Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Single Layer NRL Composite Foams

2.3. Characterization

2.3.1. Cell morphology and Cell Size

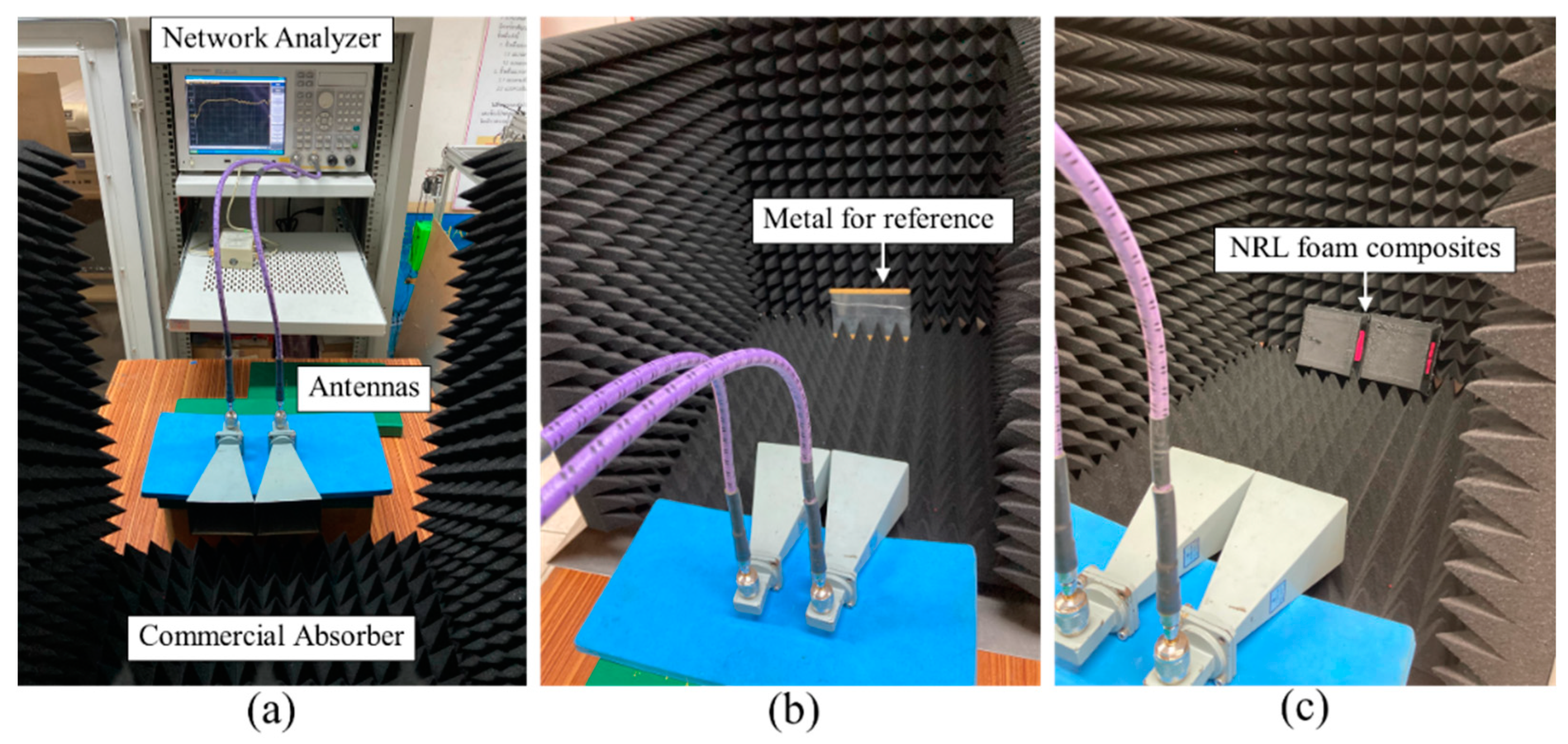

2.3.2. Electromagnetic Reflectivity of Composite Foam

2.3.3. Tensile Test

2.3.4. Compression Set

- is the 10 mm spacer bar used to maintain the compression deflection;

- is the final thickness of the foam composite.

