Textured Stainless Steel as a Platform for Black Mg2Si/Si Heterojunction Solar Cells with Advanced Photovoltaic Performance

Abstract

1. Introduction

2. Materials and Methods

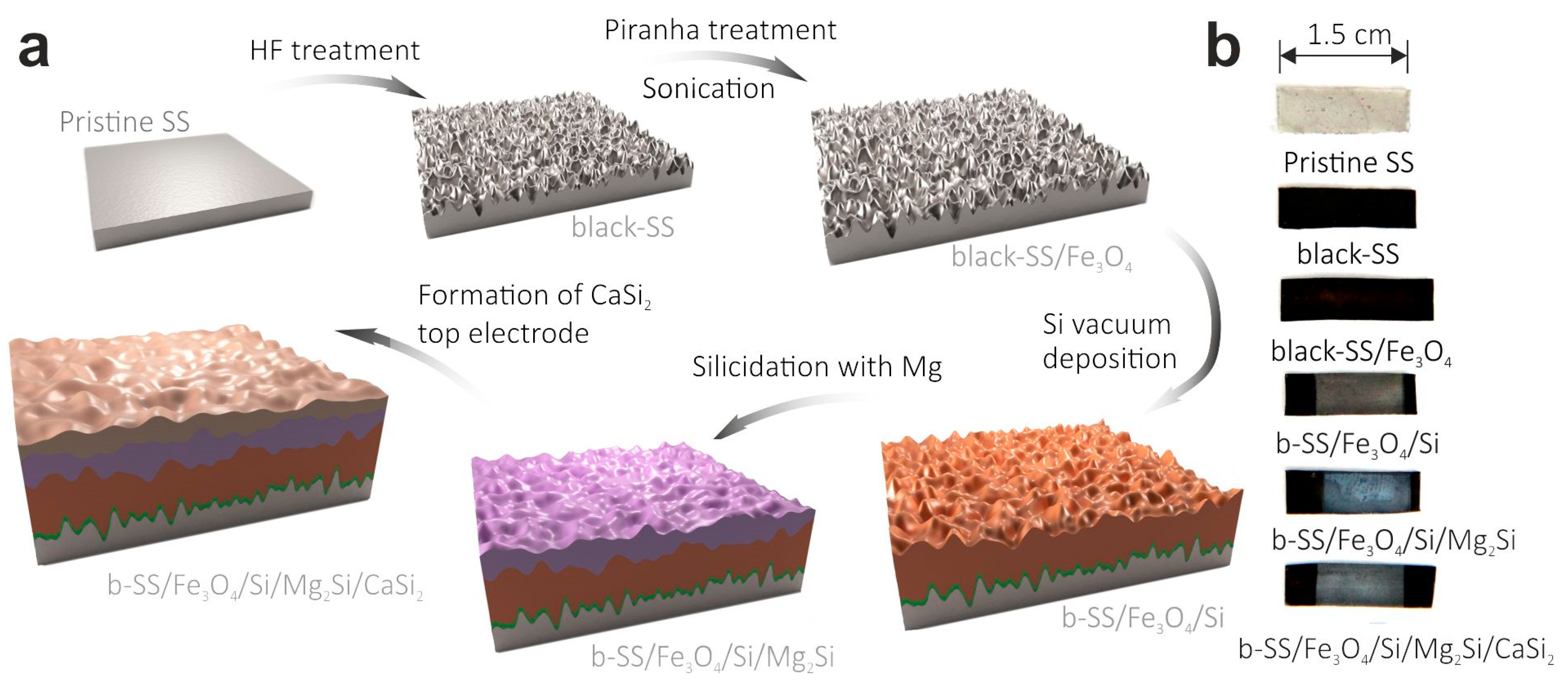

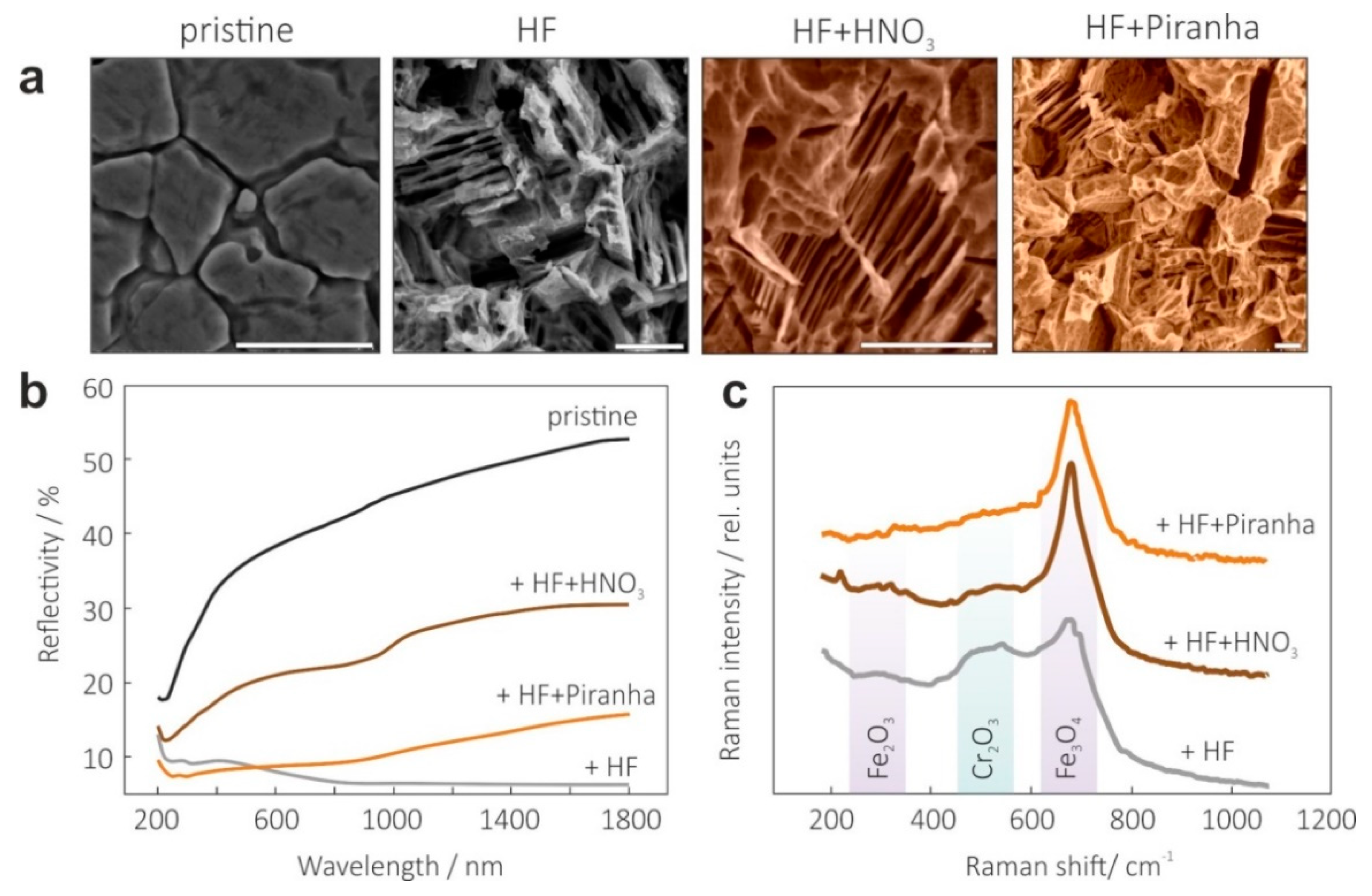

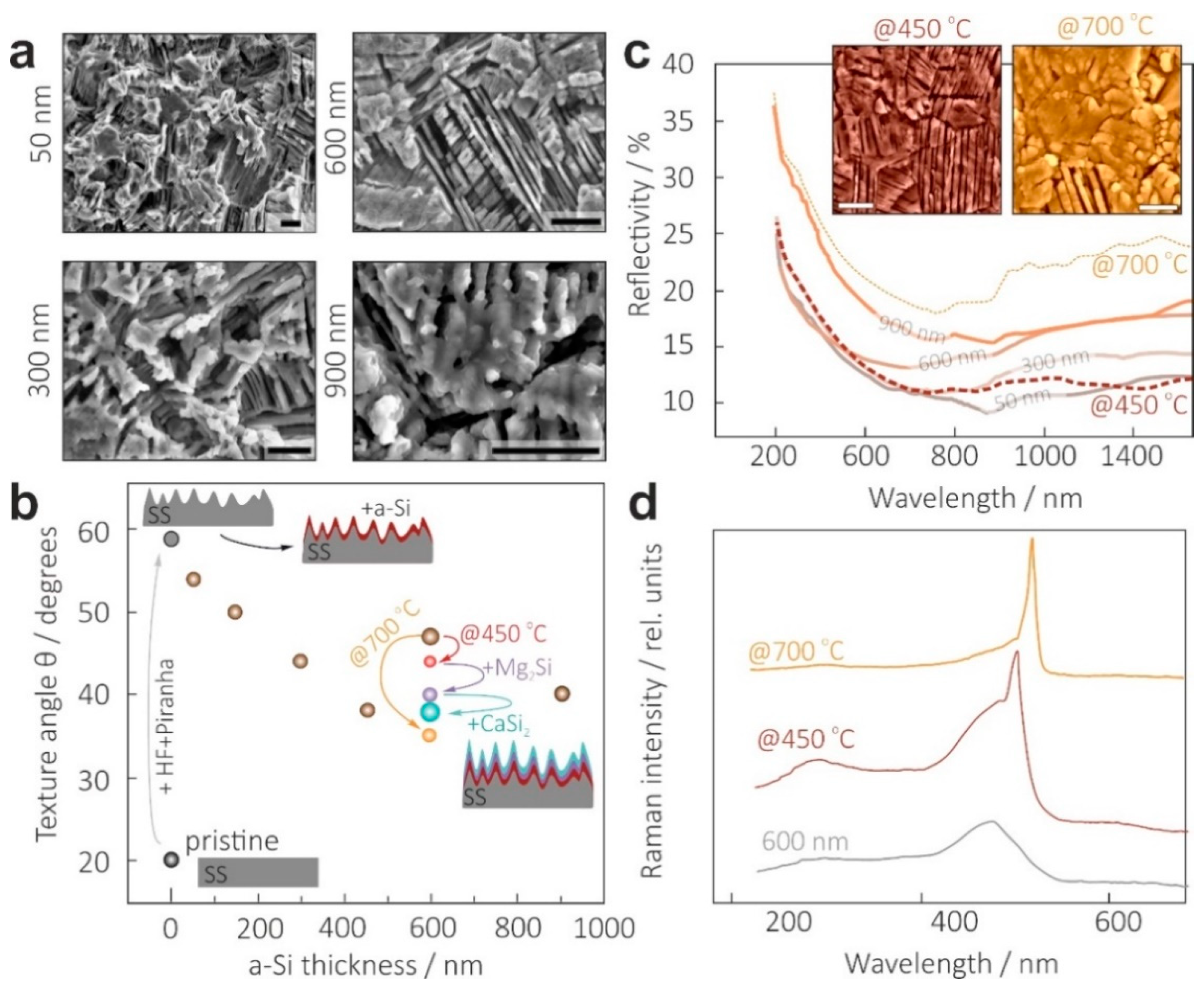

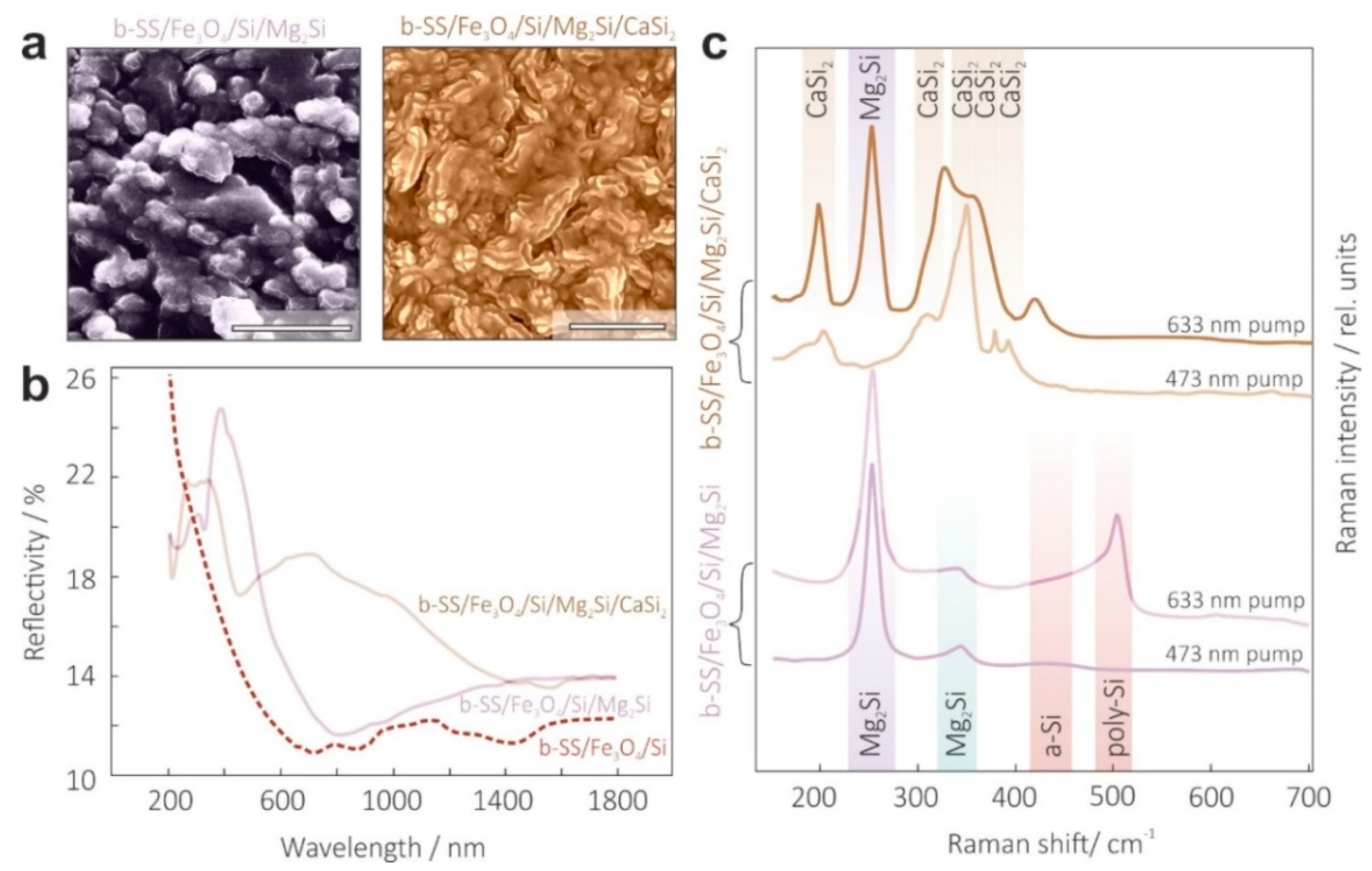

