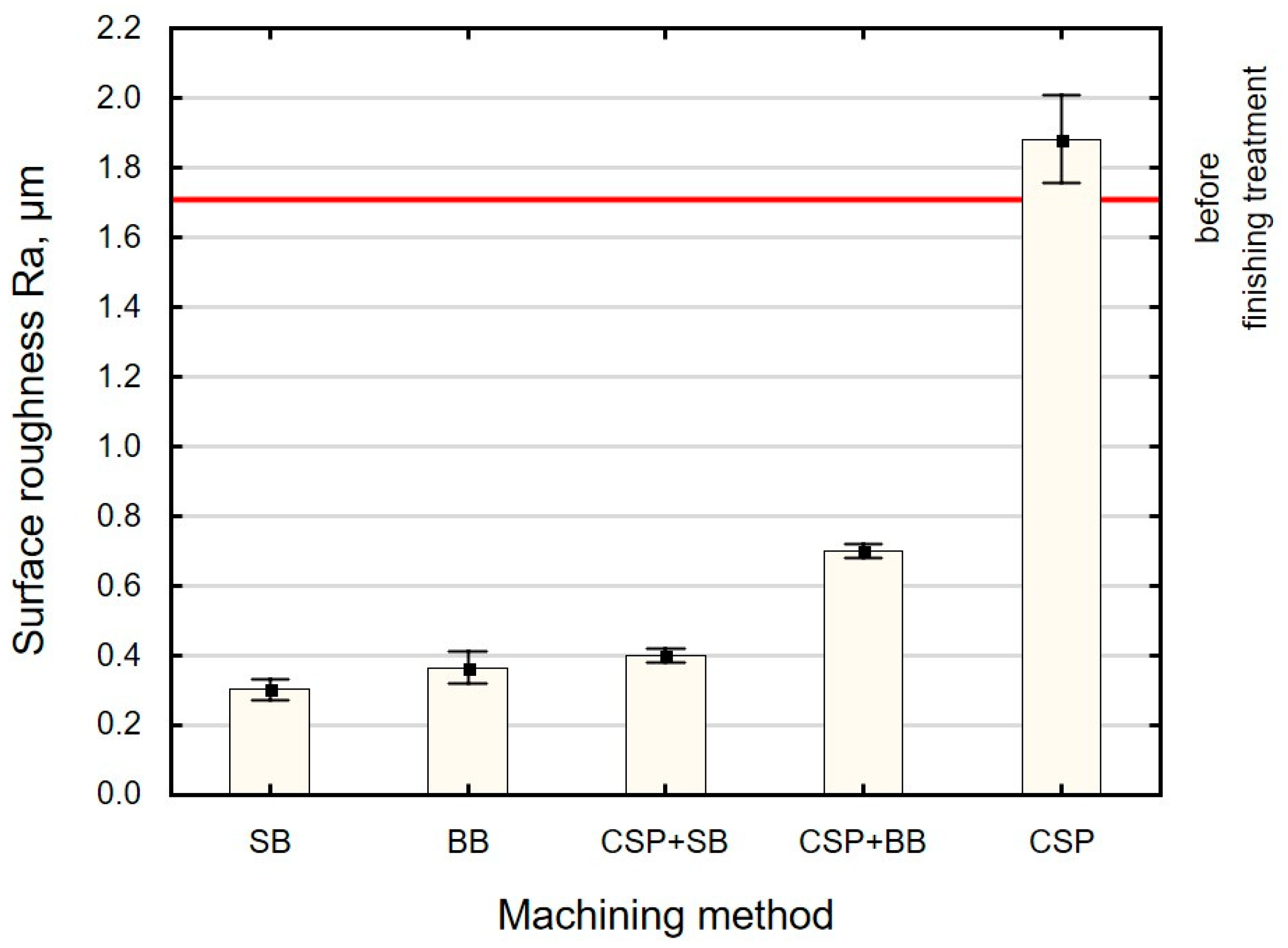

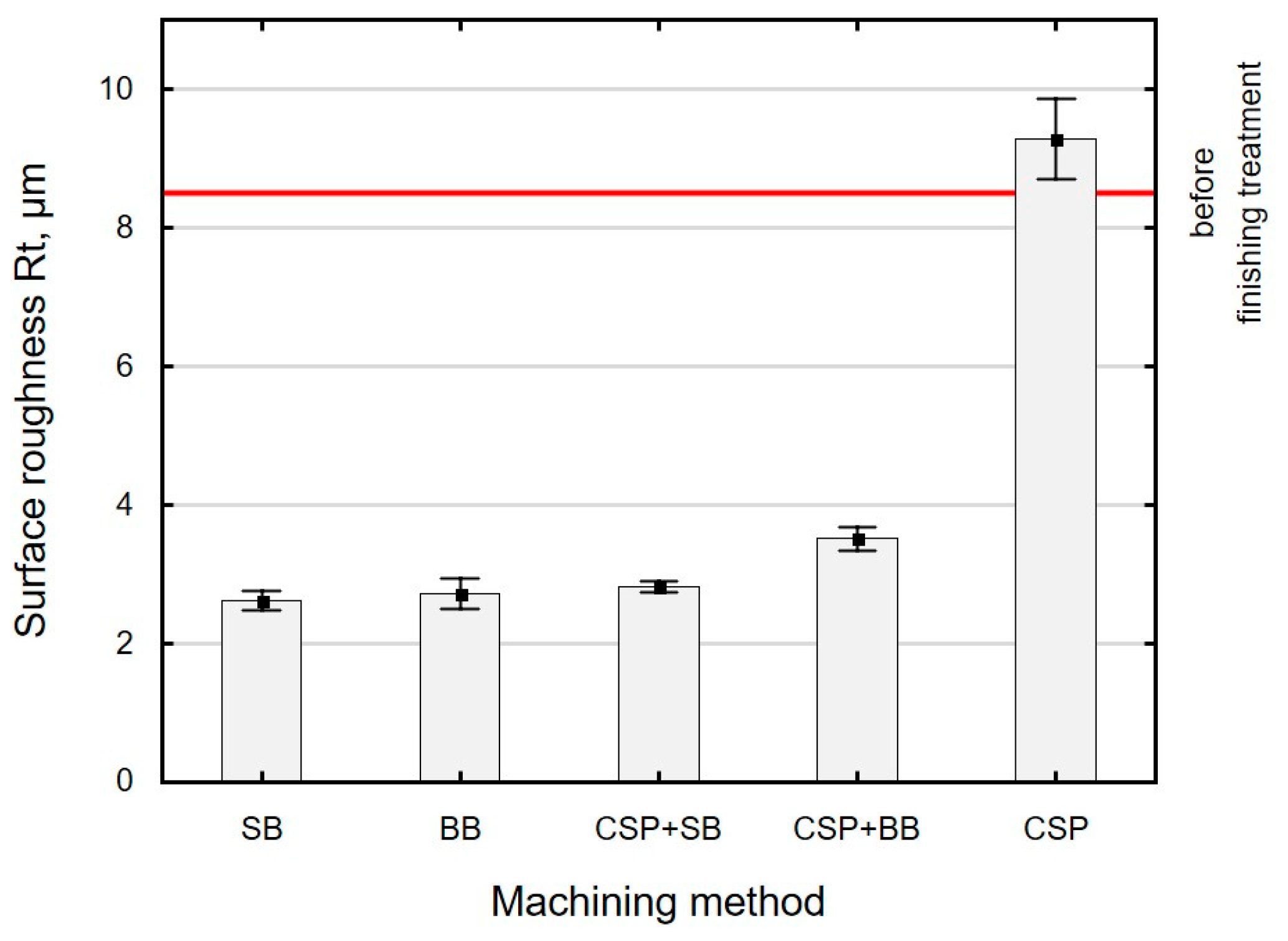

3.2. Surface Roughness

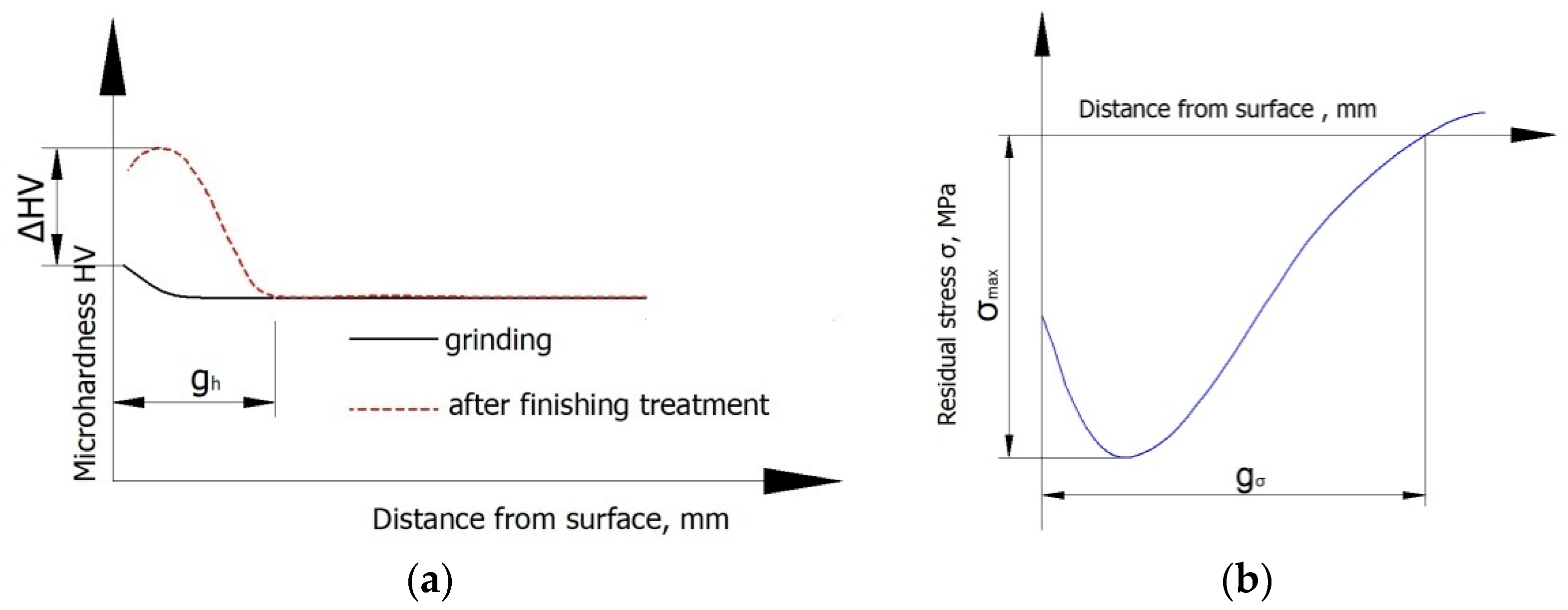

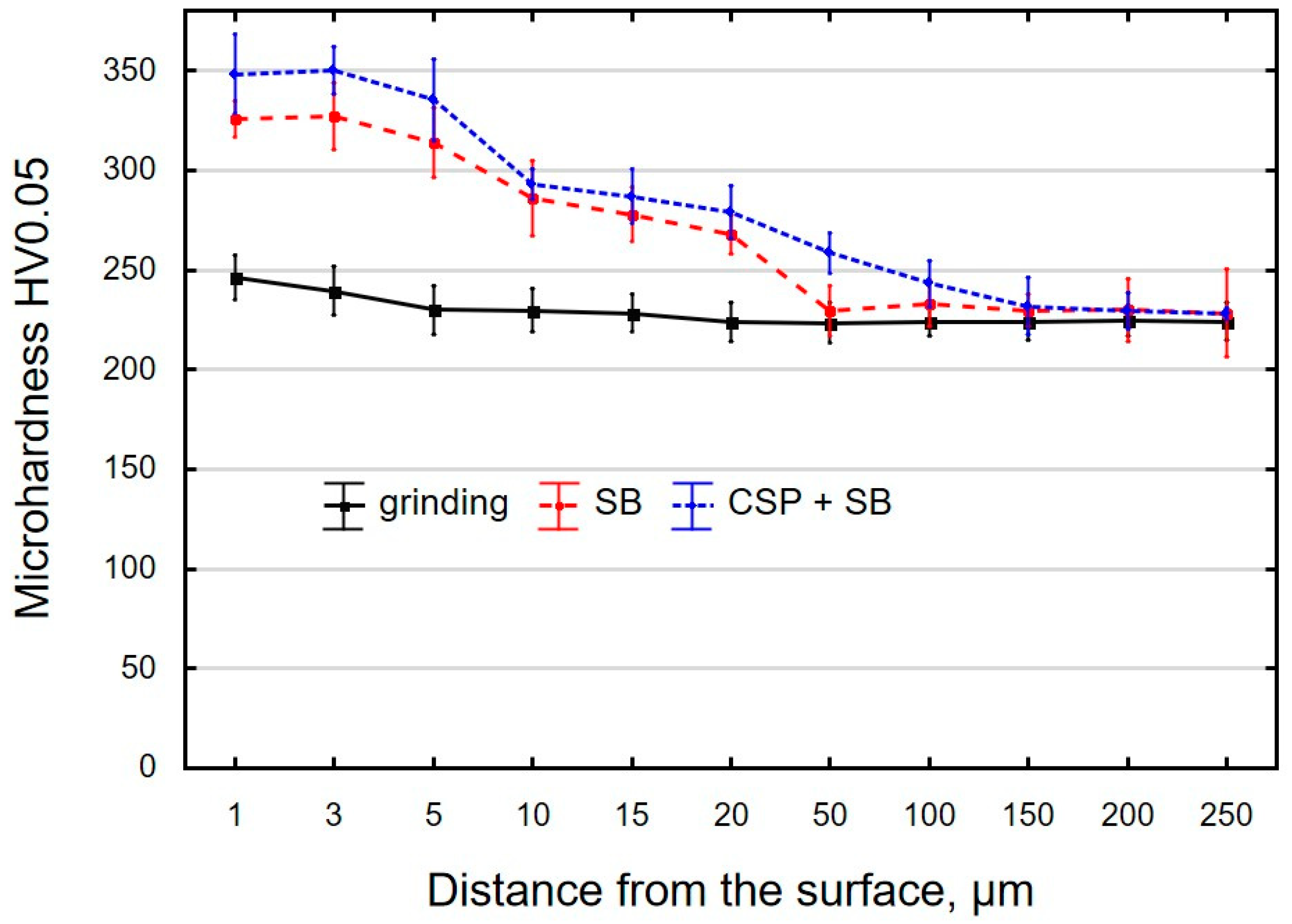

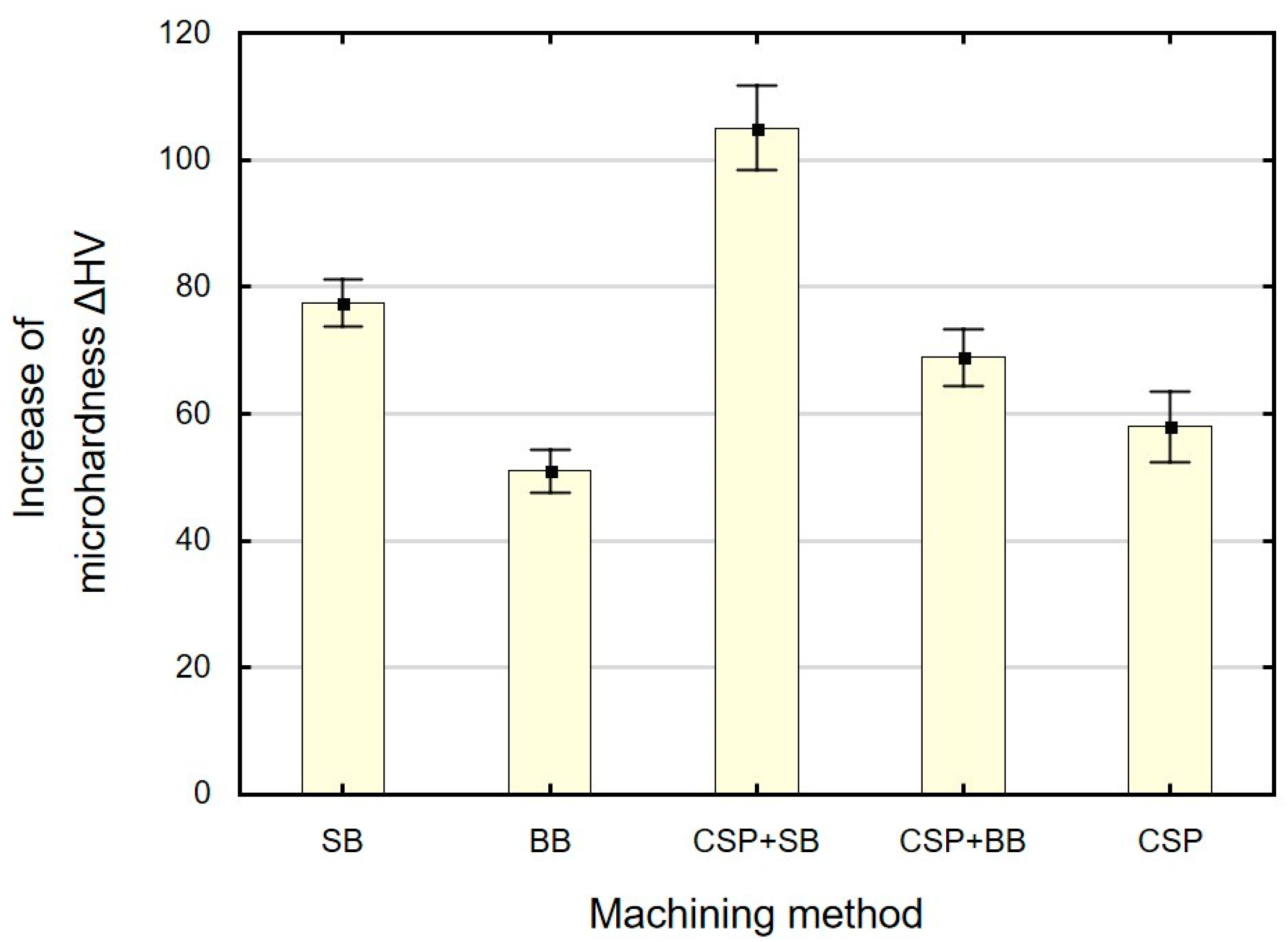

3.3. Microhardness

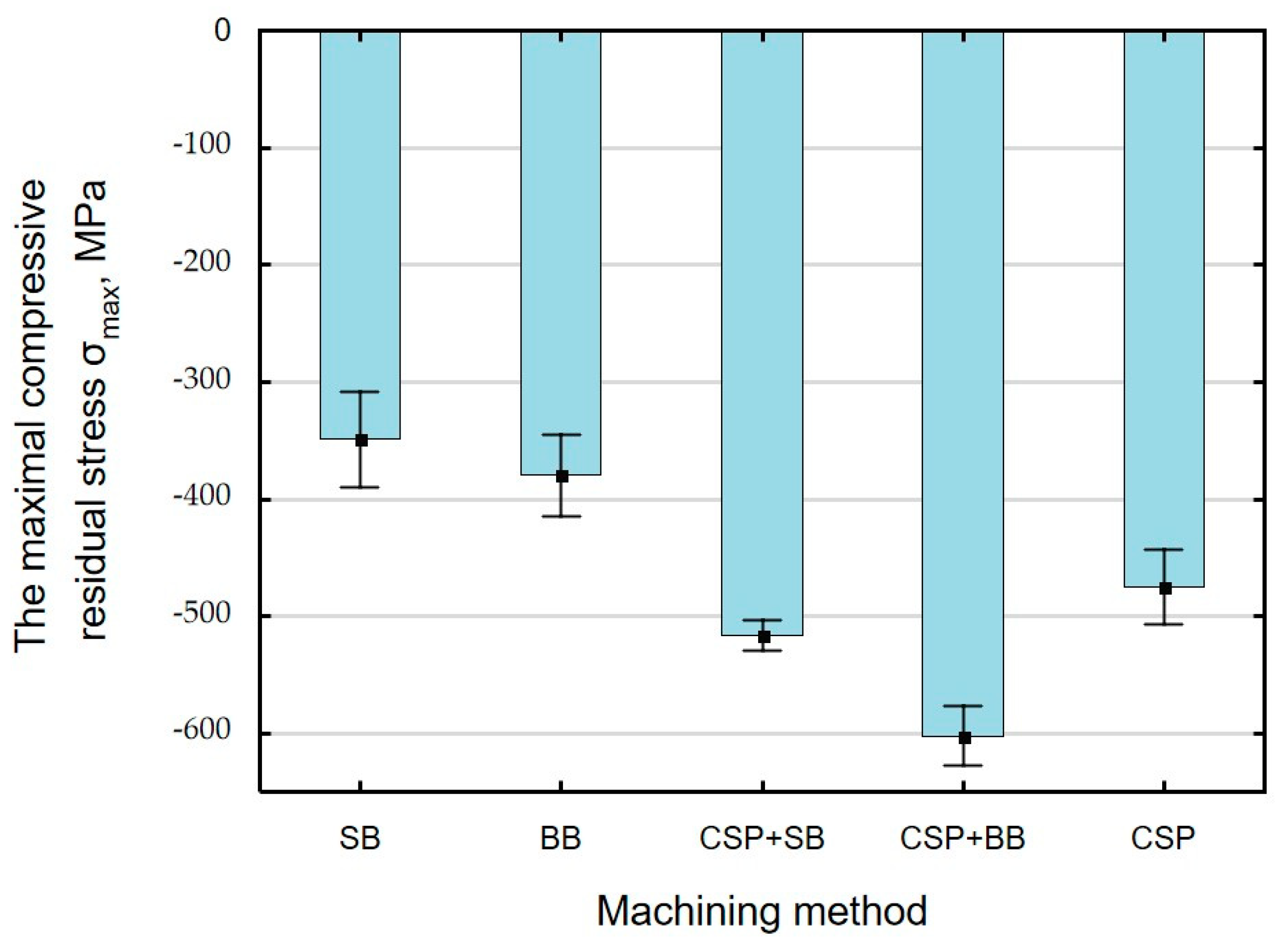

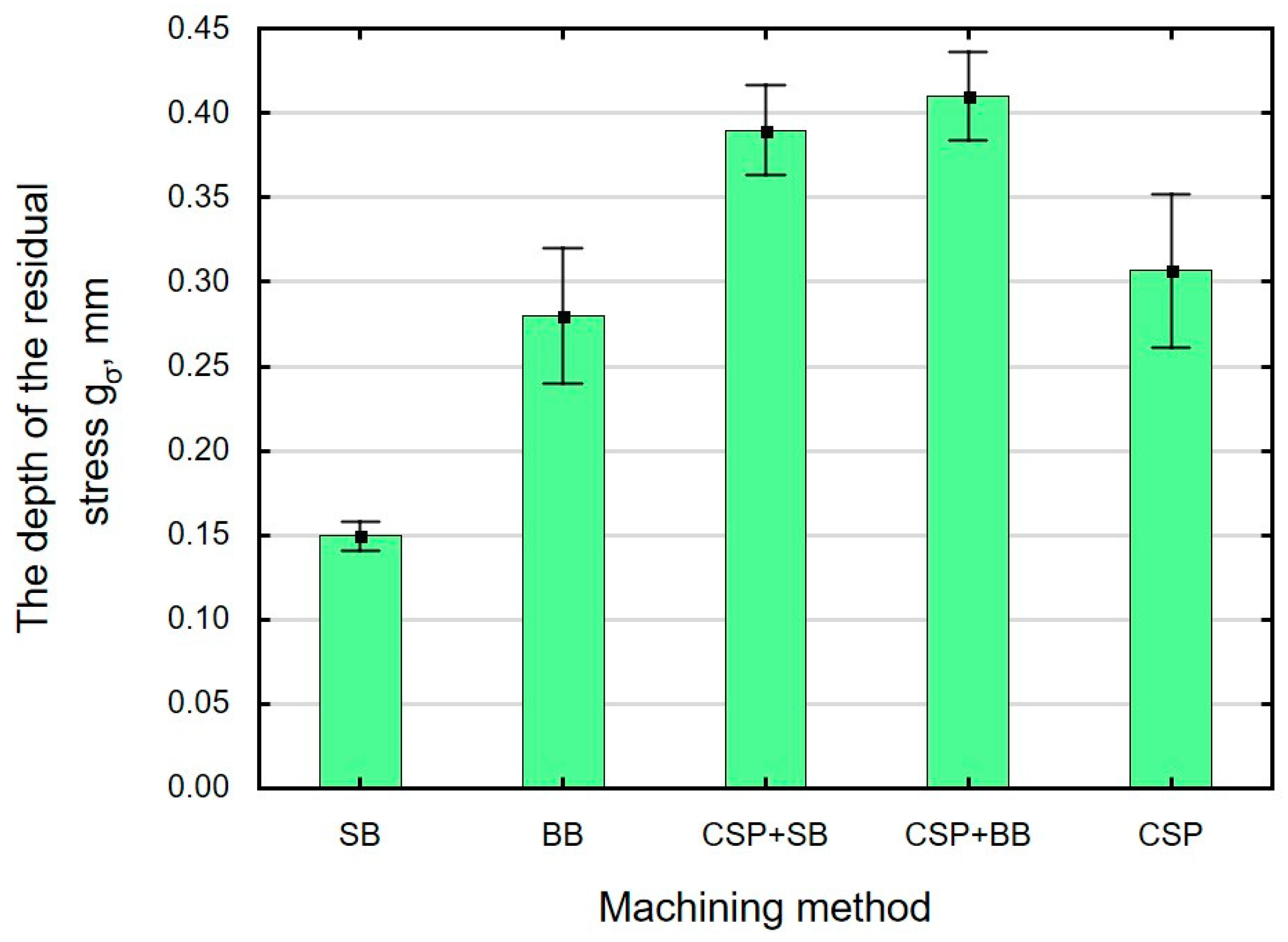

3.4. Residual Stress

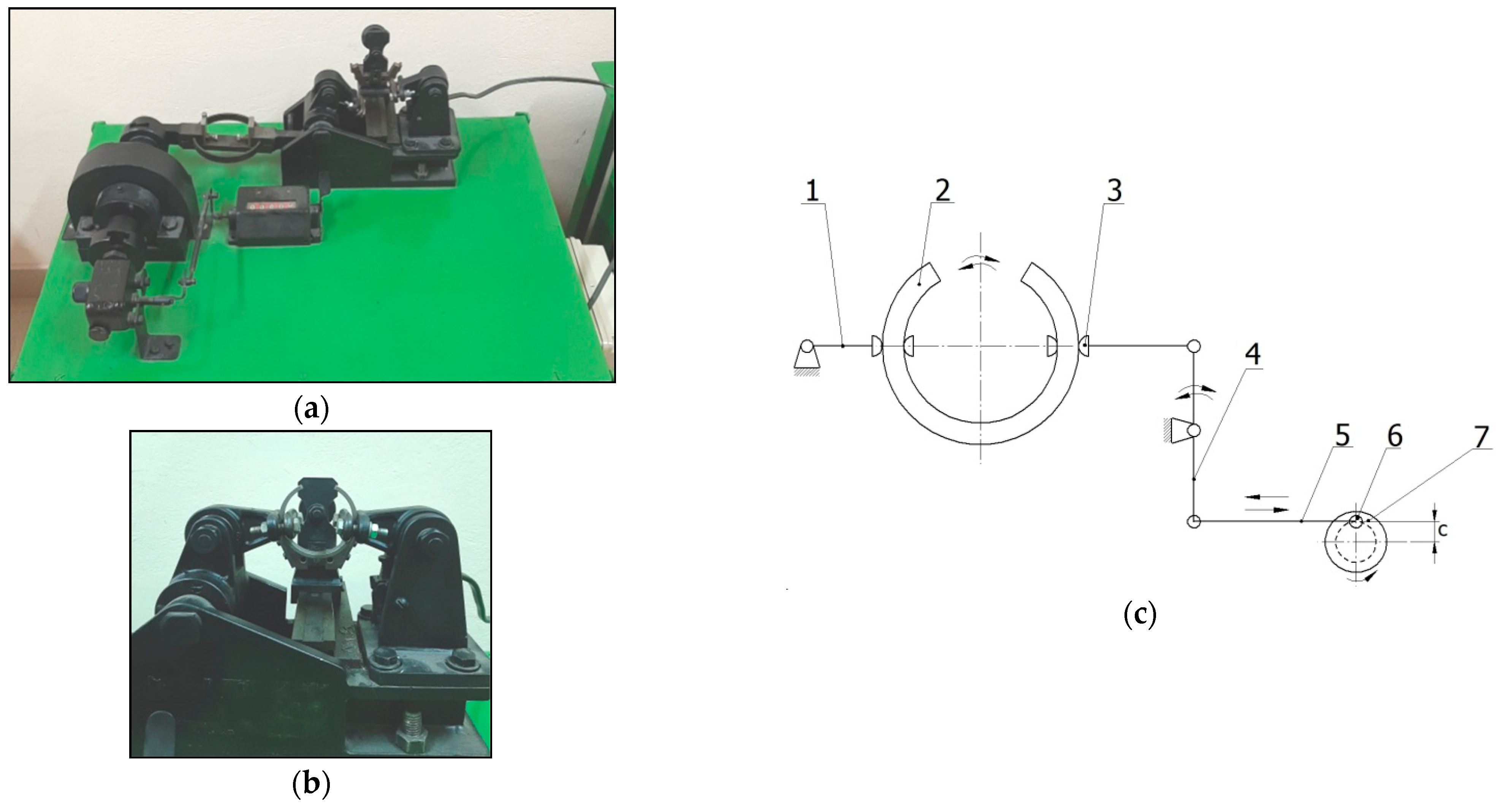

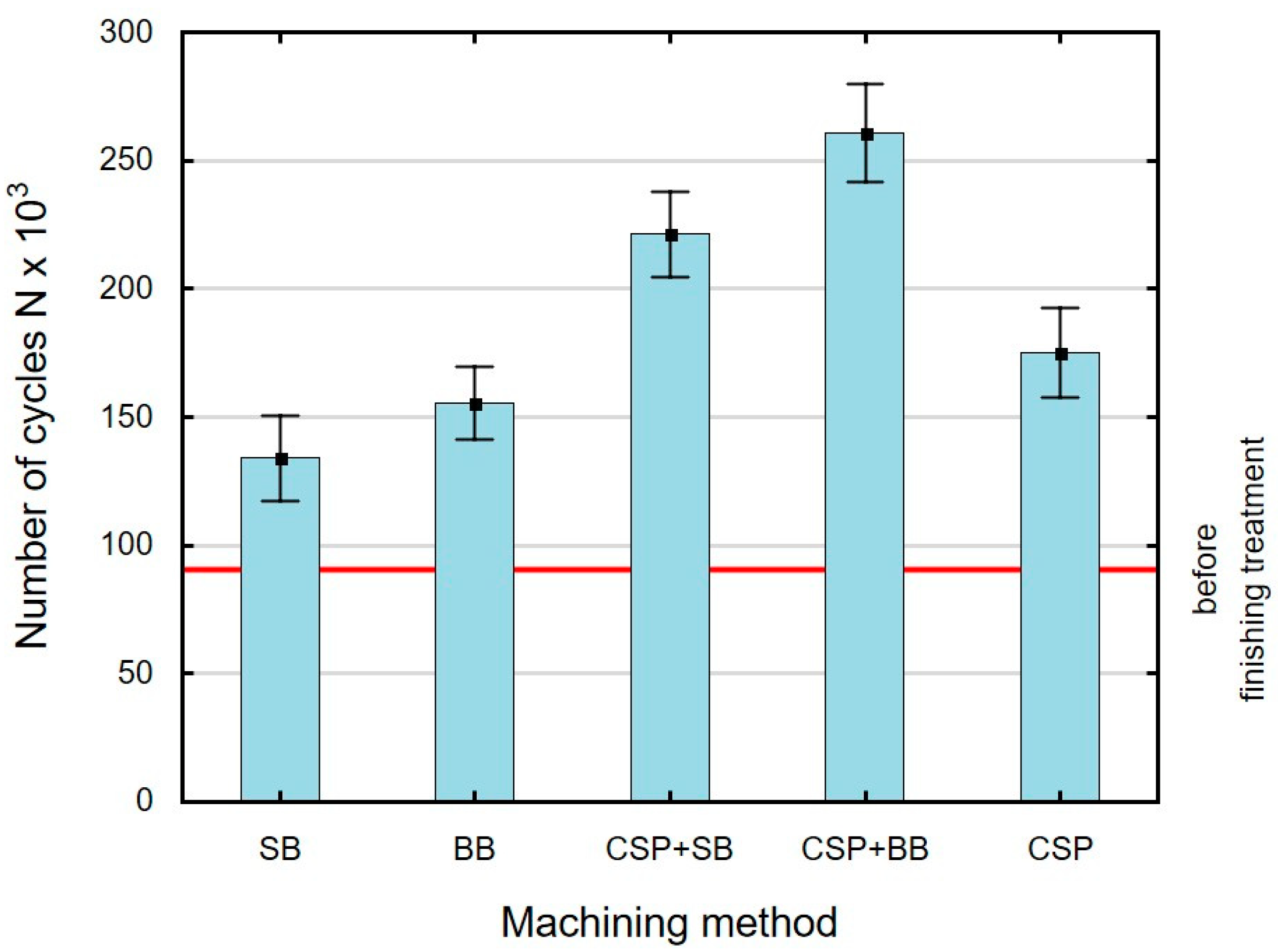

3.5. Fatigue Life

4. Summary