3. Results and Discussion

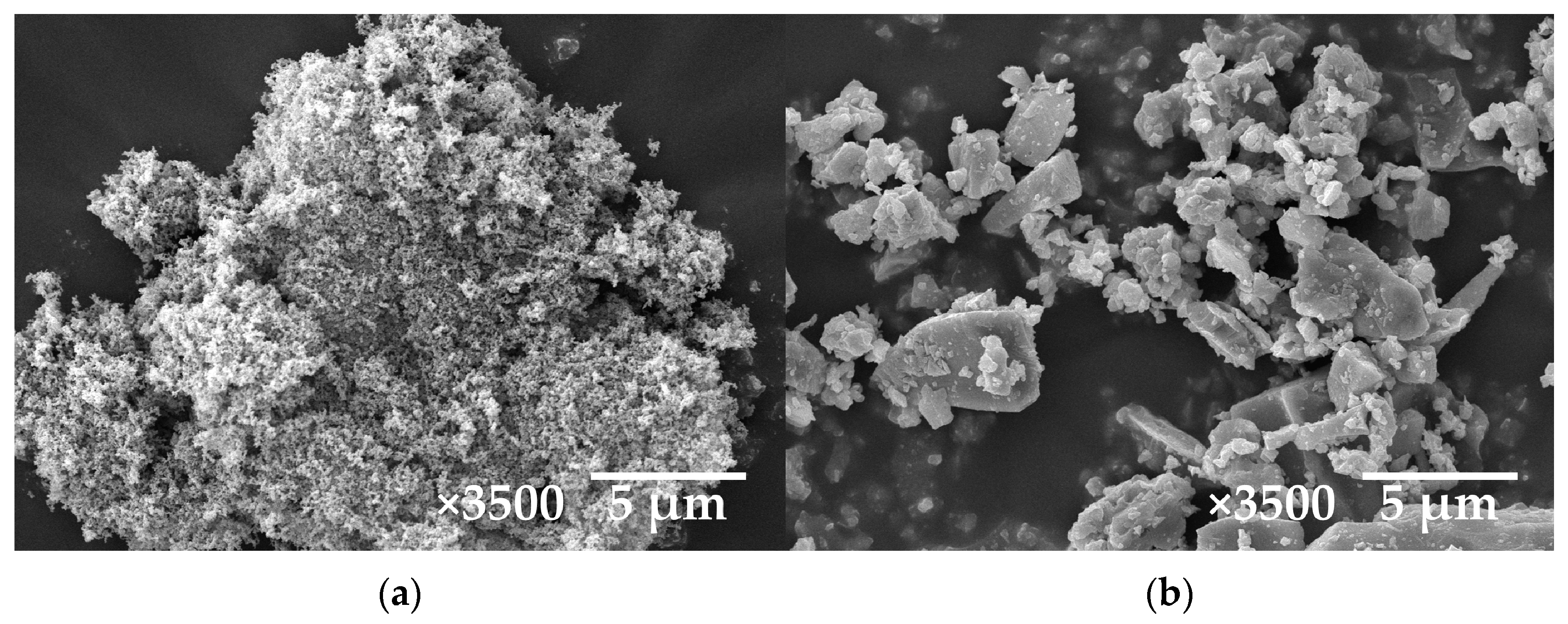

3.1. Morphology of CCB and Fe3O4 Particles

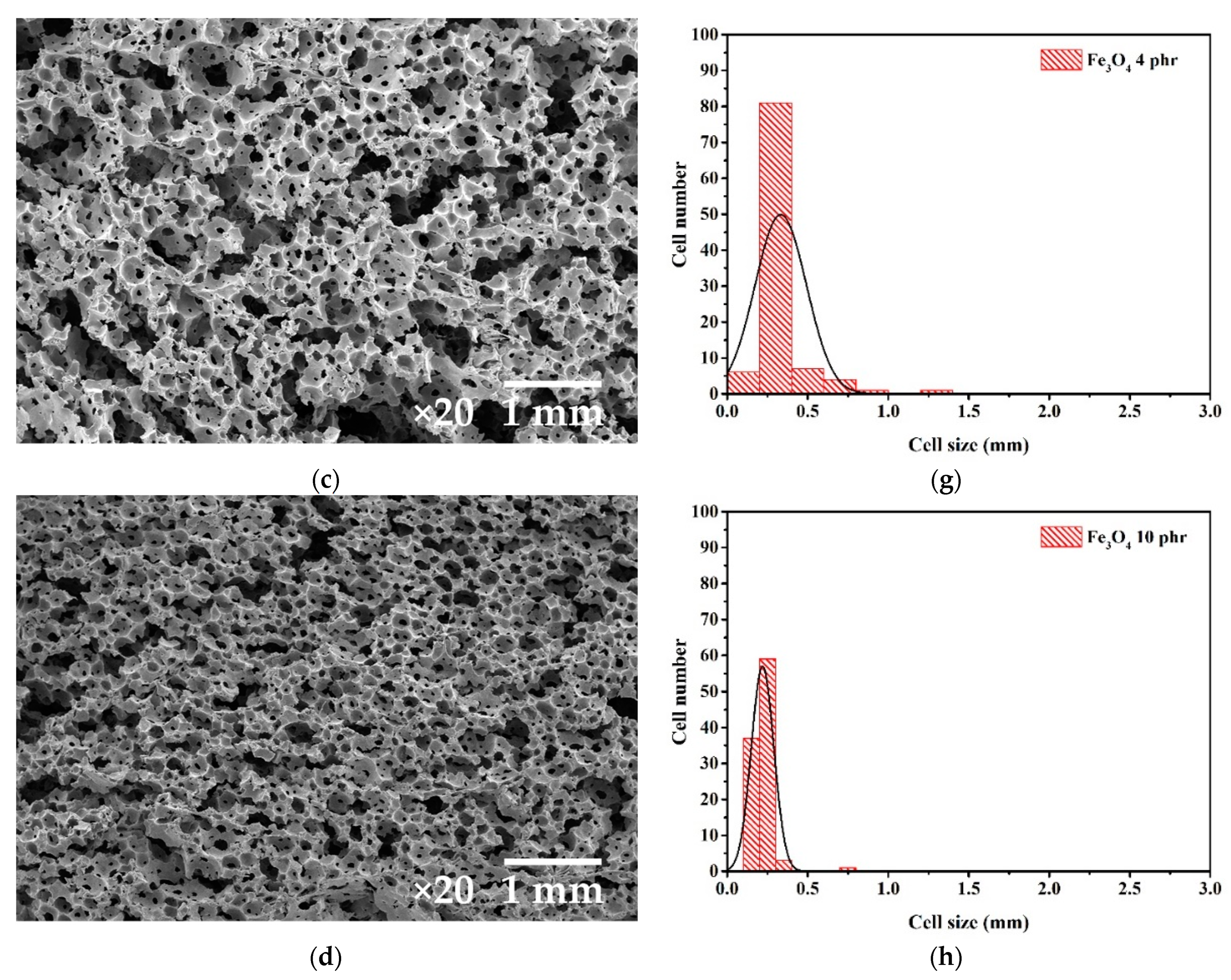

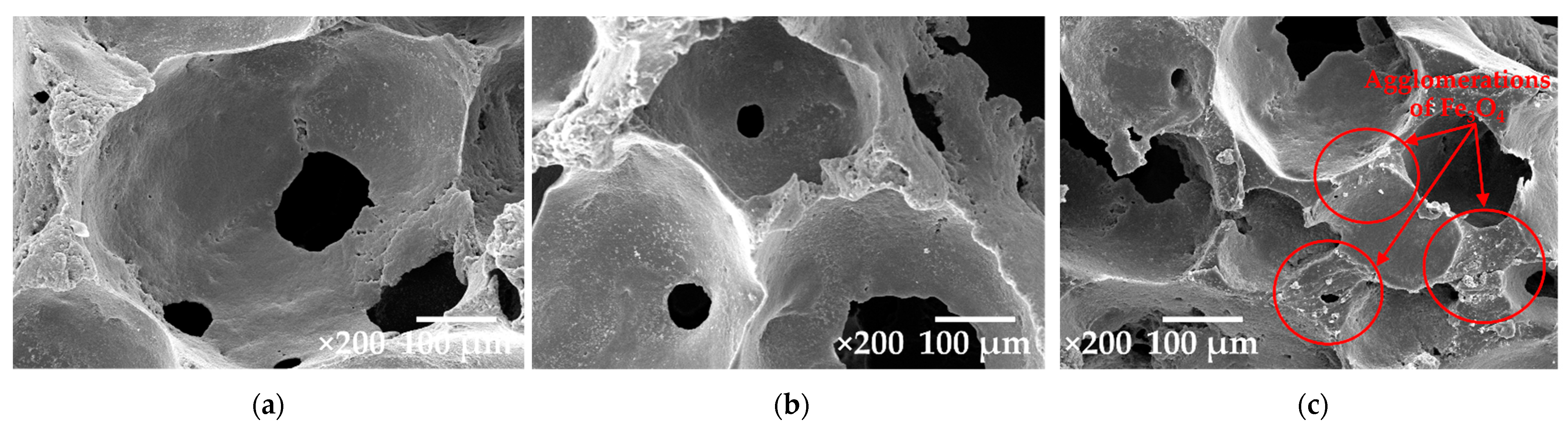

3.2. Cell Characteristics

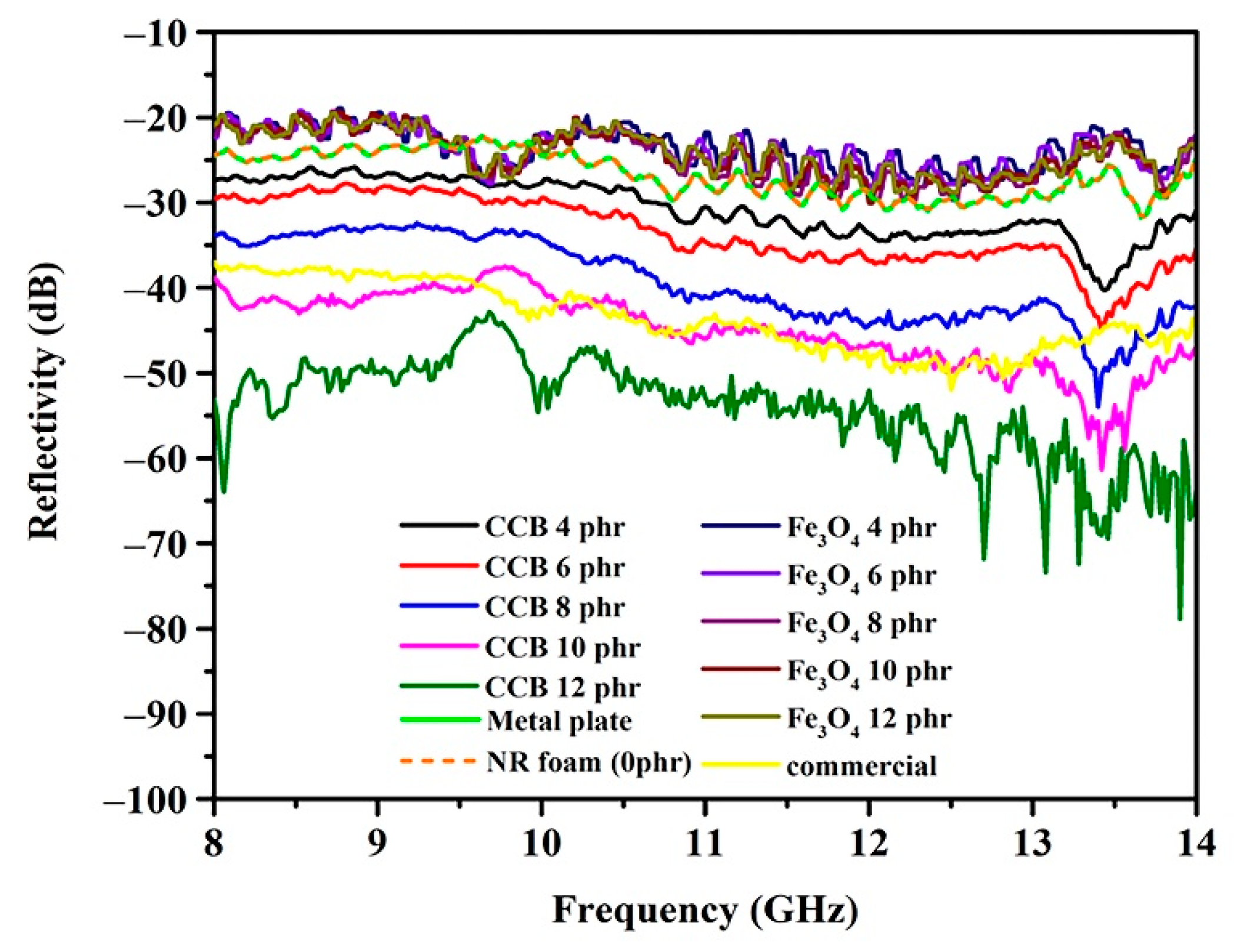

3.3. Electromagnetic Reflectivity

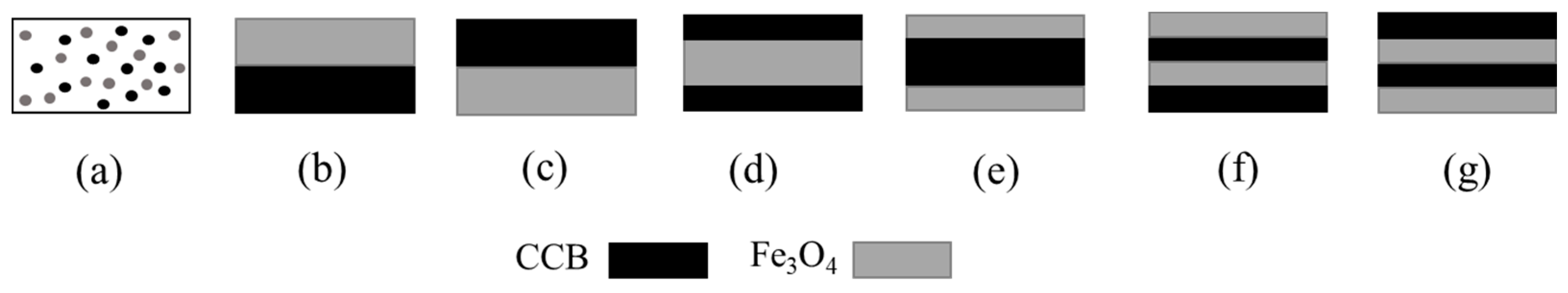

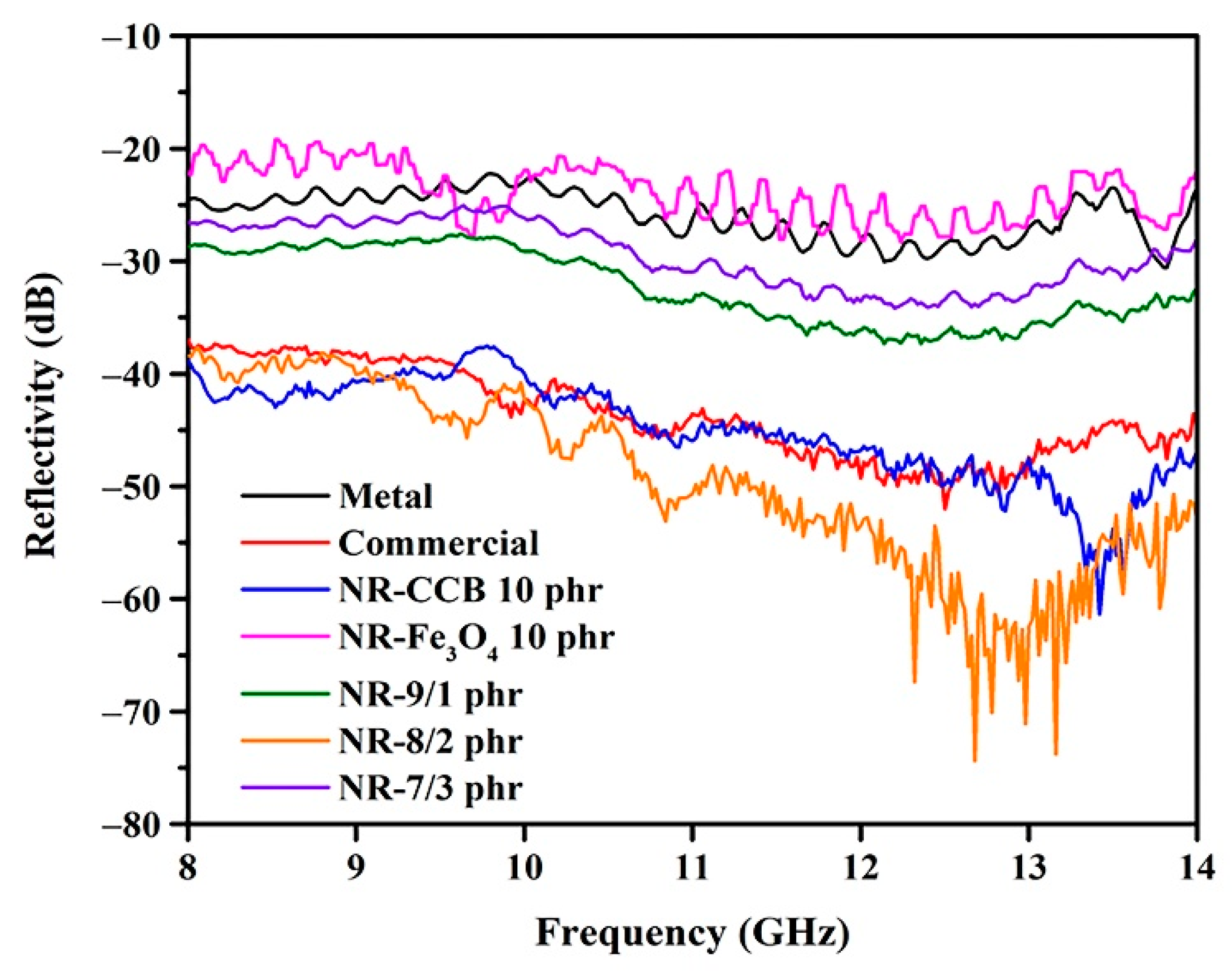

3.4. Influence of Hybrid Filler on the Electromagnetic Absorption

3.5. Influence of Multilayers Structure on the Electromagnetic Absorption

3.6. Tensile Test

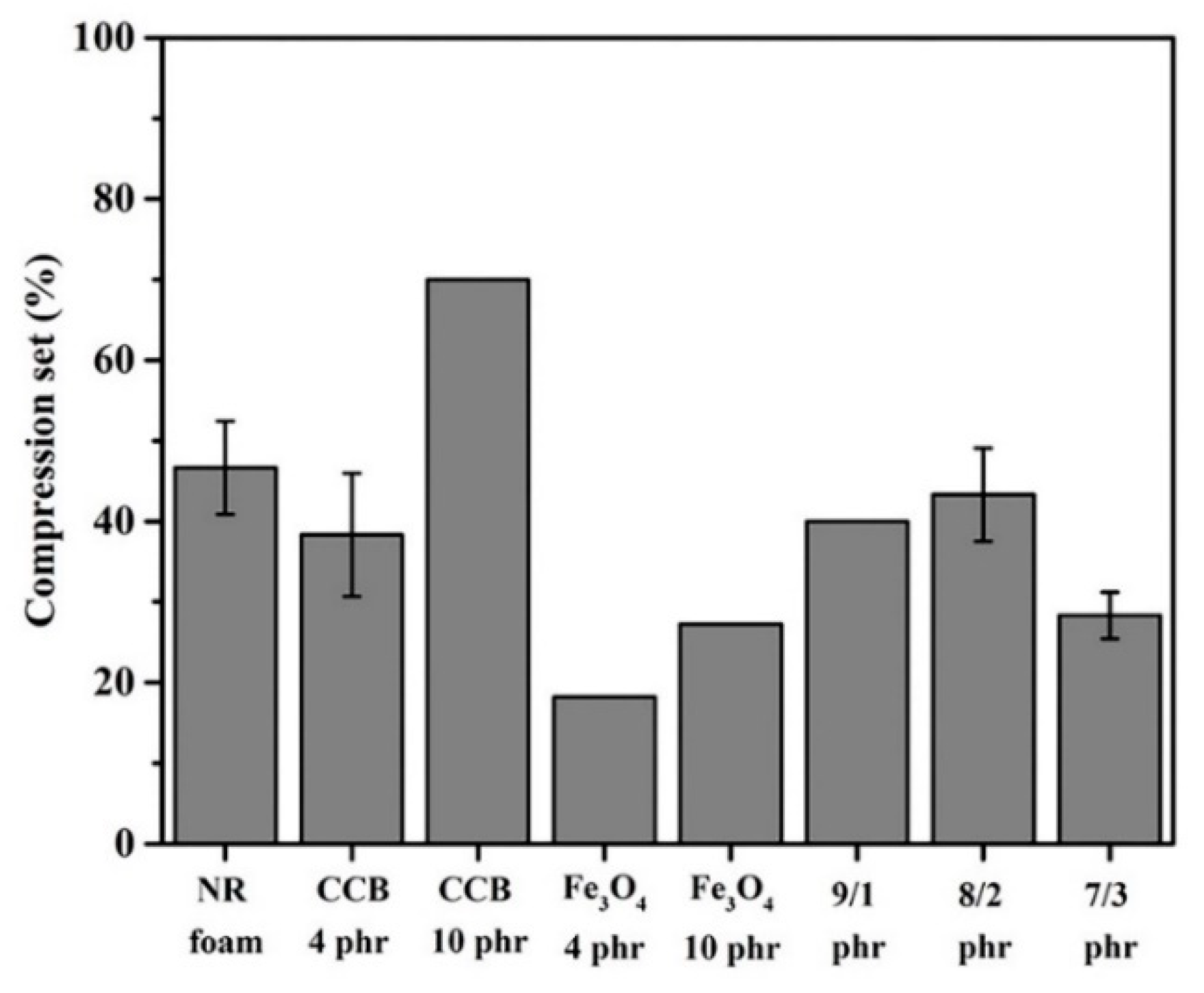

3.7. Compression Set

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, J.; Liu, J. Information leakage from computer based on electromagnetic radiation. Control Intell. Syst. 2015, 43, 101–106. [Google Scholar] [CrossRef]