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bing, J.; Caro, L.G.; Talathi, H.P.; Chang, N.L.; Mckenzie, D.R.; Ho-Baillie, A.W. Perovskite solar cells for building integrated photovoltaics—Glazing applications. Joule 2022, 6, 1446–1474. [Google Scholar] [CrossRef]

- Neugebohrn, N.; Haas, S.; Gerber, A.; Grimm, M.; Nissel, J.; Liebers, R.; Turan, B.; Gerhke, K.; Vehse, M. Flexible design of building integrated thin-film photovoltaics. Prog. Photovoltaics 2022, 30, 1188–1197. [Google Scholar] [CrossRef]

- Ballif, C.; Perret-Aebi, L.E.; Lufkin, S.; Rey, E. Integrated thinking for photovoltaics in buildings. Nat. Energy 2018, 3, 438–442. [Google Scholar] [CrossRef]

- Pillai, D.S.; Shabunko, V.; Krishna, A. A Comprehensive Review on Building Integrated Photovoltaic Systems: Emphasis to Technological Advancements, Outdoor Testing, and Predictive Maintenance. Renew. Sustain. Energy Rev. 2022, 156, 111946. [Google Scholar] [CrossRef]

- Awuku, S.A.; Muhammad-Sukki, F.; Sellami, N. Building Integrated Photovoltaics—The Journey So Far and Future. Energies 2022, 15, 1802. [Google Scholar] [CrossRef]