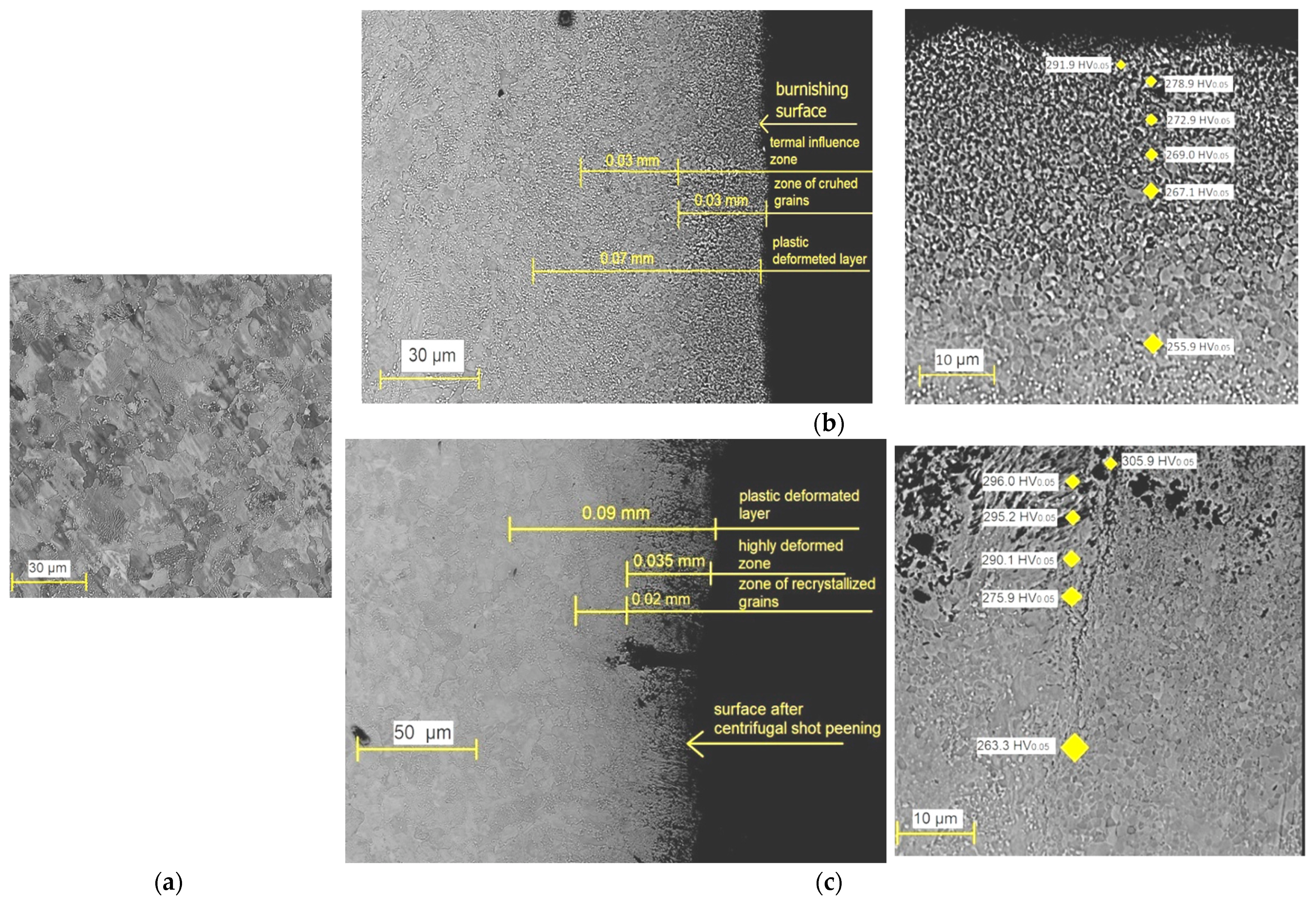

- Depending on the finishing method, the geometrical structure of the surface changed after grinding. After pre-treatment, the surface was deformed in a plastic way. One can observe the flattening of the peaks of surface irregularities after BB and SB and the formation of dimples on the surface after CSP.

- The analyzed surface roughness parameters (Ra, Rt, Rpk, Rk and Rvk) decreased after finishing compared to their reference values (after grinding). These changes range from 59% to 83% depending on the surface roughness parameter and the technique used. The exception is CSP. After CSP, the parameters Ra, Rt, Rk and Rpk are greater than after grinding.

- An unfavorable effect of the applied treatments is the reduction in the roughness parameter Rvk. This may mean that the treated surface will have lower lubricant retention.

- The use of SB or BB after CSP reduces the roughness parameters by a maximum of 82% in relation to their values after CSP.

- After burnishing and shot peening, the microhardness of the surface layer and the depth of the hardened layer increased. The maximum increase in the microhardness ΔHV was obtained after CSP + SB. However, the greatest thickness of the hardened layer was obtained after CSP + BB. Use of an additional finishing treatment after CSP causes a greater increase in microhardness and increased thickness gh.

- Compressive residual stresses are formed in the surface layer as a result of finishing, the depth of which gσ depends on the finishing method. A combination of CSP with BB or SB causes an increase in the maximum value of residual stresses and depth gσ in relation to their values after CSP.

- In relation to the reference samples, the fatigue life of the samples after finishing increased from 48% to 123%. Application of an additional operation after CSP increased the fatigue life from 27% to 49%.