- Driessen, S.; Napp, A.; Schmiedchen, K.; Kraus, T.; Stunder, D. Electromagnetic interference in cardiac electronic implants caused by novel electrical appliances emitting electromagnetic fields in the intermediate frequency range: A systematic review. Europace 2019, 21, 219–229. [Google Scholar] [CrossRef] [PubMed]

- Elmas, O. Effects of electromagnetic field exposure on the heart: A systematic review. Toxicol. Ind. Health 2016, 32, 76–82. [Google Scholar] [CrossRef]

- Gnidakouong, J.R.N.; Kim, M.; Park, H.W.; Park, Y.B.; Jeong, H.S.; Jung, Y.B.; Ahn, S.K.; Han, K.; Park, J.M. Electromagnetic interference shielding of composites consisting of a polyester matrix and carbon nanotube-coated fiber reinforcement. Compos. Part A Appl. Sci. Manuf. 2013, 50, 73–80. [Google Scholar] [CrossRef]

- Gaoui, B.; Hadjadj, A.; Kious, M. Enhancement of the shielding effectiveness of multilayer materials by gradient thickness in the stacked layers. J. Mater. Sci. Mater. Electron. 2017, 28, 11292–11299. [Google Scholar] [CrossRef]

- Formela, K.; Kurańska, M.; Barczewski, M. Recent advances in development of waste-based polymer materials: A review. Polymers 2022, 14, 1050. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef]

- Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Hudec, I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Adv. 2021, 3, 123–172. [Google Scholar] [CrossRef]

- Gao, C.; He, X.; Ye, F.; Wang, S.; Zhang, G. Electromagnetic wave absorption and mechanical properties of CNTS@GN@Ue3O4/PU multilayer composite foam. Materials 2021, 14, 7244. [Google Scholar] [CrossRef]