- Koh, T.M.; Wang, H.; Ng, Y.F.; Bruno, A.; Mhaisalkar, S.; Mathews, N. Halide perovskite solar cells for building integrated photovoltaics: Transforming building façades into power generators. Adv. Mater. 2022, 34, 2104661. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, B.; Chen, J.; Liu, K.; Zhu, B.; Chen, J. Low-Carbon Design Path of Building Integrated Photovoltaics: A Comparative Study Based on Green Building Rating Systems. Buildings 2021, 11, 469. [Google Scholar] [CrossRef]

- Feleki, B.T.; Bouwer, R.K.; Zardetto, V.; Wienk, M.M.; Janssen, R.A. p-i-n Perovskite Solar Cells on Steel Substrates. ACS Appl. Energy Mater. 2022, 5, 6709–6715. [Google Scholar] [CrossRef]

- Martins, A.C.; Chapuis, V.; Sculati-Meillaud, F.; Virtuani, A.; Ballif, C. Light and durable: Composite structures for building-integrated photovoltaic modules. Prog. Photovolt. Res. Appl. 2018, 26, 718–729. [Google Scholar] [CrossRef]

- Martins, A.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust glass-free lightweight photovoltaic modules with improved resistance to mechanical loads and impact. IEEE J. Photovolt. 2019, 9, 245–251. [Google Scholar] [CrossRef]

- Park, M.J.; Youn, S.; Jeon, K.; Lee, S.H.; Jeong, C. Optimization of Shingled-Type Lightweight Glass-Free Solar Modules for Building Integrated Photovoltaics. Appl. Sci. 2022, 12, 5011. [Google Scholar] [CrossRef]

- Menéndez, M.F.; Martinez, A.; Sánchez, P.; Gomez, D.; Andrés, L.J.; Haponow, L.; Bristow, N.; Kettle, J.; Korochkina, T.; Gethin, D.T. Development of intermediate layer systems for direct deposition of thin film solar cells onto low cost steel substrates. Sol. Energy 2020, 208, 738–746. [Google Scholar] [CrossRef]

- Bello, M.; Subramani, S.; Rashid, M.M.B.M. The impact of Fe3O4 on the performance of ultrathin Ti/AlN/Ti tandem coating on stainless-steel for solar selective absorber application. Results Phys. 2020, 19, 103582. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Huang, Y.; Yuan, W.; Tang, Y. Investigation on the performance of Mo2N thin film as barrier layer against Fe in the flexible Cu(In, Ga)Se2 solar cells on stainless steel substrates. J. Alloy. Compd. 2017, 698, 194–199. [Google Scholar] [CrossRef]

- Bello, M.; Shanmugan, S. Investigation of in-plane heat distribution, thermal stability and mechanical properties of SS-(Fe3O4)/Ti/AlN/Ti/SiO2 as absorber coatings for efficient high temperature concentrated solar power systems. J. Alloy. Compd. 2022, 901, 163576. [Google Scholar] [CrossRef]

- Kumar, K.P.; Mallick, S.; Sakthivel, S. Nanoparticles based single and tandem stable solar selective absorber coatings with wide angular solar absorptance. Sol. Energy Mater. Sol. Cells 2022, 242, 111758. [Google Scholar] [CrossRef]

- Okuhara, Y.; Kuroyama, T.; Yokoe, D.; Kato, T.; Takata, M.; Tsutsui, T.; Noritake, K. Thermal durability of solar selective absorbers consisting of β-FeSi2 with low emissive Ag layers on stainless steel. Sol. Energy Mater. Sol. Cells 2020, 206, 110304. [Google Scholar] [CrossRef]

- Kawano, Y.; Chantana, J.; Nishimura, T.; Mavlonov, A.; Minemoto, T. [Ga]/([Ga]+[In]) profile controlled through Ga flux for performance improvement of Cu(In, Ga)Se2 solar cells on flexible stainless steel substrates. J. Alloy. Compd. 2022, 899, 163276. [Google Scholar] [CrossRef]

- Zhao, Q.; Shen, H.; Xu, Y.; Gao, K.; Chen, D.; Li, Y. Effect of CZTS/CCZTS Stacked Structures Prepared through Split-Cycle on the Performance of Flexible Solar Cells. ACS Appl. Energy Mater. 2022, 5, 3668–3676. [Google Scholar] [CrossRef]

- Kim, S.T.; Bhatt, V.; Kim, Y.C.; Jeong, H.J.; Yun, J.H.; Jang, J.H. Formation of MoSe2 layer and Ga grading in flexible Cu(In, Ga)Se2 solar cell via Na diffusion. J. Alloy. Compd. 2022, 899, 163301. [Google Scholar] [CrossRef]