- The ANOVA analysis of variance and the post-hoc test results show that the finishing techniques have a significant influence on the analyzed variables (roughness parameters Ra, Rpk, values of ΔHV, gh, σmax and gσ). It should be noted that the significance of the impact was observed for most of the same cases. This may prove the existence of a correlation between the obtained values.

- An analysis of the significance of impact showed that application of additional SB or BB after CSP significantly affected the dependent variables.

- The favorable values of the analyzed properties of the surface layer and the increase in fatigue life confirm the validity of using CSP + SB and CSP + BB as finishing treatments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BB | ball burnishing |

| CSP | centrifugal shot peening |

| CSP + BB | centrifugal shot peening + ball burnishing |

| CSP + SB | centrifugal shot peening + slide burnishing |

| gh | hardened layer thickness |

| gσ | the depth of incidence of the compressive stresses |

| Ra | arithmetic average of profile height deviations from the mean line |

| Rk | core roughness |

| Rpk | reduced peak height |

| Rt | total height of the profile |

| Rvk | reduced valley depth |

| SB | slide burnishing |

| ΔHV | microhardness increase |

| σmax | absolute maximum compressive residual stresses |

References

- Astaraee, A.H.; Bagherifard, S.; Bradanini, A.; Duo, P.; Henze, S.; Talyor, B.; Guagliano, M. Applcation of shot peening to case—Hardened gears: The effect of gradient material properties and component geometry. Surf. Coat. Technol. 2020, 398, 126084. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, C.; Tan, L.; Cui, M.; Lin, Z.; Han, W.; Min, X. Shot peening parameters optimization based on residual stress—Induced deformation of large fan blades. Thin-Walled Struct. 2021, 161, 107467. [Google Scholar] [CrossRef]

- Sahoo, B.; Satpathy, R.K.; Prasad, K.; Ahmed, S.; Kumar, V. Effect of shot peening on low cycle fatigue life of compressor disc of typical fighter class aero—Engine. Procedia Eng. 2013, 55, 144–148. [Google Scholar] [CrossRef]

- Ongtrakulkij, G.; Khantachawana, A.; Kajornchaiyakul, J.; Kondoh, K. Effects of the secondary shot in the double shot peening process on the residual compressive stress distribution of Ti-6Al-4V. Heliyon 2022, 8, e08758. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wei, P.; Liu, H.; Zhang, B.; Tao, G. Effect of shot peening intensity on surface integrity of 18CrNiMo7-6 steel. Surf. Coat. Technol. 2021, 421, 127194. [Google Scholar] [CrossRef]

- Jiang, X.P.; Man, C.-S.; Shepard, M.J.; Zhai, T. Effects of shot-peening and re-shot peening on four-point bend fatigue behavior of Ti-6Al-4V. Mater. Sci. Eng. A 2007, 468–470, 137–143. [Google Scholar] [CrossRef]

- Aguado-Montero, S.; Vazquez, J.; Navarro, C.; Dominguez, J. Optimal shot peening residual stress profile for fatigue. Theor. Appl. Fract. Mech. 2021, 116, 103109. [Google Scholar] [CrossRef]

- Leguinagoicoa, N.; Albizuri, J.; Larranaga, A. Fatigue improvement and residual stress relaxation of shot-peened alloy steel DIN 34CrNiMo6 under axial loading. Int. J. Fatigue 2022, 162, 107006. [Google Scholar] [CrossRef]

- Huang, Z.-C.; Zhou, Z.-J.; Jiang, Y.-Q. Effect of shot peening on static and fatigue properties of self—Piercing riveting joints. J. Mater. Res. Technol. 2022, 18, 1070–1080. [Google Scholar] [CrossRef]

- Zaleski, K. The effect of vibratory and rotational shot peening and wear on fatigue life of steel. Eksploat. I Niezawodn.-Maint. Reliab. 2017, 19, 102–107. [Google Scholar] [CrossRef]

- Walczak, M.; Szala, M. Effect of shot peening on the Surface properties, corrosion and wear performance of 17-4PH steel produced by DMLS additive manufacturing. Arch. Civ. Mech. Eng. 2021, 21, 157. [Google Scholar] [CrossRef]

- Menezes, M.R.; Godoy, C.; Buono, V.T.L.; Schwartzman, M.M.M.; Wilson, J.C.A.-B. Effect of shot peening and treatment temperature on wear and corrosion resistance of sequentially plasma treated AISI 316L steel. Surf. Coat. Technol. 2017, 309, 651–662. [Google Scholar]

- Vantadori, S.; Valeo, J.V.; Zanichelli, A. Fretting fatigue and shot peening: A multiaxial fatigue criterion including residual stress relaxation. Tribol. Int. 2020, 151, 106357. [Google Scholar] [CrossRef]

- Matuszak, J.; Zaleski, K.; Skoczylas, A.; Ciecieląg, K.; Kęcik, K. Influence of semi—Random and regular shot peening on selected surface layer properties of aluminum alloy. Materials 2021, 14, 7620. [Google Scholar] [CrossRef]

- Hu, D.; Gao, Y.; Meng, F.; Song, J.; Wang, Y.; Ren, M.; Wang, R. A unifying approach in simulating the shot peening process using a 3D random representative volume finite element model. Chin. J. Aeronaut. 2017, 30, 1592–1602. [Google Scholar] [CrossRef]

- Harada, Y.; Fukaura, K.; Haga, S. Influence of micro-shot peening on surface layer characteristics of structural steel. J. Mater. Process. Technol. 2007, 191, 297–301. [Google Scholar] [CrossRef]

- Pron, H.; Henry, J.-F.; Flan, B.; Lu, J.; Offermann, S.; Beaudoin, J.L. Estimation of residual stresses induced by shot-peening. Measurement of the thermal dissipation with an infrared camera. Int. J. Therm. Sci. 2022, 41, 369–375. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K. Effect of centrifugal shot peening on surface properties of laser-cut C45 steel parts. Materials 2019, 12, 3635. [Google Scholar] [CrossRef] [PubMed]

- Zaleski, K.; Skoczylas, A.; Ciecieląg, K. The investigations of the surface layer properties of C45 steel after plasma cutting and certifugal shot peening. In Industrial Measurements in Machining, Lecture Notes in Mechanical Engineerig; Królczyk, G.M., Niesłony, P., Królczyk, J., Eds.; Springer: Cham, Switzerland, 2020; pp. 172–185. [Google Scholar]

- Skoczylas, A. Influence of centrifugal shot peening parameters on the impact force and surface roughness of EN-AW 2024 aluminum alloys elements. Adv. Sci. Technol. Res. J. 2021, 15, 71–78. [Google Scholar] [CrossRef]

- Nadolny, K.; Plichta, J.; Radowski, M. Reciprocal internal cylindrical grinding integrated with dynamic centrifugal burnishing of hard-to-cut materials. Proceed. Inst. Mech. Eng. Part. EJ. Process. Mech. Eng. 2015, 229, 265–279. [Google Scholar] [CrossRef]

- Kulisz, M.; Zagórski, I.; Matuszak, J.; Kłonica, M. Properties of the surface layer after trochoidal milling and brushing: Experimental and artificial neural network simulation. Appl. Sci. 2020, 10, 75. [Google Scholar] [CrossRef]

- Matuszak, J.; Zaleski, K. Edge states after wire brushing of magnesium alloys. Aircr. Eng. Aerosp. Technol. 2014, 86, 328–335. [Google Scholar] [CrossRef]

- Rinaldi, S.; Rotella, G.; Umbrello, D. Experimental and numerical analysis of roller burnishing of Waspaloy. Procedia Manuf. 2019, 34, 65–72. [Google Scholar] [CrossRef]

- Barahate, V.; Govande, A.R.; Tivari, G.; Sunil, B.R.; Dumpala, R. Parameter optimization during single roller burnishing of AA 6061-T6 alloy by design of experiments. Mater. Today Proc. 2022, 50, 1967–1970. [Google Scholar]