- Prokopchuk, A.; Zozulia, I.; Didenko, Y.; Tatarchuk, D.; Heuer, H.; Poplavko, Y. Dielectric permittivity model for polymer–filler composite materials by the example of ni-and graphite-filled composites for high-frequency absorbing coatings. Coatings 2021, 11, 172. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Feng, A.; Qu, S.; Wang, X.; Liu, X.; Wang, B.; Wu, G. Synthesis of porous carbon embedded with NiCo/CoNiO2 hybrids composites for excellent electromagnetic wave absorption performance. J. Colloid Interface Sci. 2020, 575, 130–139. [Google Scholar] [CrossRef] [PubMed]

- Deng, B.; Xiang, Z.; Xiong, J.; Liu, Z.; Yu, L.; Lu, W. Sandwich-like Fe&TiO2@C nanocomposites derived from MXene/Fe-MOFs hybrids for electromagnetic absorption. Nano-Micro Lett. 2020, 12, 55. [Google Scholar] [CrossRef]

- Sun, D.; Zou, Q.; Wang, Y.; Wang, Y.; Jiang, W.; Li, F. Controllable synthesis of porous Fe3O4@ZnO sphere decorated graphene for extraordinary electromagnetic wave absorption. Nanoscale 2014, 6, 6557–6562. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Zhou, J.; Yang, Z.; Kong, L.B. Small magnetic Co-doped NiZn ferrite/graphene nanocomposites and their dual-region microwave absorption performance. J. Mater. Chem. C 2016, 4, 9738–9749. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Ng, V.M.H.; Zhou, J.; Kong, L.B.; Yue, K. Facile synthesis of ultrasmall Fe3O4 nanoparticles on MXenes for high microwave absorption performance. Compos. Part A Appl. Sci. Manuf. 2018, 115, 371–382. [Google Scholar] [CrossRef]