- Sim, Y.H.; Yun, M.J.; Lee, D.Y.; Cha, S.I. Origami-foldable tessellated Crystalline-Si solar cell module with metal textile-based stretchable connections. Sol. Energy Mater. Sol. Cells 2021, 231, 111318. [Google Scholar] [CrossRef]

- Jung, K.H.; Yun, S.J.; Lee, S.H.; Lee, Y.J.; Lee, K.S.; Lim, J.W.; Kim, K.B.; Kim, M.; Schropp, R.E.I. Double-layered Ag-Al back reflector on stainless steel substrate for a-Si:H thin film solar cells. Sol. Energy Mater. Sol. Cells 2016, 145, 368–374. [Google Scholar] [CrossRef]

- Sim, J.-K.; Lee, S.-K.; Kim, J.-S.; Jeong, K.-U.; Ahn, H.-K.; Lee, C.-R. Efficiency enhancement of CIGS com-pound solar cell fabricated using homomorphic thin Cr2O3 diffusion barrier formed on stainless steel substrate. Appl. Surf. Sci. 2016, 389, 645–650. [Google Scholar] [CrossRef]

- Feleki, B.T.; Bouwer, R.K.; Wienk, M.M.; Janssen, R.A. Perovskite Solar Cells on Polymer-Coated Smooth and Rough Steel Substrates. Sol. RRL 2022, 6, 2100898. [Google Scholar] [CrossRef]

- Fan, Z.; Cui, D.; Zhang, Z.; Zhao, Z.; Chen, H.; Fan, Y.; Li, P.; Zhang, Z.; Xue, C.; Yan, S. Recent progress of black silicon: From fabrications to applications. Nanomaterials 2021, 11, 41. [Google Scholar] [CrossRef] [PubMed]

- Otto, M.; Algasinger, M.; Branz, H.; Gesemann, B.; Gimpel, T.; Fuechsel, K.; Kaesebier, T.; Kontermann, S.; Koynov, S.; Li, X.P.; et al. Black Silicon Photovoltaics. Adv. Opt. Mater. 2015, 3, 147–164. [Google Scholar] [CrossRef]

- Omar, H.D.; Hashim, M.R.; Pakhuruddin, M.Z. Optimization of etching time for enhanced broadband absorption in flexible black silicon on stainless steel foil. Optik 2021, 225, 165781. [Google Scholar] [CrossRef]

- Omar, H.D.; Abdulkadir, A.; Hashim, M.R.; Pakhuruddin, M.Z. Textured stainless steel foil as efficient rear reflector for flexible black silicon. Results Phys. 2021, 24, 104203. [Google Scholar] [CrossRef]

- Shevlyagin, A.; Il′yaschenko, V.; Kuchmizhak, A.; Mitsai, E.; Sergeev, A.; Gerasimenko, A.; Gutakovskii, A. Mg2Si is the new black: Introducing a black silicide with >95% average absorption at 200–1800 nm wavelengths. Appl. Surf. Sci. 2022, 602, 154321. [Google Scholar] [CrossRef]

- Shevlyagin, A.V.; Galkin, N.G.; Galkin, K.N.; Subbotin, E.Y.; Il’yaschenko, V.M.; Gerasimenko, A.V.; Tkachenko, I.A. Semimetal hR6-CaSi2 thin film: A transparent contact for Si optoelectronics. J. Alloy. Compd. 2022, 910, 164893. [Google Scholar] [CrossRef]

- Shevlyagin, A.; Chernev, I.; Galkin, N.; Gerasimenko, A.; Gutakovskii, A.; Hoshida, H.; Terai, Y.; Nishikawa, N.; Ohdaira, K. Probing the Mg2Si/Si(111) heterojunction for photovoltaic applications. Sol. Energy 2020, 211, 383–395. [Google Scholar] [CrossRef]

- Yachi, S.; Takabe, R.; Takeuchi, H.; Toko, K.; Suemasu, T. Effect of amorphous Si capping layer on the hole transport properties of BaSi2 and improved conversion efficiency approaching 10% in p-BaSi2/n-Si solar cells. Appl. Phys. Lett. 2016, 109, 072103. [Google Scholar] [CrossRef]