- Jagadeesh, G.V.; Setti, S.G. An experimental study on the surface finish of ball burnished magnesium (rare earth base) alloy. Mater. Today: Proc. 2019, 18, 4711–4716. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K. Selected properties of the surface layer of C45 steel parts subjected to laser cutting and ball burnishing. Materials 2020, 13, 3429. [Google Scholar] [CrossRef]

- Dzierwa, A.; Gałda, L.; Tupaj, M.; Dudek, K. Investigation of wear resistance of selected materials after slide burnishing process. Eksploat. I Niezawodn.-Maint. Reliab. 2022, 22, 432–439. [Google Scholar] [CrossRef]

- Yu, X.; Wang, L. Effect of various parameters on the surface roughness of an aluminium alloy burnished with spherical surfaced polycrystalline diamond tool. Int. J. Mach. Tools Manuf. 1999, 39, 459–469. [Google Scholar] [CrossRef]

- Sachin, B.; Narendranath, S.; Chakradhar, D. Effect of working parameters on the surface integrity in cryogenic diamond burnishing of 17-4PH stainless steel with a novel diamond burnishing tool. J. Manuf. Process. 2019, 38, 564–571. [Google Scholar]

- Sartkulvanich, P.; Sartkulvanich, P.; Altan, T.; Jasso, F.; Rodriguez, C. Finite element modeling of hard roller burnishing: An analysis on the effects of process parameters upon surface finish and residual stresses. J. Manuf. Sci. Eng. 2007, 129, 705–716. [Google Scholar] [CrossRef]

- Tugay, I.O.; Hosseinzadeh, A.; Yapici, G.G. Hardness and wear resistance of roller burnished 316L stainless steel. Mater. Today Proc. 2021, 47, 2405–2409. [Google Scholar] [CrossRef]

- Kowalik, M.; Trzepieciński, T. Experimental assessment of the depth of the deformed layer in the roller burnishing process. MATEC Web Conf. 2019, 290, 03008. [Google Scholar] [CrossRef]

- Kato, H.; Hirokawa, W.; Todaka, Y.; Yasunaga, K. Improvement in Surface roughness and hardness for carbon steel by slide burnishing process. Mater. Sci. Appl. 2021, 12, 171–181. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z.; Wang, B.; Hou, X. Surface modification through combination of finish turning with low plastity burnishing and its effect on fatigue performance for Inconel 718. Surf. Coat. Technol. 2019, 375, 508–517. [Google Scholar] [CrossRef]

- Aviles, A.; Aviles, R.; Albizuri, J.; Pallares-Santasmartas, L.; Rodriguez, A. Effect of shot peening and low plasticity burnishing on the high-cycle fatigue strength of DIN 34CrNiMo6 alloy steel. Int. J. Fatigue 2019, 119, 338–354. [Google Scholar] [CrossRef]

- Toboła, D.; Brostow, W.; Czechowski, K.; Rusek, P. Improvement of wear resistance of some cold working tool steels. Wear 2017, 382, 29–39. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. On the surface and tribological characteristics of burnished cylindrical Al-6061. Tribol. Int. 2009, 42, 320–326. [Google Scholar] [CrossRef]

- Dzyura, V.; Maruschak, P. Optimizing the formation of hydraulic cylinder Surfaces, taking into account their microrelief topography analyzed during different operations. Machines 2021, 9, 116. [Google Scholar] [CrossRef]

- Kryvyi, P.; Dzyura, V.; Maruschak, P.; Panin, S.; Lyashuk, O.; Vlasov, I. Influence of Curvature and Cross-sectional Shape of Cylindrical Surface Formed by Turning on Its Roughness. Arab. J. Sci. Eng. 2020, 45, 5615–5622. [Google Scholar] [CrossRef]

- Thesleff, A.; Ortiz-Catalan, M.; Branemark, R. Low plasticity burnishing improves fretting fatigue resistance in bone-anchored implants for amputation protheses. Med. Eng. Phys. 2022, 100, 103755. [Google Scholar] [CrossRef]

- Kalisz, J.; Żak, K.; Wojciechowski, S.; Gupta, M.K.; Krolczyk, G.M. Technological and tribological aspects of milling—Burnishing process of complex surfaces. Tribol. Int. 2021, 155, 106770. [Google Scholar] [CrossRef]

- Saldana-Robles, A.; Plascencia-Mora, H.; Aguilera-Gómez, E.; Saldaña-Robles, A.; Marquez-Herrera, A.; Diosdado-De la Pena, J.A. Influence of ball-burnishing on roughness, hardness and corrosion resistance of AISI 1045 steel. Surf. Coat. Technol. 2018, 339, 191–198. [Google Scholar] [CrossRef]

- Kowalik, M.; Trzepieciński, T.; Kukiełka, L.; Paszta, P.; Maciąg, P.; Legutko, S. Experimental and numerical analysis of the depth of the strengthened layer on shafts resulting from roller burnishing with roller braking moment. Materials 2021, 14, 5844. [Google Scholar] [CrossRef] [PubMed]

- Grochała, D.; Berczyński, S.; Grządziel, Z. Modeling of burnishing thermally toughened X42CrMo4 steel with a ceramic ZrO2 ball. Arch. Civ. Mech. Eng. 2017, 17, 1011–1018. [Google Scholar] [CrossRef]

- Marquez-Herrera, A.; Saldana-Robles, A.; Reveles-Arredondo, J.F.; Diosdado-De la Pena, J.A. Duplex surface treatment on ASTM A-36 steel by slide burnishing and powder pack boriding. Materials Today Commun. 2022, 31, 103703. [Google Scholar] [CrossRef]

- Kovacs, Z.F.; Viharos, Z.J.; Kodascy, J. Improvement of surface tribological properties by magnetic assisted ball burnishing. Surf. Coat. Technol. 2022, 437, 128317. [Google Scholar] [CrossRef]

- Velazquez-Corral, E.; Jerez-Mesa, R.; Lluma, J.; Wagner, V.; Dessein, G.; Traviesto-Rodriguez, J.A. wear resistance enhancement of AISI 1045 steel by vibration assisted ball burnishing process. Procedia CIRP 2022, 108, 287–292. [Google Scholar] [CrossRef]

- Kowalik, M.; Trzepieciński, T. A method of increasing the depth of the plastically deformed layer in the roller burnishing process. AIP Conf. Proc. 1960, 2018, 040011. [Google Scholar] [CrossRef]

- Zhen-yu, Z.; Qiu-yang, Z.; Cong, D.; Ju-yu, Y.; Guang-jian, P.; Zhong-yu, P. research on the promotion mechanism of surface burnishing process by two-dimensional ultrasonic vibration. J. Mater. Res. Technol. 2021, 13, 1068–1082. [Google Scholar] [CrossRef]

- Uddin, M.; Hall, C.; Santos, V.; Visalakshan, R.; Qian, G.; Vasilev, K. Synergistic effect of deep ball burnishing an HA coating on surface integrity, corrosion and immune response of biodegradable AZ31B Mg alloys. Mater. Sci. Eng. 2021, C118, 111459. [Google Scholar] [CrossRef]

- Wandra, R.; Prakash, C.; Singh, S. Experimental investigation and optimization of surface roughness of β-Phase titanium alloy by ball burnishing assisted electrical discharge cladding for implant applications. Mater. Today Proc. 2022, 48, 975–980. [Google Scholar] [CrossRef]

- Yang, Z.; Zheng, J.; Zhan, K.; Jiang, C.; Ji, V. Surface characteristics and wear resistance of S960 high-strength steel after shot peening combing with ultrasonic sprayed graphene oxide coating. J. Mater. Res. Technol. 2022, 18, 978–989. [Google Scholar] [CrossRef]