- Salayong, K.; Lertwiriyaprapa, T.; Phaebua, K.; Akkaraekthalin, P.; Chou, H.T. Electromagnetic absorber made by natural rubber. IEICE Trans. Commun. 2019, 102, 189–196. [Google Scholar] [CrossRef]

- Salayong, K.; Lertwiriyaprapa, T.; Torrungrueng, D.; Suksai, S.; Pongmuksuwan, P.; Kitisatorn, W. Electromagnetic wave absorbing properties of carbon black-filled natural rubber latex. Mater. Today Proc. 2021, 52, 2444–2448. [Google Scholar] [CrossRef]

- Al-Hartomy, O.A.; Al-Solamy, F.; Al-Ghamdi, A.; Dishovsky, N.; Ivanov, M.; Mihaylov, M.; El-Tantawy, F. Influence of carbon black structure and specific surface area on the mechanical and dielectric properties of filled rubber composites. Int. J. Polym. Sci. 2011, 2011, 521985. [Google Scholar] [CrossRef]

- Dalal, J.; Lather, S.; Gupta, A.; Dahiya, S.; Maan, A.S.; Singh, K.; Dhawan, S.K.; Ohlan, A. EMI shielding properties of laminated graphene and PbTiO3 reinforced poly(3,4-ethylenedioxythiophene) nanocomposites. Compos. Sci. Technol. 2018, 165, 222–230. [Google Scholar] [CrossRef]

- Kumari, S.; Dalal, J.; Kumar, A.; Ohlan, A. Microwave absorption performance of core–shell rGO/Ni0.5Co0.5Fe2O4@PEDOT composite: An effective approach to reduce electromagnetic wave pollution. Adv. Eng. Mater. 2022, 2200635. [Google Scholar] [CrossRef]

- Dalal, J.; Malik, S.; Dahiya, S.; Punia, R.; Singh, K.; Maan, A.S.; Dhawan, S.K.; Ohlan, A. One pot synthesis and electromagnetic interference shielding behavior of reduced graphene oxide nanocomposites decorated with Ni0.5Co0.5Fe2O4 nanoparticles. J. Alloys Compd. 2021, 887, 161472. [Google Scholar] [CrossRef]

- Tang, W.; Bai, J.; Liao, X.; Xiao, W.; Luo, Y.; Yang, Q.; Li, G. Carbon nanotube-reinforced silicone rubber nanocomposites and the foaming behavior in supercritical carbon dioxide. J. Supercrit. Fluids 2018, 141, 78–87. [Google Scholar] [CrossRef]

- Xiao, W.; Liao, X.; Jiang, Q.; Zhang, Y.; Chen, J.; Yang, Q.; Li, G. Strategy to enhance conductivity of polystyrene/graphene composite foams via supercritical carbon dioxide foaming process. J. Supercrit. Fluids 2018, 142, 52–63. [Google Scholar] [CrossRef]

- MICE Intelligence Center. Tire and Ruber Industry of Thailand. Available online: https://intelligence.businesseventsthailand.com/en/industry/tire-and-rubber (accessed on 24 October 2019).

- Salayong, K.; Lertwiriyaprapa, T. Study of electromagnetic absorber made by natural rubber. In Proceedings of the 2015 IEEE Conference on Antenna Measurements & Applications (CAMA), Chiang Mai, Thailand, 30 November–2 December 2015; pp. 3–4. [Google Scholar] [CrossRef]

- Ramasamy, S.; Ismail, H.; Munusamy, Y. Tensile and morphological properties of rice husk powder filled natural rubber latex foam. Polym.-Plast. Technol. Eng. 2012, 51, 1524–1529. [Google Scholar] [CrossRef]

- Vahidifar, A.; Nouri Khorasani, S.; Park, C.B.; Naguib, H.E.; Khonakdar, H.A. Fabrication and characterization of closed-cell rubber foams based on natural rubber/carbon black by one-step foam processing. Ind. Eng. Chem. Res. 2016, 55, 2407–2416. [Google Scholar] [CrossRef]

- Zakaria, Z.; Ariff, Z.M.; Hwa, T.L.; Sipaut, C.S. Effect of foaming temperature on morphology and compressive properties of ethylene propylene diena monomer rubber (EPDM) foam. MPJ 2007, 2, 22–30. [Google Scholar]

- Surya, I.; Nurul, S.; Kudori, I.; Ismail, H. Effect of partial replacement of kenaf by empty fruit bunch (EFB) on the properties of natural rubber latex foam (NRLF). BioResources 2019, 14, 9375–9391. [Google Scholar]

- Rostami-Tapeh-esmaeil, E.; Vahidifar, A.; Esmizadeh, E.; Rodrigue, D. Chemistry, processing, properties, and applications of rubber foams. Polymers 2021, 13, 1565. [Google Scholar] [CrossRef]