- Li, L.; Breedveld, V.; Hess, D.W. Creation of Superhydrophobic Stainless Steel Surfaces by Acid Treatments and Hydrophobic Film Deposition. ACS Appl. Mater. Interfaces 2012, 4, 4549–4556. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Ye, Y.; Jia, B.; Li, Y.; Ding, R.; Jiang, Y.; Wang, Y.; Yuan, X. Polarization and fluence effects in femtosecond laser induced micro/nano structures on stainless steel with antireflection property. Appl. Surf. Sci. 2017, 425, 1118–1124. [Google Scholar] [CrossRef]

- Kanematsu, D.; Yata, S.; Aya, Y.; Terakawa, A.; Iseki, M. Quantitative measurement and design of texture morphology for high-efficiency thin-film silicon solar cells. Jpn. J. Appl. Phys. 2014, 53, 076501. [Google Scholar] [CrossRef]

- Adhikari, S.; Dubey, M.; Galipeau, D.; Hua Fan, Q. A numerical scheme to quantify the texture characteristics of sputtered aluminum thin film back reflectors. J. Appl. Phys. 2013, 114, 154501. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J.; Lei, Y.; Wang, Y.; Zhou, G.; Xu, C.; Rao, Y.; Wang, K. Preparation of intricate nanostruc-tures on 304 stainless steel surface by SiO2-assisted HF etching for high superhydrophobicity. Colloids Surf. A 2020, 586, 124287. [Google Scholar] [CrossRef]

- Ranganathan, P.; Amrutha, V.; Barshilia, H.C. Thermal oxidation of stainless steel substrate with tunable spectral selectivity: Transition from a reflecting to a highly absorbing Cr-Fe spinel surface. Sol. Energy Mater. Sol. Cells 2021, 233, 111381. [Google Scholar] [CrossRef]

- Qu, J.; Yu, C.; Cui, R.; Qin, J.; Wang, H.; Cao, Z. Preparation of super-hydrophobic and corrosion resistant colored films on chemically etched 304 stainless steel substrate. Surf. Coat. Technol. 2018, 354, 236–245. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Lei, D.; Wang, C. A new solar spectral selective absorbing coating of SS–(Fe3O4)/Mo/TiZrN/TiZrON/SiON for high temperature application. Sol. Energy Mater. Sol. Cells 2014, 127, 143–146. [Google Scholar] [CrossRef]

- De Teresa, J.M.; Fernández-Pacheco, A.; Morellon, L.; Orna, J.; Pardo, J.A.; Serrate, D.; Algarabel, P.A.; Ibarra, M.R. Magnetotransport properties of Fe3O4 thin films for applications in spin electronics. Microelectron. Eng. 2007, 84, 1660–1664. [Google Scholar] [CrossRef]

- Liao, Y.; Long, X.; Xie, J.; Lv, B.; Xiao, Q.; Xie, Q. Magnetic Properties of 3d Transition Metal Atoms (V, Cr, Mn, Fe, Co, or Ni)-Doped Mg2Si. Phys. Status Solidi B 2022, 259, 2100538. [Google Scholar] [CrossRef]

- Liu, Z.; Osamura, M.; Ootsuka, T.; Kuroda, R.; Fukuzawa, Y.; Otogawa, N.; Nakayama, Y.; Makita, Y.; Tanoue, H. Effect of a Fe3Si buffer layer for the growth of semiconducting β-FeSi2 thin film on stainless steel substrate. J. Cryst. Growth 2007, 307, 82–86. [Google Scholar] [CrossRef]

- Liu, Z.; Osamura, M.; Ootsuka, T.; Kuroda, R.; Makita, Y.; Tanoue, H.; Fukuzawa, Y.; Otogawa, N.; Nakayama, Y. Formation of β-FeSi2 thin films on non-silicon substrates. Thin Solid Films 2006, 515, 1532–1538. [Google Scholar] [CrossRef]

- Moll, A.; Hermet, P.; Bantignies, J.L.; Candolfi, C.; Lenoir, B.; Maurin, D.; Ramonda, M.; Oliviero, E.; Fréty, N. Influence of Nanostructuration on the Vibrational, Electronic, and Optical Properties of CrSi2 Thin Films. J. Phys. Chem. C 2020, 124, 28267–28276. [Google Scholar] [CrossRef]