- Sivaramapandian, J.; Ananth, M.P.; Selvabharathi, R. Influence of plasma spray WCCrCNi coating and shot peening on surface properties and corrosion behavior of AZ31 Mg alloy. J. Mater. Res. Technol. 2022, 19, 3189–3200. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Karademir, I.; Husem, F.; Efe, Y.; Das, T. Effects of conventional shot peening, severe shot peening, re-shot peening and precised grinding operations on fatigue performance of operations of fatigue performance of AISI 1050 railway axle steel. Int. J. Fatigue 2022, 155, 106613. [Google Scholar] [CrossRef]

- Zhan, K.; Zhang, Y.; Bao, L.; Yang, Z.; Zhao, B.; Ji, V. Surface characteristic and wear resistance of QT-700-2 nodular cast iron after laser quenching combing with shot peening treatment. Surf. Coat. Technol. 2021, 423, 127589. [Google Scholar] [CrossRef]

- Shi, H.; Liu, D.; Pan, Y.; Zhao, W.; Zhang, X.; Ma, A.; Liu, B.; Hu, Y.; Wang, W. Effect of shot peening and vibration finishing on the fatigue behavior of TC17 titanium alloy at room and high temperature. Int. J. Fatigue 2021, 151, 106391. [Google Scholar] [CrossRef]

- Zielecki, W.; Bucior, M.; Trzepicinski, T.; Ochał, K. Effect of slide burnishing of shoulder fillets on the fatigue strength of X19NiCrMo4 steel shafts. Int. J. Adv. Manuf. Technol. 2020, 106, 2583–2593. [Google Scholar] [CrossRef]

| Chemical Composition (Average), % | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | Fe |

| 0.48 | 0.78 | 0.36 | 0.011 | 0.01 | 0.09 | 0.02 | 0.002 | rest |

| Yield point (min) | Re = 430 MPa | |||||||

| Tensile strength (min) | Rm = 740 MPa | |||||||

| Hardness (min) | 250 HB | |||||||

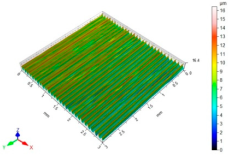

| (a) after grinding | (b) after BB | ||

| Sa = 1.96 μm Sz = 16.4 μm Sp = 9.40 μm Sv = 7.04 μm |  | Sa = 0.22 μm Sz = 3.99 μm Sp = 1.64 μm Sv = 2.35 μm |

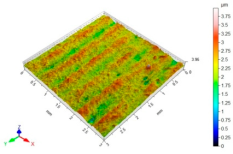

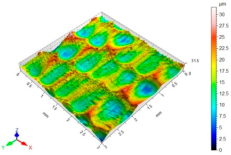

| (c) after SB | (d) after CSP | ||

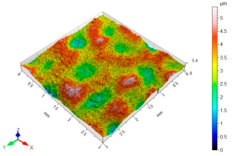

| Sa = 0.33 μm Sz = 6.00 μm Sp = 4.24 μm Sv = 1.77 μm |  | Sa = 3.01 μm Sz = 31.6 μm Sp = 15.9 μm Sv = 15.7 μm |

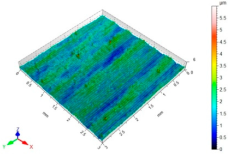

| (e) after CSP + SB | (f) after CSP + BB | ||

| Sa = 0.91 μm Sz = 10.5 μm Sp = 5.51 μm Sv = 5.03 μm |  | Sa = 0.54 μm Sz = 5.42 μm Sp = 2.10 μm Sv = 3.33 μm |

| Ra | |||||

|---|---|---|---|---|---|

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.54966 | 0.14948 | 0.00013 | 0.00013 | |

| BB | 0.54966 | 0.89950 | 0.00013 | 0.00013 | |

| CSP + SB | 0.14948 | 0.89950 | 0.00013 | 0.00013 | |

| CSP + BB | 0.00013 | 0.00013 | 0.00013 | 0.00013 | |

| CSP | 0.00013 | 0.00013 | 0.00013 | 0.00013 | |

| Rpk | |||||

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.39454 | 0.02185 | 0.00013 | 0.00013 | |

| BB | 0.39454 | 0.52877 | 0.00035 | 0.00013 | |

| CSP + SB | 0.02185 | 0.52877 | 0.00822 | 0.00013 | |

| CSP + BB | 0.00013 | 0.00035 | 0.00822 | 0.00013 | |

| CSP | 0.00013 | 0.00013 | 0.00013 | 0.00013 | |

| ΔHV | |||||

|---|---|---|---|---|---|

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.00012 | 0.00012 | 0.02034 | 0.00012 | |

| BB | 0.00012 | 0.00012 | 0.00012 | 0.05713 | |

| CSP + SB | 0.00012 | 0.00012 | 0.00012 | 0.00012 | |

| CSP + BB | 0.02034 | 0.00013 | 0.00012 | 0.00208 | |

| CSP | 0.00012 | 0.05713 | 0.00012 | 0.00208 | |

| gh | |||||

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.10676 | 0.00047 | 0.00017 | 0.00032 | |

| BB | 0.10673 | 0.01614 | 0.00030 | 0.00780 | |

| CSP + SB | 0.00047 | 0.01614 | 0.04445 | 0.98391 | |

| CSP + BB | 0.00017 | 0.00030 | 0.04445 | 0.09414 | |

| CSP | 0.00032 | 0.00780 | 0.98691 | 0.09414 | |

| σmax | |||||

|---|---|---|---|---|---|

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.73693 | 0.00052 | 0.00017 | 0.00363 | |

| BB | 0.73693 | 0.00210 | 0.00019 | 0.02201 | |

| CSP + SB | 0.00052 | 0.00210 | 0.03939 | 0.50807 | |

| CSP + BB | 0.00017 | 0.00019 | 0.03939 | 0.00347 | |

| CSP | 0.00363 | 0.02201 | 0.50807 | 0.00347 | |

| gσ | |||||

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.00392 | 0.00018 | 0.00017 | 0.00107 | |

| BB | 0.00392 | 0.01213 | 0.00399 | 0.83985 | |

| CSP + SB | 0.00018 | 0.01213 | 0.93487 | 0.05822 | |

| CSP + BB | 0.00017 | 0.00399 | 0.93467 | 0.01785 | |

| CSP | 0.00107 | 0.83985 | 0.05822 | 0.01785 | |

| Fatigue Life | |||||

|---|---|---|---|---|---|

| Finishing Treatment | |||||

| SB | BB | CSP + SB | CSP + BB | CSP | |

| SB | 0.55045 | 0.00074 | 0.000187 | 0.08226 | |

| BB | 0.55045 | 0.00531 | 0.00027 | 0.63644 | |

| CSP + SB | 0.00074 | 0.00531 | 0.09796 | 0.04410 | |

| CSP + BB | 0.00018 | 0.00027 | 0.09796 | 0.00083 | |

| CSP | 0.08226 | 0.63644 | 0.04410 | 0.00083 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skoczylas, A.; Zaleski, K. Study on the Surface Layer Properties and Fatigue Life of a Workpiece Machined by Centrifugal Shot Peening and Burnishing. Materials 2022, 15, 6677. https://doi.org/10.3390/ma15196677

Skoczylas A, Zaleski K. Study on the Surface Layer Properties and Fatigue Life of a Workpiece Machined by Centrifugal Shot Peening and Burnishing. Materials. 2022; 15(19):6677. https://doi.org/10.3390/ma15196677

Chicago/Turabian StyleSkoczylas, Agnieszka, and Kazimierz Zaleski. 2022. "Study on the Surface Layer Properties and Fatigue Life of a Workpiece Machined by Centrifugal Shot Peening and Burnishing" Materials 15, no. 19: 6677. https://doi.org/10.3390/ma15196677

APA StyleSkoczylas, A., & Zaleski, K. (2022). Study on the Surface Layer Properties and Fatigue Life of a Workpiece Machined by Centrifugal Shot Peening and Burnishing. Materials, 15(19), 6677. https://doi.org/10.3390/ma15196677