- Vahidifar, A.; Khorasani, S.N.; Park, C.B.; Khonakdar, H.A.; Reuter, U.; Naguib, H.E.; Esmizadeh, E. Towards the development of uniform closed cell nanocomposite foams using natural rubber containing pristine and organo-modified nanoclays. RSC Adv. 2016, 6, 53981–53990. [Google Scholar] [CrossRef]

- Zhan, Y.; Oliviero, M.; Wang, J.; Sorrentino, A.; Buonocore, G.G.; Sorrentino, L.; Lavorgna, M.; Xia, H.; Iannace, S. Enhancing the EMI shielding of natural rubber-based supercritical CO2 foams by exploiting their porous morphology and CNT segregated networks. Nanoscale 2019, 11, 1011–1020. [Google Scholar] [CrossRef]

- Ganapathe, L.S.; Mohamed, M.A.; Yunus, R.M.; Berhanuddin, D.D. Magnetite (Fe3O4) nanoparticles in biomedical application: From synthesis to surface functionalisation. Magnetochemistry 2020, 6, 68. [Google Scholar] [CrossRef]

- Chang, Q.; Liang, H.; Shi, B.; Wu, H. Microstructure induced dielectric loss in lightweight Fe3O4 foam for electromagnetic wave absorption. iScience 2022, 25, 103925. [Google Scholar] [CrossRef] [PubMed]

- Gui, X.; Ye, W.; Wei, J.; Wang, K.; Lv, R.; Zhu, H.; Kang, F.; Gu, J.; Wu, D. Optimization of electromagnetic matching of fe-filled carbon nanotubes/ferrite composites for microwave absorption. J. Phys. D Appl. Phys. 2009, 42, 075002. [Google Scholar] [CrossRef]

- Li, W.; Qi, H.; Guo, F.; Niu, X.; Du, Y.; Chen, Y. NiFe2O4 nanoparticles supported on cotton-based carbon fibers and their application as a novel broadband microwave absorbent. RSC Adv. 2019, 9, 29959–29966. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Liang, X.; Quan, B.; Cheng, Y.; Ji, G.; Du, Y. Investigating the synergistic impedance match and attenuation effect of Co@C composite through adjusting the permittivity and permeability. Mater. Res. Express 2017, 4, 035604. [Google Scholar] [CrossRef]

- Cao, M.S.; Yang, J.; Song, W.L.; Zhang, D.Q.; Wen, B.; Jin, H.B.; Hou, Z.L.; Yuan, J. Ferroferric oxide/multiwalled carbon nanotube vs polyaniline/ferroferric oxide/multiwalled carbon nanotube multiheterostructures for highly effective microwave absorption. ACS Appl. Mater. Interfaces 2012, 4, 6949–6956. [Google Scholar] [CrossRef]

- Ismail, H.; Suryadiansyah, S. Effects of filler loading on properties of polypropylene-natural rubber-recycle rubber powder (PP-NR-RRP) composites. J. Reinf. Plast. Compos. 2004, 23, 639–650. [Google Scholar] [CrossRef]

- Gong, W.; Jiang, T.-H.; Zeng, X.-B.; He, L.; Zhang, C. Experimental-numerical studies of the effect of cell structure on the mechanical properties of polypropylene foams. e-Polymers 2020, 20, 713–723. [Google Scholar] [CrossRef]

- Matchawet, S.; Kaesaman, A.; Bomlai, P.; Nakason, C. Effects of multi-walled carbon nanotubes and conductive carbon black on electrical, dielectric, and mechanical properties of epoxidized natural rubber composites. Polym. Compos. 2015, 38, 1031–1042. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the crosslink characteristics and mechanical properties of natural rubber compound via accelerators and reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef]

| Ingredients | Concentration (phr) |

|---|---|

| NR latex | 100 |

| K-oleate (10%) | 1.5 |

| CCB | 0, 4, 10, 12 |

| Fe3O4 | 0, 4, 10, 12 |

| Sulphur (50%) | 2 |

| ZMBT (50%) | 1 |

| ZDEC (50%) | 1 |

| Wingstay L (50%) | 1 |

| ZnO (50%) | 5 |

| DPG (33%) | 1 |

| SSF (12.5%) | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pongmuksuwan, P.; Salayong, K.; Lertwiriyaprapa, T.; Kitisatorn, W. Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4. Materials 2022, 15, 6532. https://doi.org/10.3390/ma15196532

Pongmuksuwan P, Salayong K, Lertwiriyaprapa T, Kitisatorn W. Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4. Materials. 2022; 15(19):6532. https://doi.org/10.3390/ma15196532

Chicago/Turabian StylePongmuksuwan, Pornlada, Kiadtisak Salayong, Titipong Lertwiriyaprapa, and Wanlop Kitisatorn. 2022. "Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4" Materials 15, no. 19: 6532. https://doi.org/10.3390/ma15196532

APA StylePongmuksuwan, P., Salayong, K., Lertwiriyaprapa, T., & Kitisatorn, W. (2022). Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4. Materials, 15(19), 6532. https://doi.org/10.3390/ma15196532