- Chernev, I.M.; Shevlyagin, A.V.; Galkin, K.N.; Stuchlik, J.; Remes, Z.; Fajgar, R.; Galkin, N.G. On the way to enhance the optical absorption of a-Si in NIR by embedding Mg2Si thin film. Appl. Phys. Lett. 2016, 109, 043902. [Google Scholar] [CrossRef]

- El-Amir, A.A.; Ohsawa, T.; Ishii, S.; Imura, M.; Liao, M.; Fu, X.; Segawa, H.; Sakaguchi, I.; Nagao, T.; Shimamura, K.; et al. Silicon-compatible Mg2Si/Si n-p photodiodes with high room temperature infrared responsivity. Mater. Sci. Semicond. Process. 2019, 102, 104577. [Google Scholar] [CrossRef]

- Zhu, Q.; Ye, P.; Tang, Y.; Zhu, X.; Cheng, Z.; Xu, J.; Xu, M. High-performance broadband photoresponse of self-powered Mg2Si/Si photodetectors. Nanotechnology 2021, 33, 115202. [Google Scholar] [CrossRef]

- Yu, H.; Sun, L.; Ji, S.; Deng, R.; Mo, Z.; Xie, Q. Enhanced Photoelectric Properties of Multilayer Graphene Mg2Si/Si Heterojunction Photodetector. IEEE Photonics J. 2021, 14, 6805009. [Google Scholar] [CrossRef]

- Yu, H.; Ji, S.; Luo, X.; Xie, Q. Technology CAD (TCAD) Simulations of Mg2Si/Si Heterojunction Photodetector Based on the Thickness Effect. Sensors 2021, 21, 5559. [Google Scholar] [CrossRef]

- Yu, H.; Gao, C.; Zou, J.; Yang, W.; Xie, Q. Simulation Study on the Effect of Doping Concentrations on the Photodetection Properties of Mg2Si/Si Heterojunction Photodetector. Photonics 2021, 8, 509. [Google Scholar] [CrossRef]

- Castillo, S.M.; Tang, Z.; Litvinchuk, A.P.; Guloy, A.M. Lattice Dynamics of the Rhombohedral Polymorphs of CaSi2. Inorg. Chem. 2016, 55, 10203–10207. [Google Scholar] [CrossRef] [PubMed]

- Han, K.; Chang, C.H. Numerical modeling of sub-wavelength anti-reflective structures for solar module applications. Nanomaterials 2014, 4, 87–128. [Google Scholar] [CrossRef] [PubMed]

- Jin, J. The Finite Element Method in Electromagnetic, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2002. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shevlyagin, A.V.; Il’yaschenko, V.M.; Kuchmizhak, A.A.; Mitsai, E.V.; Amosov, A.V.; Balagan, S.A.; Kulinich, S.A. Textured Stainless Steel as a Platform for Black Mg2Si/Si Heterojunction Solar Cells with Advanced Photovoltaic Performance. Materials 2022, 15, 6637. https://doi.org/10.3390/ma15196637

Shevlyagin AV, Il’yaschenko VM, Kuchmizhak AA, Mitsai EV, Amosov AV, Balagan SA, Kulinich SA. Textured Stainless Steel as a Platform for Black Mg2Si/Si Heterojunction Solar Cells with Advanced Photovoltaic Performance. Materials. 2022; 15(19):6637. https://doi.org/10.3390/ma15196637

Chicago/Turabian StyleShevlyagin, Alexander V., Vladimir M. Il’yaschenko, Aleksandr A. Kuchmizhak, Eugeny V. Mitsai, Andrey V. Amosov, Semyon A. Balagan, and Sergei A. Kulinich. 2022. "Textured Stainless Steel as a Platform for Black Mg2Si/Si Heterojunction Solar Cells with Advanced Photovoltaic Performance" Materials 15, no. 19: 6637. https://doi.org/10.3390/ma15196637

APA StyleShevlyagin, A. V., Il’yaschenko, V. M., Kuchmizhak, A. A., Mitsai, E. V., Amosov, A. V., Balagan, S. A., & Kulinich, S. A. (2022). Textured Stainless Steel as a Platform for Black Mg2Si/Si Heterojunction Solar Cells with Advanced Photovoltaic Performance. Materials, 15(19), 6637. https://doi.org/10.3390/ma15196637